Poultry Feed Manufacturing Plant In Tanzania

- 1-2T/H Poultry Feed Plant in Tanzania

- 1-2T/H Poultry Mash Feed Plant in Tanzania

- 4-5T/H Poultry Feed Making Plant in Tanzania

- Cattle Sheep Feed Plant in Tanzania

- 3-4T/H Poultry Feed Powder Plant in Tanzania

- …

- Here is a summary of the key poultry feed manufacturing projects we have done in Tanzania

Poultry Feed Manufacturing Plant In Tanzania

As one of the earliest companies engaged in the research and development and manufacture of feed equipment in China, Richi Machinery has launched high-quality small and medium-sized poultry feed manufacturing solutions to meet the growing demand for poultry feed production in Africa. It solves the problem of feed processing and brings quantifiable value-added services.

More and more Tanzanians are consuming chicken and eggs every year. The increasing demand offers many opportunities for companies looking to invest in the poultry sector in Tanzania.

The Poultry Subsector in Tanzania consists of approximately 72 million chickens, emerging steadily both in indigenous and exotic chicken. With changing eating habits in urban areas and a growing economy the domestic market for exotic chicken and eggs is likely to keep expanding.

Poultry feed processing is necessarily proportional to the scale of poultry farming and poultry meat consumption. Obviously, investing in a poultry feed mill in Tanzania is a good choice.

Richi Machinery’s poultry feed manufacturing plant projects now cover more than 130 countries and regions around the world, and have market layouts along the “Belt and Road”. Our products have been exported to the Middle East, South America, Africa, Southeast Asia, Russia, Europe, America, Australia and other high-end markets. (Maybe you want to start an animal feed mill plant)

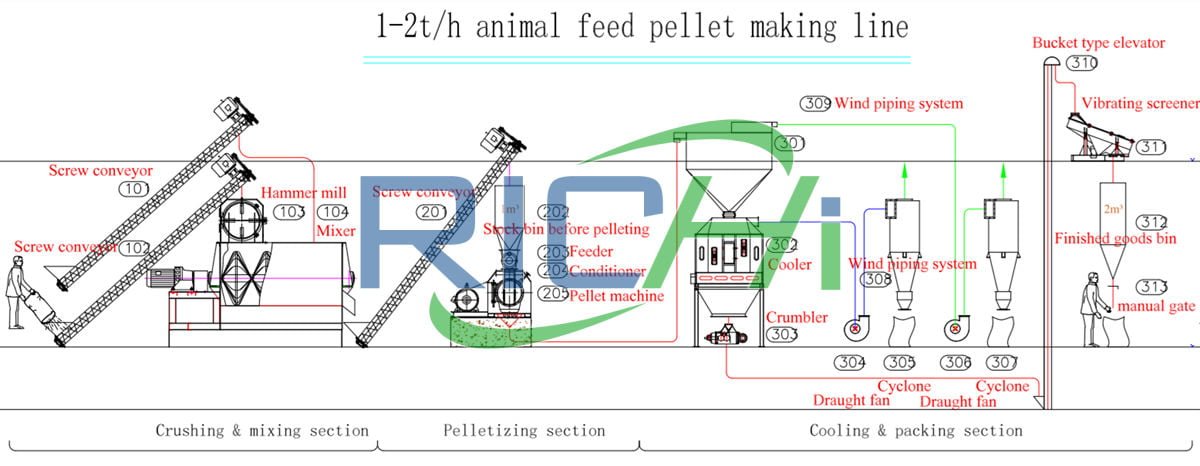

1-2T/H poultry feed manufacturing plant in Tanzania

- Project date: 2017.12.16

- Pellet Size: 1-6mm broiler feed pellets

- Poultry Feed Plant Cost: $10000-50000 USD

This poultry feed making plant in Tanzania project adopts manual weighing and batching, and the designed total production capacity is 1-2T/H of finished pellets. The raw materials need to be pre-weighed, and then fed into the poultry feed production line from two different feeding ports.

The raw materials that need to be pulverized are fed into the feed pulverizer from the pellet feeding port in batches. The powder that needs to be pulverized is pre-weighed and entered into the production line from the powder feeding port, and then mixed by the feed mixer machine.

