Fish Feed Pelleting Machine Price

The fish feed pelleting machine price usually ranges from 3,000-200,000 USD. The fish feed pelletizing machine is the core equipment in the fish feed processing process and can be used to process floating fish feed, sinking fish feed, pet feed and other products.

With the rise of the aquatic feed processing industry, fish feed pellet machines have been more widely used, and there are more types. They mainly include ring die fish feed pellet machines and extruded fish feed pellet machines. The output of a single fish pellet machine is between 0.03-12t/h.

Different types, different fish feed pelleting machine prices

Fish feed pelletizing machines are mainly divided into ring-die fish feed pelletizing machines and fish feed extruders. The fish feed extruded pellet machine can be divided into twin-screw fish feed pellet machine and single-screw fish feed pellet machine. The technologies used in these equipment are completely different, because the prices of fish feed pellet mills also vary greatly.

At present, the mainstream fish feed pellet machines used by fish feed processing plants and fish farms are the following models:

Fish feed pellet machine (ring die type)

- Fish Feed Pelleting Machine Price: 7,000-100,000 USD

- Model: SZLH

- Output: 0.6-30 T/H

- Main Power: 22-315 KW

- Application: Hard pellet feed for sinking fish and shrimp

- Features: The main transmission system adopts gear transmission, the main transmission box is made of castings, with large bearing capacity, good stability and long service life. The feed auger, conditioner, and door cover are made of stainless steel to avoid contamination of raw materials due to equipment corrosion and longer service life. It has the advantages of high output, low noise, low energy consumption, long working life and easy operation and maintenance.

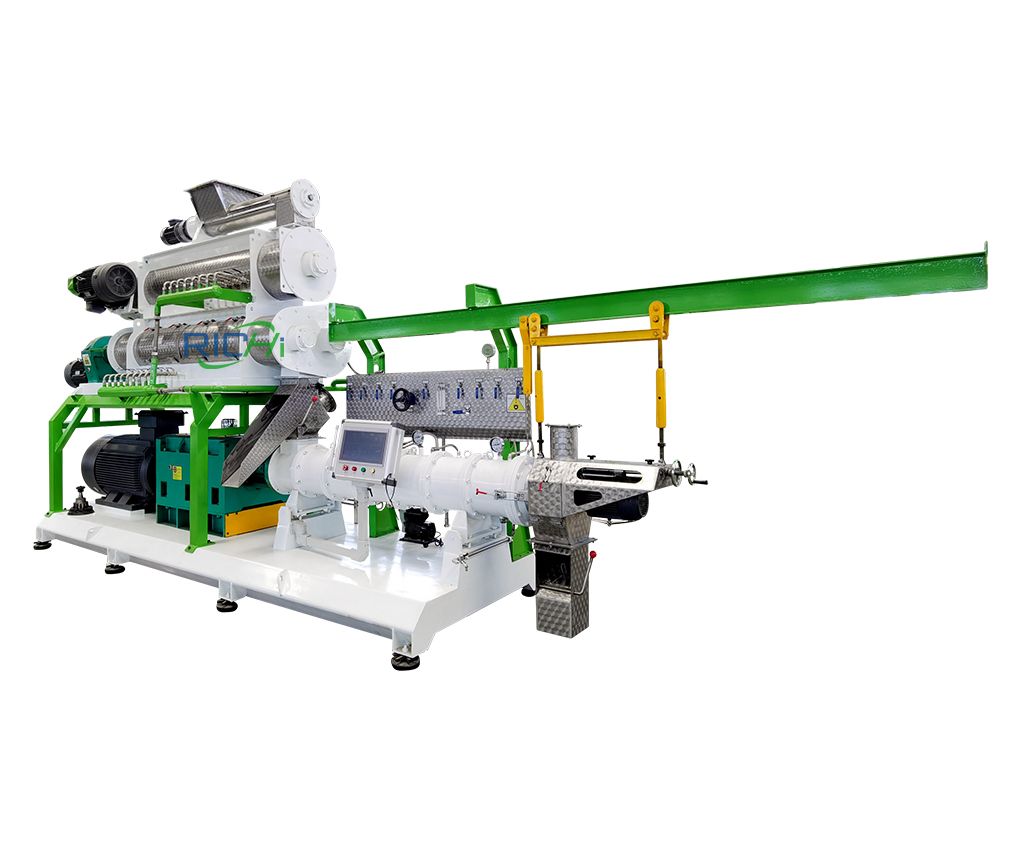

Fish feed pellet machine (twin screw type)

