cattle feed mill equipment

Cattle feed mill equipment are widely used in fields such as beef cattle feed and dairy cow feed processing and breeding. They are necessary equipment to ensure feed quality and improve feed production efficiency.

RICHI cattle feed mill machinery is essential equipment for modern cattle cow breeding and feed production. It has the characteristics of high precision, high efficiency and high degree of automation.

In cattle feed production, the rational use of complete sets of livestock feed mill equipment can improve the quality and efficiency of cattle feed production, reduce production costs, and play an important role in promoting the development of animal husbandry and feed processing industries.

We can help you to find that balance between feed quality and feed costs. With the input of your requirements and our engineering expertise and process know-how we are able to build your cattle feed mill in a configuration that will give you a competitive edge.

- Capacity: 1-160T/H

- cattle feed mill equipment Price: 10,000-5,000,000 USD

- Feed Types That Can Be Processed: Pellet Feed (2-12mm), Mash Feed, Premix Feed, Concentrated Feed

- Achievable Annual Output (T/A): 6,000 – 960,000 (Operation Is Based On 300 Days A Year, 10 Hours A Day, Two Shifts)

cattle feed mill equipment list

Below is a list of the main cattle feed equipment of a cattle cow feed mill. RICHI cattle feed mill machines are challenged to optimally process a large number of ingredients and ensure the desired feed quality while keeping capacity high and cattle feed costs low.

storage silos

Steel silo can withstand high strength and good sealing performance, and is suitable for warehousing of various sizes. Our silo equipment is also easy to assemble and transport, and is suitable for use in feed mills with temperature measurement systems, ventilation systems, automatic positioning systems, silo reversing systems, lightning protection systems, etc.

- Capacity:300 – 10000 Tons

- type: Prefabricated Storage Silos, Spiral Storage Silos

Cylindrical primary cleaning screen

It is widely used in the raw material receiving part of flour mills, animal feed mill plants, grain warehouses and other industries. It is mainly used to remove large impurities such as straw, wheat straw, hemp rope, paper, soil clods, corn leaves, corn cobs and other debris to protect cattle feed mill equipment from malfunction or damage.

- Capacity:15-50T/H

- Power: 0.75-1.5 KW

Powder cleaning sieve

It is mainly used for the initial cleaning of powdery auxiliary materials in compound feed factories. It can effectively break the agglomerates in the powdery auxiliary materials and separate large particles such as straw, hemp rope, paper, and stones mixed in the powdery auxiliary materials. complex to ensure the normal operation of subsequent equipment. This machine can also be used to screen mixed materials and remove lumps to ensure the quality of compound feed.

- Capacity:10-30 T/H

- Power: 5.5-7.5 KW

Permanent Magnet Sleeve

It is mainly composed of three parts: the cylinder, the permanent magnet and the door. Through the adsorption effect of the permanent magnet in the cylinder, the magnetic metal impurities such as nails, screws, washers, steel balls and iron blocks mixed in during the process are removed to avoid wear and damage to the machinery and equipment.

- Model: TCTX

- Capacity:20-60 T/H

cattle feed grinder machine

This series is a general-purpose feed grinder with a screen aperture of 1.5-3.0. It can crush various granular feed raw materials and is mainly used in the crushing and processing of livestock and poultry feed raw materials and various grain raw materials. Horizontal crushing equipment suitable for feed, biochemical, brewing and other industries.

- Capacity:3-25 T/H

- Power: 30-160 KW

grass hay alfalfa straw crusher machine

The grass crusher machine is specially designed for lightweight materials such as crushed grass, straw, and chaff. The forced feeding part has a large crushing chamber. This series is a fine-grade hammer crusher with a screen opening of 2.0-6.0mm.

- Capacity: 0.3-3 T/H

- Power: 22-93 KW

batching system

An imported industrial computer is used as the batching host, and is combined with the operation console, simulation screen, scale body, etc. to form a complete set of control systems. It can be flexibly composed of one machine with one scale, one machine with two scales, one machine with three scales, and one machine with four scales according to needs.

- Specifications: 250-2000 KG

- Measuring accuracy: better than ±0.1% (static), better than ±0.3% (dynamic)

Liquid addition system

It is suitable for adding nutrients such as oil, molasses, and phospholipids to batch mixers, and has a wide range of adaptability. It has simple structure, automatic control and easy operation.

