Pellet Plant project

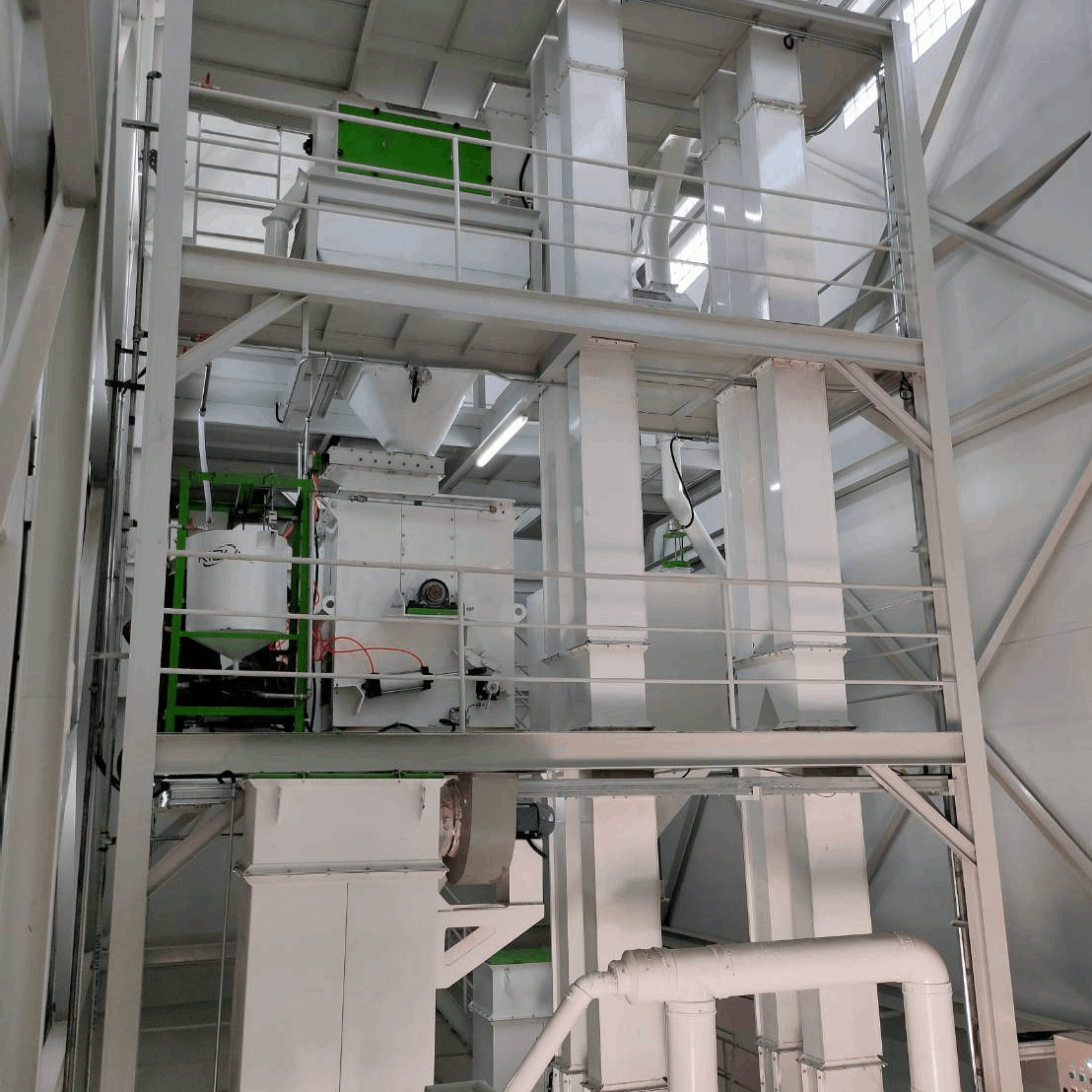

Walking into the production site, a close-up view of the actual production status of RICHI pellet plant project.

pellet plant Project videos

Our practical experience has enabled us to cooperate with thousands of customers in more than 130 countries and regions, providing them with complete pellet equipment solution and services covering the entire pellet plant project life cycle.

