floating fish feed mill

Our 0.15-60 t/h floating fish feed mill solutions are complete system for producing floating pellets with moderate protein and fat content for feeding warm-water species such as tilapia, eels and catfish. We can help you choose between a single screw and twin screw extrusion process to meet your demands and optimize floating feed production costs.

floating fish feed mill supplier——Richi Machinery

Providing floating fish feed mill solutions and approaches, Richi Machinery fully promotes the development of the aquaculture extruded feed industry.

In order to meet the market needs of the project transformation of floating fish feed production line and meet the new pattern of aquatic extruded feed factory construction, Richi Machinery actively responds to the opportunities and challenges from the era of green feed processing.

To this end, Richi Machinery has dug deep into the technical elements, combined with nearly 30 years of market experience in R&D and manufacturing, and built a series of high-quality floating fish food making machines to help customers’ projects become green and intelligent. In the future, we also look forward to more in-depth cooperation and win-win with customers.

Whether you are looking to modernize or expand your floating feed production, want to replace floating fish feed extruder machine with future-proof innovations, or need advice in the planning and setup of a completely new aqua floating feed mill, Richi Machinery is a good partner for you.

Advantages of floating fish feed mill

The process flow of RICHI floating fish feed processing line can be customized according to the requirements and characteristics of extruded feed required for large, medium and small projects, which can greatly improve production efficiency.

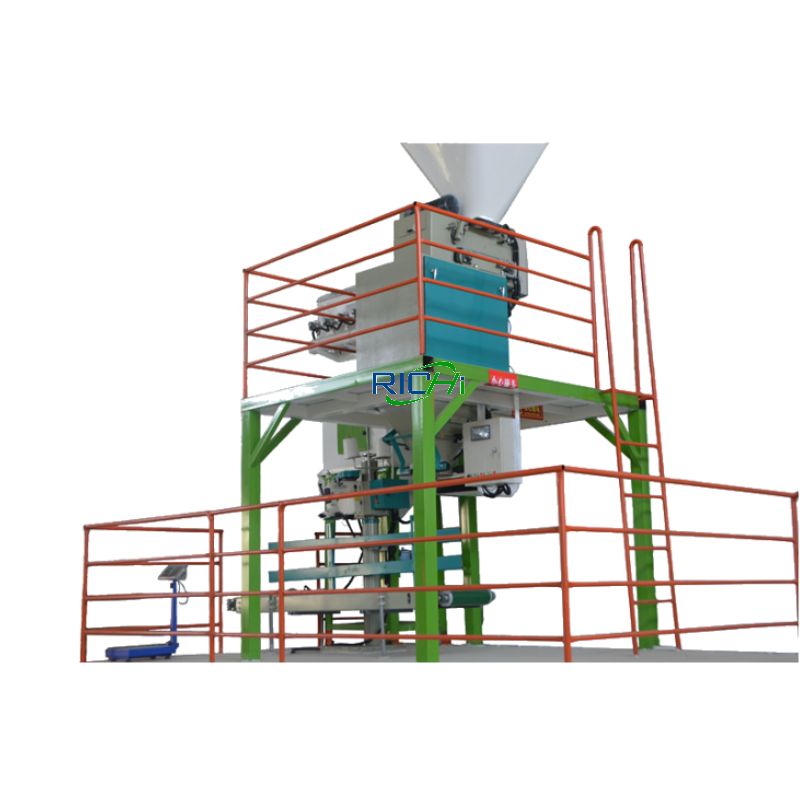

The RICHI extruded floating fish feed production plant has a relatively complete process flow, from raw material storage to finished product packaging and storage, forming a complete closed loop, a typical floating fish feed manufacturing system.

- Easy-to-build solution

- Reduced construction time

- Can be built by local contractors

- Superior flexibility & scalability

- Easy to operate, upgrade and maintain

- Better workflow & easy access to the entire plant

- Safer work environment

- Improved employee retention

- Superior performance & efficient production

- Consistent feed quality & full traceability

The RICHI floating fish feed mill plant has high efficiency, good grain shape and short equipment maintenance time, and is suitable for the processing of various types of extruded feed pellets. It is also suitable for the application of various raw materials and formulations. The replacement of wearing parts can be completed quickly, the time of downtime and maintenance is reduced, and the later maintenance cost is relatively low.

