Hammer Mill Feed Grinder

The hammer mill feed grinder developed and manufactured by Richi Machinery is mainly used for crushing feed raw materials and various roughages. The crushing of feed raw materials is an important part of feed processing. The feed grinder has considerable improvements for transportation, storage, mixing and pelleting.

By absorbing years of R&D experience and technical concepts, Richi Machinery designed and completed the special hammer mill machine. The equipment adopts a special sealing structure and has a number of patented technologies.

It has the characteristics of energy saving, long service life and wide application. It helps the feed crushing system to gradually move towards large-scale production, so as to meet the environmental protection and production capacity requirements of feed mills and medium and large farms.

The launch of the latest series of the feed hammer mill grinder is an excellent product born by Richi Machinery’s insistence on “focusing on customers’ concerns and experiencing customer experience” and through the operation of thousands of animal feed milling projects.

Application Scope Of Hammer Mill Feed Grinder

RICHI hammer mill grinder can pulverize various granular materials, such as corn, sorghum, wheat, beans, crushed cakes, etc. It is specially designed for fibrous raw materials, high-moisture, oily raw materials and finely pulverized materials.

The design is especially suitable for crushing dried fish, cottonseed meal, shrimp shells, bean husk. It can work at full load without blocking the sieve.

Since the power consumption of the feed mill grinder accounts for about 30-40% of the energy consumption in the production of the whole feed mill plant, the improvement of the efficiency of the feed mill grinder may directly reduce the power consumption per ton of material of the whole feed mill plant.

Calculated by 40%, the fine pulverization capacity If it is increased by 30%, the energy consumption of the whole feed mill plant can be reduced by 12%, so it will bring huge economic benefits to the enterprise. (Maybe you are interested in: feed mill plant in Uzbekistan)

You know that: Despite meticulous planning, you always have to be prepared for the unexpected when demolition works. Then it is good to have a tool that is not only convincing through performance, but also through high efficiency. Designed for maximum productivity and continuous use, RICHI feed hammer milling machine impresses with its robust design and versatility.

Classification Of Hammer Mill Feed Grinder

- According to the type of feed: animal feed grinder, cattle feed grinder, chicken feed grinder, poultry feed grinder, livestock feed grinder, etc.

- According to the type of raw materials: corn feed grinder, hay hammer mill, silage grinder, feed grain grinder, grinding alfalfa hay, etc.

- According to the type of application:feed mill grinder for sale, homemade feed grinder, small farm feed grinder, etc.

A number of adjustments and innovations have been made in core feed milling systems and functions, from the whole to the details, fully demonstrating Richi Machinery’s strong manufacturing capabilities and skilled craftsmanship.

Advantages Of Hammer Mill Feed Grinder

- Combined with multi-chamber crushing chamber, the life of hammer and sieve plate is greatly improved, especially the life of small aperture sieve plate is significantly improved;

- The innovative design of the rotor assembly makes the rotor run more smoothly, even if the hammer is worn out, it can still run smoothly, and the temperature of the grinding chamber is lower;

- The overall humanized design is easy to control and has lower noise;

- Reasonable design of the crushing chamber to increase the higher screening rate of materials;

- The screen pressing mechanism is improved, and the folding screen plate is more convenient, safer and more reliable;

- Easy to realize coarse and fine crushing functions to improve crushing efficiency;

- The crushed feed can increase the surface area and particle size of the feed, and improve the mixing uniformity of the raw materials;

- The hammer mill feed grinder equipped with a crushing load controller, which realizes the closed-loop control of the load current and the feeding amount, improves the crushing efficiency, and prevents the equipment from overloading production;

- Delayed closed-loop interlocking control of the main motor, pulse fan and pulse solenoid valve ensures that the solenoid valve continues to work after the main motor and pulse fan are powered off, reducing dust adsorption on the cloth bag and ensuring the breathability of the pulse cloth bag;

- The pulse bag blockage alarm ensures the negative pressure operation of the rated chamber of the crushing chamber; the setting of the main bearing temperature alarm system improves the continuous stability of the main drive. Maybe you are interested in Poultry Feed Manufacturing Plant In Tanzania)

The particle size of crushed raw materials has a very important influence on the difficulty of subsequent processes (such as granulation, etc.) and the quality of the finished product. The size of the crushed particle size directly affects the feed mill production cost. When producing powdered compound feed by feed hammer mill, the power consumption of the crushing process is about 50%~70% of the total power consumption.

