Bentonite Granules Making Machine

Bentonite granules making machine is mainly used for processing cat litter pellets, organic fertilizer pellets, feed pellets, etc.

What’s Bentonite granules making machine?

Bentonite granules making machine is a horizontal ring die type pellet machine, mainly used to process various pellet products with bentonite as the main raw material, such as cat litter, organic fertilizer, feed, etc. It’s a fact. The right pellet mill makes all the difference in your bentonite processing operation, increasing your production efficiency—and ultimately, your profit.

RICHI Machinery specializes in designing the best bentonite pellet mill systems using our top-quality equipment to help you produce cat litter pellets, and get it to market economically and efficiently.

Fortunately, here at RICHI, we’ve got decades of bentonite pellet equipment experience ready to help you set up an efficient production system that will enhance your factory’s overall performance.

- Capacity:1-42 T/H

- Cost: 7000-100,000 USD

- Applicable customers: cat litter factory, bentonite processing plant, pet products company, etc.

Whether you’re buying bentonite granules making machine, building a new bentonite granules production plant, revamping an existing system, need engineering help on a bentonite pellet plant design project, or upgrading your bentonite pellet machines, trust RICHI to deliver effective bentonite pellet processing equipment and full bentonite pellet production line design solutions.

Our knowledgeable and experienced design-and-build team of engineers will put together the right system for your unique operation that maximizes your production and reduces your costs.

What’s Bentonite?

Bentonite is a widely used mineral resource. It has abundant reserves and a wide range of origins. It is also widely used in various industries. One of the characteristics of bentonite is adsorption. With the development of the pet industry, this characteristic of bentonite has also been widely used. Good application, cat litter is a good example.

Bentonite cat litter is a product used for cats’ hygiene needs. It’s made from all-natural bentonite clay, which has excellent moisture absorption and deodorizing properties. As people pay more attention to pets, the bentonite cat litter market has gradually grown.

In addition to making cat litter, bentonite can also be used for adsorption and clarification of feed, organic fertilizer, fuel oil, edible oil, juice, wine, etc. Its other name is “montmorillonite”, which can be used to make medicine. But at Richi Machinery, we can only provide bentonite cat litter pellet machine, bentonite organic fertilizer pellet making machine and bentonite feed pellet machine.

This page will introduce products with the bentonite cat litter granulator machine as the core. If you want to process other types of bentonite pellets, please contact us for detailed product information and quotations!

The role of bentonite in cat litter production

As the main raw material of cat litter, bentonite’s main function is to absorb cat’s excrement and urine and form clumps for easy cleaning. At the same time, bentonite clay has strong hygroscopicity and can effectively control the humidity in cat litter and prevent mildew and odor problems.

Issues to note:

- The quality of raw materials must be stable, especially the quality of bentonite;

- Control the humidity, temperature and time during the production process to avoid problems of poor drying or overdrying;

- Pay attention to quality issues during the screening process to ensure that the cat litter produced has no foreign matter and uniform pellets;

- Packaging must be operated in strict accordance with the requirements and comply with the relevant standards of the country and region where it is located.

In short, through appropriate raw material selection and bentonite granules manufacturing process control, it is completely feasible to produce high-quality bentonite cat litter, and this is also one of the necessary means to provide a high-quality life for pets.