- Adding rate: 50-200 L/Min

- Power: 2.2-5.5 KW

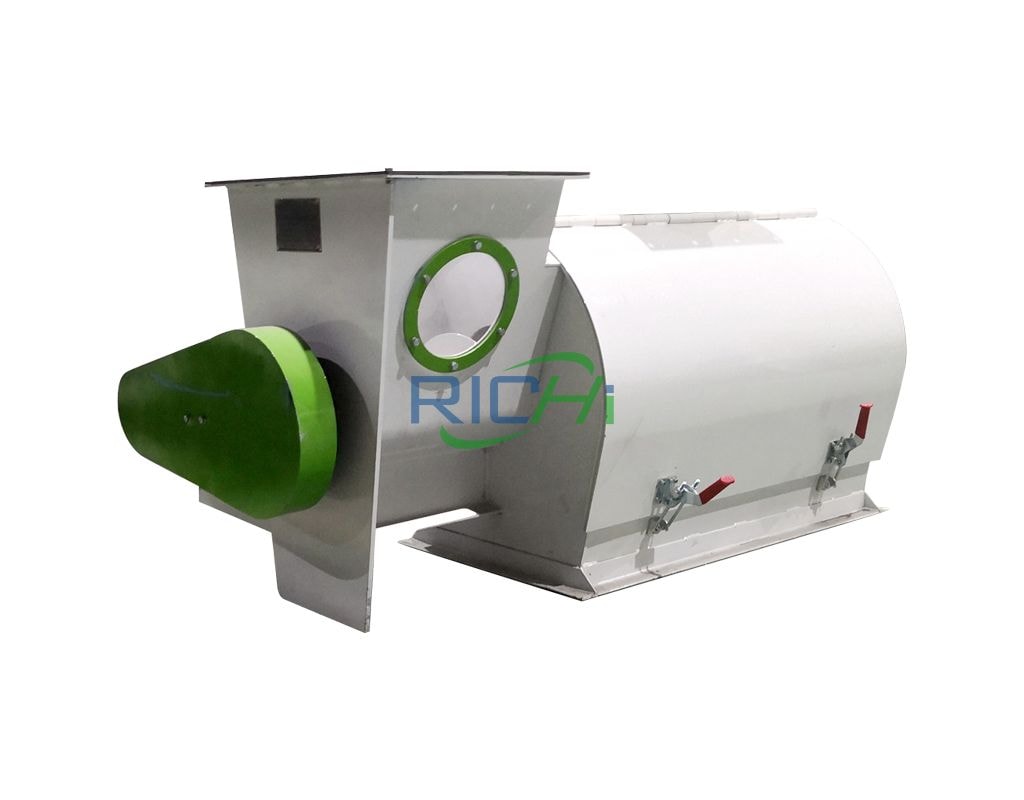

cattle feed mixing machine

Suitable for mixing feed, chemicals, organic fertilizers and viscous materials. The equipment is equipped with a casing, a machine cover, a paddle shaft, a discharge mechanism, a motor reducer, a transmission mechanism, and an air outlet. High uniformity, mixing uniformity is greater than 97.7%.

- Capacity: 250-3000 KG/P

- Power: 4-55 KW

grass straw Drying machine

Mainly used for drying high-moisture grass, straw and other cattle feed materials. It consists of a large rotating cylindrical tube supported by a steel beam. The dryer is slightly tilted so that the discharge end is lower than the feed end, allowing materials to be transported through the dryer under the influence of gravity.

- Model: ф1200*120000 – ф2400*100000 (Can bu customized)

- Cyclone: ф800*2 – ф1000*2

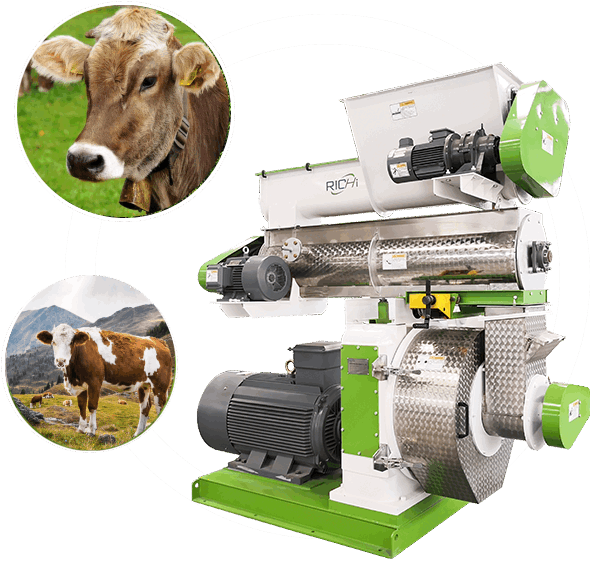

cattle feed pellet machine

The cattle feed pellet mill is a new product that RICHI has focused on research and development in recent years. It brings together decades of hard work of world experts in the industry and breaks through the structure and style of RICHI’s traditional granulator. Product technology is at the forefront, with high output and low consumption, stable and reliable. Different types of conditioners and feeders can be selected according to needs.

