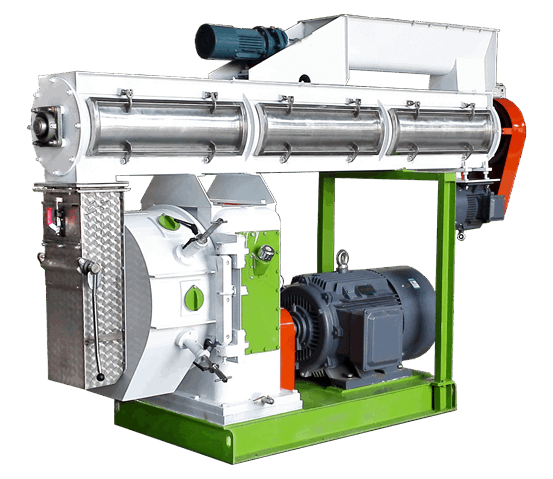

Animal Feed Pellet Mill For Sale

SZLH420 animal feed pellet mill is the key equipment for pellet feed production. We specialize in the animal feed pellet mill for sale. Our feed pellet mill machine has the characteristics of high output, good performance, low energy consumption, low noise and beautiful appearance. It is an ideal equipment for pressing pellet feed for poultry, livestock, fish and shrimp.

- Model: SZLH420

- capacity: 8-12T/H

- power: 110KW

- Price:FOB 30,000-35,000 USD

Feed pellets can be produced in several diameters and hardness, by pelletizing raw materials after grinding, mixing and conditioning.

The SZLH420 animal feed pellet mill range enables capacities up to 12 tons per hour depending on various parameters. They offer low operational costs per ton feed, even down to 1 €/ton, including dies, rollers and wear parts.

Proven features and benefits, such as high capacity, flexible production, high automation level, low maintenance costs, high feed quality and easy and safe operation, distinguish the RICHI SZLH420 feed pellet mill and other brand basic.

For a long time, Richi Machinery has focused on the R&D and manufacturing of feed pellet mill machine and provides professional animal feed pellet mill for sale, feed pellet production solutions and mature supporting products to create value for customers.

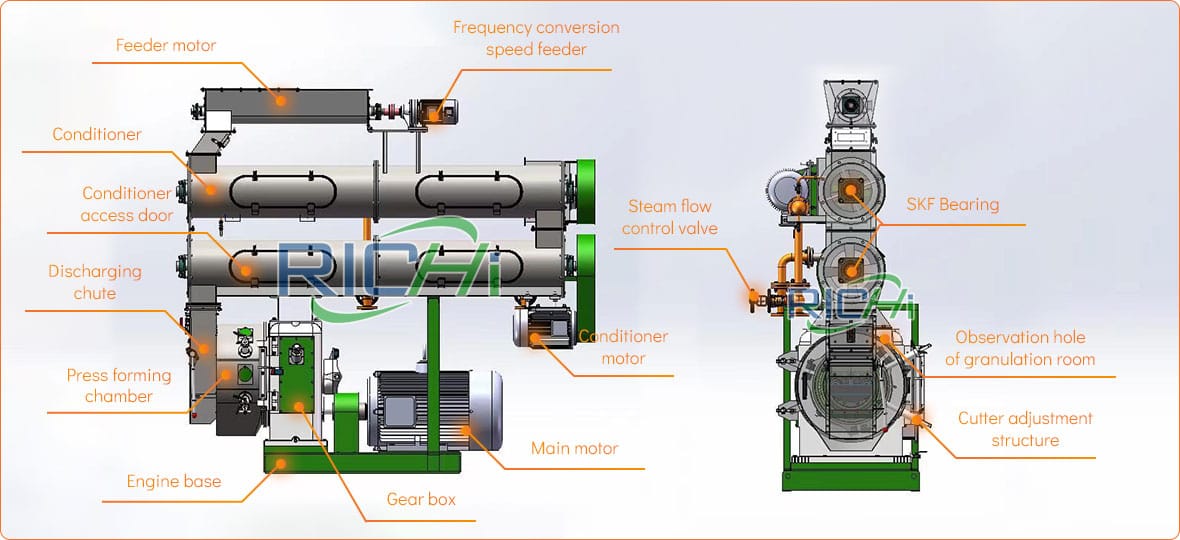

Features of SZLH420 animal feed pellet mill machine for sale

- Our animal feed pellet mill for sale more than 130 countries around the world, have the following advantages:

- The feeding system of this animal pellet mill adopts stepless speed motor control, which is convenient and reliable to adjust the speed. It can also be equipped with a microcomputer automatic control system, which can automatically adjust the feed amount and steam intake, so that the press is always in good working condition.

