Rabbit Pellet Making Machine

The rabbit pellet making machine, used to create pellets from powdered material, is one of the most important machines in rabbit feed production.

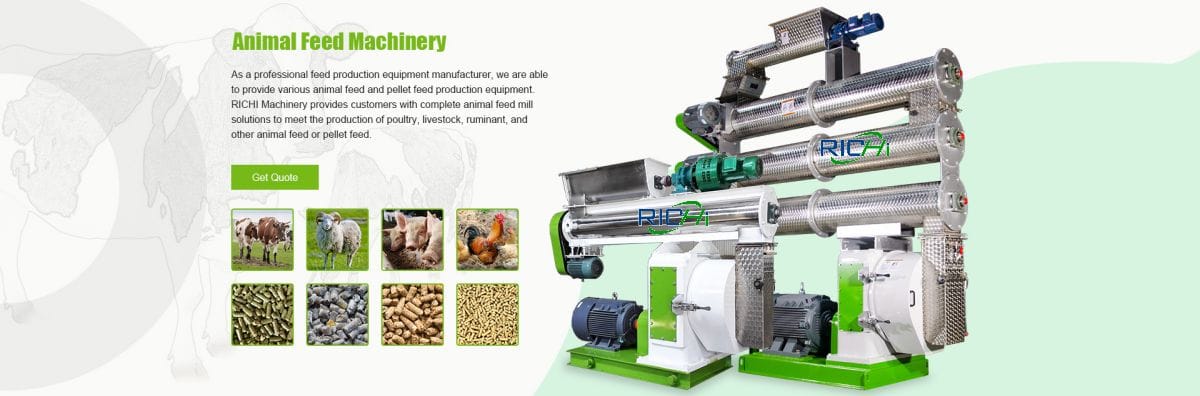

The requirements of feed pellets for different animal species differ in terms of length, diameter and composition. RICHI rabbit feed pellet mills can be used to produce pellets for poultry, cattle and pig feeding. RICHI rabbit feed pellet machines are designed for universal use for a wide range of products differing in terms of structure, bulk density, binding strength and pellet size.

The machine is also Richi Machinery’s deep listening to customers’ voices. According to the actual problems encountered by customers, customer needs and related demand chains, quickly develop special edition products with core competitiveness to meet the market.

