Animal & Aqua Feed Mill Plant In Uzbekistan

- 10-15T/H Chicken Feed Plant

- 5T/H Premix Feed Plant

- 5T/H Sinking Fish Feed Making Plant

- 10T/H Poultry Feed Processing Plant

- 2-3T/H Floating Fish and Cattle Feed Milling Plant

- …

- Here is a summary of the key feed mill projects we have done in Uzbekistan

Animal & Aqua Fish Feed Mill Plant In Uzbekistan

Thanks to the Uzbekistan government’s vigorous promotion of the development of the aquaculture industry, Uzbekistan has become the country with the largest number of Richi Machinery’s complete feed mill system projects, covering Tashkent, Samarkand, Fergana, Urgench, Nukus, Karshi and other regions; and feed processing types include poultry feed, laying hen feed, broiler feed, cattle feed, sheep feed, sinking fish feed, floating fish feed and other categories.

After more than 25 years of market hardening, Richi Machinery has formed a customer-centric integrated marketing system in Uzbekistan. It has an experienced and skilled customer service team and a global sales service network. Customers provide personalized system solutions.

10T/H Poultry Feed Mill Plant In Uzbekistan

- Project date: 2018. 12. 23

- Feed Type: poultry chicken pellets

- Pellets Size: 2-6mm

- Installation cycle: 60 Days

- Workshop size(L*W*H): 12m*12m*25m

- Guiding Price: 120,000-300,000 USD

The field trial operation proves that the actual measured output of the10t/h poultry feed processing plant is up to 13 tons (In other words, the output of this compound feed factory has reached 18t/h), the operating current only accounts for 85% of the rated current of the motor, and each ton of poultry pellet feed can be 20kW•h less than the industry average power consumption.

The output of the Uzbekistan 10t/h poultry feed plant is calculated on the average yield of 11t/h (the initial design capacity is 10-12 tons), set to produce 8 months a year, 30 days per month, and 10 hours per day. Compared with conventional poultry chicken feed mill plant of the same grade in the industry, this 10t/h animal poultry feed production project can save 288,000 kWh of electricity.

Richi Machinery always designs feed production line solutions based on production requirements, site, finished products, etc., and ultimately reduces customer investment costs. It is foreseeable that this feed production line will create a lot of profits for Uzi customers. (Maybe you are interested in this case: Poultry Feed Manufacturing Plant In Tanzania)

5T/H Premix Feed Mill Plant In Uzbekistan

- Project date: 2018. 12. 23

- Feed Type: poultry premix powder

- Installation cycle: 30 Days

- Workshop size(L*W*H): 12m*12m*25m

- Guiding Price: 50,000-150,000 USD

This 5t/h poultry premix feed plant and the above 10t/h poultry feed mill project belong to the same customer. To be precise, the customer purchased equipment for two production lines at the same time, but the two feed production lines were installed at different locations and at different times.

The 10T/H poultry feed plant has been installed in 2020 and has been put into use; and this premix feed production line is installed in 2021 and completed in 2022. What I can tell you is that the delivery time and installation time of the equipment are made according to the customer’s requirements.

Just like this Uzbekistan customer, due to the problem of the palnt area, the customer has been delaying the delivery and installation time.

We understand the problem very well, and actively coordinate the delivery and installation of equipment, and provide sufficient technical support during the customer’s civil construction stage to speed up the construction process of the customer’s workshop.

Richi Machinery specialises in high value and safe premix solutions. Growing global demand for high-protein products, rising meat consumption, increased meat quality, safety awareness, and frequent outbreaks of disease are driving the demand for feed premixes and additives, especially in emerging markets.

For this customer, rising raw material costs and regulatory factors are both constraints and potential opportunities.

RICHI is familiar with the rules, requirements and standards of premix production and application, and applies them to the design, manufacture and installation process of premix feed plant solutions, enabling customers to efficiently process raw materials and increase the added value of raw materials.

At the same time, we will introduce accurate, environmentally safe and high-quality premix products to the market.

