Bamboo Pellet Machine

Bamboo pellet machine is a ring die pellet equipment specialized in bamboo waste pellets. It can turn bamboo powder and bamboo chips into pellet product through heating and compression. It is a type of biomass fuel pellet machine equipment.

The pellets processed by this bamboo pellet mill are mainly used as biomass fuel, cat litter, organic fertilizer, bamboo boards, etc.

- Capacity: 0.3-10T/H

- Bamboo pellet machine price: 10,000-100,000 USD

- Pellet size: 2-12mm

- Application: biomass pellet plant, fuel pellet plant, bamboo products processing factory, cat litter production line, furniture factory, bamboo farms, fertilizer factory, etc.

- Note: It can process a single bamboo raw material or multiple biomass raw materials.

Many countries and regions are rich in bamboo. The bamboo powder and chips left after bamboo processing and utilization now have a good way to deal with it-processing bamboo pellet fuel.

Moreover, the calorific value of bamboo is very high, and the fuel made from it is very popular and has a good market.

If you are interested in starting a bamboo biomass energy business, you can contact us at any time to learn more about bamboo pellet machines and bamboo pellet production lines!

technical features of bamboo pellet machine

- It has the characteristics of compact structure, simple operation, low energy consumption and high efficiency. It can process bamboo powder into pellets of different sizes and be used to make biomass fuel, cat litter, bamboo plastic, wood plastic composite materials, bamboo flooring, etc. product.

- The main drive adopts high-precision gear drive, and the ring die adopts quick-release hoop type. The output is about 20% higher than that of the belt drive type.

- The transmission part of the whole machine uses high-quality imported bearings and oil seals to ensure efficient, stable transmission and low noise.

- Variable frequency feeding can be used for feeding, which can effectively prevent uneven feeding caused by voltage instability.

- Internationally advanced compensating snake spring coupling, with novel structure, compactness, safety and low failure performance.

Working principle of bamboo pellet machine

Ring die bamboo pellet machine mainly consists of overload protection device, external discharging mechanism and pressurization oil pump lubrication system.

The variable frequency and speed-changing motor is equipped for even feeding.

The raw materials are delivered into bamboo pellet machine through a conveyor and then enter into a rotating ring die by a feeder, finally pulverized material will be pressed into ring die through two rotating press rollers.

The resulting pressure compresses the material and extrudes it through the holes in the die. Then the bamboo biomass will be out directly.

Technical parameters of bamboo pellet machine

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH768 | MZLH858 |

| Output (t/h) | 0.3~0.5 | 0.5~0.7 | 1.0~1.5 | 2.0~2.5 | 2.5~4 | 4~5 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 250 | 280 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 762 | 858 |

| Finished pellet diameter (mm) | 6-12mm | |||||

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system | |||||

Bamboo pellet machine projects

Bamboo pellet machine in Thailand

- project date: 2020.09.05

- Pellet Size: 6mm

Bamboo pellet mill in Malaysia

- project date: 2021.9.26

- Pellet Size: 8mm

Bamboo pellet machine in Vietnam

- project date: 2020.10.15

- Pellet Size: 6-8mm

Bamboo pelletizer in Indonesia

- project date: 2020.06.16

- Pellet Size: 8-10mm

Bamboo pellet machine in Ghana

- project date: 2023.07.11

- Pellet Size: 6-10mm

Bamboo pellet mill in India

- project date: 2020.07.24

- Pellet Size: 8-10mm

Bamboo pellet mill in Nigeria

- project date: 2019.05.17

- Pellet Size: 8mm

Bamboo pellet machine in Mexico

- project date: 2022.07.29

- Pellet Size: 8-10mm

How to choose a bamboo pellet machine?

- Purchase on demand:

Different material properties adapt to different bamboo pellet machines and operating parameters. Therefore, when we purchase a bamboo pellet machine, we must choose the appropriate pellet mill equipment according to the size, size, hardness, dry humidity and other properties of the material.

Moreover, the bamboo pellet machine can process a variety of biomass materials. If you need to process multiple raw materials at the same time, you need to provide detailed raw material information! - Performance of the bamboo pellet machine:

The performance of the pelletizer mainly refers to the energy consumption and output of the granulator. After the crusher is selected, the output of a single piece of equipment can be maximized and the energy consumption can be minimized while meeting the process requirements. - Life of wear-resistant parts:

The loss of wear-resistant parts of the bamboo biomass pellet mill will be a large expense in the later production and operation process. Therefore, the service life of the wear-resistant parts of the bamboo pellet making machine is particularly important.

