poultry feed plant for sale

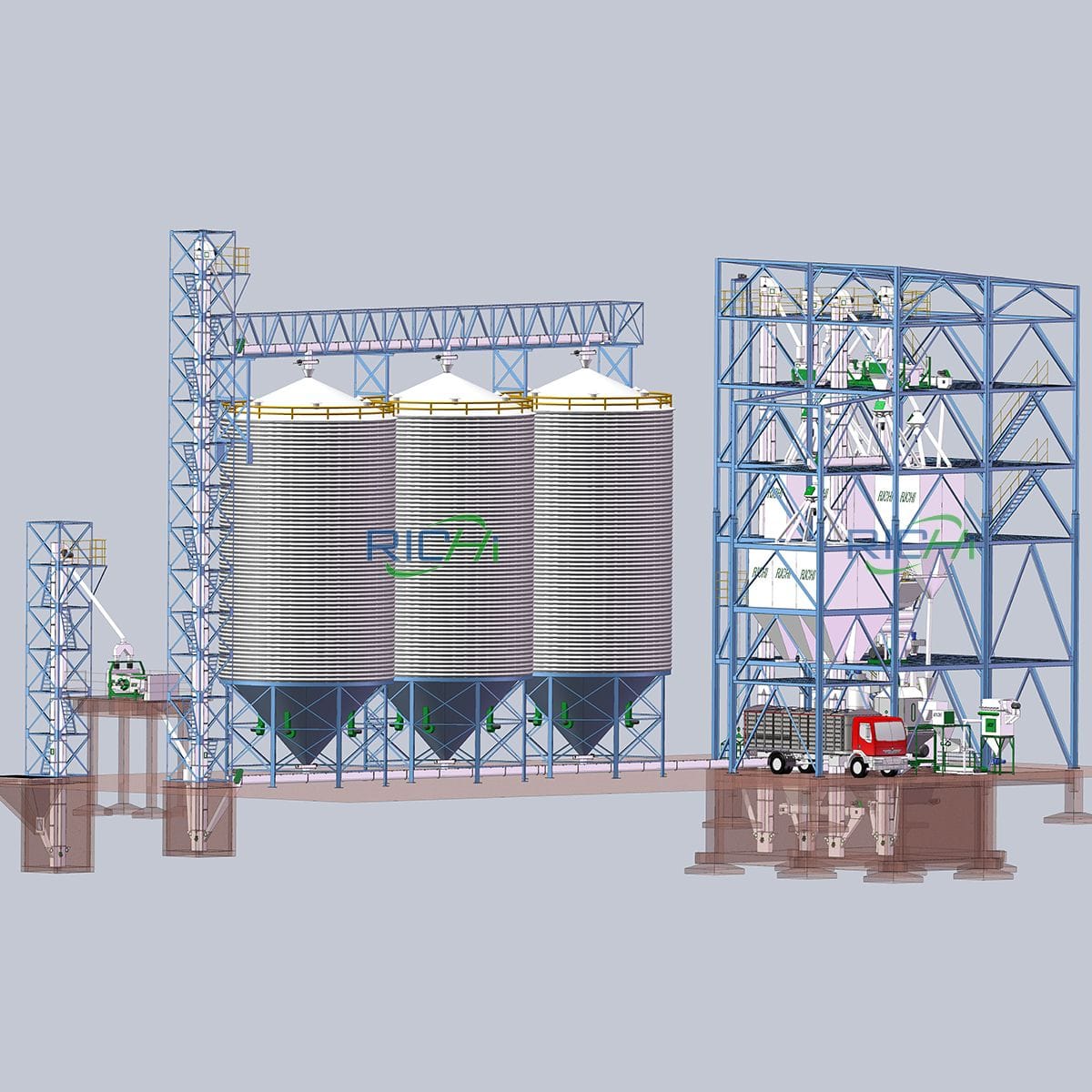

Poultry feed plant is a feed manufacturing system for chickens, ducks, geese, birds, turkeys, pigeons, etc, it includes a series of processes from silo storage, raw material crushing to feed product packaging.

Richi Machinery focus on poultry feed plant for sale, the poultry feed plant construction business we can supply:

- Capacity: 1-160T/H

- poultry feed plant Cost: 10,000-5,000,000 USD

- Application: used for one or more kinds of poultry feed production (also process multiple feeds at the same time, poultry & livestock, poultry & ruminant, poultry & aqua)

Poultry feed plants are designed on factors such as feed production, raw material technology, formula, budget, degree of automation and production goals. That’s why poultry feed plants designed to meet your unique needs.

As a manufacturer deeply involved in poultry feed plant for sale, we understand the importance of meeting poultry feed process and product needs.

Note:

- We are poultry feed plant manufacturer, not a middleman.

- We provide a full set of transportation, installation, commissioning, training, and after-sales tracking services.

- Business scope: new poultry feed plant construction, expansion of poultry feed plant, transformation of poultry feed plant

The poultry feed plant equipment is all manufactured by Richi Machinery, but it doesn’t stop there: as provider focus on poultry feed plant for sale, Richi Machinery’s team excels as the General Contractor, Engineer, Steel Fabricator, Equipment Manufacturing & Construction Millwright.

Types of Poultry Feed Plant for sale

Poultry chicken feed plant solutions and equipment configurations can be cunstomized according to different customer needs, we provide.