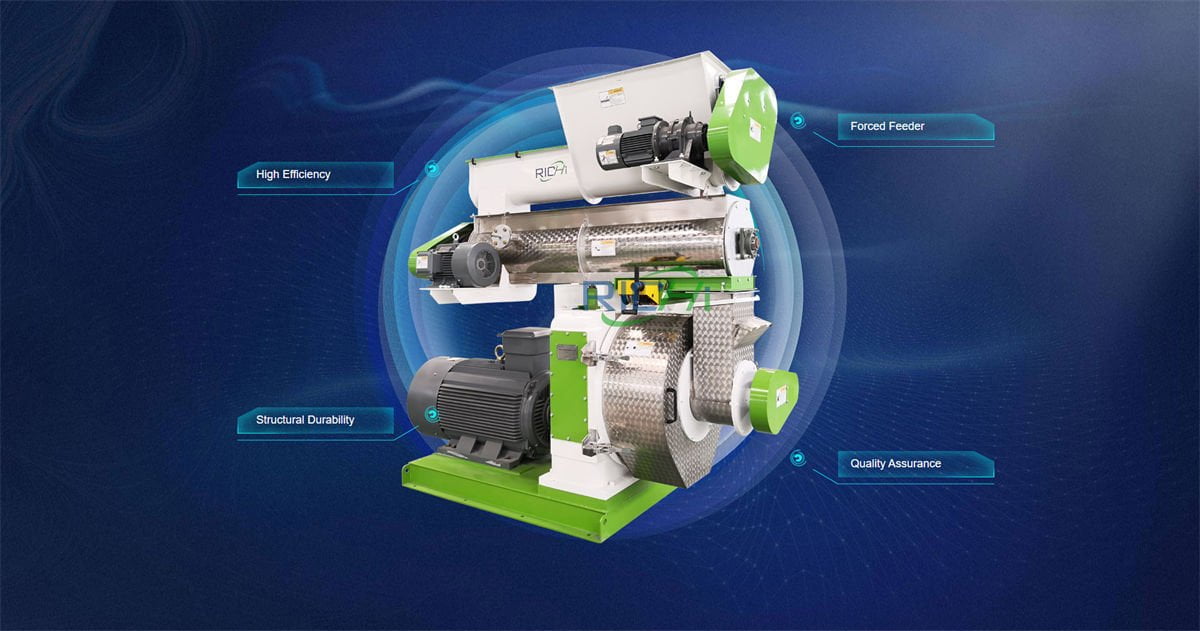

Features of rabbit pellet making machine

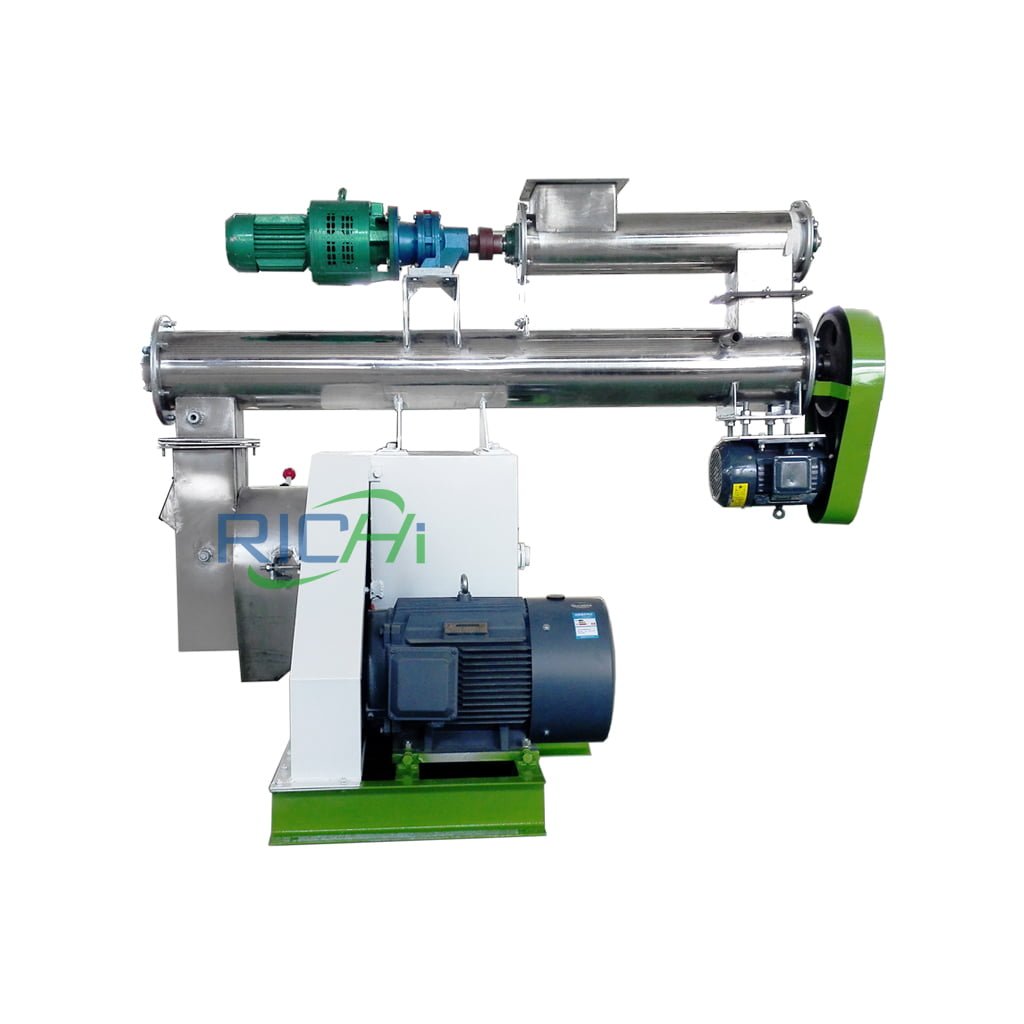

- Door: the machine door is entirely stainless steel-made with two knife assemblies.

- Magnet: a permanent magnet is fitted in the chute to avoid ferrous metal entering the die.

- Overload flap: on the feed conveyor there is an overload flap.

- Die holder: die holder is made in forging steel and it has a wear ring. Die holder front base is stainless steel lined to guarantee longer life.

