WOOD PELLET PLANT CONSTRUCTION

For over three decades, RICHI has been a trusted name in designing and constructing complete wood pellet plants for clients worldwide. We specialize in engineering solutions tailored to your specific raw materials—whether you’re processing softwood, hardwood, agricultural waste, or blended biomass—and your target pellet quality standards.

From raw material crushing, drying, and pelletizing to cooling, screening, and packaging, we deliver integrated systems that maximize output, minimize energy consumption, and ensure long-term reliability.

500+

Construction Projects

For three decades, RICHI has been at the forefront of engineering and deploying advanced wood pellet production systems worldwide. With 500+ successful biomass pellet plant construction projects under our belt, we’ve refined our solutions to handle diverse raw materials—from softwood and hardwood to agricultural residues—ensuring high yield and durability for every client.

$400M+

Total Sales

From initial site assessment and process design to commissioning and ongoing support, our team delivers fully integrated wood pellet plant construction services. We don’t just sell machinery—we build sustainable, profitable operations tailored to your local feedstock, climate, and output goals.

60+

Covering countries

Whether you’re processing pine in Scandinavia, eucalyptus in South America, or coconut waste in Southeast Asia, RICHI has the hands-on experience to optimize your wood pellet plant construction project. Our solutions are backed by robust engineering, automation-ready controls, and lifetime technical support.

WOOD PELLET PLANT PROJECT world wide

Explore our diverse portfolio of successful wood pellet plant construction projects below, showcasing our ability to handle unique challenges—from small-scale specialty production to industrial-grade pellet mills. Each project reflects our commitment to innovation, efficiency, and hands-on expertise.

If you’re planning to enter or expand in the wood pellet market, let’s discuss how we can build a system that turns your raw materials into profitable, high-quality pellets.

wood pellet plant construction project proposal

Each wood pellet plant construction project is uniquely configured according to individual needs. Our sales team is well equipped to customize your Plant to your needs with a wide range of equipment options which can be upscaled, or used in isolation. Contact Richi Machinery and discuss your wood pellet construction project with RICHI engineers.

Professional Equipment Solutions

This section provides a clear and professional overview of the core equipment required for a complete wood pellet plant construction project. From crushing and drying to pelleting, cooling, and packaging, we supply high-performance machinery designed for efficiency, durability, and consistent output.

Our solutions are engineered to handle various raw materials and production scales, ensuring you get the most value from your investment. As a specialized pellet mill manufacturer and integrated project service provider, we deliver not just equipment, but total peace of mind. Explore the technology that makes the difference—let’s build your ideal production line together.

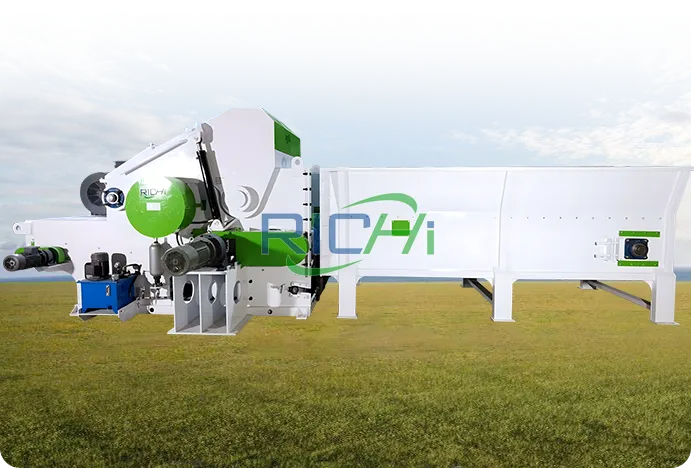

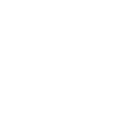

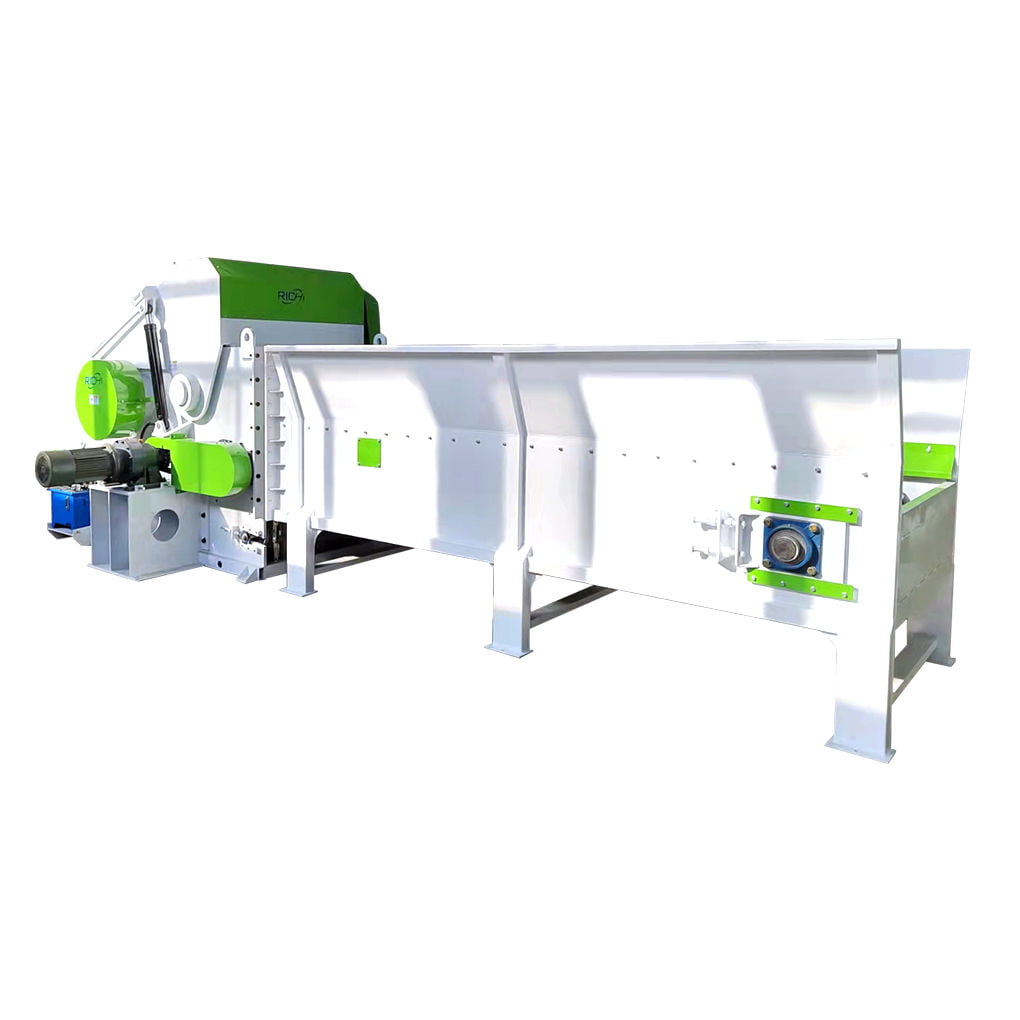

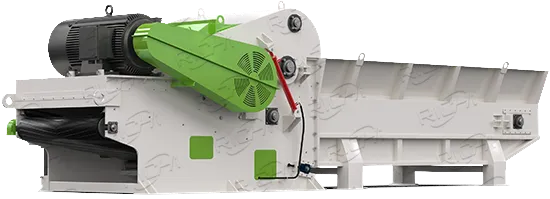

Wood chipper

Wood pelletizer

Wood crusher

Wood dryer

Wood pellet plant Project Video

From Romanian softwood to South African hardwood and Bangladeshi mixed wood processing, these real project videos showcase our equipment’s adaptability to different wood species, moisture content and production scales. Each video includes raw material preparation, production process details, and client feedback on pellet quality and operational efficiency.

Watch how we solve unique challenges for each client – then let’s discuss your specific wood pellet production needs.

These real-world examples demonstrate how we adapt to local materials and deliver results – from European softwoods to tropical hardwoods. Contact us to request full project videos and get a customized feasibility analysis for your specific raw materials and production goals. Let’s turn your wood resources into profitable pellets together.

cost to start wood pellet plant construction

When evaluating the feasibility of a new wood pellet plant construction, understanding the relationship between production capacity, initial investment, and the expected timeline for returns is crucial. The following table provides a clear reference based on our extensive experience, outlining estimated investment ranges and installation cycles for various production scales to help you in your preliminary planning.