01

According to the type of animal feed:

- Feed plant that only produce poultry feed:

Chicken feed plant, duck feed plant, goose feed plant, quail feed plant, bird feed plant, turkey feed plant, pigeon feed plant, etc. - Compound feed plant for the production of various feeds:

Cattle and poultry feed plant, fish and poultry feed plant, ruminant and poultry feed plant, shrimp and poultry feed plant, etc. - According to the processing technology of poultry feed pellets:

Poultry feed pelleting plant, poultry extruded feed plant.

02

According to the status and type of the product:

- poultry pellet feed plant

- poultry mash feed plant

- poultry premix plant

- Poultry concentrated feed plant

- …

03

According to the degree of automation:

- fully automatic poultry feed plant for sale

- semi-automatic poultry feed plant for sale

- manual poultry feed plant for sale

- PLC poultry feed plant for sale

- …

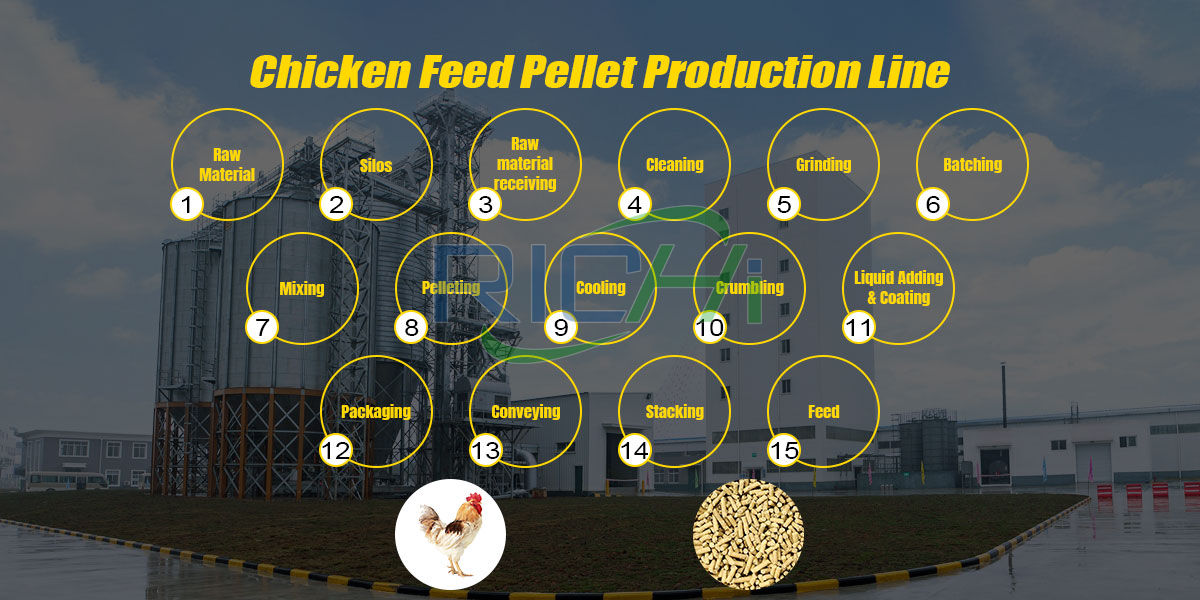

complete Poultry chicken feed plant process

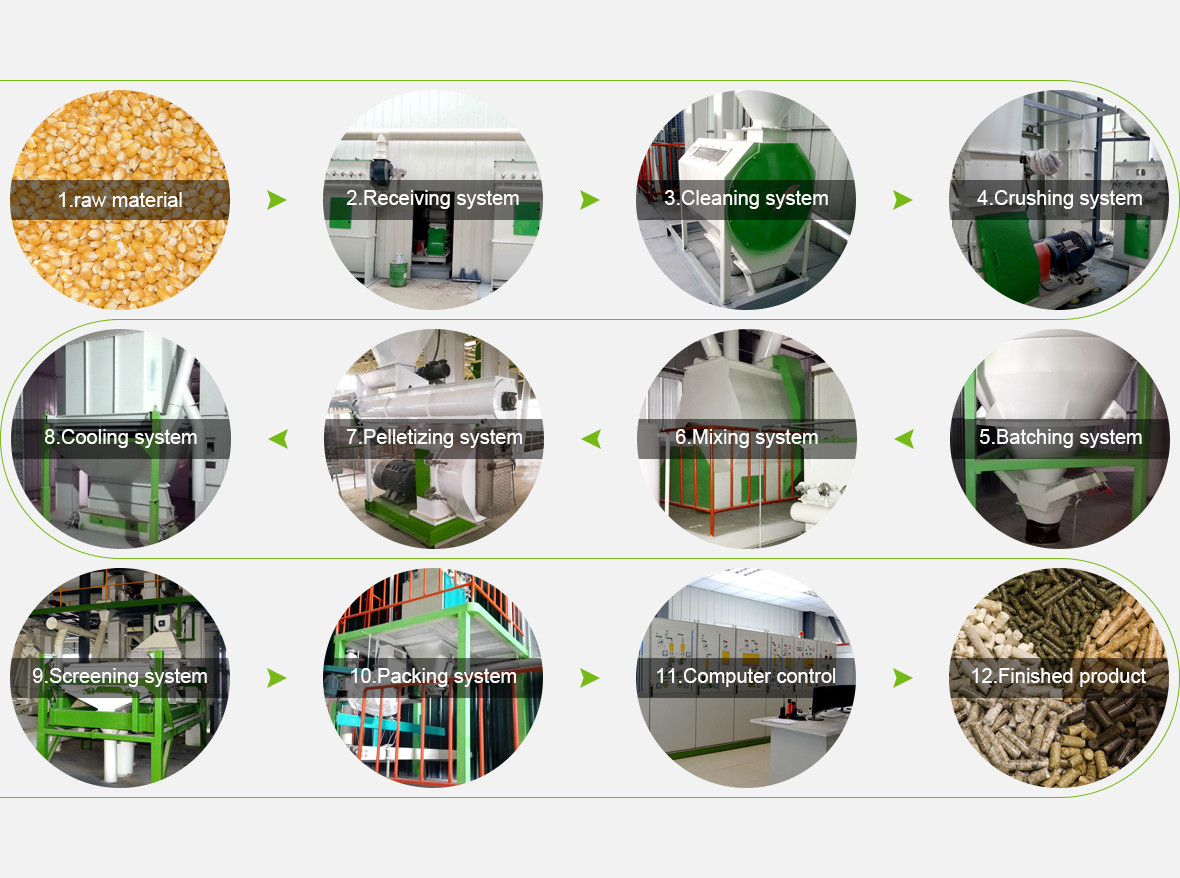

Complete Poultry Feed Plant Process Includes Grinding, Batching, Mixing And Pellet Creation, Depending On Your Needs.

The Poultry Feed Plants Technologies Are Innovative, Turn-Key Solutions That Improve Milling Efficiency, Reduce Operational Costs, And Improve The Overall Safety Of Your Operations. RICHI Has A Long History Of Designing, Engineering, And Building Custom Poultry Feed Plants For Our Clients In The Agricultural Industry.

Below, several standard Poultry feed plant processing techniques are listed.

- Poultry pellet feed plant process:

Receiving——Cleaning——Crushing——Batching——Mixing——Pelletizing——Cooling——Crumbling——Sieving——Packaging - Poultry mash feed plant process:

Receiving——Cleaning——Crushing——Batching——Mixing——Packaging - Poultry premix feed plant process:

Raw Material Pre-treatment——Batching process——Mixing process——Packing and storage

The powder line can be used in the same production line as the poultry feed pellet line, but it is packed before the pelleting section. The process of the premix production line seems to be the same as the powder processing process, but almost uses different raw materials and equipment (stainless steel).

Customized Poultry Feed Plant For Sale

All the poultry feed plant are customized,with different capacity and different finished product types. 1000 customers means 1000+, 2000+, 5000+ poultry feed plant designs. Different needs correspond to different poultry feed plant process designs.

