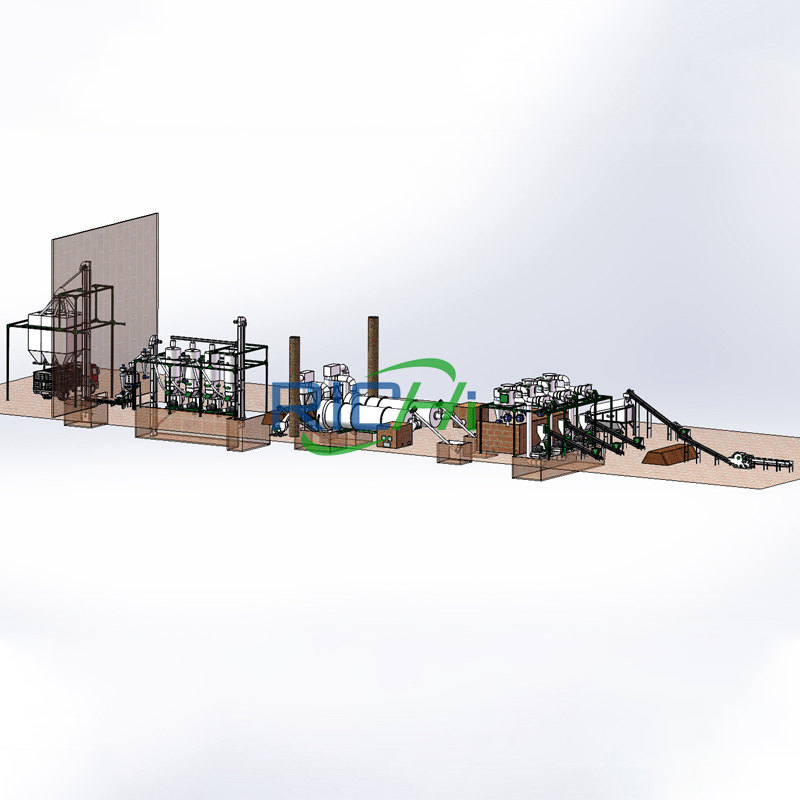

pellet machine line

The pellet machine line is a modern biomass pellet production system, mainly used to convert various waste materials into efficient and environmentally friendly pellets.

The pellet machine line converts biomass raw materials into pellet solid products through a series of process steps to facilitate storage, transportation and utilization.

From standard biomass equipment to custom biomass pellet machine line designs, RICHI Machinery is the only name you need to know in biomass pelleting operations.

We provide state-of-the-art modular control biomass pellets engineering solutions that can adapt to the processing requirements of various biomass raw material granulation.

Our expertise in pellet machine line is not just a service; it’s a partnership dedicated to transforming your business to achieve your most ambitious goals. We take a holistic approach to operational improvements, ensuring every part of your process is meticulously set up to meet your goals.

Whether that’s creating a better biomass pellet product, enhancing quality, achieving safer operations, improving efficiency, reducing headcount, or minimizing waste.

- Output: 7-12T/H

- Price: 100,000 – 1,100,000 USD

- Application: Used for processing fuel pellets, feed pellets, organic fertilizer pellets, cat litter pellets, plastic pellets, paper pellets, rat poison pellets, coal pellets, sludge pellets, etc.

- Applicable customers: biomass pellet factories, power plants, feed mills, farms, organic fertilizer factories, cat litter factories, furniture factories, sawdust factories, wood chip factories, etc.

raw materials for 7-12T/H pellet machine line

The biomass pellet machine line can adapt to different types of biomass raw materials, such as wood waste, straw, rice husk, peanut shell, palm shell, bamboo, bagasse, etc. This makes biomass pellet production play an important role in resource utilization and waste treatment, helping to promote sustainable development.

- Agricultural waste: tree trunks, stumps, wood chips, sawdust, shaving, leaves, wood discs, wood blocks, wood strips, etc.

- Forestry waste: straw, rice husk, bamboo, bagasse, miscanthus, coffee shell, palm waste, olive pomace, sunflower shell, etc.

- Municipal and industrial waste: waste paper, newspapers, cord, plastic, bean dregs, bentonite, coal, sludge, etc.

solution.jpg)

Due to flexibility and wide applicability, our pellet machine lines can process pellets using one or more raw materials simultaneously.

Types of 7-12 t/h pellet machine lines

There are many types of biomass pellet production lines, and fuel production lines are just one of them. According to different raw materials, processes and equipment, production line pellets are divided into the following types:

Fuel biomass pellet machine line

Used for processing biomass fuel pellet, mainly using biomass raw materials with high calorific value such as wood, straw, rice husk, efb, bamboo.

