1-60T/H Aqua Shrimp Fish Feed Production Line Solution

RICHI aqua shrimp fish feed production line can be used for various aquatic feed processing. We supplies state-of-the-art equipment and machines for the complete fish feed mill.

- Capacity: 1-60T/H

- Cost: 50000-4,000,000 USD

- Business Scope: New construction, reconstruction and expansion of fish feed mills

Our aqua fish feed production line solutions are simple and effective. We strive to be a “one-stop” all-round supplier for all extrusion and pelleting needs.

Whether it is individual process machines, complete processing lines, or spare parts and services that you need – RICHI will take you smoothly from raw material intake to finished feed bulk loading.

Types of aqua fish feed production line

We create complete solutions for producing floating pellets with moderate protein and fat content for feeding warm-water species such as tilapia, eels and catfish. We can help you choose between a single screw and twin screw extruding process to meet your demands and optimize production costs.

Sinking fish feed production plant

For feeding salmonids, sturgeons and sea water fish such as yellow tail, sea bream and sea bass, you need pellets with high levels of protein and fat content, that sink slowly in saline water. Our sinking fish feed production plant solutions produce high quality pellets With a good water absorption rate and the high water stability you need.

For shrimp feed, you need to be able to formulate fast-sinking pellets, which retain their elastic structure even after hours in the water. Our technology gives you the precise control of the cooking and shaping you need to create a quality product with minimal waste .

Other

RICHI engineers complete plant solutions for ornamental fish, micro pellets, crab feed, etc., enabling you to create very rich variety of floating or sinking pellets. They can be used for feeding a broad range of species. Our twin screw extruder machine and fish feed pellet machine technology delivers the flexibility you need, minimizing cross-contamination and delivering high productivity.

Need more information on our aqua feed production line? Feel free to contact Richi Machinery?

