Wood Granulator Machine

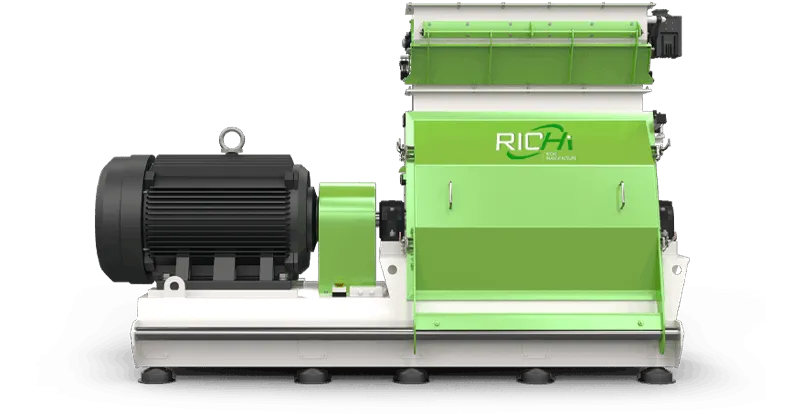

For those demanding maximum performance in the toughest pelleting conditions, the MZLH768 wood granulator machine is the definitive solution.

Model – MZLH768

Capacity – 3.0-4.0T/H

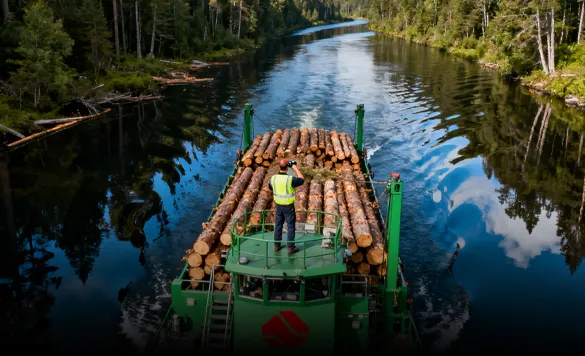

Who Uses Wood Granulator Machine?

From sawmills and furniture makers to forestry companies and biomass pellet producers, our wood granulator machine serves a global network of industries. It is the ideal solution for wood recycling companies, landscaping firms, and large farms. Energy companies, schools, and hospitals also use it to create fuel. No matter your sector, if you have wood or biomass raw material, our wood granulator equipment is built for you. It transforms your residual materials into a valuable product, reducing waste and generating new revenue streams worldwide.

APPLICATION OF wood granulator

Fertilizer Pellets

Cat Litter Pellets

Wood Fuel/Heating Pellets

Ask Us Anything

The application possibilities for a modern wood granulator machine in today’s process industries are virtually endless. Beyond its core function in the industrial production of wood and biomass pellets, the RICHI wood granulator machine proves its versatility by pelleting a vast array of materials. From animal feeds to detergents, sawdust, fertilizers, animal bedding and pharmaceuticals, this machine unlocks new potential.

Our MZLH768 model, designed specifically to withstand rough pelleting conditions, achieves maximum outputs and stands as one of the most important machines in the industry. Trusted globally for large-scale production, it combines high output with low consumption, making this wood granulator equipment a smart investment for forward-thinking operations.

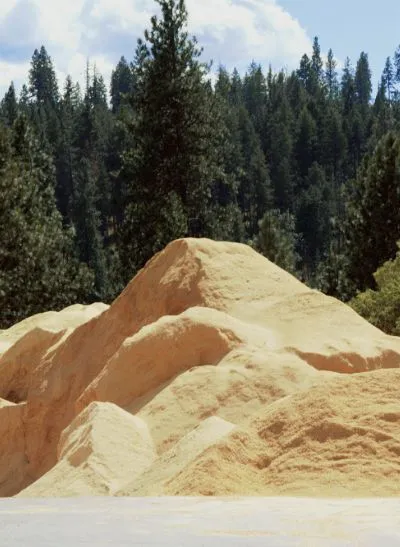

AVAILABLE RAW MATERIALS

What materials can our wood granulator machine process? Virtually any wood-based material. It efficiently transforms sawdust, wood chips, shavings, bark, and full tree parts like branches and stumps into dense pellets. It handles hardwoods like oak and softwoods like pine. It also processes industrial residues from sawmills, furniture factories (including MDF and chipboard waste), and reclaimed wood from pallets or construction. Beyond wood, it manages agricultural waste. This versatility makes our wood granulator equipment your ultimate solution for converting diverse raw materials into value.

Engineered for Endurance, Built for Output

Our MZLH768 wood granulator machine is designed to deliver maximum performance under the most demanding conditions. It combines robust construction with intelligent engineering to achieve high output and low energy consumption, making it the most reliable partner for your large-scale, continuous pellet production.

High-Precision Gear Transmission

Features direct-drive gears with a 98% transmission efficiency. The hardened and precision-ground teeth provide quiet, stable power and enhanced durability.

Alloy Steel Main Shaft

The core shaft, made from imported German alloy steel, is forged and heat-treated for superior fatigue resistance and hardness, forming the robust backbone of the wood granulator machine.

Precision-Cast Gearbox

Manufactured from high-quality steel and machined by CNC centers for zero error, the gearbox provides a solid foundation for safe and reliable long-term operation.

Automatic Thin-Oil Lubrication

An advanced circulation system with imported bearings and seals ensures critical components are constantly cooled and lubricated, guaranteeing safer and more reliable running.

Siemens Electric Motor

Guarantees powerful, stable, and energy-efficient operation for your wood granulator machine, ensuring consistent performance under heavy loads.

Arch-breaking Feeder Bin

Effectively breaks up material clumps in the hopper, ensuring a smooth and uninterrupted supply of raw material to the wood granulator machine for non-stop production.

Forced Feeder System

This feature ensures a consistent and uniform material flow into the granulation chamber, preventing blockages and maximizing the output of the wood granulator machine.

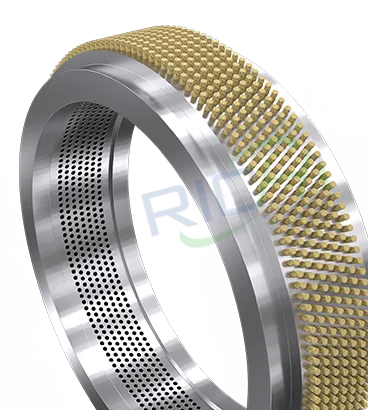

High-Nickel Steel Ring Die

Our specially formulated ring die, with its optimized compression ratio, ensures superior pellet quality and an exceptionally long service life for the wood granulator equipment.

WORKING PRINCIPLE

This wood granulator machine works by forcing raw material through a hardened ring die using rotating rollers. The intense pressure forms dense, consistent pellets. Watch the video to see the process live.

Technical Specifications: MZLH768 Wood Granulator Machine

Engineered for robust performance and high-output pelleting. This wood granulator machine is built to maximize your productivity. Explore the detailed specifications below to understand the powerful engineering behind the MZLH768 model. These parameters highlight why this wood granulator equipment is a reliable investment for continuous, large-scale production.