Feed biomass pellet machine line

Used for processing animal feed, mainly using grass, alfalfa, hay, straw, hemp, sunflower shells and other raw materials with certain nutritional value.

fertilizer biomass pellet machine line

Used to process organic fertilizer, mainly using raw materials such as straw, husk, bagasse, coconut bran and animal and livestock manure fermentation and granulation.

Special pellet machine line

Used to process special products such as tofu cat litter, bentonite cat litter pellets, paper cat litter pellets, rubber pellets, plastic pellets, rat poison pellets, etc.

Process design of 7-12 t/h pellet machine line

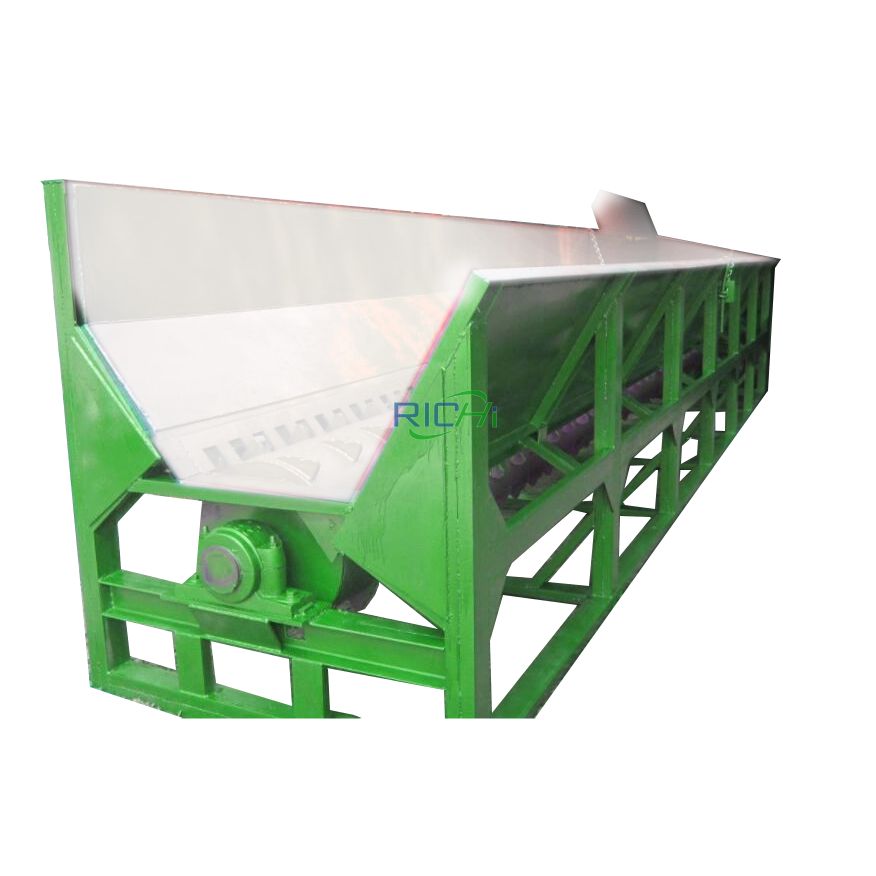

Manufacturing biomass pellet equipment, crushers, dryer machines… we are able to provide all steps in cleaning-crushing-drying-pelleting-cooling-screening-bagging.

Also ask us about our range of silo equipment, stackers and other equipment to complete your biomass pellet machine line needs. Trust our full line of solutions known for their legendary performance, versatility, and the user-friendly features that drive customer loyalty.

1.Raw material processing

The production of biomass pellets requires the use of wastes such as straw and wood chips as raw materials. Raw materials need to be preliminarily processed before production, such as removing impurities, foreign matter, etc.

Different raw materials are processed in different ways: for example, 2-meter-long wet straw needs to be cut, dried, and crushed; tree trunks need to be peeled, split, sliced, and crushed; bales of hay need to be broken and crushed.

2.Crushing and drying

The processed raw materials need to be crushed to facilitate subsequent granulation operations. The crushed raw materials also need to be dried to remove humidity and increase the hardness and density of the biomass pellets. Drying can be done by natural air drying or machine drying.

3.Granulation

Granulation is one of the most critical links in the entire biomass wood pellet production process. Currently, biomass pellets are produced using ring die pelletizing methods.

4.Cooling and screening

After the granulation is completed, the pellets need to be cooled down to avoid deformation or cracking caused by excessive humidity or temperature. The cooled biomass pellets need to be screened to remove some fine particles to ensure the uniformity and quality of the pellets.