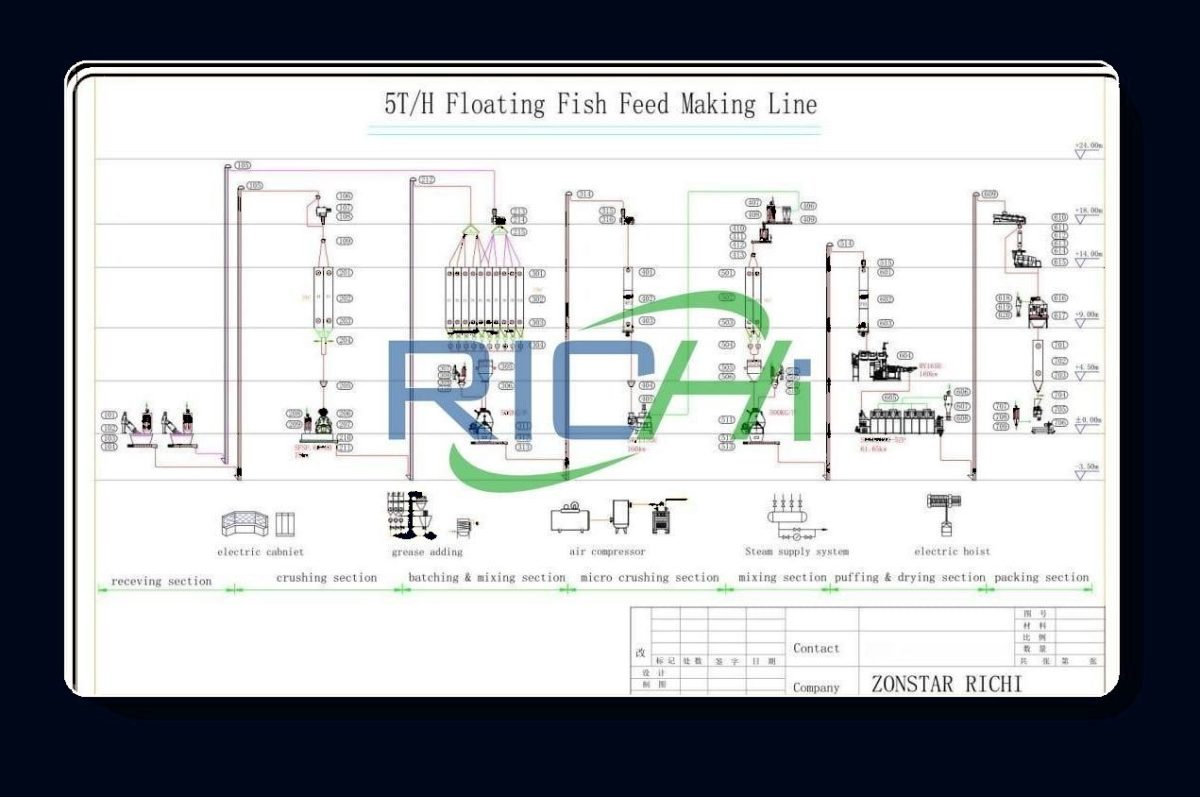

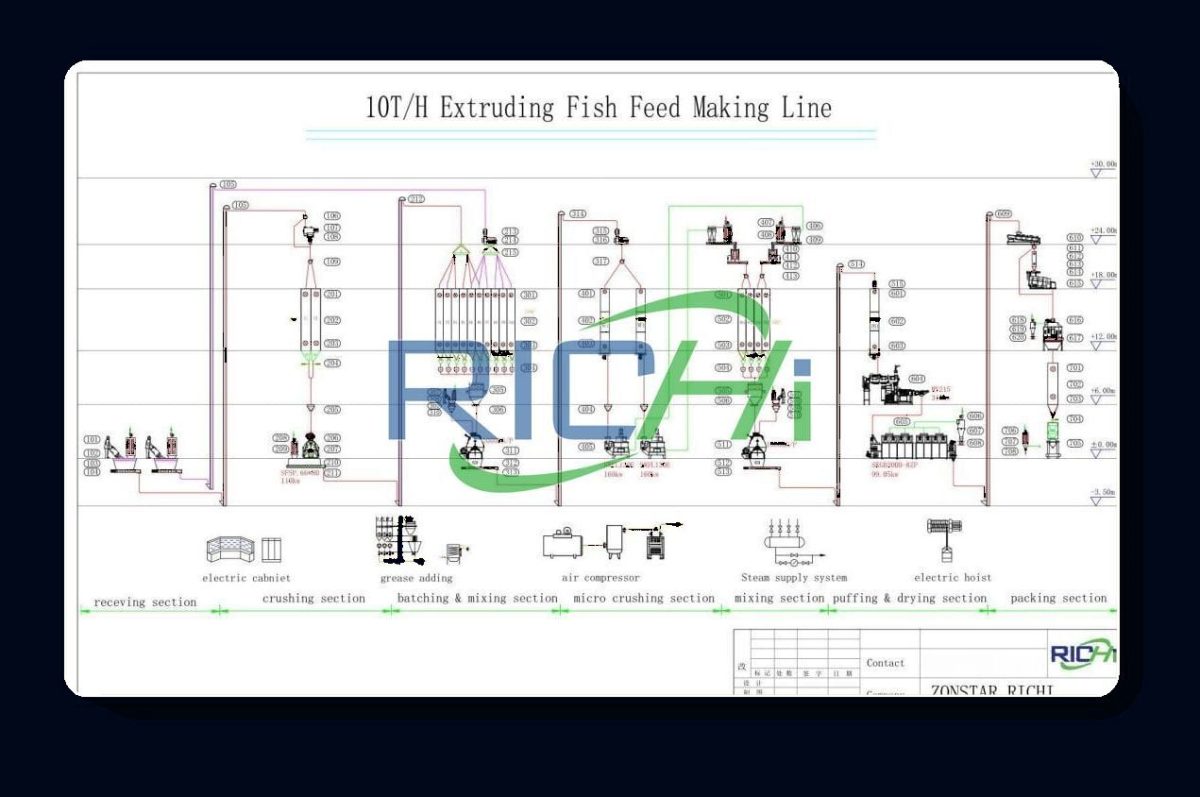

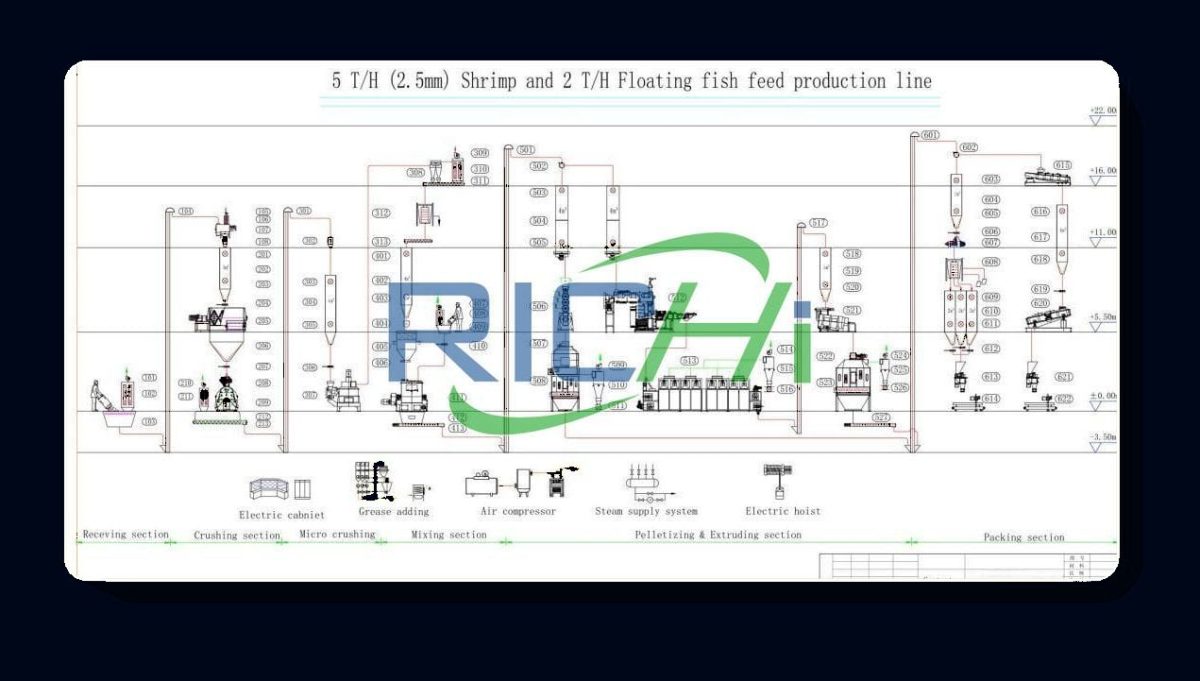

Fish feed production line design with different capacity

We offer a wide range of products and are able to meet your specific needs for any aqua feed production. With decades of experience in designing grinding, milling, mixing, extrusion & pelleting equipment for any aqua feed plant, you can rely on our expertise to get you the solution best suited for you.

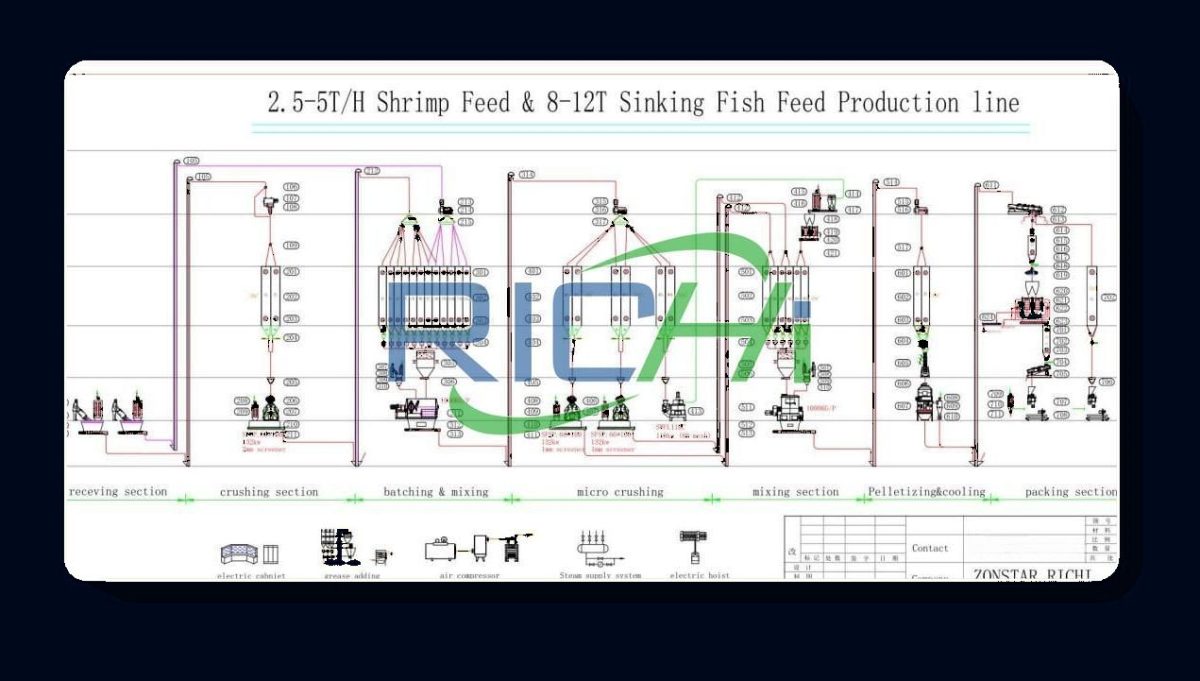

Complete Aquatic shrimp fish feed production process design

Our aqua shrimp fish feed production technologies appeal to both commercial fish feed millers producing for onward sale, as well as to farmers making feed for their aqua animals.