- Fish Feed Pelleting Machine Price: 70,000-200,000 USD

- Model: RCPH

- Output: 1.5-12T/H

- Main Power: 75-355 KW

- Application: high-grade puffed fish feed, pet feed

- Features: PLC+touch screen control system, easy to operate and simple; The main engine adopts frequency conversion control, and the screw speed can be adjusted, which is suitable for different formulas (sinking feed, semi-floating feed, floating feed). Effectively distribute the reasonable shear force in different areas of the extrusion cavity, and effectively increase the output under the premise of ensuring high quality.

Fish feed pellet machine (single screw type)

- Fish Feed Pellet Machine Price: 3,000 – 40,000 USD

- Model: DSP/DGP

- Output: 0.03-4T/H

- Main Power: 5.5-132 KW

- Application: Conventional aquatic expanded feed, pet feed

- Features: Effects of aging particularly good tone quality, increase water vapor in the process of completely soaked and set the raw materials powder uniform ripening, the same time added to fish oil, lecithin, fish soluble, etc. Strong high-energy diet feeding of formula to add materials to address the process on the past, can not overcome the added high-fat, high-viscous. add the maximum of fat up to 20% or more.

Different project, different fish feed pelleting machine price

Currently, our fish feed pellet machines have been exported to Indonesia, Russia, India, Iran, Ecuador, Nigeria, Thailand, New Zealand, Australia, Brazil, Argentina, Bolivia, Bangladesh, Ghana, Uzbekistan, Senegal, Saudi Arabia and other countries. Among the hundreds of fish feed processing projects we have built, almost every fish feed mill plant cost is different.

Although they all use fish feed pellet machines, different production scales, different process equipment, different raw materials and pellet product requirements, different equipment configurations, and different degrees of automation all ultimately lead to the fish feed pellet machine. Differences in fish feed mill project prices. Let’s take a look at some special fish feed production plant projects and their investment costs.

