Fish Feed Processing Line

1.0-2.0 T/H fish Feed Production

Richi Machinery specializes in the research and development of fish feed processing line equipment, equipped with advanced processing technology and strict quality supervision system guarantee, and can tailor-made fish feed line to meet various performance requirements. In addition to fish feed, if you want to process shrimp feed, livestock and poultry feed, pet feed, premix and other types, we can also customize the complete feed production system according to the customer’s product plan. Through our design, one fish feed processing line can process one or more feeds.

1-2T/H Fish Feed Processing Line solution

— Richi Machinery —

RICHI 1-2t/h fish feed processing line adopts feed extruding/pelleting technology and is divided into low, medium, high and other design schemes, which are suitable for the processing of various types of floating fish feed, sinking fish feed, slow sinking fish feed, micro fish feed, etc.

As the world’s leading feed equipment, storage equipment and complete fish feed processing system service provider, in recent years, Richi Machinery has made continuous breakthroughs in the continuous promotion of core extrusion/pelleting technology construction, new product research and development, and expansion of market layout, especially in aquatic products.

Today, in more than 40 countries around the world, many 1-2t/h high-tech fish feed processing plants manufactured by RICHI are helping customers create a full range of high-end aquatic feeds.

Maybe you are interested in other solutions:

1-2

Production capacity(tons/hour)

0.5-12

Pellet size(mm)

RICHI MACHINERY

video Of fish feed processing line

Below we show you two of our fish feed processing line projects: Iran 1-2t/h fish shrimp feed compound production line and Russia 1.5-2t/h trout fish feed production line.

Application of fish feed processing line

Fish feed processing line can process floating fish feed, pet feed, and some high-end extruded feed for livestock and poultry. It can also be upgraded to a combined feed production line, process shrimp feed, crab feed, eel feed, pet food livestock and poultry feed, premix and other products at the same time.

It is usually invested and built by fish feed factories, aquatic feed factories, pet feed factories, compound feed factories, fish farms, aquatic processing plants, etc. Of course, there are also many investors from different industries who are very optimistic about the prospects of fish feed processing, so they enter the aquatic feed processing industry.

aqua feed mill

Aquaculture farms

Dryland Fish Farm

Aquatic Products Company

Livestock and poultry feed factory

Investors from different industries

Fish feed processing technology

In order to support provide a balanced and stable feeding for the farmed fish, many producers have shifted to manufactured pellets. Based on the behaviour in the water, fish feed can be divided into floating feed, slow-sinking feed, and sinking feed. RICHI offers you extrusion and pelletizing solution to produce high quality fish feed.Some customers need processed powdered fish feed, such as eel feed, and we can also customize the relevant process.

twin screw extrusion——For High-grade fish feed

The twin screw feed extruding technology has strong applicability and is not only suitable for extruding materials with high starch and fat content, but also can extrude and process a wider range of feed types.

It is precisely because twin screw extrusion has so many advantages that more and more aqua feed companies have begun to apply it to the processing of special aquatic feeds, pet feeds and other animal feeds. a major development direction.

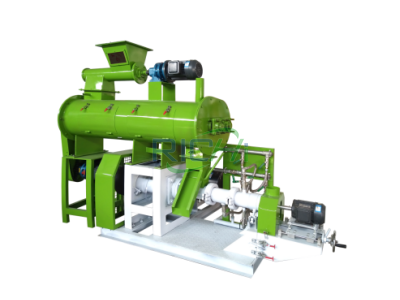

single screw extrusion——Dry and wet processes available

RICHI single-screw extruders and technology have been used worldwide for the production of premium quality feed and food. The unique design of the screw and barrel liner can generate a higher degree of cooking.

With the incorporation of numerous innovative designs, high-quality materials, and precise manufacturing processes, RICHI extruders can perform energy-efficient extrusion cooking.

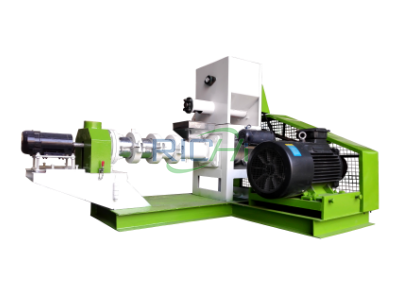

pelleting technology——For sinking fish Feed Pellets

RICHI fish feed pellet machine system is renowned for its robustness and can make high-quality pellets from 0.8 mm to 12mm. RICHI has different pellet mill model which is tailor-designed for a diverse aqua feed.