5.Packaging

The final step in biomass pellet production is packaging. Pellets are usually packed into plastic or paper bags to protect them from moisture and dust.

Our team employs state-of-the-art tools and methodologies to map out your pellet machine line production flow and design a layout that maximizes productivity and minimizes waste. We specialize in optimizing every aspect of your biomass pellet manufacturing process, from raw material handling to workflow efficiency.

The goal is to better manage your resources—biomass materials, people, and processes—to streamline operations and significantly cut down on waste.

Equipment of 7-12T/H pellet machine line

Choosing the right pellet machine line equipment is crucial for pellet processing. When choosing, you need to make a comprehensive purchase based on various factors such as pellet type, production efficiency, and performance parameters.

At the same time, only by choosing an equipment brand with good quality and considerate service can we truly realize the value that pellet machine line equipment should have.

biomass Hammer Mill

Capacity:

3-25T/H

Main Power:

30-160 KW

wood Debarker

Capacity:

5-15 T/H

Main Power:

7.5-11 KW

Wood splitter

Capacity:

3-12T/H

Main Power:

10-20 KW

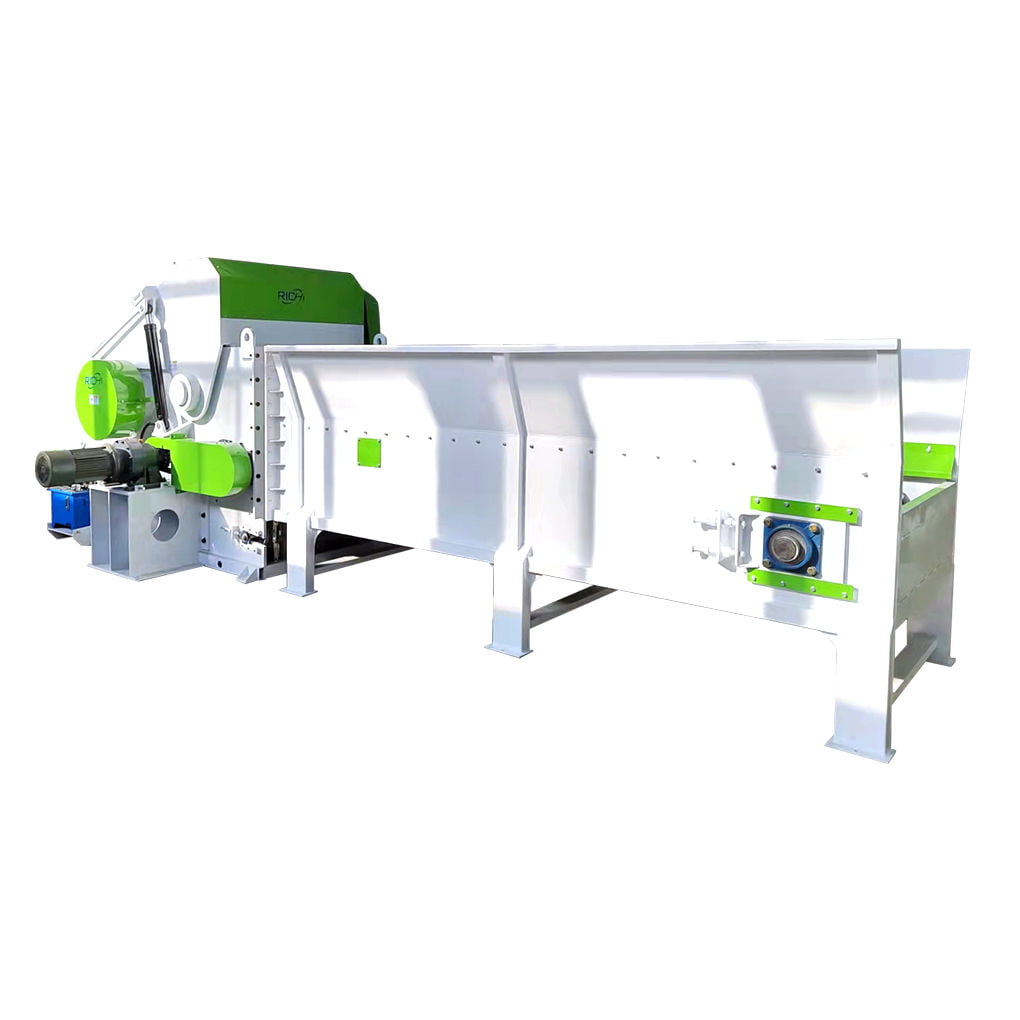

Bale breaker

Capacity:

1-20T/h

Main Power:

30-90KW

Straw Grass Crusher Machine

Capacity:

0.3-3T/H

Main Power:

22-93KW

Mixing Machine

Capacity:

250-2000KG

Main Power:

4-55KW

biomass Dryer

Capacity:

Customized

Rotate Speed:

3-8 R/Min

Our primary goal is to make your manufacturing process safer and more efficient, ensuring that your pellet machine line stay ahead of the competition.

