Global Leader in Commercial& Industrial Wood Pellet Mill Systems – 300+ Plants Worldwide

WOOD PELLET MILL

Our heavy-duty pellet mills convert wood waste into premium pellets with uncompromising efficiency – built for 24/7 operation and designed to handle the toughest feedstocks, from wet sawdust to hardwood chips, while delivering industry-leading pellet durability and energy efficiency. With 300+ installations across five continents, we’ve refined every component – from alloy steel dies to intelligent moisture control – to maximize your production output and minimize operating costs.

Application

Our industrial-grade wood pellet mills produce high-quality wood pellets for specialized markets including residential heating (ENplus certified), industrial biomass energy, animal bedding, and commercial BBQ – each requiring customized die configurations, precise moisture control, and tailored cooling systems to meet exacting quality standards.

pellets for heating Energy

pellets for Industrial Boilers

pellets for Commercial BBQ

pellets for animal bedding

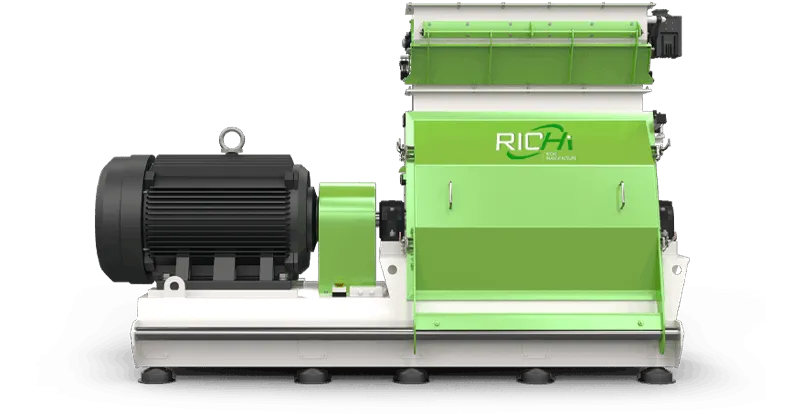

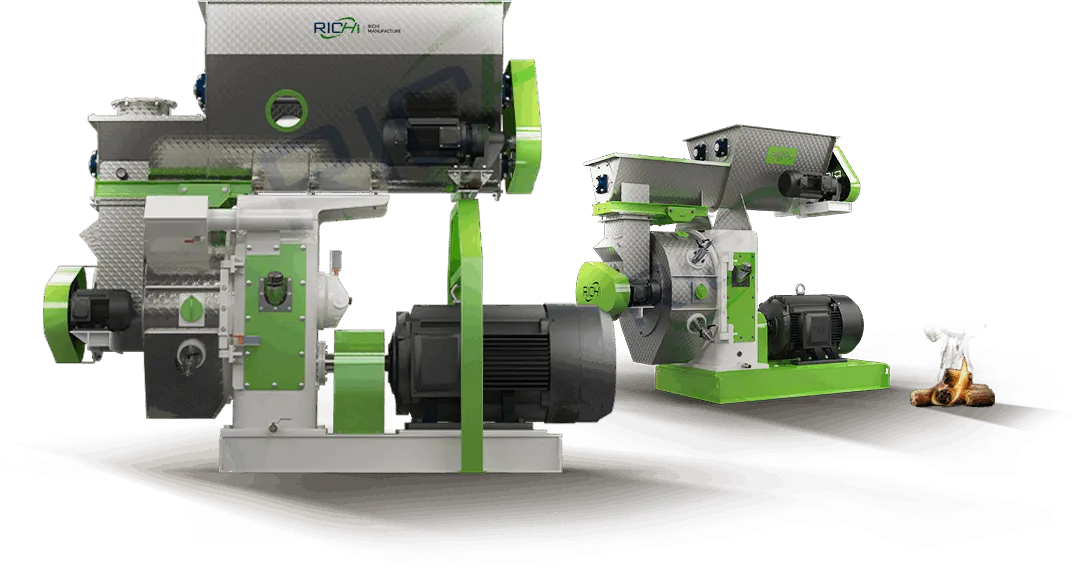

Core Equipment – Ring Die Wood Pellet Mill

At RICHI MACHINERY, we engineer industrial-grade wood pellet mills and complete production lines to transform raw wood into high-density pellets efficiently. Our ring die pellet machines deliver unmatched durability and output for commercial-scale operations, while our full-line equipment ensures seamless processing from log to bagged pellet.