RICHI MACHINERY

fish feed processing line technology

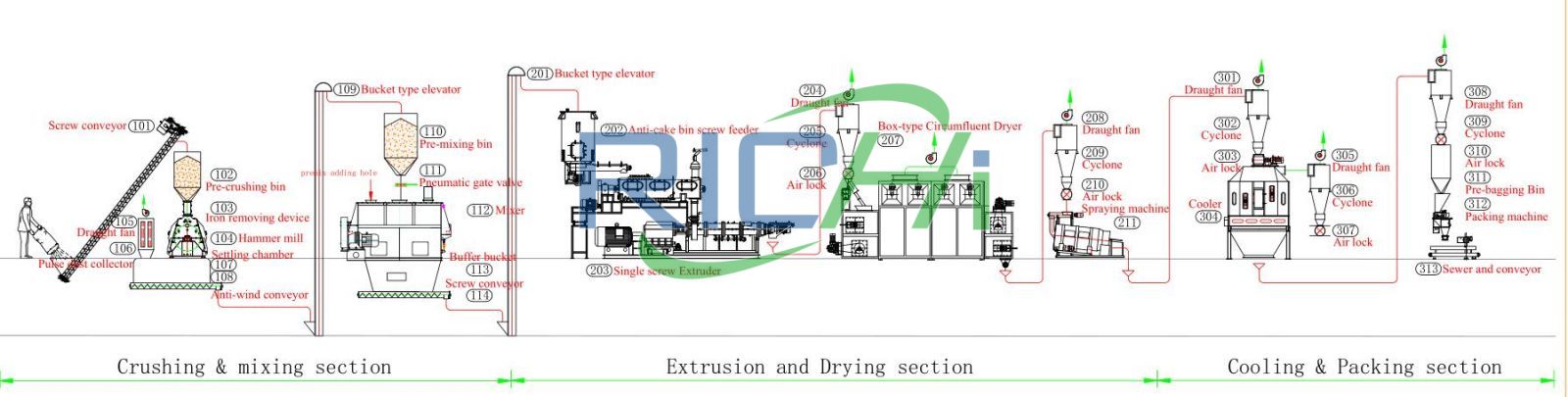

The fish feed processing line mainly includes the following procedures: raw material receiving and cleaning→crushing→mixing→→extrusion puffing→drying→cooling→spraying→pakacging. According to customer needs, we will customize production lines with different processes and equipment configurations.

The customization of processes will be affected by product type, raw material formula, plant structure, and investment budget. In addition to complete fish feed production lines, we can also provide individual processing systems and equipment, such as fish feed drying system, fish feed crushing system, fish feed packaging system, etc.

Silo system

Silos are mainly used to store raw materials in fish feed processing lines for easy management and use. For large-scale fish feed mill, silos are obviously very necessary. If it is a small-scale fish feed production line, you can decide whether to configure silos or configure small-scale silos according to your budget. We can provide customized silo services.

Receiving and cleaning

This is raw material intake system,consisting of tip hopper, mechanical conveyors, and elevators into buffer bins. Raw material such as soybean meal, corn, fish meal, and other grain or powder is sieved to remove any impurity and metals.

grinding system

Pre-grind systems are a size reduction process for raw materials that contain large particulates or grains by hammer mills. The second grinding process that grinds the formulation into finer powder with fineness up to 80 mesh 95% pass. This step becomes optional when making big extrudates with sizes of 2.5 mm and up.

mixing & batchingsystem

The first mixing system is used for dry material mixing to stabilize the following process.Other sources like pre-mix, liquid, oil, and fat are now added and mixed with raw material. Too much fat added here will affect the floatability, so a post-extrusion oil coater will be used to account for the total fat content required.

extrusion/pelleting

The mixer feeds down through a feed hopper into the feed screws which continuously feed the ingredients into a differential diameter conditioner (DDC). Water, steam, and/or oil are added in DDC, the retention time inside DDC is controlled by shaft speed. Two types of extrusion technology can be chosen: single screw extruder or twin screw extruder. A pellet mill can also be used to process fish sinking feed.