- Capacity: 1-42 T/H

- Power: 22-315 KW

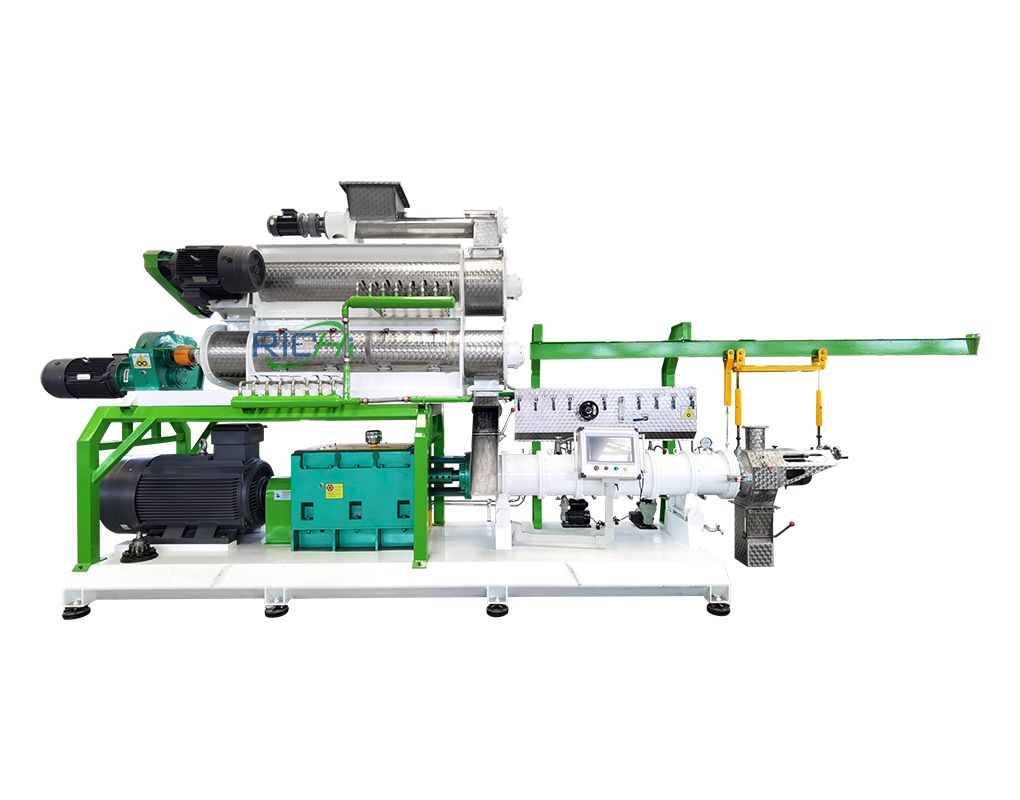

Cattle feed extruder machine

The cattle feed extruder machine is mainly used for the extrusion pretreatment of ingredients in the feed field. It can adjust the gelatinization level online according to production needs, effectively improving the quality and hygiene indicators of finished products. It is widely used in the full expansion low-temperature granulation process in the production of expanded livestock and poultry feed.

- Capacity: 1-12 T/H

- Power: 75-355 KW

Pellet Cooler Machine

Adopting the counter-flow cooling principle, the cattle feed pellets are fully and evenly cooled; a unique slide valve discharge mechanism is used to discharge materials; the slide valve discharge mechanism operates stably and reliably, and the discharge is smooth; the temperature of the cooled pellets is not higher than room temperature.

- Capacity: 1.5-18 T/H

- Power: 0.75-2.05 KW

vibrating screening machine

It is a high-efficiency feed pellet grading and screening equipment widely used in grain, feed, flour, chemical industry, food and other industries. It is suitable for the grading and secondary circulation crushing process of pellet feed and crumbled feed, as well as the cleaning and grading treatment of some granules and powders.

- Capacity: 3-20 T/H

- Power: 1.5-5.5 KW

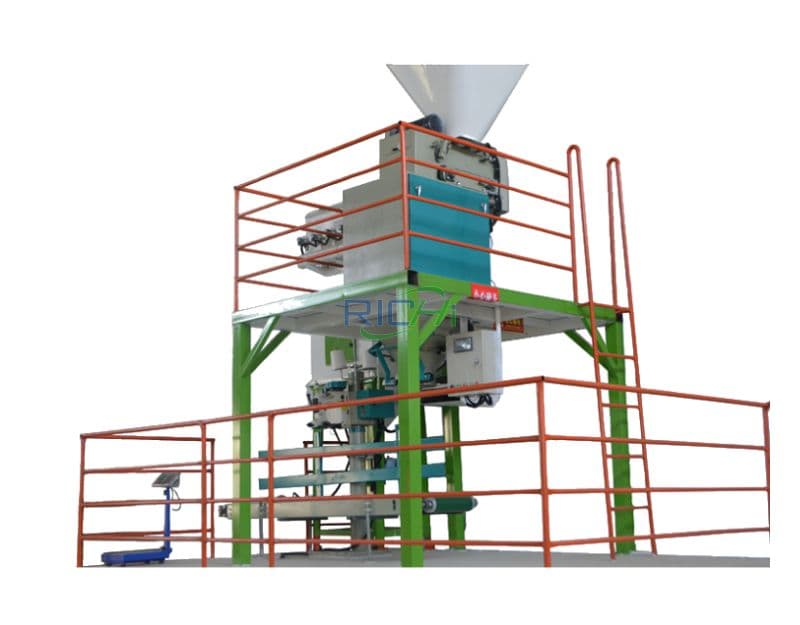

Automatic Bagging Machine

Fully automatic packaging scale, this series of automatic packaging scale is suitable for quantitative weighing and packaging of granular feed and powdery feed. It is a professional quantitative weighing and packaging equipment. The packaging has high precision, fast speed and high efficiency.

- Speed: 6-12 bags/min

- Power: 1.1-5 KW

Complete set of electronic control equipment

It is suitable for controlling the production process of cattle feed mills of all sizes; it displays a complete process picture, provides equipment parameter settings, displays equipment operating parameters; it can promptly notify faults and remind them in time.

- MCC Control Center ;Mimic control panel

- CPP Computer System

- Batching System: fully automatic, controled by computer

When purchasing a complete set of cattle feed mill equipment, you need to make a selection based on factors such as production scale, cattle feed manufacturing process flow, and feed type.

At the same time, it is also necessary to choose feed mill equipment manufacturers with high technical levels and high-quality services to ensure the quality of the cattle feed equipment and after-sales service.

cattle feed mill equipment projects

RICHI thinks and acts with you from initial idea to final completion. Dozens of turnkey cattle feed mill projects all over the world are the convincing evidence that we know how to offer the certainty of an investment that provides maximum added value. Seeing is believing. There is nothing more convincing than an actual project working well!

6-10T/H cattle feed mill equipment in Algeria

- Date: Sep 11th, 2019

- Feed type: 6-8mm cattle feed

- project cost: 80,000-400,000 USD

- cattle feed mill equipment: Feed crusher, mixer, cattle feed granulator, cooler, granulator, baling scale, screening machine, silo system, etc.

10-15T/H cattle feed mill equipment in Uzbekistan

- Date: July 16th, 2019

- Feed type: cattle feed pellets

- project cost: 150,000-400,000 USD

- cattle feed mill equipment: Feed grinder, grass grinder, mixer, granulator, cooler, baling scale, pellet screener, silo system, boiler, etc.

5T/H cattle feed mill equipment In Peru

- Date: February 2022

- Feed type: 8mm cattle goat feed

- project cost: 220,000-250,000 USD

- cattle feed mill equipment: Feed grinder, pulser, distributor, mixer, cow feed pellet mill machine, cooler, baling scale, screening machine, boiler, etc.

3-5T/H cattle feed mill equipment In Malaysia

- Date: October 29, 2022

- Feed type: 6-8mm ruminant feed

- project cost: 60,000-65,000 USD

- cattle feed mill equipment: animal Feed grinder, mixer, straw pellet machine, pellet cooler, feed bagging machine, screening machine, etc.