The wear-resistant parts of the pelleting machine mainly include: ring die, pressure roller, etc. Different working conditions and operating proficiency will have an impact on the wear-resistant parts of the bamboo pellet machine. - High-quality manufacturing raw materials:

Different bamboo pellet machines have different core components, manufacturing processes, and raw materials used. RICHI adopts excellent manufacturing technology and selects more wear-resistant materials to manufacture the bamboo pellet mill. It has a long service life, long trouble-free operation time, and good granulation effect! - Price of equipment:

The price of equipment is also an important deciding factor when purchasing a bamboo pellet machine, but it is not the only deciding factor. If the price is cheap, the quality may not be good, and if the quality is good, the price may not be expensive.

The price of a product is closely related to the manufacturer’s sales model. Some manufacturers’ pelletizer equipment is sold directly by the manufacturer, and the price is naturally favorable. But all considerations of bamboo pellet machine price should be based on the quality of the equipment. - After-sales service provided by the manufacturer:

After the on-site installation is completed, the responsible manufacturer will regularly visit the customer to discover problems in a timely manner, solve customers’ problems, and ensure production. - Qualifications and brand strength of bamboo pellet machine manufacturers:

There are many pellet machine manufacturers on the market. Choosing bamboo pellet machine produced by manufacturers with advanced technology, reliable qualifications and excellent brands will make you more worry-free and more comfortable during use.

This aspect should be considered comprehensively. It is recommended to go directly to the factory for on-site inspection and visit the project site at the same time.

Why invest in the bamboo pellet processing industry?

Biomass bamboo pellet energy technology is becoming increasingly mature, and pellet fuel has entered the stage of industrial production and application.

It is a good project for low-risk investment and entrepreneurship. The investment scale can be large or small. It is suitable for both family workshops with a low starting point and large-scale assembly lines. Production.

The raw materials are obtained locally, and investors can produce qualified products as long as they follow the operating procedures. The products have high return on investment and broad application prospects.

They can not only meet the huge demand for clean energy in ordinary households, but are also suitable for industrial energy. Large-scale production can also apply for national subsidies, which is the direction advocated by many countries’ industrial policies.

How to start a complete bamboo pellet machine system

The bamboo pellet machine is the core equipment of the bamboo pellet production line. But if you want to process bamboo pellets of a certain scale and output, a single bamboo pellet machine is obviously not enough. This requires some processes to form a complete system to achieve semi-automatic or fully automatic processing of bamboo pellets.

So, a complete bamboo pellet plant is required. Then you need a machine manufacturer to design the bamboo pellet production process and supply high quality equipment for you.

