Wood Pellet Hammer Mill

Wood pellet hammer mill is designed for the grinding of wood shavings, sawdust and chips to a particle size suitable for pelleting, it’s a hammer mill type wood grinder that specializes in processing wood sawdust or wood powder.

RICHI wood chip hammer mills are the powerful component for your wood pellet plant, It can meet the particle size requirements of fuel wood powder. From wood chips to sawdust, you just need this RICHI sawdust grinder machine.

- Capacity: 3-25T/H

- wood grinder machine price: 5,300-35,000 USD

Under the condition of economical energy consumption, RICHI’s hammer mill for wood pellets simplifies the structure as much as possible, making the entire crusher layout compact, saving materials and floor space, so as to facilitate actual placement and control operations, improve crushing efficiency and crushing quality, and maximize the degree of wood pellet hammer mill serialization and component commonality to ensure that the wood hammer mill machine can efficiently complete the crushing requirements.

We offer wood sawdust hammer mill in a wide variety of sizes and styles. From single units to complete turn-key wood chips milling systems, all of our products are custom configured to suit your application and production goals. (Related product: wood chipper machine)

Application of wood pellet hammer mill

Many people know that wood hammer mills are mainly used in wood pellet production lines.

However, in addition to wood pellet plants, the wood sawdust processed by wood pellet hammer mill machines has many other uses:

- For energy production (wood shavings, wood pellets)

- For the construction industry (insulation materials)

- For animal husbandry (bedding material)

- For logistics (packaging accessories and cardboard packaging)

- For food production (stabilisers, filling and release agents).

- …

Features of wood pellet hammer mill

RICHI wood chip hammer mills can achieve output capacities of up to 25 tons/hour depending on the application, motor rating, wood type and moisture content, and offer you an economical and powerful possibility to grind your sawmill by-products.

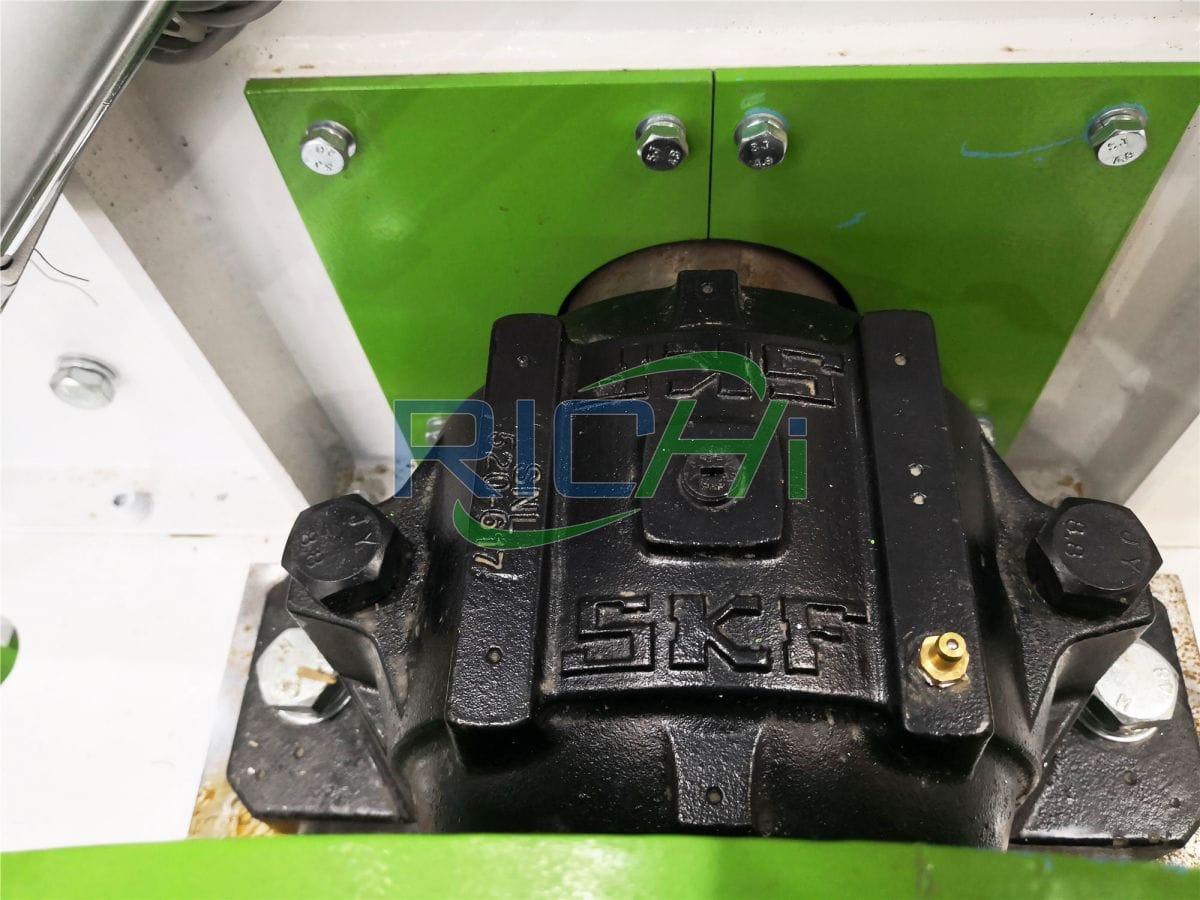

- Spindle speed: 2980r/min; Siemens motor, SKF bearings;

