CATTLE FEED PLANT

PROJECT

For over 30 years, we’ve specialized in designing and building high-performance cattle feed production lines for dairy cows, beef cattle, and calves. Our 230+ successful cattle feed plant projects worldwide include: Dairy Feed Plants, Beef Cattle Systems, Calf Starter Lines, Complete Mixed Ration (TMR) Plants, etc. From small regional feed mills to large industrial facilities, we engineer each plant to handle your specific raw materials, production goals, and local conditions. Every project begins with understanding your cattle’s needs – let’s build your ideal feed solution.

230+

Construction Projects

Three decades of grit and know-how have gone into every one of our cattle feed plant projects. That’s 20,000+ facilities now producing quality feed worldwide, each one customized to meet local needs and maximize livestock nutrition.

$200 + million

Total Sales

That’s what global cattle producers have trusted us to deliver – robust feed processing systems that stand the test of time. Not just equipment, but complete solutions that help turn feed into profit, day in and day out.

60+

Covering countries

60 Countries and Growing

From the American Midwest to the pastures of New Zealand, our cattle feed plants are running smoothly in some of the world’s most demanding environments. Wherever quality feed matters, you’ll find our equipment hard at work.

cattle feed plant projects world wide

We don’t believe in one-size-fits-all solutions. Every cattle feed plant we design starts with your specific needs. With boots-on-the-ground experience across 60 countries, we’ve solved every cattle feed challenge imaginable. Need to expand an existing mill? Modernize outdated equipment? Build from scratch? We’ve done it all – and we’ll do it for you.

Cattle feed plant project report

Global Expertise in Cattle Feed Plant Solutions

Whether you are building a new cattle feed mill or upgrading an existing production line, our professional equipment can meet the core needs of high-fiber raw material processing, low powdering rate pelleting, precise nutrient addition, etc.

The water drop mill designed for ruminant feed can easily process crude fiber raw materials such as straw and alfalfa, and the large-aperture ring die pelleting system ensures pellet hardness (PDI ≥ 90%)… There are more than 200 successful cases of ranches and cattle feed mills, with a full range of equipment from 0.5T/H to 100T/H available, providing turnkey engineering services to help you quickly put into production!

Mixing Equipment

Crushing Equipment

Pellleting Equipment

Grass Crusher

Project Video

Below, we have selected three real-life videos of cattle feed production lines in different climates, with different raw materials and different scales, to take you directly to the equipment operation site:

We have successfully delivered more than 200 cattle feed projects around the world, from small ranch dedicated lines to large industrial plants, and have accumulated rich practical experience. Whether it is cold-resistant formulas in high-cold areas, low-moisture processing in arid areas, or stable pelleting of high-fiber raw materials, we have helped customers achieve efficient production.

cost to start cattle feed plant project

The cost of building a cattle feed production line is usually between $10,000 and $3 million, depending on the scale of production, raw material characteristics, degree of automation and local infrastructure conditions. The main costs include:

- Core equipment (accounting for 60-70%): crusher, mixer, granulator, cooling and screening system, etc.;

- Auxiliary facilities (20-25%): raw material warehouse, finished product warehouse, dust removal and explosion-proof system;

- Installation and commissioning (5-10%): equipment in place, pipeline connection, trial operation;

- Hidden costs (5-15%): power capacity expansion, environmental protection approval, operation training.

The following is a reference to the typical investment range for different production capacities (equipment investment only):

| Production Scale | Total Power | Project Site Requirements | Production cycle | Installation cycle | Investment Cost(USD) | Profit cycle |

| 0.5-2T/H | 47-75KW | 300-500m² | 20 Days | 7-15 Days | 10,000-50,000 | 1-3 Year |

| 3-4T/H | 53-165KW | 300-700m² | 20 Days | 15-20Days | 50,000-120,000 | |

| 5-7T/H | 68-259KW | 400-800m² | 20-30 Days | 20-40Days | 70,000-250,000 | |

| 8-10T/H | 125-410KW | 800-2000m² | 30-40 Days | 45-60 Days | 150,000-300,000 | |

| 12-20T/H | 358-620KW | 1500-3000m² | 40-50 Days | 60-90 Days | 250,000-580,000 | |

| 25-40T/H | 545-870KW | 2000-4000m² | 50-60 Days | 90-120Days | 450,000-850,000 | |

| 50-60T/H | 710-1120KW | 3000-5000m² | 60-70 Days | 100-140 Days | 900,000-1,400,000 | |

| 60-80T/H | 815-1370KW | 5000-8000m² | 70-90 Days | 130-160 Days | 1,450,000-1,800,000 | |

| 80-100T/H | 1230-1700KW | 8000-20000m² | 90-120 Days | 160 -190Days | 2,000,000-3,000,000 |

About the profit

Flexible use of local low-priced agricultural and sideline products to replace traditional raw materials, combined with precise formula adjustment, can significantly reduce production costs. Our equipment can adapt to various special raw materials to ensure nutritional balance and efficient conversion.