TYPES oF pELLET PLANT PROJECT

Richi Machinery is a turnkey (engineering, procurement and construction) contractor from consulting to design, civil, fabrication, logistics, installation, commissioning, training and service.

animal feed factory project

Customized animal feed factory solutions tailored to meet your specific needs. From custom animal feed machinery design to efficient processes, we’re dedicated to shaping the future of feed production together.

cattle feed plant project

We provide complete and customized cattle feed plant project solutions from mixing and grinding to sifting, pelleting, cooling and packaging feed pellets for various species, match cattle feeding habits

wood pellet plant construction

Provide a full range of services and customized personalized wood pellet plant construction plan for a long time, so as to control the total use cost of wood pellet plant to the lowest level and maximize the benefits.

poultry feed mill project

With a proven track record and satisfied customers on poultry feed mill project, experience the power of co-creation with Richi Machinery – top poultry feed machine manufacturer.

fish feed mill project

Our aqua shrimp fish feed mill projects provide complete control over the entire fish feed extrusion or pelleting process so you can produce fish feed of the highest quality.

biomass pellet project cost

Richi Machinery has transformed more than 30 years of industry experience and hundreds of biomass pellet project operation sites around the world into competitive and sustainable benefits for each biomass pellet manufacturer.

pellet plant project in the world

With global deployment, Richi Machinery has exported to more than 130 countries and regions in batches, covering areas of Asia-Pacific, North America, Europe, Oceania, Latin America, Africa, the Middle East and the CIS.

Asia

As an important market, RICHI has sold more than 500 pellet production lines to Asia. From 1995 to present, RICHI’s feed mill equipment and biomass pellet equipment, especially poultry livestock feed mill equipment and aqua feed machines, have been put on the market in large quantities, accelerating the upgrading of compound feed mill plant in the region. RICHI provides overall solutions including products, technologies, services and financial support, etc. which has great influence on the region and sets a benchmark for Chinese manufacturers to go global.

At present, the pellet plants we design and build for Asian customers cover these fields: chicken feed, cattle feed, shrimp feed, extruded fish feed, sunk fish feed, premix, ruminant feed, straw pellets, wood fuel pellets, alfalfa pellets , organic fertilizer, tofu cat litter, PET plastic pellets, camel feed, pigeon feed, etc.

Pellet Making Machine Malaysia

Pelletizer Machine Philippines

Pellet Machine In India

Pelleting Machine In Oman

Pellet Machine Turkey

Pellet Mill In Iran

Pellet Machine In Afghanistan

Pellet Machine In Iraq

Pellet Making Machine In UAE

Pellet Machine In Saudi Arabia

Pellet Mill In Vietnam

Pellet Machine In Pakistan

Pellet Mill In Israel

Pellet Machine In Singapore

Pellet Making Machine In Qatar

Pellet Machine In Sri Lanka

europe

Strict quality standards, careful environmental protection design, and sustainable business model… these are the real benefits that the RICHI pellet production line project is bringing to European localities. RICHI Machinery has made tremendous effort to develop high-end pellet production line tailored for customers, meeting the strict product requirements of the European market. Thanks to the quality, efficiency, durability and high cost performance, it has gained the trust of over 200 pellet manufacturers in the Europe. In particular, the eco-friendliness of pelletizing plant has let more than 50 wood pellet factories choose RICHI pelletizing solutions.

Currently, our pellet processing fields in Europe cover: wood pellets, grass pellets, livestock and poultry feed, aquatic extruded feed, waste tire pellets, organic fertilizer pellets, tofu cat litter pellets, bentonite cat litter pellets, crop pellets, biomass pellets, paper pellets, etc.

Pellet Mill For Sale Poland

Pellet Machine U.K.

Pellet Mill For Sale Italy

Pellet Machine Austria

Pellet Machine In Romania

Pellet Mill In Netherlands

Pellet Making Machine In France

Pellet Mill In Portugal

Pellet Mill In Spain

Pellet Mill In Belgium

Pellet Mill In Iceland

Pellet Mill In Lithuania

Pellet Mill In Ukraine

Pellet Mill In Macedonia

Pellet Mill In Slovakia

Pellet Machine Czech Republic

Pellet Mill In Albania

Commonwealth of Independent States

RICHI has sold the pellet plant equipment for a total of 3000+ units in CIS countries, with a 50% market share in the field of pelletizing industry, setting a benchmark for the promotion of such a vehicle in Russia and even all Commonwealth of Independent States. All along, we supply tailor-made suitable pellet production line designs for CIS customers.