fish feed pelleing machine project in Indonesia

- Project time: 2022.06.02

- Capacity: 5 T/H

- Feed type: extruded fish feed

- fish feed pellet machine used: twin screw extruder RCPH150*2

- Feed Size: 1.5-3mm

- Workshop size: 1420 m²

- Installation time: 90 days

- complete fish feed making machine price: 520,000 US dollars

fish feed pelleing machine project in Russia

- Project time: 2022.11.16

- Capacity: 10-12 T/H

- Feed type: extruded fish feed

- fish feed pellet machine used: twin screw extruder RCPH185*2

- Feed Size: 0.8-2mm

- Workshop size:2540 m²

- Installation time: 150 days

- complete fish feed making machine price: 1,250,000 USD

fish feed pelleing machine project in Iran

- Project time: 2022.10.19

- Capacity: 3 T/H

- Feed type: extruded fish feed

- fish feed pellet machine used: twin screw extruder RCPH120*2

- Feed Size: 1.2-2mm

- Workshop size:1830 m²

- Installation time: 120 Days

- complete fish feed making machine price: 310,000 USD

fish feed pelleing machine project in Thailand

- Project time: 2022.02.16

- Capacity: 3 T/H

- Feed type: fish & prawn feed

- fish pellet machine used: twin screw extruder & ring die pelletizer

- Feed Size: 1-3mm

- Workshop size:1120 m²

- Installation time: 120 Days

- complete fish feed making machine price: 230,000 USD

fish feed pelleing machine project in india

- Project time: 2022.05.22

- Capacity: 3-4 T/H

- Feed type: shrimp & fish feed

- fish feed pellet machine used: SZLH 678 fish feed pelletizer

- Feed Size: 0.8-2mm

- Workshop size: 1,030 m²

- Installation time: 120 Days

- Whole set fish feed pelleting machine price: 430,000 USD

fish feed pelleing machine project in brazil

- Project time: 2023.08.12

- Capacity: 4 T/H

- Feed type: extruded fish feed

- fish feed pellet machine used: twin screw extruder RCPH150*2

- Feed Size: 1-2mm

- Workshop size: 1560 m²

- Installation time: 90 days

- Whole set fish feed pelleting machine price: 590,000 US dollars

fish feed pelleing machine project in Ghana

- Project time: 2023.04.15

- Capacity: 8 T/H

- Feed type: extruded fish feed

- fish feed pellet machine used: twin screw extruder RCPH185*2

- Feed Size: 0.8-4mm

- Workshop size:3,540 m²

- Installation time: 150 days

- Whole set fish feed pelleting machine price: 1,370,000 USD

fish feed pelleing machine project in Qatar

- Project time: 2023.07.11

- Capacity: 1 T/H

- Feed type: extruded fish feed

- fish feed pellet machine used: DGP160-B single screw extruder

- Feed Size: 1-3mm

- Workshop size:2,830 m²

- Installation time: 120 Days

- Whole set fish feed pelleting machine price: 51,000 USD

fish feed machine project in australia

- Project time: Jan 18th, 2021

- Capacity: 2T/H

- Feed type: floating fish feed

- fish feed pellet machine used: single screw extruder DSP160-B

- Feed Size: 2-4mm

- Workshop size: 8M*11M*14M (L*W*H)

- Installation time: 30 days

- Whole set fish feed machine price: 110,000 USD

fish feed machine project in Ecuador

- Project time: Sep 3th, 2021

- Capacity: 4-6T/H

- Feed type: pelletized fish & shrimp feed

- fish feed pellet machine used: SZLH768 ring die pelletizer

- Feed Size: 0.5-3mm

- Workshop size: 1320 m²

- Installation time: 35 days

- Whole set fish feed machine price: 750,000 USD

fish feed pelleing machine in Uzbekistan

- Project time: Nov 21th, 2021

- Capacity: 10T/H

- Feed type: sinking fish feed

- fish feed pelleting machine used: SZLH 558 ring die pelletizer

- Feed Size: 1-3mm

- Workshop size: 10m*8m*16m(L*W*H)

- Installation time: 40 days

- Whole set fish feed machine price: 1,57,000 USD

fish feed pelleing machine in UK

- Project time: May 24th, 2021

- Capacity: 100-150 kg/h

- Feed type: floating fish feed

- fish feed pelleting machine used: DGP60-C single screw extruder

- Feed Size: 1-4mm

- Workshop size: 10m*8m*16m(L*W*H)

- Installation time: 40 days

- Whole set fish feed machine price: 13,000 USD

Composition of Fish feed pelleting machine price

The fish feed pellet machine price is mainly composed of the following factors:

- Direct costs: The costs of labor, materials, energy, equipment, etc. directly involved in the equipment manufacturing process are important components of the original fish feed pelleting machine price.

- Indirect costs: Indirect costs during the equipment manufacturing process, such as R&D expenses, rent, water and electricity bills, etc., although they have a small impact on the original fish feed pelleting machine price, are still a part that cannot be ignored.

- Profit: Equipment manufacturers will include a certain profit in the sales price to maintain their production operations and ensure the improvement of quality and the development of technological levels. Therefore, the profit component of the original fish feed pellet machine price is also indispensable.

- Taxes: During the sales process, the original fish pellet machine price also includes corresponding tax components, such as value-added tax, business tax, etc.

What are the factors that affect fish feed pelleting machine price?

The fish feed pelleting machine price is a widely concerned issue among aquatic feed processors. So, what factors will affect its price? Let us analyze the factors affecting the fish feed pellet machine price.

01 Brand influence

The fish feed pellet machine prices of different brands vary greatly. Generally speaking, the prices of fish feed pellet mills of internationally renowned brands are much higher than those of ordinary brands. This is mainly because the quality of well-known brand products is more guaranteed and the after-sales service is more complete, so the price will be correspondingly higher.

02 Impact of functional configuration

The functional configuration is also one of the important factors affecting the fish feed pellet machine price. For example, for some products with rich functions, such as equipped with PLC+touch screen control system, the price of fish feed pellet machine will be relatively high; if equipped with high-end pellet machine conditioner, the price of fish feed pellet machine will also be higher.

03 Impact of output size

The output size is also one of the factors that affects the fish feed pelleting machine price. The fish pellet machine prices of different specifications and models will be different. Generally speaking, the greater the output, the higher the price of the fish feed pellet machine.