10-15T/H Chicken Feed Mill Plant In Uzbekistan

- Project date: 2018. 9. 25

- Feed Type: broiler chicken pellets and chicken powder

- Pellets Size: 2-4mm

- Installation cycle: 70 Days

- Workshop size(L*W*H): 22m*10m*23m

- Guiding Price: 100,000-300000 USD

The Uzbekistan customer’s initial demand was a 5-7t/h chicken feed plant, and according to the customer’s needs, we have successively provided 8 chicken feed mill solutions. After one month of negotiations, the output of the commercial poultry chicken feed mill became 10t/h (due to the investment increase). The engineer team of RICHI re-modified the plan according to the latest needs of customers.

The program design time of this Uzbekistan chicken broiler feed making plant project took 3 months. We provided a total of 22 customized 10tph chicken feed mill solutions to Uzbekistan customer. In the end, meticulous and rigorous attitude, stable and reliable equipment, excellent product quality, and excellent feed engineering quality made RICHI stand out.

The chicken feed mill we designed for our customers is a centralized design, which can save space and land, and at the same time facilitate the daily maintenance of the equipment and reduce the operating cost of the customer. The whole set of chicken feed mill equipment is provided by the RICHI professional engineer team to ensure reliable quality, smooth process, effectively reduced failure rate, production up to standard, and user standards.

10-15T/H Animal Feed Mill Plant In Uzbekistan

- Project date: 2019. 7. 1

- Feed Type: poultry pellet feed & mash feed

- Pellets Size: 2-5mm

- Installation cycle: 55 Days

- Workshop size(L*W*H): 35m*20m*25m

- Guiding Price: 150,000-400,000 USD

The customer of the 10t/h animal feed mill plant is from Urgench, Uzbekistan, who has been engaged in the animal feed industry for a long time and previously had his own small feed mill with 1-2 t/h production capacity.

Since the profitability is very good and based on the confidence in the prospects of the animal feed production industry, this time he plans to expand the feed mill production scale, eliminate the original feed mill plant equipment, and build a new and advanced 10-15t/h animal compound feed production plant.

This is a customized 10-15t/h automatic animal feed plant, used to produce mash feed and 2-6mm poultry feed pellets, the raw materials are corn, wheat, soybean meal, sunflower seed meal, oil, premix.

Main feed mill plant equipment used in this feed production project include galvanized silo*500T, hammer mill feed grinder, batching scale, animal feed mixer, animal feed pellet machine, pellet cooling machine, pellet crumbler, screening machine and feed mill bagging machine, etc.

At the beginning of the purchase of the feed equipment, the customer compared a number of feed mill equipment manufacturers, and finally selected Richi Machinery, which recognized the strength of the RICHI brand. Up to now, the feed production line has been used for 2 years, and it has finally lived up to expectations, creating better benefits for customers.

5T/H Sinking Fish Feed Mill Plant In Uzbekistan

- Project date: 2017. 11. 21

- Feed Type: fish feed pellet and powder

- Pellets Size: 1.5mm

- Installation cycle: 30 Days

- Workshop size(L*W*H): 8m*5m*14m

- Guiding Price: Start with 100,000 USD

This Uzbekistan 5t/h sinking fish feed plant is located in Tashkent, and this is his second cooperation with Richi Machinery. What he bought for the first time was a 3-5t/h chicken feed plant, and this time he bought a complete set 5t/h sinking fish feed plant for carp feed, a kind of sinking fish food for ponds, because he also operates his own large carp farm.

Before signing the contract, the Uzbekistan customer has made many investigations to RICHI, and visited one of our 10t/h automatic fish feed mill project in China, and he expressed his satisfaction with our professional, systematic, stable and reliable products and services through on-the-spot investigation on high-grade sinking fish pellet feed plant with 5t/h.

The sinking fish feed pellet production process of the 5t/h sinking fish feed mill mainly include material grinding, material mixing, sinking fish food pellets pelleting, sinking fish food pellets cooling, and sinking fish food pellets packing.

