Basic Information Of 1.5-2T/H Shrimp And Fish Feed production line In Iran

— Richi Machinery —

On December 27, 2021, the story of the 1.5-2T/H Shrimp And Fish Feed Production Plant Project in Iran began.

Client’s consultation content:

Hello, we need shrimp and fish food production machines with the following specifications:

1) Production capacity: 2000 kg/hours

2) Machines according to modern standards and technology.

3) Dimensions of the factory building, length 66 meters, width 13 meters, height 7 meters, please, send us the list of machines with full technical specifications along with photos, videos and prices c&f Khoramshahr port iran.

- Shrimp & fish feed production line price: approximately $330,000

- Production cycle: 60 days

- Delivery time: by sea, 40 days

- Installation period: 90 days

- Number of employees: 12

- Working system: single shift, 8 hours per shift, 250 days per year

- Project voltage: 380V/50HZ/3P

- Aqua fish feed making raw materials: fish meal (tank/barrel), starch (barrel), soybean meal (bag), oil (barrel), corn (bag), rapeseed meal (bag), bran (bag)

Product Plan

This aquafeed production line is carefully designed for the customer according to the on-site investigation or the actual requirements of the customer, which fully reflects the rationality, effectiveness and applicability of the design. Large output, low wear, and low operating costs are its notable features.

After the completion of this compound animal pet aqua fish food processing line, it mainly produces extruded feed for floating fish, feed for sinking fish and shrimp, but at the same time, the possibility of producing pet feed, poultry feed, chicken feed, cattle feed and goat feed is reserved in the future. (Notice: There is only one die on the pet & floating fish feed extruder and feed pellet machine, the Iranian client need to choose one size from the list.)

| Feed From The Combined Feed Production Line | Feed Size | Capacity | Remark |

|---|---|---|---|

| Floating fish feed/Pet food | 1.0-12mm | 1.5-2T/H | Based on different formula |

| Sinking fish feed | 1.5-12.0mm | 3-4T/H | / |

| Shrimp feed | 1.0-12.0mm | 1-2T/H | / |

| Middle chicken | 2.5-3.0mm | 5-6T/H | Chicken in 10-30 days |

| Big chickens | 3.5-4.0mm | 5-6T/H | Chicken in 30-45 days |

| Layer feeds | Powder feeds | 5-6T/H | Also can feed chicks |

| Cattle/Goat | 6.0-8.0mm | 5-6T/H | Without grass in recipe |

| Cattle/Goat | 6.0-8.0mm | X | With grass powder in recipe (Based on different percentage of grass) |

Richi Machinery

why start fish feed production line in iran?

Iran is a fishery developing country, and its aquaculture industry, fishing industry and aquatic product market have great potential. Supporting aquaculture and encouraging seafood and white meat consumption to reduce red meat imports by 150,000 tons a year has become a policy of the Iranian government.

Obviously, this kind of policy will inevitably drive the growth rate of the country’s aquaculture industry. It can be seen that in order to significantly increase fish and shrimp production, Iran will need a lot of resources, including operations, sites and construction, development and mechanization equipment. Among them, feed supply, which accounts for 65% of the cost, has a great impact on production increase and market prices.

Based on this background, the project client, a well-known Iranian aquatic product enterprise and one of the best aquatic product exporters in Iran, after several rounds of negotiation, is very satisfied with our fish feed production line design and fish feed making machine configuration, and finalized the contract with us on April 19, 2022 —— 1.5-2t/h extruded floating fish food processing line & 5-6t/h animal pet poultry livestock shrimp and sinking fish feed production combined project.

process Design Of 1.5-2T/H Floating Fish Feed Production Line In Iran

— Richi Machinery —

A detailed analysis of your production goals is the basis for a tailor-made, future-proof fish food production system solution adjusted to your specific requirements. Reasonable configuration and optimized process design enable each piece of equipment to achieve high performance, ensuring that the whole fish feed line production is smooth and stable.

The final scheme of this fish feed production line was modified 5 times, and Richi Machinery specially custom designed this fish feed production line according to the customer’s request.

This production line has a high degree of automation, low operating costs, large output, energy saving and low consumption, less pollution, and easy maintenance. The important thing is that the final feed quality is good, which can fully meet the needs of high-end aquaculture.