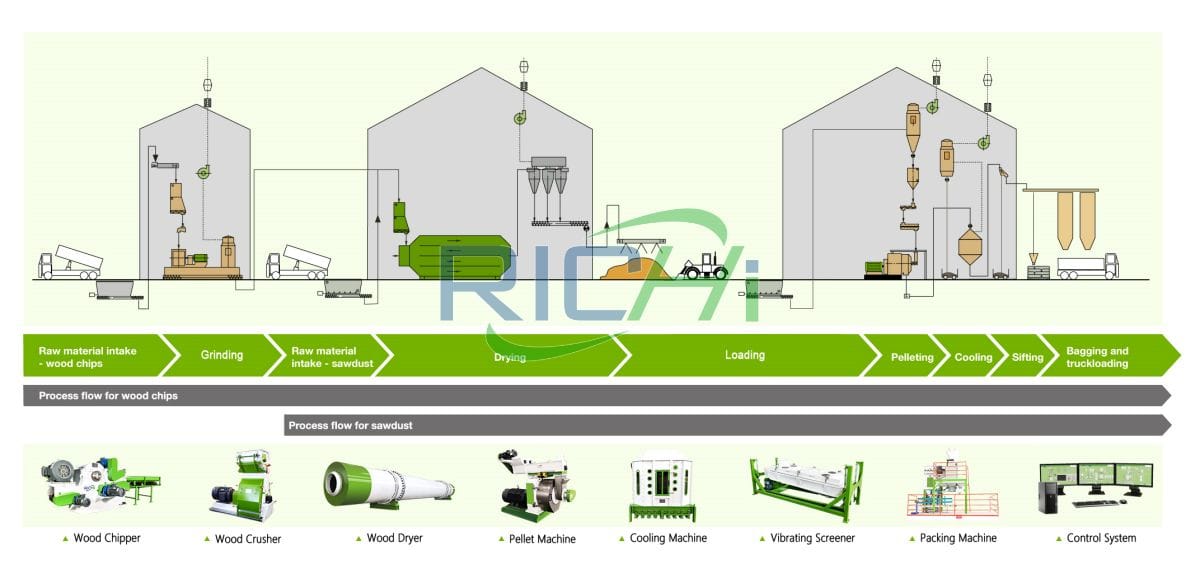

01 Bamboo pellet production process design

- The bamboo waste transported into the bamboo pellet plant is crushed into appropriate sizes.

- The processed bamboo chips are dried and sent to the bamboo pellet machine to be pressed into pellets.

- The newly extruded bamboo chip pellets are cooled and solidified into a solid and enhanced in strength.

- At the same time, they are screened to separate the bamboo pellets and bamboo powder, and then packaged for storage or transportation.

(If your raw material is complete bamboo, you need to use more pre-processing equipment to crush, slice, and pulverize the bamboo into bamboo chips.)

The entire process of bamboo biomass pellet production line is composed in a modular design and can be adjusted and customized according to the customer’s needs and raw material conditions.

02 Supporting equipment for complete bamboo pellet mill plant

In fact, some people have invested in the bamboo pellet fuel processing business for a long time, and now more and more people are investing in it.

In addition to the pellet machine,the main equipment of a pellet fuel production line is a bamboo pellet machine, a crusher, a pulverizer, cooling and screening equipment, auxiliary conveying equipment, etc.

Different process requirements require different equipment configurations. The following are several common bamboo pellet production line equipment.

Chipper Machine

Capacity:

3-18 T/H

Main Power:

4-110 KW

Hammer Mill crusher

Capacity:

3-25T/H

Main Power:

30-160KW

bamboo Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

In addition to bamboo pellets, our bamboo pellet machine and processing system can also process a variety of biomass pellets, such as bagasse pellets, rice husk pellets, grass pellets, hay pellets, efb pellets, etc.

The biggest feature of the biomass pellet fuel processing industry is the diversity of raw materials. This requires a pair of eyes to discover raw materials. If you really find a free or low-priced raw material, then the profits of your bamboo pellet plant will be very considerable. (Maybe you are interested in our EFB pellet plant and rice husk pellet plant solution)

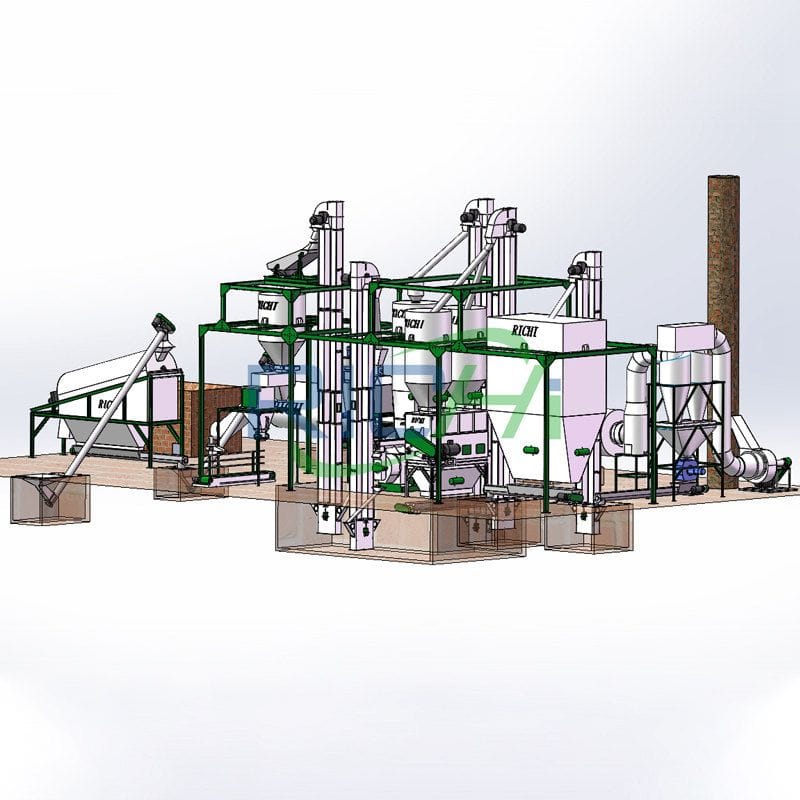

Featured Complete bamboo pellet machine system solution

How to start 4 t/h bamboo pellet machine plant?

