Animal Feed Pellet Machine Price

Animal feed pellet machine price usually range from 7,000 – 100,000 USD. Animal feed pellet machine is one of the most widely used feed machinery and is mainly used in the pelletizing section of feed mills.

The pelleting section is the most important link in the feed production process. By breaking down the plant-based structure of the material, it promotes optimal energy absorption and densifies the raw material to reduce feed transportation, storage and management costs.

Based on its wide range of applications, when this equipment is used in different types of feed pellet processing, its configuration and output are very different. Correspondingly, the animal feed pellet making machine prices will also vary.

Different models, different animal feed pellet machine prices

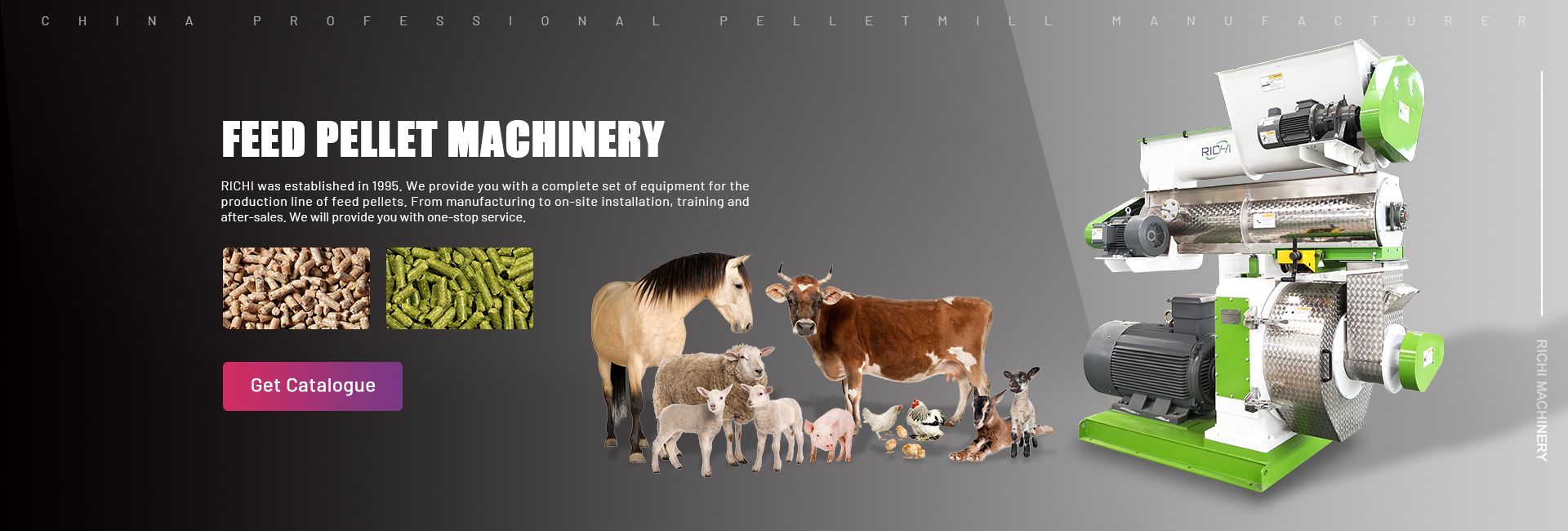

RICHI animal feed pellet machine mainly adopts ring die pelletizing technology, which is currently recognized as the “optimal technology” in the feed processing industry. RICHI animal feed pellet machines come in various types, with two transmission modes: gear transmission and belt transmission.

The two series of animal feed pellet making machines have good production performance, high quality and super controllability, which can meet the needs of various types of granule production.

Among them, the SZLH250 animal feed pellet machine adopts belt transmission, and the other 8 models of animal feed pellet machines all adopt gear transmission. The output and technical specifications of this equipment are different, and accordingly, the animal feed pellet machine prices are also different. The following will give you a brief introduction to these mainstream ring die feed pellet mill products:

SZLH250 small animal feed pellet machine

SZLH250 small animal feed pellet machine is a key equipment for the production of pellet feed. It has the characteristics of high output, good performance, low energy consumption, low noise, and beautiful appearance. It is an ideal equipment for pressing pellet feed for poultry, livestock, and fish. The conditioning time can be increased to 35 seconds, which greatly improves the maturity of the feed.

