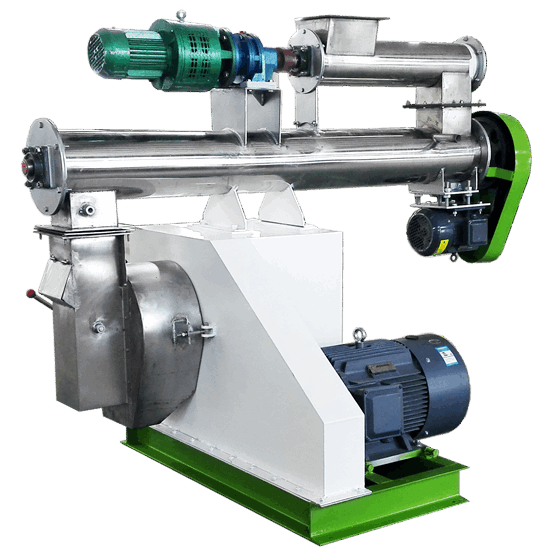

small animal feed pellet machine

Small feed pellet machine is an animal feed processing equipment, which can press corn, soybean, grass, straw and other feed raw materials into small feed pellets. This equipment is the smallest ring die feed pellet machine that RICHI can provide, not a flat die pellet machine.

- Model: SZLH250

- capacity: 1-2T/H

- power: 22KW

- Price: FOB 7,000-15,000 USD

According to the feed type, it can be divided into poultry feed pellet machine, cattle feed pellet machine, goat feed pellet making machine, rabbit pellet making machine, pig feed pellet machine, fish feed pellet making machine, shrimp feed pellet machine, etc. A variety of feed pellet machine are classified by appearance and the way of production.

Our small feed pellet machine is widely used in animal feed mill plants, animal farms, poultry farms, small and medium-sized farms, etc.

Features of SZLH250 small animal feed pellet machine

- Adopts belt driven, stable transmission is more suitable for small-capacity livestock and poultry feed pelleting.lThe feeder adopts an “O-type” cylinder, which not only improves the uniformity of feeding, but also effectively prevents steam from rising.

- The conditioner is increased by 15% based on the CPM model to improve the maturity of the material.

- The material throwing scraper is welded on the head of the tempering blade, which accelerates the fusion of materials and steam and improves the degree of maturation.