Main fish feed plant machines used in this project: fish feed grinding machine*110kw, fish feed mixing machine*1000kg/batch, sinking fish feed pellet machine*110kw, cooling machine*SKLN17*17, feed pellet crumbler*SSLG15*150, screening and packing machine, etc.

It is worth mentioning that this sinking fish feed production line adopts the secondary crushing process, from feeding material to finished product, the whole process is completed in one go, saving kinetic energy, reducing unnecessary loss of raw materials, saving electricity and fuel, and saving costs by 10-15%. (Related post: sinking fish feed production plant)

The customer adopts a standard compound animal feed milling plant to ensure that the dust, noise and other pollution can be effectively controlled during the operation of the feed mill factory, which meets the requirements of local environmental protection standards.

Uzbekistan 2-3T/H Floating Fish And Poultry Compound Feed Mill Plant

- Project date: 2019. 1. 16

- Feed Type: fish and poultry pellets

- Pellets Size: 1-4mm

- Installation cycle: 30 Days

- Workshop size(L*W*H): 15M*9.5M*8M

- Guiding Price: 25,000-150,000 USD

This 1t/h floating fish and 1-2t/h poultry compound feed mill project started in January 2019, the installation cycle is 30 days, covers an area of 15*9.5*8 meters, and the fish poultry feed making plant project was put in production in March 2020.

This client owns his own farm, and for him, even buying small-volume production is not a small investment. There are only two requirements for customers who do not know the output and finished product specifications very well, that is, the quality of the feed mill plant equipment is good, and the quality of the processed pellets is also good.

Finally customer selected the configuration plan designed by Richi Machinery, which has high output and good feed processing plant equipment performance. The reasonable collocation effectively stimulates the potential of each feed equipment.

The main compound feed mill use equipment includes: hammer mill feed grinder, feed mixer machine, floating fish feed making machine, poultry feed pellet making machine, pellet cooler, vibrating shifter, automatic packing machine, 1t/h steam boiler, etc

For RICHI, we are the same for every customer regardless of the output of the customer’s feed production line. When building a feed mill unit, the design of the feed production line is very important. Richi Machinery has senior engineers who can tailor it for each customer, combining raw materials, feed types, output, etc. for your reference. (Want to start a Fish Feed Production Plant? Click for details)

Uzbekistan 2-3T/H Floating Fish And Cattle Feed Mill Plant

- Project date: 2017. 8. 7

- Feed Type: cattle and floating fish feed pellet

- Pellets Size: 1-8mm

- Installation cycle: 30 Days

- Workshop size(L*W*H): 7.5m*7m*7.7m

- Guiding Price: start with 100,000 USD

This small capacity 2-3t/h fish and cattle feed plant project is located in Tashkent. With comprehensive advantages in feed mill machinery manufacturing, feed production technological innovation and feed formula design, RICHI MACHINERY customized a 2-3t/h cattle and fish feed processing line for compound feed production, and it just requires 4 workers to operate.

In this floating fish and cattle feed mill project, it is worth mentioning: Generally speaking, cattle feed pellet machines are used to process cattle pellet feed, but this case, the customer adopts a feed extruder to making cattle feed pellets with 8mm size.

The fish and cattle feed plant project takes 1 month in total, covers an area of 15*9.5*8 meters, and consumes 150kw/hour. The main cattle fish feed mill machine includes 37kw feed grinding machine, 500kg/batch feed mixer equipment, 90kw floating fish feed extruder, cattle feed extruder, feed dying machine, SKLN11*11 pellet cooler, vibrating shifter, etc.

The entire feed mill plant of this project is simple to set up and has an orderly production. It can be easily completed with an output of 2-3 tons per hour. It is a time-tested classic configuration. It has its different advantages. In terms of configuration, the operation is stable.