Parameter table of MZLH768 Wood Granulator

Need help matching these specs to your raw material?

Capacity:

3.0-4.0 T/H

Main Motor Power:

250 kw

Arch-Breaking Feeder Power:

4 kw

Forced Feeder Power:

1.5 kw

Finished Pellet Diameter:

4~12 mm

Full Range of Wood Granulator Machines

The MZLH768 is just one model in our comprehensive lineup. We offer five additional wood granulator machine models to precisely match your production goals. Our machines cover a wide output range from 0.2 to 4 tons per hour. For operations requiring more than 4 t/h, a multi-unit configuration of our wood granulator equipment provides the perfect scalable solution. Explore the full range below to compare specifications and find your ideal match.

Global Project Gallery

From single machines to complete lines, see our wood granulator machine in action worldwide.

USA Wood pellet Production Line

We supplied a full pellet production line to a North Carolina biomass fuel producer, enabling them to convert local pine waste into renewable energy.

See Our Machines in Action

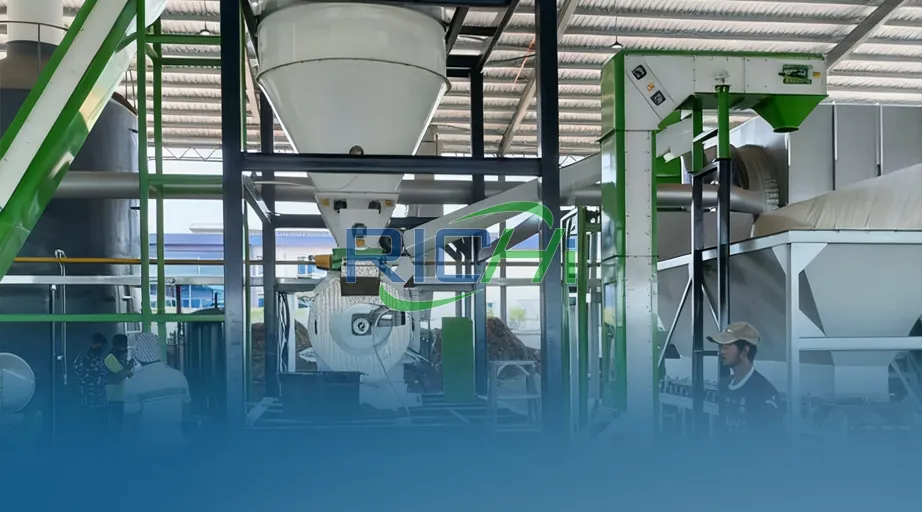

Your Complete Pellet Line, Engineered for You

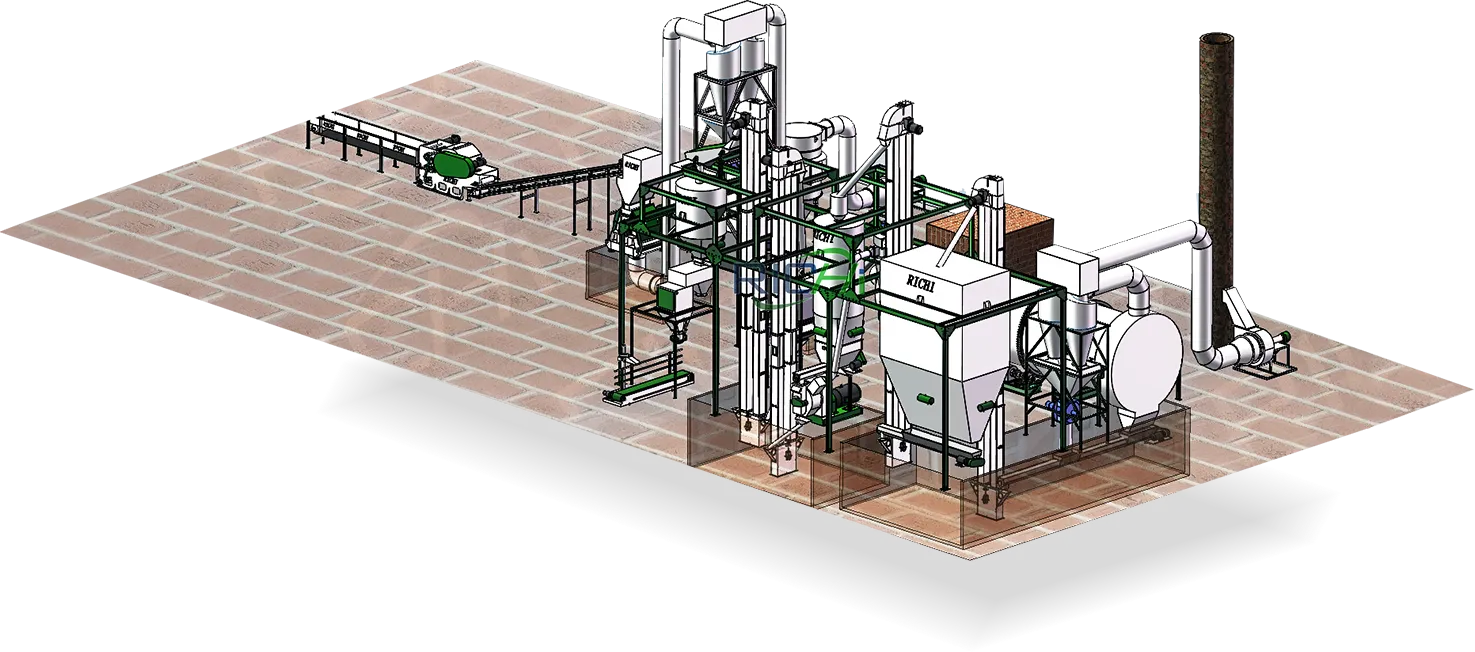

We deliver more than just a high-performance wood granulator machine. We provide complete, custom-engineered pellet production solutions. Your specific raw material—whether logs, chips, or sawdust—determines the optimal process. We design your line accordingly, integrating essential and optional stages to match your needs, budget, and site.

Based on your requirements, we integrate additional systems for mixing, cleaning, dust control, and storage. Our support covers everything from initial consultation and manufacturing to installation, training, and lifelong spare parts supply.

01.Size Reduction

Chippers and hammer mills prepare your raw material.

02.Drying

Moisture content is precisely controlled for ideal pelleting.

03.Granulating

The heart of the line is our reliable wood granulator machine.

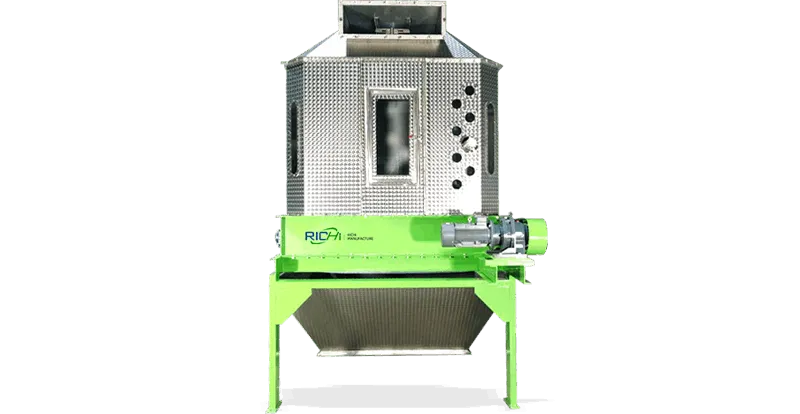

04.Cooling

Pellets are stabilized for storage and handling.