Professional technical teams can maximize equipment performance and reduce energy consumption and loss. We provide complete operation training to help customers quickly master the core production process and improve overall output efficiency.

The appropriate equipment selection directly determines production stability and product quality. We customize solutions according to the actual needs of customers to ensure that the equipment is perfectly matched with raw materials and processes to avoid hidden cost losses.

Interested in our products?

Over 230 cattle feed plant projects are running worldwide on RICHI equipment right now. Let’s put that experience to work for your operation.

Your raw materials, your recipes, our customized solutions

Whether you use grains, straw, silage, distiller’s grains or high urea additives, we can provide you with:

- Tailor-made process: Adjust the grinding particle size (adjustable from 2 to 8 mm) and the conditioning temperature (accurately controlled from 60 to 95 ° C) according to the fiber content and protein type

- One machine for multiple uses: The same production line can produce the following through modular adjustments (such as quick replacement of ring molds/screens):

- ✓ Conventional pellets (6-8 mm)

- ✓ High-fiber supplement blocks (12-15 mm)

- ✓ High-fat energy feed (adding liquid fat coating)

No need to compromise – tell us your needs and we will make them come true!

DISCOVER MORE

As one of the largest feed machinery manufacturers in Asia, RICHI Machinery has long been involved in international cattle feed machine business.

Through years of market development, it has established complete external sales channels and network services in many countries and regions around the world, bringing the best standard cattle feed machinery and production technology in the world.

Types of cattle feed plant project?

+

The cattle feed mill plant projects we can supply are mainly divided into the following types:

- fully automatic cattle feed plant Project

- semi automatic cattle feed plant project

- Manual cattle feed plant project

- grass cattle feed plant Project

- cattle feed mash plant Project

- cattle feed pellet plant Project

- cattle feed mixing plant project

- maize cattle feed plant Project

- small cattle feed plant project

- cattle premix feed mill project

- poultry & cattle feed plant project

- Aqua & cattle feed plant Project

- sheep & cattle feed plant project

- Rabbit & cattle feed plant Project

- Horse & cattle feed plant Project

- livestock & cattle feed plant Project

- …

In line with the business philosophy of customer satisfaction as the center, we proactively communicate with customers in a timely manner, select technicians or engineers with strong sense of responsibility and strong professional ability, and provide meticulous and thoughtful door-to-door services.

Solve customer problems in a timely manner and establish good cooperative relationships with customers.

Richi Machinery warmly welcomes friends from all over the world and welcomes friends at home and abroad to cooperate with us and develop your high-level cattle feed plant project.

Features of cattle feed plant project?

+

Looking at the current situation, ruminant cattle feed has great room for development in the future. At present, the breeding technology of most ruminant farmers is still at a relatively backward level, and there is a lack of professional technology in all aspects of breeding, reproduction, and feeding.

Only by solving the ration problem of ruminant animals from the source can we fundamentally promote Large-scale and specialized breeding of cattle and sheep to adapt to the increase in per capita consumption of beef, mutton and dairy products.

- Complete set of high-efficiency cattle feed production line, the overall process is advanced and flexible, and has a wide range of applications. The equipment can be matched one-to-one according to customer needs, perfectly realizing the production of multiple types of feed in one cattle feed manufacturing plant:

- Production of 100% pure alfalfa pellet crude fiber material and multi-effect forage mixture

- Pure concentrate formula cattle ruminant pellets

- Crude fiber + concentrated feed multi-proportion compound feed (production of powder and pellet feed)

- The process can also achieve perfect combination according to customers’ different raw material formulas and different crude fiber forage baling forms. Different processing techniques are customized for different raw material formulas to achieve differentiated value with high feed return rates.

- RICHI grass feed (whole diet) engineering, comprehensive nutrition, safe and environmentally friendly;

- Complete compound cattle feed patented process design, and equipped with a patented cattle feed pelletizer, which is suitable for processing both grass-containing and grass-free feeds;

- The grass powder, molasses and concentrate are fully mixed and then extruded. The pellet output of the same power model is increased by 40~50%.

- RICHI’s unique whole-diet processing technology can effectively reduce formula costs by 15-20%, increase feed utilization by 5-10%, and help feed manufacturers improve comprehensive benefits by more than 25%. It has served 65% of pasture cattle feed customers in the market It provides professional equipment, technology and technical support, and has been well received by customers.