At RICHI, we don’t just supply machinery; we deliver end-to-end wood pellet plant construction services, ensuring each project is optimized for its specific raw materials and operational goals. The figures below serve as a general guide—your actual investment can be influenced by material characteristics, automation level, and site conditions. To receive a detailed and personalized proposal tailored to your unique requirements, we encourage you to consult with our engineering specialists today.

| Production cycle | installation cycle | Investment Cost(USD) | Profit cycle |

|---|---|---|---|

| 0.2-1 T/H | 7-15 Days | 15,000-200,000 | 1-3 Year |

| 1-2 T/H | 7-15 Days | 20,000-300,000 | |

| 3 T/H | 15-20 Days | 30,000-350,000 | |

| 4 T/H | 20-40 Days | 50,000-400,000 | |

| 5-6 T/H | 45-60 Days | 80,000-500,000 | |

| 7-12 T/H | 60-90 Days | 120,000-1,500,000 | |

| 15-20T/H | 90-120 Days | 200,000-1,800,000 | |

| 20-30T/H | 100-140 Days | 300,000-2,000,000 | |

| 30-40T/H | 130-160 Days | 400,000-2,200,000 | |

| 40-60T/H | 160 -190 Days | 480,000-2,500,000 | |

| … | … | .. |

About the profit

Your profit starts with leveraging low-cost biomass – whether it’s sawmill residues, forest thinnings, or agricultural waste. Our engineers will analyze your local availability to design a system that maximizes yield while minimizing input costs. We’ve helped clients reduce material expenses by up to 40% through proper preprocessing and formulation.

The real difference comes from production consistency and energy management. Our equipment achieves 30% lower energy consumption compared to conventional systems through intelligent motor design and heat recovery. With automated controls maintaining optimal moisture levels and die pressure, you’ll produce premium pellets with less downtime and waste.

Premium pellets command better prices. Our systems produce consistent ENplus-grade pellets with density over 650kg/m³ and durability above 97.5%. We’ll help you target the most profitable markets – whether industrial heating, residential stoves, or export opportunities – with quality that justifies premium pricing.

Interested in our projects?

Ready to build your wood pellet plant? Get expert solutions tailored to your raw materials and profit goals!

The Prospect of wood Pellet Processing

The global wood pellet market continues to show strong growth driven by rising demand for sustainable energy across Europe, North America, and Asia. With increasing carbon reduction policies and the shift away from fossil fuels, investing in a modern pellet production line offers reliable long-term returns. Different regions present unique opportunities—whether using softwood residues in Scandinavia, hardwood waste in North America, or agricultural byproducts in Southeast Asia—each requiring tailored technical solutions to maximize yield and profitability.

At our company, we’ve helped over 500 clients worldwide navigate these opportunities with cost-effective and adaptive pellet line solutions. From raw material analysis and process design to automation and operational training, we ensure every project is optimized for local conditions and end-product requirements. If you’re exploring pellet production possibilities, we offer free feasibility assessments and customized project reports—let’s discuss how to turn biomass into value together.

Got questions about wood pellet production?

Our engineers have compiled the most practical FAQs from 500+ global projects – covering everything from material adaptability and moisture challenges to ROI timelines and maintenance best practices. These aren’t textbook theories but hard-won insights from processing pine, eucalyptus, bamboo, and other materials worldwide.

Still have specific questions? Get personalized answers from our technical team within 4 hours – just share your material specs.

What is the production capacity of the wood pellet plants you can provide?

+

0.3-90 T/H.

- Wood pellet plant construction cost: 50,000-3,000,000 USD

- Applicable raw materials: various types of wood waste (different moisture content), including sawdust, wood chips, tree trunks, branches, wooden pallets, wooden boards, wooden strips, etc

- Business scope: Newly built pure wood pellet production line or compound agricultural and forestry waste pellet production line

As the world increasingly turns towards renewable energy sources, the quality of wood fuels becomes pivotal.

We offer complete wood pellet plants for the treatment and production of high quality wood pellets. According to the requests of the Client and of the constructive characteristics, our plants have different construction characteristics and production capacity.

Pellet production is not a simple process so our support systems are designed to ensure product education and quick adoption of the technology. With over 30 years industry experience, we can provide the best advice on a broad spectrum of wood pelleting solutions.

What is the construction process of a wood pellet plant?

+

The wood pellet plant construction process usually includes the following key stages:

Operation monitoring and improvement:

After the wood pellet plant construction is completed, monitor and improve the production operation. Through data analysis and production process monitoring, we can identify production inefficiencies and quality problems and make improvements and optimizations to improve operational efficiency and production quality.

Planning:

This is the first step in wood pellet plant construction, involving the positioning and planning of product types, production quantities, production processes, etc. After the planning is completed, a wood pellet production line design plan needs to be formulated, including production line layout, equipment selection, logistics plan, etc. At the same time, construction costs and benefits need to be evaluated to ensure that it is economically feasible.

Equipment procurement and installation:

After planning is completed, equipment procurement and installation are carried out. Select an appropriate equipment supplier, determine the wood pellet making equipment model and quantity, and sign a contract with the supplier. After the equipment arrives, installation and debugging are carried out to ensure that the wood pellet plant equipment operates normally and meets production requirements.

Material supply and inventory management:

After the wood pellet plant construction is completed, a supply chain and inventory management system will be established to ensure adequate supply of raw materials and inventory. Optimize the distribution and inventory management of raw materials through logistics solutions to ensure production efficiency and cost control.

Employee training and management:

After the wood pellet plant construction is completed, workers will be trained and managed to ensure production efficiency and production quality. Excellent production lines rely on skilled operators.

In addition, there are other key steps, such as wood pellet mill project process flow design, equipment selection, construction, trial production and debugging, production workshop construction and power distribution, drainage system, etc.

These steps together constitute the complete process of wood pellet plant construction and ensure the smooth construction and operation of the production line.

How much does wood pellet plant construction cost?

+

The wood pellet plant construction cost mainly includes preliminary preparation, civil construction cost, equipment purchase cost, operating cost, etc.

- In the early preparation stage, a certain amount of funds need to be invested in market research, feasibility studies, and production plan formulation.

- During the construction stage, the wood pellet plant construction cost needs to be determined based on factors such as factory size, site selection, and design plan.

- In the equipment procurement stage, you need to purchase machinery and equipment, tools, testing instruments, etc. Depending on the size of the factory and equipment selection, the equipment purchase cost is approximately between US$100,000 and US$3 million.

- In the operation stage, fixed costs such as personnel wages, electricity and water bills need to be paid, and expenses such as raw material procurement and product transportation also need to be considered.

It should be noted that the specific wood pellet plant construction costs will also be affected by various factors, such as region, market demand, competition, etc. Before making investment decisions, investors need to carefully evaluate their financial strength and risk tolerance to ensure that they can bear the corresponding expenses and risks.

At the same time, biomass pellet industry investors also need to formulate reasonable financial plans and plan the use of funds and financing methods to reduce investment risks and financial risks. (Find RICHI on YouTube)

Different wood pellet plant construction projects, are the process designs also different?

+

No single wood pellet plant construction project may be the same as customer’s needs differ. Our sales team are well equipped with a range of products to customize wood pellet mill plans to your needs.