The smaller the crushing particle size, the more conducive to animal digestion and absorption, and the more conducive to granulation, but at the same time, the power consumption will increase accordingly.

Therefore, how to play the best production state of the feed mill grinder, reduce the feed mill production cost, and improve the production level and quality of feed pulverization is an important issue related to the production efficiency of the entire feed processing.

The latest upgraded RICHI feed grinding machine defines new industry standards and is tailored for your needs. More reliable product quality, higher work efficiency, and lower use costs are your first choice for profit.

Recommendations For Different hammer mill Feed Grinders

The above is an introduction to the general principles and characteristics of hammer mills. Based on the principles of hammer mill grinding machines, Richi Machinery has also developed a variety of feed grinders to adapt to different feed production. These feed crushing devices are described in detail below.

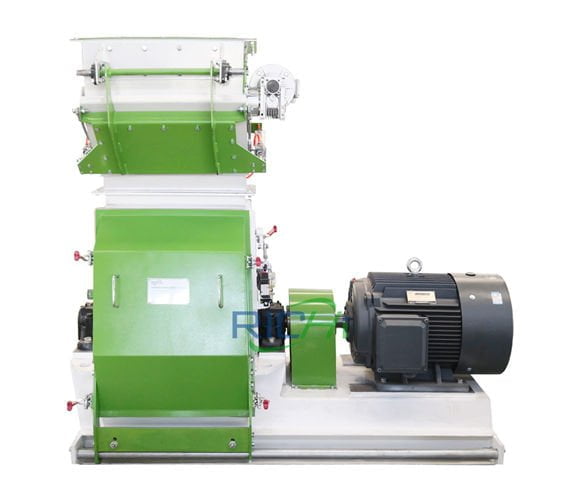

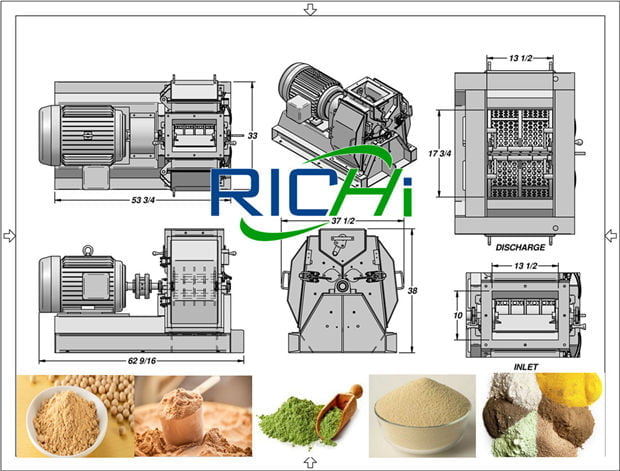

SFSP Series Feed Grinder For Sale

01 Special Design Of Hammer Mill

- Adopting water drop-shaped crushing chamber design and “W”-shaped secondary crushing structure, the output is increased by 25%;

- Fully optimized hammer arrangement and adjustable hammer-screen clearance can realize the conversion of ordinary crushing and fine crushing;

- The operation door design is a fully open type, which is more convenient for maintenance and operation, reduces the labor intensity of the operator, and improves the production efficiency;

- Each rotor has undergone strict dynamic balance test and inspection to ensure the smooth operation of the hammer mill for feed grinding and reduce the bearing, hammer frame plate and other components wear, reduce feed grinding machine maintenance, increase productivity and hammer mill feed grinder life;

- This series of feed pulverizers are widely used in large and medium-sized feed factories to produce high-grade feed and aquatic feed.