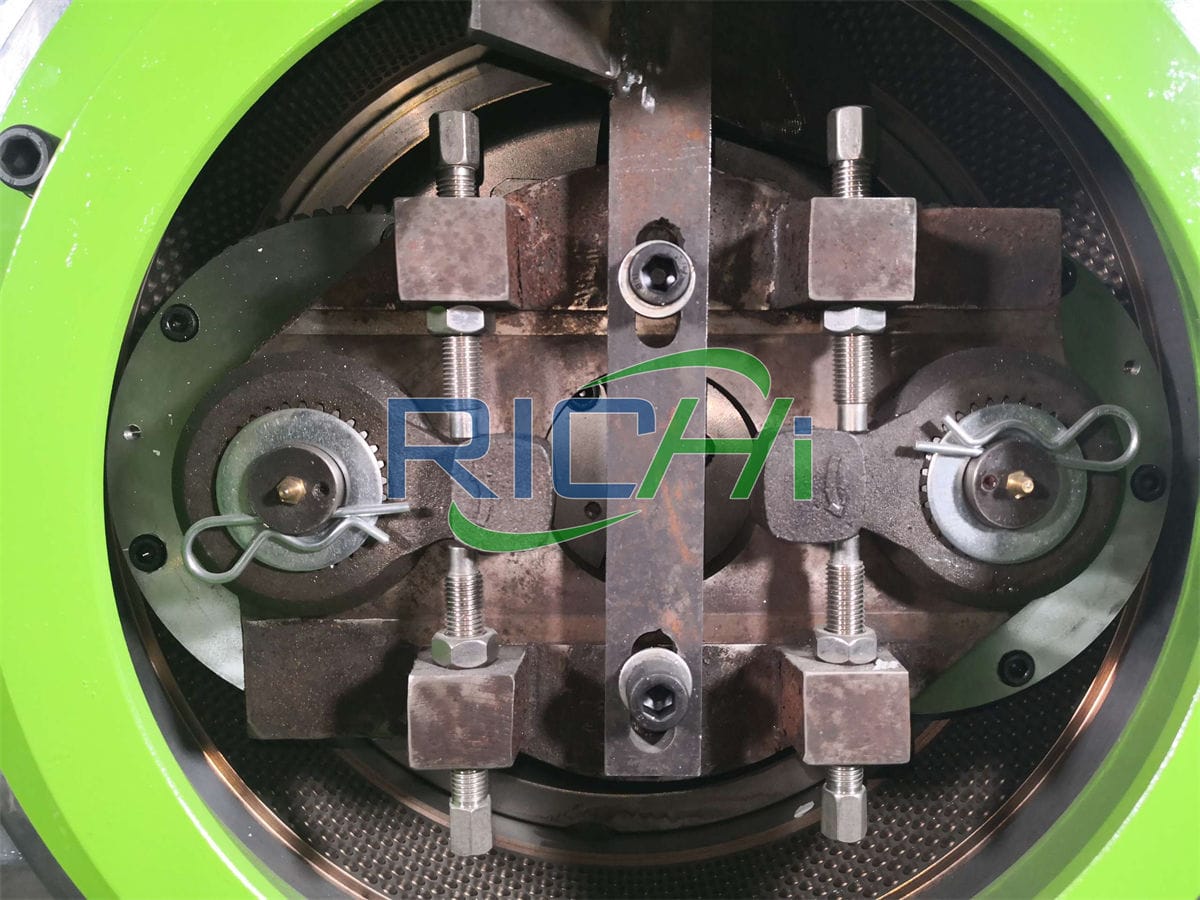

- High-precision gear direct drive, strong overload resistance, general blockage can be restored without stopping the machine.

- The rear end of the main shaft is improved to a bearing support to ensure that the hollow shaft and the main shaft axis are parallel, the main shaft does not shake, and the production capacity is improved.

- The small animal feed pellet machine housing material is made of highly wear-resistant internal combustion engine cylinder liner material, which can maintain good precision after long-term use. The service life is up to 20 years.

- RICHI small animal feed pellet making machine is easy to operate, and one feed pelletizer can operate multiple feed pelletizers at the same time. It is easier to achieve automatic control.

- Double-layer and three-layer conditioner small animal feed pellet machines can be customized to produce high-quality livestock and poultry aquatic feed.

Advantages of SZLH250 small animal feed pellet machine

- SKF bearing; auto-adjusting feeding.

- Adopting steam adjusting system.

- Auto-adjust steam inlet.

- 24 hours continously working.

- Volume of the conditioner is dia 1800mm* 273mm, larger than its peers.

- Conditioner is made by stainless steel.

- Access door at side.

- Access door at side.

- Comparable to European and American models.

- Safe and hygienic.

- Stable and efficient.

- Advanced structure, stable operation.

- Excellent feed quality.

- Suitable for the production of various livestock and poultry feed and aquatic feed.