RICHI has been committed to solving the pain points and difficult problems of the ruminant industry.

Driven by the introduction of international advanced cattle feed plant technology and combined with independent innovation, RICHI continuously upgrades ruminant cattle feed technology and equipment, helping major cattle feed manufacturers win in the increasingly competitive ruminant sheep cattle feed market.

How to build a Cattle feed plant project?

+

Building a cattle cow feed plant project and running it well is a very complicated matter, but if you find the right cattle feed plant manufacturers, the process of building a feed plant will be smooth. If you want to start a cattle feed mill project, the following content is some reference provided by RICHI for you.

01 Cattle feed plant scale, product types and specifications

- Factory scale

- Product type and specifications

02 Factory location

- Factory site selection

- Address conditions

03 Cattle feed plant design

- Cattle feed mill layout planning

- Feed mill buildings and facilities

- General plan of feed factory

- Design principles and features

- Civil engineering design

- Feed mill process design

- Main workshop design

- Warehouse design

- Laboratory design

- Process specifications and technical requirements

- Cattle feed equipment configuration and selection

- Automated control

04 Organization and supply of production raw materials

- Types and nutritional characteristics of raw materials for cattle feed production

- Demand for various raw materials in cattle feed mills

- Procurement and acceptance of feed raw materials

05 Demand and sales of cattle feed products

- Cattle feed product varieties and types

- Cattle feed formula design

- Cattle feed product standards

- Sales of feed products

06 Environmental protection and production safety

- Environmental protection

- Fire safety

07 Cattle feed plant project investment and economic benefit analysis

- Investment budget

- Total project investment estimate

- Project investment budget estimate

- Cattle feed plant cost and profit

- Market prospects and risk analysis

08 Organization structure and labor quota

- Organizational structure

- Labor quota

09 Factory construction period and implementation progress

- Site Preparation (2-4 Weeks)

- Land Leveling & Infrastructure: Clearing, grading, and utility connections (power/water/drainage).

- Regulatory Compliance: Securing environmental permits and zoning approvals.

- Civil Works (8-12 Weeks)

- Foundation & Structure: Pouring reinforced concrete for equipment bases (e.g., pellet mill foundations require vibration isolation).

- Warehouse/Silo Erection: Steel structure assembly for raw material storage (60-100MT capacity silos).

- Mechanical Installation (6-8 Weeks)

- Core Equipment Setup:

- Grinding/Mixing Line: Hammer mills (75-110kW), twin-shaft mixers (3-5min/batch).

- Pelleting System: Ring die pellet press (compression ratio 1:8-1:12) + cooler.

- Conveyance Systems: Bucket elevators (50-100TPH), pneumatic pipelines.

- Core Equipment Setup:

- Electrical & Automation (4-6 Weeks)

- Control Systems: PLC-based batching control (±0.1% accuracy), motor VFDs for energy savings.

- Safety: Dust explosion-proof wiring (ATEX standards), emergency stops.

- Commissioning & Trial Run (2-3 Weeks)

- Dry Testing: Empty-run equipment checks (e.g., pellet mill spindle alignment).

- Wet Testing: 72-hour continuous production trial with 3-5 feed formulations.

- Handover & Training (1 Week)

- Operator Training: Maintenance protocols (e.g., ring die replacement every 3,000MT).

- Documentation: As-built drawings, O&M manuals.

10 Personnel training

- Training objects

- Training content

- Training time

11 Management system

- Cattle feed production process specifications

- Cattle feed equipment operating procedures

- Job responsibilities

- Labor discipline and personnel management system

- Safety production system

- Total quality management system

- Financial system

If you want to start a cattle feed plant project, feel free to contact us to customize your cattle feed processing plan!