Feeding of raw materials:

The raw materials are transported to the feeding port for feeding by a bucket elevator, and this process generates feeding dust.

Raw material cleaning:

The existence of a small amount of impurities has a great impact on the quality of the finished feed, and it is necessary to clean up the impurities before production. The raw material cleaning process is mainly to screen and remove impurities from soybean meal and rapeseed meal.

Pulverization of ingredients:

The raw materials need to be pulverized by a hammer mill grinder, so that the components can be mixed evenly, and the automatic classification after mixing is reduced.

Mixing of ingredients:

It is mainly for the preparation of materials with a large proportion in the formula. There is a batching scale under the batching bin of each material, and each material is weighed by the batching scale and sent to the mixer by the conveyor for mixing.

Extrusion section:

The mixed semi-finished product enters the advanced floating fish feed extruder machine, and is heated and sterilized by high-temperature steam, pressurized, and then extruded from the die hole, and then suddenly depressurized to rapidly vaporize the water molecules inside, so that the material expands and becomes porous pellets feed.

Drying & Oil Coating section:

After extrusion, the feed needs to be dried with a fish feed dryer. Fish have limited ability to utilize sugar, and their energy sources are mainly provided by the decomposition of fat and protein.

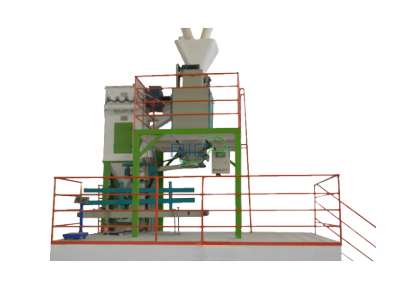

Cooling & Screening & Packaging section:

After the feed grease is sprayed, a countercurrent flap cooler is used for cooling. The cooled feed pellets enters the grading screen for classification. The finished product is packaged by workers using a packaging machine to leave the 1.5-2t/h Iran fish feed production site.

On-site pictures

Below are some on-site pictures of the Iran fish feed production line project:cording to the actual needs of customers, including voltage

Equipment needed to start 1.5-2T/H Floating Fish Feed Production Line In Iran

— Richi Machinery —

Richi Machinery’s fish feed production line has a multi-level equipment combination, which solves the current problems of discontinuous operation and low overall efficiency. In addition, the production line equipment is easy to operate, has a long trouble-free running time, and is easy to maintain, which can effectively reduce production costs.

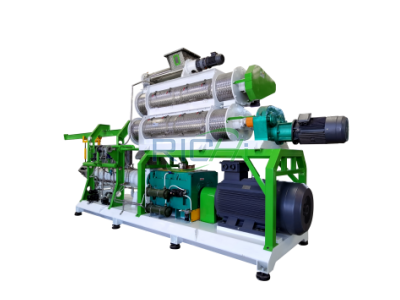

The production line adopts RICHI’s new floating fish feed making machine (floating fish feed extruder), adopts PLC Touch Screen Technology to realize man-machine dialogue and switch between manual and automatic operation.

In addition, the accessories of the production line equipment have a long service cycle, low wear rate, low maintenance rate, convenient maintenance, save downtime, and can effectively reduce production costs.

Equipment list:

| 1. Crushing system | |||||

| NO. | NAME | MODEL | QTY | POWER(KW) | |

| SINGLE | AMOUNT | ||||

| 101 | Draught fan | 4-72-3.2A | 1 | 2.20 | 2.20 |

| 102 | Pulse dust collector | TBLMa.12B | 1 | / | / |

| 103 | Air lock | GF.5 | 1 | 0.75 | 0.75 |

| 104 | Feeding hopper with grids | 1 | / | / | |

| 105 | Screw conveyor | TLSS20 | 1 | 2.2 | 2.2 |

| 106 | Drum type precleaner | SCY63 | 1 | 0.75 | 0.75 |

| 107 | Permanent magnetic sleeve | TCXT20 | 1 | / | / |

| 108 | Screw conveyor | TLSS20 | 1 | 3 | 3 |

| 109 | Pre-Crushing bin | 1m³ | 1 | / | / |

| 110 | Lower level indicator | KF1500 | 1 | / | / |

| 111 | Pneumatic gate | TZMQ30A | 1 | / | / |

| 112 | Rotary feeder | SWLY20*60 | 1 | 1.50 | 1.50 |

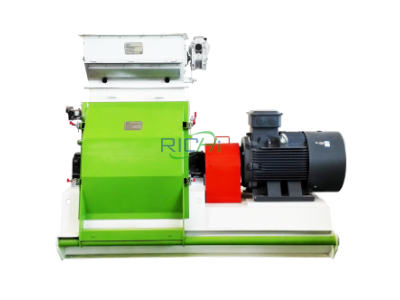

| 113 | Hammer mill feed grinder | SFSP66*60 | 1 | 55.00 | 55.00 |

| 114 | Draught fan | 4-72-4A | 1 | 5.50 | 5.50 |

| 115 | Pulse dust collector | TBLMa.24A | 1 | / | / |

| 116 | Settling chamber | 1 | / | / | |

| 117 | Screw conveyor (Air locked) | TLSS20 | 1 | 2.20 | 2.20 |

| 118 | Bucket Elevator | TDTG36/18 | 1 | 1.50 | 1.50 |

| 119 | Screw conveyor | TLSS20 | 1 | 2.2 | 2.2 |

| 2. Mixing system | |||||

| NO. | NAME | MODEL | QTY | POWER(KW) | |

| SINGLE | AMOUNT | ||||

| 201 | Pre-Mixing bin | 1m³ | 1 | / | / |

| 202 | Lower level indicator | KF1500 | 1 | / | / |

| 203 | Pneumatic gate | TZMQ30A | 1 | ||

| 204 | Feed Mixer machine | SLHY1.0A | 1 | 7.50 | 7.50 |

| 205 | Buffer bin | 1m³ | 1 | ||

| 206 | Screw conveyor | TLSS20 | 1 | 2.20 | 2.20 |

| 207 | Bucket elevator | TDTG36/18 | 1 | 2.20 | 2.20 |

| 3. Pelletizing and Extruding system | |||||

| NO. | NAME | MODEL | QTY | POWER(KW) | |

| SINGLE | AMOUNT | ||||

| 301 | Upper level indicator | KF1500 | 1 | / | / |

| Anti-caking bin | 1.5m³ | 1 | 3.00 | 3.00 | |

| Lower level indicator | KF1500 | 1 | / | / | |

| 302 | Feed mill Pellet machine | SZLH420 | 1 | 90.00 | 90.00 |

| Stainless steel conditioner | TZ420*300 | 3 | 7.50 | 22.50 | |

| Feeder | WLQ20 | 1 | 1.50 | 1.50 | |

| 303 | Anti-caking bin | 1 | 1.50 | 1.50 | |

| Inverter feeder | LY219*1200 | 1 | 1.50 | 1.50 | |

| DDC-conditioner | DC400*300-244 | 1 | 11.00 | 11.00 | |

| Twin screw extruder | RCPH120*2 | 1 | 75.00 | 75.00 | |

| 304 | Belt conveyor | PDS-50 | 1 | 1.50 | 1.50 |

| 305 | Customized conveyor | JBS-50 | 1 | 5.50 | 5.50 |

| 306 | Buffer bucket | 1 | 0.00 | ||

| 307 | fish feed Dryer machine | DHG-2000Q | 1 | 5.5+3+2.2+1.5 | 12.20 |

| 308 | Customized conveyor | JBS-50 | 1 | 3.00 | 3.00 |

| 309 | Buffer bucket | 1 | / | / | |

| 310 | Pneumatic triple gate valve | YSTZ22A | 1 | / | / |

| 311 | Buffer bucket | 2 | / | / | |

| 312 | Air lock | GF.30 | 2 | 0.75 | 1.50 |

| 313 | Pendulum stabilizer | SWDB14*14A | 1 | 1.5+0.55 | 2.05 |

| 314 | Coating machine | RISP-2000 | 1 | 4+0.55+0.09 | 4.64 |

| 315 | Customized conveyor | JBS-50 | 1 | 3.00 | 3.00 |

| 316 | Buffer bucket | 1 | / | / | |

| 317 | Air lock | GF.30 | 1 | 0.75 | 0.75 |

| 318 | pellet Cooler machine | SKLN17*17 | 1 | 1.50 | 1.50 |

| 319 | Vibrating screener | TDZS80 | 1 | 0.18 | 0.18 |

| 320 | Draught fan | 4-72-5A | 1 | 15.00 | 15.00 |

| 321 | Cyclone | SK800 | 1 | 0.00 | |

| 322 | Air lock | GF.7 | 1 | 0.75 | 0.75 |

| 4. Packing system | |||||

| NO. | NAME | MODEL | QTY | POWER(KW) | |

| SINGLE | AMOUNT | ||||

| 401 | Customized conveyor | PDS-50 | 1 | 3.00 | 3.00 |

| 402 | Upper level indicator | KF1500 | 1 | / | / |

| 403 | Finish goods bin | 1m³ | 1 | / | / |

| 404 | Automatic Bagging Machine | DCS-50 | 1 | 1.50 | 1.50 |

| 405 | Sewing + belt conveyor | 1 | 0.55 | 0.55 | |