The mixed material enters the poultry feed pellet making machine for granulation and cooling processing, and finally adopts manual weighing and packaging. The total power of the poultry feed processing plant is about 87KW; the size of the unit is about 12×6×8m; it needs to be equipped with a 0.2T boiler.

Tanzania 1-2T/H Poultry Feed Manufacturing Process:

- Raw material receiving and cleaning section

Granular and powdery raw materials enter the production line through two feeding ports respectively. The granular raw materials are cleaned by the feeding primary cleaning screen to remove impurities, and then iron is removed into the poultry feed grinder machine; the powdered raw materials need to be cleaned in advance. - Crushing section

22KW water drop type feed hammer mill crusher is used, which can be either coarsely crushed or finely crushed. Feeding is integrated with the initial cleaning equipment. It can also feed the crusher while cleaning the raw materials. Frequency conversion control, uniform feeding, equipped with pulse dust collector, mechanical sedimentation discharge, simple process and low cost, suitable for the crushing of small output and multi-variety raw materials in poultry feed processing plant. - Mixing section

There is a silo to be mixed above the double-shaft paddle feed mixer, so that when the mixer is working, the feeding continues to achieve the effect of continuous and uninterrupted production. The mixed materials can enter the silo to be granulated by poultry pellet machine and the finished powder separately. silo to meet the needs of producing powder and granular finished products at the same time. - Pelletizing section

SZLH250 chicken feed pellet machine with a single-layer conditioner is used for the production of ordinary livestock and poultry feed; after pelleting, it is lifted directly into the pellet cooler and vibrating screen, and finally bagged and packaged manually. - Auxiliary section:

Liquid addition system, which can add grease to the mixer to improve the palatability of the feed. The air compressor system provides compressed air for the pneumatic components in the poultry feed processing plant system.

1-2T/H poultry feed manufacturing plant Solution optimization

According to the needs of different customers, the Tanzania 1-2T/H poultry feed plant solution can optimize the configuration:

- Taking into account the low output, this small poultry feed processing plant unit is not equipped with a powder initial cleaning system, and manual pre-cleaning is adopted. Customers can add a powder cleaning system according to their needs;

- The powder and granule product bins are designed in the small poultry feed manufacturing unit respectively. If the customer does not need the powder product, the powder product bin can be removed. (Related case: feed mill plant in Uzbekistan)

1-2T/H poultry mash feed plant in Tanzania

- Project date: 2016.12.30

- Feed Size: powder feed

- Poultry Feed Manufacturing Plant Cost: 5000-15000USD

The 1-2t/h poultry feed manufacturing line project adopts manual weighing and batching, and the designed total production capacity is 1-2T/H of finished powder feed. The raw materials are manually pre-cleaned and pre-weighed. The raw materials that need to be pulverized are directly put into the hammer mill feed grinder in batches, and the pulverizer is artificially fed.

The pulverized raw materials and the powder that do not need to be pulverized are entered together from the feeding port according to the formula ratio. The production line is then mixed by a feed mixing machine, and the mixed material directly enters the finished product warehouse as a powder finished product, and finally adopts manual weighing and packaging. The total power of the poultry feed production line is about 75KW; the size of the unit is about 10×5.5×7m; it needs to be equipped with a 0.2T boiler.

Design Of Tanzania 1-2T/H Poultry Feed Manufacturing system

This 1-2tph small poultry feed manufacturing plant for layer feed is customized according to the customer’s chicken feed plant size and actual processing needs, equipped with 11KW chicken feed grinder machine and 250kg/batch chicken feed mixer machine and other chicken feeds mash making machine.

- Raw material receiving and crushing section

Using an integrated poultry feed hammer mill grinder, manual feeding, and centrifugal sedimentation and discharge of cyclone, the process is simple and low in cost, and is suitable for the crushing of small output and multiple varieties of poultry feed raw materials. - Mixing section

There is a silo to be mixed above the feed mixer machine, so that when the animal feed mixer is working, the material feeding can continue to achieve the effect of continuous and uninterrupted production. Powder and granular finished product requirements. Use double-shaft paddle mixer SHSJ0.5, 5.5KW, 250kg/batch, designed to produce 1.5-2T/H per hour, mixing uniformity CV≤5%. - Auxiliary section

Liquid addition system, which can add grease to the poutry feed mixing machine to improve the palatability of the feed. The air compressor system provides compressed air for the pneumatic components in the system.

