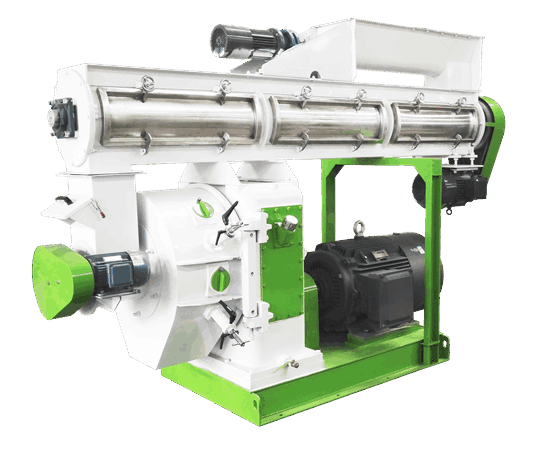

Animal Feed Pellet Making Machine For Sale

SZLH508 animal feed pellet making machine models can offer the possibility of pelleting animal feed in capacities between 10-18 tons/h. RICHI has series animal feed pellet making machine for sale more than 130 countries, they can work in small and massive facilities in optimal capacity regarding your needs.

From the morning eggs to the dinner-time steak, you’re helping feed the animals that feed the world. That’s why you can’t compromise with equipment and automation that are second best.

- Model: SZLH508

- capacity: 10-18T/H

- power: 160KW

- Price: FOB 40,000-50,000 USD

At RICHI, we have more than 30 years of experience in the animal feed industry. We’ve perfected the design of our equipment so that it provides a comprehensive solution based on your unique ingredients and production requirements.

At present, our animal feed pellet making machines have been installed in animal feed mill plants, livestock feed production lines, poultry feed production lines, cattle feed production lines, chicken feed mill plants, pig feed mills, compound feed mills, broiler feed mills, shrimp feed mills, fish feed production plants on all continents around the world.

Features of animal feed pellet making machine for sale

- RICHI animal feed pellet making machine is a low-fault model with international new technology;

- The main standard parts such as bearings, oil seals, and O-rings in the main transmission part are all directly introduced from abroad;

- High-precision gear transmission, its output is about 15-20% higher than that of belt transmission type.

- The large gear and gear shaft adopt hardened tooth surface and gear grinding technology, with high precision and a service life of up to 15 years.

- The conditioner is increased by 15% on the basis of the CPM model to improve the maturation of the material.

- The material throwing scraper is welded on the head of the conditioner blade, which accelerates the fusion of the material and steam and improves the maturation.

- High-precision gear direct drive has strong overload resistance, and general blockage can be restored without stopping the animal feed pellet machine.

- The rear end of the main shaft is improved to a bearing support to ensure that the hollow shaft and the main shaft axis are parallel, the main shaft does not shake, and the production capacity is improved.

- The feed pellet making machine housing material is made of high-wear-resistant internal combustion engine cylinder liner material, which can maintain good precision after long-term use. The service life is up to 20 years;

- Double-layer and three-layer conditioner animal feed pelletizers can be customized to produce high-quality livestock and poultry aquatic feed.

Advantages of animal feed pellet making machine for sale

01 Variable die speed, Consistent quality

You can adjust the circumferential die speed without changing the die. This enables you to precisely optimize pellet production for each feed formulation, making this a versatile solution for a wide range of recipes.