| 5. Electrical control system | |||||

| 501 | MCC Control Center ;Mimic control panel (power range from 22 kw for star triangle start, main electric components are delixi brand) | ||||

Main Spare parts:

| NO | NAME | Qty(set) | |

| 1 | Hammers | 10 | |

| 2 | Screener | 20 | |

| 3 | Roller assembly | 2 | |

| 4 | Roller shell | 12 | |

| 5 | Dies for extruder | 0.6mm | 1 |

| 1.0mm | 1 | ||

| 1.5mm | 1 | ||

| 2.0mm | 1 | ||

| 3.0mm | 1 | ||

| 4.0mm | 1 | ||

| 6.0mm | 1 | ||

| 8.0mm | 1 | ||

| 10.0mm | 1 | ||

| 12.0mm | 1 | ||

| 16.0mm | 1 | ||

| 20.0mm | 1 | ||

| 6 | Knife for extruder | 1,000 | |

| Knife shelf for extruder | 10 | ||

| 7 | Ring die for pellet machine | 0.5mm | 1 |

| 1.0mm | 1 | ||

| 2.0mm | 1 | ||

| 3.0mm | 1 | ||

| 4.0mm | 1 | ||

| 6.0mm | 1 | ||

| 8 | Safety pin | for pellet machine | 60 |

RICHI MACHINERY

video Of Iran fish feed mill plant project

We have a large number of 1-2t/h feed mill project videos and equipment operation videos to share. If you are interested in our equipment and solutions, please contact us directly for details!

RICHI MACHINERY

Customized Design Of 1.5-2T/H Floating Fish Feed Production Line In Iran

The scheme of this 1.5-2t/h extruded floating fish feed production line & 5-6t/h shrimp and sinking fish feed production project is based on our 1-2t/h extruded feed line design and has undergone 5 modifications.

1

The height limit of the workshop is 6 meters, and the conveying system scheme has been replaced

Originally, the customer only required to design a 2t/h extruded fish feed line, and in the standard plan of the 2t/h extruded line, the crushing and drying systems are on the second floor, but due to the height limitation of the customer’s factory building (up to 6 meters), and can’t break the top, so the basic plan is replaced by a horizontal plan.

(Generally speaking, in the standard design of 2t/h extruded fish feed line, all conveying equipment usually adopts the air conveying system, but due to the height limitation of the customer’s workshop, RICHI added horizontal screw conveyors and curling conveyors to reduce the height of entire shrimp fish feed processing line. In addition, the design of the raw material cleaning system and the cleaning system are also adjusted to suit the height of the production line.)

2

Increase the granulator and post-curing device to expand the product category

In addition, the fish feed production line plan has also been adjusted in terms of equipment configuration according to the budget. Because customers want to enrich their product range and increase the production of hard pellet fish feed and shrimp feed. But the cost of processing shrimp feed and sinking fish feed with an extruder is too high, and customers are well aware of this. But for RICHI, what we have to do is to use professionalism to solve customer problems.

Therefore, in response to the different dimensions of customers, we adjusted the feed pellet production line plan again, changed this fish feed production line to a composite production line, and added a three-layer conditioner ring die feed pellet machine and post-curing device to the production line.

(Actually, it is also possible to use a twin-screw extruder to process fish feed and shrimp feed, but many professionals know that in this case, the cost of feed processing is too high. Although there are also aquatic feed companies that do this, but more Aquatic feed processors will choose to use pellet mills to make shrimp feed and sinking fish feed, which is also a mainstream process in the current feed industry.)