Our extrusion and pelleting technologies enable our customers to create their own unique recipes and combinations of ingredients – making sure that the animals are given the right amount of vitamins and protein.

The processing steps of animal feed production line:

- Raw material receiving

- Steel silo

- Cleaning

- First Crushing

- Primary ingredients

- First mixing

- Superfine crushing

- Secondary ingredients

- Secondary mixing

- Extrusion/granulation

- Drying

- First screening

- Liquid addition and spraying

- Cooling

- Secondary screening

- Packaging

- Palletizing

1.Raw material receiving system

Receiving is the beginning of feed production. In the fish feed production line, the receiving area covers the active process of various purchased materials used directly or indirectly. Receiving equipment is used for bulk storage of materials before silos or warehouses, including weighing systems, inspection instruments, unloading systems, cleaning systems, dust control equipment, receiving conveyors, distributors, spouts, etc.

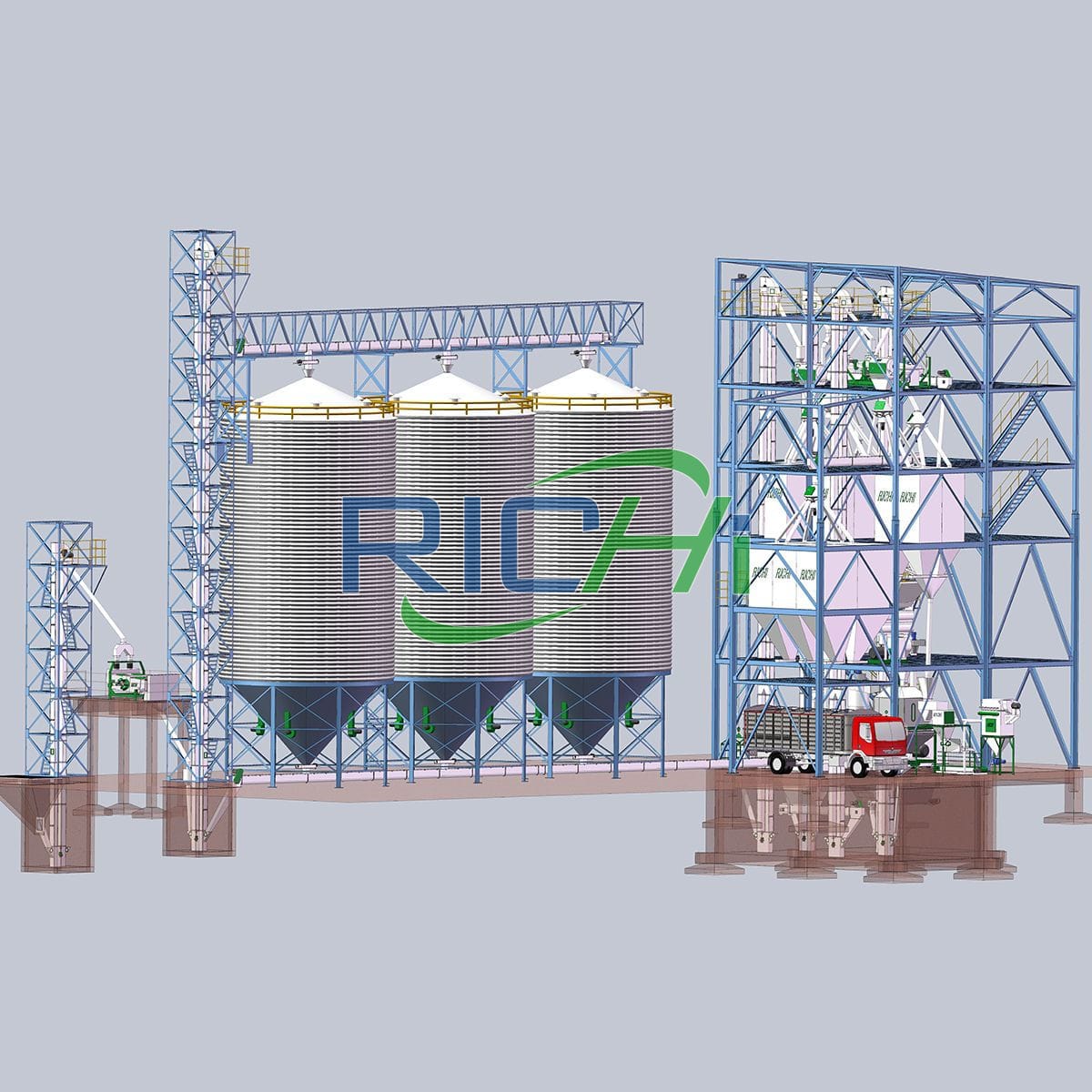

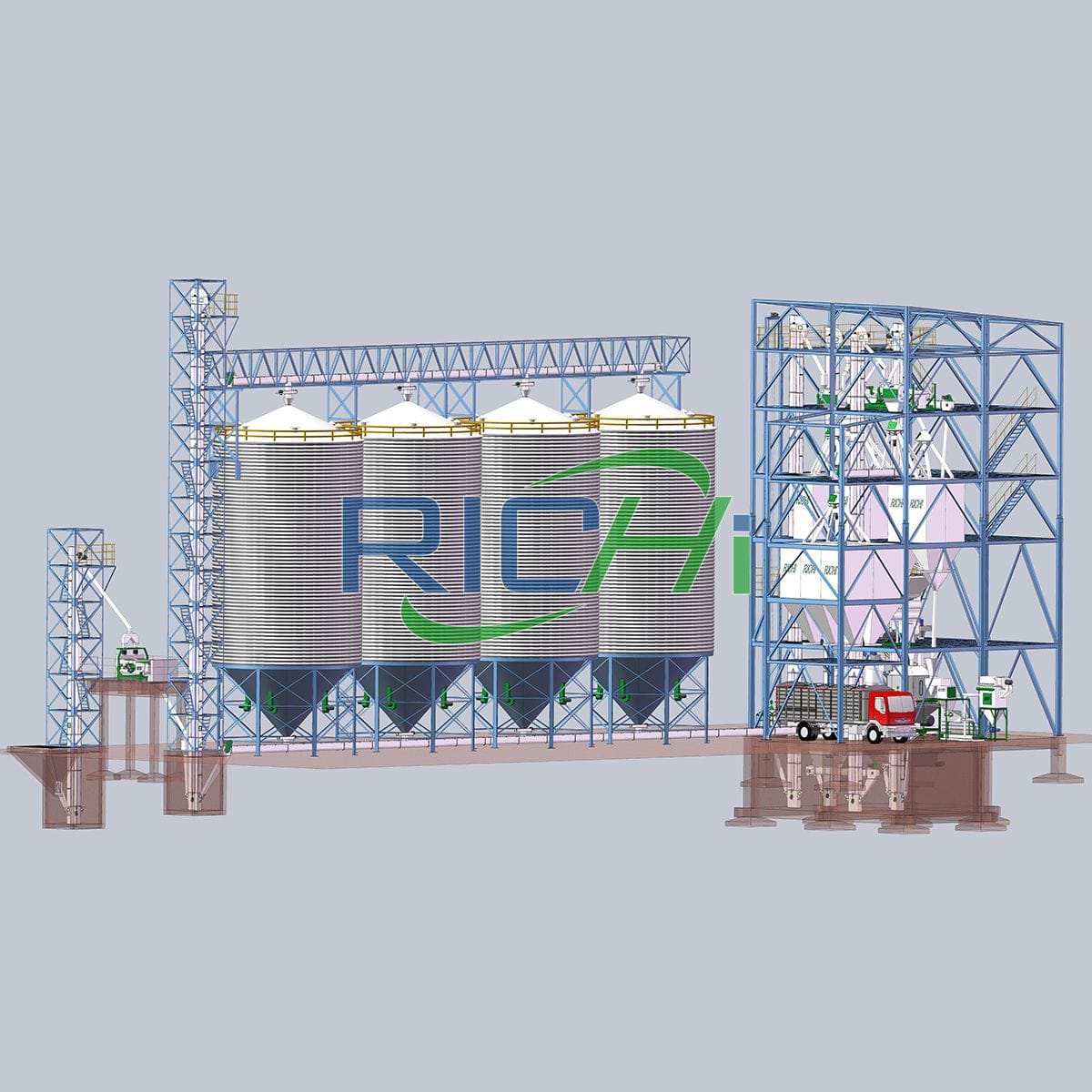

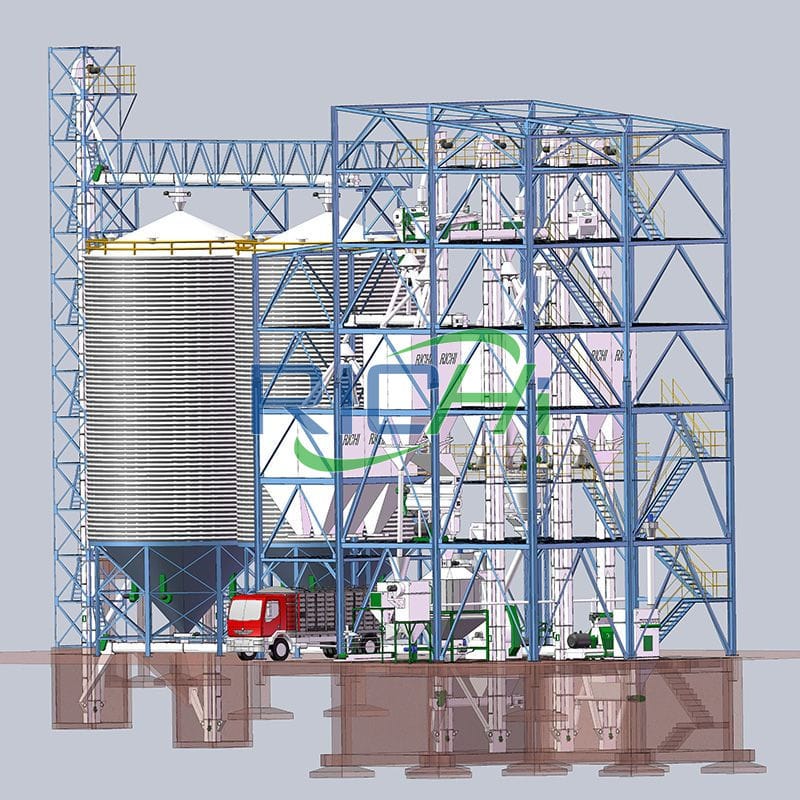

2.steel silo system

To ensure continuous To ensure continuous production, large quantities of raw materials such as corn, wheat and soybean meal need to be stored during feed processing. Steel silo raw materials are of good quality and easy to operate. The steel silo adopts galvanized steel structure, which has the characteristics of low investment, convenient and quick installation, less maintenance, and long service life. It has become the preferred silo type for bulk grain storage in feed factories.

3.Cleaning system