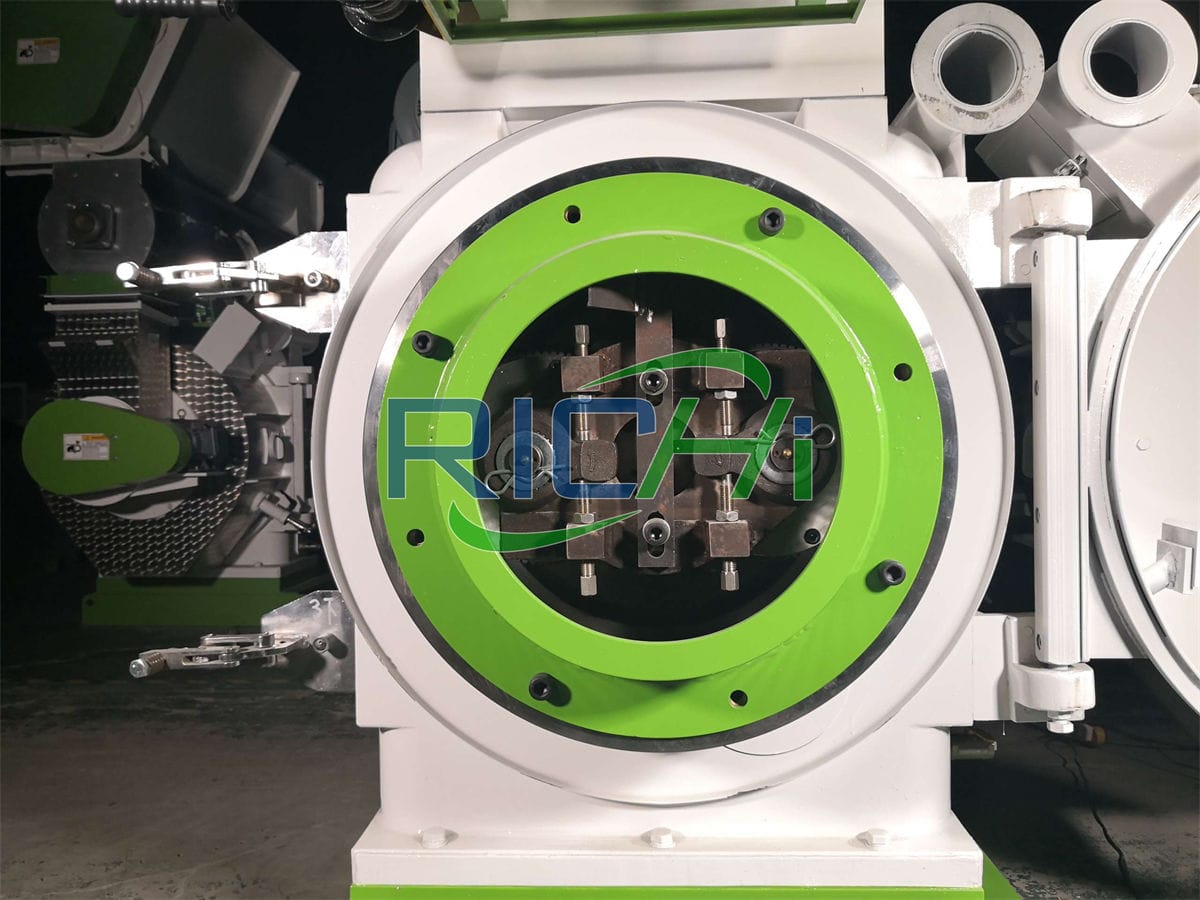

02 Automatic roller gap adjustment, High-quality pellets

The distance between the press rolls and the die can be automatically adjusted without interrupting production. This ensures consistent pellet quality without compromising productivity. It also helps reduce energy consumption and wear and tear on the die and rolls.

03 Anti-blocking system (ABS) for press rolls, Increase productivity

An anti-blocking system (ABS) prevents roll slippage and protects the machine from blockage and damage. The RICHI animal feed pellet making machine can then operate close to its upper limit with minimal risk of downtime or unplanned interruption.

04 Full range of automation solutions

You can purchase your animal feed pellet making machine as a stand-alone machine or as part of a broader solution. We offer a whole range of automation animal feed production solutions, from individual machine control to a full smart animal feed mill factory integration.

Structure of animal feed pellet making machine

SZLH508 animal feed pelleting machine is mainly composed of feeding mechanism, pressure wheel device, speed regulating device, electronic control device, etc.

1. Feeding mechanism

The feeding mechanism is generally composed of feeding port, forced feeding mechanism and regulating valve. The feeding port is connected to the feeding mechanism, and the material is pressed into the gap of the pressure wheel through the forced feeding mechanism. At the same time, the feeding speed can be adjusted by the regulating valve.