All 2-3t/h feed mill machines is equipped with Siemens motors as standard, and the production power is strong; the whole feed plant price is cheap, worry-free and labor-saving. The investment of the entire feed production line is less than 120,000 US dollars, which is one-fifth less than the expected investment, and has achieved a real cost-effective. pleted, the user will be checked, and the quotation of the entire production line equipment will be sent in a short period of time. (Maybe you are interested in building a Shrimp Feed Mill)

3-5T/H Broiler Feed Mill Plant In Uzbekistan

- Project date: 2018. 12. 17

- Feed Type: broiler chicken pellets

- Pellets Size: 1-6mm

- Installation cycle: 40 Days

- Workshop size(L*W*H): 9m*6m*13m

- Guiding Price: 50,000-250,000 USD

This 3-5t/h broiler feed production line project is located in Samarkand. RICHI’s first animal feed mill project in this area was installed in the end of 2017, and one year after that poultry feed pellet plant project was put into operation, RICHI once again cooperated with customers in the area for a 3-5t/h chicken broiler feed plant project. This is a project without any competitors, this customer directly contact RICHI to discuss the poultry broiler feed line project cooperation.

The production process plan of this feed mill factory we designed for the customer is mature, the feed mill machinery selection is reliable, the production process is more reasonable, and the equipment is connected in place, the layout is centralized, the floor space is reduced, and the operation is stable at the same time, and the daily maintenance is more convenient.

Today, The field trial operation proves that the actual measured output of RICHI’s 3-5t/h broiler feed production line is up to 5.5 tons, the operating current only accounts for 55% of the rated current of the motor.

This 3-5t/h complete broiler feed mill plant project covers an area of 9*6*13m, and the main poultry feed making equipment includes: bucket elevator*TDTG36/18, permanent magnetic sleeve*TCXT20, pre-crushing bin*1m³ , rotary feeder*SWLY20*40, chicken feed grinder*SFSP56*60, pulse dust collector, screw conveyor (Air locked)*TLSS20, bucket elevator*TDTG36/18, drum feed mixer*SLHY.1, broiler feed pellet machine*SZLH320 , pellet cooling Machine*SKLN14×14, broiler feed pellet crumbler*SSLG15X80, rotary screen*SFJH800*2C, etc.

According to the feedback from the sales staff, recently, in order to expand the poultry chicken feed production scale, introduce advanced poultry feed processing equipment, and improve economic efficiency, the customer planned to add a new poultry feed manufacturing plant. Based on the trust in RICHI products and services, the client is currently discussing this new animal feed mill project with us.

3-5T/H Poultry Chicken Feed Mill Plant In Uzbekistan

- Project date: 2015. 10. 13

- Feed Type: layer and broiler pellets

- Pellets Size: 3-4mm

- Installation cycle: 50 Days

- Workshop size(L*W*H): 9m*5m*13m

- Guiding Price: 50,000-120,000 USD

If you want to ask, which was the first feed mill project established by Richi Machinery in Uzbekistan? The answer is this, 3-5t/h poultry chicken feed plant.

This Uzbekistan layer broiler chicken feed mill is located in Samarkand, a key area of poultry farming. Because there are many poultry farms in the area, the customer’s decision to invest in the poultry feed plant business for chicken broiler feed production is very wise.

It is worth mentioning that during the complete customized poultry chicken feed plant project design stage, due to local breeding in Uzbekistan and chicken eating habits, the customer put forward requirements for the hardness of pellet feed.

Because our initial design was based on the most common chicken feed pellet compression ratio, but the hardness is somewhat high for customers, so the compression ratio is changed according to customer requirements.

It is worth mentioning that, after a clear understanding of the customer’s needs and site inspection, Richi Machinery designed a cost-effective chicken feed production line for the customer. As soon as the feed processing plant plan is completed, the user will be checked, and the quotation of the entire production line equipment will be sent in a short period of time. (Maybe you are interested in building a Floating Fish Feed Production Line)

3-5T/H Chicken Pellet Feed Mill Plant In Uzbekistan

- Project date: 2018. 11. 23

- Feed Type: poultry chicken pellets

- Pellets Size: 3-4mm

- Installation cycle: 10 Days

- Workshop size(L*W*H): 87KW

- Guiding Price: $25000-60000 USD

In order to expand chicken feed production scale, improve market competitiveness, increase productivity and benefits, the customer in Urgench accelerated the implementation of new poultry chicken feed making machine for 3-4mm broiler feed pellets. On the basis of many previous friendly cooperation, the customers reached a new cooperation consensus with RICHI to introduce professional and efficient chicken animal feed mill equipment.