Solutions for floating fish feed mill

Floating fish feed mill cost:80,000-3,000,000 USD

We can provide customers with a one-stop, complete set of professional floating fish feed production solutions to solve the problems of customers, especially pure investment customers, such as technical difficulties and lack of understanding of equipment, which makes the needs and positioning of the project clearer, and also makes the customer’s fish feed equipment selection range is more concentrated, and the cost consumption such as energy and financial resources is reduced.

Engineering content of floating fish feed mill

RICHI is responsible for the overall planning and specific implementation of the entire extrusion feed production line project, and the client is only responsible for the overall, principled and objective management and control. Most of the responsibilities and risks are borne by our company.

Design, production, installation, trial operation and other links can be undertaken by RICHI, to achieve full control of each link, customers can monitor the progress of the fish feed processing project in real time, the quality of the project is guaranteed, and the construction period is greatly shortened.

Overall project planning:

Covers: planning of fish feed mill equipment, project personnel configuration plan, workshop and office facilities, water, electricity, HVAC equipment, dust removal, noise reduction and sewage discharge equipment, etc.

Procurement of equipment:

Covers: main fish feed making equipment, belt transportation system, central control system, sewage treatment system, dust removal and noise reduction system, etc.

Construction:

Covers: floating fish feed mill area construction, equipment infrastructure, dust removal and noise reduction sewage system construction, fish feed machines installation and testing machine, technical training, etc.

RICHI aqua feed process and aqua feed plant project engineers have the skills and experience to define the best floating extruded feed production solution, making us the perfect partner at every stage of your project, from initial design to completion as well as maintenance for the lifetime of your floating fish feed mill.