Hardened alloy steel dies, adjustable compression ratios

Precision gearbox drive, 24/7 continuous operation capable

Smart Pelletizing Technology

Our ring die wood pellet mills are the heart of every high-output wood pellet line, designed for maximum uptime and efficiency.

Precision-Engineered for Diverse Biomass Applications

Whether it’s pounds of pellets per hour or tons of pellets per hour, you can depend on RICHI wood pellet mills to meet your toughest requirements. Your pellet maker will come loaded with features like our gear drive train. With 300+ global installations, we’ve mastered the technical nuances of transforming varied wood waste streams into premium pellets that command market-leading prices.

High-Performance Wood Pellet Mill Series – Engineered for Reliability & Output

MZLH320

Capacity: 0.2-0.3 T/H

Efficiency, durability and safety are the attributes that best describe small wood pellet making machines. It has a wide range of applications, equipped with the latest technology and with maximum efficiency.

MZLH350

Capacity: 0.3-0.5 T/H

Wood pellet extruder machines combine extremely efficient work processing with a particularly high level of operability and huge power. The use of high-quality branded components also ensures maximum reliability.

MZLH420

Capacity: 1.0-1.2 T/H

Wood pellet makers are stable, safe and environmentally friendly. These machines process wood pellets efficiently and flexibly, offering the ideal combination of cost-effectiveness, ruggedness and environmentally friendly operation.

MZLH520

Capacity: 1.5-2.0 T/H

With a wood pellet press, you can process high-quality wood pellets that comply with ENplus standards efficiently, safely and reliably. You can choose to use a single wood pellet mill or a complete wood pellet system.

MZLH678

Capacity: 2.5-3.0 T/H

Wood pelletizer is the perfect solution for wood pellet processing. WThanks to state-of-the-art technology and proven RICHI quality, you can handle challenging pelletizing tasks in the wood pellet industry reliably and precisely.

MZLH768

Capacity: 3.0-4.0 T/H

Wood granulator machine is a multifunctional pellet equipment that can be deployed where there are large amounts of biomass wood materials. It is a real powerhouse that impresses for its high efficiency and cost-effectiveness.

Selecting the Right wood Pellet Mill for Your Operation

Every biomass operation has unique requirements – that’s why we offer six precisely engineered MZLH series wood pellet mill models to match your. Below you’ll find detailed technical comparisons of our complete range:

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Capacity (t/h) | 0.2~0.3 | 0.3~0.5 | 1.0~1.2 | 1.5~2.0 | 2.5~3.0 | 3.0~4.0 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Main motor series | 8P | |||||

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished pellet diameter (mm) | 4-12 | |||||

A high-performance wood pellet mill is just the beginning – true wood pellet production excellence requires perfectly matched auxiliary systems for raw material preparation, process optimization, and finished product handling, all engineered to work in seamless harmony with your core pelletizing operation.

Essential Auxiliary Equipment Solutions

Systems that enhance wood pellet quality while reducing costs

See how industry leaders trust our wood pellet mills to deliver high-efficiency, low-maintenance pellet production. From small-scale biomass processors to industrial pellet plants, our solutions drive real-world results—higher output, lower energy costs, and premium pellet quality. Explore these case studies to discover how we can optimize your operation.

Proven Wood Pellet Mill Installations

Our high-capacity wood pellet mills power numerous American biomass plants processing both softwoods and hardwoods efficiently.