02 Application:

Can Crush All Kinds Of Granular Feed Raw Materials

03 SFSP Series Feed Grinder Price

5300-35000 USD

04 Model And Parameters Of SFSP Series Feed Grinder

| Model | Power | Capacity | Speed |

| SFSP56*40a | 30kw | 3-5T/H | 2980r/min |

| SFSP56*40b | 37kw | 4-6T/H | 2980r/min |

| SFSP66*60a | 55kw | 5-8T/H | 2980r/min |

| SFSP66*60b | 75kw | 6-9T/H | 2980r/min |

| SFSP66*80a | 90kw | 8-10T/H | 2980r/min |

| SFSP66*80b | 110kw | 10-13T/H | 2980r/min |

| SFSP66*100 | 132kw | 12-16T/H | 2980r/min |

| SFSP138*30E | 110/132kw | 15-20T/H | 1440r/min |

| SFSP138*40E | 132/160kw | 18-25T/H | 1440r/min |

(Note: Richi Machinery’s products are always updated and improved. Therefore, if there is any difference between the pictures, feature descriptions and performance parameters of the actual model, please refer to the actual product.)

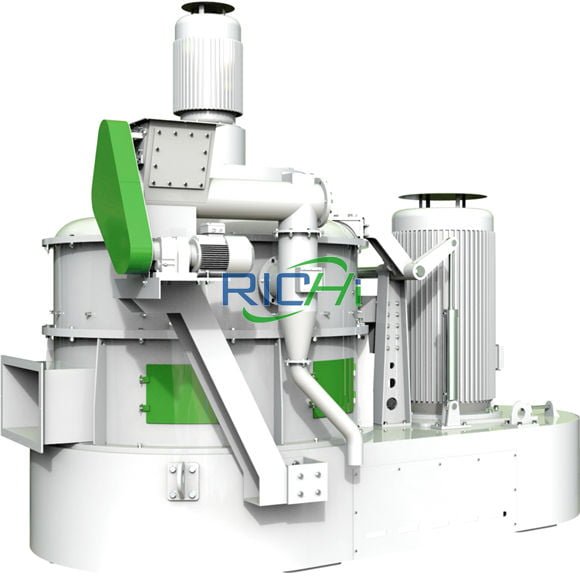

SWFL Series Ultrafine Feed Grinder

01 Special design of ultrafine feed grinder

- Hammer-type micro feed grinder has advanced design of water drop-shaped pulverizing chamber and reasonable secondary pulverizing structure, which is beneficial to increase production;

- Effectively destroy the circulation layer, which is conducive to the crushing and sieving of materials, as well as the cooling of the bearing;

- Fully optimized arrangement of hammers makes pulverizing more efficient;

- Various precision inspections including high-precision dynamic balance ensure smooth operation, lower noise and more ideal performance;

- The feed grinder rotor that can work in forward and reverse rotation greatly prolongs the life of wearing parts;

- The displaceable full-open operation door and safety lock device ensure the convenience and safety of opening the door;

- The clearance of the hammer screen is adjustable, which can adapt to the high efficiency of different materials smash.

02 Application

Micro hammer mill feed grinder is a hammer-type micro grinder produced by Richi Machinery, which is the representative of the micro feed grinder machine. It can pulverize various granular feed materials, such as corn, sorghum, wheat, crushed cakes and other materials.