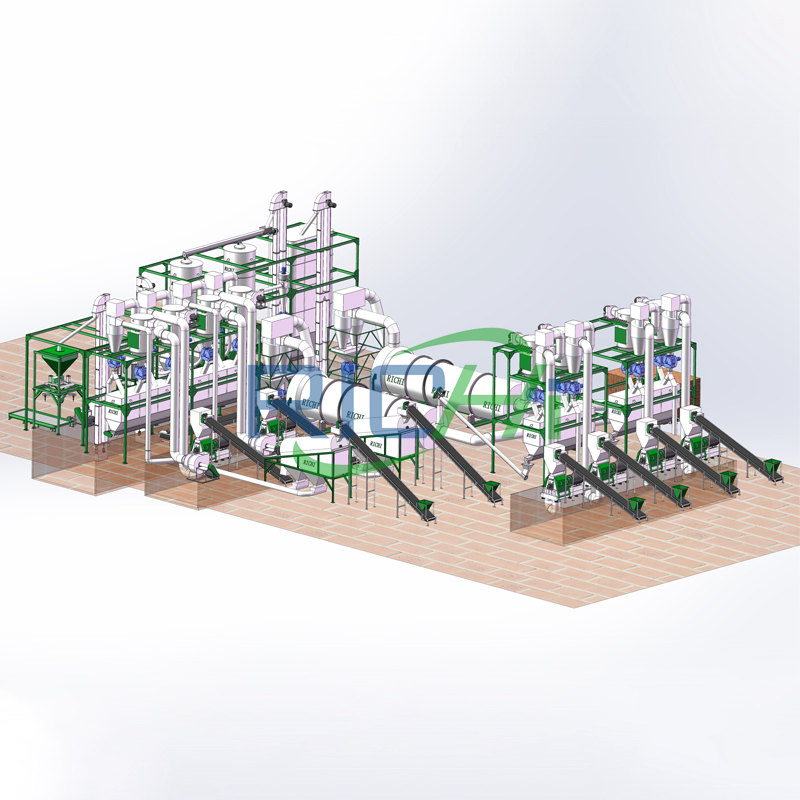

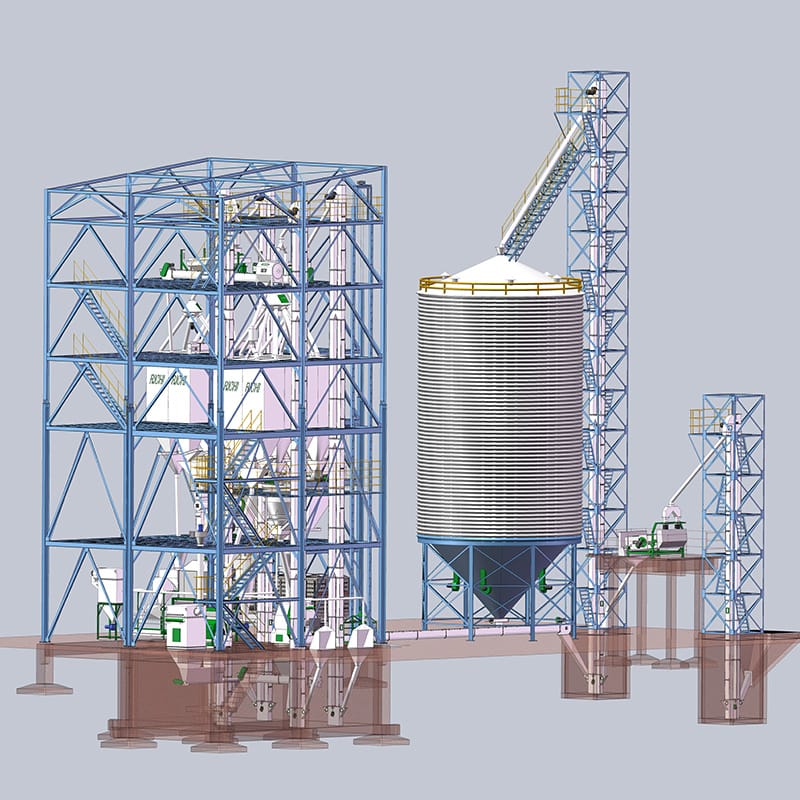

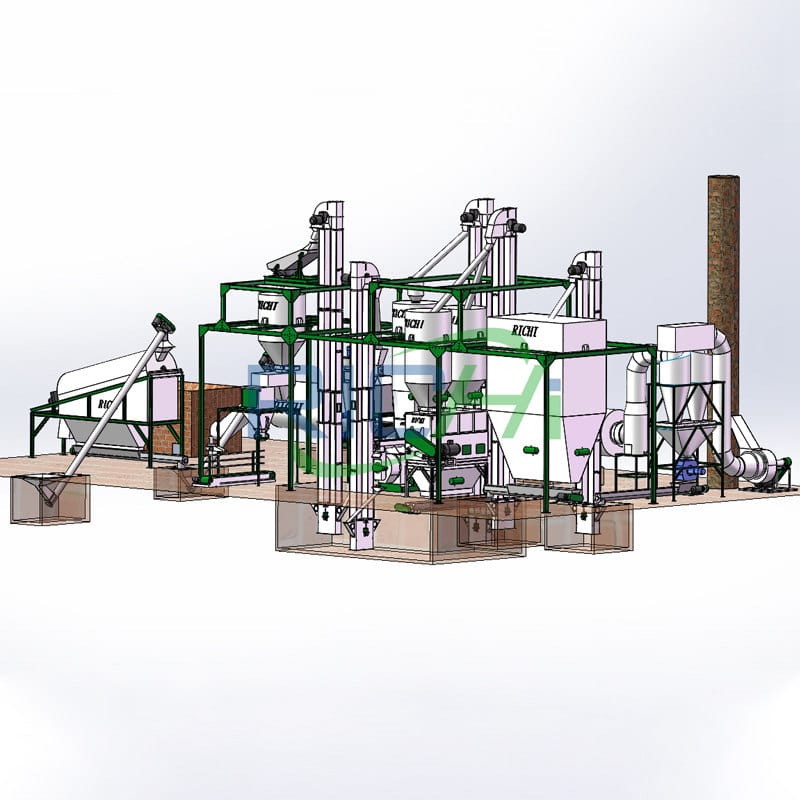

Featured 7-12 T/H pellet machine line solutions

Below, RICHI Machinery will list for you some of the pellet machine line solutions we have done. From these projects, you can see different processes, different raw materials, different equipment configurations, different construction costs, etc.

6.5-7T/H pellet machine line for sawdust straw bamboo

—— RICHI MACHINERY ——

- Annual output: 16,000 tons per year

- Pellet mill line investment: 350,000 USD

- Covered area: 1480m2

- Main construction contents: production workshop, office building, raw material warehouse, finished product warehouse

- Working system: The labor quota is 8 people, one shift is implemented, 8 hours/shift, and the number of production days is 300 days.

- Raw material consumption: sawdust*5000, straw*7000, bamboo powder*3500, chaff*850

- Energy consumption: electricity*300,000kW·h, water*270t/a. There is a power distribution room with an installed capacity of 100KVA.

- Main equipment: MZLH520 granulator, crusher, bucket elevator, fan, belt conveyor, screw conveyor, hot air furnace, screening machine, etc.

pellet machine line process design:

- First, the raw materials (sawdust, bamboo powder and rice husk) are transported to the screening machine through the conveyor belt for screening. The unqualified large pieces and the chopped straw are crushed and returned to the crusher for re-screening (that is, the large pieces account for 10 %);

- The qualified raw materials are transported to the drying furnace (the drying volume accounts for 20% of the total raw materials), and the air drying kiln (biomass fuel is used as fuel) is used to provide heat source for indirect heating to achieve the purpose of dehydrating the raw materials;

- The dehydrated raw materials are relatively dry, and then transported to the biomass pellet machine through the belt conveyor through the silo for compression and molding; due to the high temperature of the newly formed rods, the biomass pellets need to be cooled by a fan before being sent to the finished product storehouse.

8T/H pellet machine line for straw wood board

—— RICHI MACHINERY ——

- Annual output: 20,000 tons per year

- Biomass wood pellet production line price: 560,000 USD

- Area: 2052.3 square meters

- Main construction contents: production workshop, finished product warehouse, office building, etc.

- Biomass pellet specifications: diameter 8-10mm, length 20-50mm, high calorific value 3450-4200kcal/kg, moisture content 12~18%, density >1.12kg/m3, ash content <1.5%. Mainly bagged and 10kg packaged.

- Raw material requirements: moisture content ≤ 20, no gravel, iron filings, sediment, plastic and other impurities, sulfur content of waste gas sheets ≤ 0.08.

- Work system: 11 people, annual working 300 days, 1 shift, each shift lasts 8 hours.

