Powdered fertilizer, granular fertilizer, or pelletized fertilizer output – tailored to your market demands.

FERTILIZER GRANULATOR EQUIPMENT

From organic waste to precision NPK blends, our high-performance granulation equipment transforms diverse materials into premium fertilizers. Whether processing powdered livestock manure, mixed NPK formulations, or bulk-blended nutrients, our systems deliver uniform, market-ready granules with optimal hardness and nutrient consistency.

Backed by 25+ years of engineering expertise, we customize each solution to your specific raw materials and production goals—ensuring maximum efficiency from fermentation to final packaging.

APPLY

At RICHI MACHINERY, we specialize in designing and manufacturing robust fertilizer granulator equipment & systems that transform diverse raw materials into high-quality fertilizers. Our expertise spans organic, compound, organic-compound, and bulk blending fertilizer production, ensuring optimal solutions tailored to your specific requirements.

organic fertilizer pellet

manure fertilizer pellet

compost fertilizer pellet

npk compound fertilizer

Core Equipment Systems

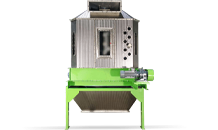

Our ring die fertilizer granulator equipment serves as the heart of efficient fertilizer production lines, engineered to transform diverse materials into uniform, market-ready granules. This precision machinery is complemented by a complete ecosystem of supporting equipment including turners for optimal fermentation, crushers for material size reduction, precision mixers for formula accuracy, drying systems for moisture control, coating drums for product enhancement, and automated packaging solutions.

Achieve granulation rates exceeding 95% across varying material densities and moisture levels.

Each system is rigorously tested with client-specific materials to optimize preprocessing requirements and process parameters.

From Raw Materials to Market-Ready Products

These robust machines deliver consistent compression across various material types – from organic waste to NPK formulations.

fertilizer crusher machine

Organic fertilizer dosing system

Organic fertilizer dosing system

fertilizer drying machine

manure compost turner

fertilizer mixing machine

fertilizer coating machine

fertilizer packaging machine

Multi-Raw Material Fertilizer Granulation Solutions

The best type of fertilizer granulation equipment will depend on your application and operations. Our fertilizer granulation equipment is engineered to process a diverse range of raw materials with exceptional adaptability, including organic waste such as livestock manure, crop residues, and food processing byproducts, chemical-based NPK formulations with precise nutrient ratios, and hybrid organic-compound blends that combine both material types.

Agricultural waste fertilizer granulator •

Municipal waste fertilizer granulator •

Food waste fertilizer granulator •

Fertilizer Granulator Machine Models Selection Guide

Richi Machinery is the most competitive fertilizer granulation equipment brand with the most complete product varieties and series. Our knowledgeable team members are ready to help you find the perfect equipment from our selection of RICHI-made Fertilizer Machines.

FZLH250

Capacity: 1-1.5 T/H

Because of the way these fertilizer pellet machines are designed, the materials are easily compressed into a pellet size, saving time, effort and money on the job site.

FZLH320

Capacity: 2-3 T/H

All manure pellet mill types for your granulation needs. It uses top fertilizer technology, featuring low noise and excellent production efficiency.

FZLH350

Capacity: 3-5 T/H

With its heavy-duty components yet suitable size, compost pellet making machines made by RICHI MACHINERY are suitable for an array of applications.

FZLH420

Capacity: 6-8 T/H

No matter which type of organic fertilizer pellet mill you go with, these high efficiency pelletizers can enhance your job site capabilities and efficiency.

FZLH520

Capacity: 9-12 T/H

If you are experienced in the world of fertilizer pellet production, then you are likely well aware of organic fertilizer manure making machines and what they can do for a project.

FZLH678

Capacity: 18-22 T/H

Compost granulating machines are the primary and most prevalent type of fertilizer machinery used to pelletize fertilizer, are commonly found on organic fertilizer factory projects.

Technical Specifications Overview

To help you compare our core fertilizer granulator equipment models, here is a detailed technical parameter table highlighting key performance data for each machine. This overview provides essential information on capacity, power requirements, and granule output to assist in selecting the ideal equipment for your production needs.

| Model | FZLH250 | FZLH320 | FZLH350 | FZLH420 | FZLH520 | FZLH678 | FZLH768 |

| Main motor power (kw) | 22 | 22 | 37 | 90 | 132 | 185 | 250 |

| Power of arch breaking feeder (kw) | 2.2 | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced feeder power (kw) | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Finished pellet diameter (mm) | 4~12 | ||||||

| Production capacity (T/H) | 1-1.5 | 2-3 | 3-5 | 6-8 | 9-12 | 18-22 | 22-26 |

While fertilizer granulator equipment form the heart of any fertilizer production line, achieving optimal results requires perfectly integrated support equipment. We design and manufacture the complete ecosystem of processing machinery that transforms raw materials into market-ready products. Each auxiliary unit is engineered to seamlessly connect with our granulation equipment, creating a cohesive production flow that minimizes bottlenecks and maximizes output.

Complete Line Support Equipment

We don’t just sell equipment – we analyze your entire production process to recommend the optimal configuration of supporting machinery.

Richi Machinery’s fertilizer granulator equipment operates successfully in diverse conditions worldwide. Our systems consistently deliver results across different raw materials, climate challenges, and production requirements.

From organic waste recycling to precision NPK production, we’ve helped clients achieve their production goals on every continent. This global experience means we understand how to adapt equipment to your specific regional needs and operational challenges. Let us demonstrate how our international expertise can work for your operation.

Global Granulation Success

fertilizer granulator equipment in Asia

Asian operations demonstrate our ability to scale from small farm installations to industrial-level production, processing diverse materials from rice husks to aquaculture waste.

Across South America’s diverse agricultural sectors, our granulation systems are processing everything from coffee processing waste in Colombia to soybean-based organic fertilizers in Argentina.

fertilizer granulator equipment in South America

fertilizer granulator equipment in Oceania

Throughout Australia and New Zealand, our systems are designed to address unique regional challenges including water conservation and remote operation capabilities.

Our African projects focus on robust, low-maintenance designs that deliver reliability in challenging operating conditions.

fertilizer granulator equipment in Africa

fertilizer granulator equipment in North America

Our North American installations range from large-scale commercial fertilizer plants to innovative organic waste recycling facilities.

fertilizer granulator equipment in Europe

European installations emphasize precision engineering and environmental compliance, with advanced emission control systems and energy recovery features.

1-1.5 t/h small scale organic fertilizer plant

2-3 t/h organic fertilizer processing plant

3-5 t/h organic fertilizer production plant

6-8 t/h organic fertilizer manufacturing plant

9-12 t/h organic manure production plant

18-22 t/h organic fertilizer factory

1-40 t/h npk compound fertilizer production line

1-60 t/h compost manufacturing plant

Solutions by Material Type

Not all materials process the same way, and our specialized lines reflect decades of material-specific engineering. We provide distinct configurations for organic materials like manure and crop residues, NPK chemical formulations, and hybrid organic-compound blends.

Each system incorporates tailored preprocessing, granulation, and finishing steps that address the unique characteristics of your raw materials – whether dealing with high-moisture organic waste or precision-blended mineral powders. This material-focused approach ensures higher yields, better granule quality, and more efficient operation for your specific production needs.

60000 +

Backed by a 60,000 m² advanced production complex

140 +

Global footprint extends across 140+ international markets

2000 +

Over 2,000 successful feed production system installations

2013

RICHI MANUFACTURE

Established in 1995, RICHI MACHINERY has grown from a medium-sized enterprise to become China’s largest pellet production line manufacturer. With two major manufacturing bases spanning hundreds of thousands of square meters, we specialize in custom pellet machines and complete plant solutions, handling every production stage in-house—from R&D to delivery.

Our vertically integrated facilities (including dedicated sections for production, testing, and logistics) ensure premium quality, environmental responsibility, and operational reliability for feed, biomass, and fertilizer industries worldwide. For nearly three decades, we’ve partnered with clients to enhance productivity, minimize risks, and achieve sustainable outcomes through innovative engineering.