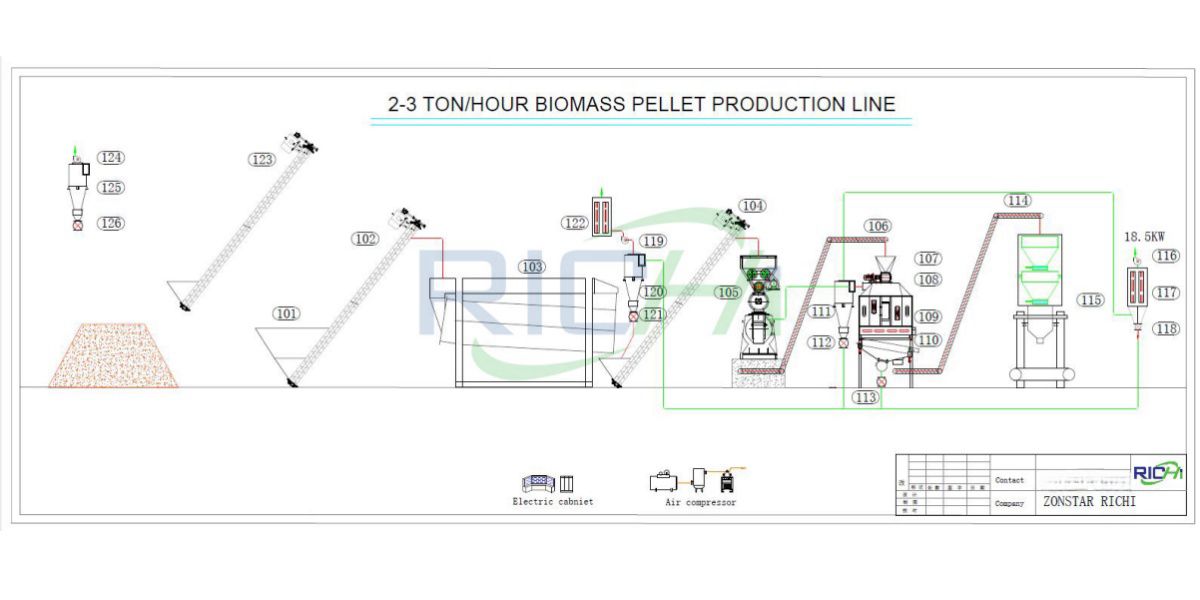

2-3T/H wood pellet plant construction project design

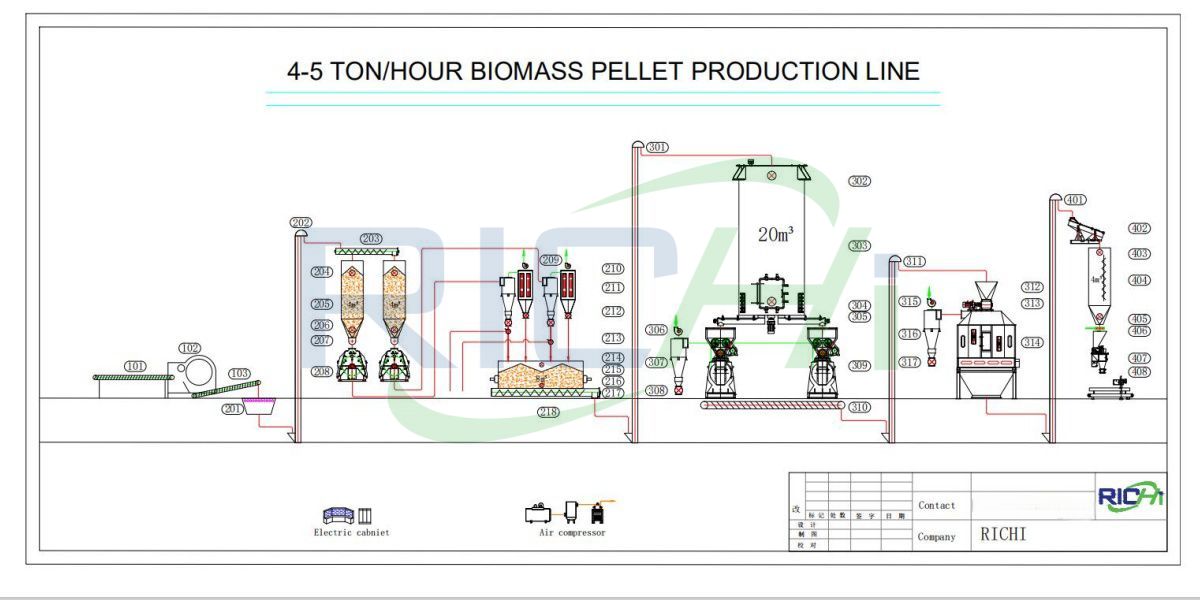

4-5 T/H wood pellet plant construction project design

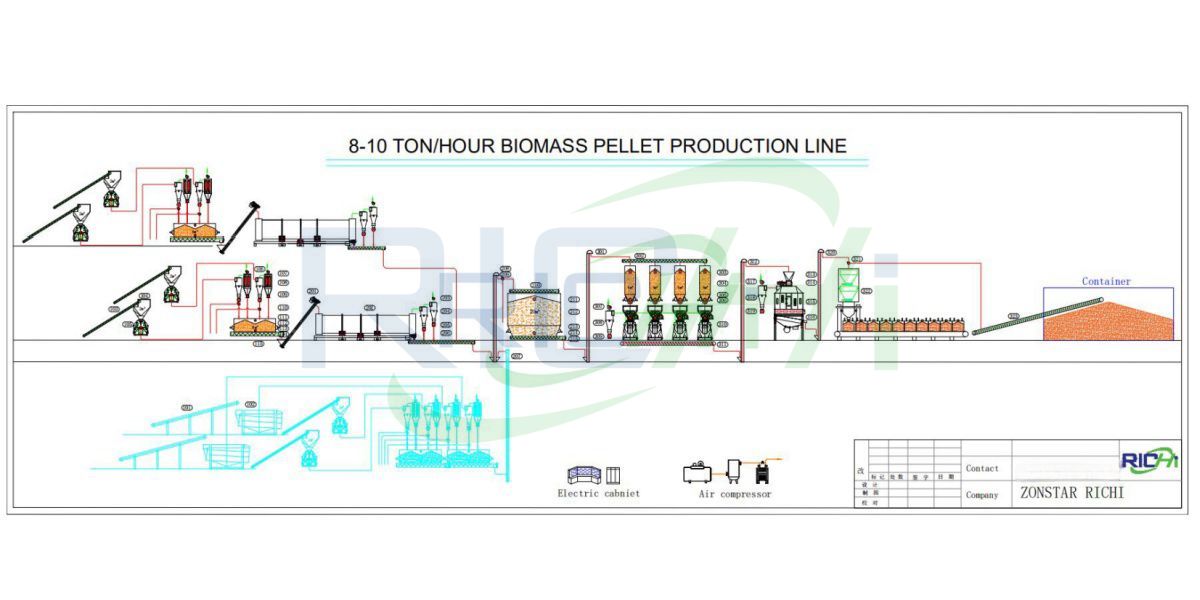

8-10 t/h wood pellet plant construction design

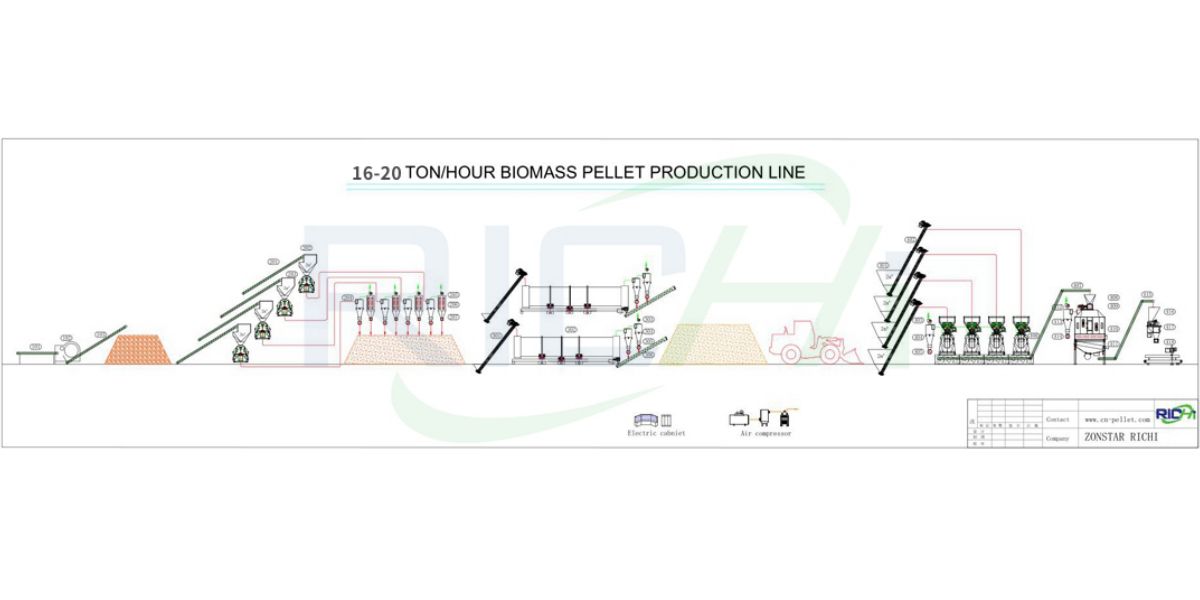

16-20 t/h wood pellet plant construction design

If you have any needs for wood pellet project construction design, contact us for technical support!

What equipment is needed for the wood pellet plant construction project?

+

A well-designed wood pellet production line is a coordinated system where each piece of equipment plays a critical role in transforming raw biomass into high-density pellets. The specific configuration depends on your raw material and production goals, but a complete setup typically includes the following core components:

1. Raw Material Preparation Section

- Chipper/Crusher: For reducing larger wood blocks or slabs into smaller, uniform chips.