05.Screening

ines are removed to ensure premium product quality.

06.Packing

The finished wood pellets are bagged or stored in bulk.

Your Single-Source Pellet Production Partner

A high-output wood granulator machine is just the start. We provide the complete ecosystem of equipment for a fully functional pellet plant. From raw material preparation to finished product packaging, we expertly select and integrate all machinery to create a seamless, efficient production line tailored to your specific process.

Frequently Asked Questions

Have questions about our wood granulator machines? Find detailed answers below. We’ve compiled expert responses to the most common inquiries about machine selection, raw materials, and production processes to help you make an informed decision.

What is the typical price range for a commercial wood granulator machine?

+

The investment for a commercial wood granulator machine is not a one-size-fits-all figure, as it is heavily influenced by the required production capacity, which directly correlates with the machine’s size and power. Based on our standard MZLH series of ring die wood granulator machines, here is a typical price range to give you a clear idea:

- For small-scale or startup operations (0.2 – 0.5 T/H): A commercial wood granulator machine like our MZLH320 or MZLH350 models ranges from $15,000 to $25,000. These are ideal for workshops or smaller farms looking to process their own wood waste.

- For mid-scale commercial production (1 – 2 T/H): An industrial wood granulator machine, such as the MZLH420 or MZLH520, represents a significant step up in output, with prices between $26,000 and $50,000. This is the most popular range for established biomass pellet producers and wood processing factories.

- For large-scale industrial output (2.5 – 4 T/H and above): A high-capacity wood granulator machine designed for continuous, high-throughput operation, like the MZLH678 or MZLH768, will typically cost from $64,000 to $85,000+. These heavy-duty wood pelletizer machines are built for 24/7 operation in major pellet plants.

It is crucial to understand that this price typically covers the standalone wood pelletizer mill. For a fully functional operation, most clients invest in a complete wood pelletizer line, which includes essential auxiliary equipment like a hammer mill, dryer, cooler, and packaging system. The total for a turnkey wood pelletizer system can therefore be 2 to 3 times the cost of the core machine, but it ensures a seamless and efficient production process from raw material to bagged pellet.

Ultimately, the final wood pelletizer price is customized based on your specific raw material characteristics, desired automation level, and output goals. We recommend contacting our engineers for a free consultation to receive a precise and customized wood pelletizer pricelist for your project.

What wood granulator machine projects have you worked on?

+

Our wood granulator machines are operating successfully in over 50 countries, helping businesses of all sizes turn wood waste into profit. From small farms to large industrial pellet plants, our robust and efficient pelletizers are engineered to handle diverse materials and production goals. Below is a snapshot of our global footprint.

1. Wood Granulator Machine in USA

A family-owned sawmill in North Carolina was looking to create a new revenue stream from their pine and oak sawdust and wood chips. They installed our MZLH520 wood granulator machine to produce 1.8 tons per hour of premium 6mm wood pellets. These pellets are primarily sold for residential heating in the local market, providing a clean-burning alternative to fossil fuels.

2. Industrial Wood Granulator Machine in Canada

A forestry cooperative in British Columbia needed a solution for their logging residues, including spruce and fir branches. They chose our MZLH678 wood granulator machine for its ability to process this fibrous material. The system now consistently produces 2.8 tons per hour of 8mm industrial boiler fuel, which is used to heat local public buildings.

3. Wood Granulator Machine for Sale UK

A large arable farm in East Anglia was seeking to utilize miscanthus and wheat straw. They purchased our MZLH420 wood granulator machine to process this agricultural waste. The unit now creates 1.1 tons per hour of 6mm pellets that are used for bedding in the region’s extensive poultry and horse industries, adding significant value to their farm operation.

4. High-Capacity Wood Granulator Machine in Germany

A specialized bioenergy company in Bavaria required a reliable pelletizer for their high-volume operation using wood waste from local furniture manufacturers. They invested in our MZLH768 wood granulator machine, which processes a mix of hardwood and softwood shavings to output 3.5 tons per hour of 6mm ENplus A1 certified pellets for the European domestic heating market.

5. Wood Granulator Machine in Australia

A plantation management company in Western Australia was tasked with processing eucalyptus forest thinnings and residues. They implemented our MZLH520 wood granulator machine to convert this challenging material into 1.7 tons per hour of 8mm utility-grade pellets, which are exported to Asian markets for power generation.

6. Biomass Wood Granulator Machine in India

A rice processing plant in Punjab was looking to manage its massive husk waste. They selected our MZLH420 wood granulator machine, configured with a special wear-resistant ring die, to pelletize the abrasive rice husk. The machine produces 1 ton per hour of 8mm pellets that are used as fuel in their own boiler system, creating a closed-loop energy solution.

7. Wood Granulator Machine in Brazil

A sugar and ethanol mill in São Paulo state sought to utilize its abundant sugarcane bagasse. Our MZLH678 wood granulator machine was the ideal solution, processing the fibrous bagasse to produce 2.5 tons per hour of 8mm pellets. These are sold to local industries as a renewable process heat source, displacing fuel oil.

8. Wood Granulator Machine in South Africa

A fruit grower and exporter in the Western Cape needed to manage pruning waste from its orchards. They installed our MZLH350 wood granulator machine to process apple and pear tree wood. The compact system generates 0.4 tons per hour of 6mm pellets, which are used in specialized smokers for the local braai (barbecue) culture.

9. Heavy-Duty Wood Granulator Machine in Russia

A large timber company in Siberia needed a robust machine to handle mixed softwood sawdust and bark in a harsh climate. Our MZLH768 wood granulator machine was installed and now reliably produces over 3 tons per hour of 8mm pellets for local district heating, reducing the community’s reliance on natural gas.

10. Wood Granulator Machine for Sale Poland

A furniture manufacturer near Poznań wanted to recycle its beech and oak off-cuts and MDF dust. They purchased our MZLH520 wood granulator machine. It now efficiently turns this industrial waste into 1.6 tons per hour of 6mm pellets, which are used to fire the company’s own factory kilns and dryers.

11. Wood Granulator Machine in Vietnam

A woodworking workshop in Ho Chi Minh City was looking to add value to its rubberwood and acacia sawdust. They installed our MZLH320 wood granulator machine. This small but efficient unit processes their daily waste, producing 0.25 tons per hour of 6mm pellets for the local restaurant and food processing market as a cooking fuel.

12. Wood Granulator Machine in Thailand

A rubber tree plantation in southern Thailand was seeking a use for old rubberwood. They chose our MZLH420 wood granulator machine to process the wood chips. The system produces 1 ton per hour of 8mm pellets that are exported to Japan and South Korea for use in industrial biomass power plants.