—— RICHI MACHINERY ——

- Annual output: 10,000 tons

- Total investment: 410,000USD

- Total project area: 1727.8 m²

- Bamboo consumption: 12467 t/a

- Energy consumption: Water consumption: 96.3 t/a, power consumption: 873,000 kW.h/a

- Product solution: Pellet diameter 6-10 mm, length 0.5-5 cm

- Labor capacity: 12 people, including 3 management personnel and 9 production personnel.

- Working system: 300 days of work per year, one shift, 8 hours per shift.

- Production equipment: Screening machine, bamboo slicer, pulverizer, bamboo dryer, horizontal ring-die bamboo pellet machine, and negative impact pelletizer, scrap conveyor, pressure dust collection chamber, bag dust collector, water film dust collector, etc.

4 t/h bamboo pelleting plant Process flow design

- Slicing: Use a slicer to cut long size bamboo branches and large pieces of bamboo material that cannot be crushed directly into small pieces.

- Crushing: chipped bamboo waste is crushed through a crusher to make the particle size less than 5mm.

- Drying: About 30% of the total raw materials have a moisture content of 55%, which does not meet the requirements for granulation. These raw materials with excessive moisture content need to be dried to make the moisture content meet the requirements for granulation (moisture content is less than 13%). The moisture content of the dried raw materials is about 10%.

- Pelletizing & cooling: The dried raw materials are fed into the bamboo pellet machine through the feeding auger, and pellets are made through extrusion molding. The granulated bamboo pellets are naturally cooled through transportation, so that their temperature can reach the conditions for packaging and storage.

- Packing: The cooled bamboo pellets pass through the screening machine, and the qualified bamboo pellets fall into the finished product bin. The bottom of the finished product bin is a funnel-shaped outlet, and the finished product can be directly dropped into the packaging bag. After the pellets are packaged, it can be stored and sold.

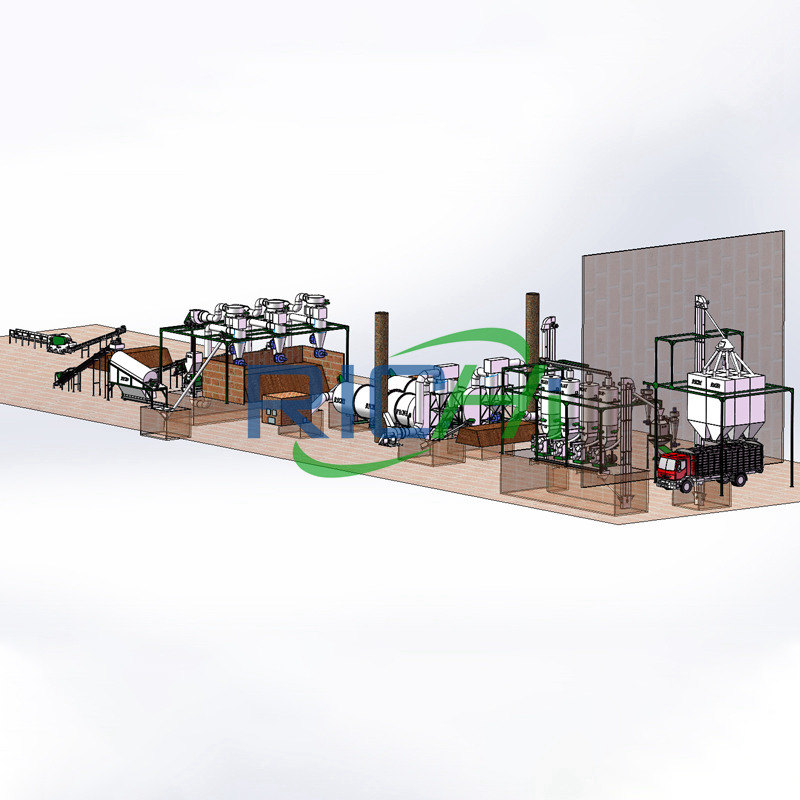

How to build 1.5-2 t/h bamboo pellet machine line project?