Core equipment of floating fish feed mill

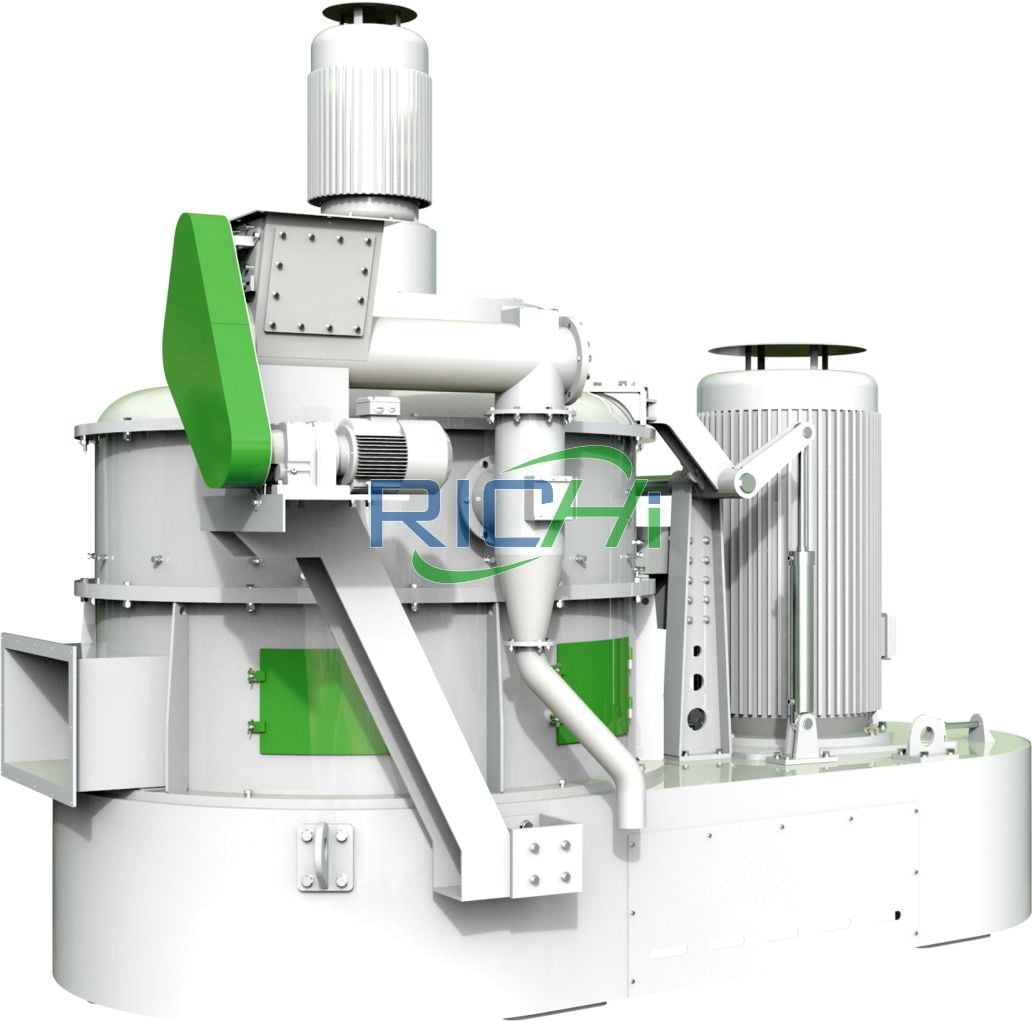

Micro Pulverizer

It is suitable for ultra-fine grinding processing of various feed materials, such as the ultra-fine grinding of aquatic feed such as shrimp feed and fish feed (60 mesh-200 mesh)

Floating fish feed extruder machine

It is suitable for the production of various floating, sinking, slow-sinking and other aquatic feeds, and can also be used in the production of pet food.

Fish feed dryer machine

According to the material characteristics, the fish feed dryer can be customized, which is more conducive to drying extruded feed of various pellet sizes.

Spraying machine

The liquid addition ratio range is large, and it is infinitely adjustable; the liquid spraying uniformity is good; there is no dead angle in the mixing, and there is no residue in the discharge.

Fish Food Grinder

Capable of several size-reduction jobs including grinding, shredding and fluffing.

In line with the benign development needs of global fishery feed for low pollution, low waste, high efficiency and high conversion, the use of floating fish feed mills to process aqua extruded feed is gradually accepted and recognized by the market, and has become a new trend in the development of the industry.

With the popularization and application of extruded feed in the breeding market, more and more feed factories have begun to introduce extruding equipment, and many enterprises are upgrading their processes and production capacity through new construction, adding production lines, and technological transformation to meet the opportunities and challenges of market development.

floating fish feed mill Projects

Over the past 30 years, we have accumulated rich practical experience, and have reached cooperative relations with more than 2000 customers in more than 130 countries and regions, providing them with complete solutions and services covering the entire product life cycle.

We can help you with the entire floating fish feed production process. From blending, mixing and grinding to control sifting, extruding, shaping, drying and coating/cooling, our experts can tailor an aqua feed solution to meet your specific needs.

01 List of latest floating fish feed mill projects

- 5-6T/H floating fish feed mill in russia

- 10T/H Floating Fish Feed Mill in Indonesia

- 4T/H Floating Fish Feed Mill in india

- 8T/H Floating Fish Feed Mill in Thailand

- 6T/H Floating Fish Feed Mill in Ecuador

- 4-5T/H Floating Fish Feed Mill in Bolivia

- 3T/H Floating Fish Feed Mill in Kyrgyzstan

- 1.5-2T/H Fish Food Production Line In Iran

- 2T/H Tilapia Feed Making Plant in the Philippines

- 5T/H Fish Feed Making Plant in Uzbekistan

- 1T/H Floating Fish Feed Extruder Line in Zimbabwe

- 1T/H Floating Fish Feed Processing Line in Senegal

- Côte d’Ivoire300-400kg/H Float Fish Feed Line

- 1-2T/H Fish Feed Extrusion Plant in Uzbekistan

- 1T/H Fish Feed Pellet Line in Tanzania

- 1T/H Wet Floating Fish Feed Extrusion Line in Honduras

- 1-1.5 T/H Small Fish Feed Line in United Kingdom

02 Featured floating fish feed mill projects

5-6 T/H Floating Aquatic Feed Plant Project

This aqua feed production project in Russia is a high-grade extruding line, which adopts RICHI’s advanced process design scheme and equipment configuration, including automatic premix adding system, soybean meal storage system, etc., and is equipped with RICHI’s new twin-screw extruder, horizontal drying system, etc. machine, vacuum spraying machine and other advanced equipment. The new type of vacuum spraying machine can realize the spraying of oil from 1-30% to meet the various oil and fat needs of farmers.