13. Wood Granulator Machine in Indonesia

A palm oil mill in Sumatra was under pressure to manage its empty palm fruit bunches. Our MZLH678 wood granulator machine, equipped with a heavy-duty feeder, was the answer. It processes the bulky EFB, producing 2.2 tons per hour of 8mm biomass fuel that powers the mill’s operations, making it more self-sufficient.

14. Wood Granulator Machine in Philippines

A coconut processing cooperative in Quezon was struggling with mounting coconut shell and husk waste. They invested in our MZLH350 wood granulator machine. It now transforms this material into 0.35 tons per hour of high-energy 6mm pellets, which are sold locally as a premium, long-burning fuel for households and bakeries.

15. Wood Granulator Machine in Mexico

An avocado grower in Michoacán needed a solution for tree prunings and waste. Our MZLH520 wood granulator machine was installed to process the avocado wood. It produces a unique 1.5 tons per hour of 6mm aromatic pellets that are marketed as a specialty fuel for high-end restaurants and pizza ovens.

16. Wood Granulator Machine in Argentina

A vineyard in Mendoza wanted to sustainably manage its annual vine pruning waste. They selected our MZLH420 wood granulator machine. The system processes the vine shoots, producing 1.1 tons per hour of 6mm pellets that are used to heat the winery’s buildings and tasting rooms, enhancing their sustainability story.

17. Wood Granulator Machine in Italy

A premium furniture maker in Northern Italy needed an eco-friendly solution for its valuable beech and cherry wood shavings. They chose our MZLH520 wood granulator machine. It produces 1.7 tons per hour of high-quality 6mm pellets that are packaged and sold under their own brand for domestic heating, creating a luxury biofuel product.

18. Wood Granulator Machine in France

A municipal authority in Normandy sought a way to manage green waste from public parks. They installed our MZLH678 wood granulator machine to process a mix of tree trimmings and branches. The project produces 2.4 tons per hour of 8mm pellets that fuel the boiler systems for a local school and swimming pool complex.

19. Wood Granulator Machine in Spain

A large olive oil producer in Jaén was looking to utilize olive tree pruning and olive pits. Our MZLH768 wood granulator machine was the chosen solution. It processes this dense, high-energy material into 3.2 tons per hour of 6mm pellets, which are used to power the extraction process itself, creating a fully sustainable operation.

20. Wood Granulator Machine in Turkey

A hazelnut producer on the Black Sea coast needed to manage shell waste. They purchased our MZLH420 wood granulator machine, configured for abrasive biomass. It processes the hard shells, producing 1 ton per hour of 6mm pellets with a very high calorific value, which are sold as a premium industrial fuel.

…

Can your industrial wood granulator machine process a mix of 60% sawdust and 40% wood chips?

+

Yes, absolutely. Our industrial wood granulator machine is specifically engineered to handle mixed feedstocks like 60% sawdust and 40% wood chips.

The sawdust acts as a filler that helps in initial compaction, while the wood chips provide the necessary fiber structure for durable pellets. For optimal performance, we recommend pairing the granulator with a hammer mill to pre-process the wood chips to a more uniform particle size.

This ensures a consistent bulk density in the mixer, leading to stable operation of the ring die wood granulator machine, higher output, and better-quality pellets. This versatility is a key reason many customers choose our professional wood granulator machine for sale.

I have furniture factory waste containing MDF and chipboard. Is a standard wood granulator suitable?

+

We strongly advise against processing MDF (Medium-Density Fiberboard) or chipboard in a standard biomass wood granulator machine. These materials often contain synthetic resins (like urea-formaldehyde) and other chemical binders that can be highly abrasive to the ring die and rollers, and may release harmful emissions when compressed and heated.

At Richi Machinery, we offer specialized granulator solutions and configurations for engineered wood waste, which may include hardened alloy dies and specific process parameters. Please contact our engineering team to discuss your specific material so we can provide a safe and effective solution.

We need to pelletize construction waste wood. What pre-processing is required for your granulator?

+

Construction waste wood often contains contaminants like nails, screws, sand, and paint. Pre-processing is critical to protect your investment in our heavy duty wood granulator machine. A typical pre-processing system we design includes:

- Secondary Grinding: A hammer mill to create a uniform particle size suitable for the ring die wood granulator machine. Only after this thorough cleaning and sizing is the material ready for pelletizing. We can supply this complete wood granulator machine plant as a turnkey system.

- Metal Separation: A powerful magnet or metal detector to remove ferrous metals.

- Primary Crushing: A robust crusher to reduce large pieces of timber.

- Screening & Cleaning: A screening system to remove sand, dirt, and fine particles.

What’s the maximum log diameter your wood log granulator machine can accept without pre-chipping?

+

Our dedicated wood log granulator machine, which is a system integrating a disc chipper and a hammer mill, can typically process whole logs with a diameter of up to 300mm without the need for a separate pre-chipping stage.

For larger diameters, we recommend a primary drum chipper to ensure consistent feedstock size and to prevent jamming, thereby maximizing the throughput and lifespan of your high capacity wood granulator machine line.

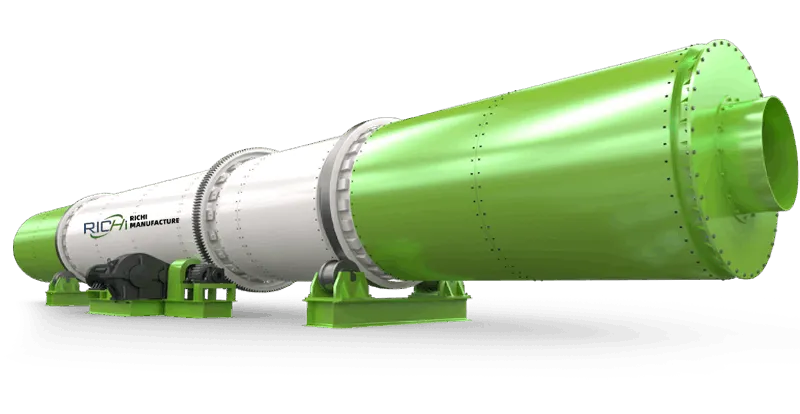

Do you offer a complete wood granulator machine plant that includes drying and cooling for wet bark?

+

Yes, we specialize in complete turnkey solutions. A system for wet bark would typically include:

- A Counter-flow Cooler: To efficiently cool down the hot pellets after they exit the pellet mill, making them stable for storage.

- This complete biomass granulator machine plant is designed for continuous, high-output operation.

- A Rotary Drum Dryer: To reduce the moisture content from over 50% down to the optimal 10-15% for pelletizing.

- A Biomass Burner: To provide heat for the dryer, which can be fueled by a portion of your finished pellets or wood waste.

- A Ring Die Wood Granulator Machine: The core of the system, built with corrosion-resistant materials to handle bark’s abrasiveness.

Can your high-capacity wood granulator machine produce both 6mm and 8mm pellets from the same material?