- Hammer Mill: Further reduces the size of chips or shavings into a fine, consistent fiber optimal for pelleting. The design and power of this mill are crucial for overall efficiency.

2. Drying System

- Rotary Drum Dryer: The most common choice for efficiently reducing the moisture content of raw material to the ideal 10-15% range. The dryer’s capacity and heat source integration are vital design considerations.

3. Pelleting Section

- Pellet Mill: The heart of the operation. This is where the conditioned biomass is compressed under high pressure and forced through a die to form dense pellets. The reliability, power, and die technology of the pellet mill directly determine output and quality.

4. Post-Pellet Processing

- Cooler: Hardens and stabilizes the hot, soft pellets exiting the mill using ambient air.

- Screening System: Removes fines and broken pellets from the finished product, which can be recycled back into the process to maximize yield.

- Packaging System: Includes weighing and bagging units for retail bags or bulk loading systems for industrial customers.

5. Supporting Systems

- Material Handling: A network of belt conveyors, bucket elevators, and screw conveyors to move material seamlessly between stages.

- Dust Collection: Essential for safety, environmental compliance, and product recovery. Cyclones and baghouse filters are standard.

- Electrical Control System: The central nervous system that automates and monitors the entire process for stable operation.

The success of your wood pellet plant construction project hinges not just on selecting individual machines, but on how these components are integrated into a seamless, efficient system.

At Richi Machinery, we focus on engineering a cohesive production line where each unit is perfectly matched to the next, ensuring maximum throughput, minimal energy consumption, and consistent product quality. This systems-based approach is what delivers a faster return on investment for your wood pellet manufacturing plant construction.

How to configure a high-performance wood pellet plant construction project? Contact us to get wood equipment configurations and quotes for different capacities!

How should we select the core equipment (such as pelletizer, dryer, and crusher) used in a wood pellet plant construction project?

+

Choosing the right equipment is the most critical technical decision you’ll make in your wood pellet plant construction project. The optimal selection depends entirely on your specific raw material characteristics and production goals. Here’s how to approach these key decisions:

Pellet Mill Selection

The heart of your operation requires careful consideration of:

- Die specification tailored to your raw material’s fiber composition and lignin content

- Power capacity matched to your target throughput without overloading

- Drive system reliability for continuous operation under heavy loads

- Quick-change features that minimize downtime during maintenance

Drying System Configuration

Your dryer choice significantly impacts energy efficiency:

- Rotary drum dryers offering robust performance for various feedstocks

- Air flow design that ensures uniform moisture reduction without over-drying

- Heat source integration capabilities with your chosen energy system

- Safety systems for fire prevention and temperature control

Size Reduction Equipment

Hammer mill selection depends on:

- Initial particle size of your incoming material

- Required final particle size for optimal pelleting conditions

- Wear protection systems for abrasive materials

- Screen configuration options for different materials

The key to successful equipment selection lies in understanding how these systems work together. A perfectly sized pellet mill won’t perform well if preceded by an improperly configured hammer mill or dryer.

This is where our approach to wood pellet processing plant construction delivers distinct advantages. We analyze your specific material properties and production requirements before recommending equipment, ensuring all components work in harmony for optimal efficiency and product quality.

The right equipment choices create a foundation for reliable operation, consistent product quality, and long-term profitability. Getting these decisions correct from the beginning prevents costly modifications and production limitations later in your project lifecycle.

Do you provide layout for wood pellet plant construction?

+

Our wood pellet plant construction projects differ in layout because of a few variable factors.

- The first factor is the physical space where the plant will be installed.

- The second is the use of the pelleting equipment which can range from single wood pelleting to many biomass waste which can become renewable energy pellets and even animal feed or fertilisers, to name a few.

- The third important layout decision is normally related to power supply and existing equipment that will be incorporated.

RICHI always aim to accommodate the client’s current situation to ensure the most cost effective wood pellet plant construction solution and optimal wood pellet project layout is suggested.

What is the typical ROI and payback period for a wood pellet plant construction project?

+

This is arguably the most critical question for any investor. While the exact figures are unique to every project, a well-engineered wood pellet plant construction project with a reliable equipment supplier can typically achieve a full return on investment (ROI) within 2 to 5 years. The payback period and overall ROI are highly sensitive to several key factors:

1. Core Equipment Efficiency: This is where your choice of partner makes all the difference. An inefficient pelleting line with high energy consumption and frequent downtime will cripple your ROI. Our flagship pellet mills, for instance, are engineered for low power consumption per ton of output and feature robust dies and rollers that maximize uptime. This directly translates to higher profitability.

2. Raw Material Availability and Cost: Your local feedstock (sawdust, shavings, hardwood, agricultural waste) is your largest operational expense. Our engineers specialize in designing a wood pellet manufacturing plant construction blueprint that is optimized for your specific raw material mix, ensuring the highest yield and lowest waste. We don’t offer one-size-fits-all solutions.

3. Plant Capacity and Automation: A larger, highly automated plant has a higher initial capital cost but significantly lower operating costs per ton. We help you model the optimal scale for your market, ensuring your investment aligns with realistic production and sales targets.

4. Final Product Quality and Market Price: Producing premium, certified pellets (like ENplus®) commands a higher market price. Our complete wood pellet processing plant construction solutions are designed to consistently meet the strictest international quality standards, ensuring your product maximizes its revenue potential.

Why Partner with Us for Your Project?

When you collaborate with us on your wood pellet plant construction, you’re not just buying machinery; you’re investing in a profitability partnership.

- Proven, High-Yield Equipment: Our pellet mills and dryers are known for their reliability and efficiency, the two most important drivers of a strong ROI.

- Custom-Engineered Solutions: Before we quote any equipment, our team conducts a thorough analysis of your raw material. We then design a system—whether it’s for a wood pelletizing plant construction or a larger facility—to extract the maximum value from it, ensuring your operational costs are minimized.

- Expert Project Scoping: Our seasoned engineers will work with you to build a realistic financial model, projecting your payback period based on your local conditions. We help you de-risk the investment from the very beginning.

A rapid ROI isn’t just a goal; it’s the measurable outcome of choosing the right technology partner. Let us demonstrate how our expertise translates into your bottom line. Contact our project engineering team today for a preliminary feasibility assessment.

Sourcing Strategy for Wood Pellet Plant Construction: Sawmill Partnership vs. Own Collection Network?

+

This is a fundamental strategic decision that impacts the entire economics of your wood pellet plant construction project. There’s no one-size-fits-all answer, as the optimal choice depends entirely on your local context, scale, and long-term vision. Here’s a breakdown to guide your decision, and more importantly, how our engineering expertise ensures your success either way.

Direct Procurement from Sawmills

- Pros: Offers a relatively simple start with lower initial logistical overhead. You secure a consistent supply of a known, often pre-processed material (e.g., dry sawdust, shavings) from a few large partners.

- Cons: Creates dependency. Price fluctuations and availability are at the mercy of the sawmill’s operational schedule and market demands. It can limit expansion and bargaining power.

Building Your Own Raw Material Collection Network

- Pros: Fosters greater independence and can significantly lower raw material costs by sourcing directly from multiple smaller generators (smaller mills, furniture makers, forestry operations). It provides superior control over supply security and quality.

- Cons: Requires a significantly more complex operation. You need to manage logistics, transportation, and contracts with numerous suppliers, which demands robust planning and infrastructure.

The Optimal Path: Often a Hybrid Approach

Most successful operations evolve into a hybrid model. They might start with key sawmill partnerships to ensure baseline production and gradually build a broader network to improve margins and mitigate risk.

This is where our deep experience in wood pellet processing plant construction becomes your critical advantage. We don’t just sell machines; we analyze your entire supply chain.

1. Storage & Pre-processing Optimization:

Regardless of your sourcing choice, raw material storage is paramount. Inconsistent moisture content is the enemy of efficient pelleting.

Our system designs always include intelligent storage solutions, from simple covered pads to automated silos, and are integrated with our high-efficiency drum dryers. This ensures a consistent, homogenous feedstock flow to the pellet mill, maximizing output and minimizing downtime.

2. Handling Diverse Feedstocks with Ease:

A proprietary collection network means you’ll encounter a wider variety of materials. This is a non-issue with our technology. Our hammer mills and preconditioning systems are engineered to handle everything from fine sawdust to larger wood chips and even certain agricultural wastes. This flexibility, built into your wood pellet manufacturing plant construction plan, allows you to capitalize on the most cost-effective materials available, turning variety from a problem into a profit driver.