This series of feed grinders for sale are widely used in the crushing of granular raw materials by various large and medium-sized livestock and poultry aquatic feed mill factories, alcohol factories, lemon factories, food factories, and oil factories. (Maybe you also need to buy: cattle feed pellet machine)

03 Ultrafine Feed Grinder Price

6000-65000 USD

04 Model And Parameters Of Ultrafine Feed Grinder

| Model | SWFL90 | SWFL110 | SWFL130 | SWFL150 | SWFL170 |

|---|---|---|---|---|---|

| Main Power (KW) | 90 | 110 | 132 | 160 | 220 |

| Graded wheel power (KW) | 7.5 | 7.5 | 11 | 15 | 18.5 |

| Feeding power (KW) | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Capacity(t/h) | 1-2 | 3-4 | 4-5 | 5-8 | 8-12 |

(Note: Richi Machinery’s products are always updated and improved. Therefore, if there is any difference between the pictures, feature descriptions and performance parameters of the actual model, please refer to the actual product.)

Animal Feed Grinder And Mixer Unit Series

01 Special Design Of Feed Grinder Mixer

- The self-priming feed grinder mixer unit can greatly reduce the power consumption of the feed production, which can save about 25% of energy consumption compared with similar equipment.

- When using the hammer mill mixer, you should pay attention to turn on the mixer first, then turn on the hammer mill for feed grinding; when shutting down, turn off the feed grinder machine first, then turn off the mixer.

- If there is a power failure and there are too many materials in the machine, the materials should be released. When the material is small, the point-opening startup method is adopted to avoid damage to the feed grinding machine.

02 Application

It Is Specially Designed For Rural Farmers, Small Farms, And Small And Medium-Sized Compound Feed Factories, And Has Been Widely Used In Small-Scale Farms.

Self-priming feed grinders and mixers are a small compound feed processing equipment specially designed for rural farmers, small farms, and small and medium-sized compound feed factories. It integrates self-priming, crushing and stirring. and other granular agricultural products.

The small feed grinder mixer has the characteristics of easy operation by one person, saving labor costs, simple structure, not easy to damage, small occupied area, convenient maintenance, etc.

And also has the characteristics of no special production site, uniform mixing, and large output, which can produce premixed feed and concentrated feed, complete formula powder, etc. The self-priminganimal feed grinder and mixer can perform crushing and mixing operations at one time, or it can work alone.

03 Animal Feed Grinder And Mixer Price

6000-65000 USD

04 Model And Parameters Of Animal Feed Grinder And Mixer

| Model | FR-250 | FR-500 | FR-1000 |

|---|---|---|---|

| Capacity(KG/P) | 250 | 500 | 1000 |

| Mixing Power (KW) | 2.2 | 3 | 3 |

| Grinding Power (KW) | 4 | 7.5 | 11 |

| Weight (kg) | 200 | 450 | 800 |

| Size (cm) | 120*100*180 | 144*104*230 | 156*116*250 |

RICHI feed hammer mill grinder machine combines maximum performance and maximum configuration flexibility. Get simple operation and the latest milling technology at a particularly attractive price.

Projects Of Feed Hammer Mill Grinder Machine

Hammer Mill Machine For Malaysia 3-5TPH Poultry Feed Mill

Feed Hammer Mill Grinder For Cape Verde 1-2TPH Poultry Feed Line

Hammer Feed Grinder For Ethiopia 5-6TPH Powder Feed Mill

Feed Grinder For Afghanistan 10-15TPH Chicken Feed Mill

Feed Hammer Mill For Algeria 10-15TPH Poultry Feed Mill

Feed Grinder For Thailand 10TPH Poultry Premix Feed Mill

Feed Grinder Hammer Mill For Uzbekistan 15TPH Feed Plant

Hammer Mill Grinder For Uzbekistan 3-5TPH Feed Mill Plant For Poultry

Feed Grinder Hammer Mill For Tanzania 3-5TPH Animal Feed Mill

As a manufacturer specializing in animal feed hammer mill grinding machine, Richi Machinery actively promotes the global strategy, cultivates an international business model, and has accumulated rich practical experience. The customer market covers six continents: Asia, Europe, Africa, North and South America and Oceania.