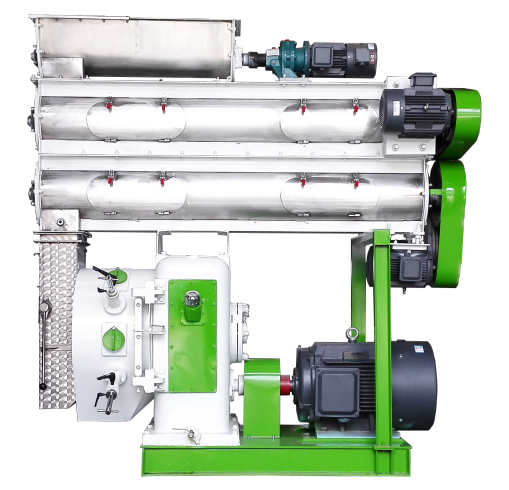

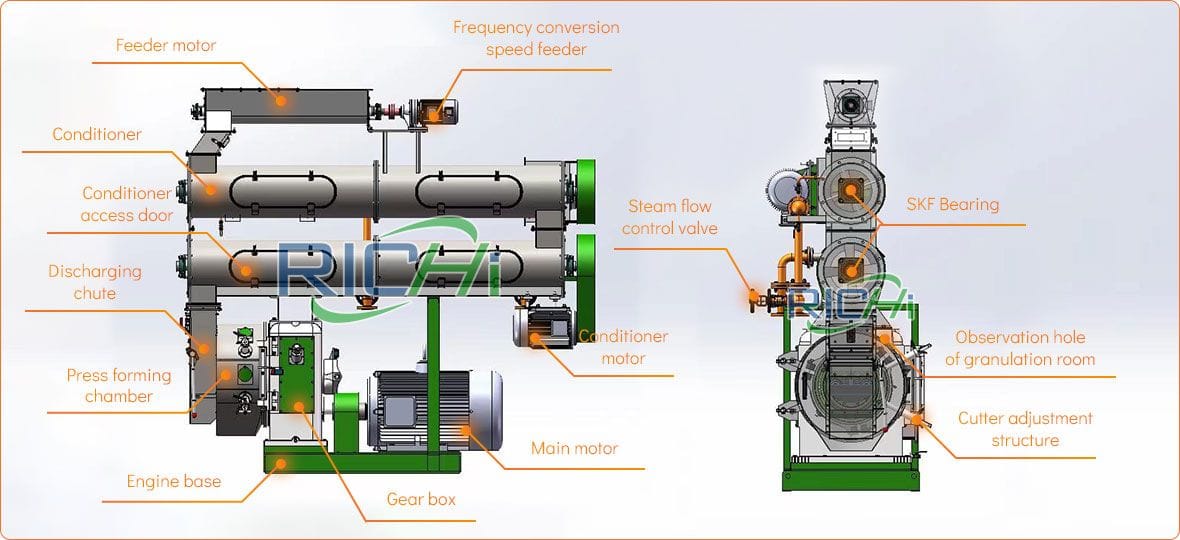

Characteristics of bentonite granules making machine

A bentonite granules making machine usually includes a base, magnet, guide plate, granulation chamber, door cover, main transmission box, speed regulating motor, reducer, hopper, unloading door, feeder, conditioner, motor, overload protection device, coupling, main motor, travel switch, lubrication system and other structural components. It has the following technical features:

- The bentonite cat litter granulator machine is equipped with brand SKF bearings to ensure the operational stability and long working life of the equipment;

- The ring die gap is automatically adjusted without stopping the machine to improve production efficiency;

- The main transmission adopts a variety of combined sealing structures to ensure the sealing reliability of the transmission system; the temperature of the main transmission system automatically monitors and alarms to ensure the stable operation of the equipment;

- Thin oil circulation cooling outside the machine improves the cooling and lubrication effect of the transmission system, allowing the equipment to work trouble-free for a long time;

- The whole bentonite cat litter granules making machine realizes automatic control of water, electricity, steam, temperature, etc.;

- Designed according to the usage habits of cat litter companies, workers can adapt quickly and operate easily;

- The operating procedures can be stored according to different cat litter formulas and started with one click;

- Equipment maintenance, automatic prompts and alarms, convenient equipment management;

- The optional automatic grease lubrication system makes adding grease more convenient, saving people, worry and effort.

Since we have very good experience to manufacture professional & high quality bentonite granules making machine, we now keep expanding our products range to include more and more pellet machine so as to offer more and more best quality pellet machine for all our customers and users.

Advantages of bentonite granules making machine

More energy saving

The RICHI bentonite cat litter making machine adopts advanced spiral blade compression technology to combine all subsequent processing processes into one, thereby avoiding energy waste caused by multiple processing of materials, thus significantly saving energy and reducing granulation costs.

Realize automated production

RICHI bentonite cat litter making machine adopts an automated production method. Through automatic feeding, automatic unloading, automatic cleaning and other technologies, it reduces the intervention of manual operations, reduces the impact of human factors on the output quality during the production process, and improves production efficiency and stability.

High production efficiency

The RICHI bentonite cat litter pellet machine also has the characteristics of high-speed rotating equipment, large torque, and high pressure, and can quickly compress and mold materials, thus improving production efficiency.

Moreover, due to its automated production method, it reduces the impact of human factors on production efficiency and increases the stability and reliability of production output.