- Basement: the rabbit pellet machine is built upon a heavy cast iron base that guarantees the absence from vibration.

- Main shaft: the front of the shaft is a chromed plate for preventing against corrosion.

- Drive: the rabbit pellet mill is driven by an electric motor via a gear transmission. The whole body of the screw feeder in contact with the feed and the screw feeder shaft are made in stainless steel.

- Shear pin: to protect the pelleting chamber, a shear pin is installed on the rear of the machine.

- Lubrication: grazing can be made by the rear of the rabbit feed pellet machine, through the main shaft. In this way, the machine can be lubricated without stop the motor.

- Conditioner: The conditioner is driven by its own motor. The conditioner is entirely stainless steel made included shafts and paddles. To obtain, the best results from the addition of steam, the paddles of the conditioner shaft are easily adjustable.(Maybe you are interested in cattle feed pellet machine)

Model And Parameters of rabbit pellet making machine

SZLH250 rabbit Feed Pellets Machine

| Capacity(T/H) | 1-2 |

| Main Motor Power(kw) | 22 |

| Feeder Motor Power(kw) | 0.75 |

| Conditioner Power(kw) | 1.5 |

| Dia.of Ring Die(mm) | 250 |

| Transmission form | Belt drive |

SZLH320 rabbit Feed Pellets Machine

| Capacity(T/H) | 3-4 |

| Main Motor Power(kw) | 37 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 2.2 |

| Dia.of Ring Die(mm) | 320 |

| Transmission form | Gear drive |

SZLH350 rabbit Feeds Pellet Machine

| Capacity(T/H) | 6-7 |

| Main Motor Power(kw) | 55 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 3 |

| Dia.of Ring Die(mm) | 350 |

| Transmission form | Gear drive |

SZLH420 rabbit Feed Making Machine

| Capacity(T/H) | 10-12 |

| Main Motor Power(kw) | 110 |

| Feeder Motor Power(kw) | 1.5 |

| Conditioner Power(kw) | 7.5 |

| Dia.of Ring Die(mm) | 420 |

| Transmission form | Gear drive |

SZLH508 rabbit Feed Pelletizer Machine

| Capacity(T/H) | 12-18 |

| Main Motor Power(kw) | 160 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 508 |

| Transmission form | Gear drive |

SZLH558 rabbit Pellet Making Machine

| Capacity(T/H) | 20-25 |

| Main Motor Power(kw) | 180/20 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 558 |

| Transmission form | Gear driveve |

SZLH678 rabbit Feed Pellet Making Machine

| Capacity(T/H) | 25-30 |

| Main Motor Power(kw) | 220/250 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 678 |

| Transmission form | Gear drive |

SZLH768 rabbit Pellet feed Processing Machine

| Capacity(T/H) | 30-35 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 11 |

| Dia.of Ring Die(mm) | 768 |

| Transmission form | Gear drive |

SZLH858 rabbit Feed Pellet production Machine

| Capacity(T/H) | 40-45 |

| Main Motor Power(kw) | 280/315 |

| Feeder Motor Power(kw) | 2.2 |

| Conditioner Power(kw) | 15 |

| Dia.of Ring Die(mm) | 858 |

| Transmission form | Gear drive |

Customizable Design:

Richi Machinery can customize the rabbit pellet making machine according to the actual needs of customers, including voltage, electrical components, door opening method, product color matching, and can also customize different conditioners, conditioner layers according to customer rabbit feed formulas and rabbit feed making process, etc. (Maybe you are interested in poultry feed pellet making machine)

Cases Of rabbit pellet making machine

rabbit pellets machine in cuba

rabbit feed pellet machine in South Africa

rabbit pellets making machine in Thailand

About rabbit feed pellets production

01 Formulation design

When designing the formula, the nutritional requirements and the types and ratios of raw materials should be determined according to the specific conditions of the rabbit’s species, sex, age, physiological stage and production purpose, referring to the corresponding feed standards.

In order to reduce the cost of feed, the raw materials should be selected from varieties with abundant local resources and low prices as much as possible. For the feed formula sold as commercial products in large rabbit farms, it must pass a feeding test and be adjusted before it can be used on a large scale.

02 Raw material selection

The quality of raw materials directly affects the quality of pellet feed. Therefore, it is necessary to check the purchase of raw materials during production.