- Raw material consumption: straw*6000, chaff*6000, waste boards (mainly wooden boards)*8000

- Energy consumption: water*148.5m3, electricity*40kwh

- Main equipment: granulator, crusher, slicer, bag dust collector, belt conveyor

pellet machine line Process flow:

- Feeding: Purchase dry straw, chaff, etc. as required. Raw material requirements: low moisture content, no gravel, iron filings, sediment, plastic and other impurities.

- Crushing and crushing: The loader loads the material to the sealed conveyor line, and transports it to the crusher via a belt for crushing to obtain crushed materials with larger particle sizes. An iron removal device is installed at the outlet of the crushed materials to remove iron from the crushed materials (waste plates). Iron and other impurities are removed, and the crushed material is fed from the loader to the belt and transported to the pulverizer for crushing to obtain crushed material with a particle size of <10mm. The crushed material is sent to a closed bin for storage via a closed conveyor belt.

- Granulation and molding: The pelletizer is the key equipment of the biomass pellet fuel production line. After the crushed raw materials pass through the pelletizer in a closed environment, finished biomass fuel pellets with a diameter of 8mm and a length of 20-40mm are formed.

- Packaging: The pressed and formed products are packaged and transported to the finished product warehouse.

7-8T/H pellet machine line for straw wood

—— RICHI MACHINERY ——

- Annual output: 20,000 tons per year

- Biomass wood pellet production line cost: 430,000 USD

- Covered area: 2500m2

- Main construction content: production workshop (including raw material area, production area, transfer material room, finished product silo), office

- Product specifications: Length: 30-60mm; Pellet size: 8mm; Density: 0.9-1.1g/cm3; Moisture content: below 8%

- Work system: Labor capacity: 5 people, 300 days of work per year, 8 hours per day

- Raw material consumption: straw 2252t/a, forestry residues 1300t/a, furniture factory scraps 200t/a, sawdust 1250t/a,

- Energy consumption: electricity*1.6 million kWh/a, water*60t/a

- Main equipment: waste wood chipper, waste wood crusher, granulator, large angle conveyor, loader, packaging machine, etc.

pellet machine line Process flow:

- Chipping: After the raw materials enter the site, they are stored in the raw material warehouse. Use a loader to transport waste wood, veneer, twigs, and scraps from furniture factories to the conveyor belt, and send them to the chipper through a closed belt to be broken into small pieces of wood. After crushing The wooden blocks enter the closed material transfer room with the conveyor belt.

- Crushing: Use a loader to move the crushed wood blocks, straw, and wood chips to the conveyor belt and send them to the crusher for crushing. The crushed materials enter the closed material transfer room from the conveyor belt.

- Granulation: Use a loading truck to add the materials to the auger screw conveyor, send them to the granulator through the conveyor, and press and shape them in the granulator. During the extrusion process, friction between machinery and biomass raw materials generates heat, which softens the lignin contained in the raw materials and acts as a binder.

- Cooling: The formed materials are transported to the finished product warehouse through a conveyor belt for natural cooling. The cooled finished products are packaged according to customer needs. Unqualified products can be used as raw materials for production.

8T/H pellet machine line for wood bamboo

—— RICHI MACHINERY ——

- Annual output: 20,000 tons/year

- Turnkey pellet plant cost: 490,000 USD

- Land area: building area is 1480m2

- Main construction content: factory building (including production area 1000m2, raw material area 1200m2, finished product area 500m2), office area

- Work system: The labor quota for this biomass pellet machine line project is 8 people, one shift (8 hours) per day, and 300 working days per year.

- Raw material consumption: chaff 4080.33t/a, wood chips 8160t/a, bamboo chips 8160t/a

- Energy consumption: Annual electricity consumption is about 100,000 KWh

- Main equipment: granulator, trommel screen, crusher, forklift, air compressor, conveyor belt

Biomass pellet machine line process:

- Sieving and crushing: Fine materials are selected through a sieve, and raw materials with irregular shapes that cannot be screened are crushed and screened again until they meet production requirements.

- Granulation and molding: The screened raw materials pass through a granulator and are pressurized into biomass granules. Qualified products enter the next process; unqualified products are returned to the production process and used as raw materials;

- Cooling and packaging: During the process of pressurizing the biomass into shape, the biomass will heat up slightly due to physical effects. The pellets coming out of the pellet machine are transferred to the finished product warehouse for cooling. The qualified pellets are measured and packaged to obtain the finished product, which is temporarily stored in the finished product warehouse in the factory. Ready for sale.