- Crush room with drop-shaped structure divided into two parallel grinding chamber and shear device, the lower the drop-shaped room with another smash to improve the hammer blow to the efficiency of materials;

- Rotor with a special design,with two different hammer screen space to meet the exchange of different granularity;

- Hammer’s face hard surfacing materials,extended service life;

- Door interlock device operation to ensure a safe operation when the motor does not start to open the door;

- Rotor motor and the electric wood hammer mill installed in the same heavy-duty base, using the pin coupling Direct transmission, rotor balancing efficacy through, the work can be positive and negative.

By analyzing the characteristics of wood powder, RICHI made comprehensive scheme design, material selection, size determination and theoretical analysis and calculation for the structural design of each component of the wood pellet hammer mill.

At the same time, the belt drive in the crusher transmission system was designed and calculated, and the main shaft components, crushing components and braking devices were designed. The particle size of the materials produced by this sawdust hammer mill can meet a variety of customer needs and fully meet the processing requirements of various types of wood powder.

Advantages of wood pellet hammer mill

In order to meet the needs of wood flour production, wood hammer mill shredder must be able to process wood sawdust of different particle sizes. The key is to design and manufacture a hammer mill crusher that can obtain wood sawdust of various mesh sizes.

- The wood pellet grinder machine designed and manufactured by RICHI has wide processing adaptability, can process various types of wood materials, and has uniform crushing particle size;

- The supporting power is reasonable, the electricity output is high, the productivity is improved, and the energy consumption is reduced;

- Simple structure, easy operation, no major technical requirements required;

- The parts of sawdust making machines have good wear resistance and can reduce the number of replacements to reduce production costs and improve economic benefits;

- Low noise and less dust to reduce environmental pollution and the machine has a simple structure, compact size, small volume, small footprint and low cost.

Whether you’re processing wood chips, biomass, like soybeans and weeds, corn stalks, wood shavings, or inorganic matter like PVC foam board, rubber, or other materials, the RICHI wood pellet grinder is the versatile machine that can help take your production to the next level.

wood pellet hammer mill parameters

| Model | Power | Capacity | Speed |

| SFSP56*40a | 30kw | 3-5T/H | 2980r/min |

| SFSP56*40b | 37kw | 4-6T/H | 2980r/min |

| SFSP66*60a | 55kw | 5-8T/H | 2980r/min |

| SFSP66*60b | 75kw | 6-9T/H | 2980r/min |

| SFSP66*80a | 90kw | 8-10T/H | 2980r/min |

| SFSP66*80b | 110kw | 10-13T/H | 2980r/min |

| SFSP66*100 | 132kw | 12-16T/H | 2980r/min |

| SFSP138*30E | 110/132kw | 15-20T/H | 1440r/min |

| SFSP138*40E | 132/160kw | 18-25T/H | 1440r/min |

wood pellet hammer mill projects

sawdust making machine for sale United States

Application: biomass pellet manufacturing plant

wood chip hammer mill for sale Austria

Application: biomass pelletizing plant

wood hammer mill for sale indonesia

Application: wood pellet processing plant

Wood Hammer Mill For Sale Malaysia

Application: small wood pellet plant

wood pellet hammer mill For Sale Australia

Application: biomass pellet making plant

Wood Hammer Mill For Sale Thailand

Application: biomass pellet line

Sawdust Making Machine For Sale Afghanistan

Application: biomass pellet production line

Working principle of wood pellet hammer mill

The crushing system of wood hammer mill mainly consists of impeller feeder, pulverizer, air net mechanism and conveying mechanism.

In the crushing system, the most important and energy-consuming part is the wood chip hammer mill, and the crushing chamber is the heart of the sawdust making machine. The crushing chamber is composed of a rotating rotor, hammers, and sieve plates.

During the crushing process, wood chips enter the crushing cavity from the feed port and are crushed by impact and friction. The wood powder materials that meet the particle size requirements are discharged through the sieve holes.

The materials that fail to pass continue to be hit and collided in the crushing cavity until the particle size is reached. It is discharged according to the requirements of the sieve holes.

How to choose a wood pellet hammer mill reasonably?

01 Select a wood dust making machine that matches the linear speed of the hammer according to the thickness of the product.

If the linear speed of the hammer does not match, the working efficiency of the sawdust grinder machine will be reduced, and even the crusher will not work properly.

- Slow linear speed will cause long crushing time, causing materials to accumulate in the crushing chamber, causing sifting, reducing screening efficiency and screening effect, increasing hammer motion resistance, causing the wood chip grinder to work abnormally;

- Excessive line speed will cause uneven grinding particle size and waste power consumption. The finer the material requirements, the more necessary it is to use a wood grinding machines with high linear speed.