The three-layer natural gas dryer can use natural gas to directly provide heat energy to achieve the purpose of reducing energy consumption and saving energy. At the same time, it can also achieve low-temperature drying to ensure that the nutrients in the feed are not lost, and the breeding effect is better.

10T/H floating fish feed factory Project

The project is a comprehensive feed factory. The workshop adopts a fully intelligent one-card management system, and automatic packaging, palletizing and system. The whole feed production line covers premix, livestock and poultry feed line, shrimp and crab feed line, aquatic extruded feed line, raw material extruded production line, etc.

The dock conveying system is equipped with four 10T raw material weighing bins, which make the feeding of raw materials more accurate, faster and more economical; 10 bulk raw material cement bins can meet the simultaneous mass production of multiple feed production lines in the workshop.

12T/H floating fish feed mill Project

The customer’s main business is the research and development and production of high-end aquatic feed. This project is a complete delivery project of Richi Machinery from fish feed process design, equipment layout, equipment selection, equipment fabrication and installation, and intelligent operation control system.

The project consists of RICHI twin-screw high-grade automatic extruding production line, aquatic pelletizing line, dozens of silos and multiple sets of finished product intelligent packaging and palletizing systems. The whole production line covers special aquatic extruded feed production line and shrimp feed pellet production line.

15T/H floating fish feed making plant

The project is equipped with cutting-edge production equipment, which can produce and distribute feeds covering the entire production process of various species of fish and shrimp from the seedling stage to the breeding stage.

The floating fish feed mill project uses RICHI’s advanced control system, which integrates functions such as order management, visual warehouse capacity, and packaging and storage management. Each section is equipped with power consumption statistics, steam flow statistics and automatic report generation to facilitate customer production cost control.

20T/H floating fish feed manufacturing project

The workshop of this project is a standard 7-storey concrete workshop. The feed mill equipment layout on each floor is well-proportioned, the layout is exquisite, the space is spacious, and the lighting and ventilation are good. The crushing air net is used for centralized dust removal, and the cooling air net is used for centralized deodorization.

All dust removal equipment is equipped with an explosion venting device as standard, which meets the environmental protection requirements and explosion-proof requirements of the construction of feed standard workshops.

The whole floating fish feed mill process has a high degree of automation, and the bulk warehouse entry and exit, and each production line in the workshop can be controlled by the central control. By pre-embedding the electric tubes, combined with the prefabricated grid bridge, the cable layout is simple and beautiful, and the atmosphere is exquisite.

20-22T/H floating fish feed mill project

The workshop of this project is a standard 7-storey concrete workshop. The equipment layout on each floor is well-proportioned, the layout is exquisite, the space is spacious, and the lighting and ventilation are good. The crushing air net is used for centralized dust removal, and the cooling air net is used for centralized deodorization.

All dust removal equipment is equipped with an explosion venting device as standard, which meets the environmental protection requirements and explosion-proof requirements of the construction of feed standard workshops. The whole process has a high degree of automation, and the bulk warehouse entry and exit, and each production line in the workshop can be controlled by the central control. By pre-embedding the electric tubes, combined with the prefabricated grid bridge, the cable layout is simple and beautiful, and the atmosphere is exquisite.

24-25T/H Floating Fish Feed Making Line

The scope of RICHI’s undertaking includes a complete set of storage equipment, a complete set of equipment in the main workshop, and a complete set of equipment in the premix workshop; the overall design of the project is: 3 feeding lines in the raw material warehouse, 5 crushing lines in the main workshop, 5 mixing lines, and 5 feed granulation lines. (one reserved), 1 raw material expansion line, 1*10-ton aquatic product puffing line, 7 packing lines, 3 sets of robot palletizing equipment, 1 set of premix production line, using manual feeding, automatic batching and automatic feeding; Configured with 10*18-foot silos, 5* 21-foot silos, and 4 *48-foot silos. (Related solution: 24-28t/h aqua feed plant )

25-28T/H Floating Fish Food Factory

At present, the project has been put into production, with an output of 25 tons of high-end aquafeed and 3 tons of high-quality shrimp feed per hour. It is committed to providing sustainable feed nutrition solutions for local aquaculture enterprises and customers, and satisfying end consumers with safety, health and deliciousness. supply and demand of high-protein aquaculture products.