1-2T/H poultry feed manufacturing plant Solution optimization

According to the needs of different customers, the poultry feed processing plant solution can optimize the configuration:

The packaging system can be optimally designed to add dust and suction equipment, which can improve the working environment of workers, but the cost increases, customers can choose according to actual needs.

- The gates and mixer discharge gates in the small poultry feed manufacturing unit are controlled by pneumatic components, which need to be equipped with a separate air pressure system. Customers can replace them with electric gates and mixer electric discharge gates according to their needs, eliminating the need for air compression systems. sole investment;

- Taking into account the low output, this small poultry feed making line t is not equipped with a raw material initial cleaning system, and manual pre-cleaning is adopted. Customers can add a raw material cleaning system according to their needs;

- The powder and pellet product bins are designed separately in the small unit. If the customer does not need the powder product, the powder product bin can be removed. (Related case: feed production line in Thailand)

4-5T/H poultry feed processing plant in Tanzania

- Project date: 2021.01.06

- Pellet Size: 6-8mm

- Main Raw material: wet and dry wood sawdust (No need to crush)

The Tanzania 4-5t/h poultry feed manufacturing plant is mainly used to make mash feed, so it is a automatic mash feed line. But this Tanzania customer also want to develop pellet feed business, so beside the mash feed, there is an another simple animal feed pellet plant with 3-4t/h.

The raw materials used in this Tanzania animal feed mill plant project are corn, soybean meal, oil, premix, etc. Because customers need to process more types of feed, and the feed sizes are different, so the Tanzania customer also ordered a large number of main accessories such as pellet machine ring dies while purchasing the main animal feed mill machinery.

During the installation process of this Tanzania poultry feed mill plant project, we sent two engineers to the site. After 50 days of work, the poultry feed plant project successfully completed. (Do you want to start a shrimp feed mill?)

The 4-5t/h poultry feed manufacturing unit in Tanzania adopts manual weighing and batching, and the designed total production capacity is 5-6T/H for powder products and 4-5T/H for pellet products. The raw materials need to be pre-weighed, and then fed into the production line from two different feeding ports. The raw materials that need to be pulverized are fed into the feed pulverizer from the pellet feeding port in batches.

The poultry feed grinding machine is fed by a screw conveyor and does not need to be pulverized. After pre-weighing, it enters the poultry feed making plant from the powder feeding port, and then is mixed by the poultry feed mixer machine. The mixed material can directly enter the finished product warehouse as the finished powder product, or can enter the poultry feed pellet machine for granulation and cooling processing, and finally manual weighing and packaging.

The total power of the 4-5t/h poultry feed manufacturing plant unit is about 172KW; the size of the unit is about 13×6×11m; it needs to be equipped with a 0.5T boiler. The whole 4-5t/h poultry feed making plant unit adopts a spliced frame, which is compact in design, reasonable in structure, meets environmental protection requirements, and can be oriented according to customer requirements.

Tanzania 4-5T/H poultry feed processing plant Design:

- Raw material receiving and cleaning section:

Granular and powdery raw materials enter the poultry feed manufacturing plant through two feeding ports respectively. Granular raw materials are cleaned by a special granule cleaning screen, and then iron is removed into the silo to be crushed; powdery raw materials need to be cleaned in advance. - Crushing section:

RICHI water drop type feed crushing machine is used, which can be used for both coarse crushing and fine crushing. Horizontal screw conveyor frequency conversion feeding, frequency conversion control, uniform feeding, equipped with pulse dust collector, mechanical settling and discharging, the process is simple and cost-effective Low, suitable for the crushing of small output and many varieties of raw materials. Crushing equipment: feed hammer mill SFSP568-II, 37KW, designed to produce 5-6T/H. - Mixing section:

There is a silo to be mixed above the feed mixer for poultry, so that when the animal feed mixing equipment is working, the material feeding can continue to achieve the effect of continuous and uninterrupted production. Powder and granular finished product requirements. The chicken feed mixing equipment adopts the double-shaft paddle feed mixer equipment SHSJ1, 11KW, 500kg/batch, and the mixing uniformity CV≤5%. - Granulation section:

A poultry pellet making machine with a single-layer conditioner is used for the production of ordinary livestock and poultry feed and ruminant feed; after granulation, it directly enters the cooler, and then is lifted by the elevator into the crushing and screening system, then adopts manual bagging and packing. The granulation equipment adopts the poultry feed granulator SZLH350, 55KW, with a designed capacity of 3-5T/H; cooling equipment: counter-flow cooler SKLN2.5, with a designed capacity of 5-6T/H. - Auxiliary section:

Liquid addition system, which can add grease to the animal feed mixer to improve the palatability of the feed. The air compressor system provides compressed air for the pneumatic components in the poultry feed manufacturing plant.

Tanzania 4-5T/H poultry feed manufacturing Solution optimization

According to the needs of different customers, the poultry feed processing plant solution can optimize the configuration:

- Taking into account the low output, this Tanzania 4-5t/h poultry feed production plant is not equipped with a powder initial cleaning system, and manual pre-cleaning is adopted. Customers can add a powder cleaning system according to their needs;

- The powder and granule product bins are designed in the Tanzania 4-5t/h poultry feed plant respectively. If the customer does not need the powder product, the powder product bin can be removed. (Hot solution: Fish Feed Production Plant)

RICHI Pellet Machine & Pellet Production Line In Tanzania

The business scope of RICHI MACHINERY covers the design, manufacture, installation and commissioning of biomass pellet production line equipment, feed production line equipment, organic fertilizer production line equipment, cat litter produciton line equipment and a complete set of engineering solutions. Therefore, our projects in Tanzania are not only poultry feed manufacturing plant projects, but also other richer applications.

Here are some of our other Tanzania pellet machine and feed production line projects showcased:

How to make your poultry feed manufacturing Plant profitable in Tanzania?

The above cases are all small poultry feed processing plant projects. With the development of society and the progress of the industry, the requirements for poultry feed mills are getting higher and higher. Is it really difficult to do business? It’s really hard to say, what’s the difficulty? For small poultry feed making plants, the most difficult part is the sales link.

01 Strengthen the overall concept and supporting sales

The overall concept is to solve the problem of where the poultry feed prodcution line survives and develops. The feed factory should formulate a set of strict and practical sales plan, and the sales of each link should strictly revolve around this overall plan, so that the sales work can be carried out in an orderly manner and help to achieve certain goals.

The poultry feed making line should have their own sales characteristics, avoid low-level imitation in sales, and flexibly apply traditional sales methods, such as: sample gifts, additional gifts, coupons, installment payments, trade-in, competition lottery, door-to-door license Distribution, price protection, joint promotion, reciprocal trade, etc., and some innovations are the breakthrough points for doing a good job in sales.

02 Efforts to increase market share

Market share and coverage are two different concepts. Market coverage refers to how much an enterprise’s products occupy within a certain market range.

The size of the market coverage rate cannot truly reflect the sales situation of the poultry feed manufacturing plant, and the size of the market share rate should be used as an evaluation index for sales performance. If the main energy is placed on a certain fixed regional market, and the sales work is done steadily and meticulously, it will have a multiplier effect.

03 Establish market research and tracking system

Market research and evaluation of products are the basis for poultry feed plants to formulate sales policies and develop new products, and all operations of poultry feed plants should be based on this foundation.

There are many contents of market research, including: capacity, livestock and poultry species, breeding level, habits, humanities, feed types, distribution, product prices, policies, etc. These objective conditions are brought together, analyzed and summarized, and then a set of sales strategies adapted to local conditions.

In the implementation process, a tracking system should also be established to assess whether the sales strategy is correct or not. Only by revising the sales strategy in a timely manner can the company take the initiative in market sales.