—— RICHI MACHINERY ——

- Annual output: 8,000 tons

- Total investment: 220,000 USD

- Construction content: Production workshop (steel frame structure, covering an area of 2700 m²), raw material warehouse (steel frame shed, building area of 1600 m²), finished product warehouse (steel frame structure, covering an area of 1000 m²), and supporting facilities.

- Consumption of raw and auxiliary materials: bamboo chips, bamboo powder, bamboo product leftovers, bamboo joints, bamboo heads, bamboo tails 32000t/a

- Energy consumption: Electricity consumption: 100,000Kw·h/a, water consumption: 3840t/a

- Working system: 2 shifts a day, 8 hours each shift, 300 days a year

- Main production equipment: feeding conveyor belt, dryer, cyclone dust collector, pulverizer, fan, bamboo pellet machine, conveyor belt, forklift, traveling crane, wet electric precipitator, water curtain spray dust collector, vibrating screen , U-shaped loader, etc.

1.5-2 t/h bamboo pellet making Process flow:

- Raw material crushing: crush the raw bamboo powder, bamboo chips and scraps through a slicer and a crusher. Bamboo powder, bamboo chips, scraps, and bamboo joints are crushed into fibrous chips.

- Drying of crumb powder: The moisture content of the raw materials entering the factory is about 40%, and the process requires a moisture content of about 10%, so the raw materials need to be dried. This project uses a drum dryer, which is mainly composed of a combustion furnace, a feeder, a drying tube, a cyclone separator, and an induced draft fan.

- Granulation: The dry powder material is sent to the dry powder silo through a screw conveyor, and the material is sent to the bamboo pellet machine through the silo rotation.

- Inspection, weighing, packaging, and storage: The prepared granules are successively sent to the cooling machine, screening machine, and packaging scale, and the packaged finished products are finally sent to the finished product warehouse.

How to build large 12-15 t/h bamboo pellet machine plant?

—— RICHI MACHINERY ——

- Annual output: 30,000 tons

- Total project investment: 670,000 USD.

- Main construction content: production workshop (area about 1500m², mainly for crushing and granulation processes), raw material storage area (800m²), finished product warehouse (800m²), office area (30m²)

- Product specifications: Φ8mm

- Annual consumption of raw materials: 10,000 tons of bamboo product waste, 20,000 tons of wood product scraps

- Working system: 8 hours a day, 300 days a year. The production time of this project is 2400 hours/year. After calculation, the production equipment can meet the production capacity requirements.

- Main equipment: storage silos, 5 sets bamboo pellet machines, 1 sets crusher, 2 sets pulverizers, 3 sets bag dust collectors, 3 sets of feeders, 6 sets of conveyor belts, 1 set of automatic packaging machines

12-15 t/h bamboo pellet plant Process flow:

- Crushing: Use a forklift to put the materials temporarily stored in the raw material storage area into the hopper, and the materials enter the crusher for crushing to obtain crushed materials with a particle size less than 5mm;

- Pelleting: The crushed material is transported into the bamboo pelletizing machine through a closed conveyor belt. After being pressed by the bamboo pellet machine, biomass shaped pellet products with a diameter of 8mm and a length of about 20~40mm are produced;

- Storage: Biomass shaped pellet products are transported through a closed conveyor belt into the silo for storage;

- Packaging: The pressed bamboo biomass energy pellet products are discharged from the discharge port of the silo and then bagged and packaged.

How to set up a 4-5 t/h bamboo pellet machine plant?

—— RICHI MACHINERY ——

- Annual output: 10,000 tons of biomass pellet construction project

- Total investment: 390,000 USD, all self-raised funds.

- Main construction content: production workshop*780m², raw material storage shed*700m², crushing workshop*1065m², finished product workshop*300m², living area*520m²

- Raw material consumption: wood scraps, bamboo chips, bamboo materials, etc.*16000t/a, the moisture content of raw materials is about 40%~50%, and they are purchased from surrounding areas

- Energy consumption: Water consumption: 270t/a, power consumption: 60,000 kWh/a

- Packaging bag consumption: 200,000 pieces/year

- Working system: The total number of people planned for this project is 9, working 8 hours a day, one shift, and 300 days of production throughout the year.