Zhengzhou Headquarters

R&D, global operations and strategic management converge

Jiaozuo New Production Base (2025)

Featuring automated production lines and Industry 4.0 technologies

Kaifeng Original Complex (Since 1995)

Our manufacturing legacy began and quality traditions endure

Certifications & Patents

As a world-leading fertilizer granulator equipment manufacturer, RICHI Machinery demonstrates its engineering prowess through internationally recognized certifications and proprietary innovations.

Our ISO quality management system, CE compliance, BV-certified production processes, GOST-R for Russian compliance, ATEX explosion-proof certification for EU safety standards, FDA registration for U.S. market access, and EHEDG hygienic design certification validate our commitment to global standards, while 50+ patented technologies in pellet mills, granulators, Crusher, mixer, dryer, turner and automation systems deliver unmatched performance.

When it comes to the top company offering the best fertilizer granulation equipment for sale, Richi Machinery is known for its superior quality, cutting edge technology and superior customer service. We can supply all of your fertilizer pelleting needs – From single fertilizer granulator machine to the fertilizer production line designs in the world.

With high-quality equipment materials and components, our customers have negligible maintenance and operational costs. Plus, our unmatched support and in-person training allow you to be confident in your new equipment.

01

Consultation

Our experts provide professional advice to understand your specific fertilizerd production requirements.

02

Design

We develop customized solutions with optimized layouts and equipment configurations for your project.

03

Manufacturing

All fertilizer granulator equipment is precision-built using quality materials in our ISO-certified factories.

04

Shipping

We handle secure packaging and global logistics with reliable delivery timelines.

05

Installation

Our engineers supervise on-site assembly and commissioning for smooth operation.

06

Training

Comprehensive operator instruction ensures proper use and maintenance of equipment.

07

After-sales

Dedicated support team provides troubleshooting and technical assistance.

08

Spare Parts

Genuine components are available worldwide with fast delivery service.

ertilizer Granulator Equipment FAQs

This section addresses the most common technical and operational questions about fertilizer granulation equipment, drawing from Richi Machinery’s extensive expertise in organic, NPK, and compound fertilizer production. Whether you’re exploring raw material adaptability, process efficiency, or equipment customization, these answers provide clear, professional insights to help you optimize your fertilizer manufacturing operations and make informed decisions about your granulation needs.

How to set up fertilizer granulation plant ?

+

At present, many countries are vigorously promoting organic fertilizers in order to accelerate the green development of agriculture. Organic fertilizers can not only provide comprehensive nutrition for crops, but also have long-lasting fertilizer effects.

They can increase and renew soil organic matter, promote microbial reproduction, and improve the physical and chemical properties and biological activity of soil. They are the main nutrients for green food production.

RICHI Machinery is committed to developing organic fertilizer solutions, we can customize the solution to suit your particular application.

When building an organic fertilizer plant, you need to consider the following aspects:

- Market research: Through market research, the positioning and price of organic fertilizer products can be determined, and the potential of the sales market can be predicted.

- Site selection: When choosing a suitable site for building an organic fertilizer plant, you need to consider factors such as site rental, transportation conditions, water resources, environmental protection requirements, and safety requirements.

- Equipment selection: When selecting equipment, factors such as production capacity, process flow, equipment quality, and after-sales service need to be considered. At the same time, it is also necessary to design appropriate workshops and facilities based on equipment and production needs.

- Raw material: When purchasing raw materials, you need to consider factors such as raw material quality, price, transportation distance, purchase volume, etc., and establish long-term cooperative relationships with suppliers.

- Fund: In the early stage, funds need to be raised through various channels, such as self-raised funds, bank loans, government subsidies, etc.

- Relevant procedures: Before building an organic fertilizer plant, relevant procedures need to be completed, such as industrial and commercial registration, tax registration, environmental protection approval, etc.

01

What is a fertilizer granulator equipment?

+

Fertilizer granulation equipment is an industrial machine system designed to transform powdered, crushed, or mixed raw materials into uniform, dense granules. At Richi Machinery, we specialize in advanced ring die granulator systems that produce premium-quality fertilizer pellets with precise size, hardness, and nutrient consistency.

Our fertilizer granulator machines serve multiple production needs:

- For organic fertilizer granulation, we process composted manure, crop straw, and other bio-wastes into slow-release organic granules.

- For NPK fertilizer production, our systems blend and granulate chemical compounds with micronutrients.

- For organic-compound fertilizers, we combine organic matter with NPK components in optimized ratios.

- For BB fertilizer systems, we ensure homogeneous mixing of urea, DAP, potassium chloride, and other raw materials.

Unlike conventional granulators, Richi Machinery’s ring die granulation equipment offers distinct advantages:

- Superior Granule Quality: Produces smooth, uniform pellets (2-8mm) with high crushing strength (>10N) to minimize dust and breakage during handling.

- Material Flexibility: Handles diverse inputs – from moist organic compost to dry NPK powder blends – without requiring binders in most cases.

- Energy Efficiency: Our patented ring die design reduces power consumption by 15-20% compared to flat die or rotary drum granulators.

- Low Maintenance: Heavy-duty construction with wear-resistant alloy dies ensures 3,000+ hours of continuous operation between replacements.

With 25 years of field experience, Richi Machinery has deployed fertilizer granule making machines in 300+ plants worldwide. Our engineering team provides complete solutions – from material testing and recipe development to production line layout and after-sales support.

Whether you need a compact organic granular fertilizer making machine for farm use or a large-scale fertilizer plant system, we customize each granulator’s parameters (die hole size, roller pressure, moisture control) to your specific materials and output requirements.

For operations prioritizing nutrient precision and production efficiency, our fertilizer granulation equipment represents the industry benchmark. Contact us to discuss your project specifications or request material trial testing at our facility.

02

What is the price range for fertilizer granulator machines?

+

At Richi Machinery, we specialize in manufacturing high-performance ring die fertilizer granulation equipment with capacities ranging from 1-22 tons per hour. With 25+ years of industry expertise and over 300 successful global installations, we provide reliable granulators that combine competitive pricing with exceptional quality and performance.

Standard Models & Pricing for Our Ring Die Fertilizer Granulator Machines:

| Model | Capacity (T/H) | Power (KW) | Ring Die Size (mm) | Price Range (USD) | Best For Application |

|---|---|---|---|---|---|

| FZLH250 | 1-2 | 22 | Ø250 | $12,000-$15,000 | Small farms processing organic fertilizer from manure/compost |

| FZLH320 | 2-3 | 22 | Ø320 | $14,000-$16,000 | Medium-scale organic granular fertilizer production |

| FZLH350 | 3-5 | 37 | Ø350 | $19,000-$21,000 | Both organic and NPK fertilizer manufacturing |

| FZLH420 | 6-8 | 90 | Ø420 | $28,000-$30,000 | Professional fertilizer plant operations |

| FZLH520 | 9-12 | 132 | Ø520 | $44,000-$46,000 | Large-scale compound fertilizer production |

| FZLH678 | 18-22 | 185 | Ø673 | $66,000-$68,000 | Industrial-scale fertilizer manufacturing facilities |

Key Factors Affecting Equipment Pricing:

- Material Versatility: Our granulators expertly process various materials including livestock manure, agricultural waste, NPK formulations, and organic-compound blends

- Energy-Saving Design: Innovative ring die technology reduces power consumption by 15-20% compared to traditional granulators

- Robust Construction: Premium alloy components and heavy-duty design ensure extended operational life

- Customization Options: Available modifications include die hole specifications, moisture control systems, and specialized configurations

For complete fertilizer production line solutions (incorporating preprocessing, mixing, granulating, drying, cooling, and packaging systems), our engineering team provides:

- Complimentary equipment selection consultation based on your specific materials and output requirements

- Pre-shipment factory testing and validation

- Comprehensive installation support and operator training programs

- Ongoing technical support throughout equipment lifespan

All Richi Machinery fertilizer granulator equipment includes:

- 12-month warranty on core components

- Guaranteed access to genuine spare parts

- 24/7 remote technical assistance

For a customized quotation and expert guidance in selecting the optimal fertilizer granulation solution for your operation, contact Richi Machinery today. Our specialists will help you identify the most efficient and cost-effective equipment configuration for your production needs.