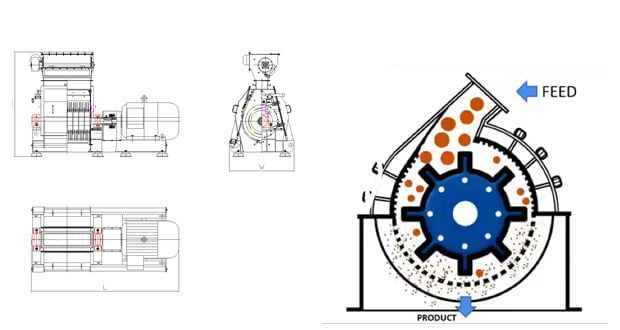

Working Principle Of Hammer Mill Feed Grinder

The working principle of electric feed grinder is that the products are input from the feed, and in the crushing chamber, they collide with the hammers in the high-speed rotating state, and are brought into the acceleration zone..

Under the action of its own gravity, the material enters the output of the feed grinding machine, and the particles that meet the requirements of pulverization can be discharged through the screen, and the particles that do not meet the requirements continue to be pulverized.

Structure Of Hammer Mill Feed Grinder

The structure of the feed grinder machine mainly includes the base, the feeding port, the crushing chamber, etc. The base is the installation base of the hammer mill grinder, which is used to support and connect the crushing rotor and other components.

Due to the main shaft, bearing, bearing seat, hammer frame plate, hammer plate, pin shaft and other parts, the role of the rotor component is to be in contact with the material during the rotation process. When a collision occurs, the material will be smashed. The main function of the hammer is to strike and smash the feed, which is a wear workpiece.

There are three types of hammer arrangement: spiral arrangement, symmetrical arrangement and staggered arrangement; in addition, the sieve piece is also one of the feed grinder machine parts that are easy to wear, and its function is to control the thickness of the feed. The tight window is fixed on the body to form a closed crushing chamber, so that the materials are crushed and screened out from the sieve holes to meet the crushing requirements.

Richi Machinery focus on high quality feed hammer mill production, and always in accordance with market trends and customer needs, constantly seeking changes and improving, timely innovation, and relying on its standard body, reasonable configuration, stable performance, mature design, has won the favor of customers on all continents around the world. It has played a positive role in major projects undertaken and participated by global feed manufacturers.

How To Choose A Hammer Mill Feed Grinder?

Selection based on production capacity

The feed grinder machine’s manual and nameplate will contain the feed grinder’s rated production capacity (kg/h). The stated rated production capacity refers to the output in a specific state of the feed grinding machine, such as a feed grain grinder, which means that the pulverized raw materials are corn, its moisture content is storage-safe moisture (about 13%), and the production efficiency when the sieve aperture diameter is 1.2mm.

Because corn is a commonly used grain feed, the sieve with a diameter of 1.2mm is the smallest sieve commonly used, and the production capacity is small at this time, which is the maximum production efficiency limit in production.

Therefore, when choosing a hammer mill grinder for corn, the production capacity should be slightly larger than the actual required production capacity, otherwise it will increase the wear of the hammer and the air leakage of the air duct, which will lead to a decline in production capacity, affecting the safe production of feed and the service life of the corn grinder for feed.

Selection according to the crushing object

Reasonable selection of the feed mill grinder according to the crushing object is an important prerequisite for ensuring product quality and improving production efficiency. In the feed processing process, if the grain feed is mainly crushed, the top-feeding hammer mill can be selected; Good performance, mainly for crushing grains, and taking into account the cake and straw, you can choose a tangential feeding hammer mill.

If it is used as a pre-treatment of pre-mixed feed, the particle size of the product is required to be very fine and can be processed according to needs. For adjustment, special sieveless feed grinders should be used.