We specialize in rugged pellet mills optimized for Indonesia’s challenging palm waste and tropical wood residues.

Our customized systems handle Australia’s unique eucalyptus species while meeting export quality standards.

Canadian producers rely on our extreme-climate pellet mills designed for reliable operation in harsh winters.

We enable effective wood waste conversion across South Africa with durable, high-output pellet mills.

Precision engineered wood pellet mills deliver ENplus-certified quality through automated control systems.

Wood Pellet Line Solutions – From Small-Scale to Industrial Output

Whether you’re starting with 1 TPH or scaling to 50+ TPH, our wood pellet mill lines are engineered for efficiency and reliability. We design each system around your target output, ensuring optimal equipment sizing—from raw material prep to final packaging. Our modular approach allows for future expansion without costly overhauls. Tell us your production goals, and we’ll configure the right solution with the ideal balance of performance and investment.

Specialized Wood Pellet Lines by Feedstock Type

Not all wood processes the same. Our lines are fine-tuned for specific feedstocks—softwood, hardwood, recycled timber, or mixed biomass—to maximize pellet quality and machine longevity. We adjust shredding, drying, and pelletizing parameters based on your material’s fiber content, resin levels, and abrasiveness. Share your feedstock details, and we’ll propose a system that handles it efficiently, with minimal fines or downtime.

60000 +

Backed by a 60,000 m² advanced production complex

140 +

Global footprint extends across 140+ international markets

2000 +

Over 2,000 successful feed production system installations

2013

RICHI MANUFACTURE

Established in 1995, RICHI MACHINERY has grown from a medium-sized enterprise to become China’s largest pellet production line manufacturer. With two major manufacturing bases spanning hundreds of thousands of square meters, we specialize in custom pellet machines and complete plant solutions, handling every production stage in-house—from R&D to delivery.

Our vertically integrated facilities (including dedicated sections for production, testing, and logistics) ensure premium quality, environmental responsibility, and operational reliability for feed, biomass, and fertilizer industries worldwide. For nearly three decades, we’ve partnered with clients to enhance productivity, minimize risks, and achieve sustainable outcomes through innovative engineering.

Zhengzhou Headquarters

R&D, global operations and strategic management converge

Jiaozuo New Production Base (2025)

Featuring automated production lines and Industry 4.0 technologies

Kaifeng Original Complex (Since 1995)

Our manufacturing legacy began and quality traditions endure

Certifications & Patents

As a world-leading wood pellet mill manufacturer, RICHI Machinery demonstrates its engineering prowess through internationally recognized certifications and proprietary innovations.

Our ISO quality management system, CE compliance, BV-certified production processes, GOST-R for Russian compliance, ATEX explosion-proof certification for EU safety standards, FDA registration for U.S. market access, and EHEDG hygienic design certification validate our commitment to global standards, while 50+ patented technologies in pellet mills, extruders and automation systems deliver unmatched performance.

When you choose RICHI, you’re selecting globally validated, future-proof solutions backed by the industry’s most comprehensive certification portfolio.

01

Consultation

Our experts provide professional advice to understand your specific wood-based pellet production requirements.

02

Design

We develop customized solutions with optimized layouts and equipment configurations for your project.

03

Manufacturing

All wood pellet mill equipment is precision-built using quality materials in our ISO-certified factories.

04

Shipping

We handle secure packaging and global logistics with reliable delivery timelines.

05

Installation

Our engineers supervise on-site assembly and commissioning for smooth operation.

06

Training

Comprehensive operator instruction ensures proper use and maintenance of equipment.

07

After-sales

Dedicated support team provides troubleshooting and technical assistance.

08

Spare Parts

Genuine components are available worldwide with fast delivery service.