3. Engineering the Entire System for Logistics:

We think beyond the factory walls. Our project engineers will model your inbound logistics to determine the most efficient receiving, storage, and conveying layout.

This might involve designing for high-volume truck dumping or implementing conveyor systems that minimize fuel-guzzling front-end loader operation. This holistic view is what separates a functional plant from a highly profitable one.

The Bottom Line:

The right sourcing strategy is the one tailored to your specific location and goals. Our role is to provide the robust, flexible technology and strategic planning that makes either choice viable.

By building a plant capable of processing a wide spectrum of materials with high efficiency, we give you the leverage to build the most competitive and resilient sourcing model possible.

Let us evaluate your local conditions and help you build a resilient and cost-effective raw material strategy for your wood pellet plant construction project.

How to Choose Between a 10,000 TPY and a 100,000+ TPY Wood Pellet Plant?

+

Selecting the scale of your operation is a defining strategic decision. It’s not merely about ambition; it’s a calculated choice based on tangible factors that directly impact profitability and risk. Both small-scale and large-scale wood pellet plant construction projects can be viable, but their success hinges on different prerequisites.

Here’s how to determine the right scale for your venture, and why our engineering approach is critical for both.

Key Factors Influencing Your Decision:

1. Raw Material Security (The Primary Constraint):

This is the non-negotiable starting point. You must have a guaranteed, long-term supply of feedstock.

- 10,000 TPY: Requires approximately 30-35 tons of raw material per day. This can often be sourced from a few local sawmills or woodworking shops, making supply chain management simpler.

- 100,000+ TPY: Requires over 1,000 tons of material per day. This demands formal, long-term contracts with large sawmills or the development of an extensive, sophisticated raw material collection network covering a large radius. The logistics become a major operation in themselves.

2. Capital Investment (CAPEX) and Financing:

The investment is not linear. A larger plant benefits from economies of scale, meaning a lower cost per ton of production capacity.

- 10,000 TPY: A lower absolute investment, which can be easier to finance and presents a lower initial financial risk. It’s often suitable for private investors or smaller enterprises.

- 100,000+ TPY: A significantly higher capital requirement, typically necessitating bank loans or investor backing. The financial risk is greater, but the potential return on investment (ROI) and profit margins are also substantially higher due to lower per-unit costs.

3. Target Market and Off-Take Agreements:

Who are you selling to, and on what terms?

- 10,000 TPY: Ideal for serving local or regional markets—e.g., homeowners, small-scale district heating, poultry farms. Sales are often more fragmented and based on spot market prices.

- 100,000+ TPY: Almost essential for securing lucrative export contracts or supplying large-scale power plants and industrial users. These buyers require large volumes and often demand long-term off-take agreements, which in turn provide revenue certainty for securing project financing.

4. Automation and Operational Costs (OPEX):

The operational model differs drastically.

- 10,000 TPY: May involve more manual labor for material handling, bagging, and logistics. While simpler, the cost per ton for labor and energy is generally higher.

- 100,000+ TPY: Justifies and requires a high degree of automation. Automated conveyor systems, centralized control rooms, and advanced monitoring are standard. This reduces labor costs per ton and ensures consistent, high-quality production, which is paramount for large contracts.

Why Our Expertise is Your Strategic Advantage

This decision is not one you make alone. Our role is to provide the data-driven analysis and technological flexibility to support either path.

- For the 10,000 TPY Project: We offer robust, simplified lines that prioritize ease of operation and reliability. Our SKID-mounted solutions can reduce installation time and cost, providing a swift entry into the market. We focus on designing for efficiency at a smaller scale to protect your margins.

- For the 100,000+ TPY wood pellet plant construction: This is where our full engineering prowess comes to the fore. We design and integrate complex, fully automated production lines. Our engineers perform detailed feasibility studies, focusing on plant layout optimization, advanced logistics handling, and energy integration (like utilizing excess heat from the dryer) to minimize operational expenses from day one.

Crucially, our technology portfolio is scalable. Whether you are starting with a smaller wood pelletizing plant construction or planning for a major facility, the core principles of our machinery—reliability, energy efficiency, and adaptability to various raw materials—remain consistent. This allows for future expansion with a trusted technology partner.

The Right Choice is an Informed Choice.

We recommend a phased feasibility study that models both scenarios against your specific local conditions. We provide the technical and economic modeling to help you visualize the CAPEX, OPEX, and potential ROI for each option, turning a complex decision into a clear strategic roadmap.

Let’s analyze your local feedstock and market to build a data-backed business case for the right scale of your project.

Wood pellet plant construction project, what is its production process?

+

A well-optimized production process is the backbone of any successful wood pellet operation. While the core steps may seem straightforward, the efficiency, consistency, and quality of the final product are entirely dependent on the engineering excellence of the equipment and the system integration. Here’s a detailed look at the typical production flow, and how our approach to wood pellet plant construction ensures superior performance at every stage.

1. Raw Material Receiving and Preliminary Screening

The process begins with the intake of raw feedstock, which can range from sawdust and wood shavings to wood chips and planer shavings. The first critical step is removing contaminants like metals, stones, or plastics.

Our systems include heavy-duty receiving hoppers and magnetic separators, designed to protect downstream equipment from damage—a fundamental consideration in any durable wood pellet processing plant construction.

2. Size Reduction (Coarse and Fine Grinding)

Consistent particle size is crucial for efficient pelleting. Larger pieces must be reduced in a hammer mill. The design of this stage is vital; our grinding systems are engineered for low energy consumption and minimal heat generation, preserving the natural binding properties of the lignin in the wood. This attention to detail is what sets our preparation technology apart.

3. Drying: The Key to Efficiency

This is often the most energy-intensive stage. Incoming raw material must be dried to a precise moisture content (typically 10-15%). We design and integrate high-efficiency rotary dryers, which can be configured to utilize various heat sources.

The precision of this stage directly impacts the stability of the pellet and the load on the pellet mill. Properly engineered drying is non-negotiable for a profitable wood pellet manufacturing plant construction.

4. Conditioning and Pelletizing: The Heart of the Operation

The dried and finely ground material is conditioned with steam or water to temperature, making the lignin plasticizable. It is then fed into the pellet mill, where it is forced through the holes of a die by rollers.

This is where equipment quality is paramount. Our pellet mills are renowned for their robust construction, superior die and roller technology, and ability to maintain stable operation under high load, ensuring high output and low energy consumption per ton.

5. Cooling and Screening

The pellets exiting the mill are hot and soft. They must be cooled and hardened in a counter-flow cooler to achieve their final durability and stability. Subsequently, they are screened to remove any fine particles (fines).

These fines are recycled back into the process, maximizing yield. Our cooling and screening systems are designed for gentle handling to minimize pellet breakage.

6. Weighing and Packaging

The finished pellets are conveyed to storage silos and then to automated weighing and packaging systems for bagging (for retail) or loaded in bulk for large-scale industrial customers. The entire conveying system is designed to prevent degradation of the pellet quality.

Why Our Process Design Delivers Better Results

Many suppliers can list these steps. The difference lies in the integration and deep understanding of how each stage affects the next.

- Seamless Integration: We don’t just sell individual machines; we engineer a cohesive system. The conveyor capacities, airlocks, and control systems are meticulously matched to prevent bottlenecks and ensure a smooth, continuous flow from raw material to finished product.

- Adaptability to Feedstock: A plant designed solely for pine sawdust will struggle with mixed hardwood or agricultural waste. Our engineers have extensive experience configuring the process parameters—grind size, drying temperature, conditioning—for a vast range of materials. This flexibility is built into the design of your wood pelletizing plant construction project from the very beginning.

- Focus on Energy Optimization: We design with total cost of ownership in mind. This means optimizing heat recovery from the cooler, recycling fines, and selecting drives that minimize power consumption. These efficiencies, often overlooked, are what make the difference between a marginal operation and a highly profitable one.

In essence, the process is a symphony of interconnected operations. The success of your wood pellets plant construction project depends on having a conductor who understands every instrument. We bring that expertise, ensuring your plant is not just built, but precision-engineered for longevity, efficiency, and maximum return on investment.

How many operators and maintenance personnel are needed for a wood pellet plant construction project?

+

A critical question for any investor is understanding the human resource requirements for running a pellet plant. The number of personnel needed is not a fixed figure; it is a direct reflection of the plant’s design, level of automation, and the reliability of the equipment installed.

While a basic, low-automation facility might require a larger crew, our core philosophy in wood pellet plant construction is to engineer solutions that maximize output while minimizing labor dependency through intelligent design and superior equipment reliability. This approach directly controls your long-term operational expenditures.