03

What types of fertilizer granulators do you offer?

+

Richi Machinery provides comprehensive fertilizer granulation solutions designed to handle virtually any raw material in the fertilizer production industry. With our 25+ years of engineering expertise and 300+ successful installations worldwide, we’ve developed specialized granulation systems for every production need.

Our Core Fertilizer Granulator Equipment Range:

- Organic Fertilizer Granulator Machines

- Specifically engineered for processing animal manure (poultry/cattle/swine), agricultural waste (straw/compost), and other organic materials

- Features our advanced ring die technology that ensures high granulation rate (≥95%) and uniform particle size (2-8mm)

- Includes specialized models for both small-scale farm operations and large commercial organic fertilizer plants

- NPK Compound Fertilizer Granulators

- Designed for precise blending and granulation of nitrogen, phosphorus, potassium and micronutrients

- Capable of processing various formulations (15-15-15, 17-17-17, etc.) with consistent nutrient distribution

- Our ring die systems maintain low moisture content (<5%) for superior granule hardness

- Organic-Compound Fertilizer Granulation Systems

- Hybrid solutions that combine organic matter with chemical nutrients

- Perfect for producing enhanced-efficiency fertilizers with both immediate and slow-release properties

- Customizable NPK:organic ratio to meet specific crop requirements

- BB Fertilizer (Bulk Blend) Equipment

- Complete systems for mixing prilled urea, DAP, MOP and other raw materials

- Special anti-segregation design ensures uniform nutrient distribution

- Available in batch or continuous processing configurations

Material Adaptability:

Our fertilizer granule making machines can process:

- All types of animal manure (fresh or composted)

- Crop residues and green waste

- Various NPK formulations

- Industrial byproducts suitable for fertilizer production

- Custom organic-inorganic blends

Technical Advantages of Richi Machinery Granulators:

- Ring die systems offer 20-30% higher output than conventional granulators

- Minimal binder requirements due to optimized pressure design

- Energy-efficient operation with power savings up to 15%

- Heavy-duty construction for 10,000+ hours of continuous operation

- Customizable die specifications for different granule sizes (1-10mm)

For operations requiring complete production lines, we provide integrated solutions including:

- Raw material pretreatment systems

- Precision mixing equipment

- Granulation units

- Drying & cooling systems

- Screening and packaging machines

All our fertilizer granulator machines for sale come with:

- Factory-direct pricing (no middleman markup)

- On-site installation supervision

- Operator training programs

- Lifetime technical support

With 300+ reference plants across 40+ countries, Richi Machinery has the practical experience to recommend the optimal granulation solution for your specific materials and production goals. Contact our engineering team today for a customized equipment proposal.

04

What’s the difference between organic and compound fertilizer granulation ?

+

At Richi Machinery, with our 25 years of experience manufacturing fertilizer granulation equipment and completing over 300 successful projects globally, we’ve developed deep expertise in both organic and compound fertilizer production processes. Here’s a detailed comparison:

1. Raw Material Differences

Organic Fertilizer Granulation:

- Uses biological materials including:

- Animal manure (poultry, cattle, swine)

- Agricultural waste (straw, husks, compost)

- Food processing byproducts

- Municipal green waste

- Requires thorough fermentation (15-30 days) before granulation

- Natural binders like lignin or plant starches may be used

Compound Fertilizer Granulation:

- Utilizes chemical components:

- Nitrogen sources (urea, ammonium nitrate)

- Phosphates (DAP, MAP, SSP)

- Potassium (MOP, SOP)

- Micronutrients (Zn, Fe, B, etc.)

- May use chemical binders or rely on salt bridges

- Precise formula control is critical

2. Granulation Process Variations

Organic Fertilizer Granulator Machine:

- Typically uses ring die or rotary drum systems

- Operates at lower temperatures (50-70°C)

- Handles higher moisture content (25-35%)

- Produces softer granules (5-15N hardness)

NPK Fertilizer Granulator:

- Primarily employs ring die or double roller systems

- Requires higher pressure and temperature

- Processes drier materials (moisture <8%)

- Creates harder granules (15-30N hardness)

3. Equipment Design Distinctions

Our organic granular fertilizer making machines feature:

- Corrosion-resistant materials

- Larger die holes for fibrous materials

- Adjustable moisture control systems

- Specialized mixing chambers

For compound fertilizer granulator machines, we incorporate:

- Precision dosing systems

- Intensive mixers

- Temperature-controlled zones

- Anti-caking technology

4. End Product Characteristics

Organic Fertilizer Granules:

- Irregular surface texture

- Darker coloration

- Variable nutrient content (typically 3-8% NPK)

- Slow-release properties

Compound Fertilizer Granules:

- Smooth, uniform appearance

- Light-colored (usually white or grey)

- Precise nutrient content (e.g., 15-15-15)

- Immediate nutrient availability

5. Production Line Configuration

Complete organic fertilizer plants require:

- Fermentation systems

- Crushing equipment

- Bio-stabilization units

- Specialized drying solutions

NPK fertilizer production lines need:

- Raw material storage bins

- Precision weighing systems

- Chemical mixing equipment

- Advanced cooling systems

Richi Machinery designs customized fertilizer granulation equipment for both processes, with key advantages:

- Ring die technology ensuring 95%+ granulation rate

- Energy-efficient designs saving 15-20% power

- Durable construction for 10,000+ hour lifespan

- Flexible configurations for any production scale

Whether you need an organic fertilizer granulator machine for farm waste recycling or a high-capacity NPK fertilizer granulator for commercial production, our engineering team can recommend the optimal solution based on your specific materials, capacity requirements, and product goals. Contact us today for a professional consultation.

05

Can Your fertilizer Granulators Handle Wet or Dry Materials?

+

At Richi Machinery, our fertilizer granulation equipment is engineered to process both wet and dry materials efficiently, ensuring optimal granule quality across various fertilizer types. Here’s how our systems adapt to different moisture conditions:

1. Wet Granulation for Sticky or High-Moisture Materials

Our organic fertilizer granulator machines excel in processing wet, sticky inputs such as:

- Fresh or composted manure (poultry, cattle, swine)

- Agricultural waste (straw, green compost, food byproducts)

- High-moisture organic blends (up to 30-35% moisture content)

Key Features for Wet Granulation:

- Ring die granulator design with reinforced extrusion pressure to bind moist particles without clogging.

- Adjustable moisture control—compatible with liquid binders (optional) for better pellet formation.

- Post-granulation drying & cooling integration to stabilize granules for storage.

2. Dry Granulation for Powdered or Low-Moisture Materials

Our NPK fertilizer granulators and BB fertilizer blending systems are optimized for dry materials, including:

- NPK powder mixes (urea, DAP, potassium chloride)

- Mineral micronutrients (zinc, boron, iron powders)

- Pre-dried organic compounds (for organic-NPK blends)

Key Features for Dry Granulation:

- High-pressure ring die system compresses dry powders into dense, dust-free granules without added water.

- Precision mixing ensures uniform nutrient distribution before granulation.

- Anti-caking technology prevents re-powdering during storage.

Hybrid Solutions for Variable Materials

For operations processing both wet and dry inputs (e.g., organic-compound fertilizers), our flexible granulation systems allow:

- Adjustable processing parameters (pressure, temperature, die size) to switch between material types.

- Inline moisture sensors to auto-adjust granulation conditions.

Why Choose Richi Machinery’s Granulation Equipment?

- Material-specific designs: Customized ring die holes, roller pressure, and auger speeds for optimal results.

- Minimal binder use: Our mechanical granulation reduces dependency on chemical binders.

- Low maintenance: Robust construction handles abrasive materials (e.g., manure, mineral powders) with extended wear life.