Wood Pellet Production: Expert Answers to Your Top Questions

Struggling to choose the right wood pellet mill or optimize your production? Get straightforward, experience-backed answers to the most pressing questions from biomass producers worldwide. Whether you’re weighing equipment options, troubleshooting quality issues, or calculating ROI, we break down complex topics into actionable insights – no jargon, just real-world solutions proven across 300+ installations.

how to set up wood pellet mill plant ?

+

Your funds and budget are the first things to consider in your wood pellet mill plant construction. Your budget tends to tell the scale of the wood pellet plant regarding large size or small scale. In case you do not have sufficient funds, then consider lowering your capacity.

Consequently, you can get even lower some relatively unimportant equipment. However, in cutting cost, it is never advisable to substitute the necessary equipment with low price and low-quality ones. You might end up regretting the move.

Your workshop is another thing that you need to consider in wood pellet mill line construction. In fact, the funds available to you will tend to determine your workshop size in that the higher the resources, the bigger the workshop you can build.

Again, consider having your wood pellet plan design near your raw material to ensure that you cut the cost of raw material transportation. Consequently, if you have a workshop, determine its height, width, and length. Consider then designing your wood pellets depending on your workshop size to ensure it is enough to lace the equipment.

Please provide us with wood pellet mill plant project information as much as possible:

- For a complete wood pellet mill plant project: the raw material availability, the required production capacity, the process technology, your budgetary and financing status, the estimated starting time, etc.

- For single wood pellet mill machine: the model, the capacity, your budget information, other requirements, etc.

- For spare parts: size and dimensions, material and weight, and your drawings with details, you can send the drawing to enquiry@richipelletmachine.com.

01

What are the uses of pellets processed by wood pellet mill??

+

Our wood pellet mills produce versatile biomass pellets for:

1. High-Value Industrial Uses

- Foundry additives (replacing sand in metal casting)

- Rubber/plastic filler materials (5-15% cost reduction)

2. Premium Animal Solutions

- Dust-controlled horse bedding (€0.45/kg in EU markets)

- Absorbent pellets for poultry/livestock operations

3. Specialized Consumer Products

- Cat litter (expands 3x when wet)

- BBQ smoking pellets (hardwood blends for chefs)

4. Agricultural Enhancements

- Mushroom cultivation substrates

- Slow-release fertilizer carriers

02

What are the raw materials suitable for wood pellet mill??

+

Our wood pellet mills process 50+ biomass types efficiently:

1. Primary Wood Materials

- Softwoods (Pine, Spruce, Fir)

- Hardwoods (Oak, Maple, Beech)

- Mixed sawdust (30% moisture max)

2. Agricultural Byproducts

- Rice husks (40-60% yield after processing)

- Corn stalks (requires pre-crushing <5mm)

- Coconut shells (special wear-resistant dies needed)

3. Industrial Waste Streams

- MDF/Plywood residues (binder adjustment required)

- Paper mill sludge (drying pretreatment essential)

Key Equipment Adaptations:

• Variable die thickness (6-12mm) for different densities

• Heavy-duty rollers for abrasive materials

• Optional pre-drying systems

03

Why is the ring die wood pellet mill the most widely used equipment at present??

+

After decades of engineering improvements and real-world testing across hundreds of installations, ring die wood pellet mills have proven to be the superior choice for serious biomass producers. Here’s why:

1. Unmatched Production Capacity & Efficiency

Unlike flat die wood pellet mills that operate in batches, our ring die systems feature continuous 360-degree compression for non-stop processing. The rotating die design maintains consistent throughput whether you’re running 8-hour shifts or 24/7 operations. Our SRD series achieves 3-30+ TPH depending on model – that’s enough to supply entire district heating plants or export-scale operations.