04 Market supply and demand relationship

The market supply and demand relationship will also directly affect the fish feed pelleting machine price. When the market demand is large, the price will rise accordingly; and when the market demand is small, the price will also fall accordingly.

05 After-sales service

The after-sales service of the fish feed pellet machine is also an important factor affecting the price. Generally speaking, the better the after-sales service, the higher the fish feed pelleting machine price.

06 Customization requirements

Some fish feed factories and aqua feed plants have special needs and may need to customize exclusive fish feed pellet machines. The price of such personalized customized products will naturally be relatively high.

When actually purchasing a fish feed pellet machine, fish feed processors need to make reasonable choices based on their own needs and budget regarding these factors that affect the price. At the same time, suppliers also need to be carefully selected to ensure product quality and service reliability.

To sum up, there are many factors that affect the fish feed pelleting machine price, including brand, functional configuration, output, market supply and demand relationship, after-sales service and customization needs, etc.

When purchasing fish feed pellet mills, fish feed processors should make reasonable choices based on actual needs and budget, and at the same time choose reputable manufacturers and suppliers to ensure they obtain the most cost-effective products. (Find RICHI on youtube)

How to choose the most cost-effective fish feed pellet machine?

As an important piece of aqua feed mill equipment in a modern fish feed production line, the fish feed pelletizing machine has an important impact on the production efficiency and cost control of fish feed processing enterprises. The following is a comprehensive price guide for fish feed pellet mills to help you find the most cost-effective equipment when choosing a fish feed pellet mill.

1. Understand production needs

Before choosing a fish feed pellet machine, you first need to clarify your production needs. This includes the type of product required for fish feed, production scale, pellet size, raw material formulation, etc. By understanding these needs, you can narrow down your choices by determining the specifications and performance requirements of the fish feed pellet machine you need.

2. Compare different brands and models

There are many brands and models of fish feed pellet machines on the market, with different prices, performance, functions, etc. You can learn about the characteristics, advantages and disadvantages of different brands and models of fish feed pellet mills through online searches, industry exhibitions, professional forums, etc.

At the same time, you can pay attention to some well-known brands, which have high visibility and market share in the field of fish feed pellet machines.

3. Pay attention to performance parameters

When choosing a fish feed pellet machine, pay attention to its performance parameters, such as labeling speed, accuracy, stability, durability, etc. These parameters will directly affect the production efficiency and quality of the fish feed pellet making machine. At the same time, factors such as the degree of automation and ease of operation of the equipment must also be considered.

By comparing the differences in performance parameters of different brands and models of fish feed pellet machines, you can choose the equipment that is more suitable for your production needs.

4. Consider price factors

The basic information of the fish feed pellet machine price and quotation includes the equipment model, brand, manufacturer, etc. This information plays an important guiding role in guiding users when selecting equipment. Users can choose different brands and models of equipment according to their needs and budget range.

Price is an important factor to consider when choosing a fish feed pellet machine. However, don’t just go for the low price and ignore the performance and quality of the device. Generally speaking, branded fish feed pellet machines are more guaranteed in terms of quality and after-sales service, but the fish feed pelleting machine price may also be relatively high.

Therefore, you need to find a balance between fish feed pelleting machine price and performance. It is recommended to choose the most cost-effective fish feed pellet mill within your budget.

5. Consult professionals

If you don’t know much about fish feed pellet machines, you can consult professionals in the industry or experienced fish feed processors. They can provide you with more specific suggestions and recommendations based on your production needs and budget.

At the same time, they can also help you understand the market conditions and price trends of different brands and models of fish feed pelletizers.

6. Pay attention to after-sales service

When choosing a fish feed pellet machine, in addition to considering price and performance, you should also pay attention to after-sales service.

A good after-sales service can ensure that the equipment is repaired and maintained in time during use, thereby extending the service life of the equipment and improving production efficiency. Therefore, when choosing a fish feed pellet machine, you must understand the supplier’s after-sales service policy and service quality.

To sum up, choosing the most cost-effective fish feed pellet machine requires comprehensive consideration of production needs, performance parameters, after-sales service and fish feed pelleting machine price.

By understanding the features, pros and cons of different brands and models, and comparing and choosing within your budget, you will be able to find the fish feed pellet machine that best suits your production needs. If you are interested in our fish feed pellet machine, feel free to contact RICHI Machinery to get a full set of fish feed pelleting machine prices and fish feed production line solutions