Here’s a breakdown of how staffing needs are determined:

1. The Role of Automation and Plant Scale

The single greatest factor influencing staffing is the degree of automation designed into the system. A large, fully automated plant may not require many more personnel than a smaller, manual one.

- A Highly Automated Plant (Our Standard Approach): For a modern facility engineered by our team, the core control room might require only 1-2 operators per shift to monitor the entire process from a centralized Human-Machine Interface (HMI). Material handling—from receiving to conveying—is automated through programmed conveyors and feeders. This significantly reduces the need for manual labor and front-end loader operation.

- A Manual or Semi-Automated Plant: This scenario requires personnel for every major step: a dedicated loader operator for raw material intake, workers for manual bagging, and more frequent manual quality checks, easily requiring twice the number of people or more per shift.

2. Core Operational Shifts

A plant designed for 24/7 operation typically runs with three 8-hour shifts, plus a maintenance crew. A basic shift team for a well-automated plant might include:

- Control Room Operator (1)

- Field Operator / Patrol (1 for visual inspections and minor adjustments)

- Loader Operator (1, if raw material intake isn’t fully automated)

3. The Critical Maintenance Function

This is where equipment quality proves its value. A plant built with robust, low-maintenance components requires less frequent and less intensive intervention.

- We strongly recommend a dedicated maintenance team, which may be shared across shifts. This team is responsible for the scheduled preventative maintenance—such as die and roller changes, lubrication, and inspection—that is vital for preventing unplanned downtime. The size of this team depends on the complexity of the plant.

How Our Engineering Reduces Your Labor Burden

Our approach to wood pellet processing plant construction focuses on building in efficiency and reliability from the ground up, which directly translates to leaner staffing.

- Design for Reliability: We specify components known for their durability and ease of service. This means less time spent on emergency repairs and a smaller maintenance crew can effectively manage the preventative schedule.

- Integrated Control Systems: Our plants are built around a centralized PLC-based control system that provides operators with a clear overview of the entire process. Alerts for potential issues allow for proactive intervention, reducing the need for constant manual patrols and checks.

- Simplified Maintenance Access: Our system layouts are designed with serviceability in mind. Easy access to key components like pellet mills and dryers reduces the time and labor required for routine maintenance tasks.

Ultimately, the goal of a successful wood pellet manufacturing plant construction project is to create a facility that is a profit center, not a high-overhead operation. By investing in intelligent, automated design and superior equipment from the start, you invest in a lower and more predictable operational cost structure for the lifetime of the plant.

Let us show you how our detailed plant designs include staffing and maintenance plans tailored to achieve the highest operational efficiency for your specific project.

In a wood pellet plant project, the drying process consumes the most energy. How can we use biomass energy (such as the waste heat generated) to reduce energy costs?

+

A critical factor in the feasibility of any wood pellet plant project is understanding its energy profile. Potential investors rightly ask about expected consumption, as energy is a major ongoing operational cost.

While exact numbers vary based on raw material characteristics and plant design, we can provide reliable benchmarks and, more importantly, detail the proven strategies we employ to minimize these costs from the outset.

Estimated Energy Consumption Benchmarks

A well-designed plant strives for optimal energy efficiency. Consumption is typically measured per ton of pellets produced.

- Thermal Energy (Drying): This is the largest energy demand, accounting for roughly 60-70% of total energy use. To evaporate moisture from raw feedstock, a modern plant can expect to use between 900 – 1,300 kWh of thermal energy per ton of pellets. The specific figure depends heavily on the initial moisture content of the material.

- Electrical Energy (Process Power): This powers all motors—conveyors, grinders, pellet mills, coolers, and fans. A highly efficient operation can achieve an electrical consumption between 90 – 130 kWh per ton of finished pellets.

It’s important to understand that these are not just numbers; they are a direct reflection of the quality of engineering and equipment selection in your wood pellet plant construction project.

Integrated Strategies for Energy Conservation

Our approach goes beyond simply supplying equipment. We design integrated systems where every component is selected and configured for maximum energy efficiency. Here are the key strategies we implement:

1. Biomass-Based Thermal Energy Generation:

The single most effective energy-saving solutions is to eliminate fossil fuels. We specialize in integrating automated biomass burners that use low-value feedstock (bark, shavings, fines) to generate heat for the drying process.

This creates a closed-loop system, turning waste into free fuel and stabilizing your largest operational cost against market volatility.

2. Intelligent Heat Management and Recirculation:

Modern dryer systems are not one-way streets. We design systems with sophisticated heat recirculation capabilities. A portion of the moist, warm air exiting the dryer can be treated and recirculated back into the system.

This reduces the total volume of fresh air that needs to be heated from ambient temperature, significantly cutting thermal energy demand.

3. Deployment of High-Efficiency Motors and Drives:

Every motor in the plant is a opportunity for savings. Our layouts prioritize high-efficiency (IE3/IE4) electric motors and variable frequency drives (VFDs) on equipment like conveyors, fans, and pumps. VFDs allow motors to run only at the speed needed for the required throughput, eliminating the energy waste associated with constant-speed operation.

4. Process Optimization to Reduce Load:

Efficiency starts before material even reaches the dryer.

- Particle Size Consistency: Ensuring proper grinding reduces the energy required in the pellet mill.

- Moisture Management: Intelligent storage solutions to prevent feedstock from re-wetting minimizes the drying load.

- Heat Recovery from Pellet Cooling: The pellets exiting the pellet mill are very hot and must be cooled. We can design systems to capture this low-grade heat and repurpose it for pre-heating air or other auxiliary needs, improving overall system efficiency.

The Richi Machinery Advantage: Designing for Low OPEX

When you partner with us for your wood pellet manufacturing plant construction, you are investing in a system engineered for low lifetime operating costs.

We don’t just provide a list of machines; we perform energy modeling during the design phase to predict consumption and identify the most effective energy-saving solutions for your specific raw material and climate conditions.

Our expertise in creating cohesive, automated systems ensures that all components work in harmony, eliminating energy bottlenecks and waste. This results in a plant that is not only productive but also exceptionally economical to run, maximizing your return on investment for years to come.

What is the estimated energy consumption (electricity and heat) for a wood pellet plant project? What energy-saving solutions are available?

+

Understanding the energy profile of a pellet production operation is crucial for assessing its operational costs and environmental footprint. While specific numbers vary based on material characteristics and plant configuration, here’s what you can expect from a properly engineered system.

Typical Energy Consumption Benchmarks

For a modern facility designed with efficiency in mind, energy consumption generally falls within these ranges per ton of pellets produced:

Thermal Energy (Drying Process): 850-1200 kWh/ton

Electrical Energy (Process Power): 95-125 kWh/ton

The variation depends primarily on initial moisture content of the raw material and the specific technology package implemented in your wood pellet plant construction project. Higher moisture content naturally requires more thermal energy for evaporation, while older or less optimized equipment typically shows higher electrical consumption.

Comprehensive Energy Optimization Strategies

What separates a marginal operation from a highly profitable one is the implementation of integrated energy solutions. Here’s how modern engineering addresses energy challenges:

1. Self-Sufficient Thermal Energy Solutions

The most significant energy breakthrough in wood pellet processing plant construction is the implementation of biomass-fired thermal systems. Instead of relying on expensive fossil fuels, these systems use process residues (bark, fines, dust) to generate the required thermal energy. This approach typically achieves 100% thermal self-sufficiency while eliminating external fuel costs.

2. Advanced Heat Management Systems

Sophisticated heat recovery and recirculation systems represent another layer of efficiency. Modern designs incorporate:

- Partial exhaust gas recirculation to reduce fresh air heating requirements

- Multi-stage drying processes that optimize temperature profiles

- Heat recovery from cooler exhaust air for supplemental space heating

3. Intelligent Process Optimization

True efficiency comes from optimizing the entire production chain, not just individual components. Key strategies include:

- Moisture management through covered storage to minimize drying load

- Particle size optimization to reduce grinding energy requirements

- Process control systems that automatically adjust operations based on real-time material analysis

4. High-Efficiency Power Systems

Electrical consumption is addressed through:

- Premium efficiency (IE4/IE5) motors throughout the system

- Variable frequency drives on all appropriate equipment

- Energy-optimized fan and pump selections

- Automated power management systems that reduce idle consumption

The Operational Impact of Smart Design

When evaluating wood pellet manufacturing plant construction options, it’s essential to consider how these energy solutions translate to operational benefits:

A well-executed wood pelletizing plant construction project should deliver energy costs representing 25-35% of production expenses, compared to 40-50% for less optimized facilities. The integration of biomass thermal systems typically provides a 12-24 month return on investment through eliminated natural gas or propane expenses.