2. Superior Pellet Quality That Commands Premium Prices

The radial compression of ring dies creates more uniform density (650kg/m³ ±5%) and exceptional durability (95%+ by ISO 17831). This means:

- Fewer fines during transport (under 3% vs 8-12% with flat die)

- Consistent combustion performance for energy customers

- Ability to meet strict export market specifications

3. Lower Operating Costs That Boost ROI

While the initial investment is higher, ring die mills save money long-term:

- Energy efficiency: Our gear-drive systems use 30% less kWh/ton

- Die longevity: Special alloy dies last 5,000+ hours vs 1,200-2,000 for flat die

- Labor savings: Automated lubrication and remote monitoring reduce staffing needs

4. Unparalleled Material Flexibility

From dusty sawmill residues to tough agricultural waste, our mills handle what others can’t:

- Mixed biomass blends stay homogeneous during processing

- Adjustable compression ratios (6:1 to 15:1) accommodate everything from pine to rice husks

- Optional pre-conditioning systems optimize moisture for each material

Why Our Ring Die Mills Outperform Competitors

✔ Quick-Change Die System – Swap dies in 30 minutes vs industry-standard 2 hours

✔ Dual-Layer Alloy Dies – Hardened outer surface with tough inner core lasts 3x longer

✔ Smart Pressure Monitoring – Real-time adjustments ensure perfect pellet formation

✔ Modular Design – Easily upgrade from 5TPH to 15TPH as your business grows

This isn’t just equipment – it’s your competitive edge in the global biomass market. Let’s discuss how to maximize your production potential.

04

Do you only offer horizontal ring die wood pellet mills? Do you also offer vertical wood pellet mills? ?

+

We design and manufacture complete wood pellet production systems, offering both horizontal and vertical ring die pellet mills to match different operational requirements. All our equipment is 100% built in-house at our manufacturing facilities, ensuring strict quality control from raw materials to finished machines.

Horizontal Ring Die Pellet Mills:

- Ideal for high-volume commercial production (1-30+ tons per hour)

- Superior durability when processing abrasive materials like hardwood or agricultural residues

- Optimized gravity-fed design ensures consistent material flow

- Heavy-duty construction withstands 24/7 industrial operation

- Easier access for maintenance and die replacement

Vertical Ring Die Pellet Mills:

- Perfect for space-constrained facilities

- 15-20% more energy efficient for certain materials

- Excellent for softer biomass like pine sawdust or straw

- Compact footprint reduces installation requirements

- Lower minimum production thresholds

Our Manufacturing Advantages:

• Complete vertical integration – we cast, machine and heat-treat all critical components

• Custom engineering for your specific raw material characteristics

• Proprietary die designs that outlast industry standards

• On-site testing facility to verify performance before delivery

Which configuration works best for you?

The optimal choice depends on:

- Your available floor space

- Production volume targets

- Material characteristics

- Long-term expansion plans

[Contact our engineers for a facility layout review and equipment recommendation based on your actual requirements]

We don’t just sell machines – we provide complete pelletizing solutions backed by 15 years of biomass processing expertise. Let us help you select the perfect mill configuration for your operation.

05

Do you export your wood pellet mill to the EU? ?

+

We have successfully delivered and commissioned pellet mills across multiple EU countries, including Germany, France, Italy, and Scandinavia. Our equipment meets all EU regulatory requirements:

✔ CE Certification – Full compliance with Machinery Directive 2006/42/EC

✔ EN ISO 13849-1 – Safety-rated control systems

✔ EHEDG Guidelines – Hygienic design for biomass applications

Recent EU Projects Include:

- A 10-ton/hour hardwood pellet line in Sweden (2023)

- Three 5-ton/hour mixed biomass plants in Germany (2022-2023)

- An olive pit pelletization system in Spain (2024)

Key Adaptations for EU Clients:

• ATEX-compliant dust explosion protection systems

• Energy-efficient drives meeting EU Ecodesign standards

• Multilingual control interfaces (German/French/Italian)

Full Documentation Support:

- Declaration of Conformity

- Risk assessment reports

- Technical construction files

[Ask for our EU project portfolio – See actual installation photos and test reports]

All shipments include:

→ On-site commissioning by EU-trained engineers

→ Spare parts stocked in Rotterdam warehouse

→ Ongoing compliance updates for evolving regulations

Let’s discuss how we can meet your specific country requirements.