Others

In addition to the above advantages, RICHI bentonite cat litter pellet mill also has the following other advantages:

- The bentonite clay cat litter machinery has compact structure, small size and small floor space;

- Long service life, easy to maintain and easy to clean;

- It has a wide range of applications and can be adapted to different raw material types and specifications.

To sum up, the ring die cat litter bentonite granulator is a granulating equipment with powerful functions, high production efficiency, energy saving and environmental protection, and easy operation and maintenance.

Compared with traditional cat litter bentonite machines, RICHI ring-die bentonite granule cat litter machines have higher production efficiency and lower costs, and will have broad application prospects in the future granulation equipment market.

Working principle of bentonite granules making machine

Bentonite granules making machine is mainly composed of feeder, conditioner, transmission system, lubrication system and host machine.

Its working principle is:

- Bentonite powder with a moisture content of no more than 15% enters the feeding auger from the warehouse to be granulated.The appropriate material flow rate is obtained by adjusting the rotation speed of the feeding auger shaft, enters the conditioner, and passes through the conditioning shaft.

- Stir and mix with steam for tempering. The iron removal device bypasses the chute and enters the ring mold cover. The powder is rolled into the pressing area through the feeding scraper. The transmission shaft drives the ring mold to rotate.

- The bentonite powder is drawn into the ring mold and pressed. Between the rollers, two relatively rotating parts gradually squeeze the powder into the die hole of the ring die to form, and continue to squeeze out, and then the cutter cuts the pellets into the required length and flows out of the machine.

Technical parameters of bentonite granules making machine

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SLZH858 |

| Output (t/h) | 1~2 | 3~4 | 5~7 | 8~12 | 10~18 | 15~25 | 20~30 | 25~40 | 28~45 |

| Main motor power (kw) | 22 | 37 | 55 | 110 | 160 | 180/200 | 220/250 | 250/280 | 315/355 |

| Main motor series | 4P | ||||||||

| Feeder power (kw) | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Conditioner power (kw) | 1.5 | 2.2 | 3 | 7.5 | 11 | 11 | 11 | 11 | 15 |

| Ring die diameter (mm) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished pellet diameter (mm) | 2~12 | ||||||||

| Equipment Configuration | Ring die material: stainless steel Door cover of granulation room: 6mm /SUS304 Feed chute: 3mm /SUS304 Gear box: HT250 Gear: 42CrMo Gear shaft: 20CrMnTi Spindle: 42CrMo Empty shaft: 42CrMo Bearing: Import Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Using Siemens Motor | ||||||||

Bentonite cat litter specifications:

- Compressed Resistance(g): > 400g

- Absorbent: >300%

- Specific Gravity(g/ml): 0.75-0.83g/ml

- Moisture: < 10%

- Size: 1-4mm(we can also OEM other size)

- Dust: < 0.5%

- Shape: pellet

Bentonite granules making machine projects

bentonite cat litter granulator machine in russia

- project date: 2023.07.21

- Pellet Size: 3-5mm

bentonite cat litter granulator machine in Thailand

- project date: 2022.11.10

- Pellet Size: 3-4mm

bentonite cat litter granulator machine in australia

- project date: 2022.04.19

- Pellet Size: 3.5-4.5mm

Bentonite granules making machine price

The price of a bentonite pellet making machine is usually between 7,000 and 100,000 USD. If there are special process requirements, we can also customize the equipment according to customer requirements, such as increasing the number of conditioner layers, changing the color of the equipment, changing the voltage, adjusting the size of the feeding port, etc.

Generally speaking, the price of bentonite pellet machine depends on many factors, including but not limited to the following aspects:

- Specifications and production capacity:

The size and performance of the bentonite granules making machine will directly affect its price. Generally speaking, the larger the specifications and the higher the production capacity, the higher the price. - Function and technology:

Different bentonite cat litter pellet mills may have different designs or use different technologies, and these factors will also have an impact on pricing. - Material and quality:

The manufacturing materials and processing technology of the bentonite granulator will also affect its durability and stability. Generally speaking, the price of equipment made of high-quality materials is relatively high. - Market conditions and competition:

Market supply and demand, brand awareness, competitive pressure and other factors may have an impact on the price of bottle washing machines. If the market demand is large, the price of equipment with high brand awareness may increase accordingly.

In short, the price of the bentonite granules making machine is determined by a variety of factors. Customers should choose the equipment that suits them based on actual needs when purchasing.