- Animal feed pellet machine price: FOB 7,000-15,000 USD

- Output (t/h):1~2

- Main motor power (kw):22

- Main motor series:4P

- Feeder power (kw):1.1

- Conditioner power (kw):1.5

- Finished pellet diameter (mm):2~12

SZLH320 animal feed granulator

The SZLH320 animal feed granulator adopts high-precision gear transmission, and its output is about 15-20% higher than that of the belt-driven type. The alloy steel ring die is processed using the internationally advanced German gun drill and American vacuum furnace heat treatment manufacturing processes. It has a long service life, smooth graining and high quality.

- Animal feed pellet machine price: FOB 15,000-20,000 USD

- Output (t/h):3~4

- Main motor power (kw):37

- Main motor series:4P

- Feeder power (kw):1.5

- Conditioner power (kw):2.2

- Finished pellet diameter (mm):2~12

SZLH350 animal feed pellet press

The upgraded SZLH350 animal feed pellet press has increased production capacity. The gear transmission efficiency is as high as 97%, allowing every kilowatt hour of electricity to create profits; the feed quality is good, improving breeding efficiency. Steam is introduced at multiple points for conditioning, so the feed heats up quickly and increases the degree of maturation. Humanized operation, fully automatic operation.

- Animal feed pellet machine price: FOB 20,000-25,000 USD

- Output (t/h):5~7

- Main motor power (kw):55

- Main motor series:4P

- Feeder power (kw):1.5

- Conditioner power (kw):3

- Ring die diameter (mm):350

- Finished pellet diameter (mm):2~12

SZLH420 animal feed pellet mill

The transmission part of the SZLH420 animal feed pellet mill (including the motor) uses high-quality bearings from Switzerland and Japan to ensure effective, stable and low-noise transmission; the all-stainless steel enlarged reinforced feeding conditioner adopts frequency conversion speed control to ensure that the pellet feed high quality.

- Animal feed pellet machine price: FOB 30,000-35,000 USD

- Output (t/h):8~12

- Main motor power (kw):110

- Main motor series:4P

- Feeder power (kw):1.5

- Conditioner power (kw):7.5

- Ring die diameter (mm):420

- Finished pellet diameter (mm):2~12

SZLH508 animal feed pellet making machine

The main drive of the SZLH508 animal feed pellet making machine adopts high-precision gear transmission, and the ring die adopts a quick-release hoop type. The output is about 20% higher than that of the belt-driven type. The whole machine is simple to operate, and one pelletizer can achieve Simultaneous operation of two granulators. It is easier to achieve automatic control.

- Animal feed pellet machine price: FOB 40,000-50,000 USD

- Output (t/h):10~18

- Main motor power (kw):160

- Main motor series:4P

- Feeder power (kw):2.2

- Conditioner power (kw):11

- Finished pellet diameter (mm):2~12

SZLH558 feed granulator machine

The SZLH558 animal feed granulator machine box body is made of highly wear-resistant internal combustion engine cylinder liner material, which can maintain good accuracy after long-term use. The service life is up to 20 years; high-precision direct-coupled gear transmission has strong overload resistance and can be restored without shutting down if the machine is blocked.

- Animal feed pellet machine price: FOB 48,000-55,000 USD

- Output (t/h):15~25

- Main motor power (kw):180/200

- Main motor series:4P

- Feeder power (kw):2.2

- Conditioner power (kw):11

- Finished pellet diameter (mm):2~12

SZLH678 feed pellet granulator

The SZLH678 animal feed pellet granulator adopts a gear transmission system with higher transmission efficiency; it is equipped with an external thin oil lubrication device (with cooling, filtration and oil cutoff alarm functions), and forced lubrication of the main shaft, gear shaft and empty shaft rear bearing , reduce the temperature of the entire box and increase the service life of oil seals and O-rings.

- Animal feed pellet machine price: FOB 65,000-700,000 USD

- Output (t/h):20~30

- Main motor power (kw):220/250

- Main motor series:4P

- Feeder power (kw):2.2

- Conditioner power (kw):11

- Finished pellet diameter (mm):2~12

SZLH768 commercial feed pellet mill

RICHI SZLH768 commercial feed pellet mill is a low-fault model with international new technology; the feeding system of this machine adopts stepless variable speed motor control, which makes speed adjustment convenient and reliable. It can also be equipped with a microcomputer automatic control system, which can automatically adjust the feed volume and steam volume to keep the press in good working condition.

- Animal feed pellet machine price: FOB 70,000-80,000 USD

- Output (t/h):25~40

- Main motor power (kw):250/280

- Main motor series:4P

- Feeder power (kw):2.2

- Conditioner power (kw):11

- Finished pellet diameter (mm):2~12

SZLH858 ring die feed pellet machine

The large gear and gear shaft of the SZLH858 ring die feed pellet machine adopt hard tooth surface and gear grinding technology, with high precision and a service life of up to 15 years. The conditioner is increased by 15% based on the CPM model to improve the maturation degree of the material. The feeder adopts an “O-shaped” cylinder, which not only improves the uniformity of feeding, but also effectively prevents steam from escaping upward.