Choose according to the layout method

There are three ways to output the pulverized finished product through the discharge device, namely self-weight blanking, negative pressure suction and mechanical conveying. Small single machine mostly adopts self-weight cutting method to simplify the structure. Most of the medium-sized feed grinders for sale are equipped with a negative pressure suction device. (Maybe you are interested in chicken feed pellet machine)

The advantage is that it can absorb the moisture of the pulverized material, reduce the humidity in the pulverized material and facilitate storage, improve the pulverization efficiency by 10% to 15%, and reduce the dust in the pulverizing chamber. , and the mechanical conveying method is to use a scraper or a bucket to convey the crushed material to the next processing and tempering link.

According to the matching power selection

The power range of the matched motor of this hammer mill feed grinder is listed on the manual and the nameplate of the grinder. Depending on the variety and strength of the raw materials to be ground, the required power is also quite different. When the power is doubled, the crushing strength of soybean meal and cotton meal is similar, and the crushing strength of salt is the largest.

According to dust and noise selection

Most of the dust and noise generated in the processing of feed raw materials come from the hammer mill feed grinder. If a feed grinder machine with high noise and dust is selected, necessary noise reduction and dustproof measures should be taken to improve the working environment and reduce pollution and waste.

Especially in the production process of aquatic feed, the dust generated during the crushing process of feed raw materials is more prominent. This is because aquatic animals have small food intake, short digestive tracts, and poor digestion ability.

Usually, aquatic feeds are required to be pulverized more finely than livestock and poultry feeds. The larger it is, the digestibility of the feed can be improved and the feed rate of return can be increased.

Usually fish feed should be crushed to a geometric average particle size of 0.5mm or less before granulation. For example, ordinary freshwater fish meal should pass through a 20-mesh sieve, and no more than 30% of the materials above the 40-mesh sieve should pass through a 40-mesh sieve. 80% pass through a 60-mesh sieve, eel and soft-shell turtle feeds are required to pass through a 60-mesh sieve, and 95% pass through an 80-mesh sieve.

Therefore, in the process of crushing these feeds, adequate noise reduction and dust-proof work should be done.

Note:

- When producing aquafeed, a micro-grinder must be selected. It is difficult for ordinary micro feed grinders with sieves to have a crushing particle size below 0.25mm, otherwise the efficiency will be very low, and they can meet the feed crushing requirements of general fish (such as carp, grass carp, etc.) or larger fish.

The sieve and sieveless feed grinder machine using airflow classification can meet the processing requirements of eel, shrimp feed, etc., and the particle size can be conveniently adjusted steplessly (within a certain range).

Air-flow classification feed grinding machines with built-in classification screens or devices have greater advantages. They simplify the management of equipment and save investment. - When processing cattle and sheep feed, it is necessary to chop, pulverize and knead raw materials such as straw and hay, so it is most appropriate to choose a model that integrates these three functions.

Here, the function of chopping should meet the requirements of chopping different kinds of straw and hay and continuously adjusting chopping length.

If you want to know about the hammer mill grinder machine with high efficiency, high output, high quality and more stability, please click the button below for details.You can also Specify your requirements for tailored services.

Operation And Maintenance Of Hammer Mill Feed Grinder

If you choose a good hammer mill for feed grinding, if you do not pay attention to the correct use and maintenance, it will shorten the service life of the feed grinder , and also affect the work efficiency, resulting in twice the result with half the effort.

Attention should be paid to the safe operation and daily maintenance of the feed hammer mill machine. (Maybe you are interested in: poultry feed pellet making machine)

01 Safe Operation Of Hammer Mill Feed Grinder

- For long-term operation of the feed grinder machine, it should be fixed on the cement foundation. If the working location is changed frequently, the feed grinding machine and the motor should be installed on the frame made of angle iron, and the anti-vibration device should be installed. If the hammer mill feed crusher is powered by a diesel engine, the power of the two should be matched, that is, the power of the diesel engine is slightly larger than that of the feed grain grinder, and make the pulley grooves of the two consistent, and the outer end faces of the pulleys are on the same plane.