In this process, the mesh belt dryer is also used as a post-cooker when processing shrimp feed, and together with the newly added post-cooker, it contributes to the maturity of the feed.

When processing fish feed, post-curing is generally not required, but if customers want to improve the quality of fish feed and increase feed remuneration, they can turn on the post-curing machine or mesh belt dryer.

In addition, the customer is also considering that it will start processing livestock and poultry feed in the later stage.

Compared with aquatic feed, post-curing is not required for processing livestock and poultry feed, but it does not matter, our engineers have also considered this point: the mesh belt dryer can still be turned on, but no heat is supplied to it, only the conveying function needs to be turned on, let the mesh belt run; then open the discharge port of the post-cooker.

3

In order to save customer costs, use the optimized equipment configuration to process more types of feed

Actually, our engineers hesitated when adding granulator and post-curing machine, because there is a more efficient process; but under the premise of taking into account high-quality process design and customer budget, our engineers optimized the design again, and finally decided , When processing different feeds, a set of coolers and packaging machines are shared to save customer costs.

4

Environmental protection facilities

It is worth mentioning that Iran has strict requirements on environmental protection. Therefore, the production line is equipped with dust removal equipment, which is very necessary in the environment that promotes green production.

- Feeding. The project is equipped with a special feeding room, in which large-diameter materials such as corn, sorghum, and soybean meal are set up with a special feeding room for closed feeding. The feeding room is closed during the feeding process, which can be regarded as 100% airtight. Small particle size powders such as vitamins, minerals, and trace elements are manually fed. After two sets of bag dedusting treatment facilities are set up, they are led to an 8m exhaust pipe for discharge. Very little dust is generated during the feeding process.

- Crushing section. The dust generated in the crushing process is collected and processed by a pulse bag filter, and the dust concentration is lower than 120 mg/m3, which meets the local Iranian standard.

- The imported super steam fish meal used in this project, because the raw material supplier has steamed the fish meal in advance, the fishy smell of the raw material itself is smaller than that of the conventional fish meal. The curing and drying process is the main odor generating process of the project. For such waste gas, photochemical oxidation and deodorization device should be used for treatment, and the treated waste gas will be led to the roof of the workshop through a 40m-high exhaust pipe.

● RICHI MACHINERY

Service

This project “5-6T/H Animal Shrimp Sinking Fish & 1.5-2T/H Floating Fish Feed Production Line In Iran” adopts the form of EPC general contracting, and Richi Machinery independently completes all procedures from design, supply, construction, training to after-sales service.

At different stages of pre-sale, mid-sale and after-sale of the animal & fish feed processing line project, we will successively provide customers with customized design schemes, production line equipment, configuration schemes of project personnel, plant office facilities, water, electricity, HVAC equipment, dust removal, noise reduction and sewage equipment. planning, dust removal, noise reduction and sewage system construction, equipment installation and testing, technical personnel training, stocking lists, steel lists and other documents and drawings.

● Consulting

Customer Consultation

We want to have a deep understanding of your industrial process, to know your exact needs of feed, wood, biomass, fertilizer or other pellet processing.

● Design

Plant Design

Based on your unique situation and industrial process, we will tailor complete feed plant you need, and inform you of every additional detail that could facilitate operation, minimize total cost.

● Manufacturing

Equipment Manufacturing

The critical components of the of the feed mill equipment are built in our own workshops in Asia. Additional equipment is manufactured by our worldwide network of reliable partners.

● Testing

Quality Inspection & Testing

Before leaving the factory, all equipment will be inspected by the quality inspection department. We can also provide customers with testing services from a single machine to a complete pellet plant system, and provide you with real actual data for “worry-free use.”

● Delivery

Equipment Delivery

In equipment boxing and packaging, we adopt professional packaging and modular solutions to ensure the safe and non-destructive delivery of animal feed plant machinery.

● Installation

Installation & Commissioning

Whether you choose your own subcontractor for the erection phase or you want to install everything together with us, a Richi supervisor will be around to make sure everything is mounted in a safe and thorough way.

● Training

Staff Training

We provide comprehensive training for the technicians of each project. We can also continue to provide support for the technicians during latter project operation.

● After-sales

Project Follow-Up

When everything is up and running our Richiers will help you further whenever needed. We are ready to answer your call 24/7.We’ll also visit you regularly to learn about your needs.