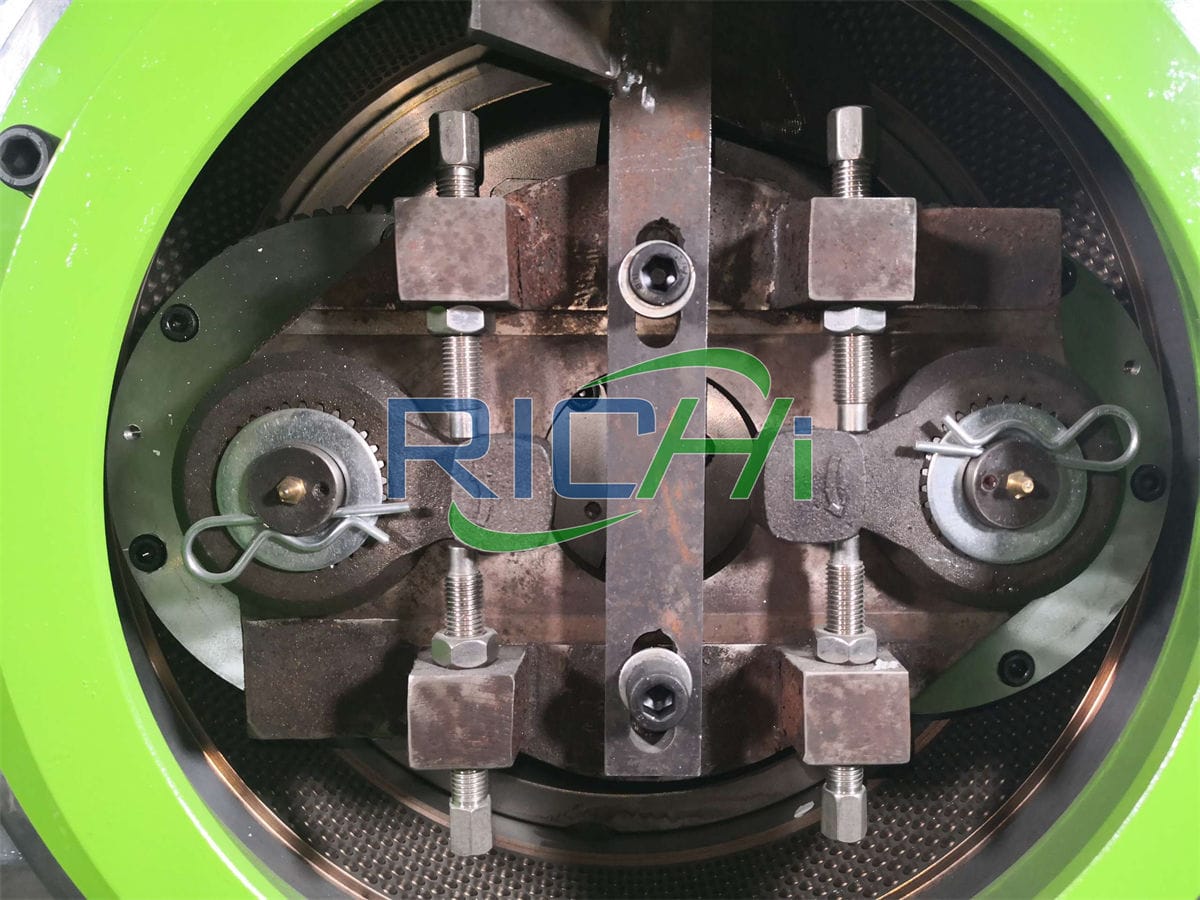

2. Pressure wheel device

The pressure wheel device is the core component of the animal feed pellet making machine and the most vulnerable part. The pressure wheel is composed of a pressure wheel shell, a pressure shaft, a template, a template seat, etc. The pressure shaft is driven by the motor to rotate, and the pressure shaft drives the template to rotate, compressing the material into particles, and then discharged through the template hole outlet.

