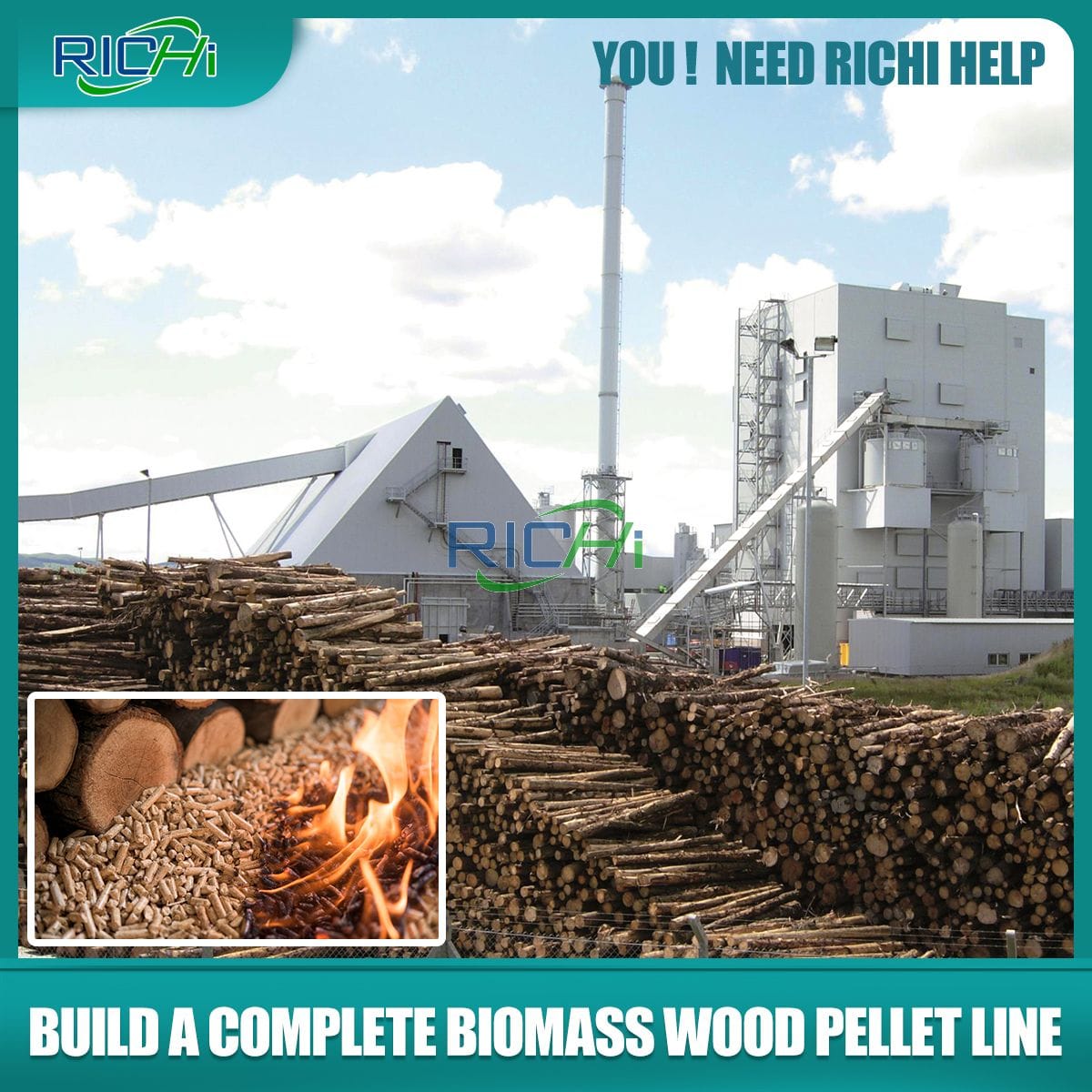

1-30T/H Wood Pellet Production Line Price

1-30T/H wood pellet production line price is generally 50,000-3,000,000 USD. According to the customer’s process requirements, production scale, raw materials, and plant conditions, we provide customized solutions for customers.