1-2T/H cattle feed mill equipment in Nigeria

- Date: June 20, 2020

- Feed type: cow feed 6mm

- project cost: 25,000-29,000 USD

- cattle feed mill equipment: Feed grinder, mixer, cattle feed pellet making mill, post-ripener, pellet cooler, baling scale, screening machine, etc.

15-20T/H cattle feed mill equipment in Vietnam

- Date: December 2021

- Feed type: cattle feed 8mm

- project cost: 500,000 USD

- cattle feed mill equipment: Feed crusher, mixer, cattle feed pellet mill, post-ripener, cooler, baling scale, screening machine, silo system, etc.

5-7 t/h cattle feed mill equipment in Kyrgyzstan

- date: 2022.07.09

- Feed type: cattle pellet 8mm

- project cost: 97160 USD

- cattle feed mill equipment: Feed crusher, mixer, cattle feed extruder, cooler, baling scale, screening machine, silo system, grease adding equipment, etc.

10T/H cattle feed mill in the Philippines

- Project date: 2018.06.13

- Feed type: 4-8mm cattle feed

- project cost: 460,000 USD

- cattle feed mill equipment: Feed crusher, mixer, cow feed pellet machine, cooler, baling scale, screening machine, silo system, boiler system, etc.

5 T/H cattle feed mill In El Salvador

- date: 2022. 09.13

- Feed type: cattle premix

- project cost: 480,000 USD

- cattle feed mill equipment: Feed grinder, stainless steel mixer, stainless steel batching scale, packaging scale, stainless steel silo system, boiler system, etc.

10 T/H dairy cow feed mill In Thailand

- date: 2021. 07. 22

- Feed type: cattle premix

- project cost: 120,000 USD

- cattle feed mill equipment: Ultrafine pulverizer, stainless steel mixer, stainless steel batching scale, packaging scale, silo system, boiler system, etc.

50T/H cattle feed mill plant in russia

- Date: June 2019

- Feed type: 2-8mm cattle & poultry

- project cost: 960,000USD

- cattle feed mill equipment: Feed crusher, feed mixer, batching scale, feed pellet mill, cooler, screening machine, baling scale, boiler system, etc.

30T/H dairy cattle feed mill in Kazakhstan

- Date: December 2018

- Feed type: 3-6mm cattle & poultry

- project cost: 1,250,000 USD

- cattle feed mill equipment: Feed crusher, feed mixer, batching scale, feed pellet mill, cooler, screening machine, baling scale, silo system, etc.

5 t/h cow feed mill in Argentina

- Project date: 2021.10.11

- Feed type: 2-8mm chicken & cow feed pellets

- project cost: 184500USD

- cattle feed mill equipment: Alfalfa grinder, feed mixer, batching scale, alfalfa pelletizer, cooler, screening machine, baling scale, silo system, etc.

5-10 t/h cow feed mill in angola

- Project date: 2022.10.14

- Feed type: 1-8mm hen & cattle & goat feed

- project cost: 131820 USD

- cattle feed equipment: grass crusher, corn crusher, feed mixer, grass pellet machine, chicken feed granulator, cooler, screening machine, packaging scale, etc.

15 T/H cow feed mill In Uganda

- Project date: 2022.06.30

- Feed type: 0.5-8mm cattle & aqua fish feed pellets

- project cost: 159070 USD

- cattle feed mill equipment: Feed grinder, ultra-fine grinder, feed mixer, cattle feed granulator, fish feed extruder, cooler, screening machine, packaging scale, etc.

20T/H cow feed mill in USA

- Project date: 2019.05.10

- Feed type: 6-10mm ruminant cattle pellet feed

- project cost: 550000 USD

- cattle feed mill equipment: Bale breaker, grass crusher, feed mixer, hemp pellet mill, cooling machine, screener, baling scale, oil adding system, etc.

cattle feed mill equipment price

The following are the cost of core equipment for cattle cow feed mills:

- Grain grinder: 5300-35000 USD

- Forage crusher: 1000-4000 USD

- Mixer for cattle feed: 2800-36500 USD

- cattle feed pellet making machine: 7000-100000 USD

- pellet Cooler: 4000-20000 USD

- Vibrating screen: 2000-10000 USD

- Packing scale: 5000-10000 USD

There are so many cattle feed mill equipment used in semi automatic or fully automatic cattle feed plants that I won’t list them all here. The price of a complete set of cattle feed mill machinery for a 1-160 t/h cattle feed factory is usually 10,000-5,000,000 USD.

If you want to build a cattle feed mill plant, contact us and we will customize a cattle feed mill plan for you for free and send you a complete cattle feed equipment quotation!