specifications of SZLH250 small animal feed pellet machine

| model | SZLH250 |

| Output (t/h) | 1~2 |

| Main motor power (kw) | 22 |

| Main motor series | 4P |

| Feeder power (kw) | 1.1 |

| Conditioner power (kw) | 1.5 |

| Ring die diameter (mm) | 250 |

| Finished pellet diameter (mm) | 2~12 |

configuration of SZLH250 small animal feed pellet machine

- Ring die material: stainless steel

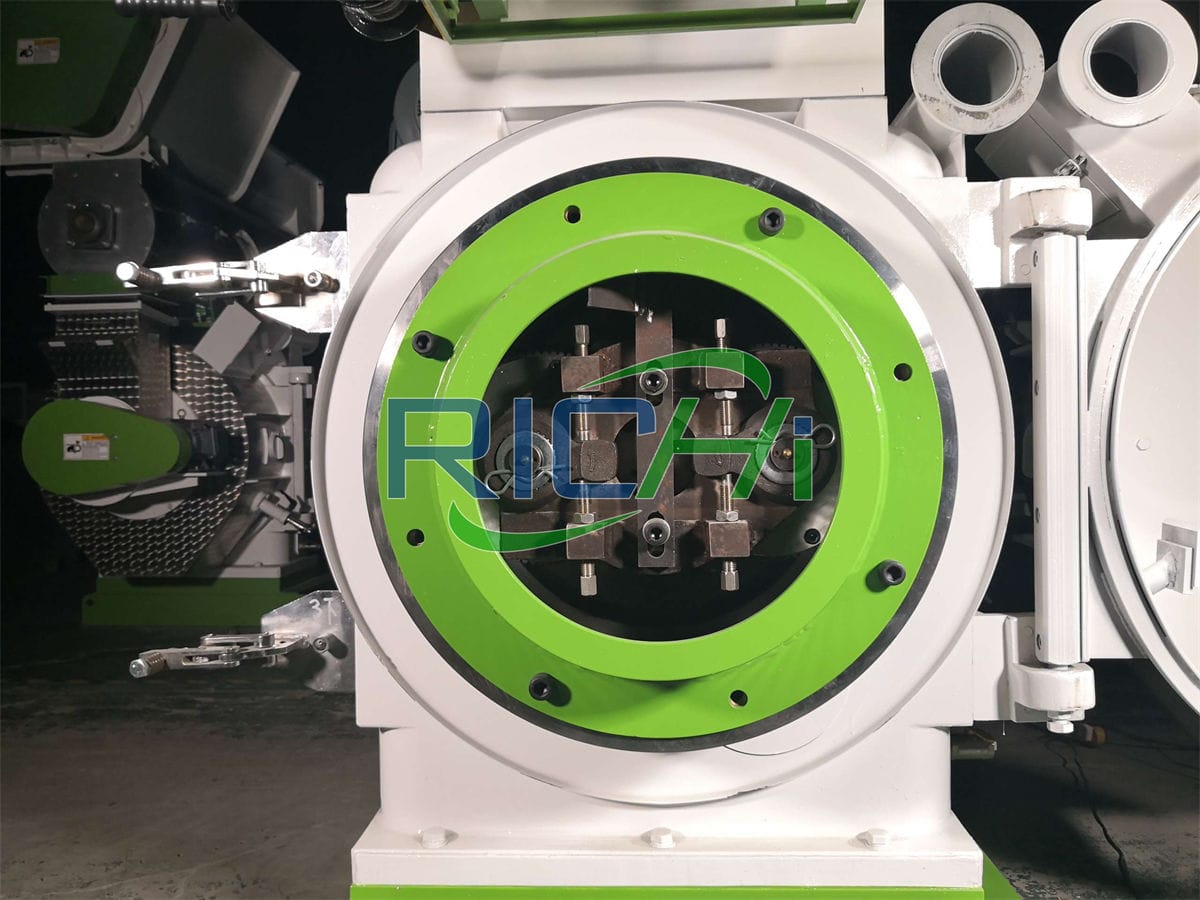

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Spindle: 42CrMo

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

operation requirements of SZLH250 small animal feed pellet machine

| Animal feed types | Requirements Before Entering Granulator(mm) | Pellet Diameter(mm) | Pellet Length(mm) | Ring Die Compression Ratio | Conditoning Temperature(℃) | Conditoning Time(s) | Equipped Conditioner |

| Poultry chicken | 2.0-3.0 | 2-4 | 4-8 | 1:10—-1:13 | 150 | 60-120 | one layer/two-layer |

| Cattle | 3-5mm | 6-12 | 12-18 | 1:6:1:9 | 150 | 30-60 | one layer/two-layer |

| pig | 2-3 | 2-4 | 3-8 | 1:3.5—-1:5 | 150 | 60-120 | One layer/two layer |

| fish | 1.0-2.0 | 2-6 | 4-12 | 1:16—-1:18 | 150 | 90-180 | Two layer/three layer |

| shrimp | 95%≥80 mesh | 1.2-2.0 | 1.8-4 | 1:20—-1:25 | 150 | 120-180 | three layer |