+

Yes, our high capacity wood granulator machine is designed for this exact kind of flexibility. The key component is the ring die. To switch between 6mm and 8mm pellets, you simply need to change the ring die.

Our machines feature a user-friendly die housing that allows for this changeover with minimal downtime. The same material can be used to produce different pellet sizes, provided the moisture content and particle size are correctly maintained for both.

We have large volumes of palm husk. What modifications are needed for a standard biomass wood granulator?

+

Palm husk is extremely fibrous and abrasive, requiring a specially configured granulator. For a standard biomass wood granulator machine, we recommend several key modifications:

- Extended Inlet and Forced Feeder: To ensure the low-bulk-density palm husk is consistently and forcefully fed into the compression zone.

- Our palm husk granulator machine is a proven solution for this challenging material.

- Reinforced Ring Die: We use a thicker ring die with specialized compression ratios and hardened materials to withstand the abrasion.

- Heavy-Duty Rollers: Upgraded rollers with a more robust bearing assembly to handle the high resistance.

What is the energy consumption of a 10 t/h automatic wood granulator production line?

+

The total energy consumption of a 10 t/h automatic wood granulator production line is complex as it includes the dryer, crusher, conveyor, cooler, and the main pellet mill. Focusing on the core machine, our 10 t/h ring die wood granulator machine typically has a main motor power of around 250-300 kW.

However, the total plant power can range from 800 kW to over 1,100 kW depending on the feedstock and auxiliary equipment. Our engineers focus on designing a low energy consumption wood granulator machine system overall, optimizing the entire line for maximum efficiency.

How does your ring die wood granulator machine handle abrasive materials like recycled pallets?

+

Our ring die wood granulator machine is built for durability against abrasives like recycled pallets (which often contain sand and dirt). Key features include:

- Optimized Die & Roller Gap Adjustment: Precise mechanical or hydraulic systems prevent metal-to-metal contact while ensuring efficient compression, reducing wear.

- Hardened Alloy Steel Dies and Rollers: We use premium materials that are deeply carburized or made from high-chrome alloy for extended service life.

- Quick-Disassembly Design: Our machine design allows for fast replacement of worn parts, minimizing maintenance downtime.

We process forestry residues with sand contamination. How does your heavy-duty granulator handle wear?

+

Sand is one of the biggest challenges for any wood granulator machine. Our heavy duty wood granulator machine addresses this with:

- Preventive Maintenance Plans: We provide detailed schedules for inspecting and rotating wear parts to ensure even wear distribution and maximize their lifespan.

- Wear-Parts Protection: Critical components like the ring die, rollers, and feeder screws are manufactured with wear-resistant alloys or can be fitted with tungsten carbide overlays.

- Strategic Design: The internal geometry of the pelletizing chamber is designed to allow for sand to be expelled more easily, rather than being continuously ground between moving parts.

Have you ever worked on 4 t/h wood granulator plant projects?

+

Yes, we have. Below, we’ll show you one of our 4 t/h pellet plant projects.

4T/H Wood Pellet Plant Project

—— RICHI MACHINERY ——

The development of agricultural and forestry waste in rural areas to make them into resources and energy, and the implementation of strategies to promote the development of biomass energy play an important role in economic development. Based on this development background, the project client invested 300,000 US dollars to rent office space and idle space, and build a new wood pellet line project with an annual output of 20,000 tons.

The labor quota of this project is 60 people, and the annual working days are 300 days. Two shifts are implemented, and each shift works for 8 hours. The 4t/h wood pellet factory has board and lodging. The construction period is planned to be 6 months, and it has been invested and operated in October 2017.

Construction Content And Scale

The total area of the project is 6500m², and the total construction area is 4500m².

- Main construction:1 wood pellet fuel production plant, construction area 2750m², 1F, newly built, steel structure;

- Supporting construction:Dormitory building (1750 m2), leased building, 5F, canteen on the first floor.

Consumption Of Main Raw And Auxiliary Materials

- Sawdust: 11,000 tons, Local procurement, transported by car, packed in bags, with a maximum storage capacity of 3,000 tons;

- Bamboo chips: 6,000 tons, Local procurement, transported by car, packed in bags, the maximum storage capacity is 10,000 tons;

- Corn pistils, corn stalks, bran powder, etc.: 6,000 tons, Local procurement, transported by car, packed in bags, the maximum storage capacity is 10,000 tons.

Energy Consumption

| Name of raw material | Annual consumption | Remarks |

|---|---|---|

| Water | 0.3344 million m³ | Local water pipe network |

| Electricity | 100,000 kWh | Local Power Grid |

| Fuel | 200 tons | Biomass produced by this project |

Machine For Making Wood Pellets

| Device name | QTY |

|---|---|

| Slicer | 2 |

| MZLH768 wood granulator machine | 1 |

| Wood Pellet Hammer Mill | 2 |

| Wood chip dryer | 1 |

| Bag filter | 2 |

| Cyclone | 2 |

| Conveyor belt | 4 |

| Forklift | 1 |

| Forklift | 3 |

| Truck (25 tons) | 2 |

4T/H Wood granulating Plant Process Flow

The raw materials of the 4t/h wood pellet production line project are sliced by a slicer, then pulverized by a wood pulverizer, and then dried by a dryer (the dryer of this project uses biomass fuel produced by this project, and the annual biomass consumption is 200t), and then sent by a conveyor belt after being mixed and batched.

Put it into the wood granulator machine for pressurization, densification and molding, and after simple packaging, it will be put into storage for sale. Unqualified products can be reused as raw materials, reprocessed and recycled.

The molded biomass fuel is small in size, high in proportion, resistant to combustion, and convenient for storage and transportation. The drying furnace produces 30t of ash a year, which is collected and sold to local farmers for use as fertilizer.

Public Works

01 Water supply and drainage

The water supply adopts a branched water supply pipe network to supply water to each water point, and the water supply pipe is a PPR pipe. All pipelines in the plant area are laid underground, and the depth of burial is not less than 1.8 meters.

In this design, the domestic water is connected to the nearest tap water pipeline in the factory area, and it is calculated independently for the convenience of measurement.

02 Power supply

The 4t/h wood granulator machine plant project power supply is introduced from the local power grid, which can meet the project’s production and domestic electricity demand.

Richi Machinery specializes in wood granulator machine. No matter what kind of raw material you are, we can provide suitable wood pellet plant and production process solutions.

Can your system process 100% softwood sawdust, and what is the expected output for a 1500kg/h model?

+

Yes, 100% softwood sawdust is an excellent raw material for our wood sawdust granulator machine. Softwood has high lignin content, which acts as a natural binder, often resulting in very high-quality, durable pellets.

For a model rated at 1500kg/h using softwood sawdust, you can expect to achieve that rated output consistently, and potentially even exceed it, provided the moisture content is optimized between 12-15%. Our 1500kg/h wood granulator machine is a popular model for its perfect balance of output and energy efficiency.

What is the lead time for a turnkey wood granulator system with a capacity of 15-20 t/h?

+

A turnkey wood granulator system of this scale is a major project. The lead time typically ranges from 4 to 6 months from order confirmation.