04 Provide a full range of services to end customers

Now the competition in the feed market has shifted from competing for partners to competing for end customers. People of insight put forward the concept of a comprehensive customer service system, which will surely become the mainstream of the market in the 21st century.

The comprehensive customer service system has a wide range, including customer management system, perfect pre-sale, in-sale and after-sale service system, end product sales service system, risk sharing, benefit sharing system, etc. In the final analysis, all business activities of enterprises revolve around users.

Recognizing this point, the poultry feed manufacturing plant should provide a full range of services to customers while doing a good job in promotion and publicity. Only by capturing customers can they seize the market, and products in the market can be accepted by users for a long time and sell well.

05 High-quality product strategy

As the main body of sales, feed products are very important in terms of their technological content and intrinsic quality. Commodity development and sales is an eternal topic, and feed products are no exception. If the poultry market is sluggish, it will directly affect the product quality and sales in the feed market.

Some people believe that in this specific environment, poor-quality feed can prolong the time of livestock and poultry slaughter, create conditions for waiting for the market to recover, and bring benefits to farmers.

In fact, the recovery of the market is not easy to wait for, and the inferior feed brings farmers not economic benefits but disasters. With the improvement of breeding level, most farmers realize this.

Regardless of the price of poultry products, the desire to buy high-quality feed products is getting stronger and stronger, and inferior feed products will be gradually eliminated. If the poultry feed manufacturing plant insists on supplying the market with high-quality products, it will form a good product image and lay a foundation for expanding the market share of the products.

In addition, improving the scientific and technological content of products, constantly realizing product upgrades, and finding new selling points are the basis for feed products to survive in the market, and create conditions for poultry feed mmill plants to win the market. Competition is brutal, and the market economy does not believe in tears.

To survive, a poultry feed plant must rely on scientific and technological progress, rely on good equipment and technology, and continuously improve product image and product quality.

The key to entering the market lies in sales, and the key to sales lies in following the rules of the market economy, examining the market with keen insight, analyzing the market with a calm mind, and controlling the market with skilled skills, so as to withstand the ups and downs of the market, practicing and actively responding to the challenges of the unpredictable market economy.

How does a poultry feed manufacturing plant control product quality?

With the rapid development of animal husbandry, the development of the feed industry has also accelerated accordingly, especially small and medium-sized poultry feed lines have sprung up and become an important force in the feed industry. However, only by improving the quality of the product can we finally obtain high profits.

In order to improve the quality of feed, first of all, it is necessary to improve the quality awareness of all employees in the poultry feed plant. It is clear that product quality determines the survival of the enterprise, directly affects the development of animal husbandry, determines the quality of animals raised, and is related to everyone’s health, make them conscious to improve product quality in the first place.

Second, strengthen quality management. Practice has proved that the quality management of the production process is the key link that affects the product. Effective quality control of the poultry feed production process can achieve twice the result with half the effort.

01 Strengthen the quality inspection of raw materials

At present, the quality of some raw materials in the market is not stable, coupled with the lack of strict market management, fake and inferior products often appear, and small and medium-sized poultry feed manufacturing plants often lack a fixed raw material supply base.

Therefore, when the raw materials enter the poultry feed processing plant, they must be checked and accepted in strict accordance with the standards, so that the unqualified raw materials will not enter the factory and will not be stored in the warehouse.

The raw materials entering the warehouse, especially the raw materials with large quantities and long storage periods, shall be checked regularly to ensure that the raw materials entering the production line meet the requirements of quality standards.

02 Strengthen the quality control of formula design

Doing a good job in formula design is the basis for ensuring the quality of compound feed. Therefore, when designing the formula, it is necessary to consider the requirements and influence of the physiological stage of poultry, feeding conditions, and feed raw materials on the formula, but also pay attention to the nutrition, palatability, digestibility, disease resistance, economy and other aspects of the feed. quality problems in order to achieve the purpose of high efficiency, high quality and low cost.

03 Strengthen the hygiene management of feed quality

At present, due to imperfect testing methods in small and medium-sized feed processing plants, the main problems of feed quality are: pesticide content in feed raw materials exceeds the standard; too much antibacterial drugs are added to the feed, resulting in drug residues; additives and hormone drug residues exceed the standard.