02 Select the chipper hammer mill according to the production output

The size of the wood grinder machine model determines the output. According to the configuration of the crushing process, the selected wood sawdust machine output should be greater than 10% of the design output.

Wood sawdust is an important raw material in industrial and agricultural production such as wood biomass pellets, bio-oil and wood gasification, and is an important form of energy utilization of wood biomass. Therefore, wood sawdust machines are very important for related industries.

FAQs of wood pellet hammer mill

What is the voltage of wood chip hammer mill?

Usually, the wood chip hammer mill machines we provide are 3-phase, 380V, 50HZ. If you have special requirements for the motor, please inform us in time.

What Is The Raw materials for wood sawdust maker?

Wood, straw, grain, bark, branches and other biomass materials.

How long is the lead time?

Richi Machinery arranges the production sequence according to the time of payment. Please consult the sales staff for the specific delivery time of the hammer mill for wood chips.

Payment method of your sawdust machine?

T/T

How to improve the production efficiency of the wood pellet hammer mill

(1) Minimize the gap between the hammer of the sawdust making machine and the tooth plate or screen.

The smaller the gap between the pulverizer hammer and the tooth plate or screen, the higher the frequency of the hammer hitting the material and the slower the circulation speed. Thereby improving the crushing efficiency.

(2) Take auxiliary measures

Taking effective measures can effectively improve the working efficiency of the wood grinder machine.

Adding an exhaust system to the crushing process makes it easier for materials to pass through the screen holes, improves the screening efficiency of the wood pellet hammer mill, and reduces the pressure on the crushing process.

(3) Micro-grinding and ultra-fine grinding

Micro-grinding and ultra-fine grinding require the wood pellet hammer mill to operate at a higher linear speed. However, the higher the linear speed of the crusher, the greater the noise, the smaller the safety factor, and the design is subject to certain restrictions.

Micro-grinding requires a screen with apertures below 1㎜ or even below 0.5㎜. The current micro-wood chip hammer mill is very inefficient in achieving such fineness standards and consumes a lot of power.

Pay attention to the following points when using wood pellet hammer mill crusher

- The grinding fineness is determined by the size of the sieve aperture. This kind of wood hammer mill is equipped with screens of various apertures, which can be selected according to requirements.

- The hammer of the hammer mill crusher needs to be fixed firmly. The crushing rotor is a high-speed rotating component, and the hammer and other parts must be fixed firmly. During work, metal, stones and other hard objects must be prevented from entering the hammer mill shredder machine to avoid damage accidents.

- Check the wear of the hammer regularly. The hammer is a wearing part, and its wear should be checked frequently. When one corner of the hammer is worn to the point that it has no edges, it can be flipped or turned around for use.

However, the installation positions of the hammers cannot be replaced with each other, nor can they be used. Replace with new ones to avoid affecting the balance of the rotor. - When the size of the material to be crushed is long or large, it should be fed into small pieces or segments first.

Why are the hammers of some wood pellet hammer mills severely worn?

- Improper surface heat treatment, because the hammer is made of high-quality steel, and the head has been carburized and quenched. The quenching hardness is HRC60~65. If the heat treatment is improper, it will wear out quickly during use;

- The thickness of the hammer is small, because rectangular double-pin hole hammers are commonly used in crushers, and their service life is 200 to 500 hours. Although a small thickness can reduce the weight and increase the crushing productivity, the service life is short, and generally 2 to 8mm should be selected;

- The air suction volume is too large, because wood grinding machines generally adopt air suction measures to reduce the temperature and humidity inside the machine and prevent dust from leaking out.

However, too much air suction volume will also cause uneven wear of the hammer, so the air volume should be appropriately controlled; - The gap between the hammer and the screen is too small and should generally be kept at 4 to 12 mm.

Why do some wood grinding machines vibrate and make noise during operation?

- The wood pellet hammer mill machine base is not installed firmly and the fastening screws are loose;

- After the hammer blades are worn, they are not replaced in pairs at the same time, or the hammer blades are unevenly worn, resulting in a large weight difference between the hammer blades;

- The rotor rotation is unbalanced and the speed exceeds the rated speed;

- Foreign matter such as stones or metals mixed in the material will cause noise and damage the hammer and screen.

Why does the productivity of some wood pellet hammer mills drop significantly?

- The motor power is insufficient or the supporting power is inappropriate;

- If the rotor speed is too low or the belt slips, check whether the pulley size meets the requirements or adjust the belt tightness;

- Uneven feeding causes the wood chip hammer mill’s rotation speed to become unstable, leading to a decrease in productivity;

- The hammer blade is severely worn and the gap between the hammer and the screen is too large;

- The moisture content of the material is too high.

Why are the finished products processed by the wood pellet hammer mill too coarse?

- The screen plate and the screen frame are not tightly fitted or the side gap is too large;

- If the screen is seriously worn or has holes, the holes should be repaired or the screen should be replaced with a new one. (Find us on YouTube)