The Uzbekistan 3-5t/h chicken feed milling plant consists pelletizing system and pellet cooling system, including 37kw chicken feed pellet machine, with output of 3-4 tons per hour, one chicken feed pellet cooler, and some accessories.

This chicken feed mill system project, from the selection of the production line plan, to the configuration of the feed equipment, to the later on-site installation, trial operation, etc., the entire process is undertaken by Richi Machinery.

The customer’s investment and engineering construction are quite clear, and the customer only needs to wait until You can start the operation during the start-up period, and the whole process is labor-saving and worry-free. The environmental protection design level of this chicken feed pellet making plant is quite high, which conforms to the local environmental assessment standards.

The operation noise and dust pollution of the entire chicken feed production line have been reasonably controlled, which will not affect the surrounding environment, which improves the economic benefits of customers and also takes into account the social benefits.

The following is the customer’s feedback: I think RICHI sales staff, engineers and after-sales staff have a very good service attitude, and the design scheme is more reasonable, and will consider it for customers sincerely, only design suitable chicken feed plants for users, and compared several feed machine manufacturers.

In terms of feed mill production machine quality, scheme design, price investment, etc., Richi Machinery is more cost-effective in a comprehensive comparison. (Maybe you are interested in building a Fish Feed Plant)

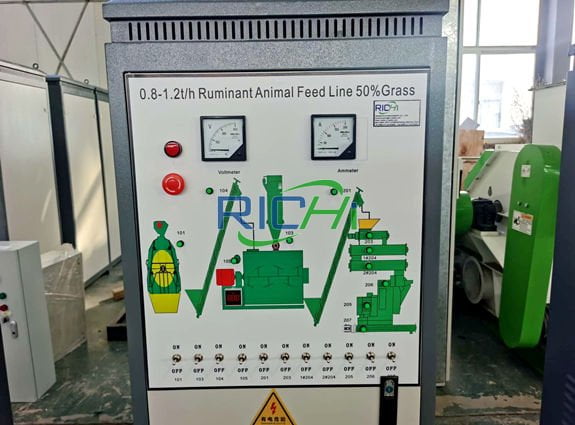

0.8-1.2 T/H Cattle Sheep Feed Mill Plant In Uzbekistan

- Project date: 2020. 9. 21

- Feed Type: poultry, fish and cattle sheep feed pellets

- Pellets Size: 2.5-8mm

- Installation cycle: 20 Days

- Workshop size(L*W*H): 6m*5m*5.5m

- Guiding Price: $15,000-80,000 USD

The 0.8-1.2t/h animal cattle sheep chicken fish feed manufacturing plant project is located in Karsi, and the customer has not had any contact with the animal feed production industry before. Like many Uzbekistan customers, this customer also saw the prospects of the local animal feed industry, so he wanted to invest in a small scale feed mill to try.

The customer’s farm raises cattle, sheep, chickens and fish, so this feed plant proejct pellets must be used to process a variety of feeds, including 8mm cattle and sheep feed, 3mm sinking fish feed, 2.5mm chicken feed, and mainly processed ruminants. According to to the customer’s need and budget, we finally customized a small capacity but high-efficiency feed mill for him.

It is worth mentioning that the installation of this 0.8-1.2t/h farm use poultry fish cattle feed processing plant is very easy, all of which adopt the pair-mounted type, which is easy to install and easy to maintain. According to customer feedback, this small capacity animal feed plant was installed in only 3 days, and it was put into use directly one week after installation.

4-6 T/H Poultry And Cattle Feed Mill Plant In Uzbekistan

- Project date: 2018. 3. 13

- Feed Type: poultry powder and goat cattle pellets

- Pellets Size: 3-8mm

- Installation cycle: 30 Days

- Workshop size(L*W*H): 12m*10m*23m

- Guiding Price: $60,000-150,000 USD

The Tashkent, customer visited Richi Machinery in 2017 and signed a contract in 2018 for this 4-6t/h customized cattle sheep poultry feed mill project. This is the decision made by the Uzbekistan customer after nearly a year of research and investigation on many domestic and foreign animal feed equipment and complete poultry feed mill manufacturers.