Bulk grain received from farms often includes grain by-products and impurities such as straw, stones, metal, paper, wood chips, small animal carcasses and powder. The cleaning operation is to remove these impurities with equipment and systems such as magnets, screens, dust collectors, etc., to ensure that the stored grain is of good quality and to protect the machinery during subsequent processing steps.

4.Crushing system

Crushing is the operation of reducing feed particle size and increasing its specific surface area, which can enhance animal digestion, improve feed utilization, and improve the processing quality and work efficiency of subsequent process steps such as batching, mixing, and pelleting.

5.Primary ingredients

The first batching and mixing process in aqua fish feed production line refers to the combination of bulk dry raw materials, liquid raw materials into value-added, homogeneous proportioned mixtures.

6.First mixing system

Mixing is a key link in the production of compound feed. Components with unique properties are blended together to formulate rations under the action of external forces to meet the nutritional needs of animals and add value to the blended product.

7.Superfine Pulverization

In order to meet the fish feed production line process requirements, it is necessary to finely or ultra-finely pulverize raw materials to meet the requirements of processing finer particles, so as to improve the durability of pellets and increase the capacity of extruding/pelleting.

8.Secondary Ingredients

Secondary ingredient and mixing processes in aquafeed production refer to the scaling, addition and mixing of dry and/or liquid trace elements and premixes to form complete feed mixtures, i.e. formulated rations.

9.Secondary Mixing

Mixing is a key link in the production of compound feed. Components with unique properties are blended together to formulate rations under the action of external forces to meet the nutritional needs of animals and add value to the blended product.