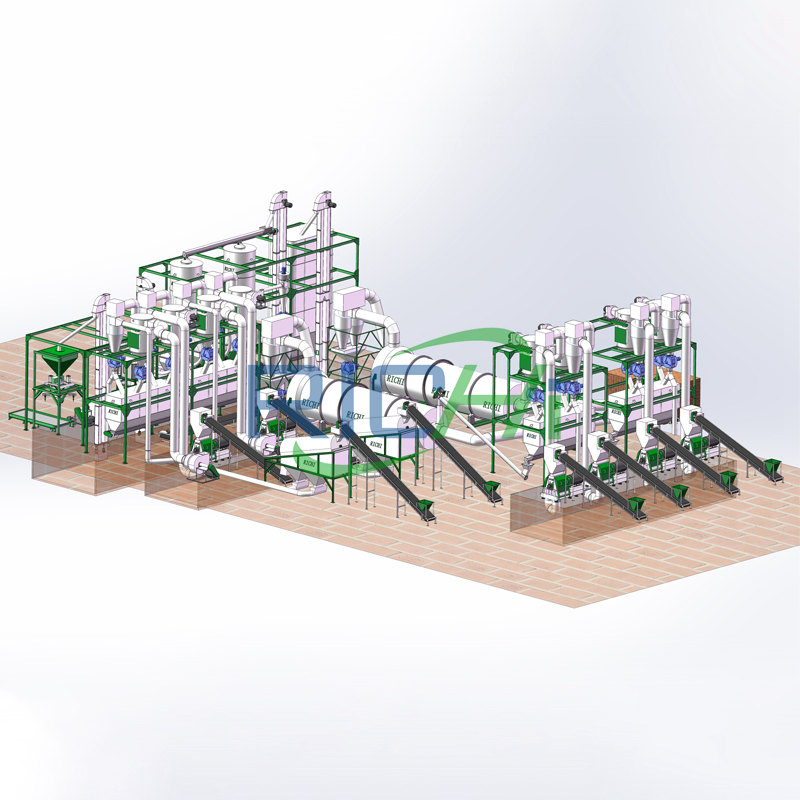

We customize every project to fit the clients needs and requirements, we are also manufacturers and suppliers of wood pellet equipment and complete wood pellet production lines, such as wood dryers, wood pellet mills, wood chipper machine, wood hammer mills, wood pellet cooler machines, wood pellet bagging machines, etc.

Types of wood pellet production line

The RICHI wood pellet production line range offers customized solutions for a wide variety of different applications.

- Pure sawdust production line

- Pure wood chips pellet production line

- Trunk Pellet Production Line

- Wood log pellet production line

- wood shaving pellet line

- pellet production line for wood pallet

- A variety of waste wood pellet production lines

- Wood and agricultural and forestry waste mixed pellet production line

- Wood and coal mixed pellet production line

- Wood and sludge mixed pellet production line

- wood pellet line for cat litter

- …

Different capacity, different wood pellet production line price

small wood pellet plant

- Hourly Capacity: 0.3-1T/H

- Wood pellet production line price: 50,000-200,000USD

wood pellet processing plant

- Hourly Capacity: 5 t/h

- complete wood pellet production line price: 100,000-500,000 USD

wood pellet processing equipment

- Hourly Capacity: 4 t/h

- wood pellet production line price: 100,000-500,000 USD

wood pellet production plant

- Hourly Capacity: 6-7 t/h

- complete wood pellet production plant price: 140,000-600,000 USD

wood pellet making equipment

- Hourly Capacity: 7-8 t/h

- wood pellet production line price: 160,000-800,000 USD

wood pellet manufacturing equipment

- Hourly Capacity: 8-10 t/h

- pellet production line price: 200,000-1,300,000USD

wood pellet factory for sale

- Hourly Capacity: 12-15 t/h

- Complete wood pellet production line price: 200,000-1,800,000USD

wood pellet manufacturing plant

- Hourly Capacity: 15-20 t/h

- wood pellet line price: 320,000- 2,500,000USD

wood pellet making line

- Hourly Capacity: 20-30 t/h

- wood pellet production line price: 400,000- 3,000,000 USD

different wood pellet production line price with different process design

Each customer has different raw materials, capacity, plant, budget and needs. Correspondingly, the wood pellet production line process we design for them is also different.

Different capacity, different wood pellet production line price; different process, the wood pellet production line cost will be different. Even though different customers require the same capacity, the final design solutions are also different due to the different raw materials or plant conditions.

Therefore, we always provide customized wood pellet production lines and equipment to build high-quality wood pellet line projects for customers.