The needs of customers are different, the process design of RICHI’s poutlry feed production plant is also changing, and the poultry feed equipment configuration will also be different.

The followings are some featured poultry chicken feed plant solution we have done.

10 T/H poultry feed plant for sale

poultry feed plant composition:

- Materials receiving& pre-cleaning system

- Crushing system

- Batching& mixing system

- Pelletizing& cooling& screening system

- Packing& dust collecting system

- Bulk bin system

- Oil adding system

- MCC Control Center ;Mimic Control Panel

- Batching System (Computer controlled)

- Cables & Cable Bridge Tube

- 10 t/h Poultry Feed Plant Cost:300,000-350,000 USD

- Feed from the 10 t/h poultry feed plant:

| Small baby chicks | 1.0-1.5mm | 5-6T/H | Chicks in 0-10 days |

| Middle chicken | 2.5-3.0mm | 8-10T/H | Chicken in 10-30 days |

| Big chickens | 3.5-4.0mm | 10-12T/H | Chicken in 30-45 days |

| Layer feeds | Powder feeds | 12-15T/H | Also can feed chicks |

3-4 T/H poultry feed plant for sale

poultry feed plant composition:

- Raw materials receiving and cleaning section

- Crushing section

- Mixing section

- Pelletizing& Cooling Section

- Packing section and centralized dedusting section

- MCC Control Center ;Mimic Control Panel

- Cables & Cable Bridge Tube

- 3-4 t/h Poultry Feed Plant Cost:100,000-120,000USD

- Feed from the 3-4 t/h poultry feed plant:

| Small baby chicks | 1.0-1.5mm | 1-1.5T/H | Chicks in 1-10 days |

| Middle chicken | 2.5-3.0mm | 2-3T/H | Chicken in 10-30 days |

| Big chickens | 3.5-4.0mm | 3-4T/H | Chicken in 30-45 days |

| Layer feeds | Powder feeds | 4-5T/H | Also can feed chicks |

30 T/H chicken feed plant for sale

poultry feed plant composition:

- Materials receiving& pre-cleaning system

- Crushing system

- Batching& mixing system

- Pelletizing& cooling& screening system

- Packing& dust collecting system

- Auxiliary system

- MCC Control Center ;Mimic Control Panel

- CPP Computer System

- Batching System (Computer controlled)

- Cables & Cable Bridge Tube

- chicken feed plant cost: 700,000-800,000USD

- Feed from the 30 t/h poultry feed plant:

| Small baby chicks | 1.0-1.5mm | 15-16T/H | Chicks in 0-10 days |

| Middle chicken | 2.5-3.0mm | 28-30T/H | Chicken in 10-30 days |

| Big chickens | 3.5-4.0mm | 30-32T/H | Chicken in 30-45 days |

| Layer feeds | Powder feeds | 30-35T/H | Also can feed chicks |

20 T/H poultry feed plant for sale

poultry feed plant composition:

- Materials receiving& pre-cleaning system

- Crushing system

- Batching& mixing system

- Pelletizing& cooling& screening system

- Packing& dust collecting system

- Auxiliary system

- MCC Control Center ;Mimic Control Panel

- CPP Computer System

- Batching System (Computer controlled)

- Cables & Cable Bridge Tube

- 20 t/h poultry feed plant Cost:580000-600000USD

- Feed from the 20 t/h poultry feed plant:

| Small baby chicks | 1.0-1.5mm | 10-12T/H | Chicks in 0-10 days |

| Middle chicken | 2.5-3.0mm | 16-20T/H | Chicken in 10-30 days |

| Big chickens | 3.5-4.0mm | 18-22T/H | Chicken in 30-45 days |

| Layer feeds | Powder feeds | 22-24T/H | Also can feed chicks |

60 T/H poultry feed plant for sale

poultry feed plant composition:

- Materials receiving& pre-cleaning system

- Crushing system

- Batching& mixing system

- Pelletizing& cooling& screening system

- Packing& dust collecting system

- Auxiliary system

- MCC Control Center ;Mimic Control Panel

- CPP Computer System

- Batching System (Computer controlled)

- Cables & Cable Bridge Tube

- 60 t/h poultry feed plant price:1400000-1500000USD

- Feed from the 60 t/h poultry feed plant:

| Small baby chicks | 1.0-1.5mm | 40-42T/H | Chicks in 1-10 days |

| Middle chicken | 2.5-3.0mm | 56-60T/H | Chicken in 10-30 days |

| Big chickens | 3.5-4.0mm | 60-64T/H | Chicken in 30-45 days |

| Layer feeds | Powder feeds | 60-70T/H | Also can feed chicks |

As one of the well-known poultry feed plant manufacturers in China, we’d love to hear about your project, answer a quick question, or run the numbers and submit a proposal on your poultry feed plant machinery installation. Get started by calling us or completing our contact form, and we’ll be in touch with some next steps.(Maybe you are interested in our post: 1-20t/h poultry feed manufacturing plant cost)