3. Speed regulating device

The speed regulating device can adjust the rotation speed of the pressure shaft according to production needs, and adjust the distance between the pressure wheel shell and the template to meet different pressing requirements.

4. Electronic control device

The electronic control device is mainly composed of an electronic control box, a motor, a frequency converter, a control panel, etc. By adjusting the AC voltage and frequency output by the frequency converter, the speed of the motor is controlled to achieve the normal operation of the animal pellet feed machine.

In summary, the animal feed pelleting machine is mainly composed of four major components: a feeding mechanism, a pressing wheel device, a speed regulating device, and an electronic control device. Each part has its own unique function and role, and together completes the work of pellet production.

how does a feed pellet machine work?

How to make animal feed pellets with animal feed pellet making machine?

The modulated crushed animal feed raw material is fed from the chute through the die cover, and with the help of gravity, the centrifugal force generated by the rotation of the ring die, and the action of the feeding scraper, it is evenly fed into the two pressing areas in the ring die, that is, the wedge-shaped space formed by the two pressing rollers and the ring die.

Under the strong extrusion of the ring die and the pressure roller, the material is gradually compacted, squeezed into the die hole of the ring die, and formed in the die hole.

Since the extrusion of the material between the die and the roller is continuous, the formed material is continuously discharged from the die hole in a columnar shape, and then cut into animal feed pellets of the required length by the cutter.

specifications and parameters of animal feed pellet making machine for sale

| model | SZLH508 |

| Output (t/h) | 10~18 |

| Main motor power (kw) | 160 |

| Main motor series | 4P |

| Feeder power (kw) | 2.2 |

| Conditioner power (kw) | 11 |

| Ring die diameter (mm) | 508 |

| Finished pellet diameter (mm) | 2~12 |

configuration of SZLH508 animal feed pellet making machine for sale

- Ring die material: stainless steel

- Door cover of granulation room: 6mm /SUS304

- Feed chute: 3mm /SUS304

- Gear box: HT250

- Gear: 42CrMo

- Gear shaft: 20CrMnTi

- Spindle: 42CrMo

- Empty shaft: 42CrMo

- Bearing: Import

- Oil seal: Germany/Taiwan

- Overload mechanical protection: safety pin

- Serpentine spring coupling drive

- Using Siemens Motor

operation requirements of animal feed pellet making machine

| Animal feed types | Requirements Before Entering Granulator(mm) | Pellet Diameter(mm) | Pellet Length(mm) | Ring Die Compression Ratio | Conditoning Temperature(℃) | Conditoning Time(s) | Equipped Conditioner |

| Poultry chicken | 2.0-3.0 | 2-4 | 4-8 | 1:10—-1:13 | 150 | 60-120 | one layer/two-layer |

| Cattle | 3-5mm | 6-12 | 12-18 | 1:6:1:9 | 150 | 30-60 | one layer/two-layer |

| pig | 2-3 | 2-4 | 3-8 | 1:3.5—-1:5 | 150 | 60-120 | One layer/two layer |

| fish | 1.0-2.0 | 2-6 | 4-12 | 1:16—-1:18 | 150 | 90-180 | Two layer/three layer |

| shrimp | 95%≥80 mesh | 1.2-2.0 | 1.8-4 | 1:20—-1:25 | 150 | 120-180 | three layer |

| … | |||||||

animal feed pellet making machine for sale the world

Richi Machinery has lots of projects animal feed pellet making machine for sale the United States, Canada, Mexico, Brazil, Russia, Kazakhstan, Turkey, Kuwait, Algeria, Saudi Arabia, Angola, South Africa , Egypt, Vietnam, Malaysia, Indonesia, India, Indonesia, Chile, Australia and other 130 countries and regions.