2.5 t/h wood pellet line design

—— RICHI MACHINERY ——

- Annual output: 5,000 tons of biomass fuel projects per year

- Wood pellet production line price: $110,000

- Total area: 1300m2

- Annual working days: 250 days

- Staff: 4 people

- Raw materials: waste furniture, waste wood from furniture factories (irregular pieces of wood, grain diameter 1-5cm)

- Pellet use: supply to biomass power plants

- Annual water consumption: 120m3/a

- Annual power consumption: 140,000 kW·h

- Main equipment: crusher, wood hammer mill, wood pellet machine, screening machine, belt conveyor, etc.

Main process design:

This project uses the existing idle factory buildings for construction, and does not involve civil engineering and other projects. First use the loader to put the purchased waste furniture, waste wood from furniture factories and waste packaging boxes into the crusher, and then crush them into wood pieces with a diameter of 1-5cm, and then transport them to the truck by the belt conveyor.

During the conveying process, magnets are used to separate and remove impurities from waste hardware accessories. The removed wood chips enter the wood chip crusher for crushing, and then granulate them.

At the same time, the finished products are obtained through natural cooling. (The design is relatively simple, the investment is less, and there is no equipment such as screening machines).

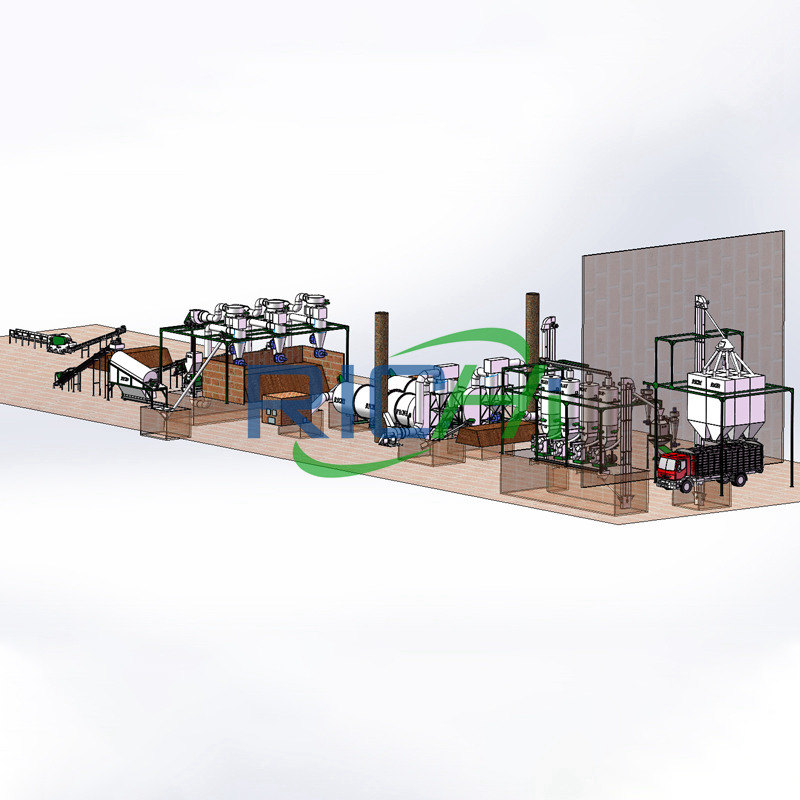

6-7 t/h wood pellet production line plan

—— RICHI MACHINERY ——

- Annual output: 20,000 tons of material particles produced annually

- Wood pellet production line price: 430,000USD

- Total area: 5000m2

- Annual working days: 300 days, 10 hours a day

- Employees: 11 people

- Raw materials: waste wood 10000t/a, sawdust 7000t/a, straw 3000t/a

- Product index: calorific value: ≥16.9MJ/kg, volatile matter: ≥80%, total sulfur: ≤0.07%, moisture: ≤8%, ash content: <2% apparent density: >1.0g/cm3, broken rate: < 2%

- Annual water consumption: 328t/a

- Annual power consumption: 3.5 million kW·h

- Main equipment: wood crusher, wood pellet hammer mill, straw baler breaker, wood pellet making machine, baler breaker, bag filter, cyclone dust collector, etc.

Main process design:

- Unloading: The purchased wood, straw, and wood chips are transported to the factory area by car, and the unloading is stored in the warehouse.