①Concentrate feed. Commonly used concentrated feeds for rabbits include corn, barley, sorghum, bran, bean cake, sunflower cake, peanut cake, sesame cake, fish meal, etc. It is required that the water content of the concentrate should not exceed the safe storage water, without mildew, and the impurities should not exceed 2%. Moldy, spoiled and adulterated raw materials are resolutely not used.

② Roughage. Commonly used roughage for rabbits includes corn stalks, bean stalks, forage grass, peanut seedlings, cultivated dry pastures, leaves, etc. The moisture content of well-dried roughage is 14%-17%, the leaves fall off less, the color is green and has aroma. Roughage with mildew or high moisture content is prohibited.

Corn stalks have a small bulk density, are not easy to granulate during processing, and the processed finished products have low hardness, so they should be used in conjunction with large-volume feeds such as grain grass and bean stalks. (Related project: feed mill plant in Uzbekistan)

03 Raw material crushing

Various raw materials must be crushed before being processed into pellet feed with rabbit pellet making machine. The aperture of the sieve plate of the pulverizer is preferably 1-1.5mm. For the roughage in reserve, it should generally be processed at noon on a sunny day.

04 Weighing and mixing

To process pelleted feed, the concentrate is generally pulverized, weighed and mixed, and then mixed with the coarse feed according to the ratio of fine and coarse feed. Mixing is an important part of the rabbit pellet feed production process, the purpose is to make various raw materials blend with each other, so that the various nutrients are evenly distributed.

The measures to ensure the mixing quality are:

- ① Add trace elements or preventive drugs to make a premix.

- ② Control the stirring time. Generally, each batch of horizontal ribbon screw mixer should be mixed for 2-6 minutes, and vertical mixer should be mixed for 15-20 minutes.

- ③Appropriate loading amount. It is advisable to fill each mixture to 60%-80% of the capacity of the mixer.

- ④ Reasonable feeding sequence. The components with large ratio are added first, and those with small amounts are added later; those with small specific gravity are added first, and those with large specific gravity are added later.

05 Pelletizing

This process is to compress the mixture into pellets through a granulator. The physical properties of pellets (such as length, diameter, hardness, etc.) are important performances of pellet quality.

Adding 1%-2% bentonite to high-roughage diets can improve the surface finish and hardness of pellets.

Factors affecting the physical properties and output of pellets In addition to the above-mentioned factors, the key factor is the performance of the rabbit feed pellet mill.

For this reason, large-scale rabbit farms, professional rabbit raising households or feed processing factories, when choosing a rabbit pellet making machine, in addition to considering the length of production history of the rabbit feed pellet making machine manufacturer, the size of the scale, whether the after-sales service is thoughtful, and the life of the wear parts, should be based on the rabbit farm. According to the existing scale or development goal, determine the model of the rabbit feed pellet machine.

06 Storage and transportation

Pellets that have been stored for a long period of time or transported over long distances have different moisture content depending on the location. For example, in dry areas, it should not be higher than 14%, and in humid areas, it should be below 12.5%.

In addition, adding 0.1% sodium propionate or 2% calcium propionate to the raw material can prevent the feed from mold and deterioration. (Maybe you want to start an animal feed mill plant)

Factors Affecting the Production of rabbit pellet making machine

Compared with powdered feed, pelleted feed has great advantages, and the proportion of pelleted feed in the feed market is increasing. Due to weak technical force, many small and medium-sized feed mills are unsatisfactory in the quality of pellets. The quality is good and bad, but they don’t know where to start to improve.

Feed users often use indicators such as color, texture, water content, pulverization rate, and durability to describe pellet quality. The main factors affecting the quality of pelleting are: feed formula, crushing particle size, tempering, compression molding performance and cooling.

Feed formula

Feed formulation has the greatest impact on pellet quality. In addition to meeting the nutritional needs of animals, formula designers should also take into account the influence of feed material composition characteristics on pellet quality, so as not to cause trouble in production, and try to make the prepared pellets meet the needs of users as much as possible.

- Protein: animal glue such as cakes and other low-fat protein raw materials can increase viscosity after heating, which is helpful for granulation.

- Coarse fiber: It is non-adhesive. Because of its light specific gravity and long time to pass through the die hole, the particles are relatively hard, but it has great mechanical wear and tear, and the production efficiency is poor. If the content is too high, it will also block the ring die.