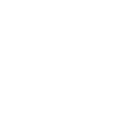

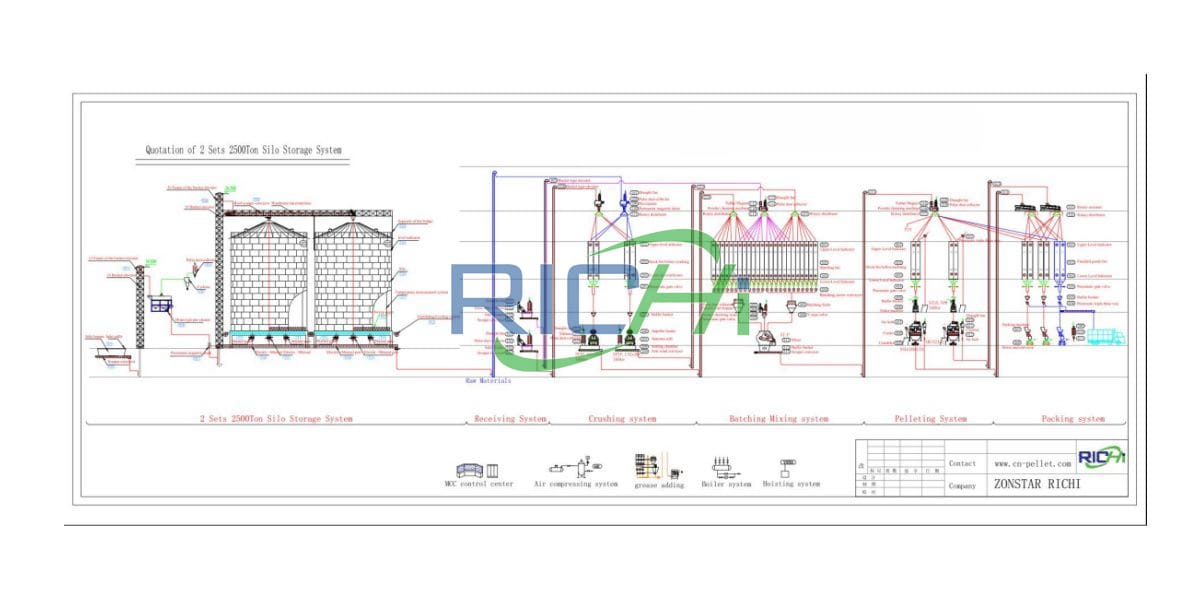

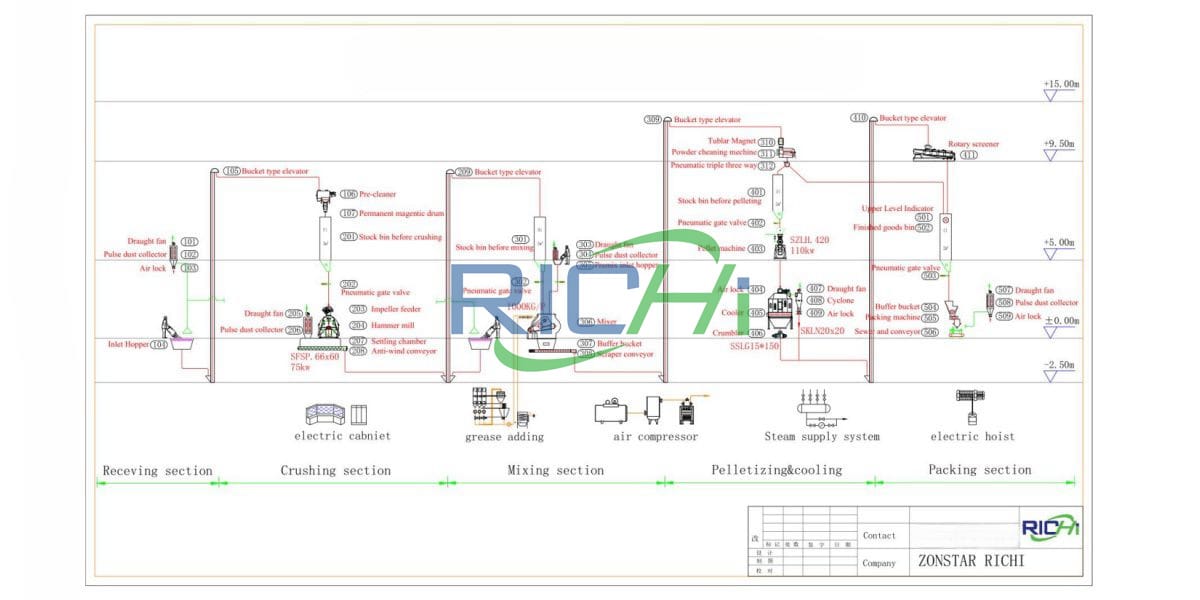

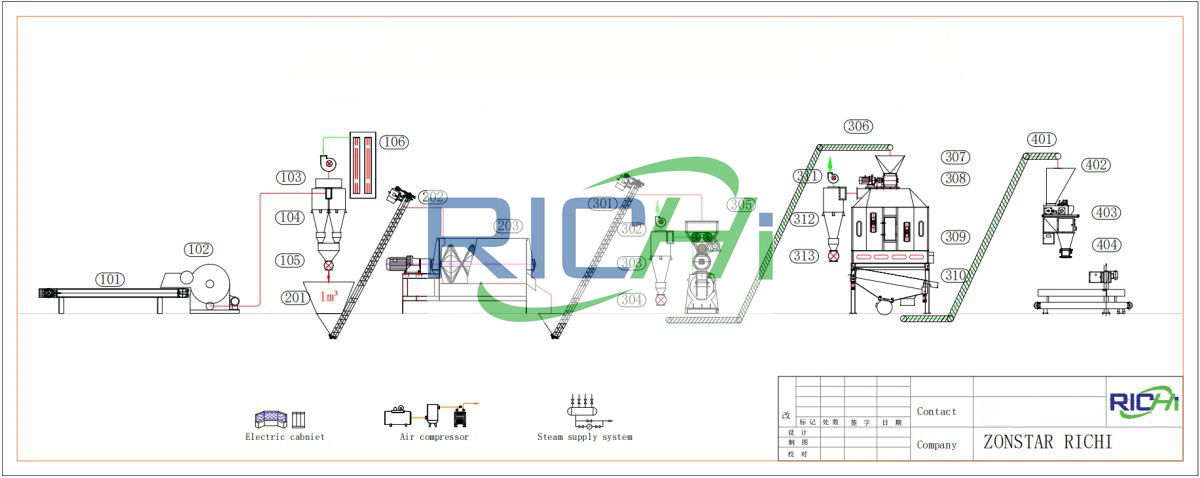

Can you show some of the cattle feed mill process designs you have worked on?

+

For the processing technology of cattle, sheep and ruminant feed, different raw materials and product types will make the processing technology very different. Whether you want to process complete compound feed, concentrate feed, grass feed, premix or fermented feed, you are welcome to contact Richi Machinery to customize your cattle feed factory process and obtain the corresponding equipment quotation!

Production lines and processes designed for cattle feed plant projects in different countries:

40-50 T/H cattle feed mill project design

- Type: combined feed plant

- feed product: chicken and cattle pellets

- Applicable to large feed company

10 T/H cattle feed mill project design

- Type: full feed plant

- feed product: cattle feed pellets

- Applicable to Medium-sized feed mills and medium- and large-scale breeding farms

3-12 T/H grass feed line for cattle feed (from grass alfalfa hay)

- Type: grass feed plant

- feed product: ruminant cattle pellets

- Suitable for small and medium-sized farms and feed mills

0.8-4 T/H cattle feed processing design (From corn straw & rice straw)

- Suitable for small sized farms and cattle feed mills

- Type: cattle straw feed plant

- feed product: ruminant cattle pellets

If you have any needs or questions for cattle animal feed production line project process design, contact Richi Machinery for professional technical support!

Equipment needed to start cattle feed plant project?

+

Generally speaking, cattle feed mill projects mainly require the following livestock feed mill equipment:

- Raw material pretreatment: floor scale, cleaning screen, permanent magnetic drum (iron stone removal)

- Crushing system: water drop type crusher (for fiber raw materials), micro powder machine (premix)

- Ingredient mixing: electronic scale, double-shaft paddle mixer (with molasses addition port)

- Pelletizing section: ring die feed pellet machine (compression ratio 1:5-1:7), conditioner (high temperature steam)

- Post-processing equipment: countercurrent cooler, crusher (optional), screening machine

- Packaging and warehousing: automatic packaging scale, palletizer, steel plate warehouse (moisture-proof)

- Auxiliary system: pulse dust removal (explosion-proof type), boiler (above 0.8MPa), central control room

hammer mill feed grinder

Used in cattle feed materials crushing section.

- Capacity: 3-25 T/H

- Main Power: 30-160 KW

Feed Mixer machine

Used in cattle feed raw materials mixing section.

- Capacity: 250-2000 KG

- Main Power:

- 4-55 KW

cattle feed pellet machine

Used in cattle cow feed raw materials pelleting section.

- Capacity: 1-48 T/H

- Main Power: 22-315 KW

animal Feed Extruder

Used in extruded cattle feed production process, especially aquatic feed and pet feed.

- Capacity: 0.5-12 T/H

- Main Power: 0.75-355 KW

Bale breaker

For grass-containing animal ruminant and livestock feed production.

- Capacity: 1-20 T/H

- Main Power: 30-90 KW

Grass crusher

Mainly used for crushing grass, straw, hay and related feed raw materials.

- Capacity: 0.3-3 T/H

- Main Power: 22-93 KW

animal Feed Dryer

Used in the drying section of cattle feed processing plant.

- Capacity: 2-12T/H

- Main Power: 44.3-71.8KW

grass dryer machine

Used in the drying stage of feed processing containing grass and agri raw materials.