- Main equipment: crusher*1, pulverizer*1, dryer*1, bamboo pellet machine*2, belt conveyor*3, packaging machine*1, fan*4, pulse dust collector *3 sets, etc.

4-5 t/h bamboo pellet machine plant Production process

- Crushing and crushing: The main task of the crushing process is to decompose the larger raw materials, and then transport them to the crusher in a closed state via the conveyor belt. The pulverizer crushes the raw materials into powder with a particle size of less than 3mm.

- Drying: The moisture content of the biomass raw materials collected in this bamboo pellet plant project is mostly between 20 and 50%, and the highest can reach 60%. So a bamboo dryer machine is needed. The bamboo dryer is equipped with a cyclone separator, which introduces heat into the drying cylinder. Most of the raw materials fall into the lower collection tank from the tail of the drying cylinder, and a small amount enters the cyclone separator with the induced draft fan.

- Granulation: The mixed material is extruded by physical high pressure in the mold of the bamboo pellet press machine to form a cylindrical-shaped biomass molded fuel product.

- Cooling: When discharging biomass, the temperature of the molded pellet fuel is as high as 80~90°C. The structure is relatively loose and easily broken. It must be naturally cooled to normal temperature before being bagged and stored.

How to start a small 1-2T/H bamboo pellet machine line project?

—— RICHI MACHINERY ——

- Annual output: 4000t/a

- Total project investment: 300,000 USD

- Main construction content: Production plant (mainly equipped with granulation area, crushing and drying area, total construction area 800m², raw material room*200m², finished product warehouse*150m², office *50m²)

- Power supply mode: Provided by the local power grid, the power supply line goes to the outside of the factory, and the 10kV line is directly introduced from the outside.

- Consumption of raw and auxiliary materials: sawdust (including bamboo knots), wood scraps*4300t/a, moisture content ≤30%

- Working system: 10 people. Annual production is 300 days, and the production shift is one shift. Each shift is 8 hours, and the annual working hours are 2,400 hours.

- Main equipment: bamboo chips crusher*2, crushing bag dust collector*2, feeding belt conveyor*4, finished product belt conveyor*3, bucket elevator*1, storage bin*1 sets, bamboo pellet machine*3, finished product silo*1, hot air stove*1, cyclone dust collector*1, fan*1, drying cylinder*1, etc.

1-2T/H bamboo pellet Production Process

- Crushing: Since the purchased wood chips contain large-diameter raw materials such as bamboo chips, they need to be crushed to avoid affecting the normal operation of the subsequent granulation process.

- Drying: After the raw materials are crushed, they are transported to the drying cylinder by a belt for drying. The drying heat source is provided by a biomass-fired hot air stove. The initial moisture content of raw materials is about 20~40%, and the moisture content can be reduced to less than 15% after drying.

- Granulation: The dried materials are transported by belts into the bamboo pelletizer machine for granulation. The temperature inside the bamboo pellet machine is controlled at 110~120℃, and the raw materials are pressed into granules; the granulation process uses electric heating.

- Packaging and storage: After the bamboo biomass energy pellets are naturally cooled, they are packed into bags and stored in storage.

Faqs of bamboo pellet machine

I have four raw materials: bamboo chips, sawdust, rapeseed straw, and rice straw. How can I make a better ratio? What are the economic benefits of investing in bamboo pellet machines and bamboo pellet plants?

Economic benefit indicators mainly include raw material acquisition costs, labor costs, mechanical loss and depreciation costs, and product production process performance, consumption, product sales price and sales volume, etc.

Among them, for the use of different raw materials, the difference in labor costs and mechanical loss and depreciation costs is not significant and can be ignored. The sales price of the product is 1,000 yuan/ton (the price is based on the Chinese market price.

The calorific value is greater than 4,200kcal/kg), so the main economic benefit indicators considered are the cost of raw material acquisition and the energy consumption of the product production process.

The purchase price of raw materials is: bamboo chips: 250 yuan/ton, wood chips (fruit tree branches): 200 yuan/ton, rapeseed straw: 150 yuan/ton, rice straw: 400 yuan/ton.