Need a Granulator for Your Specific Material?

→ Contact us to test your raw materials in our facility and receive a tailored granulation solution.

06

What’s the capacity range of your fertilizer granulation equipment?

+

Richi Machinery offers a complete range of fertilizer granulator machines to meet diverse production needs, from small farm operations to large-scale commercial fertilizer plants. Our ring die granulation systems are available in multiple configurations with varying throughput capacities:

Standard Capacity Ranges:

- Compact Granulation Lines (1-5 T/H)

- Ideal for:

- Small organic fertilizer producers

- Farm-based manure recycling operations

- Pilot plants and research facilities

- Typical applications:

- Converting livestock manure into organic granules

- Processing agricultural waste into premium fertilizers

- Small batch specialty fertilizer production

- Ideal for:

- Mid-Scale Production (5-15 T/H)

- Suitable for:

- Regional organic fertilizer manufacturers

- Medium NPK compound fertilizer plants

- Municipal waste recycling facilities

- Common uses:

- Commercial organic fertilizer production

- Custom NPK formulations

- Organic-compound fertilizer manufacturing

- Suitable for:

- Industrial-Scale Systems (15-30 T/H)

- Designed for:

- Large commercial fertilizer plants

- Government agricultural projects

- Export-oriented fertilizer production

- Typical configurations:

- Complete NPK granulation lines

- High-volume organic fertilizer plants

- Bulk blending fertilizer systems

- Designed for:

- Heavy-Duty Production (30-60 T/H)

- Engineered for:

- Multinational fertilizer corporations

- National agricultural programs

- Large-scale organic waste recyclers

- System features:

- Fully automated control

- Continuous processing capability

- Integrated quality control systems

- Engineered for:

Key Technical Specifications:

- Organic fertilizer granulator machines:

- Capacity: 1-30 T/H

- Moisture tolerance: 20-35%

- Granule size: 2-8mm adjustable

- NPK fertilizer granulators:

- Capacity: 1-60 T/H

- Moisture content: <8%

- Granule hardness: >15N

- Bulk blending systems:

- Capacity: 1-50 T/H

- Mixing uniformity: >95%

- Anti-segregation design

Custom Capacity Solutions:

We understand that every fertilizer production requirement is unique. Our engineering team can design:

- Specialized granulation systems for unusual material characteristics

- Hybrid configurations for combined organic/NPK production

- Modular systems for future capacity expansion

- Customized granule specifications (size, density, hardness)

Factors Affecting Capacity Selection:

- Raw material characteristics (moisture, texture, composition)

- Desired granule specifications (size, shape, density)

- Available production space and layout

- Power supply and utility considerations

- Future expansion requirements

For precise capacity recommendations, we offer:

- Material testing and analysis

- Production simulation

- Factory acceptance trials

- Process optimization consulting

All Richi Machinery fertilizer granulation equipment features:

- Robust ring die construction for consistent performance

- Energy-efficient operation

- Minimal maintenance requirements

- Long service life

To determine the ideal capacity for your specific needs, contact our technical team for a detailed evaluation and equipment proposal. We’ll help you select the perfect fertilizer granule making machine configuration to match your production goals and operational requirements.

07

What raw materials can be used for organic fertilizer granulation?

+

Richi Machinery’s organic fertilizer granulator machines are engineered to process a wide variety of organic materials into high-quality fertilizer granules. Our ring die granulation systems can effectively transform numerous organic waste streams into valuable, nutrient-rich fertilizers.

Primary Raw Material Categories:

- Animal Manures

- Poultry manure (chicken, duck, turkey)

- Livestock waste (cattle, pig, sheep)

- Horse stable bedding

- Rabbit and other small animal droppings

- Agricultural Residues

- Crop straw (rice, wheat, corn)

- Husk and shell materials (peanut, coconut)

- Spent mushroom substrate

- Pruned orchard and vineyard waste

- Food Processing Byproducts

- Fruit and vegetable waste

- Brewery and distillery grains

- Coffee grounds and tea waste

- Oilseed meal residues

- Municipal and Industrial Organics

- Composted green waste

- Sewage sludge (properly treated)

- Food service organics

- Biodegradable packaging materials

- Specialty Additives

- Seaweed and aquatic plants

- Fish processing waste

- Biochar and wood ash

- Beneficial microbial inoculants

Material Preparation Requirements:

For optimal granulation in our organic fertilizer granulator machines:

- Moisture content should be adjusted to 25-35%

- Particle size reduced to <5mm through crushing

- Proper composting completed (for raw manures)

- Carbon-nitrogen ratio balanced (25-30:1 ideal)

Technical Considerations for Different Materials:

- Fibrous materials (straw, husks): Require additional crushing and moisture adjustment

- High-nitrogen materials (poultry manure): May need carbon-rich bulking agents

- Sticky substances (food waste): Benefit from absorbent additives

- Low-nutrient materials (wood waste): Often blended with nutrient-dense components

Our fertilizer granulation equipment features specialized adaptations for challenging materials:

- Reinforced ring die designs for abrasive mixtures

- Variable compression settings for different material densities

- Adjustable moisture control systems

- Wear-resistant components for long service life

End Product Applications:

Depending on input materials, our organic granular fertilizer making machine can produce:

- General-purpose organic fertilizers

- Specialty crop formulations

- Soil conditioners and amendments

- Biofertilizer carriers

- Organic-mineral blended products

For operations handling multiple material streams, we offer:

- Customized material blending systems

- Pre-processing equipment (shredders, mixers)

- Moisture adjustment technology

- Quality control instrumentation

Material Testing and Optimization:

We provide:

- Laboratory-scale material evaluation

- Pilot-scale granulation trials

- Process parameter optimization

- Recipe development assistance

All Richi Machinery organic fertilizer production systems are designed for:

- Consistent granule quality

- Efficient material utilization

- Low energy consumption

- Easy operation and maintenance

To determine the best granulation solution for your specific raw materials, contact our technical team for a comprehensive evaluation and equipment recommendation. We’ll help you transform your organic waste streams into valuable fertilizer products.

08

Do I need a fermentation process before granulation?

+

For most organic materials, proper fermentation is indeed a critical pretreatment step before granulation in fertilizer production systems. At Richi Machinery, we’ve developed specialized solutions to optimize this essential process for superior granule quality and safety.

Why Fermentation Matters:

- Pathogen Elimination

- Destroys harmful bacteria (E. coli, Salmonella)

- Reduces parasite eggs and weed seeds

- Makes manure and waste products safe for agricultural use

- Material Transformation

- Breaks down complex organic compounds

- Stabilizes nutrient content

- Reduces phytotoxicity risks

- Improves material uniformity for granulation

- Process Optimization

- Adjusts moisture to ideal granulation levels (25-35%)

- Develops natural binding properties

- Reduces odor issues in final product

- Enhances granule structure and durability

Our Complete Fermentation Solutions:

Richi Machinery provides integrated fermentation systems specifically designed to work with our organic fertilizer granulator machines:

- Windrow Turners

- Crawler type for large-scale operations

- Wheel type for medium facilities

- Hydraulic lifting models for space constraints

- In-Vessel Fermenters

- Fully enclosed systems

- Temperature and aeration control

- 7-15 day processing time

- Continuous feed options

- Ancillary Equipment

- Moisture adjustment systems

- Aeration control technology

- Temperature monitoring

- Deodorizing components

Technical Specifications:

- Processing capacity: 1-500 tons/day

- Fermentation cycle: 15-30 days (ambient) or 7-15 days (accelerated)

- Temperature range: 55-75°C for pathogen kill

- Turning frequency: 1-3 times weekly

Material-Specific Recommendations:

- Animal Manures

- Minimum 25-day fermentation

- Requires regular turning

- Carbon supplementation often needed

- Crop Residues

- 15-20 day process

- Moisture critical (50-60% ideal)

- Particle size reduction beneficial

- Food Wastes

- 20-30 day stabilization

- Bulking agents required

- Frequent turning recommended

Integrated System Advantages:

When combining our fermentation equipment with Richi Machinery’s organic fertilizer granulation equipment:

- Consistent material quality for granulation

- Optimized moisture content

- Improved granule formation

- Higher nutrient retention

- Better product stability

Custom Configuration Options:

We design fermentation systems based on:

- Available raw materials

- Site conditions

- Production scale

- Climate factors

- End product requirements

Post-Fermentation Processing:

Our complete lines include:

- Crushing systems for fermented material

- Precision mixing equipment

- Moisture adjustment technology

- Granulation preparation systems

For operations seeking turnkey solutions, Richi Machinery provides:

- Complete facility layout design

- Equipment selection and integration

- Process optimization consulting

- Operator training programs

Technical Support Services:

- Fermentation recipe development

- Process parameter optimization

- Quality control protocols

- Troubleshooting assistance

To determine the ideal fermentation solution for your organic fertilizer granulator machine setup, contact our engineering team for a detailed evaluation of your materials and production requirements. We’ll help you develop the most efficient and effective pretreatment system for your specific needs.