Furthermore, these energy strategies contribute to operational resilience by insulating your business from external energy price volatility and ensuring consistent production costs regardless of market conditions.

The key to achieving these results lies in selecting a partner who understands how to properly size, integrate, and optimize these systems for your specific raw material characteristics and production goals. This holistic approach to energy management transforms what is typically the largest operational expense into a competitive advantage.

For a wood pellet plant construction project, how can we meet the strict local environmental regulations and avoid future complaints or production suspensions?

+

Navigating environmental regulations is a fundamental aspect of sustainable pellet production. A properly designed facility doesn’t just meet requirements—it integrates environmental stewardship into its core operations. Here’s how a carefully planned wood pellet plant construction project addresses these critical concerns.

Proactive Environmental Protection Measures

The most effective approach to compliance begins during the design phase. Rather than treating environmental systems as add-ons, we integrate them into the plant’s fundamental architecture:

1. Comprehensive Dust Management Systems

Dust control represents perhaps the most visible environmental challenge. Our designs incorporate multiple layers of protection:

- Closed conveying systems with dedicated dust extraction points at all transfer locations

- High-efficiency cyclone separators followed by baghouse filtration systems

- Centralized vacuum systems for maintenance and cleaning operations

- Strategic ventilation design that maintains negative pressure in processing areas

2. Advanced Emission Control Technology

Modern thermal systems require sophisticated emission management:

- Multi-stage combustion systems that maintain optimal temperatures for complete combustion

- Integrated dust separation prior to exhaust systems to reduce particulate loading

- Carefully designed stack height and placement considerations to ensure proper dispersion

3. Noise Abatement Strategies

Industrial equipment naturally generates noise, but proper engineering can mitigate its impact:

- Acoustic enclosures for high-noise equipment like hammer mills and air compressors

- Vibration isolation systems for rotating equipment

- Strategic plant layout that places noisier operations away from property boundaries

- Sound-absorbing materials in building construction where appropriate

4. Water Management and Protection

Even in a relatively dry process, water protection remains crucial:

- Impervious surfaces under storage areas with proper drainage containment

- Stormwater management systems that prevent runoff contamination

- Closed-loop cooling systems where water is required

The Engineering Difference in Environmental Performance

What separates a compliant facility from one that faces ongoing challenges often comes down to engineering details that might not be immediately apparent:

System Integration Approach

Rather than treating environmental controls as separate systems, we design them as integrated components. For example, dust collected from processing equipment can often be directly conveyed to the thermal system as fuel, creating a closed-loop solution that eliminates waste while generating energy.

Precision Equipment Selection

The choice of individual components significantly impacts environmental performance. We specify equipment with demonstrated compliance records, paying particular attention to:

- Pellet mills with efficient die designs that minimize fine generation

- Dryers with precise temperature control to prevent overheating and emissions

- Motors and drives that operate at optimal efficiency levels

Operational Transparency and Monitoring

Modern facilities incorporate continuous monitoring systems that:

- Track dust emission levels in real-time

- Monitor stack emissions parameters

- Record noise levels at property boundaries

- Provide automated reporting capabilities for regulatory compliance

Building Community Confidence

Beyond regulatory requirements, successful wood pellet manufacturing plant construction projects address community concerns through thoughtful design:

- Attractive architectural treatments that blend with local surroundings

- Comprehensive landscaping plans that provide visual and acoustic buffering

- Traffic management plans that address local road concerns

- Odor control strategies where organic materials are stored

The reality is that environmental compliance isn’t a single achievement but an ongoing commitment. By designing systems that exceed minimum requirements and incorporate redundant safeguards, we help create facilities that operate as good neighbors while protecting your investment from operational disruptions.

This approach to wood pellet processing plant construction ensures that environmental protection becomes embedded in your operation’s DNA rather than being an afterthought or constant concern. The result is a facility that not only meets today’s standards but is prepared for tomorrow’s requirements as well.

How can finished wood pellets be protected from moisture and deterioration? Should they be shipped in bulk or bags? What are the storage requirements?

+

Maintaining the quality of your finished wood pellets from production to end-user is crucial for preserving their energy value and marketability. The choices made in handling, storage, and transportation directly impact product integrity and customer satisfaction.

Preventing Moisture Damage and Quality Degradation

Wood pellets are highly susceptible to moisture absorption, which causes swelling, disintegration, and reduced calorific value. Effective protection requires a multi-layered approach:

1. Comprehensive Cooling and Conditioning

Proper post-production processing is the first defense against moisture. Our systems ensure pellets are discharged from the cooler at ambient temperature and optimal moisture content (below 8%). This prevents condensation that would occur if warm pellets were packaged or stored immediately.

2. Strategic Packaging Solutions

For bagged products, we recommend:

- Multi-layer polypropylene bags with water-resistant barriers

- Sealed pallet covers with desiccant packets for high-humidity climates

- Automated bagging systems that ensure consistent, secure seals

3. Bulk Storage Integrity

For bulk operations, protection requires:

- Silo design with insulated walls to prevent condensation

- Climate-controlled ventilation systems maintaining relative humidity below 60%

- Temperature monitoring systems with automated aeration cycles

Transportation Mode Selection: Bulk vs. Bagged

The choice between bulk and bagged transportation depends on your market segment and distribution model:

Bulk Transportation is ideal for:

- Industrial clients and power plants with receiving facilities

- High-volume deliveries reducing per-ton transportation costs

- Specialized bulk trucks or containers with weather-proof seals

Bagged Transportation suits:

- Retail and residential markets requiring smaller quantities

- Markets requiring brand presentation and product information

- Situations requiring extended storage at distribution points

Many successful operations maintain both capabilities to serve multiple market segments effectively.

Optimal Storage Facility Design

Proper storage conditions are non-negotiable for quality preservation. Whether designing new storage or retrofitting existing facilities, these elements are essential:

1. Environmental Control Systems

- Concrete or steel silos with protective interior coatings

- Temperature and humidity monitoring with automated ventilation

- Protection from ground moisture through proper flooring and drainage

2. Material Handling Considerations

- Gentle conveyor systems that minimize pellet degradation

- Dedicated areas for bagged product storage away from potential moisture sources

- Inventory management systems implementing first-in-first-out rotation

3. Integrated Quality Preservation

Our approach to wood pellet plant construction considers the entire product journey. We design systems that:

- Maintain quality from production through loading operations

- Incorporate moisture monitoring at critical transfer points

- Ensure smooth material flow that minimizes particle breakdown

The storage and transportation strategies implemented in your wood pellet manufacturing plant construction project should reflect your target market requirements and environmental conditions. By addressing these factors during the design phase, we help create facilities that deliver consistent product quality regardless of destination or storage duration.

This comprehensive approach to product protection ensures that the premium quality achieved during production is maintained throughout the supply chain, protecting your brand reputation and maximizing customer satisfaction.

What level of automation should a wood pellet plant have?

+

The ideal level of automation for your wood pellet plant construction project depends on several key factors, with each option offering distinct advantages depending on your operational goals and investment capacity.

Manual Operation

Suitable for smaller operations where:

- Initial investment needs to be minimized

- Labor costs are relatively low

- Production runs may be intermittent

- Operators can directly monitor and adjust processes

Basic Automation

Provides fundamental controls for:

- Key process parameters like temperature and moisture

- Equipment protection and safety interlocks

- Basic production data collection

- Reduced operator involvement in routine adjustments

Full Automation

Recommended for larger operations seeking:

- Consistent product quality through precise control

- Minimal labor requirements per production ton

- Comprehensive data logging and performance analytics

- Remote monitoring and troubleshooting capabilities

- Integration with upstream and downstream systems

The choice ultimately balances initial investment against long-term operational costs. While manual systems require lower capital expenditure, they typically have higher operating costs and greater product variability. Automated systems command higher upfront investment but deliver lower cost per ton, better quality consistency, and easier scalability.

In our wood pellet processing plant construction projects, we help clients evaluate these tradeoffs based on their specific circumstances. The right solution often involves strategic automation – implementing control systems where they provide the greatest return while maintaining practical operation where manual intervention remains cost-effective.

Modern control systems can often be implemented in phases, allowing operations to start with essential automation and add capabilities as production grows and budgets allow. This approach spreads investment while building toward optimal efficiency.

What are the special requirements for plant design and construction in wood pellet plant construction projects?