- From the perspective of the product quality of pellet fuel, that is, the calorific value, the products produced using 100% bamboo chips have the highest calorific value and the best quality, and can basically replace raw coal.

- From the perspective of economic benefits, the best product is to use 80% bamboo chips + 20% fruit tree branches or other agricultural and forestry wastes such as rapeseed straw:

- On the one hand, the caloric value of the product can meet customer requirements;

- On the other hand, the purchase price of agricultural and forestry waste raw materials such as fruit tree branches and rapeseed straw is relatively low, and the energy expenditure in the production of pellet fuel is minimal.

- From the perspective of environmental benefits, these four raw materials can rationally utilize agricultural and forestry wastes and improve their utilization efficiency.

According to the actual situation of raw materials in various places, starting from the quality requirements of pellet fuel products, combined with economy and resource reuse,

The optimal raw material ratio of 80% bamboo chips + 20% rapeseed straw is selected to achieve the best social, economic and environmental benefits. (Maybe you want to know more about straw pellet machine and wood pellet mill)

Why use bamboo as the raw material for pellets?

Bamboo is considered a promising renewable resource. The advantages of bamboo are fast growth, easy processing, good mechanical properties, low cost, and universal uses.

- Bamboo is a natural choice for biomass energy production. Bamboos are a member of the grass family, although they are woody in nature. There are approximately 1250 species of bamboo in the world, ranging in height from 10-40 cm. Bamboo can be harvested four times a year and covers millions of hectares globally, meaning it is a potentially sustainable biomass fuel or raw material.

- Bamboo has been commonly used in daily life. Bamboo has been used in general construction, paper and textile production, handicraft production, food production, furniture production and biomass energy production. In addition, bamboo is a promising renewable resource due to its fast growth rate, simple processing, good mechanical properties, low cost, and universal uses.

Which countries are suitable for customers to invest in bamboo pellet machines and bamboo pellet production lines?

- First of all, of course, those countries that are rich in bamboo.

- Asia-Pacific Bamboo Area:

This is the largest bamboo area in the world. The main bamboo-producing countries include China, India, Myanmar, Thailand, Bangladesh, Cambodia, Vietnam, Japan, Indonesia, Malaysia, Philippines, South Korea, Sri Lanka, etc. - American Bamboo Area:

Bamboo distribution is mainly concentrated in the east. Among them, in Latin America, the Amazon stream between the Tropic of Cancer, Mexico, Guatemala, Costa Nica, Nicaragua, Honduras, Colombia, Venezuela and Brazil is the center of bamboo distribution. Bamboo species are very abundant, from there south to Argentina. then gradually decreases. - African Bamboo Area:

From the west coast of Africa to southern Senegal, Guinea, Liberia, southern Ivory Coast, southern Ghana, Nigeria, Cameroon, Rwanda, Burundi, Gabon, Congo, Zaire, Uganda, Kenya, and Tanzania , Malawi, Mozambique, until the island of Madagascar on the east coast, which is the center of bamboo distribution in Africa. - European and North American introduction areas:

In the past century, a large number of bamboo species have been introduced by European countries such as the United Kingdom, France, Germany, Italy, Belgium, and the Netherlands, and some bamboo-producing countries in Asia, Africa, and Latin America such as the United States and Canada.

- Asia-Pacific Bamboo Area:

At present, the vast majority of bamboo forests in the world are still in a state of desolation, with severe deforestation, low management levels, and low yields.

Among them, China and Japan have longer operating histories and higher management levels.

However, some tropical and subtropical countries are now paying attention to the development of bamboo production, and purchasing bamboo pellet machines and establishing bamboo pellet production lines are very good development channels.

- In addition, no matter which country you are in, if you can recycle waste bamboo at a lower cost, then the bamboo pellet machine and bamboo pellet processing business is also an area worth investing in.

For pellet processing, is bamboo a substitute for wood?

After a complete bamboo is cut as needed, the tips and areas close to the root are no longer useful. This means that only about 70% of a bamboo can be made into products in the end, and the remaining 30% becomes useless waste.

The content of cellulose and hemicellulose in the dry matter content is higher than that of sawdust, and the lignin content is also higher than that of sawdust.