- After the feed grinder crusher is installed, check the fastening of each fastener, and tighten it if it is loose.

- Check whether the belt tightness is appropriate and whether the motor shaft and the feed hammer mill shaft are parallel.

- Before starting the feed hammer mill, first turn the rotor by hand to check whether the hammer and the rotor operate flexibly and reliably, whether there is any collision in the shell, whether the rotation direction of the rotor is consistent with the direction indicated by the arrow on the machine, and whether the motor and the feed grinder are well lubricated.

- Do not replace the pulley casually, in order to prevent the crushing chamber from exploding due to too high rotating speed, or the working efficiency being affected if the rotating speed is too low.

- After the feed grinder is started, it will idle for 2 to 3 minutes, and then start feeding and work if there is no abnormal phenomenon.

- Pay attention to the operation of the crusher at any time during work.

- Conditions, the feeding should be uniform to avoid blocking the boring car, and do not overload for a long time. If it is found that there are vibrations, noises, high temperature of the bearing and the substrate, and material spraying out, it should be stopped immediately for inspection, and the work can be continued after troubleshooting.

- Clean up the iron removal device in time to avoid accidents such as copper and iron entering the crushing chamber.

By providing value-added services to customers, Richi Machinery will maximize the value of each customer’s equipment. By implementing the highest service standards in the industry, Richi Machinery will achieve the highest customer satisfaction.

02 Daily Maintenance Of The Hammer Mill Feed Grinder

The necessary daily maintenance and repair of the hammer mill machine should be carried out to prevent the failure of the feed grinder machine and prolong its service life.

Repair and replacement of screen mesh

The screen is made of punched thin steel plate or iron sheet. When the screen is worn or broken down by foreign objects, if the damaged area is not large, it can be repaired by riveting and soldering; if it is damaged in a large area, a new screen should be replaced.

When installing the screen, the burr side of the screen hole should be facing inward, the smooth side should be facing out, and the screen and the screen frame should be tightly fitted. When the ring screen screen is installed, the stubble of the inner layer of the connection should be along the direction of rotation to prevent the material from being stuck at the connection. (Hot post: animal feed mill plant)

Bearing lubrication and replacement

The bearings should be cleaned after every 300 hours of operation of the hammer mill for feed grinding. If the bearing is lubricated by oil, it is advisable to fill the bearing seat with 1/3 of the gap when adding new oil, and no more than 1/2 at most. Just tighten the cover of the constant-cover oil cup a little before operation.

When the bearing of the feed grinder machine is seriously worn or damaged, it should be replaced in time, and attention should be paid to strengthening lubrication; if the tapered roller bearing is used, the axial spacing of the bearing should be checked to keep it at 0.2~0.4mm. The paper pad at the bearing cap can be adjusted.

Replacement of hammer

Among the crushing parts, the hammer is the vulnerable part of the hammer mill feed grinder , and it is also the main component that affects the crushing quality and production efficiency. The hammer should be replaced in time after wear. Some of the hammers of the feed grinding machine are symmetrical.

When the hammers are worn to 5mm, they should all be replaced, and it should be noted that the weight difference of each group of hammers should not be greater than 5g; After completion, a static balance test should be done to keep the rotor balanced and prevent the unit from vibrating.

In addition, due to the wear and tear of the pin shaft of the fixed hammer and the circular hole where the pin shaft is installed, the pin shaft will gradually become finer, and the circular hole will gradually become larger, should be repaired or replaced in time.

Richi Machinery has a professional technical team with 25 years of practical experience in design, manufacture and installation. Whether in pre-sale or after-sale technical support, we are always ready to provide customer satisfaction services.

After the installation and commissioning is completed, we will provide one-to-one technical guidance according to the actual situation of the customer, and be responsible for training the operators until the customer can fully operate the feed mill euqipment and pellet machine production by himself. Truly ‘customer-centric’, to provide customers with excellent service.