Therefore, strengthening the hygiene management and testing of feed quality is a major event related to the improvement and long-term development of the feed industry.

04 Strengthen the management of feed equipment and technological processes

Feed equipment needed in the poultry feed manufacturing plant must strictly implement the maintenance system, especially the critical equipment should be inspected at any time and regularly overhauled. For the key parts and weak links in the poultry feed making process, it is necessary to establish and improve the corresponding management system.

Establish the idea that the previous process serves the next process and the awareness that the next process provides quality feedback for the previous process, and deal with the problems that arise in a timely manner.

05 Strict management of measuring instruments

The accuracy of measuring instruments directly affects the qualification rate of products. Therefore, it is necessary to strictly control the measurement management system, and conduct regular appraisal of measuring instruments to ensure that qualified products are finally listed.

Popular Products In Thailand

Service And Support

Richi Machinery have more than 25 years of complete feed production line and pellet production line service experience to help you develop your business in all aspects and realize personalized value.

Personalized customization & provide 3D renderings

We can design poultry feed manufacturing plant project planning schemes according to the different needs of customers, and provide 3D renderings to enhance the user experience. Help customers to accurately sort out their own needs, repeatedly scrutinize the rationality and scientificity of the process with customers, try to optimize the design of the product system, and meet customers’ reasonable personalized needs at all costs.

With perfectionism and ingenuity, we create a turnkey poultry pellet plant project, seek our own value for our customers, and use the ‘differentiated competitive strategy’ to improve our market competitiveness for our customers, so as to achieve strong alliances and common development.

On-the-spot investigation & adapting measures to local conditions

We design comprehensive problem solutions for animal feed mill equipment engineering according to different requirements of customers, different raw materials, and different sites. Our professionals go deep into the construction site and do a good job of planning.

In practice, we can truly adjust measures to local conditions, and adopt different design schemes and construction methods according to different survey results to ensure that it is scientific and reasonable, economical and practical, and meets environmental protection. So as to create a safe, efficient and stable feed production line and pellet production line for customers.

Professional team & door-to-door installation

Richi Machinery has a professional technical team with 25 years of practical experience in design, manufacture and installation. Unified management and unified training. Strict technical assessment is carried out every year, and it has rich on-site installation and maintenance experience, professional quality and high sense of responsibility.

With a high degree of professionalism, we help customers to quickly put into production and achieve production benefits, allowing customers to seize market opportunities and win at the starting line.

Technical Service & Whole Process Guarantee

Whether in pre-sale or after-sale technical support, we are always ready to provide customer satisfaction services. To ensure the highest work efficiency in a rigorous order, 24-hour reception of customers’ technical inquiries, on-site service, feed mill equipment maintenance, production failures, service complaints and a series of problems to improve customer satisfaction.

Through telephone consultation and door-to-door service, we can find and solve problems in a timely manner to ensure the rights and interests of customers. Provide professional and targeted services for different users, and escort customers throughout the process.

One-to-one guidance & worry-free production

After the installation and commissioning is completed, we will provide one-to-one technical guidance according to the actual situation of the customer, and be responsible for training the operators until the customer can fully operate the poultry animal feed mill plant and pellet machine production by himself. Truly ‘customer-centric’, to provide customers with excellent service.

Follow-up questions will be answered by professionals, and feedback will be recorded in a timely manner, and solutions will be provided. If there is a need for on-site guidance, Richi Machinery will arrange relevant professionals to provide timely guidance at the designated location according to the specific circumstances.

Quick response & lifetime maintenance

In terms of service quality control, we insist on life-long service and infinite improvement. In addition to the warranty period, we provide customers with life-long service. As long as the equipment is in use, RICHI’s service to customers will not be terminated. In the service, we insist on the first response and the fastest speed to solve the problem.

At the same time, a product dynamic improvement system is established. After solving the typical problems reported by customers, the poultry feed manufacturing plant design will be improved immediately, and the product will be continuously improved. For the problems in the service process, the RICHI service process will be improved and optimized immediately after they are solved.

Want to buy poultry feed making machine or start your poultry feed manufacturing plant?

Feel free to contact Richi Machinery!