Complete poultry feed plant for sale the world

5 t/h fish feed & 10 t/h poultry feed plant for sale Russia

- Feed Size:1-5mm pellets

- Construction Time: 6 months

Poultry Feed Plant cost: 1,350,600USD

- date: 2022.09.27

7-8T/H sunflower seed meal poultry feed plant in Russia

- Feed Size: 2-4mm pellets

- Construction Time: 2 months

- Poultry Feed Plant cost: 150,300USD

- date: 2022.10.27

5-6 t/h poultry chicken feed plant for sale Kazakhstan

- Feed Size: 2-4mm pellets

- Construction Time: 2 months

- Poultry Feed Plant cost: 92,600 USD

- Date: 2022.12. 06

5-6T/H poultry feed plant for sale Ethiopia

- Feed Size: powder feed

- Construction Time: 3 weeks

- Poultry Feed Plant cost: 84,900USD

- Date: 2019.11.06

6-10T/H poultry feed plant for sale Algeria

- Feed Size: 2-6mm pellets

- Construction Time: 8 months

- Poultry Feed Plant cost:80,000-400,000 USD

- Date: Sep 31th, 2015

10-15T/H chicken poultry feed mill plant in Uzbekistan

- Feed Size: 2-5mm pellets

- Construction Time: 1 year

- Poultry Feed Plant cost: 150,000-400,000 USD

- Date: July 1th, 2019

5T/H poultry feed plant for sale Peru

- Feed Size: 3-6mm pellets

- Construction Time: 5 months

- Poultry Feed Plant cost: 220,000-250,000 USD

- Date: February 2021

3-5T/H poultry feed plant for sale Malaysia

- Feed Size: 2-4mm pellets

- Construction Time: 4 Months

- Poultry Feed Plant cost: 60,000-65,000 USD

- Date: October 29, 2021

5 T/H poultry premix feed plant for sale El Salvador

- Feed Size: powder

- Construction Time: 6 months

- poultry feed plant cost: 480,000 USD

- date: 2022. 09.13

10 t/h poultry premix plant for sale Thailand

- Feed Size: powder

- Construction Time: 8 months

- Poultry Feed Plant cost: 120,000 USD

- date: 2021. 07. 22

30-40T/H chicken feed plant for sale China

- Feed Size: 2-6mm pellets & powder

- Construction Time: 14 months

- Poultry Feed Plant cost: 960,000USD

- Date: June 2019

35-40T/H chicken duck goose poultry feed plant for sale China

- Feed Size: powder & 1.5-8mm pellets

- Construction Time: 9 months

cost: 1,250,000 USD

- Date: December 2018

1-2T/H livestock and poultry feed plant for sale Nigeria

- Feed Size:2-4mm pellets

- Construction Time: 30 days

Poultry Feed Plant cost: 25,000-29,000 USD

- Date: June 30, 2020

16T/H stock poultry feed plant for sale Afghanistan

- Feed Size: 2-8mm pellets

- Construction Time: 11 months

Poultry Feed Plant cost: 500,000 USD

- Date: December 2020

5-7 t/h cattle and poultry feed plant for sale Russia

- Feed Size: 2-10mm pellets

- Construction Time: 2 months

- Poultry Feed Plant cost: 97160 USD

- date: 2022.06.09

10T/H Livestock cattle chicken feed plant for sale Uzbekistan

- Feed Size: 2-8mm pellets

- Construction Time: 7 months

- Poultry Feed Plant cost: 460,000 USD

- Project date: 2018.09.13

5 t/h cow goat poultry feed plant for sale Argentina

- Feed Size: 2-10mm pellets

- Construction Time: 6 months

- Poultry Feed Plant cost: 184500USD

- Project date: 2021.10.11

5-10 t/h aqua and poultry feed plant for sale New Zealand

- Feed Size: 1.5-6mm pellets

- Construction Time: 4 months

- Poultry Feed Plant cost: 131820 USD

- Project date: 2022.10.14

15 t/h chicken feed plant for sale in Uganda

- Feed Size: 2-3mm pellets

- Construction Time: 9 months

Poultry Feed Plant cost: 159070 USD

- Project date: 2022.06.30

20T/H Ruminant & poultry feed plant for sale USA

- Feed Size: 2-10mm pellets

- Construction Time: 10 months

- Poultry Feed Plant cost: 550000USD

- Project date: 2019.05.10

As Richi Machinery’s most experienced designer and builder of the modern-day poultry feed plant machine, RICHI is staffed by experts who have worked for decades in the Feed Machinery Industry.

Over the past ten years, RICHI has commissioned more than 200 complete design-build poultry feed plants, and RICHI has fully engineered, multi-standard (such as OSHA and NFPA) compliant poultry chicken feed plant designs ready for operation. (Maybe you are interested in our post: 1-40t/h animal feed manufacturing plant cost)

Poultry feed plant machinery for sale

poultry Feed Extruder

Capacity:

1-12T/H

Main Power:

0.75-355KW

A 1-160t/h poultry feed factory requires at least dozens to hundreds of equipment and accessories.

Richi Machinery is mainly engaged in poultry feed plant for sale, we offer the whole set poultry feed plant machinery and accessories, includes silos, environmental protection facilities, and laboratory instruments.

If you want to learn more about our poultry feed equipment, feel free to contact Richi Machinery!

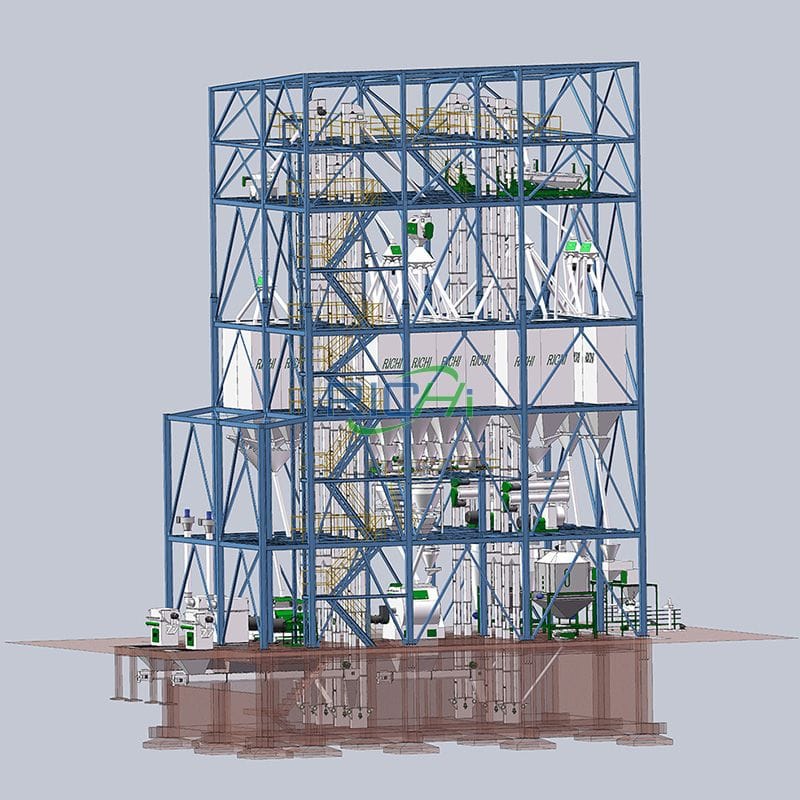

Poultry feed plant machinery selection

Poultry feed plant machinery selection is a very serious step, which will have a huge impact on the profitability of the feed mills.

The customer first needs to determine the production scale and product type based on market forecast and analysis, formulate the supporting processing technology (including supporting production line and liquid addition, etc.), and select the equipment and manufacturer suitable for the process needs.