Cattle feed mill equipment video

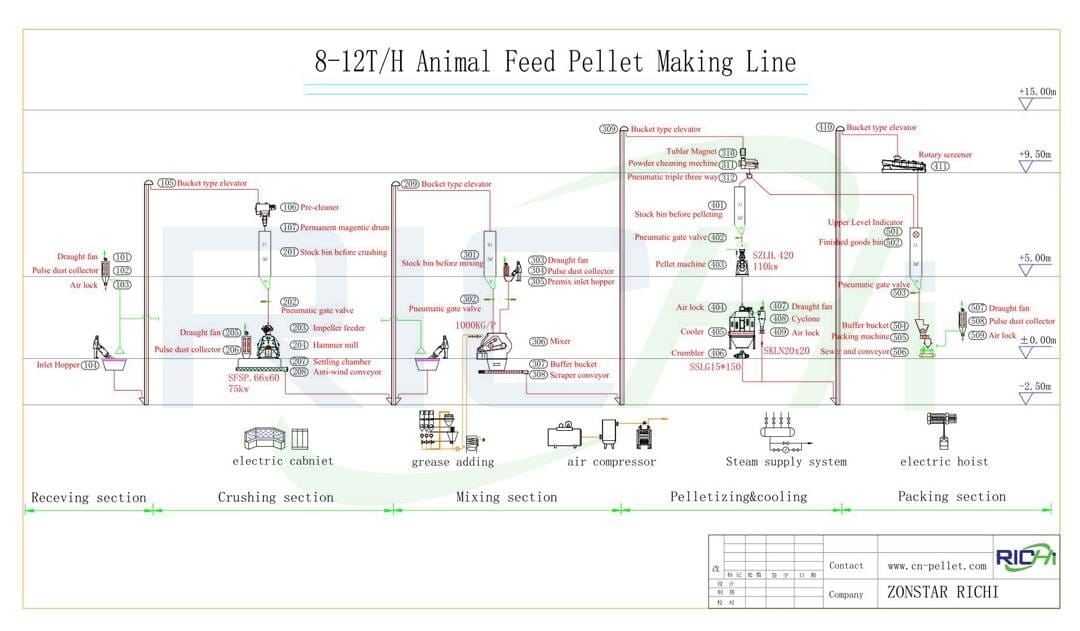

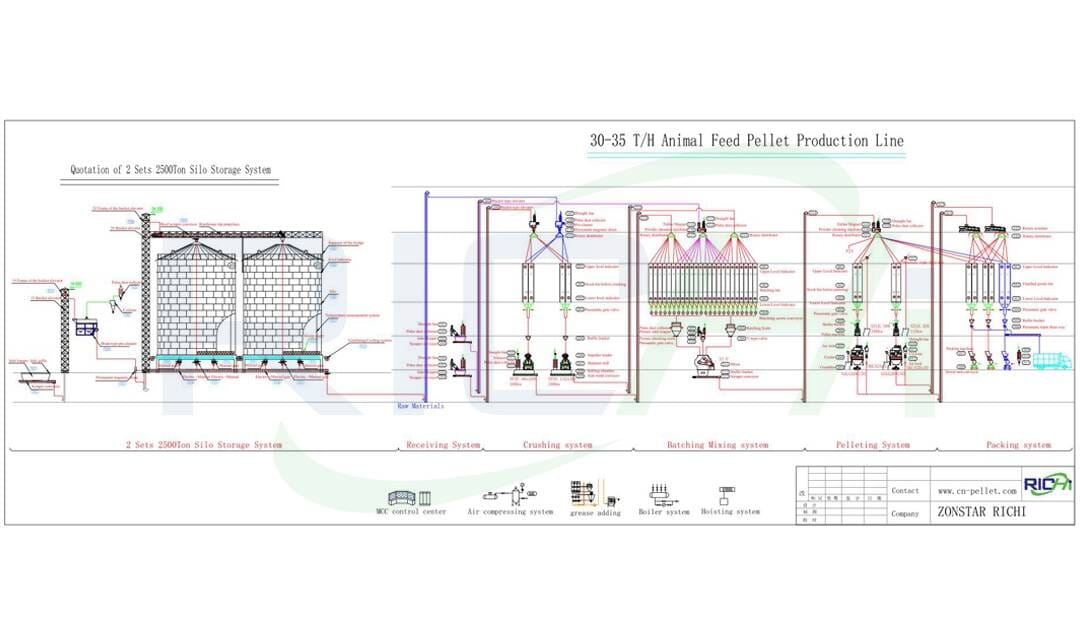

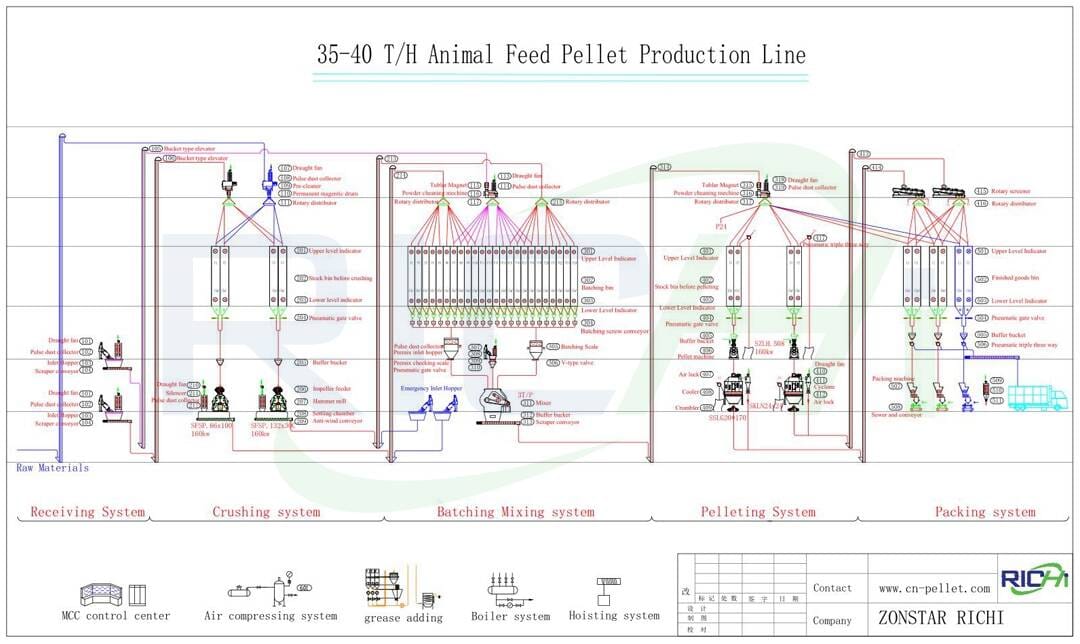

cattle feed mill equipment configuration for different scale

The actual cattle feed equipment configuration can be adjusted according to user needs. According to the cow feed process flow of different cattle feed production lines, the relevant cattle feed equipment configurations can be further adjusted to meet the user’s work needs in detail and provide you with a better production experience in details.

cattle feed production process:

Silo storage – raw material reception and cleaning – crushing – mixing – granulation – cooling – screening – baling.