09

Which fertilizer granulator equipment is best for organic fertilizer?

+

After extensive technical evaluation and field testing across numerous organic fertilizer applications, Richi Machinery confirms that the ring die granulator stands as the superior choice for organic fertilizer production. Here’s why this specific fertilizer granulation equipment outperforms other alternatives:

Technical Advantages of Ring Die Granulators for Organic Materials:

- Superior Material Adaptation

- Handles high-moisture organic matter (25-35% optimal)

- Processes fibrous materials (straw, manure) without clogging

- Accommodates variable particle sizes in feedstock

- Enhanced Granule Quality

- Produces uniform spherical granules (2-8mm adjustable)

- Achieves higher granule density (1.2-1.5g/cm³)

- Delivers superior crushing strength (>10N)

- Process Efficiency Benefits

- Higher yield rates (95%+ granulation efficiency)

- Lower energy consumption per ton output

- Continuous operation capability

Comparative Analysis Against Other Granulator Types:

- Versus Disc Granulators

- Higher production capacity (30%+ greater throughput)

- Better granule uniformity (±0.5mm size variation)

- Lower binder requirements

- Versus Flat Die Granulators

- Greater die longevity (3,000+ operating hours)

- More consistent pressure application

- Easier maintenance access

- Versus Rotary Drum Granulators

- Smaller footprint for equivalent capacity

- Precise moisture control

- Reduced dust generation

Key Design Features of Our Organic Fertilizer Granulator Machines:

- Specialized Ring Die Configuration

- Larger die holes for organic materials

- Reinforced alloy steel construction

- Optimized L/D ratio for organic compounds

- Advanced Pressure System

- Adjustable roller pressure (50-100kN)

- Balanced compression across material flow

- Wear-compensation mechanism

- Material-Specific Modifications

- Anti-corrosion treatment for acidic organics

- Reinforced scrapers for sticky materials

- Special discharge mechanisms for light granules

Application-Specific Performance Data:

- Animal Manure Processing

- Throughput: 3-8% higher than alternatives

- Granule stability: 15% improved

- Moisture tolerance: up to 38%

- Crop Residue Granulation

- Fiber handling: 50mm max length

- Binder reduction: 20-30% less required

- Energy efficiency: 0.8-1.2kWh/ton

- Food Waste Conversion

- Odor control: integrated deodorizing

- Contaminant tolerance: 5-8% inert materials

- Nutrient retention: 95%+ preservation

Complete System Integration:

Our ring die organic fertilizer granulator machines seamlessly integrate with:

- Pre-processing systems (crushers, mixers)

- Post-granulation equipment (dryers, coolers)

- Quality control components (screeners, coaters)

- Packaging automation

Customization Options Available:

- Die hole size configuration (2-10mm)

- Throughput capacity adjustment

- Special material handling adaptations

- Automation level selection

Operational Benefits:

- 30% lower maintenance requirements

- 20% faster die changeout

- Simplified operator training

- Reduced spare parts inventory

For operations seeking the most reliable and efficient organic fertilizer granule making machine, Richi Machinery’s ring die granulators deliver unmatched performance across all critical parameters. Contact our engineering team to discuss your specific organic material characteristics and production requirements for a tailored equipment recommendation.

10

Can your organic fertilizer production line include crushing and mixing?

+

Absolutely. At Richi Machinery, we design and manufacture complete organic fertilizer production lines that integrate all essential processing stages – from raw material preparation to final packaging. Our systems are engineered to handle the unique challenges of organic material processing while maximizing efficiency and output quality.

Complete Line Configuration Options:

- Pre-processing Stage

- Heavy-duty crushers for:

- Breaking down compost clumps

- Reducing straw and fibrous materials

- Processing hardened manure cakes

- Specialized mixers for:

- Homogenizing diverse organic materials

- Precise additive incorporation

- Moisture content adjustment

- Heavy-duty crushers for:

- Granulation Stage

- Ring die granulators specifically designed for:

- Variable organic material densities

- High-moisture content processing

- Fiber-rich composition handling

- Ring die granulators specifically designed for:

- Post-granulation Processing

- Efficient drying systems:

- Low-temperature preservation of nutrients

- Moisture reduction to <15%

- Odor control integration

- Precision cooling:

- Granule stabilization

- Preparation for coating

- Screening and recycling:

- Size classification

- Oversize material recirculation

- Efficient drying systems:

Technical Highlights of Our Integrated Systems:

- Material-Specific Engineering

- Crushers with adjustable rotor speeds (18-55 rpm)

- Mixers with paddle configurations for sticky organics

- Granulators with reinforced die designs

- Process Optimization Features

- Moisture control throughout all stages

- Dust suppression systems

- Continuous flow design

- Automated process monitoring

- Capacity Matching

- Component sizing for balanced throughput

- Buffer zones between stages

- Production rate synchronization

Customization Options:

- For Diverse Organic Inputs

- Special crusher configurations for:

- Palm waste and coco peat

- Mushroom substrate

- Aquaculture waste

- Special crusher configurations for:

- For Specific Product Requirements

- Mixer adaptations for:

- Microbial inoculant addition

- Mineral supplementation

- Binder incorporation

- Mixer adaptations for:

- For Space Constraints

- Compact line layouts

- Vertical design options

- Modular system configurations

Quality Control Integration:

Our complete lines can include:

- Online moisture detection

- Granule strength testing

- Nutrient content monitoring

- Automated weight control

Operational Advantages:

- Single-source responsibility

- Unified control system

- Matching equipment capacities

- Streamlined maintenance

Complete Line Capacities Available:

- Small-scale: 1-3 tons/hour

- Medium-scale: 3-10 tons/hour

- Large-scale: 10-30 tons/hour

- Industrial: 30+ tons/hour

Additional Optional Components:

- Automatic batching systems

- Fermentation turners

- Coating drums

- Packaging automation

- Palletizing systems

For operations seeking a truly optimized organic fertilizer granule making machine system, our complete line solutions ensure:

- Consistent product quality

- Maximized nutrient retention

- Efficient energy use

- Reliable continuous operation

To discuss your specific organic fertilizer production needs and receive a customized complete line proposal, contact Richi Machinery’s engineering team today. We’ll analyze your raw materials, production goals, and site conditions to recommend the perfect integrated system configuration.

11

How do you control moisture in organic granules?

+

Effective moisture control is critical in organic fertilizer production, and Richi Machinery has developed specialized drying solutions that integrate seamlessly with our fertilizer granulation equipment. Our systems precisely regulate moisture content while preserving the valuable nutrients in organic materials.