Currently, the types of pellet plants we provide to customers in the CIS countries cover: trout feed, sturgeon feed, catfish feed, sunken fish feed, cat and dog pet feed, livestock and poultry feed, salmon feed, sunflower seed shell pellets, grass feed Pellets, alfalfa pellets, beet pellets, sawdust fuel pellets, sawdust cat litter pellets, tofu cat litter pellets, reed pellets, straw pellets, waste paper pellets, oil residue pellets, vegetable waste, coal pellets, corn pellets, bran pellets , waste tire pellets, grain pellets, etc.

complete Pellet production line in Russia

Pellet Making Machine For Sale Kazakhstan

Pellet Making Machine For Sale Kyrgyzstan

Pellet Making Machine For Sale Moldova

Pellet Production Line In Tajikistan

Pellet Making machine In Azerbaijan

Pellet Making Machine For Sale Armenia

Pellet Machine For Sale Turkmenistan

North America

The North American market is known for its high entry barriers and strict requirements. RICHI’s pellet plant projects and equipment have been exported to North America in batches, which once again verified its excellent product quality. In order to better adapt to the local market, our technical team went deep into the front line many times. After many years, we finally completed a high-end customized pellet machine model suitable for the local area, creating cutting-edge products for Richi Machinery to enter the North American market.

Currently, our pellet plant projects in North America cover these areas: sawdust pellets, wood chips pellet, fuel pellets, biomass pellets, cattle feed, fish feed, straw pellets, peanut shell pellets, hemp pellets, grass pellets, alfalfa pellets , organic fertilizer pellets, EFB pellets, bagasse pellets, bamboo pellets, paper pellets, chicken manure pellets, horse manure pellets, waste tire pellets, hop pellets, rice husk pellets, cat litter pellets, etc.

Pellet Mill For Sale Mexico

Pellet Mill For Sale El Salvador

Pellet Mill For Sale Haiti

Pellet Mill For Sale Honduras

Pellet Mill For Sale Cuba

Pellet Mill Trinidad And Tobago

Oceania

The ultimate pursuit of equipment efficiency and economy is a major feature of RICHI’s export to high-end markets such as New Zealand and Australia. In addition to “leading technology and durability” pellet production line equipment, Richi Machinery also focuses on the construction of a service spare parts system for the Oceania market. In recent years, RICHI has worked closely with import and export companies to deeply explore the Oceania market. It has now established a complete market, channel, product, service, and spare parts management system, with multiple sales and service outlets, fully covering the global market.

Currently, our pellet plant projects in Oceania cover these areas: wood pellets, biomass pellets, coal pellets, cat litter pellets, fish feed pellets, extruded feed, livestock and poultry feed, straw pellets, grass pellets, alfalfa pellets, organic fertilizer pellets , paper pellets, organic fertilizer pellets, hop pellets, pet feed, husk pellets, etc.

South America

RICHI Machinery officially entered the South American market in 1998. Up to now, RICHI’s sales network in the South American market has taken shape and can provide pre-sales and in-sales pellet production line equipment to South American customers such as Argentina, Brazil, Chile, Peru, and Ecuador. , full range of after-sales and spare parts supply services. At the same time, RICHI is stepping up efforts to further improve its sales network in the South American market, striving to provide better products and services to South American customers and embody the responsibility and style of the RICHI brand.

Currently, our pellet plant projects in South America cover these fields: wood pellets, alfalfa pellets, floating fish feed, shrimp feed pellets, cat litter pellets, fish feed pellets, cattle and sheep feed, chicken feed, straw pellets, grass pellets , agricultural waste pellets, fertilizer pellets, paper pellets, organic fertilizer pellets, hop pellets, rabbit feed, etc.

Pellet Mill For Sale Argentina

Pellet Mill For Sale Brazil

Pellet Machine For Sale Chile

Pellet Machine In Peru

Pellet Machine In Ecuador

Pellet Machine In Paraguay

Pellet Mill In Bolivia

Pellet Mill For Sale Guyana

Pellet Machine in Columbia

Pellet Mill In Jamaica

africa

As an important force of Chinese machinery overseas, Richi Machinery’s experience in establishing hundreds of feed mill plant and biomass pellet production line projects in Africa is something that many peer companies cannot replicate. RICHI is bringing development opportunities to countries in the African region through real projects, and bringing a sense of participation and gain to local granule processors.

Currently, our pellet factory projects in Africa cover these fields: broiler feed, laying hen feed, beef cattle feed, dairy cattle feed, sheep feed, pig feed, fish feed, shrimp feed, straw pellets, peanut shell pellets, rice husk pellets, Coffee shell pellets, sawdust pellets, dog feed, grass feed, alfalfa pellets, organic fertilizer pellets, etc.