If it is a raw material formula containing grass, the process of breaking bales and crushing grass is processed in the crushing stage; depending on the moisture content of the raw material, a dryer may also be required.

The above is the processing process of pellet feed. If you want to process cattle mash feed or cattle mixing feed or cattle premix feed, the process of cattle feed will be different. If you have any questions about this, please contact RICHI technical consultants directly online!

For different process designs, our main cattle feed equipment with different outputs configured for cattle feed mills are as follows:

4-6 T/H cattle feed mill equipment configuration (100% Wet Bale Straw/Hay)

| Bale breaker | MPKJ170*225 | 1 |

| Belt conveyor | TDSJ120*400 | 2 |

| Straw/Grass crusher | 9FQ50-120 | 2 |

| straw grass dryer | ф2400*100000 *3 Layer | 1 |

| Storage bin | 20m³ | 1 |

| hay pellet machine (Anti-caking equipment) | MZLH 520 | 2 |

| Cooling machine | SKLN17*17 | 1 |

| Vibrating screener | TDZS80 | 1 |

| Packing machine | DCS-50 | 1 |

| Belt and sewing machine | / | 1 |

10T/H cattle feed mill equipment configuration (70-90% Fresh straw Grass Materials)

| Straw/Grass crusher | 9FQ50-120 | 2 |

| Storage bin | 2m³ | 2 |

| Straw Dryer | ф2400*100000 *3 Layer | 2 |

| Straw/Grass crusher | 9FQ50-120 | 2 |

| Single shaft double ribbon mixer | SLHY5.0L | 2 |

| cattle Pellet machine (Stainless steel conditioner + Force feeder) | SZLH 508 | 3 |

| Cooling Machine | SKLN20*20 | 1 |

| Rotary screener | SFJH125*2C | 1 |

| Packing machine | DCS-50 | 1 |

| Belt and sewing machine | / | 1 |

30-35T/H cattle feed mill equipment configuration (Dryed Straw Alfalfa Grass)

| Belt conveyor | TDSJ150*600 | 6 |

| Straw/Grass crusher | 9FQ60-150 | 6 |

| Bucket elevator | TDTG60/23 | 2 |

| Storage bin | 40m³ | 2 |

| Anti-caking equipment | / | 6 |

| Alfalfa pellet machine | MZLH 558 | 6 |

| Cooling machine | SKLN24*24 | 2 |

| Vibrating screener | TDZS120 | 2 |

| Packing machine | DCS-50*2 | 2 |

| Belt and sewing machine | / | 2 |

1-2 t/h cattle feed mill equipment configuration (No grass-based ingredients)

| Hammer mill for cattle feed | 15-200 | 1 |

| cattle feed Mixing machine | SLHY0.5A | 1 |

| Feeder | WLQ16 | 1 |

| Stainless steel condtioner | TZQ22*180 | 1 |

| cattle Pellet feed machine | SKLH-250 | 1 |

| Counterflow cooling machine | SKLN1.0*1.0 | 1 |

| Vibrating sifter | ZDS60*1 | 1 |

| Cooling draught fan | 4-72-3.6A | 1 |

| Cooling cyclone | SK60 | 1 |

| Cooling pipes | / | 1 |

3-4 t/h cattle feed mill equipment configuration (No grass-based ingredients)

| cattle feed Hammer mill | SFSP56*60 | 1 |

| Premix adding hopper | / | 1 |

| Mixing machine (Pneumatic door) | SLHY.1 | 1 |

| cattle feed Pellets machine | SZLH320 | 1 |

| Stainless steel conditioner | TZ320*200 | 1 |

| Feeder | WLQ25 | 1 |

| Cooling Machine | SKLN14×14 | 1 |

| Rotary screener | SFJH800*2C | 1 |

| Automatic Packing machine | DSC-50 | 1 |

| Sewing machine and belt conveyor | / | 1 |

5-7 t/h cattle feed mill equipment configuration (No grass-based ingredients)

| cattle feed Hammer mill | SFSP66*60 | 1 |

| Rotary distributor | TFPX6 | 1 |

| Batching scale | PLC0.5A | 1 |

| Mixing machine (Pneumatic door) | SLHY.1 | 1 |

| 1-Layer Conditioner | TZ35*244 | 1 |

| cattle feed Pellet mill | SZLH350 | 1 |

| Cooling Machine | SKLN17x17 | 1 |

| Rotary screener | SFJZ100*2C | 1 |

| Automatic Packing machine | DCS-50 | 1 |

| Sewing machine+conveyor | / | 1 |

20 t/h cattle feed mill equipment configuration (No grass-based ingredients)

| cattle feed Hammer mill | SFSP66*80 | 1 |

| cattle feed Hammer mill | SFSP138*40E | 1 |

| Batching scale | PLC1.0A | 2 |

| cattle feed Mixing machine | SLHJ4.0A | 1 |

| 1-Layer Conditioner | TZ42*3000 | 2 |

| cattle feed Pellet machine | SZLH420 | 2 |

| Cooling Machine | SKLN20x20 | 2 |

| Rotary screener | SFJZ125*2C | 2 |

| Automatic Packing machine | DCS-50 | 2 |

| Sewing machine&belt conveyor | / | 2 |

60-80 t/h cattle feed mill equipment configuration (No grass-based ingredients)

| Hammer Mill | SFSP66*100 | 2 |

| Hammer Mill | SFSP138*50E | 2 |

| Single-shaft mixer | SLHJ6.0A | 2 |

| Pellet machine | SZLH508 | 4 |

| 1-layer SS Conditioner | TZ42*3000 | 4 |

| Variable-frequency Feeder | TWLL32 | 4 |

| Cooling Machine | SKLN24x24 | 4 |

| Rotary screener | SFJZ150*2C | 4 |

| Packing machine | DCS-50 | 4 |

| Sewing machine and conveyor belt | / | 4 |

The cattle feed manufacturing plant includes but is not limited to the above configurations. The surrounding environment, physical and chemical properties of raw materials, discharging requirements, etc. will affect the selection of equipment.