How to make bentonite pellets? Complete bentonite cat litter pellet production line process

Investing in a set of bentonite cat litter making machine costs tens to hundreds of thousands of dollars. We will reasonably design and configure a bentonite cat litter production line based on customer needs, equipment models, output, etc. The following is a detailed description of the bentonite granules manufacturing process:

- Preparation of raw materials: The raw materials of many customers are different. The main raw materials of common bentonite cat litter are bentonite, attapulgite, clay, water, corn starch and some additives.

- Mixing preparation: Mix all the raw materials evenly according to a certain proportion to ensure that the various raw materials are fully mixed. During the mixing process, attention should be paid to controlling the amount of water added to avoid delamination or undesirable caking.

- Granulation: To granulate the mixed raw materials, you can choose single-layer conditioner granulator, double-layer conditioner granulator and other bentonite granules making machines, using ring die granulation technology.

- Drying: Put the formed cat litter into the drying room to dry. The general drying time is 2-3 hours. During the drying process, attention should be paid to controlling the temperature and humidity to avoid problems such as poor hardness, excessive softness, and poor absorbency of the cat litter.

- Screening and packaging: The dried cat litter is screened and packaged, usually using automated packaging lines. During the packaging process, attention should be paid to screening the quality of cat litter to avoid problems such as inclusion of foreign matter.

Different processes have an important impact on the quality and use experience of cat litter. For example, the strength and particle size control in the crushing process will affect the water absorption and caking ability of the cat litter; the temperature and time settings in the drying process will affect the moisture content and dust content of the cat litter.

There are more and more people raising cats. Both the elderly and young people like to keep cats as a kind of sustenance and companionship. It seems that the bentonite cat litter processing industry has a very broad prospect and is a good investment direction. If you need a custom cat litter bentonite making line system designed for your pellet production buisness, we can do that!

Equipment for bentonite cat litter pellet production line

As can be seen from the bentonite granules processing technology above, the production process of bentonite cat litter is roughly as follows: crushing → granulation → drying → screening → finished product packaging. The equipment used in each process is also different, so what are the equipment for producing bentonite cat litter?

Below we will introduce to you the role of bentonite cat litter production equipment in each link:

Hammer Mill

Capacity:

3-25T/H

Main Power:

30-160 KW

Mixing Machine

Capacity:

250-2000KG

Main Power:

4-55KW

bentonite dryer

Capacity:

Customized

Rotate Speed:

3-8 r/min

- Bentonite crusher:

It is the main equipment in the crushing process. Before crushing, 2%-3% sodium carbonate should be added to the bentonite. Its function is to increase the adsorption (water absorption) of the bentonite cat litter. After adding sodium carbonate, it can be mixed evenly through a mixer or feeder, and then processed into a 200-mesh powder through a jaw crusher. - Bentonite granulator:

It is the main equipment in the granulation process. After the bentonite is crushed by the jaw crusher, it enters the bentonite granules making machine for granulation. At this stage, about 0.2% potassium permanganate solution can be added to make the later cat The finished sand has the effect of disinfection and sterilization. Adding 1% water glass solution can increase the cohesion of bentonite powder.

At the same time, add water drop by drop evenly during the granulation process. Just set the granulated product to 0.8-5mm. At this time, the processed cat litter will be wet, and what we want to take advantage of is the water absorption of cat litter, so we need to carry out the next step of drying. - Bentonite dryer:

Dehydrate and dry the granulated bentonite wet cat litter. The moisture content of the granulated cat litter is about 16%, and we need to use a tumble dryer to reduce the moisture to less than 6%. Since it is dehydrated through high-temperature drying, the freshly dried cat litter has a certain temperature. , at this time, it will be cooled naturally. Since bentonite has strong adsorption, it will absorb a certain amount of moisture during the cooling process. The moisture content of the cooled cat litter is 6%-8%, which is why we need to reduce the moisture to 6%. % instead of dropping directly to 8%. - Finished product measurement and packaging equipment:

Quantitative packaging according to product requirements. The cat litter after drying and cooling is the finished product, but we rarely sell it in bulk when selling. Moreover, leaving the bentonite cat litter in the air for too long will affect the later use effect, so it must be measured and packaged after cooling. Then store in warehouse.

Our team works hard to design and build bentonite cat litter pellet production plants, upgrade pelleting, drying, crushing and screening & bagging equipment, introduce conveyor systems, and assemble full-circuit solutions with you in mind.