- Chipping: Use a forklift to pour the wood into the hopper and use a crusher to break it into small pieces. Because the wood is leftovers from furniture factories, a very small amount of dust is generated during the processing.

- Crushing: The crushed wood blocks, wood chips and straw are poured into the feeding port of the crusher by a forklift for further crushing processing, and the crushed particles are sent to the closed warehouse through the pipeline. A large-scale bag filter is used to centrally process the dust in the closed warehouse and the dust collected by the feed port of the pulverizer, and the treated waste gas is discharged in the warehouse.

- Pelletizing: Sawdust is fed into seven wood pellet presses through pipelines. The die diameter is 6-10mm.

- Packaging: The qualified finished products produced are packed in bags, weighed, packed, and put into storage for stacking.

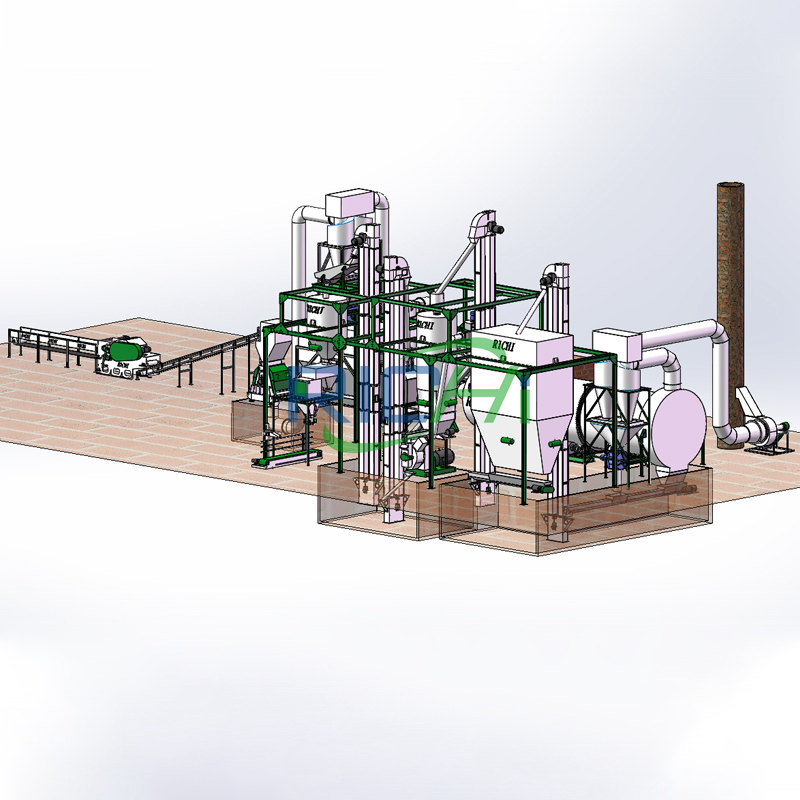

11-12 t/h wood pellet production line plan

—— RICHI MACHINERY ——

- Annual output: 70,000 tons of material particles produced annually

- Wood pellet production line price: 780,000 USD

- Total land area: 9075m2

- Annual working days: 2 shifts per day for the project, 10 hours per shift, 300 days per year

- Employees: 20 people

- Raw materials: waste construction formwork*76000t/a (solid, plate, the largest stock is 250 tons)

- Product specifications: diameter 6~8mm, density 1~1.3t/m3

- Annual water consumption: 576t/a

- Annual power consumption: 500,000 kW·h

- Main equipment: crusher, belt iron remover, screw conveyor, pulverizer, screening machine, bucket elevator, wood pellet maker machine, belt conveyor, cyclone dust collector, etc.

Main process design:

- Raw material area: After the raw materials are purchased, they are transported by car to the raw material area for temporary storage.

- Pallet crushing: The use of a crusher to crush the waste building formwork is mainly to process the raw materials into small pieces that are good for impurity removal. The crushed raw materials are transported into the iron remover through the feeding hopper through the conveyor.

- Screening: After the raw materials are removed, they are transported to the magnetic drum by the belt conveyor for screening, and the smaller iron nails are further screened out.

- Crushing: The screened raw materials are transported to the pulverizer for further pulverization, and the particle size after pulverization is less than 5mm. The crushed wood chaff is transported into the stacker, which is sealed.