06

Can you provide all the equipment needed to process wood pellets? What does it include ?

+

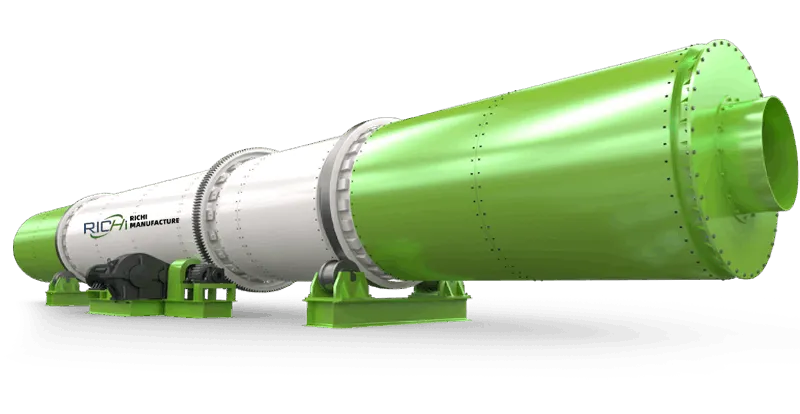

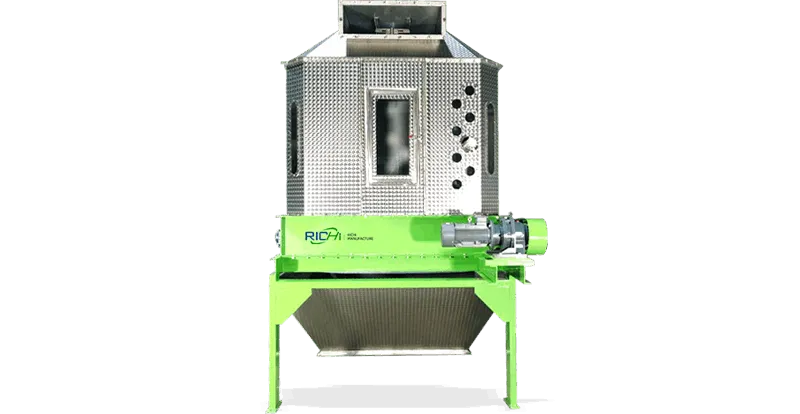

Yes, we engineer and manufacture the entire wood pellet production ecosystem, with all equipment designed to work seamlessly together. Here’s what our turnkey systems include:

Core Processing Equipment

- Size Reduction: Heavy-duty crushers & hammer mills (for logs, chips, or waste wood)

- Drying Systems: Rotary drum dryers with biomass-fired hot air generators (moisture control ±1%)

- Pelletizing: Ring die pellet mills (horizontal & vertical) with automated lubrication

- Cooling & Screening: Counterflow coolers with integrated fines removal

Material Handling & Storage

- Belt/Pneumatic conveyors

- Silo systems (raw material & finished pellets)

- Fire-protected dust collection

Quality Control & Packaging

- Metal detectors & sieving systems

- Automated weighing & bagging (15-1000kg bags)

- Palletizing robots

Critical Auxiliaries

- Biomass burners (wood chips/sawdust fired)

- Steam boilers for conditioning

- PLC control rooms with SCADA systems

Why Choose Our Integrated Systems?

✔ Single-source responsibility – No compatibility issues between vendors

✔ Proven layouts – 50+ reference plants operating globally

✔ Energy optimization – Heat recovery between drying & pelleting

[Request our “Wood Pellet Mill Plant Configuration Guide” – Includes 20+ proven layout options]

All equipment is:

→ Manufactured in our 60,000m² facility

→ Tested as complete systems before shipment

→ Supported by multilingual engineers

Let’s discuss your specific feedstock and output goals to recommend the optimal configuration.