| … | |||||||

SZLH250 small animal feed pellet machine projects

1-2T/H small animal feed machine in indonesia

- Pellet Machine selection: SZLH250

- Feed Size: 2-4mm pellets

- project cost: 59,000 USD

- Application: Fish Feed Production Plant

1-2T/H small animal pellet machine in Uzbekistan

- Pellet Machine selection: SZLH250

- Feed Size: 4-8mm pellets

- project cost: 42,000 USD

- Application: livestock feed production line

1-2T/H small animal feed machine for sale Peru

- Pellet Machine selection: SZLH250

- Feed Size: 3-6mm pellets

- project cost: 25,000 USD

- Application: poultry feed production line

1-2T/H small cattle feed machine for sale Algeria

- Pellet Machine selection: SZLH250

- Feed Size: 4-8mm pellets

- project cost:50,000 USD

- Application: cattle feed production line

1-2T/H small animal feed pellet machine in Russia

- Pellet Machine selection: SZLH250

- Feed Size:2-4mm pellets

- project cost: 13,600 USD

- Application: chicken feed mill plant

1-2T/H small animal feed machine in Ecuador

- Pellet Machine selection: SZLH250

- Feed Size: 2-4mm pellets

- project cost: 27,300 USD

- Application: broiler feed mill

1-2T/H small chicken feed pellet machine in Australia

- Pellet Machine selection: SZLH250

- Feed Size: 2-4mm pellets

- project cost: 38,600 USD

- Application: poultry feed pellet plant

1-2T/H small poultry feed making machine in Angola

- Pellet Machine selection: SZLH250

- Feed Size: 1-4mm pellets

- project cost: 46,900 USD

- Application: chicken feed pellet plant

Application of SZLH250 small animal feed pellet machine

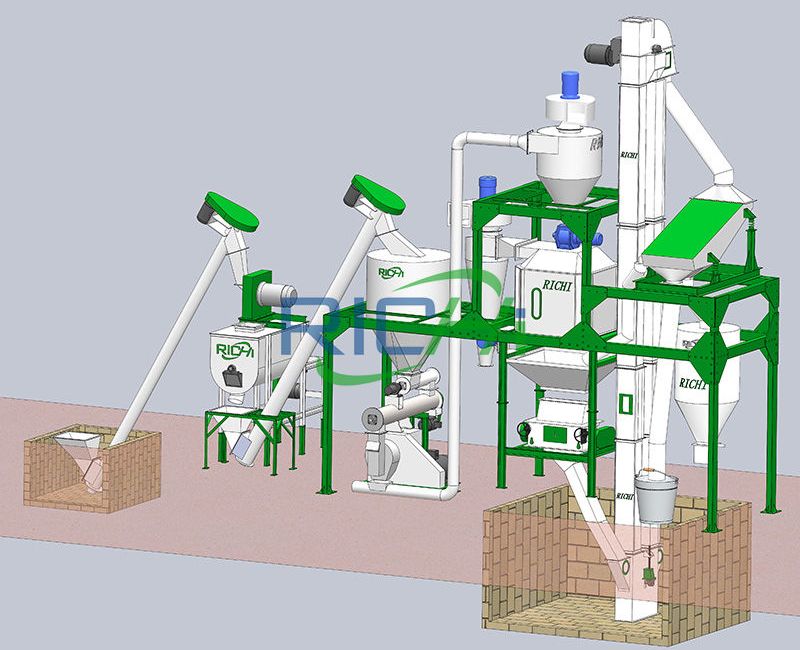

SZLH250 small animal feed pellet machine is mainly used for 1-2 ton feed production line, which is widely used in small feed processing plants, pig feed mill, livestock feed production line, poultry feed production line, cattle feed production line, fish feed production plant, chicken feed mill plant, broiler feed mill, livestock farms, poultry farms, aquaculture farms, and livestock farms, etc.

In order to meet more customer’s demands, RICHI Machinery not only offers large scale feed pellet plant, but also provides the 1-2t/h small scale animal feed production line that is in compact size and is very much suitable for home use or farm use.

In addition, we also offer customized animal feed production business plan to help our customer know the feed pelletizing industry quickly.

If you want to get 1-2t/h feed pellet production line solution, click the button below to get detailed solution design, feed mill equipment configuration list and feed plant quotation.

Video of small animal feed pellet machine

FAQs of SZLH250 small animal feed pellet machine

How much does SZLH250 small animal feed pellet machine cost?

The price of SZLH250 small animal feed pellet mill machine is generally between FOB 7,000-15,000 USD.

As an important industrial equipment, the price of feed pellet mill in the market fluctuates greatly. Understanding the factors affecting the price of feed pellet mills not only helps to choose suitable equipment, but also saves costs for feed processors.

The following will explore the main factors affecting the animal feed pellet machine price to help better understand and understand the reasons for market price fluctuations.

- Power and output:

The power and gas production of small animal feed pellet machines are one of the important factors that determine the price of feed pellet mills. Generally speaking, the higher the power and the higher the gas production of feed pellet mills, the higher the cost.

High-power feed pellet mills have high manufacturing costs and energy consumption, so the price of feed pellet mills is relatively high. However, it is necessary to choose the power and output that suits you according to actual needs to avoid over-investment. - Brand and quality:

The prices of small animal feed pellet machines of different brands differ in performance and quality, which also leads to differences in the prices of feed pellet mills. Well-known brands usually have higher technical levels and more reliable quality, so they are relatively high.

Some non-well-known brands may attract customers at lower prices, but they need to pay attention to product quality, reliability and after-sales service. - Configuration and accessories:

The price of small feed pellet mills will also be affected by configuration and accessories. For example, the price of a feed pellet mill with a variable frequency feeding system, a multi-layer conditioner, a large-size conditioner, a stainless steel ring die, and a forced feeder may be relatively high, but it can automatically adjust the operating status according to actual needs to achieve energy saving.

Although it will increase the price of the feed pellet mill, it can improve the performance and reliability of the equipment. - Market supply and demand:

Market supply and demand also have an important impact on the price of small animal feed pellet machines. When the market demand is large and the supplier’s resources are limited, the price of small feed pelleting machines is usually relatively high.