- Granulation: The pretreated raw material wood bran is transported to the wood pelletizer through a closed conveyor to make granules. The project adopts a normal temperature molding process without adding binders.

- Cooling: In this project, a counter-flow cooler is installed on the finished product conveyor belt to cool down the surface of the material. The cooling method is wind cold.

- Screening: The unqualified finished products that are screened out, that is, unqualified products, are returned to the crushing process for crushing and then granulated.

- Bagging: Send the qualified finished wood pellets after processing to the finished product area, and then they can be packaged and shipped.

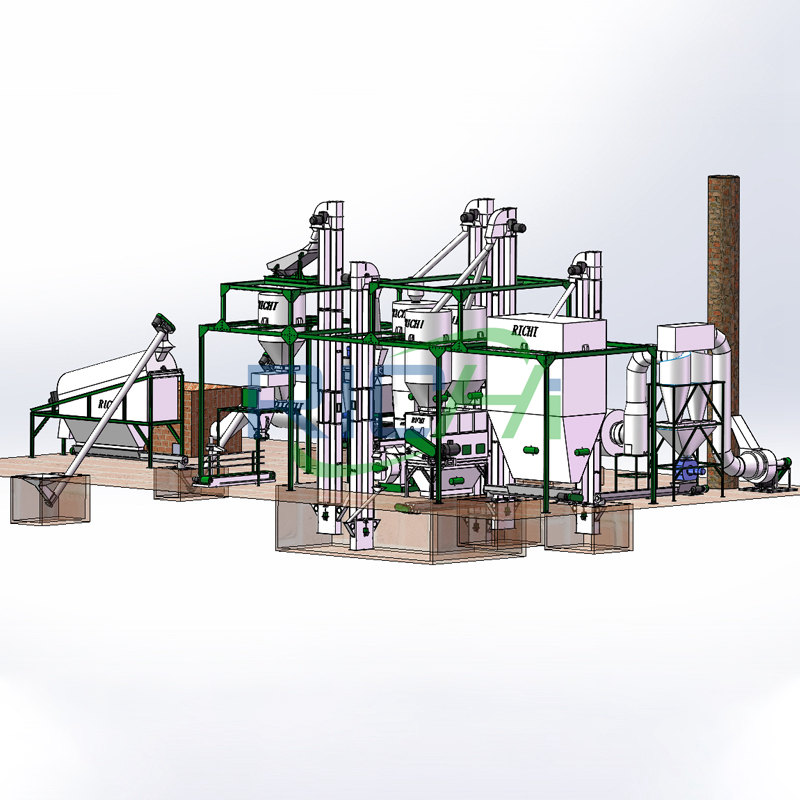

20-21 t/h wood pellet production line

—— RICHI MACHINERY ——

- Annual output: 50,000 tons of biomass pellets per year

- Wood pellet production line price: 1,200,000 USD

- The project covers an area of about: 10000m2

- Construction area: 3800m2

- Working system: About 300 working days per year, 8 hours per day.

- Employees: 15 people

- Raw materials: waste wood * 50005 tons, mainly from the waste generated during log processing

- Specifications: 8-12mm in diameter

- Annual water consumption: 180t/a

- Annual power consumption: 1.2 million kW h

- Main equipment: crusher, pulverizer, bucket elevator, wood pellet press machine, belt conveyor, cyclone dust collector, forklift, forklift, etc.

Main process design:

- Primary crushing: The raw materials of the project are purchased wood chaff and waste wood. The waste wood needs to be crushed first due to its large volume and unevenness. After primary crushing, the diameter of the particle is about 2cm, and the moisture content of the project raw material is about 10%, no need to be air-dried or dried);

- Screening: After the primary crushing, the material enters the simple sieve for screening, and the material with larger particle size is screened and returned to the primary crushing process, and the qualified material undergoes secondary crushing.

- Secondary crushing: The sieved qualified raw materials are transported to the pulverizer through the conveyor belt and pulverized into smaller size powder (crushed to a particle size of about 0.05cm);

- Granulation: The crushed raw materials are fed into the wood granulator from the hopper, and the extruded material is cut into the required pellet shape at the exit of the wood pelletizer machine. The finished products coming out of the outlet are naturally cooled, screened and packaged for storage.