+

The structural design of your production facility requires specialized planning to accommodate the unique demands of pellet manufacturing. Several critical factors must be integrated into the building design from the initial planning stages.

Structural and Layout Requirements

The building must support heavy equipment loads and facilitate efficient material flow. Key considerations include:

- High bay clearance for equipment installation and material handling systems

- Reinforced foundations capable of supporting vibrating machinery and heavy storage loads

- Adequate door and access points for equipment maintenance and replacement

- Optimized process flow layout to minimize material transfer distances

Environmental Control Systems

Proper environmental management ensures both product quality and operational safety:

- Ventilation systems designed for heat and moisture removal

- Dust control infrastructure integrated into the building design

- Temperature management for both process requirements and operator comfort

- Moisture protection for stored materials and finished products

Safety and Regulatory Compliance

The facility design must incorporate specific safety features:

- Explosion venting and safety systems where required

- Fire separation between high-risk areas

- Dust containment through proper room segregation

- Emergency access and evacuation route planning

Utility Infrastructure

Adequate utility provisions are essential for operation:

- Electrical capacity planning for future expansion

- Compressed air systems for instrumentation and controls

- Drainage and containment for process areas

- Lighting systems suitable for industrial maintenance

The success of your wood pellet plant construction project depends on addressing these requirements during the design phase rather than attempting to modify facilities after construction. Proper planning ensures your building becomes an asset that supports efficient operation rather than a constraint that limits production potential.

We recommend involving equipment suppliers early in the design process to ensure the facility meets both current needs and allows for future operational flexibility.

How to determine the appropriate production capacity?

+

Selecting the right production capacity requires balancing several practical considerations rather than simply choosing the largest possible output. The ideal capacity emerges from analyzing these key factors:

Raw Material Availability

Your sustainable production volume cannot exceed what your local feedstock can reliably support. We analyze:

- Annual available quantities of your primary materials

- Seasonal variations in supply

- Competing uses for the same materials

- Transportation logistics for collection

Market Demand Analysis

Production must align with sales opportunities:

- Existing offtake agreements or target contracts

- Local versus export market requirements

- Growth projections for your target sectors

- Competitive landscape in your region

Investment Considerations

Financial parameters directly influence scale:

- Available capital for equipment and infrastructure

- Target return on investment timeline

- Operating cost structure at different volumes

- Financing options for various project sizes

Practical Implementation

Most successful operations begin with a phased approach:

- Initial capacity that matches proven feedstock contracts

- Design that allows for future expansion

- Equipment selection that can be upgraded cost-effectively

- Building infrastructure that supports growth

The most successful wood pellet plant construction projects match capacity to these real-world constraints rather than theoretical maximums. We help clients identify the sustainable scale that maximizes profitability while managing risk – whether that means starting with a 10,000 TPY operation or planning a 100,000+ TPY facility from the outset.

Proper capacity planning ensures your operation runs at optimal efficiency rather than struggling with insufficient raw materials or excess equipment costs. The right balance differentiates between a struggling operation and a profitable enterprise.

What are your featured wood pellet plant construction projects?

+

Richi Machinery is the world leader in supplying industrial wood pellet making machines and full wood pellet plants. We specialize in providing our customers with turnkey wood pellet plant construction system solutions catered to their specific needs and uses.

Currently, you can find our wood pellet factory construction projects in the United States, Canada, Russia, Indonesia, India, Australia, Poland, Germany, Netherlands, Argentina, Brazil, Japan, South Africa, etc.

wood pellet plant construction In United States

- Capacity: 10 TPH

- Pellet Size: 6-8mm

- The install period: 60 Days

- Guiding Price: 1,300,000USD

- Main Raw material: wood waste from furniture factories, paper mills and other factories

- Main Machines: Wood chipper, wood hammer mill, rotary dryer, wood pellet mill, Pellet cooling machine, Screener machine, packing machine, Sewing machine,etc.

wood pellet plant construction In canada

- Capacity: 2-2.5T/H

- Pellet Size: 8mm

- The install period: 45 Days

- Guiding Price: 330,000USD

- Main Raw material: wood off cuts, wood chip and sawdust different types of wood sizes

- Main Machines: Wood sawdust making machine, Mixing machine, MZLH520 sawdust pellet press, Wood pellet cooler, Wood pellet screener, Wood pellet bagging machine, etc.

wood pellet plant construction In Vietnam

- Capacity: 4T/H

- Pellet Size: 6-10 mm

- The install period: 90 Days

- Guiding Price: US$390,000

- Main Raw material: Sawdust, Bamboo chips, Corn stamens, corn stalks, bran powder, etc.

- Main Machines: Slicer, wood granulator, wood waste Grinder, wood sawdust dryer machine, Bag filter, Cyclone, Conveyor, Forklift, Truck, etc.

wood pellet plant construction In Thailand

- Capacity: 10-12T/H

- Pellet Size: 6-10 mm

- The install period: 70 Days

- Guiding Price: US$770,000

- Main Raw material: Scrap wood blocks, Sawdust, Wood shavings

- Main Machines: Slicing machine, Belt conveyor, wood chip silo (10m*3m*1.5m), Crusher, wood pellet mill (MZLH420), Cooling screening machine (Φ800), packaging machine, etc.

wood pellet plant construction In Argentina

- Capacity: 4-5T/H

- Pellet Size: 8 mm

- The install period: 50 Days

- Guiding Price: US$430,000

- Main Raw material: tree branches, Sawdust, wood pallets, Wood shavings

- Main Machines: Wood crusher, Pulse dust collector, U-screw conveyor, Drum dryer, wood fuel pellet mill MZLH520, Belt conveyor, Cooling machine, Vibrating screener, Packing machine, etc.

wood pellet plant construction In Indonesia

Main Machines: Pallet shredder, Wood hammer mill, Wood pellet mill machine, Wood pellet cooler, Screening machine, Bucket elevator, Conveyor, Automatic weighing and baling machine, etc.

- Capacity: 1-2T/H

- Pellet Size: 10 mm

- The install period: 40 Days

- Guiding Price: US$ 350,000

- Main Raw material: various discarded wooden pallets

RICHI is reliable partner in high-end equipment for pelleting and grinding a large variety of wood waste products. Our equipment processes hard and soft woods, torrefied wood worldwide.

Durability is crucial in this segment of the market where the load on the equipment can be extreme while using it 24/7, 365 days a year. With Richi Machinery, you have complete control over every step of production, and we offer tailored wood pellet plant construction solutions for the whole process: chipping, grinding, drying, pelleting, cooling, screening and bagging.

We consider as a primary factor to find the most appealing technical solutions for our customers, which are economical, effective and sustainable combined with high quality.

About RICHI

Since founding in 1995, RICHI MACHINERY has grown to become the world’s leading designer and builder of pellet production line systems. RICHI has delivered over 2000 projects to clients located in more than 140 countries across six continents. Altogether we have over 200 employees, and from start to finish, RICHI can design, manufacture, build and deliver your entire project – there’s no need to manage multiple project partners.

RICHI Technology

Adhering to the R&D tenet of “independent innovation”, Richi Machinery’s annual R&D investment accounts for more than 3% of total sales. It is supported by CAD, Solidworks and other computer-aided design systems, Ansys, matlab simulation analysis software, and VCC, EasyBuoder8000 and other programming software.

Project Management

For the construction of a complex pellet plant, process design, equipment manufacturing, precise logistical organization, accurate work, a combined installation team of experienced subcontractors are essential, which our company has retained for decades.

Patents & certifications

In the process of our continuous development, exploration and innovation, relying on our strength, we have more than 30 patent technologies, and all products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

Service You Can Count On

When customers need support, our customer service is the solution.

consultation

We assess our client’s long-term development needs, what the products manufactured by it require, what it intends to manufacture and what quantity it wants to produce.

Design

Advanced design technology combined with years of experience, specialist skills and innovative thinking drives advanced, cost-effective and productive solutions for our customers.

manufacturing

The technological equipment and machines comprising the pellet plant are manufactured by our permanent expert staff in continuous consultation with our engineers.

Installation

We offer a range of start-up field services across a variety of industries to get your new equipment set up and running as quickly as possible. Once installed, we test and analyze key operations to maximize performance.

Industrial maintenance

Regular maintenance achieves a longer service life for investments and maximises production efficiency. We are able to react quickly to problem situations and serve you flexibly with a package tailored to your needs.

Accessories

Your pellet plant equipment will require regular maintenance and wear parts will need to be replaced. We have a large parts inventory so you can rely on us to have in stock what you need and be able to get it to you in a timely manner.