07

Do you provide design and installation of wood pellet mill plants? ?

+

We deliver complete turnkey wood pellet mill plants, handling every project phase with in-house expertise:

1. Custom Engineering & Design

- Site-specific layouts optimizing workflow (tested in 3D simulation first)

- Material flow analysis to eliminate bottlenecks

- Utility planning (power/water/air requirements)

2. Professional Installation

- Certified millwright teams (speaking English/Spanish/Russian)

- Laser-aligned equipment installation (±0.5mm tolerance)

- Integrated safety systems (dust explosion protection, emergency stops)

3. Commissioning & Training

- 150-point startup checklist

- 7-day intensive operator training (includes troubleshooting drills)

- Production trials with your actual feedstock

Recent Project Example:

A UK client’s 8-ton/hour plant achieved full production 18 days faster than scheduled because we:

✔ Pre-assembled modules in our factory

✔ Used augmented reality for equipment positioning

✔ Had local-certified electricians on our team

Included in Every Project:

◉ Foundation drawings & steel structure calculations

◉ Pneumatic/electric schematics

◉ Spare parts inventory planning

◉ 24-month process optimization guarantee

[Ask for our “Project Execution Plan” – Details milestones from soil testing to first pellets]

We’ve successfully installed 47 plants across 21 countries last year alone. Let’s discuss your site specifics – our engineers will identify at least 3 cost-saving opportunities during the first consultation.

08

My raw material is dock wood, which has a high moisture content. Can it be pelletized?

+

Yes, dockyard wood (pier decking, fenders, or bollards) can be effectively pelletized with proper pretreatment. Here’s how we handle such challenging materials:

Key Challenges & Solutions

- High Moisture (30-60%)

- Our two-stage drying system first air-dries to ~25%, then precision-dries to 12-15%

- Handles saltwater-saturated wood (special 316 stainless steel components)

- Contaminants (Nails/Sand)

- Magnetic separators + abrasion-resistant dies (last 3,500+ hours)

- Pre-washing option for salt/sand removal

- Variable Density

- Adjustable compression (8:1 to 14:1) for mixed hardwood/softwood

- Pre-shredding to <5mm for uniform conditioning

Proven Configurations

✔ For <5 TPH: Rotary dryer + heavy-duty pellet mill

✔ For 5-15 TPH: Belt dryer + pre-breaker + twin-pelletizer setup

09

Have you exported wood pellet mill to South and North American countries? ?

+

We have an established track record delivering industrial pellet mills to key markets throughout the Americas, with multiple commissioned projects in:

North America

• USA: 14 plants (1-20 TPH) processing West Coast sawdust & Midwest corn stover

• Canada: 9 installations for softwood pellets (ENplus A1 grade)

• Mexico: 5 biomass lines for agri-waste utilization

South America

• Brazil: 3 large-scale eucalyptus pellet operations (8-30 TPH)

• Argentina: 2 sunflower hull pellet plants with CHP integration

• Colombia/Ecuador: 4 palm waste-to-pellet facilities

Regional Adaptations We Implement:

- Tropical Climate Packages: Enhanced cooling for 90% humidity environments

- High-Altitude Kits: Airflow adjustments for Andean operations

- Local Compliance: NRCan (Canada), EPA (USA), ANEEL (Brazil) certifications

Recent Project Highlights

→ A Quebec sawmill’s 12 TPH system achieving 96% uptime at -30°C

→ An Oregon hazelnut shell operation reducing energy use by 22%

→ A Brazilian sugarcane bagasse plant exceeding 8,000 annual runtime hours

Let’s discuss how we’ve solved challenges similar to yours in your specific country. Our team knows the permitting, feedstock quirks, and market demands across the Americas.

10