- Screening and packaging: The wood pellets after granulation enter the simple sieve for screening, and the biomass pellets that do not meet the requirements are returned to the secondary crushing process, and the qualified wood pellets are transported to the packaging area by the conveyor belt for packaging in woven bags.

Different wood pellet production line price in different projects

At present, we have exported wood pellets to more than 60 countries such as the United States, Indonesia, India, Canada, Germany, Australia, Austria, Poland, Argentina, Brazil, Russia, Kazakhstan, Romania, Spain, Thailand, South Africa, Chile, Peru, etc.

In accordance with the contract, we undertake all phases of the project design, budget, equipment and material procurement, construction, trial operation, and acceptance, and finally submit a complete biomass wood pellet processing plant project that meets the functions and conditions of use to the customer, and undertakes the quality, full responsibility for schedule, cost, and safety.

America

10T/H pellet mill for sale USA

- Annual capacity:24000 tons(1600T/M,80T/D)

- Raw materials: waste wood

- Project construction period: 2 months

- Project construction land: 1200m²

- wood pellet production line price: 1,300,000USD

Canada

2-3 t/h wood pellet machine canada

- Annual capacity:4800-11000 tons(400-900T/M,16-24T/D)

- Raw materials: wood chips , sawdust

- Project construction period: 2 months

- Project construction land: 15 acres

- wood pellet production line price: 330,000USD

Brazil

4-5 t/h wood pellet production line in brazil

- Annual capacity:10000 tons(833T/M,33T/D)

- Raw materials: wood log, chips, sawdust

- Project construction period: 8 months

- Project construction land: 800m²

- wood pellet production line price: 1,700,000USD

Germany

2T/H wood pellet production line in Germany

- Annual capacity:4800 tons(480T/M,16T/D)

- Raw materials: wood chips

- Project construction period: 1 months

- Project construction land: 1100m²

- wood pellet production line price: 230,000 USD

Indonesia

1-1.5T/H wood pellet production line in Indonesia

- Annual capacity:3000 tons(250T/M,10T/D)

- Raw materials: bamboo powder, wood chips

- Project construction period: 4 months

- Project construction land: 1500m²

- wood pellet line price: 250,000 USD

Vietnam

8T/H wood pellet production line in Vietnam

- Annual capacity: 20000 tons(1666T/M, 66T/D )

- Raw materials: miscellaneous wood, peanut shells, straw

- Project construction period: 7 months

- Project construction land: 2000m²

- wood pellet line price: 520,000 USD

Thailand

10T/H wood pellet production line in Thailand

- Annual capacity: 25000 tons(2083T/M,83T/D)

- Raw materials: wood, wood sawdust, straw

- Project construction period: 8 months

- Project construction land: 2333m²

- wood pellet line price: 850000USD

Argentina

20T/H wood pellet production line in Argentina

- Annual capacity: 50000 tons (4166T/M, 166T/D)

- Raw materials: branches, leaves, straw, bagasse, banana stalk, miscanthus

- Project construction period: 11 months

- Project construction land: 2861.6m²

- wood pellet line price: 1,600,000 USD

If you are interested in 1-30t/h wood pellet production line price, please feel free to consult Richi Machinery!

Composition of 1-30T/H wood pellet production line price

The above is basically the price of all the equipment of the wood pellet production line. However, when actually building the wood pellet production line, we must pay attention to many aspects of investment. Generally speaking, a wood biomass pellet project cost consists of two parts:

01

Daily Operating Cost

- Labor cost:

- Energy cost

- Maintenance cost

- Repairs and lifecycle maintenance cost

- Transportation for bulk shipments cost

02

Basic Project Setup

- Cost of wood pelletizing line equipment

- Pellet warehousing, rail car loading facility cost

The following will explain the main components of the wood pellet production line price in detail from different aspects.

01 Size and Capacity

When constructing a wood pellet production line, one of the most important considerations to make is selecting the proper wood pellet line size and capacity. The yearly output capacity of a plant is frequently used as a measurement of its size; this capacity is typically stated in tons.

Wood pellet mill machines can range in size from small-scale facilities producing a few thousand tons yearly to huge industrial plants with capacity surpassing hundreds of thousands of tons, depending on the scope of operations and the demand in the market.

The total cost of maintaining a certain plant size depends on a number of factors. The initial wood pellet production line price with smaller scale may be lower, but it may only have a limited capacity for output.