Moreover, there are many models to choose from for the cattle feed equipment configuration of each processing link, so basically the detailed configuration of the cattle feed mill will be different. .

Want to know more about how our complete cattle feed mill solutions can help grow your business? Fill in the form and we’ll get in touch with you within 1 business day.

Advantages of cattle feed mill equipment

- Efficiency. Cattle feed mill equipment can realize automated production, greatly reducing labor costs and improving production efficiency. At the same time, its unique crushing, mixing, granulating and other technologies have greatly improved the quality of feed and provided animals with a higher quality source of nutrition. In addition, the cattle feed processing machinery can also flexibly adjust the feed formula according to the different growth stages and needs of the animals to meet the individual needs of the animals.

- Energy saving and environmental protection. Cattle feed making machinery adopts advanced energy-saving technology to reduce energy consumption and noise pollution. At the same time, its closed production process and strict environmental protection standards effectively control dust, exhaust gas and other pollutants generated during the production process, reducing the impact on the environment. This not only helps protect the ecological environment, but also saves energy costs for enterprises and improves economic benefits.

- Strong adaptability. Cattle feed plant machinery has strong adaptability and can be adjusted and optimized according to different raw materials and product requirements to meet the diversified needs of the market. At the same time, its intelligent control system and remote monitoring functions make the operation of the production line easier, reduce the difficulty of operation, and improve production stability.

- Short investment payback period. Cattle feed mill equipment has the advantages of efficient production performance, energy saving and environmental protection, and strong adaptability, allowing companies to recover their investment in a short period of time. At the same time, as the technology continues to mature and the market continues to expand, its market competitiveness will continue to improve, bringing more benefits to cattle feed manufacturers.

cattle feed mill equipment selection

Equipment selection for a cattle feed mill is a key decision-making process, which directly affects the operating efficiency, product quality and economic benefits of the cattle livestock feed production line. The following is an analysis of equipment selection for cow feed mill factory:

- Cattle Pellet machine:

The cattle feed pellet making machine is the core equipment of the cattle feed mill and is used to process raw materials into pellets. When selecting a cattle feed pelletizer machine, factors such as the production capacity, particle size range, energy consumption, operational stability and ease of maintenance need to be considered.

A cow feed pellet machine suitable for the scale and production requirements of the cattle feed mill should be selected to ensure its high efficiency, stability and durability. - Pre-granulation treatment equipment:

Pre-granulation treatment equipment includes crushers, cleaning equipment. The cattle feed grinder is used to crush the raw materials, the cleaning equipment is used to remove impurities and pollutants, and the pretreatment equipment is used to adjust the moisture and temperature of the raw materials.

When selecting, you need to consider the scope of application, processing capacity and ease of operation of the cattle feed mill equipment. - Feeding and conveying equipment:

Feeding and conveying equipment is used to convey raw materials from the storage bin or storage area to the feeding port of the cattle pellet machine. Common feeding and conveying equipment include screw conveyors, belt conveyors and bucket elevators. Factors such as conveying distance, conveying capacity, wear resistance and safety need to be considered when selecting. - Drying and cooling equipment:

During the production process of cattle pellet feed, drying and cooling are required. Drying equipment is used to remove moisture from granular materials. Common equipment includes ovens and rotary dryers, coolers and cooling towers. Factors such as equipment processing capacity, energy consumption and temperature control need to be considered when selecting. - Screening equipment:

Screening equipment is used to classify and separate pellet feed. Common equipment includes vibrating screens, air flow screens, and rotating screens. When selecting, consider screening efficiency, mesh size, cleanability and ease of maintenance. - Packaging equipment:

Packaging equipment is used to package and encapsulate the pellets produced by the cattle feed mill. Factors such as packaging speed, packaging specification range, degree of automation and packaging quality control need to be considered when selecting. - Automated control system:

The automated control system plays an important role in the cattle feed mill and can realize automatic control of equipment, monitoring and adjustment of production parameters, fault diagnosis and alarm, etc. When selecting, the reliability, flexibility, ease of operation and scalability of the system need to be considered.

To sum up, the selection of cattle feed mill equipment needs to comprehensively consider factors such as production line scale, product requirements, equipment performance and economic benefits. Through reasonable equipment selection, the operating efficiency and product quality of the animal feed production line can be improved, and sustainable development and competitive advantage can be achieved.

Are you looking for a manufacture or supplier of cattle feed mill machinery and services that go beyond the ordinary? Then you have come to the right place.

In addition to high-end technology and the cutting edge cattle feed equipment and turnkey project solution for complete animal feed processing plant, we provide exceptional after sales service and all-inclusive training of cattle feed mill operation.

What are the advantages of cattle feed processed by cattle feed mill equipment?

The cattle feed equipment unit is mainly composed of raw material receiving and cleaning, crushing and mixing, pelleting and cooling, and packaging sections. At present, RCIHI cattle livestock feed mill equipment has reached a certain scale and level. So, what are the advantages of feed processed by RICHI cattle feed machinery? Here are some advantages.