Multi-Stage Moisture Management System:

- Pre-Granulation Moisture Control

- Fermentation monitoring to achieve ideal starting moisture (30-40%)

- Adjustable mixing systems for precise water/binder addition

- Moisture sensors with real-time feedback to mixing process

- In-Line Drying Technology

- Counter-flow rotary dryers with indirect heating options

- Temperature range: 60-120°C (adjustable for material sensitivity)

- Residence time control: 15-45 minutes

- Moisture reduction from 30-35% down to 12-15%

- Post-Drying Stabilization

- Fluidized bed coolers to set granule structure

- Equilibrium moisture adjustment chambers

- Final moisture verification sensors

Technical Specifications of Our Organic Fertilizer Drying Systems:

- Capacity Range: 1-30 tons/hour

- Heat Sources: Biomass, gas, steam, or electric

- Thermal Efficiency: 75-85%

- Moisture Reduction: Typically 18-22% absolute reduction

- Energy Consumption: 80-120kWh/ton water evaporated

Key Advantages of Our Moisture Control Approach:

- Nutrient Preservation

- Low-temperature zones for heat-sensitive organics

- Short exposure times to minimize nutrient loss

- Antioxidant protection in drying atmosphere

- Granule Quality Maintenance

- Minimized cracking and breakage

- Uniform drying across all granule sizes

- Surface polishing effect for better flowability

- System Integration Benefits

- Continuous moisture monitoring

- Automatic feedback to dryer controls

- Linked with granulator for process adjustment

Material-Specific Drying Solutions:

- For Animal Manure-Based Granules

- Higher temperature zones (90-120°C)

- Enhanced odor control systems

- Anti-caking agent injection

- For Plant Waste Granules

- Moderate temperatures (70-90°C)

- Longer retention times

- Gentle tumbling action

- For Mixed Organic Granules

- Zoned temperature control

- Adjustable flight patterns

- Moisture balancing technology

Advanced Control Features:

- PLC-based moisture regulation

- Hot air volume and velocity control

- Emergency moisture override systems

- Data logging for process optimization

Optional Upgrades:

- Heat Recovery Systems

- Pre-heating of incoming air

- Energy savings up to 30%

- Exhaust Treatment

- Odor scrubbing

- Dust recovery

- Heat recycling

- Automation Packages

- Moisture-based speed control

- Self-adjusting weir gates

- Predictive drying algorithms

Quality Assurance Measures:

- Post-drying moisture testing stations

- Granule integrity checks

- Cool-down rate monitoring

- Final product stabilization

For operations requiring complete moisture management solutions, Richi Machinery offers:

- Pilot testing of your materials

- Custom dryer sizing

- Complete thermal system design

- Operator training programs

Our organic fertilizer granulator machines and drying systems work in perfect harmony to deliver:

- Stable, storage-ready granules

- Consistent product quality

- Maximum nutrient retention

- Efficient energy use

To discuss your specific moisture control challenges and receive a customized solution proposal, contact Richi Machinery’s drying technology experts today. We’ll analyze your material characteristics and production requirements to recommend the optimal configuration for your organic fertilizer production line.

12

Is your fertilizer granulator equipment suitable for small farms?

+

Richi Machinery understands the unique needs of small-scale farming operations, which is why we’ve developed specialized compact fertilizer granulation equipment specifically designed for small farm applications. Our small-scale solutions maintain the same quality engineering as our industrial systems, just scaled for modest production requirements.

Small Farm Granulation Solutions:

1. Model FZLH250 (Compact Farm Edition)

- Capacity: 1–2 T/H

- Power: 22 KW (3-phase, farm-compatible)

- Ring Die Diameter: 250mm

- Best For: Poultry/cattle manure, composted organics, crop residues

2. Model FZLH320 (Enhanced Farm Pro)

- Capacity: 2–3 T/H

- Power: 22 KW (same power, higher output)

- Ring Die Diameter: 320mm

- Best For: Mixed farm waste, high-fiber materials, small commercial production

Key Features of Our Small Farm Equipment:

- Space-Efficient Design

- Narrow equipment profile fits standard farm buildings

- Vertical configuration options available

- Modular components for easy expansion

- Simplified Operation

- Basic control systems requiring minimal training

- Quick-change die assemblies

- Visual maintenance indicators

- Material Flexibility

- Processes all common farm wastes:

- Livestock manure (fresh or composted)

- Crop residues

- Small batches of mixed organic materials

- Processes all common farm wastes:

- Economic Advantages

- Lower power consumption (15-25 kW range)

- Minimal infrastructure requirements

- Affordable spare parts inventory

Complete Small Farm Systems Include:

- Basic Configuration:

- Crusher-mixer combo unit

- Ring die granulator

- Basic drying rack system

- Upgrade Options:

- Small rotary dryer

- Vibrating screener

- Semi-auto bagging station

Technical Specifications:

- Granule size: 3-6mm standard (adjustable)

- Moisture tolerance: 25-32% input

- Production efficiency: ≥90%

- Noise level: <75 dB

Farm-Specific Adaptations:

- For Livestock Operations

- Manure-specific die configurations

- Integrated odor control

- Wet material handling options

- For Crop Farms

- Straw processing attachments

- Fiber-cutting enhancements

- Dry material optimization

- For Mixed Operations

- Versatile material handling

- Quick-change tooling

- Adaptive control settings

Why Small Farms Choose Richi Machinery:

- Appropriate Scaling

- No overbuilt components

- Right-sized for farm needs

- Pay-as-you-grow potential

- Genuine Farm Understanding

- Seasonal operation features

- Intermittent use durability

- Simple maintenance protocols

- Real-World Practicality

- Standard farm power compatibility

- Standard building clearance

- Routine farm tool maintenance

Support Services for Small Farms:

- On-farm installation assistance

- Operator training programs

- Seasonal maintenance packages

- Emergency troubleshooting

Production Scenarios:

- Poultry Farm Example

- Input: 1.2 tons chicken manure/day

- Output: 1 ton premium organic granules/day

- System payback: 10-14 months

- Dairy Farm Application

- Input: 2 tons cattle waste/day

- Output: 1.6 ton fertilizer/day

- Value-added product creation

- Market Garden Setup

- Input: Crop residues + green waste

- Output: Specialty vegetable fertilizer

- Closed-loop sustainability

For small farms looking to enter fertilizer production or improve waste management, Richi Machinery offers the most practical, farm-proven fertilizer granulator machines at true small-scale capacities. Contact our agricultural specialists to discuss which compact granulation solution best fits your operation’s needs and budget.

13

What’s the granule size range for organic fertilizer?

+

Richi Machinery’s organic fertilizer granulator machines produce precisely sized granules to meet various agricultural applications. Our ring die granulation systems offer flexible size control to accommodate different spreading methods and crop requirements.

Standard Granule Size Specifications:

- Size Range Capability

- Minimum diameter: 2.0mm

- Maximum diameter: 8.0mm

- Standard production tolerance: ±0.3mm

- Common Production Sizes

- Fine granules: 2.0-3.5mm (for seed coating/fertigation)

- Medium granules: 3.5-5.5mm (standard field application)

- Large granules: 5.5-8.0mm (orchard/vineyard use)

Technical Control Features:

- Ring Die Configuration

- Interchangeable dies with hole diameters from 2-8mm

- Precision-machined die holes for consistent sizing

- Special anti-clogging design for organic materials

- Size Adjustment Methods

- Die hole diameter selection

- Roller pressure modulation

- Cutting system calibration

- Moisture content optimization

Application-Specific Recommendations:

- For Broadcast Spreading

- Optimal size: 3.5-5.0mm

- Sphericity: >85%

- Recommended moisture: 12-15%

- For Bagged Products

- Preferred size: 2.5-4.5mm

- Hardness requirement: >8N

- Surface smoothness control

- For Specialty Applications

- Nursery crops: 2.0-3.5mm

- Row crops: 4.0-6.0mm

- Tree fertilization: 6.0-8.0mm

Material Considerations for Granule Size:

- Fibrous Materials (straw, manure)

- Minimum practical size: 3.0mm

- Recommended compression ratio: 4:1

- Binder requirements for small granules

- Dense Materials (compost, food waste)

- Size range: 2.0-7.0mm

- Lower pressure requirements

- Better shape retention

Quality Control Measures:

- Laser sizing sensors

- Automated screening systems

- Real-time size distribution monitoring

- Recycle loops for off-size granules

Customization Options:

- Special die configurations

- Non-standard size ranges

- Mixed-size production capability

- Surface texture modification

For operations requiring specific granule sizing, Richi Machinery provides:

- Material testing and size optimization

- Die selection consultation

- Process parameter adjustment

- Quality control system integration

Our organic fertilizer granule making machines ensure:

- Consistent size distribution

- Uniform nutrient content

- Excellent flow characteristics

- Minimal dust generation

To determine the ideal granule size for your specific application, contact our technical team for a professional assessment of your requirements and material characteristics. We’ll recommend the optimal configuration for your fertilizer production needs.