- Animal feed pellet machine price: FOB 80,000-100,000 USD

- Output (t/h):28~45

- Main motor power (kw):315/355

- Main motor series:4P

- Feeder power (kw):2.2

- Conditioner power (kw):15

- Finished pellet diameter (mm):2~12

Complete poultry feed plant for sale the world

At present, we have exported animal feed pellet machines and a complete set of animal feed mill equipment to more than 100 countries around the world, with a cumulative number of cases of more than 1,200. These animal feed pellet machines we export are mainly used in poultry feed mills, cattle feed mills, pig feed mills, livestock feed mills, ruminant feed mills, fish feed mills, shrimp feed mills, etc.

Every project is unique and no project is exactly the same. These differences can lie in the customer’s raw materials and formulations, the size of the pellet product, the design of the process flow, the configuration of the equipment or the degree of automation.

In total, each animal feed mill plant project is different. Even for animal feed factory projects with the same output, the customer’s investment amount may not be exactly the same.

15-20T/H animal feed pellet machine in Australia

- Feed Size: 2-6mm pellets & powder

- Feed Type: chicken, pig

- Construction Time: 14 months

- Whole animal feed making machine price: 960,000USD

- Date: June 2022

25T/H animal feed pellet machine in Brazil

- Feed Size: powder & 1.5-8mm pellets

- Feed Type: chicken, cow, pig

- Construction Time: 9 months

- Whole animal feed making machine price: 1,250,000 USD

- Date: December 2022

10-15 t/h animal feed pellet machine in Tajikistan

- Feed Size: 2-10mm pellets

- Feed Type: chicken, goat, cattle

- Construction Time: 2 months

- Whole animal feed making machine price: 97160 USD

- date: 2022.06.09

10T/H animal feed pellet machine in Argentina

- Feed Size: 2-8mm pellets

- Feed Type: chicken, livestock

- Construction Time: 7 months

- Whole animal feed making machine price: 460,000 USD

- Project date: 2022.09.13

6-10T/H animal feed pellet machine in Algeria

- Feed Size: 2-6mm pellets

- Feed Type: chicken, sheep, cattle

- Construction Time: 8 months

- Whole animal feed pellet machine price:80,000-400,000 USD

- Date: Sep 31th, 2022

10-15T/H animal feed machine in Uzbekistan

- Feed Size: 2-5mm pellets

- Feed Type: chicken, cow

- Construction Time: 1 year

- Whole animal feed pellet machine price: 150,000-400,000 USD

- Date: July 1th, 2022

5T/H animal feed pellet machine in Angola

- Feed Size: 3-6mm pellets

- Feed Type: chicken, pig

- Construction Time: 5 months

- Whole animal feed pellet machine price: 220,000-250,000 USD

- Date: February 2021

3-5T/H animal feed pellet machine in Malaysia

- Feed Size: 2-4mm pellets

- Feed Type: chicken, cattle

- Construction Time: 4 Months

- Whole animal feed pellet machine price: 60,000-65,000 USD

- Date: October 29, 2022

10 t/h animal feed pellet machine in Russia

- Feed Size:1-5mm pellets

- Feed Type: chicken, cow

- Construction Time: 6 months

- Whole Animal feed machine price: 1,350,600USD

- date: 2023.09.27

7-8T/H animal feed pellet machine in peru

- Feed Size: 2-4mm pellets

- Feed Type: poultry chicken

- Construction Time: 2 months

- Whole Animal Feed Machine Price: 150,300USD

- date: 2023.10.27

5-6 t/h animal feed machine in Kazakhstan

- Feed Size: 2-4mm pellets

- Feed Type: chicken broiler

- Construction Time: 2 months

- Whole Animal Feed Machine Price: 92,600 USD

- Date: 2023.10. 06

5-6T/H animal feed pellet machine in Ethiopia

- Feed Size: 3-4mm pellets

- Feed Type: broiler chicken

- Construction Time: 3 weeks

- Whole Animal Feed Machine cost: 84,900USD

- Date: 2023.08.06

5 T/H animal feed pellet machine in El Salvador

- Feed Size: 3-6mm pellets

- Feed Type: chicken, cattle

- Construction Time: 6 months

- Complete animal feed pellet making machine price: 480,000 USD

- date: 2022. 09.13

10 t/h animal feed pellet machine in Thailand

- Feed Size: 3-6mm pellets

- Feed Type: chicken, duck, bird

- Construction Time: 8 months

- Complete animal feed pellet making machine price: 120,000 USD

- date: 2021. 07. 22

1-2T/H animal feed pellet machine in Nigeria

- Feed Size: 2-4mm pellets

- Feed Type: chicken poultry

- Construction Time: 30 days

- Complete animal feed pellet making machine price: 25,000-29,000 USD

- Date: June 30, 2022

16T/H animal feed pellet machine in Afghanistan

- Feed Size: 2-8mm pellets

- Feed Type: chicken, cow

- Construction Time: 11 months

- Complete animal feed pellet making machine price: 500,000 USD

- Date: December 2022

8-12 t/h animal feed pellet machine in Vietnam

- Feed Size: 2-10mm pellets