12-14T/H pellet machine line for rice husk sawdust

—— RICHI MACHINERY ——

- Annual output: 100,000 tons per year

- Pellet mill plant price: 870,000 USD

- Land area: total floor area 3700m2

- Main construction contents: raw material warehouse, crushing workshop, biomass pellet processing workshop, packaging workshop, finished product warehouse, equipment auxiliary workshop, machine repair workshop, office building, fire pool, etc.

- Work system: Production capacity is 30 people, production is implemented in three shifts, each shift works 8 hours, and the annual production days of the project are 300 days

- Raw material consumption: sawdust*12990t/a, rice husk*25980t/a, sawn wood scraps*16252t/a

- Energy consumption: annual power consumption is about 1.5 million kwh, and the power supply voltage is high voltage 10KV

- Main equipment: crusher, crusher conveyor belt (U-shaped width 0.8m, length 8m), semi-finished product silo (4×4×3.6), crusher, conveyor belt (U-shaped width 0.6m, length 8m), drying Machine, screw conveyor (length 7.5m), granulator, granulator conveyor belt (U-shaped width 0.6m, length 6m), cooler, dust removal system, finished product warehouse (4×4×3.6), packaging conveyor belt (U-shaped width 0.6m, length 6m), automatic distributor, forklift, etc.

pellet machine line Process flow:

- Raw materials arrive at the factory: The sawdust and scraps are purchased from local wood processing plants and bamboo processing plants, and are transported to the factory in bags by transport vehicles. The transport vehicles are covered with tarpaulin and unloaded into the raw material warehouse.

- Chipping: The purchased waste wood is broken into small wood chips that are easy to transport through the crusher, and then transported to the crusher through the conveyor belt for further crushing.

- Crushing: Crush small wood chips, bamboo chips, branches, crop straw and other waste into particles below 5mm.

- Drying: For waste wood scraps with high moisture content, the crushed particles need to be dried. This project uses a drum dryer to dry them so that their moisture content meets the requirements. In this project, the outlet of the screen machine and the dryer are connected to the hopper through a belt conveyor. The screened raw materials are introduced into the dryer by an induced draft fan.

- Pelleting: The raw materials pass through the feeding auger and enter the feed port of the agri pellet machinery. Electric heating is used to control the temperature inside the granulator at 110~120°C, and granules are made through extrusion. The extrusion process is a physical process, without adding any adhesive and without chemical reactions.

- Conveying and screening: After granulation of biomass pellets, smaller biomass pellets that do not meet specifications are collected into cloth bags under the screen, and qualified products are transported to the finished product warehouse.

- Packaging and storage: The cooled biomass pellets in the finished product warehouse are packaged and put into storage.

12 t/h pellet machine line for straw sawdust

—— RICHI MACHINERY ——

- Annual output: 30,000 tons per year

- Production line price: 540,000 USD

- Covered area: 2000m2

- Main construction contents: raw material warehouse, processing area, finished product warehouse, office, weighing room, power distribution room, storage room

- Work system: 5 people, about 300 days of work per year, 8-hour work system

- Raw material consumption: 20,000t of chaff, 10,000t of sawdust & straw

- Main equipment: granulator, crusher, conveyor belt, silo, transformer, floor scale, forklift, bag dust removal device

pellet machine line Process flow:

- Raw materials: The raw materials for the project will be transported to the raw material storage yard by truck for later use. The raw materials purchased for this project are all dry rice husks, sawdust, straw, etc. This project will no longer carry out the drying process on the raw materials.

- Crushing: The collected wood chips/straw raw materials are sent to the crusher for crushing, and are broken into material particle sizes that meet the requirements of the granulator. The crushed wood chips/straw raw materials directly enter the granulator for granulation. The chaff raw materials in this pellet machine line project do not need to be crushed and can be directly fed into the granulator for granulation.

- Granulation: The chaff and crushed wood chips/straw are transported to the pelletizer through a belt, and the pelletizer presses the raw materials into pellet shapes under high pressure.

- Natural cooling: The pressed biomass pellets generally have a temperature of 40-50°C and need to be cooled during packaging. After being collected in the silo, they are naturally cooled and transported to the finished product yard for packaging. Unqualified products can be reused as raw materials, reprocessed, and recycled. The formed biomass fuel is small in size, has a large specific gravity, is resistant to combustion, and is easy to store and transport.

RICHI understands that a well-designed pellet machine line is the backbone of efficient manufacturing operations. With our expertise, we go beyond the conventional to address not only the immediate challenges but also to lay the groundwork for the long-term success of your business.

7-12T/H pellet machine line cost

Investing in a biomass pellet making plant is an attractive business decision. However, before investing, it is crucial to conduct a thorough analysis of the investment costs of the production line. The cost of a biomass pellet machine line is generally between 100,000 – 1,100,000 USD.