On the contrary, when the market competition is fierce or there is an oversupply, the price of feed pellet mills may fall. When purchasing, you can pay attention to market dynamics and supply conditions to choose the right time to buy. - Geographic location and transportation costs:

Geographic location and transportation costs will also have a certain impact on the price of small feed pellet making machines. Due to different geographical locations, the supplier’s transportation costs will vary, so they will also change.

The price of feed pellet mills is affected by many factors. Knowing and understanding these influencing factors will help feed processors make wise decisions when purchasing and choose equipment that suits their needs and budget.

At the same time, when purchasing, it is necessary to comprehensively consider the quality, configuration and after-sales service to ensure that the purchased small animal feed pellet machine has the best cost-effectiveness.

How to choose a small animal feed pellet machine?

When choosing a small animal feed pellet machine, it is necessary to consider multiple aspects to ensure that the purchased equipment can meet production needs and bring long-term economic benefits.

- First, from the perspective of product structure, when purchasing small animal feed pellet machine, it is necessary to consider whether the overall structure of the equipment is suitable for the production process and production efficiency requirements.

In addition, the material and appearance of the equipment should also be considered to ensure that the equipment can meet the function while being durable, safe and reliable. - Secondly, when purchasing small animal feed pellet machine, it is necessary to analyze from the product perspective.

It is necessary to ensure that the purchased equipment can meet production requirements and has reliability, stability and durability; it is also necessary to consider the energy consumption and environmental performance of the equipment to reduce production costs and reduce the impact on the environment.

In addition, equipment maintenance and maintenance are also one of the factors that need to be considered when purchasing. Simple maintenance can reduce the maintenance cost of the enterprise. - Furthermore, when purchasing a small animal feed pellet machine, it is necessary to understand the advantages of the product.

Different equipment has different advantages. For example, some equipment has a simple structure and is easy to operate, while some equipment has higher precision and faster processing speed. Therefore, when purchasing equipment, you need to combine your own production needs and process characteristics to choose the most suitable equipment. - Finally, the usage scenario is also one of the factors that need to be considered when purchasing a small animal feed pellet machine.

Different production scenarios require different equipment, such as poultry feed factories need to use professional poultry feed pelletizers, cattle grass feed factories need to use professional forage feed pellet machines, etc. Therefore, when purchasing equipment, you need to choose the right equipment according to your own production scenarios and needs.

In short, there are many aspects to consider when purchasing a small animal feed pellet machine. Only by comprehensive consideration can you ensure that you purchase the right equipment.

Before purchasing, you need to fully understand the product’s performance, characteristics and price information, and at the same time pay attention to the after-sales service and maintenance of the equipment.

How to choose a small animal feed pellet machine manufacturer?

(1) Pay attention to the relevant qualifications and certifications

When choosing a small animal feed pellet machine manufacturer, you should first check whether the manufacturer has the corresponding operating qualifications and ISO certification. Such as ISO9001 quality management system certification, CE EU certification, etc. This can prove that the manufacturer’s product quality has reached the corresponding standards and is more reliable.

(2) Inspecting equipment performance

You can conduct field visits to different manufacturers, compare the differences between different small animal feed pellet machines, and choose the processing equipment that suits your needs. When inspecting, you can focus on the equipment’s processing technology, manufacturer’s strength, R&D level, and subsequent technical support.

The quality of the small animal feed pellet machine is directly related to the feed pelleting effect and feed quality. Not only should we pay attention to the quality and performance of the equipment, but also the subsequent maintenance and maintenance, the difficulty of equipment operation, etc., which will affect the service life of the small animal feed pellet machine.

(3) Considering cost-effectiveness

In addition to paying attention to quality, we should also pay attention to cost-effectiveness, and comprehensively consider the price, operating cost, and long-term return on investment of the equipment. Even if the price of the small animal feed pellet machine is relatively high, if it can bring long-term economic and environmental benefits, it is still a cost-effective choice.

(4) Manufacturer’s reputation

A small animal feed pellet machine that can withstand market testing is a good product. For customers, the reputation and word of mouth of the manufacturer represent the recognition of the market and users. Manufacturers with good reputation and good reputation are often more popular with users. This is not only a symbol of quality, but also a guarantee of service.

From these, it is not easy to choose a reliable small animal feed pellet machine manufacturer. You need to investigate more and choose carefully to ensure that the selected equipment and manufacturer are beneficial to the long-term stable operation of the enterprise. (Find RICHI on youtube)