14

Do you provide bio-fermentation equipment?

+

Richi Machinery provides complete bio-fermentation solutions specifically designed to prepare organic materials for our fertilizer granulation equipment. Our fermentation systems optimize the biological pretreatment process to ensure ideal material characteristics for subsequent granulation.

Core Fermentation Equipment Offerings:

- Compost Turner Systems

- Crawler-type turners

- Capacity: 200-3000 m³ per turn

- Turning depth: 0.8-2.5m

- Mobility: Self-propelled with 360° rotation

- Wheel-type turners

- Ideal for windrow widths of 2-4m

- Hydraulic lifting mechanism

- Fuel-efficient diesel or electric options

- In-Vessel Fermentation Tanks

- Cylindrical fermentation reactors

- Volume: 50-500 m³ per unit

- Retention time: 10-20 days

- Automated aeration control

- Tunnel fermentation systems

- Continuous feed design

- Temperature monitoring zones

- Integrated deodorization

Technical Specifications:

- Temperature range: 50-75°C (adjustable)

- Oxygen concentration: 10-18% (automatically regulated)

- Moisture control: 50-65% optimal

- PH monitoring: Integrated sensors

- Turning frequency: Programmable cycles

Key Process Advantages:

- Pathogen Elimination

- Sustained thermophilic conditions

- Complete parasite egg destruction

- Weed seed deactivation

- Material Transformation

- Lignin-cellulose breakdown

- Humic acid development

- Odor reduction

- Natural binder formation

- Granulation Preparation

- Moisture standardization

- Particle size reduction

- Enhanced binding properties

- Nutrient stabilization

System Integration with Granulation:

Our bio-fermentation equipment is designed to work seamlessly with Richi Machinery’s organic fertilizer granulator machines, featuring:

- Compatible material discharge systems

- Moisture conditioning interfaces

- Capacity-matched throughput

- Unified control options

Customization Options:

- For Specific Materials

- Poultry manure configurations

- Crop residue adaptations

- Food waste specialties

- Municipal sludge variants

- For Climate Conditions

- Cold weather packages

- High humidity solutions

- Arid environment designs

- For Space Constraints

- Compact layouts

- Vertical configurations

- Mobile solutions

Advanced Control Systems:

- PLC-based process management

- Remote monitoring capability

- Data logging and reporting

- Automated safety protocols

Support Services:

- Microbial strain selection

- Process parameter optimization

- Operator training programs

- Maintenance planning

For operations seeking complete organic fertilizer production lines, we provide integrated systems from initial fermentation through final granulation, ensuring:

- Consistent material quality

- Efficient process flow

- Optimal nutrient retention

- Maximum production yield

To discuss your specific bio-fermentation requirements and how they integrate with fertilizer granulation equipment, contact Richi Machinery’s organic process specialists for a customized solution proposal.

15

What’s the advantage of NPK compound fertilizer granules?

+

Richi Machinery’s NPK fertilizer granulation equipment produces superior quality compound fertilizer granules that offer significant benefits over conventional powder fertilizers. Our ring die granulators create precisely formulated NPK granules with optimized physical and chemical properties.

Key Technical Advantages:

- Precision Nutrient Delivery

- Uniform NPK distribution within each granule (±2% variation)

- Controlled-release formulations available

- Reduced nutrient leaching (15-20% less than powders)

- Balanced nutrient ratios maintained during application

- Enhanced Physical Properties

- High granule hardness (15-30N crush resistance)

- Low dust generation (<1% by weight)

- Excellent flow characteristics (angle of repose <25°)

- Moisture resistance (<5% absorption in humid conditions)

- Agricultural Performance Benefits

- 20-30% improved nutrient use efficiency

- Root-zone targeted nutrient placement

- Reduced foliar burn potential

- Compatible with precision farming equipment

Production Advantages with Our Equipment:

- Superior Granulation Quality

- 95%+ granulation rate

- <5% return material

- Precise size control (2-5mm standard)

- Spherical granule formation

- Material Flexibility

- Handles various NPK formulations (15-15-15, 17-17-17, etc.)

- Accommodates micronutrient additives

- Processes both dry and semi-wet materials

- Compatible with organic-mineral blends

- Economic Benefits

- 15-20% lower production costs vs. traditional methods

- Reduced packaging requirements

- Lower transportation costs

- Minimal storage losses

Technical Specifications of Our NPK Granulators:

- Capacity range: 1-30 tons/hour

- Granule density: 1.3-1.6 g/cm³

- Moisture content: <5% in final product

- Temperature control: 50-80°C during process

- Power consumption: 25-35 kWh/ton

Special Features for NPK Production:

- Advanced Mixing System

- Horizontal twin-shaft design

- Micro-ingredient dosing accuracy

- Homogeneity >98%

- Granulation Technology

- Ring die compression principle

- Adjustable roller pressure (50-100 bar)

- Quick-release die mechanism

- Post-Granulation Processing

- Multi-stage drying

- Counter-flow cooling

- Precision screening

- Anti-caking treatment

Customization Options:

- Special NPK formulations

- Coated granule production

- Custom granule sizes

- Automated batching systems

For producers looking to manufacture premium NPK compound fertilizers, Richi Machinery’s fertilizer granulation equipment delivers:

- Consistent product quality

- Flexible production capabilities

- Energy-efficient operation

- Reliable performance

To discuss your specific NPK granulation requirements and receive a customized equipment proposal, contact our compound fertilizer specialists today.

16

Which granulator is best for NPK fertilizers?

+

For professional NPK fertilizer production, Richi Machinery recommends ring die granulators as the optimal solution. Our NPK fertilizer granulator machines utilize advanced ring die technology specifically engineered for compound fertilizer manufacturing.

Technical Advantages of Ring Die Granulators for NPK:

- Superior Granule Quality

- Uniform spherical granules (2-5mm)

- High crushing strength (15-30N)

- Low dust content (<1%)

- Precise nutrient distribution (±2% variation)

- Enhanced Production Efficiency

- 95-98% granulation rate

- Continuous 24/7 operation capability

- Fast die changeover (under 30 minutes)

- Low energy consumption (25-35kWh/ton)

- Material Processing Benefits

- Handles diverse NPK formulations

- Accommodates micronutrient additives

- Processes both dry and semi-wet mixes

- Maintains precise nutrient ratios

Comparative Performance Data:

| Feature | Ring Die Granulator | Alternative Granulators |

|---|---|---|

| Granule Density | 1.3-1.6 g/cm³ | 1.1-1.4 g/cm³ |

| Production Yield | 95-98% | 85-92% |

| Nutrient Uniformity | ±2% | ±5-8% |

| Maintenance Interval | 500+ hours | 300-400 hours |

Key Components of Our NPK Granulator Machines:

- Precision Ring Die Assembly

- High-chrome alloy construction

- Multiple hole size options (2-8mm)

- Special anti-corrosion treatment

- Quick-release mechanism

- Advanced Compression System

- Hydraulic pressure adjustment

- Balanced roller configuration

- Wear compensation technology

- Automatic gap control

- Intelligent Control Features

- Real-time pressure monitoring

- Temperature regulation

- Production data logging

- Safety interlock system

Production Line Integration:

Our NPK fertilizer granulation equipment seamlessly connects with:

- Raw material batching systems

- High-intensity mixers

- Multi-stage dryers

- Precision coolers

- Automated screening units

Customization Options:

- Special NPK formulations (10-50-10, 15-15-15, etc.)