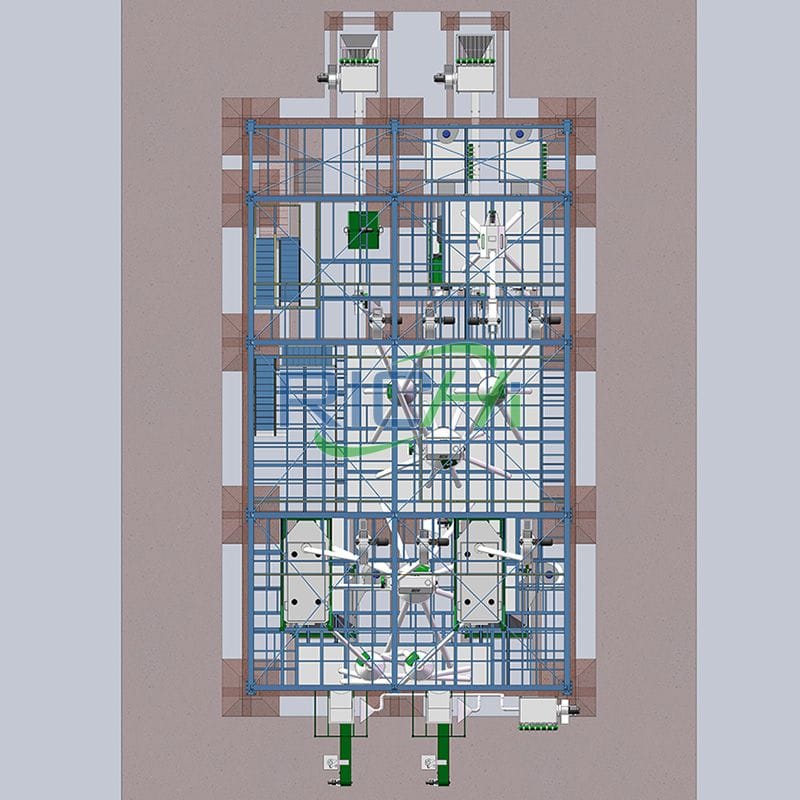

Then, according to the process and equipment, design the floor plan and elevation of the production workshop.

As a manufacturer rooted in poultry feed plant for sale, RICHI has always believed that we are responsible for the efficient operation of customer’s poultry feed plants. Therefore, we always choose the most suitable poultry feed plant machines and provide the most professional technical solutions.

Here are some of our suggestions for poultry feed plant equipment selection:

- When designing and selecting a process, it is necessary to verify the feasibility of the process and equipment based on the real production formula, fully consider the production efficiency, product quality and economic benefits, require less investment, flexible process, adapt to the continuous changes of raw materials and products, and give full play to maximum benefit;

- The process flow should be concise and smooth, which can not only ensure the basic production requirements, but also increase or decrease the process according to actual requirements;

- Try to adopt advanced technological processes and poultry feed mill equipment to ensure product quality and save energy consumption. So, find a professional poultry feed machine manufacturer who can tell you this, and specializes in poultry feed plant for sale.

- The poultry feed plant layout should be compact to reduce the occupied area, but it should not affect the operation and maintenance;

- The poultry feed equipment should adopt the same model as much as possible, with unified accessories and strong interchangeability;

- The Poultry Feed Plant Design Capacity Should Generally Be 15%~20% Larger Than The Actual Production Capacity;

- The follow-up production capacity should generally be 5%~10% larger than the production capacity of the previous equipment;

- The poultry feed plant construction of complete compound powdered feed and concentrated feed for laying hens should fully consider the anti-grading measures of finished feed. Different types of silos containing different materials will produce different discharge methods;

- The selection of the poultry feed grinder should be determined in combination with the technical requirements of the product and the matching requirements of the production capacity;

- A secondary negative pressure suction system should be used to improve the crushing efficiency and recover dusty materials for the pulverizer that finely powders the material. A good auxiliary suction system can increase the output of the pulverizer by more than 20%;

- The number of batching bins should be determined in combination with the formula of the product and the variety of incoming raw materials;

- The number and size of batching scales should be determined in conjunction with the number of bins, formula and batching speed;

- The gear transmission type poultry pellet mill has high production efficiency and is suitable for the production of livestock and poultry feed;

- Due to the difference in precision and speed, the price of packaging scales varies greatly, so it is advisable to choose a brand with better quality and service;

- The layout of steam pipelines must be standardized, and designers often ignore the layout of steam pipelines from the steam boiler to the poultry feed pellet machine, which is the key to ensuring the quality of steam;

- Molasses should be added by means of conditioner;

- The air compressor displacement design should adhere to the principle of “rather big than small”;

- The full-screen computer control system is easy to operate, and requires relatively high skills for maintenance personnel. The analog screen control system is easy to operate manually, and is more suitable for small and medium-sized poultry feed plants;

- Whether the position of the baling port is partially raised or not should be determined before the design according to the operation method after completion. The two methods of horizontal baling and elevated baling have their own advantages and disadvantages;

- The installation quality of different poultry feed plant equipment manufacturers varies greatly, so it is necessary to select equipment manufacturers and installation companies that meet their own construction positioning through investigation.

Whether the poultry feed plant process design is perfect and whether the feed equipment is selected correctly plays a very important role in reducing repeated investment, improving production efficiency and reducing production costs after operation.

Reach out to answer your questions, start talking about your next poultry feed plant project, or discuss the details for a proposal by calling us or completing our contact form.

poultry feed plant videos

Faqs of building poultry feed plant

How to conduct a feasibility study for the construction of a poultry feed plant?

The feasibility study of a poultry chicken feed plant mainly includes:

- Demonstration project construction market forecast analysis

- Construction scale and product scheme

- construction site selection,

- Construction equipment plans and civil works plans

- Raw materials for production and power fuel supply

- Evaluate production energy saving and environmental protection

- Health and Safety Assessment

- Organizational structure and resource allocation

- Project implementation progress

- investment estimate

- financing plan

- Financial Evaluation

- Social evaluation

- Investment Risk Analysis

- …

During the feasibility study, it is necessary to fully consider the construction content, conduct detailed analysis and research on every detail of the poultry feed factory project, and make a good estimate of the project construction funds according to the regulations of the local government department and in combination with market conditions, and do not intentionally compress or extend construction estimates.