This includes engineering design, procurement of all components, factory assembly and testing of key sections, disassembly for shipping, and preparation for dispatch. We always strive to shorten this timeline and can provide a precise schedule upon project confirmation.

We have a mix of hardwood and softwood. Will this affect the performance of your granulator?

+

A mix of hardwood and softwood will not negatively affect the performance of our professional automatic wood granulator. In fact, it can be beneficial. Hardwoods provide high calorific value and density, while softwoods have higher lignin content for better natural binding.

Our machines, with their consistent conditioning and robust compression, are perfectly capable of processing mixed feedstocks. For the best results, we recommend using our dual-shaft mixer to ensure the blend is homogeneous before it enters the pellet mill.

Does your wood granulator machine with crusher handle whole tree branches and stumps efficiently?

+

Our systems are designed to handle these materials, but the process is staged. The “wood granulator machine with crusher” refers to a system where a powerful crusher or chipper pre-processes the whole branches and stumps.

Whole branches are not a problem for our primary chippers. Stumps, however, are much more demanding due to their size, soil contamination, and potential for hidden metals. We offer heavy-duty stump grinders and specialized crushers as part of the pre-processing line to prepare this material for the final grinding stage before it enters the ring die wood granulator machine.

What is the recommended moisture content for feeding sugarcane bagasse into your granulator machine?

+

Sugarcane bagasse is a fibrous material that can be challenging to pelletize. The ideal moisture content for feeding it into our sugarcane bagasse granulator machine is between 12% and 16%.

If the bagasse is too dry, it won’t bind properly; if it’s too wet, it can clog the die holes and cause excessive pressure. Our complete wood granulator machine plant for bagasse always includes an efficient dryer and a moisture control system to achieve this critical parameter.

Can you supply a high-throughput wood granulator machine that can run continuously for 24 hours?

+

Absolutely. Our high throughput wood granulator machine and continuous wood granulator machine models are engineered specifically for 24/7 industrial operations. Key features that enable this are:

- Heavy-Duty Construction: From the base frame to the main shaft, every component is over-engineered for relentless operation.

- We offer these industrial wood granulator machine for sale to clients with large-scale, continuous production needs.

- Robust Gearbox: Designed for high torque and continuous duty.

- Forced Lubrication System: Ensures bearings and gears are constantly cooled and lubricated.

What kind of output can I expect from a 2000kg/h wood granulator machine using rice husk?

+

Rice husk is a unique material with very high silica content and low lignin, making it difficult to pelletize. A standard 2000kg/h wood granulator machine might see a reduced output of approximately 1200-1500 kg/h when processing 100% rice husk.

However, Richi Machinery offers a specialized rice husk granulator machine with a customized ring die (specific compression ratio and hole design) and enhanced power to achieve outputs closer to the 2000kg/h mark. Mixing rice husk with a small percentage of a binder-rich material like wood dust can also significantly boost production.

Do you provide a biomass wood granulator machine that is suitable for making animal bedding pellets?

+

Yes, we provide a perfect solution for this. Our biomass wood granulator machine for animal bedding pellets is configured to produce a high-quality, absorbent, and dust-free pellet, typically from softwood shavings or sawdust.

The key is precise control over the raw material cleanliness, moisture content, and the use of a ring die that creates a smooth, firm pellet without being overly dense. We have many successful installations for wood shavings granulator machine systems dedicated to animal bedding production.

For a 500kg/h startup, what is the total investment for a basic wood granulator machine line?

+

The total investment for a basic 500kg/h wood granulator machine line can vary significantly based on the level of automation and the inclusion of a dryer. A basic setup, including a hammer mill, screw conveyor, 500kg/h wood granulator machine, and cooler, can start from approximately $35,000 to $60,000.

If a dryer is required, the cost will increase. We provide detailed quotations to help startups like yours make an informed decision, and our 500kg/h model is an excellent entry-level industrial wood granulator machine for sale.

How does your automatic wood granulator machine ensure consistent pellet density with mixed feedstocks?

+

Our automatic wood granulator machine ensures consistent density through several integrated systems:

- Consistent Mixing: We recommend and supply high-efficiency mixers to ensure the feedstock blend is homogeneous before it even reaches the pellet mill.

- PLC Control System: It constantly monitors the main motor load and can automatically adjust the feed rate to maintain a consistent amperage, preventing overloading and ensuring stable compression.

- Steam Conditioning: A precisely controlled steam injection system softens the lignin in the mixed feedstock uniformly, which is crucial for consistent binding.

We need to pelletize cotton stalks. What is the ideal hammer mill setup before your granulator?

+

Cotton stalks are long, fibrous, and can be tough. The ideal pre-processing setup for our cotton stalk granulator machine involves a heavy-duty hammer mill configured with:

- A High-Tip Speed: Sufficient rotor speed is needed to cleanly cut the fibers rather than just beating them.

- A Larger Screen Size: Typically a 6-8mm screen to produce longer fibers that help in interlocking within the pellet die.

- Reinforced Hammers: The hammers should be made of durable, heat-treated steel to withstand the abrasive nature of the stalks.

Can your wood chip granulator machine process material directly from a drum chipper without further crushing?

+

It depends on the size and uniformity of the chips from your drum chipper. Our wood chip granulator machine requires a consistent particle size, generally below 5mm. If your drum chipper produces very fine, uniform chips, it might be possible.

However, in most cases, the chips are too large and uneven. We always recommend a secondary hammer mill to grind the chips into a uniform “flour” that ensures high output and stable operation of the ring die pellet mill, preventing die blockage and ensuring pellet quality.

What safety features are included in your professional automatic wood granulator machines?

+

Safety is paramount. Our professional automatic wood granulator machines come with multiple safety features:

- Zero-Speed Switch: Monitors the feeder to prevent overfeeding which can cause a choke and damage the machine.

- Electrical Overload Protection: The main motor is protected by overload relays.

- Emergency Stop Buttons: Located at multiple, easily accessible points on the machine.

- Mechanical Safety Guards: Robust guards cover all rotating parts like the gearbox and drive belts.

- Interlock Systems: The machine will not start if the door to the pelletizing chamber is open, preventing access to moving parts during operation.

For a large-scale operation using port timber, what is the recommended complete biomass granulator plant configuration?

+

For large-scale port timber operations, we recommend a high-output, heavily ruggedized system. A typical configuration from Richi Machinery would be:

- Automation: A central PLC control system to manage the entire complete wood granulator machine plant efficiently. This turnkey solution is designed for the toughest materials and highest volumes.

- Primary Processing: A high-capacity drum chipper for initial log reduction.

- Screening & Metal Detection: To remove oversized pieces and metallic contaminants.

- Secondary Grinding: Two or more large hammer mills operating in parallel for consistent particle size reduction.

- Drying: A high-capacity rotary drum dryer with a biomass burner.

- Pelletizing: Multiple units of our large scale wood granulator machine (e.g., our 3000kg/h models) for maximum throughput and redundancy.

- Cooling & Screening: Counter-flow coolers and vibrating screens to achieve final product quality.