- High-precision gear transmission, its output is about 15-20% higher than that of belt drive type.

- The large gear and gear shaft adopt hardened tooth surface and grinding technology, with high precision and a service life of up to 15 years.

- The feed pellet mill machine housing material is made of highly wear-resistant internal combustion engine cylinder liner material, which can maintain good precision after long-term use. The service life is up to 20 years;

- The overall technical improvement makes the daily maintenance cost of RICHI animal feed pellet mill much lower than that of belt type.

- RICHI pellet mill for animal feed is easy to operate, and one animal feed pellet mill can operate multiple animal feed pellet mills at the same time. It is easier to achieve automatic control.

- Double-layer and three-layer conditioner animal feed pellet mills can be customized to produce high-quality livestock and poultry aquatic feed.

Structure of SZLH420 animal feed pellet mill for sale

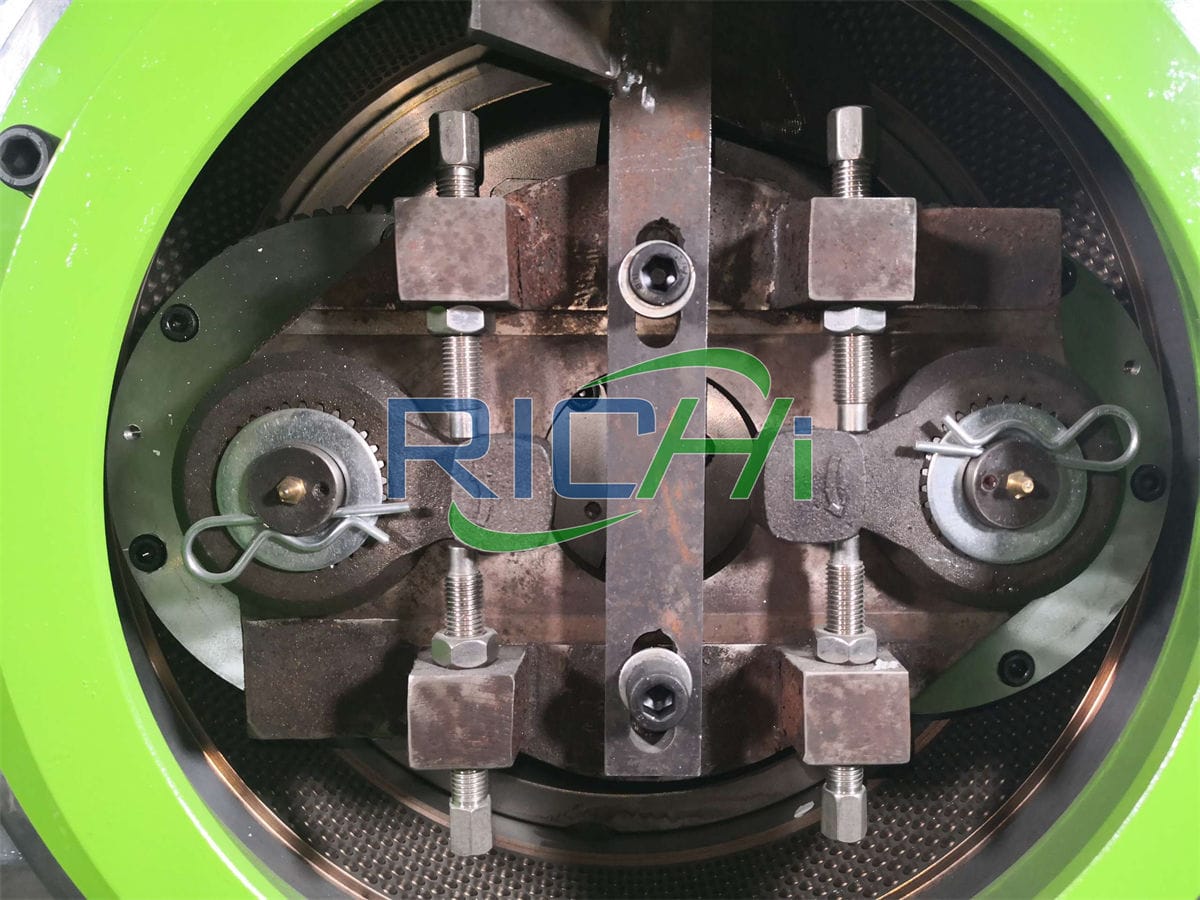

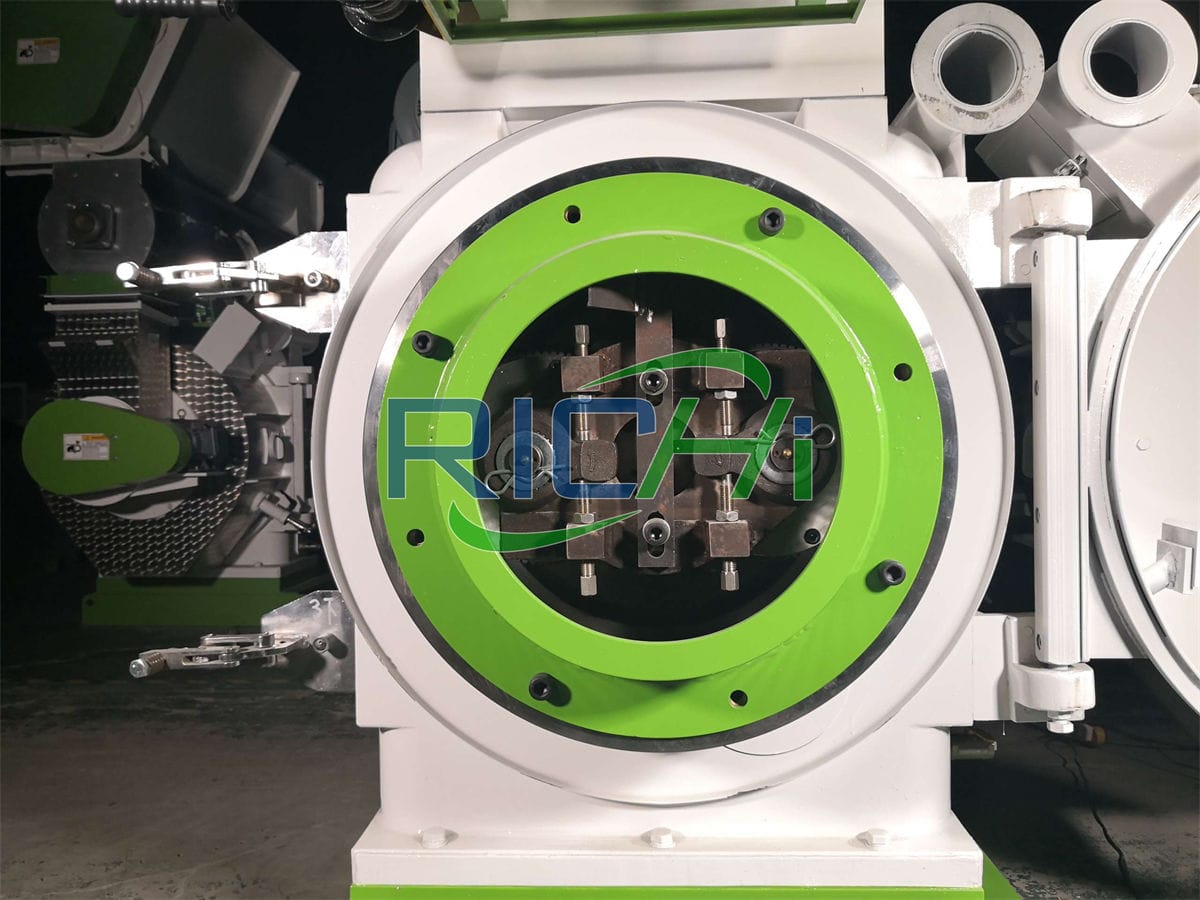

The structure of the main transmission box of the SZLH420 animal feed pellet mill mainly includes gear shaft, large gear, main shaft, transmission wheel, hollow shaft, box body, ring die, roller assembly and other parts.