10.Extrusion/Pelleting

During the fish feed production line process, fish feed extruder is used to extrude starch and protein materials and process them into extruded feed. In the submerged feed process, the treated feed pellets enter the fish feed pellet making machine and are compressed into pellets by rollers and molds in the pelletizing chamber.

11.drying/cooling system

Drying is to reduce the moisture content in the product, thereby improving the stability and shelf life of aquatic products During feed pelleting, cooling of the feed pellets is essential. The cooling process cools pellets down, reduces their moisture content to a safe standard (≤12.5%), for easy transportation and storage.

12.Crumbing system

Crumbing is the process of breaking feed pellets into smaller pellets using crumbler machines. Crumbled feed is used in different stages of early animal development.

13.Liquid addition and spraying

Spraying is an industrial process. Apply liquid or powder such as oil/fat, pigment, spice, functional improver or vitamin to the surface of the feed pellet after drying and screening, before the feed pellet cools, to improve the taste and acceptability of the feed pellet .

14.Cooling System

During feed pelleting, cooling of the feed pellets is essential. When leaving the fish feed pellet mill, the feed pellets are very hot, soft and rich in moisture, the cooling process cools them down to 3℃-5℃ slightly above room temperature and reduces their moisture content to a safe standard (≤12.5%), For easy transportation and storage.

15.screening

After cooling and drying, the whole pellet or extruded pellet is sieved to remove fines and spills and bring the pellets to acceptable size.

16.Packaging System

The packing operation begins when the finished feed enters the supply box above the packer and ends when the bagged feed is put into storage. The procedure includes weighing each bag of feed, placing the weighed item in the bag, closing the mouth of the bag, applying a label to the bag, coding the bag, palletizing the bag, and moving the bag to a warehouse for storage.

The most important goal is the creation of a complete diet with the highest feed conversion rate, providing a healthy and easily digestible diet for fish. At the same time, the feed must maintain its shape and texture in water and be durable for transport and storage reasons.

We can help you with the entire shrimp fish feed production line process. From blending, mixing and grinding to control sifting, extruding, shaping, drying and coating/cooling, our experts can tailor an aqua feed solution to meet your specific needs.

Equipment for starting a fish feed production line

Spraying Machine

Capacity:

3-15T/H

Main Power:

22KW

RICHI manufactures and supplies all the machine in the fish feed production line and partners with each of our customers to design a solution that best matches their specific processing needs.

Video of fish feed production line

Need more information on our aqua fish feed equipment? Feel free to contact Richi Machinery?

Aqua fish feed production line projects

We offer the complete package of equipment and accessories for your fish feed production line. On this page, you will find information on our previous international projects and learn about our equipment.

Russia

10 T/H Livestock & 5 T/H fish feed production line In Russia

- Transaction Date: 2022.09.27

- Project type: Combined Feed Line

- Feed Type: Extruded Feed & Pig Feed

- Project cost: 1,360,000USD

Iran

1.5-2T/H Fish Feed pellet Production Line In iran

- Transaction Date: 2022.09.21

- Project type: Complete Feed Line

- Feed Type: Sturgeon, Trout Feed

- Project cost: $ 680,000

Indonesia

2T/H Shrimp Feed production line In Indonesia

- Transaction Date: 2022.06.02

- Project type: Complete Production Line

- Feed Type: Shrimp feed

- Project cost: 600,000USD

Thailand

5-6T/H floating fish feed production line In Thailand

- Transaction Date: 2020.11.16

- Project type: Complete Feed Plant

- Feed Type: Trout Feed

- Project cost: $ 970,000

Uzbekistan

5T/H sinking fish feed production line Uzbekistan

- Transaction Date: 2017.11.21

- Project type: Complete Feed Plant

- Feed Type: Sinking Fish Feed

- Project cost: $ 350,000

Australia

3-4T/H animal & fish feed production line In australia

- Transaction Date: 2022.08.17

- Project Type: Combined Feed Plant

- Feed Type: Fish Feed & Animal Feed

- Project Cost: $ 250,000

New Zealand

1.5-2T/H Aqua Feed Production Line In New Zealand

- Transaction Date: 2022.04.19

- Project Type: Combined Feed Plant

- Feed Type: Fish Shrimp Feed & Animal Feed

- Project Cost: 360,000 USD

Bolivia

2T/H fish feed production line in Bolivia

- Transaction Date: Jan 18th,2019

- Project Type: Complete Feed Plant

- Feed Type: Tilapia floating fish Pellets

- Project Cost: Start with 100000 USD

Bangladesh

15T/H large capacity fish feed production line In Bangladesh

- Transaction Date: September 2019

- Project Type: Combined Feed Plant

- Feed Type: Fish feed, Prawns feed, broiler feed

- Project Cost: 250000-780000USD

Vietnam

25T/H Automatic fish feed production line in Vietnam

- Transaction Date: November 2018

- Project Type: Combined Feed Plant

- Feed Type: 0.5-4mm shrimp & Fish & poultry feed

- Project Cost: 1.8 million USD

Argentina

30000 t/a pet and fish feed production line in Argentina

- Transaction Date: March 2018

- Project Type: Combined Feed Plant

- Feed Type: pet & Fish & livestock feed

- Project Cost: 900,000 USD

Brazil

15T/H large scale fish feed production line in Brazil

- Transaction Date: July 2016

- Project Type: Combined Feed Plant

- Feed Type: Eel & Shrimp & Crab & poultry feed

- Project Cost: 68,138,000 USD

India

20T/H commercial Floating fish feed production line in india

- Transaction Date: November 2020

- Project Type: Complete Feed Plant

- Feed Type: floating fish feed & poultry feed

- Project Cost: 3140000 USD

Qatar

2T/H Chicken Feed & 1-2T/H Floating fish feed production line in Qatar

- Transaction Date: 2018.03.08

- Project Type: Combined Feed Plant

- Feed Type: Floating Fish Feed & chicken feed

- Project Cost: 70,000 USD

Need more information on our animal feed production line? Feel free to contact Richi Machinery?

Different project, different fish feed production line design

Products from Richi Machinery ensure fish feed production line process consistency and flexibility. With multiple design features and modular systems as a starting point, our engineers are capable of designing a solution that meets the demands for high production capacity and quality.

Below, RICHI will share some examples of animal feed production lines that he has done. I hope you can learn more about the construction of fish feed production lines.