The regeneration of wood resources is slow, time-consuming, and relatively expensive. Bamboo powder is made from natural fresh bamboo. Bamboo production is fast and the supply is large. Using bamboo powder instead of wood powder can save costs and improve economic benefits if applicable.

The pellet fuel pressed and formed by the bamboo pellet machine has a large specific gravity, small size, combustion resistance, and is easy to store and transport.

The volume after molding is 1/30~40 of the volume of the raw material, and the specific gravity is 10~15 times that of the raw material (density: 0.8-1.4). The calorific value can reach 3400~6000 kcal, and it is a highly volatile solid fuel.

How to choose a suitable bamboo pellet machine?

As the core of bamboo pellet production, the pellet machine determines the bamboo quality of the entire production line. The RICHI ring-die bamboo pellet machine is very suitable and is highly recommended due to its strong adaptability, simple operation, and easy maintenance.

For large-scale bamboo pellet production, it is recommended to use a ring die bamboo pellet machine because of its high production capacity. If you have an abundant source of bamboo, this is an opportunity to make bamboo pellet fuel through a pellet machine for home use or profit.

When choosing bamboo pellet machine and equipment, you also need to choose based on the characteristics of bamboo powder and production needs. It is also necessary to select and operate according to the actual situation to achieve the best processing effect and economic benefits.

Generally speaking, factors such as the production capacity, energy consumption, and floor space of the equipment need to be considered.

If you want to know the specific selection method of bamboo pellet machine, contact Richi Machinery for details! (Find RICHI on YouTube)

What are the market prospects for bamboo pellet machine and bamboo pellet processing plants?

Bamboo pellet processing factory refers to a factory that processes bamboo into pellet product.

As people’s awareness of environmental protection and sustainable development continues to increase, bamboo, as a renewable resource, has become more and more widely used.

Therefore, the market prospects for bamboo pellet processing plants are very broad.

(1)First of all, the products of bamboo pellet processing plants have many uses.

- On the one hand, bamboo pellets can be used as biomass energy for combustion to generate electricity, heat, etc. With the adjustment of the energy structure, the demand for biomass energy continues to increase, providing a broad market space for bamboo pellet processing plants.

- On the other hand, bamboo pellets can also be used in the agricultural field as organic fertilizers, soil improvers, etc. With the development of green agriculture, the demand for organic fertilizers and soil conditioners is also increasing, which also provides business opportunities for bamboo pellet processing plants.

(2)Secondly, the selection of the construction location of the bamboo pellet processing plant is also very important.

Choosing an area with abundant bamboo resources and convenient transportation to establish a processing plant can make more effective use of local resources, improve production efficiency, and reduce costs.

In addition, factors such as the local policy environment and market competition need to be considered to formulate reasonable business strategies to ensure the sustainable development of the enterprise.

(3)Finally, bamboo pellet processing plants need to pay attention to product quality and safe production.

In order to ensure product quality, it is necessary to establish a complete quality management system and conduct production and management in strict accordance with standards.

At the same time, it is also necessary to strengthen employee training, improve employees’ safety awareness and operational skills, and ensure safety and stability in the production process.

(4)In addition, although the application prospects of processing bamboo into pellets are very broad, there are also some issues that need to be paid attention to.

For example, the quality and stability of bamboo, processing costs, environmental pollution during production and other factors.

Therefore, in the production process of bamboo pellets, it is necessary to strengthen technology research and development and management, and improve product quality and environmental protection levels to ensure the sustainable development of the market.

In short, bamboo pellet processing plants have broad market prospects and good development potential.

With the improvement of people’s awareness of environmental protection and the continuous development and utilization of renewable resources, the application fields of bamboo pellets will become more and more extensive.

At the same time, attention must be paid to technology research and development and environmental protection issues in the production process.

Start your Bamboo pellet production business

With the development of large-scale agriculture and forestry industry, more and more bamboo waste is generated during production and processing. The utilization rate of these bamboo wastes is generally low. Preparing bamboo pellet fuel is currently one of the main ways to utilize bamboo waste.

Therefore, effectively improving the quality of pellet fuel products has become the main method to improve the utilization rate of agricultural and forestry waste.

In recent years, as people have become more concerned about environmental protection and if you are interested in our bamboo pellet machine and bamboo pellet production line, please feel free to contact Richi Machinery for details!