During the construction, RICHI installation team overcome a series of difficulties. After three months of struggle, they completed the new design high technology poultry powder feed mill and cattle sheep feed plant in Tashkent on schedule, and won the praise of our customer and local farmers!

It is worth mentioning that after this pleasant cooperation, the customer has carried out a second cooperation with RICHI: 5 tons/hour sinking fish feed project in Uzbekistan.

The combined compound feed production project includes 3-5t/h poultry mash feed mill and cattle feed mill plant, which can produce cattle and sheep ruminant feed, pure straw, forage pellets, various biomass pellets, fine cattle and sheep feed, fine poultry powder feed, etc., to fundamentally help local farmers to solve the breeding problem.

The equipment motors of this poultry and cattle feed processing plant are all Siemens energy-saving motors with low unit energy consumption. At the same time, the closed animal feed production mode is adopted, and a pulse dust collector is installed.

The dust emission is less than or equal to 10mg/m3, which is lower than the local emission standard and meets environmental protection requirements . In addition, this feed production line has large output, good product quality, uniform particle size and high economic value. (Maybe you are interested in building a Fish Feed Mill)

3-5T/H Animal Chicken Broiler Feed Mill Plant In Uzbekistan

- Project date: 2020. 7. 6

- Feed Type: chicken powder and pellets

- Pellets Size: 1-4mm

- Installation cycle: 42 Days

- Workshop size(L*W*H): 9m*7m*13m

- Guiding Price: $50,000-120,000 USD

In the face of increasingly fierce market competition, Samarkand’s customer plans to build a 3-5 t/h chicken broiler feed plant to produce both powder feed and pellet feed. The customer previously bought a small flat die chicken pellet machine in Richi, and he trusted Richi’s product quality and after-sales service. The customer found us again to reach a cooperation. The Uzbekistan 3-5t/h chicken feed mill project was signed on July 6, 2020 and has been put into production in the August 2021.

Before the 3-5t/h chicken broiler feed plant project started, we provided the customer with a comprehensive design program from the overall planning, layout design, process design, broiler feed mill plant equipment personalization, installation and commissioning, electrical control, to production technology, etc.

The chicken feed processing line we designed for our customers is easy to operate, does not require a lot of manual labor, has a high degree of automation, long working hours, short downtime, and shortens the estimated construction period. The output of the whole chicken feed mill plant is not high, and the dust of the pulverizer is less, and the advanced noise reduction device can effectively control the environmental pollution.

The investment cost of this broiler feed plant is relatively low, while maintaining high efficiency and high quality. For customers, less investment is the best. On the basis of low cost, quality is guaranteed, maintenance is reduced in the later period, and income is indirectly increased.

Although it is a few simple devices, it fully meets the user’s feed production requirements, and the advantages of each feed making device play well and are loved by customers. (Maybe you are interested in building a Fish Feed Factory)

3-5 T/H Poultry Chicken Feed Plant In Uzbekistan

- Project date: 2018. 12. 11

- Feed Type: poultry feed pellet

- Pellets Size: 1-6mm

- Installation cycle: 60 Days

- Workshop size(L*W*H): 9m*6m*13m

- Guiding Price: $50,000-120,000 USD

The Urgench customer of this chicken feed production project is mainly engaged in chicken breeding, chicken feed processing, chicken slaughtering, and meat product processing.

For management, the customer has continuously invested to upgrade his automatic chicken feed mill plant, introduce advanced chicken feeds production technology, chicken feed factory equipment and develop new technologies.

In the process of implementing the chicken feeds production project, the Urgench customer carried out on-the-spot investigation on the construction sites of many China well-known feed mill machine suppliers in the industry.

- The whole chicken feed plant design scheme is tailored according to the size and requirements of the user’s field site, with a compact and reasonable layout, reducing the land occupation and saving unnecessary economic investment.