What are the suitable raw materials for a wood granulator machine?

+

This is one of the most critical questions we receive at Richi Machinery, and the answer highlights a key strength of our equipment. The versatility of a wood granulator machine is paramount for a profitable operation, as it allows you to source the most readily available and cost-effective biomass in your region.

Our industrial wood granulator machine is engineered to process a remarkably wide spectrum of woody biomass, transforming various forms of wood waste into high-value, dense pellets.

The core principle is that any lignocellulosic material—meaning it contains the natural polymer lignin which acts as a binder under heat and pressure—can potentially be pelletized. Here is a detailed breakdown of the raw materials our wood granulator machine can efficiently process:

1. Primary Wood Processing Residues:

These are some of the most ideal and consistent materials for a wood granulator machine.

- Sawdust & Wood Shavings: Generated from sawmills and planing mills, these are fine, uniform materials that are often ready for the pellet mill with minimal pre-processing. They are excellent for a high efficiency wood granulator machine.

- Wood Chips: A very common feedstock. Our wood chip granulator machine may require a secondary hammer mill to ensure a consistent particle size for optimal pellet quality, but it handles this material with ease.

- Wood Bark: While abrasive, bark is a viable material. Our heavy duty wood granulator machine is built with wear-resistant components to handle the higher silica content, often producing pellets with a higher ash content but good energy value.

- Sawmill Residues: This is a broad category including off-cuts, trimmings, and slabs. These are first chipped and then ground before being fed into the ring die wood granulator machine.

2. Forest-Derived & Whole Timber Materials:

Our systems are designed to handle materials directly from the forest.

- Tree Branches, Trunks, and Logging Residues: Through an integrated system that includes a chipper and hammer mill, our tree branch granulator machine can process this entire category. Forest thinnings and residues are excellent for promoting forest health and creating a valuable product.

- Tree Stumps: Stumps are challenging due to potential soil and rock contamination, but a robust pre-processing system with cleaning and a powerful wood log granulator machine can successfully incorporate them.

- Whole Tree Logs (Hardwood & Softwood): Whether it’s Hardwood like Oak, Maple, and Birch, or Softwood like Pine, Fir, and Spruce, our complete lines can process entire logs. Softwoods, with their higher lignin content, often pelletize more easily, but our professional automatic wood granulator is calibrated to handle the density of hardwoods effectively. Fast-growing species like Eucalyptus, Acacia, Poplar, and Willow are also excellent candidates.

3. Recycled & Recovered Wood Waste:

This category turns waste disposal problems into a revenue stream.

- Pallet Wood, Construction Waste Wood, Reclaimed Timber, and Port Timber: These materials are excellent feedstocks but require rigorous pre-processing. Our systems for these materials include strong magnets to remove nails and metal, and sometimes density separators to remove other contaminants. Our industrial wood granulator machine for this application is built with extra protection for the ring die and rollers to handle any residual abrasiveness.

- Painted or Treated Wood Warning: We must emphasize that wood treated with preservatives, painted, or coated with chemicals should NOT be processed in a standard biomass wood granulator machine, as it can release toxic emissions and damage the equipment.

4. Agricultural & Specialty Biomass:

The flexibility of our wood granulator machine extends beyond traditional wood.

- Furniture Factory Waste: This includes wood dust, shavings, and solid wood off-cuts. However, caution is needed with composite boards like MDF and chipboard due to the synthetic resins; we offer specialized solutions for these streams.

- Fruit Tree Wood, Rubber Wood: These are excellent, clean raw materials after the end of their productive life.

- Agricultural Residues: While not strictly “wood,” our machines can be configured for materials like cotton stalks, rice husk, sugarcane bagasse, and bamboo. These often require specific conditioning and die designs to compensate for lower lignin content, which is a specialty of our engineering team.

The list of suitable materials for a Richi Machinery wood granulator machine is extensive. From pristine sawdust to complex construction waste, our goal is to provide a high capacity wood granulator machine that turns your available biomass into a consistent, high-quality pellet.

We invite you to share your specific raw material with our engineers, who can demonstrate exactly how our wood granulator machine for sale is the ideal solution for your project.

What are the key advantages of using wood pellets as a biofuel, and how does the right wood granulator machine ensure these benefits are maximized?

+

Wood pellets have become a premier biofuel source globally because they offer a powerful combination of environmental and economic advantages. Producing pellets that consistently deliver on these promises, however, hinges entirely on the quality and capability of the wood granulator machine used in their manufacture. Here’s a breakdown of the core advantages of wood pellets and how Richi Machinery’s engineering ensures you achieve them.

Key Advantages of Wood Pellets:

- A Sustainable and Eco-Friendly Resource: Pellets are manufactured primarily from residual sawdust and wood shavings, transforming waste into valuable energy. This process is a model of circular economy, utilizing materials that would otherwise decompose in landfills. Our biomass wood granulator machine is specifically designed to process these waste materials efficiently, ensuring nothing goes to waste.

- Reduced Emissions and Environmental Impact: Wood pellets generate CO₂ emissions significantly below the threshold of fossil fuels. Their combustion is part of a carbon-neutral cycle, as the CO₂ released is roughly equivalent to what the tree absorbed during its growth. Furthermore, the amount of ash and waste residue after burning is negligible. The consistent density and low moisture content achieved by a high-performance wood granulator machine are critical for this clean, efficient combustion.

- Energy Independence and Economic Contribution: By utilizing domestic wood waste, pellets reduce a nation’s reliance on imported fossil fuels, keeping energy spending within the local economy and contributing to energy security. Investing in a local complete wood granulator machine plant from Richi Machinery not only provides you with a revenue stream but also supports regional economic development and creates jobs.

- High Energy Density and Ease of Handling: The pelletizing process dramatically increases the energy density of the original biomass. This makes pellets easy to transport in bulk and drastically reduces the storage space needed compared to loose wood chips or logs. This advantage is a direct result of the compression force inside a ring die wood granulator machine, which compacts the material into a hard, dense pellet.

- Versatility in Application: Wood pellets are incredibly versatile. They can be used for residential heating in pellet stoves, for commercial-scale thermal energy, and even to produce electrical energy in power plants. This market flexibility requires a pellet that can meet various quality standards, which is why our professional automatic wood granulator allows for precise control over pellet size (from 2mm to 12mm) and durability to suit different applications.

How Richi Machinery’s Wood Granulator Machine Maximizes These Advantages:

The benefits listed above are only fully realized with high-quality, durable pellets. A poorly made pellet will be dusty, break easily during transport, and burn inefficiently. This is where the engineering of the wood granulator machine becomes paramount.

Our industrial wood granulator machine is not just a press; it is the heart of a system designed to optimize every pellet characteristic. Features like our proven gear drive system deliver unwavering power and stability, ensuring consistent pressure is applied to the material through the ring die. This consistency is what creates a pellet with high mechanical durability (low dust) and the optimal density for high energy output.