animal feed pellet machine for sale United States

- pellet making machine selection: SZLH508

- Feed Size: 2-8mm pellets

- project cost: 320,000 USD

feed pellet making machine for sale Australia

- pellet making machine selection: SZLH508

- Feed Size: 2-6mm pellets

- project cost: 460,000 USD

feed pellet making machine for sale Algeria

- pellet making machine selection: SZLH508

- Feed Size:1.5-8mm pellets

- project cost: 650,000 USD

animal feed pellet machine for sale El Senegal

- pellet making machine selection: SZLH508

- Feed Size: 2-6mm pellets

- project cost: 380,000 USD

animal food pellet making machine for sale Kazakhstan

- pellet making machine selection: SZLH508

- Feed Size: 2-8mm pellets

- project cost: 82,600 USD

animal feed pellet making machine for sale Vietnam

- pellet making machine selection: SZLH508

- Feed Size: 2-4mm pellets

- project cost: 54,900USD

animal feed pellet making machine for sale Russia

- pellet making machine selection: SZLH508

- Feed Size:1-5mm pellets

- project cost: 370,600 USD

animal feed pellet making machine for sale south africa

- pellet making machine selection: SZLH508

- Feed Size: 2-4mm pellets

- project cost: 550,000 USD

Application of animal feed pellet making machine

SZLH508 animal feed pellet making machine is mainly used for feed production lines with an output of more than 10 tons and less than 20 tons.

The advanced animal feed pellet plant can not only improve the production capacity, but also help to lower the maintenance and energy cost.

RICHI Machinery provides various models of feed mill equipment to meet customers’ different demands for efficient animal feed pellet plant, including cattle feed plant, poultry feed plant, fish feed plant, etc.

Our animal feed manufacturing plant is designed with efficient transmission and pelletizing system and updated technology.

All of our animal feed mill equipment can achieve automatic production and can ensure the flexibility and quality of final pellets. In addition, it can also save the maintenance cost on the equipment and reduce the downtime.

If you want to get a 12-20t/h animal feed production line solution, click the button below to get a detailed solution design, equipment configuration list and production line quotation.

Video of animal feed pellet making machine

FAQs of animal feed pellet making machine for sale

How much does a SZLH508 animal feed pellet making machine cost?

The SZLH508 animal feed pellet making machine price is generally between FOB 40,000-50,000 USD.

The animal feed pellet machine price is indeed affected by many factors:

- First, technical complexity is one of the key factors that determine the price of an animal feed pellet making machine for sale.

With the continuous advancement of science and technology, the production technology of lithium battery modules is also constantly improving, and the equipment involved is becoming more and more complex.

Some high-end equipment uses advanced technology and precision manufacturing processes, so the price is relatively high. Some equipment with relatively simple technology has a relatively low price. Therefore, when choosing equipment, manufacturers need to weigh their own technical strength and production needs. - Second, brand awareness will also affect the price of animal feed pellet machines for sale.

Well-known brands often have a good reputation and credibility in the market, and their product quality and technical level are relatively high, so the animal feed pellet machine price will be correspondingly higher.

Some emerging brands or less well-known brands may adopt a low-price strategy to attract customers in order to gain a certain share in the market. However, this does not mean that low price means low quality, and manufacturers need to conduct comprehensive inspections and evaluations when choosing equipment. - Finally, production scale is also one of the important factors affecting the price of animal feed pellet making machines for sale.

Generally speaking, the larger the production scale, the more equipment is needed, so more discounts and offers can be obtained. At the same time, large-scale production can also reduce the cost per unit product, thereby improving the competitiveness of the enterprise.

Therefore, when considering purchasing equipment, manufacturers need to choose the appropriate type and quantity of equipment based on their own production scale and development plan.

In summary, the price of animal feed pellet making machines for sale is affected by many factors such as technical complexity, brand awareness and production scale.

When choosing equipment, manufacturers need to consider these factors comprehensively and make wise decisions based on their actual situation.

How to choose animal feed pellet making machine?

1. Recognize the needs

Before purchasing animal feed pellet making machine for sale, you first need to carefully analyze your production needs to determine the type and specifications of the required equipment. Set production goals, determine production capacity indicators, analyze the problems that may be encountered in actual production, and then choose suitable equipment for these problems.