- The motor drives the gear shaft to rotate through the coupling, and the gear shaft meshes with the large gear, thereby driving the large gear to rotate.

- The large gear is connected to the hollow shaft through the key, so it drives the hollow shaft to rotate.

- The hollow shaft is fixedly connected to the transmission wheel through bolts, so that the transmission wheel rotates with the hollow shaft.

- The ring die is connected to the transmission wheel through the hoop and key, so that the ring die rotates.

- The main shaft does not rotate during normal operation (except for overload). The front end is a fixed support for the roller assembly and the pressing plate, and the rear end is equipped with an overload protection device.

- The main transmission box of this pellet mill machine has a compact structure design, stable and reliable operation, and can ensure the smooth progress of the pellet pressing process.

Advantages of SZLH420 animal feed pellet mill machine for sale

- Double shaft conditioners – better absorption of steam.

- Separate motor for each shaft.

- Minimum 60 seconds of retention – adjustment up to 90 seconds.

- All steam contacting parts – SS 304

- Magnet at pellet mill Chute.

- Quick die changing arrangement.

- Split housing of pellet mill for easy maintenance

- Automatic greasing mechanism

- Spherical roller bearings.

Working principle of SZLH420 animal feed pellet mill for sale

The modulated crushed feed material is fed evenly from the chute through the die cover, with the help of gravity, the centrifugal force generated by the rotation of the ring die, and the action of the feeding scraper into the two pressing areas in the ring die, that is, the wedge-shaped space formed by the two rollers and the ring die.

Under the strong extrusion of the ring die and the roller, the material is gradually compacted, squeezed into the die hole of the ring die and formed in the die hole.

Since the extrusion of the material between the die and the roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape, and then cut into animal feed pellets of the required length by the cutter.

specifications of SZLH420 animal feed pellet mill for sale

| model | SZLH420 |

| Output (t/h) | 8~12 |

| Main motor power (kw) | 110 |

| Main motor series | 4P |

| Feeder power (kw) | 1.5 |

| Conditioner power (kw) | 7.5 |

| Ring die diameter (mm) | 420 |

| Finished pellet diameter (mm) | 2~12 |

configuration of SZLH420 animal feed pellet mill for sale

- Ring die material: stainless steel

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearing: Import

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

We can customize the animal feed pellet mill for sale the world according to the actual needs of customers, including voltage, electrical components, product color matching, and can also customize feed pellet mill process, animal pellet mill parts and different compression ratio according to different feed raw materials, formula, etc. (Find RICHI on youtube)

operation requirements of SZLH420 animal feed pellet mill

| Animal feed types | Requirements Before Entering Granulator(mm) | Pellet Diameter(mm) | Pellet Length(mm) | Ring Die Compression Ratio | Conditoning Temperature(℃) | Conditoning Time(s) | Equipped Conditioner |

| Poultry chicken | 2.0-3.0 | 2-4 | 4-8 | 1:10—-1:13 | 150 | 60-120 | one layer/two-layer |

| Cattle | 3-5mm | 6-12 | 12-18 | 1:6:1:9 | 150 | 30-60 | one layer/two-layer |

| pig | 2-3 | 2-4 | 3-8 | 1:3.5—-1:5 | 150 | 60-120 | One layer/two layer |

| fish | 1.0-2.0 | 2-6 | 4-12 | 1:16—-1:18 | 150 | 90-180 | Two layer/three layer |

| shrimp | 95%≥80 mesh | 1.2-2.0 | 1.8-4 | 1:20—-1:25 | 150 | 120-180 | three layer |

| … | |||||||

animal feed pellet mill for sale Different countries

We have exported animal feed pellet mill for sale more than 130 countries and have reached strategic cooperation with thousands of customers around the world.