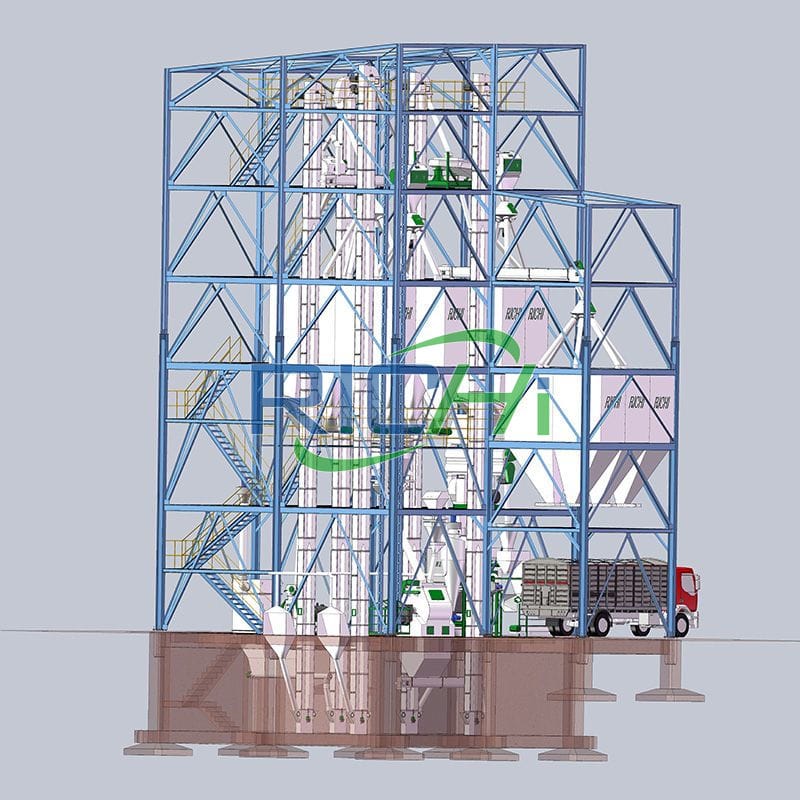

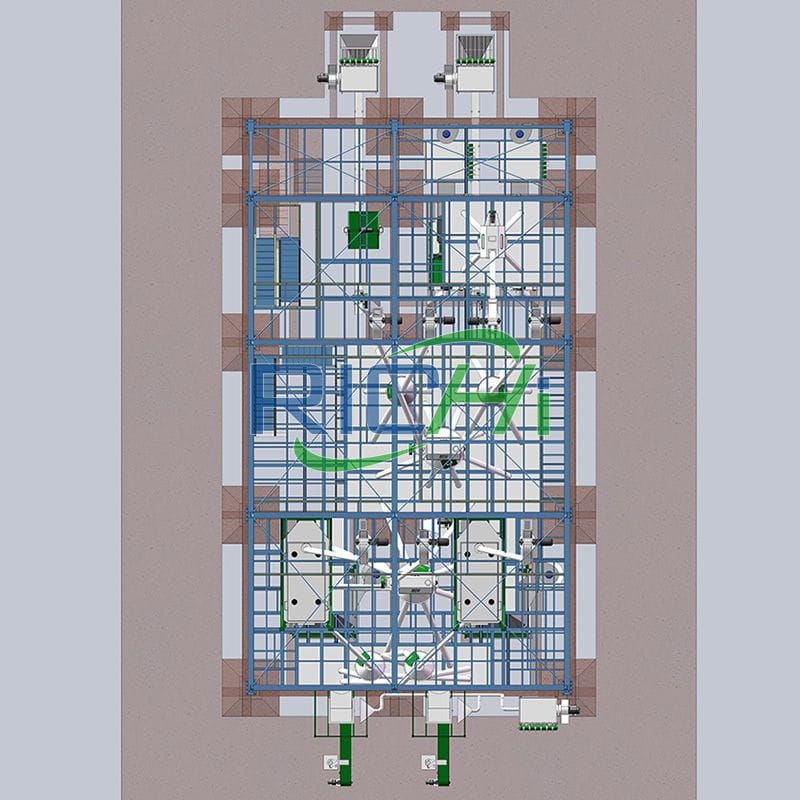

27-28T/H Aquatic Compound fish feed production line design

—— RICHI MACHINERY ——

- Annual output: 110,000 tons (90,000 tons of pellets and 20,000 tons of extruded materials.)

- The total land area: 81069.64m²

- The main construction contents are: 1 workshop building with 1 floor, 1 workshop tower with 5 floors, staff dormitory building with 6 floors, and warehouse with 1 floor.

- Power consumption: 1.6 million kWh

- Water consumption: 3300t/a

- Labor quota and work system: 120 employees work 250 days a year, 16 hours a day.

- Consumption of main raw and auxiliary materials: animal protein raw materials 15000t/a, pregelatinized starch 10000t/a, trace element raw materials 1000t/a, vegetable protein raw materials 4000t/a, soybean meal 20000t/a, fish meal 30000t/a, peanut meal 10000t/a a. Flour 20000t/a, starch 10000t/a, additive 1000t/a, premix 20000t/a, etc.

- Main production equipment: computer control system, scraper conveyor, bucket elevator, cylinder initial cleaning screen, batching bin group, micro pulverizer, batching weighing bucket, distributor, double paddle mixer, superfine pulverizer , metering electronic scale, extruder machine, dryer, counterflow cooling tower, grading screen, automatic packing scale, palletizer, conveyor belt, vacuum spraying machine, drum spraying machine, electronic control equipment, liquid adding system, automotive hydraulic pressure flaps, feed granulators, liquid addition systems, etc.

Brief description of 27-28 t/h fish feed production line process flow:

(1) Pellet feed

After the raw materials are screened and magnetically separated, the meal first enters the primary crushing system, and then is transported to the batching bin, while the powder directly enters the batching bin, and then the various materials are mixed in proportion through the weighing system, and then enters the The ultra-fine pulverization system pulverizes, and after pulverization, the secondary ingredients are mixed, and then granulated, post-cured, cooled (air-cooled), screened to remove impurities, and packaged to obtain qualified products.

(2) Extruded feed

The production process of extruded feed adopts the complete production process of crushing first, then batching, intermittent mixing, (ultra)fine crushing, secondary batching, extruding, drying, oil spraying, cooling (air cooling), screening into finished product warehouse and packaging.

28-30T/H aquatic fish feed production line project design

—— RICHI MACHINERY ——

- Annual output: 150,000 tons

- Water consumption: 7330 (tons/year)

- Power consumption: 5 million (kwh)

- Annual consumption of natural gas: 170,000 cubic meters per year

- The total labor quota: 60 people, with 330 working days per year and two shifts

- Main equipment: pulse dust collector, scraper conveyor, closed air conveyor, double-layer initial cleaning screen, permanent magnet cylinder, rotary distributor, fan, powder initial cleaning screen, pulverizer, feeder, feeding auger , Air shutoff device, extruder, pendulum cooler, warehouse distribution, warehouse discharge machine, double-shaft high-efficiency mixer, granulator, counterflow cooler, crusher, rotary grading screen, finished product warehouse, packing scale, sewing bag conveyor combination machine, air preheater, low temperature drying system, 2t/h boiler, etc.