2. Consider quality

For animal food pellet making machines, quality is a crucial factor. A good equipment needs to have excellent performance, stable operation, durable life and other quality guarantees.

Therefore, when choosing a supplier, you should pay attention to the other party’s factory files, production capacity, service level and other factors. Only by choosing excellent equipment can you ensure that production efficiency and product quality are met.

3. Consider cost performance

When choosing animal feed pelletizer, it is not enough to only focus on the price. You should consider the cost performance of the equipment itself, including the initial price and subsequent maintenance costs. We should consider more factors such as equipment performance, quality and life, and choose the right equipment to truly maximize the investment.

4. Consider after-sales service

The after-sales service level of the animal pellet machine has an important impact on production efficiency and equipment life. Therefore, when purchasing equipment, we need to understand the supplier’s after-sales service quality and service response speed.

In order to avoid affecting production efficiency due to after-sales service problems, you must choose a suitable supplier according to your own needs.

Selecting a high-quality animal feed pellet maker plays a vital role in improving production efficiency and product quality. If you have any questions about the selection of a pellet maker for animal feed, you can contact us directly for free technical support!

How to choose animal feed pellet making machine manufacturer?

Selecting a suitable manufacturer who specializes in animal feed pellet making machine for sale is crucial to ensuring product quality and improving production efficiency. So, how to choose a reliable feed pellet machine processing manufacturer?

1. Pay attention to the manufacturer’s equipment and technology

Diversified processing equipment and technology are the key to ensuring the quality of pellet making machine for animal feed. When inspecting manufacturers who focus on animal feed pellet machine for sale , pay attention to whether the newness and oldness of their equipment and the technical level meet the industry standards.

Generally speaking, manufacturers with large scale and more equipment have stronger processing and production capabilities, and can better guarantee the quality and precision of animal pellet making machine products.

2. Understand the production strength of manufacturers

Different manufacturers have different production capacities. Some manufacturers who focus on animal feed pellet making machine for sale can only handle small batch orders and produce a single type of feed pellet machine, while some manufacturers have strong feed pellet machine processing capabilities.

They can process multi-diameter, multi-material, and multi-model animal pellet maker products, and can also provide customized processing services for customers. Before choosing a animal feed pellet maker machine processing manufacturer, you must first clarify your own needs and then choose a suitable factory.

3. Inspecting the manufacturer’s service and after-sales service is a guarantee

In addition to the product itself, the manufacturer’s service and after-sales service are equally important. When choosing animal feed pellet making machine manufacturer, you may want to ask about the required product inventory, delivery cycle and delivery method.

Only by understanding these contents can you avoid buck-passing and wrangling in the later cooperation process, making the entire cooperation process smoother.

In short, choosing a suitable manufacturer who rooted in animal food pellet making machine for sale requires comprehensive consideration of the manufacturer’s equipment and technology, production strength, quality and delivery time, as well as service and after-sales. (FInd RICHI on youtube)

What does your animal feed pellet making machine after-sales service include?

High-quality after-sales service is one of the important factors for animal feed pelleting machine manufacturers to win the trust of consumers. As an animal feed pellet making machine manufacturer, we provide the following after-sales services:

- Installation and commissioning: Provide free installation and commissioning services for equipment to ensure the normal operation of the equipment.

- Regular maintenance: Regularly maintain the equipment to ensure the stability and service life of the animal feed pellet making machine.

- Repair service: When the animal pellet feed machine fails, the animal pellet machine manufacturer provides timely repair services to restore the normal operation of the equipment as soon as possible.

- Customer return visits: Regularly return visits to customers to understand the use of equipment, collect customer feedback, and continuously improve product and service quality.

- Training service: For animal feed mill plants, animal pellet making machine manufacturers provide training services on equipment operation and maintenance to improve users’ usage experience and maintenance capabilities.

Richi Machinery focuses on animal feed pellet making machine for sale, and can provide customers with one-stop, complete set of professional animal feed plant solutions to solve the problems of customers, especially pure investment customers, such as technical difficulties and lack of understanding of feed mill equipment, which makes the animal feed factory project more cost-effective.