animal feed pellet mill for sale Russia

- feed pellet mill selection: SZLH420

- Feed Size: 2-4mm pellets

- project cost: 290,300 USD

animal feed pellet mill for sale Germany

- feed pellet mill selection: SZLH420

- Feed Size:1-5mm pellets

- project cost: 350,600 USD

animal feed pellet mill for sale Thailand

- feed pellet mill selection: SZLH420

- Feed Size: 2-4mm pellets

- project cost: 440,900 USD

animal feed pellet mill for sale Kazakhstan

- feed pellet mill selection: SZLH420

- Feed Size: 2-4mm pellets

- project cost: 520,600 USD

animal feed pellet mill for sale Cote d’Ivoire

- feed pellet mill selection: SZLH420

- Feed Size: 2-6mm pellets

- project cost: 370,000 USD

animal feed pellet mill for sale Ghana

- feed pellet mill selection: SZLH420

- Feed Size: 2-5mm pellets

- project cost: 430,000 USD

animal feed pellet mill for sale Mauritania

- feed pellet mill selection: SZLH420

- Feed Size: 3-6mm pellets

- project cost: 290,000 USD

animal feed pellet mill for sale New Zealand

- feed pellet mill selection: SZLH420

- Feed Size: 2-4mm pellets

- project cost: 350,000 USD

Application of SZLH420 animal feed pellet mill

SZLH420 animal feed pellet mill is mainly used for 8-10 tons feed production line or commercial feed mill with larger output.

As a feed pellet mill machine manufacturer, Richi Machinery can not only focuses on the animal feed pellet mill for sale, but also undertake all feed pellet production line stages design, budget, feed pellet mill machinery and material procurement, construction, trial operation and acceptance of a complete feed pellet production line system project, and finally submit a feed pellet production line.

The complete set of animal feed pellet production line is designed with transmission, crushing, mixing, pelletizing, cooling, screening and packing, so it is easy to operate it due to its customized and complete structure.

This model has 1.5-12mm between a variety of aperture and thickness of the ring die, users can choose according to different needs, in oder to obtain the best technical and economic benefits.

The complete set of feed mill equipment for producing feed pellets usually includes raw material processing equipment, pelletizing equipment, drying equipment, whole grain equipment, packaging equipment and auxiliary equipment.

The functions of these equipment cover the entire production process from raw material processing to product packaging. The price will vary depending on the type and function of the equipment.

If you are looking for manufacturer who focus on animal feed pellet mill for sale, If you want to get 8-12t/h animal feed mill plant solution, click the button below to get detailed solution design, animal feed mill equipment configuration list and production line quotation.

Video of animal feed pellet mill

FAQs of animal feed pellet mill for sale

How much does a SZLH420 animal feed pellet mill cost?

The price of SZLH420 animal feed pellet mill is generally between FOB 30,000-35,000 USD.

With the advancement of science and technology and the development of the feed industry, the technology and performance of feed production equipment are also constantly improving. As an important part of feed production, the SZLH420 animal feed pellet mill price varies due to many factors.

1. Equipment Performance and Price

The performance of the equipment is one of the important factors that determine the animal pellet mill price. The more advanced the performance and the higher the degree of automation, the higher the price. For example, an efficient and stable feed pellet mill can improve production efficiency, reduce energy consumption and reduce manual intervention, so the price is relatively high.

2. Equipment Brand and Price

The prices of feed pellet mills of different brands also vary. The animal feed pellet machine price from internationally renowned brands is usually higher, but the performance is stable and the quality is guaranteed.

The price of equipment from general brands is relatively low, but the performance and quality vary. Although the cost of choosing equipment from well-known brands is higher, it can reduce the risk of later maintenance and repair.

3. Market Supply and Demand

The market supply and demand relationship is also an important factor affecting the price of animal feed pellet mill machines. When market demand is greater than supply, equipment prices usually rise; conversely, when supply is greater than demand, equipment prices fall. In addition, the intensity of market competition will also affect equipment prices.

4. Purchase method and price

The purchase method of pellet mill animal feed will also affect its price. Generally speaking, the price of equipment purchased through bidding or long-term cooperation is relatively favorable. However, single purchase or short-term cooperation may result in higher prices.