- Raw material storage: The raw materials and finished products of this project are stored in the raw material warehouse and the finished product warehouse. Corn is stored in two 800m3 silos through airtight pipelines, barley is stored in one 800m3 silo through airtight pipelines, and soybean oil and molasses are stored in six silos. 10 m3 storage tank, off-site transportation relies on social professional logistics companies.

Brief description of fish feed production line process:

- Feed materials such as corn, soybean meal, corn stalks, rice straw, etc. pass the sensory and laboratory analysis, and then are fed into the pulverizer through the feeding port by screw conveyor for pulverization.

- After being pulverized, it is transported to the batching bin by the elevator and conveyor, and the proportion is according to the production requirements. After the proportioning, it is transported to the mixer for mixing (mixing uniformity ≤ 7%).

- After the mixing is complete, it is transported to the aqua feed extruder and aqua feed pellet machine for puffing & granulation.

- After the granulation is completed, it is transported to the finished product warehouse for packaging, and the packaging adopts automatic packaging.

Capacity matching analysis:

- Each cylinder primary cleaning screen can screen up to 280 tons of pellets per day. There are 2 sets of equipment in the project, and the annual production is 300 days. requirements.

- The pulverizer can crush up to 550 tons of raw materials per day. The project has a total of 1 equipment, with an annual production of 300 days. The annual full-load crushing capacity is 165,000 tons, meeting the annual crushing requirement of 150,000 tons.

- The twin-shaft paddle mixer can mix up to 550 tons of raw materials per day. The project has a total of 1 equipment, and the annual production is 300 days. The annual full-load mixing capacity is 165,000 tons, which meets the annual mixing requirement of 150,000 tons.

15-16T/H aquatic fish feed production line project design

—— RICHI MACHINERY ——

- Annual output: 100,000 tons (shrimp and crab feed 40,000 tons/year, fish feed production line 40,000 tons/year, extruded feed 20,000 tons/year)

- Total construction area: 46102m²

- Water consumption: 7058 (tons/year)

- Power consumption: 15.65 million (kWh/year)

- Gas consumption: 1.15 million (standard cubic meters/year)

- Construction content: new aquatic products workshop, silo area, raw material workshop, finished product workshop, canteen, dormitory, boiler room, toilet, bathroom and other buildings.

- Working system: The project has 40 employees, working 270 days a year, 24 hours a day, and 6,480 hours a year. This project uses a 6t/h natural gas boiler, which runs for 270 days, 10 hours a day, and runs 2,700 hours a year.

- Main raw and auxiliary materials: soybean meal 37000t/a, corn distillers grains 3110t/a, rapeseed meal 8200t/a, rice bran 6000t/a, meat and bone meal 3200t/a, calcium dihydrogen phosphate 1200t/a, cottonseed meal 5800t/a, bentonite 1400t/a , fish meal 10900t/a, flour 9400t/a, secondary flour 3800t/a, wheat gluten powder 800t/a, lecithin 370t/a, salt 600t/a, soybean oil 600t/a, fish oil 370t/a, bran 4000t/a , stone powder 1000t/a, etc.

- Production equipment: Coarse pulverizer, batching scale weighing bucket, double-shaft high-efficiency mixer, bucket elevator, ultrafine pulverizer, fan, granulator, grading screen, crusher, grading sieve, packing scale, twin-screw extruder , drying machine, drum spraying machine, countercurrent cooler, packing scale, automatic packing line, air compressor, gas boiler (with low nitrogen burner), transformer, soft water preparation equipment, etc.

15-16 t/h fish feed production Process design:

This project mainly produces shrimp and crab feed, fish feed and extruded feed. Shrimp and crab feed, fish feed and extruded feed have the same production process in the front stage.

During production, various raw materials are first put into the silo, and then pass through the metering system, batching system, and mixing system according to the set ratio requirements, and the metering, material transportation and batching process are all Automatic airtight operation.

This aqua animal feed mill plant project has a silo area, a raw material workshop, a production workshop and a finished product workshop. The silo area uses a slide elevator to transport the raw materials to the silo, and the raw material workshop is used to store various bagged raw materials.

The raw materials in the silo are transported to the production line by a slide elevator, and the raw materials in the raw material workshop are transported to the production line by manual feeding. Each section of the production line adopts mechanical transportation, the superfine grinding section adopts pneumatic transportation, and the finished product is sent to the finished product workshop by mechanical transportation.

25T/H floating and sinking fish feed production line design

—— RICHI MACHINERY ——

- Annual output: 120,000 tons (30,000 tons of prawn feed, 90,000 tons of extruded and granular fish and crab feed)

- Total land area: 66661m²

- Number of employees and operating system: 96 employees, operating in three shifts; the equipment runs 200 days a year, 24 hours a day, 4800 hours a year;

- Annual water consumption: 14622m3/a

- Annual electricity consumption: 18 million kWh

- Annual steam consumption: 48000t/a

- Main construction contents: office building 460.8m², production workshop 2212.31m², raw material warehouse 6851.17m², finished product warehouse 9109.99m², dormitory building 890.42m², canteen 394.62m², bulk warehouse 478.2m², unloading workshop 280.8m².

- Storage system: 15 silos with a volume of 3000t are set up in this project to store bulk raw materials, including 5 soybean meal silos, 5 wheat silos, and 5 rapeseed meal silos. Five vertical oil tanks of 60m3 and one vertical oil tank of 30m3 are set up to store soybean oil.

Process flow design of 25 t/h fish feed production line:

- Unloading and feeding: bagged raw materials such as flour, fish meal, additives, peanut bran, etc. are unloaded to the raw material workshop, and manually put into the feeding port in the raw material workshop;

- Primary crushing: grains such as meal and peanut bran have large particle sizes and need to be crushed;

- Batching and mixing: According to the requirements of the product formula, various raw materials are quantitatively weighed by computer control and sent to the mixer for mixing;

- Micro-grinding: the mixed raw materials are sent to the ultra-fine pulverizer for micro-grinding;

- Secondary mixing: the finely pulverized raw materials are sent to the mixer to add oil for secondary mixing;

- Tempering, granulating, and extruding: adjust the temperature of the raw material (10% water content) by steam to 80-85°C and 13% water content, and then granulate it through a pellet machine or feed extruder; the granular fish and crab feed also needs post-aging;

- Drying: The pellets in this state are fragile and not suitable for storage and transportation, so they are heated indirectly with steam. The air dries the pellets to reduce the moisture content to 13%, making the pellets hard and easy to store and transport;

- Cooling: The dried pellets are cooled by fan to close to room temperature, and the water content is 10%;

- Classification and packaging: The cooled feed is sieved through a high square sieve, classified and packaged, and the finished product is put into storage.