- Avoid picky eaters

The compound feed formula contains a variety of raw materials and is comprehensive in nutrition, which can prevent animals from choosing what they like to eat from the powder and refusing to take in other ingredients. Since the pellet feed can maintain uniformity during storage, transportation and feeding, it can reduce feeding losses by 8% to 10%. - High rate of return

During the cattle pelleting process, due to the combined effects of moisture, temperature and pressure, some physical and chemical reactions occur in the feed, which gelatinizes starch and enhances the activity of enzymes, allowing the animals being fed to digest the feed more effectively, which translates into weight gain.

Feeding cattle with pellet feed can increase the feed conversion rate (i.e. rate of return) by 10%-12% compared with powdered feed. When fattening pigs are fed with pellet feed, the average daily weight gain is 4%, and the feed-to-meat ratio is reduced by 6%; when broilers are fed, the feed-to-meat ratio can be reduced by 3%-10%. - Reduce pollution

Avoid automatic grading of cattle feed ingredients. During the storage and transportation process of powder materials, due to the different volume and quality of various powder materials, it is easy to produce classification.

After being made into pellets, there is no grading of feed ingredients, and the pellets are not easy to dust. During the feeding process, the cattle pellets pollute the air and moisture much less than powdered materials. - Good liquidity

Easy to manage. Many powders, especially velvet feeds with small specific gravity, and feeds with added molasses or high fat and urea often stick to the feed bin. Because cattle pellet feed has good fluidity and rarely adheres, pellet feed is the most popular for those farms that use automatic feeders to raise dairy cows or poultry on a large scale. - Sterilization

Salmonella in cattle feed. After being ingested by cattle, Salmonella remains in the animal’s tissues. People who eat animals infected with this bacteria can suffer from Salmonella gastrointestinal disease. Salmonella present in animal feed can be killed by using high-temperature steam conditioning and then granulation. - Transport economy

After pelleting, the bulk density of cattle feed will generally increase by 40%-100%, which can reduce warehouse capacity and save transportation costs.

The RICHI cow feed unit adopts a spliced frame, has a compact design, reasonable structure, meets environmental protection requirements, and can be designed according to customer requirements. The building-block modular design is convenient for disassembly, transportation and installation; it saves investment and provides quick results.

It has a compact structure, small floor space, low factory building requirements and small infrastructure investment. It is especially suitable for use in cattle feed mills and cattle breeding farms. If you want to know more about cattle feed mill equipment, please feel free to consult Richi Machinery.

Starting cattle feed mill

If you want to build a cattle feed mill, you probably need the following steps:

01 Researching the market and developing a plan

Learning the market demand, competition to determine the feasibility of the implementation of the plan is the basis for the subsequent steps.

02 Obtaining investment capital

Getting enough capital through self-financing, bank loans or co-operation in various ways.

03 Choosing the plant site and purchasing the cattle feed mill equipment

Finding a suitable location and purchasing the necessary cattle feed equipment is another crucial step.

04 Obtaining production licenses from relevant authorities

Obtaining the required licenses and certifications is imperative to ensure regulatory compliance.

05 Developing a reliable supply chain

Addressing logistical and storage issues through supply chain is also crucial.

06 Conducting effective marketing

Identifying sales channels and establishing a cattle feed brand image will help the business to succeed.

Our approach of doing business is focusing on your objectives. We want to know how you do your business. What your expectations of quality are? What type of cattle feed you want to produce?

We take the time to understand all the subtleties underlying the different aspects of your cattle feed mill. We consider the exchange of knowledge important to maximize performance together.

Why Choose RICHI Machinery?

We are the most efficient cattle feed mill equipment manufacturer that will reduce your costs through our innovative services that include:

- Low prices and high quality given our commitment to efficiency and competitiveness.

- Best cattle feed manufacturing technology which can make efficient use of energy and cattle feed materials.

- Offer turnkey cattle feed mill solutions that is fully customizable to meet your needs and expectations.

- Extensive experiences on cattle feed milling machine project design and management, which makes it possible for us to customize our offering according to your specific requirements..

- All inclusive pre and after sales support so that you can get up to speed on how to use the product to achieve your objectives. (Find RICHI on YouTube)

Our service

Professional design and personalized customization

We can carry out the whole cattle feed mill equipment project planning and design according to the different needs of global customers, and provide 3D renderings of the cattle feed mill project, carry out “one-to-one” customized process design for each customer, and tailor-made personalized solutions for the entire cattle feed factory construction.

On-site investigation for local conditions

Professionals will go to the construction site in advance to conduct on-site measurements and optimize the cattle feed plant layout. In practice, we adapt to local conditions and adopt different design plans and construction methods based on different survey results to ensure that it is scientific, reasonable, economical, practical, and environmentally friendly.

Professional team, professional installation

With a high degree of professionalism, we take “customer needs as our responsibility” to help customers achieve project delivery in the shortest construction period, allowing customers to seize market opportunities. Provide one-stop worry-free services from early design, equipment production and manufacturing to post-construction, maintenance and after-sales support.

Technical guidance and full escort

After installation and commissioning are completed, RICHI will provide one-on-one technical guidance, customize a training plan according to the customer’s actual situation, and train all operators until the customer can operate production safely. In the subsequent production process, remote technical guidance will be provided 24 hours a day, and on-site service will be provided according to the situation.

Professional services, worry-free production

No matter in terms of pre-sales, in-sales or after-sales technical support, we provide customer-satisfactory services at any time, ensure the highest work efficiency in a strict order, and receive customers’ technical inquiries 24 hours a day, on-site services, cattle feed mill equipment maintenance, production failures and a series of other issues ,increasing customer satisfaction.

Rapid response and lifelong maintenance

In terms of service speed, we must respond as soon as possible and solve the cattle feed production line problems as quickly as possible. As long as the cattle feed mill equipment is in use, RICHI’s service to our customers will not end. RICHI Machinery uses lifelong service to relieve customers of their worries and is committed to becoming a partner that customers can always trust.