- Feed Type: chicken, cattle, sheep

- Construction Time: 6 months

- Complete animal feed pellet machine price: 184500USD

- Project date: 2022.10.11

10-15 t/h animal feed pellet machine in New Zealand

- Feed Size: 1.5-6mm pellets

- Feed Type: chicken, pig

- Construction Time: 4 months

- Complete animal feed pellet machine price: 131820 USD

- Project date: 2022.10.14

15 t/h animal feed pellet machine in Australia

- Feed Size: 2-3mm pellets

- Feed Type: chicken broiler

- Construction Time: 9 months

- Complete animal feed pellet machine price: 159070 USD

- Project date: 2022.06.30

20T/H animal feed pellet machine in USA

- Feed Size: 2-10mm pellets

- Feed Type: broiler, ruminant

- Construction Time: 10 months

- Complete animal feed machine cost: 550,000 USD

- Project date: 2023.05.10

Components of animal feed pellet machine price

How is an animal feed pellet machine priced? This requires understanding the components of animal feed pellet machine price:

1. Material cost

Material cost is an inevitable cost element in the manufacturing of animal feed pellet machines. The price and purchase quantity of materials are the two main factors that affect the material cost.

In machinery manufacturing, commonly used materials include steel, plastic, rubber, etc. The prices of various materials are different, and the purchase quantities are also different, which will have a certain impact on the animal feed pellet machine price.

2. Processing fee

Processing fees refer to the costs required to process materials into semi-finished products or finished products through turning, milling, drilling, grinding, polishing and other processing methods. Processing fees are generally calculated based on working hours or processing quantity.

Factors such as difficulty of processing technology, degree of automation, and performance of processing machines will affect the level of processing fees.

3. Labor costs

Labor costs refer to the labor costs required in the manufacturing process of animal feed pellet machines, including workers’ wages, benefits, social security, etc. The field of machinery manufacturing has certain requirements for the quality, skills and quantity of employees, which will also affect the level of labor costs.

4. Management fees

Management fees are fees that feed pellet machine processors need to pay to ensure the normal operation of the mechanical animal feed pellet mill manufacturing process, including production workshop space rent, water and electricity fees, employee training fees, equipment maintenance fees, and production management personnel salary etc.

The amount of these administrative expenses is related to the size of the enterprise, management level and other factors.

In addition to the above components, there are also other costs that need to be considered, such as R&D costs, quality inspection costs, sales expenses, etc. These costs will have an impact on the animal feed pellet machine price.

Animal feed pellet machine manufacturers will comprehensively consider various cost factors when formulating the animal feed pellet machine price to ensure the rationality and market competitiveness of the animal feed pellet machine prices.

What are the factors that affect animal feed pellet machine price?

There are hundreds of models of animal feed pellet machines on the market, with various functions, appearances and prices. So what kind of price is a good deal? How can you buy an animal feed pellet machine that suits you at a reasonable price? Then let us understand the factors that affect the animal feed pellet machine price.

01 Brand cost

With the development of the animal feed pellet machine industry, many brands emerge every year, and some old-fashioned animal feed pellet machines have their own unique characteristics. They incorporate brand technology into their appearance and internal structure, making animal feed pelletizing easier.

The function highlights the brand culture and brand characteristics, because each brand manufacturer has a unique process that has been developed after many painstaking studies, discussions, tests, and reinventions. Therefore, the brand process will affect animal feed pellet machine price to a certain extent.

02 Material cost

A standard animal feed pellet machine consists of gear shaft, gear, main shaft, transmission wheel, hollow shaft, box body, ring die, pressure roller assembly and other parts. The internal body and parts of the animal feed pellet mill are important factors that enable the pelleting function to be exerted, and are also the guarantee of the quality of the animal feed pellet machine.