6-7T/H aquatic fish feed production line project design

—— RICHI MACHINERY ——

- Annual output: 20,000 tons of complete compound feed for fish and shrimp

- Project area: 19999.08m². Two new workshops were built with a construction area of 9111.4m²

- Construction content: production line, finished product workshop, raw material workshop, office building

- Natural gas consumption: 500,000 m3/a

- Power consumption: 200,000 Kwh/a

- Water consumption: 6753m3/a

- Consumption of main raw materials: fish meal 4320 t/a, soybean meal 6400 t/a, flour 4800 t/a, fish oil 240 t/a, soybean oil 240 t/a, other auxiliary materials 0.17 t/a, etc.

- Working system: The annual operation of the project is 300 days, and one shift system is implemented, with 10 hours per shift. Labor capacity 20 people

- Main equipment: bucket elevator, cylinder initial cleaning screen, permanent magnet cylinder, pulse dust collector, cone powder initial cleaning screen, primary batching mixing system, batching bin, screw feeder, mixer, screw Belt mixer, screw conveyor, ultrafine pulverizer, settling chamber, high square sieve, stainless steel feeder, three-axis differential speed conditioner, twin-screw extruder, belt dryer, vacuum spraying machine, finished product warehouse, rotary grading screen, belt feeding double scale hopper packing scale, sewing machine belt conveyor, air compressor, gas storage tank, gas steam generator, etc.

process flow of 6-7 t/h fish feed production line

- Fishmeal, soybean meal, and flour are packed in bags, transported to the feeding port by forklift, manually unpacked, and then put into the hopper, and then enter the batching bin after preliminary cleaning to remove impurities, permanent magnetic cylinder to remove iron, and accurately pass the central control system according to the formula Batching to the mixer for one batch mixing.

- The mixed raw materials are transported to the ultrafine pulverizer by the screw conveyor for secondary ultrafine pulverization, and various auxiliary materials and fish oil (or soybean oil) are added to the pulverized raw materials for secondary ingredient mixing. After the mixing is completed, the raw materials enter the conditioner of the extruder, add water and steam (steam is provided by a gas steam generator, the temperature of the material reaches 100°C-130°C, and the moisture reaches 28%), forming puffing during the extrusion process of the twin-screw extruder feed.

- The extruded feed is being dried (gas hot air oven), and the dryer will take away the moisture of the feed through the flowing hot air to reduce the moisture of the feed. After drying, it enters the silo, and the pressure is provided by the oil pump in the oil injection system, and the liquid oil is atomized and evenly sprayed on the pellet feed. The formed pellet feed is sent to the cooler and cooled by natural wind.

- After cooling, the feed is sieved, and those that meet the particle size are qualified products, which are automatically weighed and packaged into the warehouse through the puffed material packaging system; the feed with unqualified particle size enters the return system and is used as raw materials.

20 t/h fish feed production line design

—— RICHI MACHINERY ——

- Annual output: 50,000 tons

- Total land area: 3333m², construction area 3200 m²

- Labor quota: 15 people

- Annual working days: 300 days, 8 hours a day

- Total annual profit: 8,000,000USD

- Main construction content: production workshop, one floor, construction area 3200m2, 100m*32m, mainly including raw material area, production area and finished product area.

- Water consumption: 249m³/a

- Annual power consumption: 2 million kWh

- Main raw material consumption: corn 20000t/a, soybean meal 20000t/a, rice 8000t/a, other auxiliary materials 2000t/a, etc.

- Main feed mill equipment: magnetic separator, pulverizer, fish feed extruder, screening machine, conveyor, finished product pulverizer, screening machine, packaging machine, etc.

Main process flow of 20 t/h fish feed production line

- Feeding: Raw materials enter the elevator through the screw conveyor, and are lifted to the upper part by the elevator to enter the magnetic separation equipment.

- Magnetic separation: Mainly remove the iron-containing impurities in the raw materials.

- Raw material crushing: The materials after magnetic separation are temporarily stored in the bin to be crushed, and then slowly enter the raw material crushing by the screw conveyor through speed-adjusting feeding.

- Extruding: After the material is pulverized by the pulverizer, the material will be fed by frequency conversion on the extruder machine, and at a constant speed to heat up, increase the pressure, knead, and then quickly spray out from the die hole to complete the puffing process.

- Cooling: The temperature of the material after puffing is 110-140 degrees Celsius, and the temperature needs to be lowered in the cooling section to meet the requirements of the subsequent crushing and packaging sections.

- Finished product screening: The pellets that meets the requirements enters the finished product bin, and the material that does not meet the requirements enters the pulverizer for re-crushing, and after crushing, it is lifted again for screening.

- Finished product packaging: After screening, the finished product materials flow into the finished product warehouse and enter the automatic packaging scale.

The key to producing quality aqua feed without losing essential nutrients is a gentle extrusion & pelleting process. Our extrusion and pelletizing fish feed production line solutions give you precise control over the cooking and shaping process so that you can produce fish feed of the highest quality. (Find us on YouTube)

ABOUT OUR SERVICE

Richi Machinery has been linked to the feed sector since 1995 and covers every process within the automatic fish feed production line. Today RICHI is the leading Chinese company in the production of aqua fish feed machines and turnkey fish feed plants.

pre-sale service

Demand communication, according to the needs of customers, RICHI assigns technical personnel to visit the fish feed production line construction site, customizes plans according to customer production needs and actual conditions, and escorts your production.

Sale service

In the aqua feed mill equipment manufacturing stage, we organize customers to visit the factory and introduce the equipment and technological process information in detail; in the equipment installation stage, let customers visit the construction site in person to understand the relevant plant planning work; in the equipment debugging stage, we guide customers to operate and maintain the machine.

After-sales service

If the equipment fails within the warranty period or outside the warranty period, after we receive the notice, we can arrive at the scene and start maintenance within 1-7 days after the getting of the foreign visa.

During the warranty period, we will repair and replace parts damaged due to quality reasons free of charge.

Outside the warranty period, the accessories provided are only charged at cost; for equipment damage caused by human factors on the demand side, the accessories repaired or provided by us are priced at cost.