- Coarse ash content: including minerals, sand and gravel, etc. Such substances have high friction and are not conducive to forming; but among them, bentonite has water-absorbing swelling and lubricating properties. Adding 1% to 2% can increase viscosity and improve pellet hardness, but the content too high is not good for granulation.

- Fat: It can improve the production efficiency of granulation and make the surface of granules smooth. When the content is too high, it is easy to slip and difficult to extrude, which seriously affects the quality of granulation.

- Starch: Starch is gelatinized by steam heating and becomes viscous, especially wheat starch has a higher sticking effect, but if the steam is insufficient or the granules are too coarse, the effect will be reduced.

- Heat-volatile substances: skimmed milk powder, whey powder, sucrose, glucose, etc., become more viscous after being heated by steam, but when these substances are heated too much, they are easy to coke, too sticky, and block the mold hole.

- Feed moisture: Grains with high adsorbed water content in grains are not easy to granulate, because the adsorbed water in the conditioner prevents enough water (in the form of steam) from entering the powder, making the conditioning unsatisfactory.

Crushing particle size

Generally speaking, the finer the powder particle size, the better the particle quality. The reason is that small particles can absorb more water and allow steam to fully penetrate into the center of each particle, thus becoming softer, more plastic, and able to withstand a higher degree of tempering; while large particle size is easy to cause particle breakage and break.

It should be pointed out that in most cases, the difference in particle size has a greater impact on particle quality than the absolute size of the particles. Excessive crushing will reduce equipment productivity, increase energy consumption, and increase production costs.

Conditioning

The purpose of tempering is to improve the quality and output of granules, and through proper conditioning, the adverse effects caused by poor crushing or improper formulation can be overcome. Tempering is the most difficult part to operate. The factors that affect the tempering effect are: steam quality, tempering temperature and moisture, and tempering time.

Steam quality is extremely important to feed conditioning, and the steam before entering the conditioner requires saturated steam to remove condensed water. The steam pressure is also required to reach a certain value. The tempering temperature is mainly achieved by adding steam. Generally, the tempering temperature is required to reach 70-80°C, and the tempering moisture is 15%-16%. Under normal circumstances, the steam addition amount is calculated according to 4% to 6% of the maximum granulation production rate.

The length of conditioning time directly affects the degree of maturation of the material. Within a certain range, the longer the tempering time, the better the degree of maturation of the material, the better the mutual cohesion of the material, and the easier it is to granulate.

Generally speaking, the conditioning time of the conditioner is fixed. Feed mills can properly extend or shorten the residence time of materials in the conditioner through the angle between the paddle blade and the palm shaft in the conditioner.

Die performance

Including die thickness, hardness, aperture ratio, inlet taper. If the thickness of the die is too thin, the extruded particles will be loose and easily pulverized.

The longer the effective length of the die hole, the greater the pressure of the material in the die hole, the greater the degree of solidity of the corresponding particles, and the better the quality of the obtained particles, but the output of the granulator will decrease.

When producing different products, the aperture ratio of the die is slightly different. It is generally believed that when producing high-grade feed, such as suckling pig feed and chicken feed, the aperture ratio should be larger, so that the extruded pellet feed is firm and smooth; when producing economical feed, such as meat duck feed, the aperture ratio should be smaller.

Yes, so the output is larger, but the appearance of the feed is slightly worse. According to the quality of raw material granulation, the inlet of the die hole can be tapered or stepped, and sometimes the pressure must be increased or decreased. (Related solution: animal feed mill plant)

Cooling

The pelleted feed is cooled so that the temperature is not higher than the ambient temperature by 6℃, and the moisture content is less than or equal to 13%. Excessive temperature and high moisture are not conducive to storage, easy to mildew, high powder content, poor hardness. One of the counter-current and convective coolers should be selected in production.

Excessive drying will consume more energy, reduce economic benefits, and make the produced particles brittle and shrunk. Uneven cooling and drying can create wet spots in stored feed, causing bacteria and mold growth and reducing pellet quality. The factors that affect pellet quality also influence each other and restrict each other. Only by fully understanding the influence of various factors on pellet quality can we find out the cause in production, prescribe the right medicine, and make the pellet feed quality better.