Some people may be curious: “Why is there such a big difference in amounts?” Because the biomass pellet lines we design for our customers are all customized according to their actual needs.

- Some customers have a very sufficient investment budget and use a wide variety of raw materials. They also want a very complete process and require a fully automatic control system. This requires customizing a fully automatic production line that includes complex pre-treatment processes. Correspondingly, The price of this kind of production line is also very high;

- But for some customers who do not want to invest so much in the early stage and use a very single raw material, we will design a relatively simple production line system for the customer. This system generally uses broken With the new design, the conveyor and some supporting facilities are reduced, and the price of this production line will be relatively low… Every customer’s situation is different. Here, we only briefly list two situations for you.

If you want to build a biomass pellet manufacturing plant, tell us your raw material situation and your process requirements. We will ultimately deliver to you a very distinctive design that fully meets your needs.

The following are some considerations and analysis of pellet machine line investment costs:

01 Production equipment cost:

- Equipment configuration: biomass pellet making machines, crushers, dryers and other equipment are the core equipment of the production line, and their prices depend on the scale and brand. Investors need to carefully select the right equipment to meet production capacity needs.

- Equipment models and specifications: The prices of pellet line equipment of different models and specifications vary greatly, and investors need to make choices based on production needs and budget.

02 Factory building and land costs:

- Production plant: The area and structure of the pellet machine line will directly affect the investment cost. Proper design and site selection can reduce construction costs.

- Land costs: The location, size and use of land have a direct impact on investment costs. Areas on the outskirts of a city or in easily accessible areas may be more expensive.

03 Labor cost:

Line Operators: Biomass pellet machine lines require operators to monitor and maintain. Labor costs include wages, social security and training costs.

04 Energy and water resources costs:

- Electricity consumption: The operation of pellet machine lines depends on electricity, and electricity bills are an important operating cost.

- Water resources: Some production processes may require water, and investors need to consider the availability and cost of water resources.

05 Cost of environmental protection and safety facilities:

- Wastewater treatment, dust control equipment: Facilities that comply with environmental regulations may require additional investment.

- Safety equipment: To keep employees safe, you may need to invest in safety equipment and training.

06 Transportation and logistics costs:

- Raw material transportation: Consider the procurement and transportation costs of biomass raw materials.

- Distribution of pellets: the transportation cost of delivering finished pellets to the customer’s location.

07 Preparatory expenses and emergency funds:

- Project management and consulting fees: Set aside a certain fee to cover possible project management and consulting fees.

- Emergency funds: Set aside a certain amount of emergency funds to deal with emergencies or market fluctuations.

Investment in pellet machine lines requires comprehensive consideration of the above factors and adjustments based on actual conditions. Delicate investment cost analysis helps investors formulate reasonable budgets and operating plans to ensure long-term stable operation and profitability of the biomass pellets production line.

Before investing, it is recommended to consult a professional pellet machine line manufacturer to ensure the feasibility and sustainability of the investment decision.

Profit from investing in 7-12T/H pellet machine line

The profit of investing in a biomass pellet machine line is related to multiple factors, including the scale of the production line, equipment configuration, raw material costs, market demand, sales price, etc. Therefore, a definite answer cannot simply be given.

Generally speaking, the market demand for biomass pellets as a renewable energy source continues to grow. With the increase in environmental awareness and the promotion of renewable energy policies, the market prospects for biomass pellets are broad.

If investors can choose appropriate sources of raw materials, control production costs, and successfully develop sales channels, then the profits of the biomass pellet machine line are likely to be considerable.

However, investing in a pellet machine line also has certain risks and challenges.

- First of all, the competition in the biomass pellet market requires investors to conduct sufficient research and analysis.

- Secondly, the fluctuation of raw material prices and supply stability are also important factors affecting profits.

- In addition, the operation and maintenance of production lines also require certain professional knowledge and skills.

Therefore, before investing in a biomass pellet plant, investors need to conduct comprehensive market research and risk assessment, and formulate reasonable investment plans and business strategies.

It is also necessary to pay attention to factors such as the policy environment, technological development trends, and market changes, so as to adjust business strategies in a timely manner and ensure the sustainable development of investment.

To sum up, the profits from investing in a pellet machine line vary depending on the specific situation, and investors need to consider multiple factors and conduct a comprehensive assessment.

pellet machine line video

Customize your pellet machine line

The RICHI team consists of experienced consultants and skilled engineers with mechanical, structural, and industrial engineering expertise. Design your production line into a paragon of efficiency and safety with RICHI Machinery.

Contact us today to discover how to customize your biomass pellet manufacturing process with our integrated pellet machine line systems and technologies. (Find us on Youtube)