5. Regional differences and prices

The prices of animal feed pellet mills in different regions also vary. Generally speaking, the price of equipment in developed regions is relatively high, while the price of equipment in developing regions is relatively low. This is mainly due to the influence of factors such as the level of economic development, labor costs and market competition in different regions.

In summary, the factors affecting the price of animal feed pellet mill are multifaceted, including equipment type and function, performance and price, brand and price, market supply and demand, purchase method and price, and regional differences and price.

When choosing a animal feed pellet mill, manufacturers should make comprehensive considerations based on their actual situation, choose equipment that suits them and reasonably control costs.

At the same time, in order to reduce risks and improve production efficiency, animal feed mill plants should also pay attention to the maintenance and care of equipment to ensure the long-term stable operation of the equipment.

How to choose animal feed pellet mill?

When choosing animal feed pellet mill, you need to consider multiple aspects to ensure that the equipment can meet production needs, improve production efficiency, and reduce costs. The following is an analysis of selecting production equipment:

- First, you need to consider the product structure.

Different products may require different equipment and process flows. For example, if you are producing broiler feed, you need a standard poultry feed pellet mill machine with a conditioner; if you are producing grass feed for cattle, you need to use a grass feed pellet mill machine. Therefore, when choosing production equipment, you need to choose the right equipment based on the product structure. - Second, you need to consider the quality requirements of the product.

Different equipment will produce different product quality due to differences in performance and precision. Therefore, when choosing an animal feed pellet mill, you need to choose equipment that can meet production needs based on the quality requirements of the product. - Third, you need to consider the use scenario of the animal feed pellet mill.

Different equipment is suitable for different production scenarios. For example, if you want to produce a large number of standard parts, you need to choose a production line with a high degree of automation; if you want to produce small batches and multiple varieties of products, you need to choose modular equipment with good flexibility. Therefore, when choosing animal feed mill equipment, you need to choose the right equipment according to the usage scenario.

In short, choosing animal feed pellet mills and feed equipment requires considering many aspects, including product structure, product quality requirements, and usage scenarios.

Only by comprehensively considering these factors can we choose the right equipment, improve production efficiency and quality, reduce costs, and obtain better economic benefits.

How to choose animal feed pellet mill manufacturer?

In recent years, animal feed production lines have been very popular, and animal feed pellet mills are naturally a hot topic. With the increase in animal feed pellet mill manufacturers, market competition has become increasingly fierce. How should feed factories choose equipment?

- First of all, when choosing animal feed pellet mill, you should look at the quality of the product.

For all users, product quality is the most concerned topic. If the quality of the equipment is high, the quality of the products produced will be good, and at the same time, it can save maintenance costs, and production failures will be greatly reduced.

Overall, it can greatly improve the overall production efficiency. Therefore, when choosing a feed pellet mill manufacturer, we must first pay attention to the quality and production efficiency of the product. - The reputation and strength of the animal feed pellet mill manufacturer are also very important.

Generally speaking, animal feed pellet mill manufacturers with good brands, good reputations, high credibility and considerate services are basically strong.

Some large manufacturers will have a lot of investment in scientific and technological research and development, so the continuous innovation and reform of their production processes will be very advanced. Of course, the equipment produced is of reliable quality and high wear resistance, and the service life of the animal feed pellet mill will also be very long. - When choosing a manufacturer who focus on animal feed pellet mill for sale, we must also pay attention to whether its after-sales service is perfect.

You must know that as long as it is a regular manufacturer, its after-sales service is generally very perfect.

However, when understanding, we must also pay attention to whether the after-sales service contains operator training, whether it provides users with feed pellet production line design services and other projects. In this way, the after-sales service covers a wider range, and their rights and interests are more effectively protected.

There are many animal feed pellet mill manufacturers, and all users should pay attention to factors such as product quality, manufacturer reputation and after-sales service when choosing.

Only when these aspects are thoroughly understood can we make effective judgments in a timely manner and compare prices reasonably. The selected animal feed pellet mill will be more efficient in production and the feed pellet production line will operate more efficiently.