Whether you are processing softwood sawdust, hardwood chips, or a mix of agricultural residues, our heavy duty wood granulator machine is built to the highest possible standards to handle your toughest demands. By choosing a Richi Machinery wood granulator machine for sale, you are not just buying equipment; you are investing in a solution that guarantees your final pellet product delivers on the full promise of being a superior, sustainable, and economical biofuel.

What engineering strengths and processes does RICHI Machinery employ to ensure the success of a wood pelletizing project, from initial design to final operation?

+

At RICHI Machinery, our engineering strength is the cornerstone of our reputation and the critical differentiator that ensures every wood pelletizing project we undertake is optimized for performance, reliability, and return on investment. Our capability to deliver a successful, high-output wood granulator machine line stems from a deeply ingrained, multi-disciplinary engineering philosophy.

Our Multi-Disciplinary Engineering Team

We believe that complex industrial projects require a fusion of expertise. Unlike suppliers who offer a standard wood granulator machine for sale, we deploy a dedicated team of specialists to analyze and design a solution tailored to your specific raw materials and production goals. Our team includes:

- Mechanical Engineers: They focus on the robustness and durability of the ring die wood granulator machine, ensuring the gearbox, bearings, and die-roller assembly are engineered for heavy-duty, continuous operation.

- Electrical & Automation Engineers: They design the control systems for our automatic wood granulator machine, integrating PLCs and safety interlocks to ensure smooth, efficient, and safe 24/7 operation with minimal manual intervention.

- Industrial Engineers: They optimize the entire material flow—from raw material intake to bagging—to eliminate bottlenecks and maximize the throughput of your complete wood granulator machine plant.

- Wood & Agricultural Engineers: This unique expertise is vital. These specialists understand the distinct pelleting characteristics of diverse biomasses—from hardwood and softwood to challenging agricultural residues like straw and bagasse. They specify the ideal pre-processing, conditioning, and most importantly, the correct compression ratio for the ring die in your biomass wood granulator machine to ensure high-quality pellet formation.

The RICHI 9-Stage Project Engineering Process

Our rigorous, proven process ensures no detail is overlooked, transforming a concept into a fully operational and profitable pellet plant.

- Basic Evaluation & Preliminary Planning: Our engineers conduct a thorough analysis of your raw material type, moisture content, and desired capacity. This is where we determine whether a high capacity wood granulator machine or a more standard model is the best fit, and what auxiliary equipment (like dryers or specific hammer mills) is required.

- Blueprint & Approval Planning: We create detailed plant layouts and technical specifications for your industrial wood granulator line. This includes structural, electrical, and mechanical drawings for your review and approval, ensuring the proposed turnkey wood granulator system meets all your expectations.

- Contract Preparation & Award Participation: We provide a transparent, itemized quotation. Our team can also assist in the tender process, providing all necessary technical documentation to support your project’s approval.

- Implementation Planning & Construction Management: This is the execution phase. Our project managers and engineers oversee the fabrication of equipment like the MZLH wood granulator machine, coordinate shipping, and can provide on-site supervision during installation and commissioning to ensure everything is built to our exacting standards.

- Documenting and Addressing Deficiencies: We believe in total project closure. We conduct final testing and create a comprehensive handover package, including operational manuals and maintenance schedules for your professional automatic wood granulator.

Proven Global Expertise in Customized Solutions

Our engineering processes are not theoretical; they are proven across the globe. We have successfully commissioned complete biomass granulator machine plants worldwide, from large-scale 20MT/h biofuel plants in Europe to specialized lines for rubber wood in Southeast Asia.

This vast experience means we have pre-engineered solutions and valuable insights for virtually any feedstock, whether you need a wood chip granulator machine for forestry waste or a specialized system for palm husk or cotton stalks.

When you partner with RICHI Machinery, you are not just buying a wood granulator machine; you are investing in decades of engineering excellence and a partnership dedicated to the long-term success of your pellet production business.

What is the complete process design for an industrial wood pelletizing system, and how does each stage contribute to final pellet quality?

+

A complete wood pelletizing system is an integrated production line where each stage is critically engineered to transform raw biomass into high-density, commercial-grade pellets. The design’s sophistication directly determines output efficiency, pellet durability, and operational cost. At Richi Machinery, we design our turnkey wood granulator machine plants with a focus on seamless integration and robust performance from raw material intake to final packaging.

Here is a detailed breakdown of the standard process, highlighting the role of our specialized equipment:

- Raw Material Pre-Processing & Size Reduction: The process begins with preparing the feedstock. Raw materials like logs, branches, wood chips, and pallets are first reduced to a consistent, smaller size. This is typically a two-stage process. A Wood Chipper Machine (3-18 T/H capacity) processes larger wood waste, while a Sawdust Hammer Mill (3-25 T/H capacity) further grinds the material into a fine powder. This step is crucial as it increases the total surface area of the material, making subsequent drying and conditioning more efficient and ensuring a uniform feedstock for the core wood granulator machine.

- Drying to Optimal Moisture Content: The moisture content of the ground material must be precisely controlled. Wet material will not pelletize effectively. A Rotary Drum Dryer is used to reduce the moisture content to an ideal 10-15%. Proper drying is non-negotiable; it allows the natural lignin in the wood to act as a binder under heat and pressure within the pellet mill, creating strong pellets without synthetic additives.

- Pelletizing – The Heart of the System: This is the core compression stage where the dried, powdered biomass is transformed into dense pellets. The material is fed into our MZLH Series Ring Die Wood Granulator Machine. Inside the machine, the material is pressed by heavy-duty rollers through the holes of a rotating ring die under extreme heat and pressure. This process liquefies the natural lignin, binding the particles together. Our industrial wood granulator machine is renowned for its high compression efficiency, which is what increases the burning energy efficiency of the wood by up to 3-4 times, creating a concentrated fuel source. The MZLH granulator equipment, for instance, is a high-output model capable of producing 0.2-4 T/H of consistent pellets.

- Cooling and Screening: The pellets exiting the ring die wood granulator machine are hot (80-90°C) and soft. They must be cooled and hardened to become stable for storage. A Counter-flow Pellet Cooler (1.5-18 T/H capacity) uses ambient air to cool them efficiently without making them brittle. After cooling, a Vibrating Pellet Screen removes fine dust and broken pellets, ensuring only high-quality, whole pellets are sent for packaging. This step is vital for maintaining the premium quality associated with pellets from a professional wood granulator machine.

- Weighing and Packaging: The final stage involves automated weighing and bagging. An Automatic Bagging Machine packages the finished pellets into bags for easy distribution and sale, completing the automatic wood granulator production line.

The Richi Machinery Advantage in System Design:

Our expertise goes beyond simply selling a wood granulator machine for sale. We provide custom-configured complete wood pelletizing systems. Whether you are processing forestry residues, agricultural waste like straw or bamboo, or industrial wood waste, our engineers design a system tailored to your specific raw material and output goals.

We don’t just offer a cheap wood granulator machine; we deliver a high-performance wood granulator machine line built for endurance and reliability, backed by a global support network.

From a 200kg/h wood granulator machine for startups to a large-scale 4000kg/h wood granulator machine plant for industrial operations, Richi Machinery is your one-stop partner for building a successful wood pellet factory.