How to determine the production process of poultry pellet feed plant?

Regarding this question, as a manufacturer deeply involved in poultry feed plant for sale, RICHI must give you the most professional answer:

The formulation of feed production process should take full account of production capacity (output), product type and investment conditions and other factors.

(1) Determine the process of batching first and then crushing or crushing first and then batching:

The batching first and then crushing process is suitable for small feed mills with a single product type. The process is simple and requires less equipment, which can save the civil construction investment of multiple batching bins.

However, the batching accuracy is low and the batching time is long. Without batching bins and feeders, it is difficult to achieve automatic and high-precision batching.

The process of crushing first and then batching is suitable for large-scale feed factories, and there are many types of products. The whole batching system is equipped with distributors, batching bins (multiple), feeding machines and electronic scales.

The degree of automation and batching accuracy are high. Although the one-time investment is large, considering the production efficiency and product quality, large-scale feed It is necessary for the poultry feed plant to choose this process.

(2) Determine primary crushing or secondary crushing process

Crushing process is an important process of feed processing, the proportion of materials that need to be crushed is generally 50% to 80%, and the power consumption of the crushing process accounts for 60% of the total power consumption of powder product processing %~70%.

- Generally speaking, one poultry feed pulverizer is used in one pulverization process, and it is required to be equipped with standard screens for classification. It has high energy consumption and low output, so it is suitable for small feed mills.

- Secondary crushing process is divided into: secondary open crushing process, the process flow is to use two feed grinders of different specifications, which can reduce energy consumption by 25% to 50%, and is suitable for large-scale poultry feed plants.

(3) Determine the technological process according to the product type

The type of feed product determines the basic production process in the production technological process, which should be selected reasonably. Generally include:

- The receiving process of raw materials, according to the different forms of raw materials, determine the different receiving processes such as transportation, metering, cleaning, drying, and storage;

- Powder finished product processing procedures, including crushing, batching and mixing procedures;

- Pellet material processing procedures, including granulation, grease spraying, cooling, screening, and puffing procedures;

- Finished product processing procedures, including conveying, metering, packaging, transportation and storage procedures.

(4) Formulate the technological process according to the investment conditions

The investment conditions determine the mechanization and electrification level of the feed processing plant, which is the prerequisite to ensure the reasonable matching and advanced nature of the technological process.

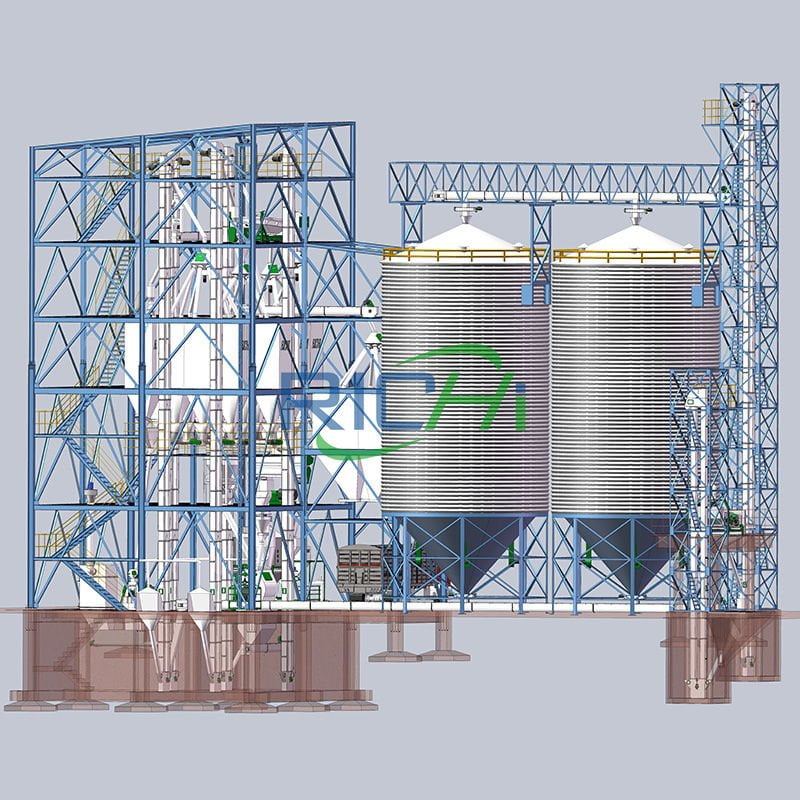

How to design poultry feed plant layout?

Poultry feed plant layout design plays an important part in the design and engineering phases of poultry feed plant. As a manufacturer deeply involved in poultry feed plant for sale, below, RICHI will give you some suggestions.

Ease of operation; avoiding disturbance in material flow i.e. raw material & finish goods, sufficient space for turning of vehicles, space for movement of fire fighting vehicle, parking, other utilities like:

- Weighbridge: near main gate & security –with straight approach access; unloading and waiting areas for truck ;

- Boiler: height & location of chimney as per government norms ,should be at a distance from living , office area and inflammable products, storage space for fuel as per density – wood , oil & husk,

- Machinery: Select the location of machinery in such a way; that there should be sufficient distance between the dust control equipment’s and nearby residential area. Select the location of blower duct outlet opposite to the nearby residential area.

- Store: Select the location of store and daily need equipment’s as per the process flow and ease of operation.