The fish food making machines layout of the large capacity floating fish feed mill project workshop is reasonable, and there is a special glass curtain wall visiting channel. The equipment has obvious color separation and division, focusing on environmental protection odor treatment, and centralized treatment of indoor dust. As one of the RICHI model projects, the installation quality is excellent, the customer is satisfied, and it has a certain representativeness and influence in the customer’s local area.

28-30T/H extruded floating fish feed mill

The project is a complete set of feed with an annual output of 200,000 tons, including 2 poultry and fish feed pellet lines, 2 aquatic puffing lines, 3*300T soybean meal silos, and 3 1000T corn silos. Among them, the floating fish extruder is the latest extruded model developed by RICHI, with a wide range of applications, convenient operation, high production capacity and stable performance.

Based on the design concept of energy saving, hygiene, environmental protection, standardization and high efficiency, RICHI provided a complete process design scheme and excellent feed equipment for the project, and is committed to providing the market with high-quality, green, safe and healthy feed products.

Richi Machinery will fully understand the customer’s raw material situation, and then calculate the fish extrusion feed production line capacity, finished product size, output demand and investment cost required by the customer, and conduct professional analysis on it, discuss, conceive design, and plan according to the specific situation of the customer.

Finally formulate the ideal fish floating feed mill and planning layout scheme to ensure the maximum benefit of customers. The final floating fish feed mill provided is reasonable in design, compact in structure and smooth in operation, which maximizes production efficiency and minimizes operating costs, effectively reducing fish feed factory production costs.

Typical design of floating fish feed mill

We are strongly committed to excellent performance and the quality of our products, making us a strong partner for our customers. Our focus is on innovation and keeping up with technological developments in the industry.