- The design scheme of this chicken feed plant is excellent and then optimal, regardless of the matching between the main engine and auxiliary equipment, the overall production line runs well, the failure is reduced, and the production is more efficient.

- From equipment selection to production line design, we follow the principle of less pollution and low noise to create a green feed pellet production line.

- The investment cost of the entire chicken feed production line can be saved by 5%. At the same time, the high-efficiency operation mode and the excellent finished feed can double the user’s income and be trusted by the surrounding farmers. (Maybe you are interested in building a Fish Feed Manufacturing Plant)

1-2T/H Layer Feed Mill Plant In Uzbekistan

- Project date: 2020. 9. 21

- Feed Type: powder feed for laying hen

- Installation cycle: 15 Days

- Workshop size(L*W*H): 6m*4m*5.5m

- Guiding Price: $7000-50,000 USD

The 1-2t/h layer feed powder mill plant is located in Urgench, RICHI designs the output according to the actual needs, with high energy saving and high quality. The customer built the 1-2t/h laying hen powder feed production line for laying hen feed making, and all the processed feed will be used in his chicken farm.

The main laying hen feed mill machines includes 37kw chicken feed grinding machine, 500kg/batch chicken feed mixer machine, screw conveyor and some accessories. This feed production project can be regarded as a manual chicken feed plant, which is very suitable for the customer who owns small chicken farm and has low investment. The powder feed mill cost is very low, but it can greatly reduce his feeding cost.

This 1-2tph chicken powder feed plant can be directly used to feed laying hens. If the customer needs to sell the chicken mash feed, a packing machine can be added later. With the continuous innovation and progress of technology, it has become a trend to choose RICHI chicken feed processing technology to make layer and broiler feed.

All equipment of this small capacity hen feed production line is made of high-quality steel, and the wear-resistant parts are made of high-chromium steel, which is impact-resistant, wear-resistant, and has a large impact force. The replacement parts have a long cycle and reduce maintenance investment. The design of the whole layer feed process plant follows the characteristics of “scientific, reasonable, environmentally friendly, and high efficiency”, which makes our customer quite satisfied. (Maybe you are interested in this case: pellet production line in Thailand)

RICHI Feed Mill Plant In Uzbekistan

For the profitability of agriculture and animal husbandry, cost control is very important, and the proportion of feed costs is particularly prominent. The rational design of feed factories and the selection of energy-saving and efficient feed production equipment are also the focus of consideration. The use of RICHI feed mill plant equipment has improved production efficiency and greatly satisfied the development needs of Uzbekistan’s one-stop agricultural and animal husbandry industrialization.

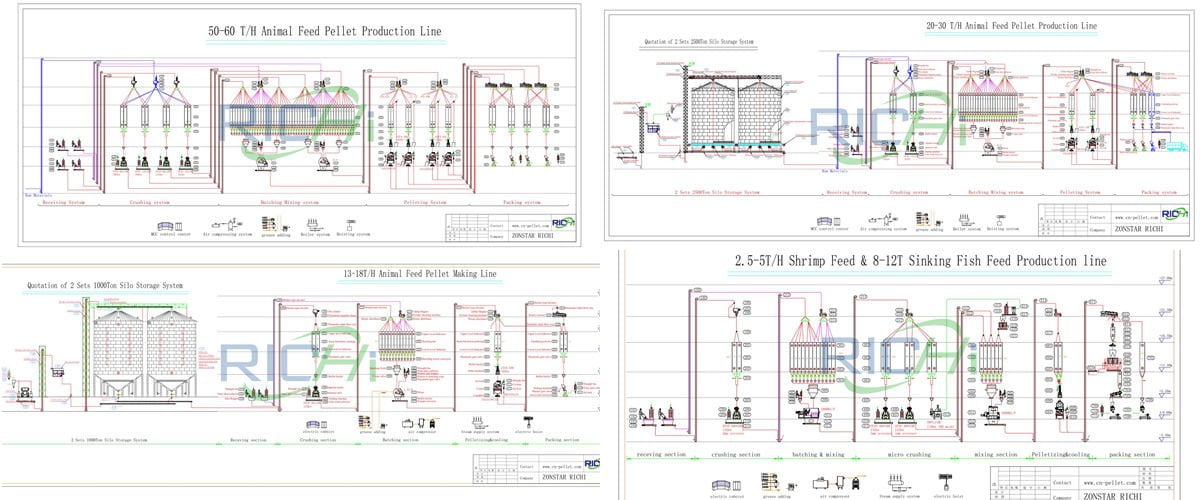

Our feed production plant projects in Uzbekistan are more than the above, but also other feed production cases. Here are some of our other Uzbekistan pellet machine projects showcased:

Popular Products In Uzbekistan

Service And Support

Richi Machinery have more than 25 years of complete feed mill System projects service experience to help you develop your business in all aspects and realize personalized value. (Maybe you are interested in building a Fish Feed Mill Plant)

Personalized customization & provide 3D renderings

We can design feed mill plant project planning schemes according to the different needs of customers, and provide 3D renderings to enhance the user experience. Help customers to accurately sort out their own needs, repeatedly scrutinize the rationality and scientificity of the process with customers, try to optimize the design of the product system, and meet customers’ reasonable personalized needs at all costs.

With perfectionism and ingenuity, we create a turnkey pellet plant project, seek our own value for our customers, and use the ‘differentiated competitive strategy’ to improve our market competitiveness for our customers, so as to achieve strong alliances and common development.

On-the-spot investigation & adapting measures to local conditions

We design comprehensive problem solutions for animal feed pellet plant engineering according to different requirements of customers, different raw materials, and different sites. Our professionals go deep into the construction site and do a good job of planning.

In practice, we can truly adjust measures to local conditions, and adopt different design schemes and construction methods according to different survey results to ensure that it is scientific and reasonable, economical and practical, and meets environmental protection. So as to create a safe, efficient and stable feed mill plant for customers.

Professional team & door-to-door installation

Richi Machinery has a professional technical team with 25 years of practical experience in design, manufacture and installation. Unified management and unified training. Strict technical assessment is carried out every year, and it has rich on-site installation and maintenance experience, professional quality and high sense of responsibility.

With a high degree of professionalism, we help customers to quickly put into production and achieve production benefits, allowing customers to seize market opportunities and win at the starting line. (Maybe you are interested in building an Aqua Feed Plant)

Technical Service & Whole Process Guarantee

Whether in pre-sale or after-sale technical support, we are always ready to provide customer satisfaction services. To ensure the highest work efficiency in a rigorous order, 24-hour reception of customers’ technical inquiries, on-site service, feed mill machines maintenance, production failures, service complaints and a series of problems to improve customer satisfaction.

Through telephone consultation and door-to-door service, we can find and solve problems in a timely manner to ensure the rights and interests of customers. Provide professional and targeted services for different users, and escort customers throughout the process.

One-to-one guidance & worry-free production

After the installation and commissioning is completed, we will provide one-to-one technical guidance according to the actual situation of the customer, and be responsible for training the operators until the customer can fully operate the feed mill plant and pellet machine production by himself. Truly ‘customer-centric’, to provide customers with excellent service.

Follow-up questions will be answered by professionals, and feedback will be recorded in a timely manner, and solutions will be provided. If there is a need for on-site guidance, the company will arrange relevant professionals to provide timely guidance at the designated location according to the specific circumstances.

Quick response & lifetime maintenance

In terms of service quality control, we insist on life-long service and infinite improvement. In addition to the warranty period, we provide customers with life-long service. As long as the equipment is in use, RICHI’s service to customers will not be terminated. In the service, we insist on the first response and the fastest speed to solve the problem.

At the same time, a product dynamic improvement system is established. After solving the typical problems reported by customers, the animal and aqua feed mill plant or feed mill machine design will be improved immediately, and the product will be continuously improved.

For the problems in the service process, the RICHI service process will be improved and optimized immediately after they are solved. (Maybe you are interested in building a Floating Fish Feed Mill)

Want to buy pellet machine or start your feed mill plant?

Feel free to contact Richi Machinery