- Coated granule production

- Custom granule sizes

- Automated process control levels

Technical Specifications:

- Capacity range: 1-30 tons/hour

- Power requirements: 22-160kW

- Operating pressure: 50-100 bar

- Moisture content: <5% final product

- Granule hardness: 15-30N

Why Choose Richi Machinery NPK Granulators:

- Proven NPK Formulation Expertise

- Over 100 successful NPK plant installations

- Specialized knowledge in compound fertilizers

- Custom formulation development

- Reliable Performance

- Heavy-duty construction

- Premium component selection

- Stable continuous operation

- Comprehensive Support

- Process optimization services

- Operator training programs

- Spare parts availability

- Technical troubleshooting

For NPK fertilizer producers seeking the most efficient and reliable granulation solution, Richi Machinery’s ring die granulators deliver unmatched performance in:

- Product quality consistency

- Production efficiency

- Nutrient precision

- Operational reliability

Contact our compound fertilizer specialists today to discuss your specific NPK granulation requirements and receive a customized equipment proposal.

17

Do you offer BB fertilizer blending lines?

+

Richi Machinery designs and manufactures professional bulk blending (BB) fertilizer production lines that deliver precise nutrient formulations with exceptional homogeneity. Our systems integrate advanced batching technology with specialized blending equipment to create uniform fertilizer mixes.

Core Components of Our BB Fertilizer Lines:

- Automated Batching System

- Computer-controlled weigh hoppers

- Precision load cells (±0.5% accuracy)

- Sequential ingredient dosing

- Recipe management software

- High-Efficiency Blenders

- Dual-shaft paddle mixers

- 60-90 second blending cycles

- Anti-segregation design

- Minimal power consumption

- Packaging Integration

- Bulk bag filling stations

- 25-50kg bagging machines

- Automatic weighing systems

- Palletizing options

Technical Specifications:

- Capacity range: 5-50 tons/hour

- Mixing uniformity: >95%

- Particle size tolerance: ±1mm

- Residual rate: <0.3%

- Power requirements: 15-75kW

Material Handling Capabilities:

Our BB fertilizer equipment processes:

- Urea granules (1-4mm)

- DAP/MAP (2-5mm)

- MOP/SOP (2-4mm)

- Micronutrient additives

- Custom NPK blends

Key System Advantages:

- Precision Formulation

- ±1% nutrient accuracy

- Micro-ingredient capability (down to 0.5%)

- Automatic formula adjustment

- Batch traceability

- Advanced Blending Technology

- Counter-rotating paddles

- Variable speed control

- Wear-resistant liners

- Quick-clean design

- Quality Control Features

- In-line screening

- Metal detection

- Moisture monitoring

- Automated sampling

Custom Configuration Options:

- Raw Material Handling

- Dump hoppers

- Pneumatic conveying

- Vibratory feeders

- Pre-screening

- Process Automation Levels

- Semi-automatic

- PLC-controlled

- Full SCADA systems

- Specialty Applications

- Coated blends

- Fortified mixtures

- Organic-mineral combinations

- Slow-release formulations

Production Line Layout Options:

- Linear modular design

- Vertical tower configuration

- Mobile blending units

- Expandable systems

Operational Benefits:

- 30-50% faster than manual blending

- 95% less material loss

- Flexible small-batch capability

- Easy recipe changes

Why Choose Richi Machinery BB Systems:

- Particle Matching Expertise

- Granule size optimization

- Density balancing

- Surface treatment advice

- Segregation Prevention

- Specialized mixer design

- Optimal free-fall heights

- Controlled discharge rates

- Complete Solution Provider

- Structural support design

- Dust collection systems

- Utility planning

- Installation supervision

For fertilizer producers requiring bulk blending solutions, Richi Machinery offers:

- Pilot testing of your materials

- Custom system engineering

- Performance guarantees

- Ongoing technical support

Contact our blending specialists today to discuss your BB fertilizer production requirements and receive a tailored equipment proposal.

18

What’s the difference between BB fertilizer and compound granules?

+

Richi Machinery specializes in both bulk blend (BB) and compound fertilizer production systems. While both produce nutrient-rich fertilizers, they differ fundamentally in production methods and characteristics.

1. Production Process Comparison

BB Fertilizer:

- Physical blending of pre-formed granules

- No chemical reaction during production

- Components maintain original properties

- Typical ingredients: prilled urea, granular DAP, KCl

Compound Granules:

- Chemical granulation process

- Raw materials react under heat/pressure

- New compounds form during production

- Uniform nutrient distribution per granule

2. Equipment Requirements

BB Fertilizer Lines:

- Precision batching scales

- Gentle-action mixers

- Particle size matching systems

- Anti-segregation conveyors

Compound Fertilizer Equipment:

- Reactor vessels

- High-intensity mixers

- Granulation equipment (ring die/pin)

- Drying/cooling systems

3. Granule Characteristics

BB Fertilizer:

- Variable color (component-dependent)

- Mixed granule shapes

- Component-specific hardness

- Visible individual nutrients

Compound Granules:

- Uniform coloration

- Consistent spherical shape

- Standardized hardness

- Homogeneous appearance

4. Nutrient Distribution

BB Fertilizer:

- Nutrients separate in individual granules

- Variable N-P-K per granule

- Requires uniform particle sizing

- Potential for segregation

Compound Granules:

- Balanced N-P-K in each granule

- Precise nutrient ratios

- No segregation concerns

- Controlled release profiles

5. Application Considerations

BB Fertilizer Advantages:

- Faster production changeovers

- Lower energy requirements

- Flexible small-batch production

- Easier formula adjustments

Compound Granule Benefits:

- More precise placement

- Better nutrient synergy

- Reduced application frequency

- Improved storage stability

6. Material Compatibility

BB Fertilizer Compatible Materials:

- Urea (46-0-0)

- DAP (18-46-0)

- MAP (11-52-0)

- MOP (0-0-60)

- SOP (0-0-50)

Compound Granulation Materials:

- Ammonium phosphates

- Potassium salts

- Sulfur compounds

- Micronutrient powders

- Binder additives

7. Quality Control Differences

BB Fertilizer QC Focus:

- Particle size matching

- Density compatibility

- Blend uniformity

- Segregation testing

Compound Granule QC:

- Nutrient homogeneity

- Granule hardness

- Moisture content

- Dissolution rates

8. Economic Factors

BB Fertilizer:

- Lower capital investment

- Reduced energy costs

- Higher raw material costs

- Faster ROI

Compound Granules:

- Higher equipment costs

- Greater energy use

- Lower material costs

- Premium product value

9. Storage & Handling

BB Fertilizer:

- Requires careful handling

- Potential for separation

- Moisture sensitivity varies

- Limited coating options

Compound Granules:

- More stable in storage

- Resists segregation

- Uniform moisture content

- Coating compatibility

10. Customization Options

BB Fertilizer Flexibility:

- Rapid formula changes

- Small batch capability

- Seasonal adjustments

- Custom blends

Compound Granule Customization:

- Controlled-release coatings

- Specialty formulations

- Enhanced nutrient packages

- pH-modified products

Richi Machinery provides optimized equipment solutions for both production methods:

- Complete BB blending lines

- Compound granulation systems

- Hybrid configuration options

- Custom plant engineering

For producers considering which method best suits their needs, we offer:

- Material testing services

- Process feasibility studies

- Pilot-scale trials

- Economic analyses

19

Can organic and chemical fertilizers be granulated together?

+

Richi Machinery’s advanced fertilizer granulation equipment enables the production of high-quality hybrid fertilizers that combine the benefits of organic and chemical nutrients in a single granule. Our specialized organic-compound fertilizer systems are engineered to overcome the technical challenges of co-granulating these diverse materials.

Technical Process Overview:

The production of organic-compound fertilizers requires careful material preparation and specialized equipment configurations. Our systems begin with precise organic matter conditioning, where composted materials are reduced to optimal particle size and moisture content.