- Capacity: Customizable

- Rotate speed: 3-8 R/Min

Pellet Cooler Machine

Used in cattle feed pellet cooling section.

- Capacity: 3-25 T/H

- Main Power: 30-160 KW

vibrating screening machine

Used in cattle feed pellet grading section.

- Capacity: 3-20 T/h

- Main Power: 1.5-5.5 KW

Automatic Bagging Machine

Used in cattle pellet & mash feed packing section.

- Capacity: 6-12 Bags/Min

- Main Power: 1.1-5 KW

Spraying Machine

Used in the spraying section of cattle feed mill plants

- Capacity: 3-15T/H

- Main Power: 22KW

When purchasing a complete set of cattle feed making machines, you need to make a selection based on factors such as production scale, process flow, and feed type. At the same time, it is also necessary to choose cattle feed equipment manufacturers with high technical levels and high-quality services to ensure the quality of cattle feed plant project and after-sales service.

How does the cattle feed mill equipment handle high-fiber raw materials (such as alfalfa, straw) ?

+

Cattle feed often contains 30%-50% crude fiber (such as straw, hay), and ordinary grinders are prone to clogging. Need to confirm:

- Grinding machine type: Recommended water drop grinder (with pre-cutting function), screen aperture ≥ 8mm, to avoid fiber entanglement.

- Conditioning process: High temperature and short-time conditioning (85℃/30 seconds) can soften the fiber, but the steam pressure ≥ 0.5MPa is required.

How to ensure the stability of cattle feed pellets (low powdering rate) ?

+

Ruminants need hard pellets (PDI ≥ 90%) to prolong chewing time. Key points:

- Ring die parameters: compression ratio 1:5-1:7 (1:8-1:12 for ordinary poultry feed), die hole diameter 6-8mm.

- Binder addition: 1%-2% molasses or lignin sulfonate is recommended to reduce powdering.

- Actual measured data: After a ranch in South Africa used a double-layer conditioner, the powdering rate dropped from 12% to 5%.

Can the equipment of the cattle feed plant project be upgraded to a higher output later ?

+

Cattle feed plants often need to reserve space for expansion (such as from 10T/H to 15T/H). Need to be clear:

- Main equipment margin: The power of the grinder motor should be over-equipped by 15% (such as 110kW instead of 90kW for a nominal 10T/H).

- Steel structure load-bearing: The platform load needs to be designed according to the maximum future production capacity (such as embedded parts bearing 200% dynamic load).

- Case lesson: A factory in Brazil was forced to rebuild the steel structure when expanding production due to the lack of reserved space, and the cost increased by 40%.

What special cattle feed mill projects have you done?

+

cattle feed plant project In indonesia

- Output: 4-6T/H

- Feed type: Cattle Sheep Feed

- Workshop size: 12m*10m*23m

- Main equipment of the project: Cattle feed hammer mill*110KW; 2.Cattle feed mixer*1000kg/batch; 3.batching scale*1000kg/batch; 4. cattle feed pelletizer machine*110kw; 5.cooling machine*SKLH20*20; 6. grass crusher machine; 7.screen machine, etc.

- Installation time: 30 Days

- cattle feed plant project cost: FOB $280,000

cattle feed plant project In USA

- Output: 10-12T/H

- Feed type: cow & poultry feed

- Workshop size: 16m*7m*7.5m

- Main equipment of the project: 1.feed hammer mill*90KW; 2. feed mixer*1000kg/batch; 3. feed pellet machine*160kw; 4. cooling machine; 5. crumbler machine; 6. screen machine; 7. automatic packing machine, etc.

- Installation time: 40 Days

- cattle feed plant project cost: FOB $550,000

cattle feed plant project In south africa

- Output: 3-4T/H

- Feed type: Ruminant cattle goat feed

- Workshop size: 60m*24m*12m

- Main equipment of the project: 1. Hammer mill * 110 kw; 2. Mixer * 1000kg/batch; 3. Pellet machine * 110 kw; 4. Cooling machine* 0.93 kw; 5. screen machine*0.25kw, It’s full automatic control system.

- Installation time: 90 Days

- cattle feed plant project cost: FOB $320,000

cattle feed plant project in Argentina

- Output: 5T/H

- Feed Type: Ruminant Alfalfa Feed

- Project area: 320m2

- Main equipment of the project: bale breaking machine, alfalfa crusher machine, ring die alfalfa pellet machine for cattle, scraper conveyor, belt packaging scale, molasses adding machine, gas boiler, screener, etc.