Pellet Mill For Sale Algeria

Pellet making Machine In Zimbabwe

Pellet Machine For Sale Angola

pelleting machine in nigeria

Pellet Machine In Congo

Pellet Machine In Tanzania

Pellet Machine In Ethiopia

Pellet Machine In Senegal

pellet making machine in kenya

Pellet Machine In Uganda

Pellet Machine In Egypt

Pellet Machine In Rwanda

Pellet Machine In Mauritius

Pellet Machine In Somalia

Pellet Machine In Botswana

Pellet Machine In Mauritania

Pellet Machine In Cote D’Ivoire

Pellet Machine In Gambia

Pellet Machine In Cape Verde

Pellet Machine In Ghana

Pellet Machine In Burkina Faso

Pellet Machine In Cameroon

Pellet Machine In Burundi

hot equipment for pellet plant project

You can trust us because we don’t have to rely on others. We are offering all manufacturing, assembling, testing and after sales services from a single source by proven RICHI quality!

wood pellet mill

Used for processing wood waste and othe agricultural forestry waste pellets of 6-12 mm with different sizes and moisture.

poultry feed pellet machine

Used for processing 2-6 mm pellet feed for broiler chicken, duck, goose, quail and turkey, etc. Usually only one layer conditioner is required.

livestock feed pellet mill

Used for processing 2-12 mm feed pellets for cattle, sheep, pigs, rabbits, horses, deer, camels, donkeys and other animals.

Auxiliary equipment

It is suitable for application in different sections of different types of pellet plants such as feed, biomass, and organic fertilizer.

SERVICE for pellet plant project

You can make an appointment at any time for the solutions you need, and request our expert team to return to you at any time!

Customer Consultation

We want to have a deep understanding of your industrial process, to know your exact needs of feed, wood, biomass, fertilizer or other pellet processing.

Pellet Plant Design

Based on your unique situation and industrial process, we will tailor complete pellet plant you need, and inform you of every additional detail that could facilitate operation, minimize total cost.

Equipment Manufacturing

The critical components of the of the complete pellet production line equipment are built in our own workshops in Asia. Additional equipment is manufactured by our worldwide network of reliable partners.

Equipment Testing

We can provide customers with testing services from a single machine to a complete pellet plant system, and provide you with real actual data for “worry-free use.”

Equipment Delivery

In equipment boxing and packaging, we adopt professional packaging and modular solutions to ensure the safe and non-destructive delivery of pellet plant equipment.

Installation & Commissioning

Whether you choose your own subcontractor for the erection phase or you want to install everything together with us, a Richi supervisor will be around to make sure everything is mounted in a safe and thorough way.

Staff Training

We provide comprehensive training for the technicians of each pellet mill project. We can also continue to provide support for the technicians during latter pellet production line project operation.

Project Follow-Up

When everything is up and running our Richiers will help you further whenever needed. We are ready to answer your call 24/7.We’ll also visit you regularly to learn about your needs.

1

Can You Provide Turnkey Service ?

We offer a complete turnkey pellet plant project service including project consultation, site survey, sample analysis to plan design, manufacturing, delivery, installation and commissioning, and maintenance guidance to ensure that all links are in place with customers in a timely manner solve customer needs.

2

Are all the pellet plant equipment manufactured by RICHI?

Yes, all pellet production line equipment is processed by us, and only supporting electrical components, bearings and other components are provided by well-known manufacturers we cooperate with.

3

What is the construction price of a pellet plant project?

Since our pellet plant project can cover so many types of applications, the investment costs of all different pellet production lines vary greatly, ranging from tens of thousands to millions of dollars. And our pellet production line solutions can be customized according to customer needs, raw materials, factories, and processes.

4

What special raw material pellet factory projects can you build?

Our pellet plant project is suitable for all raw materials (agricultural and forestry waste, grain, urban waste). At present, the special raw material pellet projects we have done cover cat litter pellets, waste paper pellets, coal powder pellets, bentonite pellets, clay pellets, and concave and convex pellets, rat poison pellet, air purification pellets, paper pellets, plastic pellets, waste tire pellets, etc.

5

Where is your headquarters?

As a well-known pellet factory and pellet equipment manufacturer, we are always proud to tell all our customers that we are from China and are headquartered in Zhengzhou City, Henan Province. Thousands of our pellet production line projects are running in every corner of the world. Facts always speak louder than words. RICHI is taking one step at a time and using actions to refute some noise and prejudice against “made in China”.