About Us

Do you want to start Animal & Floating Fish Feed Production Line?

Aquafeed fish feed production plant solution is one of the cores of Richi Pellet Machine‘s business segment. It integrates R&D, manufacturing and service. It is committed to providing safe, intelligent and environmentally friendly integrated solutions for global aquatic feed processing, helping users reduce operating costs, improve production efficiency and effectiveness.

Do you want to start feed processing business?

- How to choose the processing technical plan of top-grade shrimp feed, crab feed and special aquafeed with the high quality,but the cost is low?

- How to choose the micro grinding and super micro grinding equipment,the sound grinding fineness is not only suitable for aquatic animals’need, but also reduce energy consumption?

- How to make the conditioner to control the feed curing extent better,the curing extent and digestibility will be improved?

- How to use hypoxia sterilization conditioning to treat post-curing, kill all kinds of bacteria effectively, improve How to control the sinkable and float character of extruded feed accurately?

- Grinding equipment and optimal sieve system to improve the grinding efficiency and reduce energy consumption?

- How to choose post-spraying technology such as vacuum spraying fat equipments to improve the feed nutritional quality?

- How to make the starch of feed pellet gelatinizate and proteid transforms completely through post curing?

- In shrimp pellet production,how to use conditioner to control the curing extent,the curing extent and digestibility will be improved?

- Especially the starch in pellet surface gelatinize and harden completely, improving the water resistence?

- How to choose the vacuum spraying fat equipment to improve the feed nutritional quality?

- …

Build your fish feed production line in Iran

According to the different production and scale of different factories, different raw materials and processes, different feed types and formulas, RICHI MACHINERY is committed to providing customized aquatic feed production line construction solutions for global aquatic feed processors. We provide full-process services from solution design, equipment processing, production line installation and commissioning, operator training, civil engineering layout, etc.

At present, our fish feed production line equipment has been exported to more than 80 countries around the world, with a minimum output of 100kg/h and a maximum output of more than 20t/h. If you are interested in our projects, equipment and processes, please feel free to contact us for professional technical support, equipment quotation and production line solutions.

floating fish feed mill

For all types of extruded fish feed pellets (floating fish feed and sinking fish feed), you can find targeted solutions at RICHI Machinery.

shrimp feed mill

For the processing of different grades of pellet shrimp feed and extruded shrimp feed, you can find suitable shrimp feed factory solutions at RICHI Machinery.

FAQ of fish feed production line in Iran

For any questions about equipment, production line construction, solution design, and project planning, please feel free to contact us for technical support.

What is the price of the full set of equipment for this project?

Based on the design plan, equipment configuration and customer budget of this Iran fish feed production line project, the final price of the equipment for this project was US$340,000.

Do you have many pelleting projects in Iran?

Yes, we have exported a lot of equipment to Iran, and have built more than 20 pellet production line projects, covering livestock and poultry feed processing, aquatic feed processing, biomass pellet processing, organic fertilizer pellet processing, cat litter pellet processing and other fields. If you are interested in our Iran pellet production line project, or want to visit a project site, feel free to contact us, our technical consultant will arrange a site visit for you.

Can one aqua feed production line process various fish feeds and shrimp feeds?

If the fish feed and shrimp feed you want to process are the same, such as using the basic process, then the answer is “Yes”. However, for professional aquatic feed processing, the fish feed process and shrimp feed process must be different. However, you can use the same production line and then add some production equipment. We need to confirm your actual needs before we can carry out customized design. (Find RICHI on youtube)

Global AquafeedDevelopment Trends

Who we are

RICHI Machinery is one of the world’s leading suppliers of technology and services for the animal feed, aqua feed and pet food industries, also the largest pellet production line manufacturer in China.

Since 1995, RICHI’s vision to build a first-class enterprise, to foster first-class employees, and to make first-class contributions to society has never wavered.

In the past three decades, we have expanded our business to a wide range of areas, including animal feed mill equipment, aqua feed equipment, pet feed equipment, biomass pellet equipment, fertilizer equipment, cat litter equipment, municipal solid waste pellets equipment, etc.

1995

RICHI Established

2000+

Serving More Than 2000 Customers

120+

RICHI Employees

140+

Exported To 140 Countries