- Installation time: 40 days

- cattle feed plant project cost: 350,000 USD

cattle feed plant project in Uzbekistan

- Output: 0.8-1.2T/H

- Feed type: cattle and goat feed

- Workshop size: 6m*5m*5.5m

- Main equipment of the project: Cattle feed crusher machine, single-shaft ribbon mixer for cattle feed, SZLH-250 1-2T/H double-layer conditioner cattle goat feed pellet making machine, cooling belt, etc.

- Installation time: 30 Days

- cattle feed plant project cost: FOB $57,000

cattle feed plant project in U.K.

- Output: 12T/H

- Feed type: Ruminant premix Feed

- Workshop size: 3500 m2

- Main equipment of the project: Hopper and fence, Pulse dust collector, Twin shaft mixer, Bucket elevator, Finished product warehouse, automatic packing scale, etc.

- Installation time: 135 Days

- cattle feed factory project cost: FOB $650,000

cattle feed plant project in india

- Output: 16-20T/H

- Feed type: cattle & poultry sheep feed

- Project area: 4193m2

- Main equipment of the project: Pulse dust collector, Permanent cylinder magnet, cattle feed pellet machine, Counter flow cooler, Bucket elevator, Permanent magnet cylinder, Pulse dust collector, Rotary distributor, Rotary grading screen, Electronic packing scale, Weighing grease adding machine, Steam line , Air compressor, silo sytems, etc.

- Installation time: 130 days

- cattle feed plant project cost: 670,000 USD

cattle feed plant project In Russia

- Output: 60T/H

- Feed type: Cattle horse goat rabbit feed

- Project area: 5650m2

- Main feed mill equipment of the project: Scraper conveyor, Bucket elevator, Initial cleaning and screening of materials, Permanent magnet cylinder, Grinder, Single shaft mixer, cattle livestock feed pellet machine, stock pellet cooler, screening machine, extruder, Double bucket belt packing scale, Sewing conveyor , Boiler, etc.

- Installation time: 300 days

- cattle feed plant project cost: 2,700,000 USD (Including silos)

cattle feed plant project in Vietnam

- Output: 40-50T/H

- Feed type: cattle & fish feed

- Project area: 4574m2

- Main equipment of the project: Dust removal fan, Scraper conveyor, Bucket elevator, Auger conveyor, Spiral distributor, Rotary grading screen, Impeller feeder, Powder sieve, Animal feed granulator, Twin screw extruder, Feed grinder, Ultrafine grinder, Twin-shaft paddle mixer, Counter flow cooler, dryer machine, bagging machine, etc.

- Installation time: 270 days

- cattle feed plant project cost: US$1.8 million (Including silos)

cattle feed plant project in brazil

- Output: 20-30T/H

- Feed type: Dairy Cow Feed

- Project area: 1996.3m2

- Main equipment of the project: Cow feed crusher, Rotary distributor, cow feed mixer, Cow feed pellet making machine, Scraper conveyor, Belt packaging scale, Molasses adding machine, Electric hoist, Gas steam generator, Silo system, etc.

- Installation time: 120 days

- cattle feed mill project cost: 1,640,000 USD

cattle feed plant project in Thailand

- Output: 3-5T/H

- Feed type: Cattle mash feed

- Workshop size: 8m*7m*6.5m

- Main equipment of the project: 1.cattle feed hammer mill*37KW; 2.cattle feed mixer*500kg/batch; 4.cattle powder feed packing machine and other auxiliary equipment, etc.

- Installation time: 15 Days

- cattle feed mill project cost: FOB $140,000

cattle feed plant project In New Zealand

- cattle feed plant project cost: FOB $90,000

- Output: 1-2T/H

- Feed type: maize cattle feed

- Workshop size: 6m*3m*7m

- Main equipment of the project: 1.feed hammer mill*11KW; 2.feed mixer*250kg/batch; 3.animal feed pellet mill*22kw; 4.cooling machine; 5. screen machine; 6. packing machine and other equipment.

- Installation time: 50 Days

We have successfully helped our clients understand, plan, and execute their goals with our expertise in cattle feed manufacturing industry. We are proud to showcase our work and the success our clients obtain through our initiatives.

How to deal with the explosion risk of high-starch raw materials (such as corn) ?

+

In some cattle feed plant projects, the proportion of corn in cattle feed is high (60%+), and the lower limit of dust explosion is only 20g/m³. Must:

- Equipment selection: pulse dust collector with spark detection + inert gas fire extinguishing (such as CO₂ injection).

- Pipeline design: horizontal conveying wind speed ≥18m/s, vertical ≥22m/s, anti-dust accumulation.