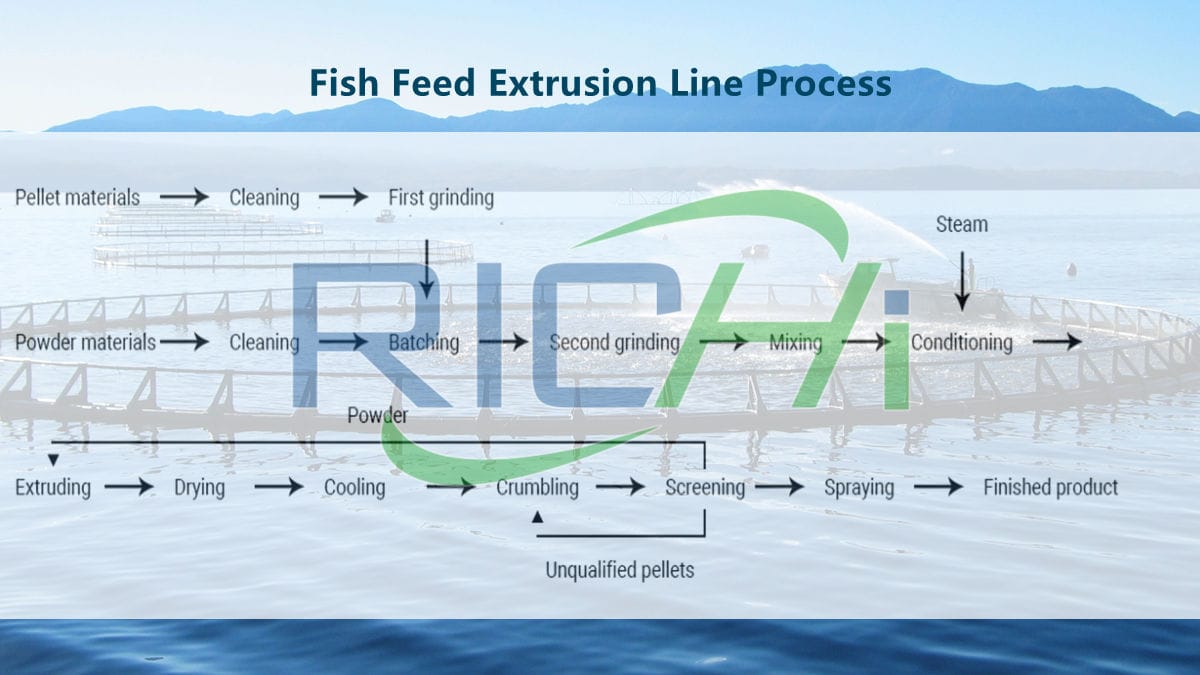

We strive to provide our customers with the newest technologies, the floating aquatic feed production process should generally be: cleaning of raw materials, primary crushing – ingredients – primary mixing – fine crushing – weighing – mixing – puffing and extrusion granulation – drying – grading – (Grease, heat-sensitive substances) coating – cooling – packaging of finished products.

To produce floating, sinking and slow sinking aquatic feed by screw extrusion and puffing process, it is necessary to ensure that the powdery raw materials are mixed evenly and meet the particle size requirements. The crushing particle size is generally controlled at 20 mesh (0.85mm), and when the diameter of the die hole is less than 1.5mm, the crushing particle size is generally controlled at 95% passing through 60 mesh (0.25mm).

According to experience: when producing aquatic feed and pet feed, the aperture of the raw material crushing screen is 1/3 of the diameter of the die hole, and the maximum cannot exceed 1.5mm. The raw material receiving, cleaning, magnetic separation, batching, primary and secondary crushing process is basically the same as the production process of aquatic shrimp pellet feed.

The raw materials entering the extrusion and puffing section need to pass through a safety screen and a magnetic separation device to remove the agglomerates and ferromagnetic impurities generated during the conveying process. After cleaning, it is necessary for floating fish feed mill to configure a secondary homogenizing mixing device to ensure uniform feeding of the floating fish feed extruder machine.

The secondary mixing equipment is equipped with a weight-reducing or volumetric quantitative feeder to ensure continuous quantitative feeding to the conditioner, which performs hydrothermal treatment (conditioning) on the powdery mixture.

The pellets after extrusion and puffing are relatively soft, and should be conveyed by pneumatic conveying or belt to the dryer for drying. 7min, the temperature of the product that needs to be greased and added should be lowered to 30-40℃ (fat temperature 60℃), sprayed first, and then cooled.

When producing sinking and slow sinking aquafeed, attention should be paid to drying temperature and uniform drying to prevent “Maillard reaction” from occurring, thus affecting the quality of the product. The dried product needs to go through a grading sieve to remove the powder to ensure that the particles entering the next channel are clean.

If you need to add fat or flavoring agents and trace additives, you need to go through a grease sprayer or a vacuum spraying system. The former is sprayed on the outside of the particles. layer, a small amount of absorption penetrates into the interior, and the addition amount is 1%-15%; the latter penetrates into the interior of the pellets, and the spraying amount of fat and liquid can reach 5%-30%.

After adding liquid, the extruded fish feed pellets enter the cooler for cooling, and then enter the finished product warehouse for packaging or bulk shipment after classification.

RICHI floating fish feed mill ensures the feed you are producing has the right properties, giving it the appropriate attributes necessary to deliver the food to the correct location in the water.

RICHI Service

—— RICHI MACHINERY ——

Our excellent aftermarket service and support is what sets us apart from our competitors. Our cooperation with our customers does not end with the sale ——or the floating fish feed mill machine installation. The good customer relationship is extended through important after-sales service and support.

Please remember:

We will keep your business growing with our global service network! Our highly skilled and motivated employees stand ready to help you with:

- After-sales services, support, and follow-ups

- Spare and wear parts, maintenance, and repairs

- Floating fish food making machine and floating fish feed mill process optimization

- Training of fish feed plant operators

We offer our customers excellent field services, where our service technicians come to you and your floating feed plant for assistance. The depth and experience of our field service specialists is unmatched——backed by the full knowledge and technical support that only the floating feed equipment manufacturer can provide.

The application of extrusion technology used in the floating fish feed mill is an important milestone in the development history of the feed industry. In the future, the equipment of floating fish feed mill will continue to develop in the direction of large-scale, high-efficiency, automation and specialization.