- Rodent proof construction: Rats and mice cause serious damage to all kinds of grains if they are allowed access to them. As rodents cannot crawl upside down; so a 2 feet extended platform above 3 feet plinth level helps to prevent rodents in poultry feed plant.

- Electric Transformer: should near the mail line & security.

What is the product or recipe that you’re looking to process?

You’ll need to consider the incoming product when creating your feed mill. Different products like flour, grain, and rice require different milling techniques.

For example, roller mills cannot process flour, while hammer mills can. If you’re combining different materials and products into the same poultry feed plant, you’ll need a mill that’s designed for universal applications.

What capacity is needed?

You also need to consider how much feed you’ll need to produce at any given time.

Some poultry feed plants come with strict throughput limits, so you may want to consider choosing a different model if you plan on producing large quantities of feed.

Some models are prone to excess heat, friction, and costly repairs when operating at high volumes, so make sure your new system can handle the intake to maximize your milling efficiency.

Are there any Space limitations or Electrical limitations for poultry feed plant?

You should also know the limitations of your facility before investing in a poultry animal feed production line, including the size of the space, how you plan on having your employees move throughout the facility, as well as any electrical limitations.

Your employees should be able to move throughout the space freely without running into equipment or potential hazards. You’ll also need to position your equipment for optimal efficiency, so your employees can complete their work in less time.

Is this a new product, something that no one has milled before?

If not, what type of testing is needed? If you’re creating a new product or working with a new recipe, you’ll need to test the product beforehand to make sure it’s safe for your poultry feed mill equipment.

Additional steps may be required before putting the material through the machine.

What safety issues should be paid attention to in the operation of poultry feed plant?

The health and safety of your employees should always be a top concern. Some poultry feed plants can generate excess heat and friction that may put your employees at risk. Some machines are prone to spontaneous combustion, so you may need to invest in explosion protection, as well.

Once you’ve done your research, you can start planning out the details of your new facility. Consider partnering with an experienced poultry feed plant design and construction firm, so you don’t have to make all these decisions on your own.

The professionals at RICHI Machinery can help you design and construct the perfect poultry chicken feed plant for your business.

our service

RICHI Machinery is a full-service construction company that provides its clients with a turn-key project solution for any challenge. Our extensive experience and depth of expertise allow us to anticipate your needs regardless of the poultry feed plant project.

We have the finest engineers, designers, construction personnel, and support staff to provide you with the most innovative solutions available, we are constantly providing training to add to our teams depth of understanding. Here, learn more about RICHI’s poultry feed plant design and construction services.

Project Planning and Budgeting

When we begin a new design-build construction project, our team will plan out and analyze every aspect of the proposed design to make sure it will elevate your current business model and address specific concerns in the production process. Every aspect of the planning phase is designed with your business in mind, so you can eliminate any potential bottlenecks or delays ahead of time.

Design and Engineering

Our team at RICHI manages every aspect of the build process, including the design, planning, engineering, and construction of your new system. With expertise across the agricultural, industrial and manufacturing industries, we can create a custom solution for your poultry feed plant. These systems are made with the latest technological trends and industry standards in mind, ensuring optimal efficiency at every turn.

Equipment Specification and Procurement

Our team provides a range of poultry feed plant equipment specification services to make sure every aspect of your workplace is performing at peak efficiency. We thoroughly test our equipment before incorporating it into your animal feed mill plant construction project, so you don’t have to worry about downtime and equipment failure when launching your new facility.

Steel Fabrication

Whether you’re looking to construct a new building or facility from scratch or remodel your existing facility, the professionals at RICHI Machinery are here to bring your vision to life. We specialize in all types of steel fabrication, including single parts and full-scale construction projects. Regardless of what you’re looking to achieve, you’ve come to the right place.

Maintenance and Support

If a piece of equipment or an existing poultry feed plant system needs repairs, our team will analyze the situation and propose a solution that works for your poultry feed production business. From troubleshooting to expansive remodeling, we will address the problem in terms you can understand, while minimizing any disruptions to your business.

Equipment Installation

Our team goes above and beyond the competition to make sure you have access to the best poultry feed plant equipment specifications for the job at hand. Once installed, we test and analyze key operations to maximize performance. We will be there for you as the equipment goes online to make sure everything is working properly with safety as our top priority.

Start Up and Commissioning

We remove any guess work when we complete a poultry feed plant project. Every site is ready and operational when we finish so that you can get to work immediately.

Construction

We specialize in construction management, maintenance, and engineering to create facilities in the agricultural, industrial, and manufacturing industries that are built to last.

Warranty Management

RICHI will not sell you warranties that do not provide you with long-term value. Our poultry feed plants are built to last and we stake our name and reputation on it.

Richi Machinery——Rooted in Poultry Feed plant for sale

Every day, billions of people cover their basic needs for food and mobility thanks to our process technologies and animal feed mill equipment. As a globally relevant industrial solution provider, we want to contribute to a better and more sustainable world with collaborative innovation, new technologies, training, and services.

Planning, engineering and manufacturing full solutions and systems across 3 platforms: Feed, Biomass, Fertilizer. Our products, poultry feed equipment, technology, and services help poultry feed plant the storage, blending, mixing, conveying, conditioning, processing, and protection of agricultural inputs and produce around the world.

If you’re ready to take the next step in designing and building your poultry feed processing plant, as a manufacturer focusing on poultry feed plant for sale, we’re ready to help. Simply give us a call or complete our contact form, and we’ll be in touch to learn more about your poultry feed plant project.