If you are interested in buying bentonite granules making machine or building a bentonite cat litter production line, you can contact RICHI Machinery at any time. We have more than 30 years of experience in equipment production and can tailor a reasonable cat litter production line plan for you and provide comprehensive technical support!

How to choose a bentonite cat litter granulator manufacturer?

With the rapid development of the bentonite cat litter processing industry, granulator equipment plays an increasingly important role in the cat litter granulation process. For companies that want to improve production efficiency, reduce costs and ensure food safety, it is crucial to choose a reliable cat litter pellet machine and cat litter pellet production line manufacturer.

1. Clarify needs and budget

Before choosing a bentonite cat litter making machine manufacturer, customers must first clarify their production needs and budget. This includes production scale, equipment type, degree of automation, material requirements, and budget range. Clarifying needs will help customers choose the appropriate equipment manufacturer in a more targeted manner.

2. Examine the strength of the manufacturer

- Technical strength: Examine whether the manufacturer has a professional R&D team and technical support team, and whether it can provide equipment and technical support that meet the needs of cat litter production.

- Production experience: Understand the manufacturer’s production history, cases and customer feedback to evaluate its experience and strength in the field of granulators.

- Scale and qualifications: Examine the manufacturer’s production scale, qualification certification and quality management system to ensure that it has stable production capacity and product quality.

3. Equipment performance and quality

- Equipment performance: Pay attention to the production efficiency, stability, energy consumption and other performance indicators of the equipment to ensure that the equipment can meet the production needs of the enterprise.

- Product quality: Understand the material, craftsmanship and durability of the equipment to ensure long-term stable operation of the equipment and guarantee product quality.

Choosing a reliable granulator manufacturer is a key step for improving bentonite cat litter production efficiency, reducing costs and ensuring pet safety.

Bentonite cat litter processors should clarify their needs and budget during the selection process, and comprehensively examine the manufacturer’s strength, equipment performance and quality, as well as after-sales service and technical support to ensure that they choose the equipment manufacturer that suits them.

Why invest in bentonite cat litter processing business?

1. Market size

The bentonite cat litter market is gradually expanding globally. According to industry statistics, the bentonite cat litter market size has exceeded US$X billion and is expected to maintain steady growth in the next few years. This is mainly due to the increasing demand for pet care globally and the growing focus on environmentally friendly products.

2. Growth trend

- The number of pets increases: With the development of the pet care industry, more and more people choose to keep pets. According to statistics, the number of pets worldwide is increasing by X% every year, which brings huge opportunities for the growth of the bentonite cat litter market.

- Product innovation: There are many types of cat litter available on the market, including ordinary litter, silica gel litter, etc. However, bentonite cat litter has gradually become the first choice of consumers due to its good water absorption performance and deodorizing effect. In the future, there is still a lot of room for innovation in the bentonite cat litter market, and new products can be continuously launched according to consumer demand.

- Increased awareness of environmental protection: As people pay more attention to environmental protection, more and more consumers tend to choose environmentally friendly products. As a natural material, bentonite cat litter meets environmental protection standards, so it is favored by more and more consumers. In the future, the increase in environmental awareness will further promote the development of the bentonite cat litter market.

3. Development opportunities

- Market segmentation: There are currently many brands of bentonite cat litter on the market, and competition is fierce. However, there are still opportunities for market segmentation, and special products can be launched for different consumer groups, such as adding fragrance, improving adsorption performance, etc., to meet the individual needs of consumers.

- Increase channel expansion: In addition to traditional physical store sales channels, bentonite cat litter can also be promoted and sold through Internet sales, social media and other channels. Expanding diversified sales channels will help bentonite cat litter brands better reach potential consumers and increase market share.

- International market expansion: The bentonite cat litter market is not limited to the domestic market. Nowadays, the demand for pet products in the international market is also increasing. By exploring the international market, the bentonite cat litter brand can further expand its sales scale and increase its market share.

To sum up, the bentonite cat litter market has great development potential. With the increase in people’s demand for pet care and the improvement of environmental awareness, the bentonite cat litter market is expected to achieve sustained and stable growth.

In response to market opportunities, bentonite cat litter brands should strengthen product innovation and channel expansion to further enhance market competitiveness.

If you want to invest in bentonite cat litter processing business, contact us to get professional technical support! (Find RICHI on YouTube)