High-quality internal body and parts are incomparable with low-quality ones in terms of scientific research costs and manufacturing costs. The animal feed pellet machine will produce a relatively large price difference, and the quality of its ring die, pressure rollers, bearings, motors, etc. are important factors that determine the overall quality of the animal feed pellet machine.

03 Configuration cost

Different functions have different animal feed pellet machine prices, and different functional configurations will have price differences, even huge differences.

For example, a double-layer conditioner pellet mill is more expensive than a single-layer conditioner pellet mill, while an animal feed pellet machine made entirely of stainless steel is more expensive than an alloy steel pellet mill. This is especially true for non-standard customized animal feed pellet machines.

04 Production cost

Labor costs are getting higher and higher now. Not only that, as environmental protection, safety, industrial and commercial taxation and other management become increasingly strict, companies are spending more and more on production and operations. This will also affect the animal feed pellet machine price.

05 Service and after-sales costs

Only with good pre-sales service can we get good products, and with good after-sales service can we get better product experience to protect the consumer rights of customers.

Therefore, service content and warranty content are very important for customers who want to buy animal feed pellet mills. It is also a value factor. Therefore, the service content and warranty content will also have some impact on the animal feed pellet machine price.

How to choose animal feed pellet machine?

In today’s animal feed processing industry, the use of efficient and high-quality animal feed pellet mills has become the key for feed companies to improve efficiency and reduce costs.

As an important part of the animal feed production line, animal feed pellet mill selection is crucial for feed companies. RICHI will provide you with an animal feed pellet machine selection guide to help you choose the automation equipment that best suits you.

1. Understand the basic types of animal feed pellet machines

Animal feed pellet mills are mainly divided into two types: ring-die feed pellet mills and flat-die feed pellet mills. The flat die feed pellet mill is only suitable for feed processing of less than 1 ton, and is suitable for occasions with small production volume and low efficiency requirements.

The most versatile ring-die feed pellet mill can process various animal feeds of more than 1 ton, and can automate the entire pelleting process, which greatly improves production efficiency and is suitable for large-scale, high-efficiency production environments.

2. Clarify production needs

When choosing an animal feed pellet making machine, you must first clarify your production needs. Factors including production scale, feed type, particle size range, compression ratio, raw materials and formulation all need to be taken into consideration.

For example, if your production line needs to produce feed pellets of multiple sizes, it would be more appropriate to choose an animal feed pellet mill with multi-size adaptability and be equipped with multiple types of ring dies.

3. Evaluate equipment performance

The performance of animal feed pellet machine is directly related to production efficiency and product quality. When selecting, the equipment’s output, produced particle quality, molding rate, stability, noise and other properties should be evaluated. Relevant information can be obtained by consulting product manuals, watching test machine videos, consulting manufacturer customer service, etc.

4. Consider device compatibility and scalability

As your feed processing business grows, production needs may change. Therefore, when selecting an animal feed pellet machine, the compatibility and scalability of the equipment should be considered. Choose equipment that is easy to upgrade and modify to better adapt to changes in future production needs.

5. Compare cost-effectiveness

The different types animal feed pellet machine prices vary greatly. Feed processing companies should comprehensively consider the purchase cost, operating cost and maintenance cost of the equipment when selecting.

At the same time, we should also pay attention to the return on investment of the animal feed machine and choose equipment that can bring obvious benefits to the feed company in the short term.

6. Examine the manufacturer’s strength and after-sales service

The quality and after-sales service of animal feed pellet machines are directly related to the production stability and cost control of feed companies. When selecting, the strength of the animal feed pellet machine manufacturer should be investigated, including its production scale, technical level, market reputation, etc.

At the same time, we should also pay attention to the manufacturer’s after-sales service policy to ensure that we can receive timely technical support and maintenance services during use.

Through comprehensive consideration of the above aspects, I believe you have a clearer understanding of how to choose an animal feed pellet machine that suits you.

In the actual selection process, it is recommended that you choose animal feed pellet machines with stable performance, easy operation, and high cost-effectiveness based on your own production needs and animal feed pellet machine price budget.

At the same time, we must also pay attention to the manufacturer’s strength and after-sales service to ensure that the equipment can operate stably in the long term and create greater value for the feed processing business.

get animal feed pellet machine price

The process of animal feed pelleting requires extremely high coordination of pressure, temperature and humidity of materials to achieve perfect consistency. RICHI Machinery will select appropriate feed equipment for customers in each production process.

From conditioners and extruders to dryers, coolers and other auxiliary equipment, our solutions cover the complete needs of our customers, effectively converting existing resources into ideal pellet feed. If you are interested in our equipment, feel free to contact RICHI Machinery to get animal feed pellet machine prices and complete animal feed production line quotations!