In some cattle feed plant projects, how to accurately add non-protein nitrogen (such as urea) and avoid agglomeration ?

+

The amount of urea added is usually ≤1%, but it is easy to absorb moisture and agglomerate. Solution:

- Liquid spraying system: After the urea is dissolved, it is evenly sprayed through a high-pressure nozzle (error ±0.05%).

- Mixing order: Premix with a carrier (such as bran) first, and then enter the main mixer.

In some cattle feed plant projects, how to accurately add non-protein nitrogen (such as urea) and avoid agglomeration?

+

Rice husks contain 15%-20% silica, and the wear coefficient is 5 times that of corn. Countermeasures:

- Material upgrade: The hammer is welded with tungsten carbide electrodes, and the life is extended to more than 800 hours.

- Airflow design: The cyclone separator is lined with ceramic sheets, and the wear resistance is increased by 3 times.

- Cost comparison: The annual replacement cost of ordinary steel increases. Although the wear-resistant solution is 50% more expensive, it saves 60% in the long run.

How do boiler specifications meet the high tempering temperature requirements of cattle feed plant projects ?

+

Cattle feed tempering requires high temperature (90-95℃), and ordinary boilers have insufficient pressure. Key points:

- Boiler selection: saturated steam pressure ≥0.8MPa, gas supply ≥200kg/ton of feed.

- Pipeline insulation: rock wool wrap + aluminum skin outer protection, temperature drop controlled within 5℃.

How to switch recipes (e.g., fattening cows vs. lactating cows) ?

+

There are big differences in the recipes of cattle feed (e.g., fat powder needs to be added to lactating feed). Required configuration:

- Intelligent central control: recipe library stores ≥50 groups, switching time <3 minutes.

- Liquid addition system: independent metering pump controls grease/molasses (accuracy ±0.1%).

- User feedback: A ranch with 10,000 heads in Ningxia has reduced labor costs by 70% through an automatic recipe system.

How to solve the on-site hoisting problem of large equipment (such as pellet mills) in large cattle feed plant projects? ?

+

The pellet mill weighs 5-8 tons per cattle livestock feed production line unit and needs to be planned in advance:

- Factory opening: reserve ≥3m×4m equipment entrance, or design removable wall panels.

- Hoisting plan: require the manufacturer to provide force analysis diagram (such as floor load ≥5t/m²).

Can a feed production line be designed to process cattle feed, chicken feed, and fish feed at the same time?

+

Yes, not only can we process different feed types, but also different feed forms at the same time, such as pellet, mash, extruded feed, etc. We will customize the production line process according to customer needs, and we have a large number of projects belonging to this type of composite production line. You can contact us directly, and RICHI engineers will provide you with technical support from 0 to 1.

About RICHI

Since founding in 1995, RICHI MACHINERY has grown to become the world’s leading designer and builder of pellet production line systems. RICHI has delivered over 2000 projects to clients located in more than 140 countries across six continents. Altogether we have over 200 employees, and from start to finish, RICHI can design, manufacture, build and deliver your entire project – there’s no need to manage multiple project partners.

RICHI Technology

Adhering to the R&D tenet of “independent innovation”, Richi Machinery’s annual R&D investment accounts for more than 3% of total sales. It is supported by CAD, Solidworks and other computer-aided design systems, Ansys, matlab simulation analysis software, and VCC, EasyBuoder8000 and other programming software.

Project Management

For the construction of a complex pellet plant, process design, equipment manufacturing, precise logistical organization, accurate work, a combined installation team of experienced subcontractors are essential, which our company has retained for decades.

Patents & certifications

In the process of our continuous development, exploration and innovation, relying on our strength, we have more than 30 patent technologies, and all products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

Service You Can Count On

When customers need support, our customer service is the solution.

consultation

We assess our client’s long-term development needs, what the products manufactured by it require, what it intends to manufacture and what quantity it wants to produce.

Design

Advanced design technology combined with years of experience, specialist skills and innovative thinking drives advanced, cost-effective and productive solutions for our customers.

manufacturing

The technological equipment and machines comprising the pellet plant are manufactured by our permanent expert staff in continuous consultation with our engineers.

Installation

We offer a range of start-up field services across a variety of industries to get your new equipment set up and running as quickly as possible. Once installed, we test and analyze key operations to maximize performance.

Industrial maintenance

Regular maintenance achieves a longer service life for investments and maximises production efficiency. We are able to react quickly to problem situations and serve you flexibly with a package tailored to your needs.

Accessories

Your pellet plant equipment will require regular maintenance and wear parts will need to be replaced. We have a large parts inventory so you can rely on us to have in stock what you need and be able to get it to you in a timely manner.