On the other hand, larger wood pellet lines may be able to accept higher production volumes, but they may demand a higher initial investment. Before completing the plant size and capacity, it is imperative to do an in-depth analysis of the projected demand in the market as well as the available financial resources.

02 Wood Pellet Production Line Cost

When it comes to determining how much it will cost to build a wood pellet production line from the ground up, one of the most important factors to consider is the machinery and methods that will be used in the manufacturing of wood pellets that costs 50,000-3,000,000 USD.

The production of pellets calls for the use of a wide range of specialized pieces of wood pellet equipment, such as machines for producing wood pellets, hammer mills, dryers, coolers, conveyors, and packaging machines.

The wood pellet production line price that are associated with these various pieces of equipment could alter based on the quality, efficiency, and capacity of the individual pieces of equipment itself.

03 Raw Material Costs

A wood pellet production line that makes wood pellets has a number of significant factors that determine the degree to which it is profitable. Two of these major variables are the availability of raw materials and the price of those commodities.

In the manufacturing of wood pellets, examples of biomass resources that are often employed include sawdust, wood chips, and agricultural leftovers.

Recycled wood or natural fibers can be used as the primary ingredient in the production of wood pellets. The price of recycled wood is from $55 to 65 dollars per tonne, which is significantly lower than the price of native fibers, which is $70 to 80 dollars per tonne.

There are a number of factors that may considerably impact the costs connected with acquiring these raw materials. These factors include the geographic location of the business, the conditions of the local market, and the fees associated with transportation.

In order to bring down the cost of raw materials, it is very necessary to forge strategic partnerships with various suppliers. In addition, it is essential to do research into the availability of more cost-effective procurement methods and to work toward improving existing logistical arrangements.

In addition, it may be possible to reduce the cost of raw materials by putting in place efficient waste management systems and making use of by-products from the forestry and agricultural sectors. Both of these sectors produce a wide variety of by-products.

04 wood pellet production line Operation Costs

The operating costs required is $42.34 per ton. The operation of a wood pellet production line that makes wood pellets has a number of continuing expenditures, all of which need to be accounted for in the cost analysis of the overall project in order to provide an accurate picture of the total cost.

In most cases, operational expenses comprise not only the wages of employees but also the cost of maintenance and repair work, the cost of utilities such as electricity and water, as well as any other incidental expenditures.

It is very necessary for these expenditures to be effectively managed in order to ensure that the wood pellet production line will continue to be profitable and viable over the course of the long term.

The installation of tight maintenance practices, the investment in technologies that are energy efficient, and the optimization of production processes are all things that may aid in the reduction of operating expenditures.

At the wood pellet production line that creates wood pellets, it is important to conduct periodic assessments and study various choices for cost-saving measures. It is important that this be done without compromising the quality or productivity of the wood pellet production line.

05 Licensing and Regulatory Compliance Costs

The big challenge that can come in the way of wood pellet production line establishment is the strict licensing and regulatory compliance costs. Although various countries are trying to reduce the costs, the process of acquiring the necessary licenses and certifications is not that easy.

The costs that are involved with getting permits and following laws may vary greatly from one jurisdiction to another, depending on the specific limitations that are imposed by local authorities in each of those jurisdictions.

It is vital to have a full awareness of the environmental and safety standards that control the wood pellet industry in order to avoid the possibility of incurring penalties or having operations interrupted. In addition, it is essential to comply with the requirements that have been set down.

If you are not sure what the exact cost of establishing a wood pellet production line in your local area is, it is better to reach out to the local experts and consultants who are well equipped with the knowledge of the laws and the rules and regulations.

Their expertise and experience may be of assistance in navigating the complicated landscape of permits and compliance, so ensuring that the wood pellet production line complies with all of the applicable criteria.

RICHI Service

RICHI’s professional team consists of a multidisciplinary group of people which makes possible to cover every stage of the wood pellet plant construction projects, understanding every single need and reaching the best wood pellet production line solution for our clients:

- Design feasibility studies

- Basic and detailed engineering

- Process and manufacturing engineering

- Electrical and mechanical engineering

- Manufacturing

- Assembly and commissioning

- Training client´s personnel

- Plant control and programming

- Maintenance and technical after-sales assistance

- Spare parts management and supply

- Plant operation and management