drying system

The fish feed dryer will lower the moisture content of the extrudate from 20% to 28% in the dryer inlet down to 10-12%. This drying is needed to lower the water activity and achieve shelf-stable moisture for the products. The system uses a belt dryer developed and manufactured by RICH itself, which can be used to dry various feeds, foods, vegetables and fruits.

coating & cooling

Oil coating is needed to increase the nutritional value and palatability of the feed. Depending on the fat content that needs to be added, a drum coater or a vacuum coater can be chosen. Cooler lowers the temperature of the hot pellets to +3°C of room temperature by utilizing ambient air.

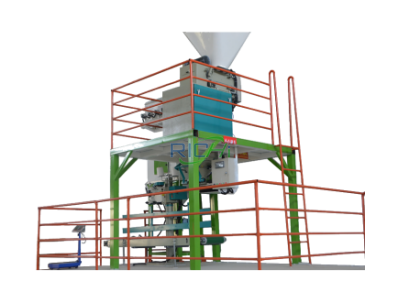

screening & Packaging

All fish feed pellets will go through a vibration sieve to remove any irregular pellets or impurities before bagging. Weighing cell and bagging machines bag pellets with chosen quantity ex: 20 Kg. or 25 Kg. per bag and seal the bags for storage. Finished products can also be loaded by trucks or in container bags.

RICHI MACHINERY

equipment for fish feed processing line

Generally speaking, a 1-2t/h fish feed processing line requires fish feed extruder or fish feed pelletizer, hammer mill, ultrafine grinder, feed mixer, fish feed dryer, fish feed sprayer, bagging machine, cooler, screening machine, conveyor, batching scale, oil adding equipment, etc. It also needs to be equipped with auxiliary equipment such as boiler, air compressor, dust removal equipment, etc.

According to the budget, you can choose general configuration and high-end configuration, manual configuration and fully automatic configuration. For example, choose high-end configuration, including twin-screw extrusion solution, vacuum spraying system, fully automatic batching system, fully automatic packaging and palletizing system, etc.

1-2T

Efficient production capacity

1-2T

High degree of automation

1-2T

Flexible customization

1-2T

Wide range of applications

fish food grinder

Used in the first crushing stage to coarsely crush the granular materials.

feed mixer machine

Used in the mixing section of fish feed. Available in ribbon and paddle types.

Micro Pulverizer

Used for the second crushing of fish feed raw materials, with fineness up to 80 mesh 95% pass.

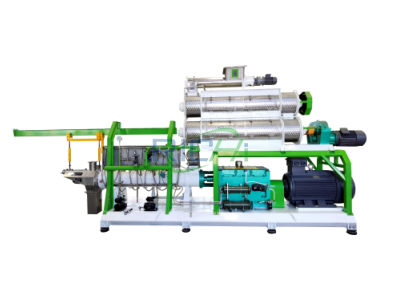

twin screw extruder

It is the most advanced model in the fish feed processing industry. It is suitable for all fish feed and pet feed raw materials and formulations.

wet type fish feed extruder

It is a single screw extruder. Its output is lower than that of a twin screw extruder. But it is suitable for economical fish feed processing.

dry type fish feed extruder

Very suitable for fish farms and small feed mills. Suitable for small fish feed processing business with low investment cost.

fish feed dryer machine

Mesh belt drying machine is able to dry fish feed pellets, shrimp feed pellets and other animal feed pellets with great drying performance.

Fish feed sprayer

The fish feed pellets coating machine adopts excellent post-addition technology, which can spray nutriment and medicine on the formed pellets surface.

pellet cooler machine

The aqua fish feed pellet cooler machine can cool down the hot feed pellets from 80 – 90℃ to about 3-5℃ above ambient temperature.

vibrating screening machine

The vibrating grading sieve is used to collect the qualified fish feed pellet products by screening and grading. It bases on the probability screening principle.

Automatic Bagging Machine

Our fish feed bagging machine is known for its automatic weighting, high bagging accuracy, perfect working performance and long service life.

Electric control cabinet

Electrical enclosures, which could also be called electric boxes or cabinets, are structures that keep electrical components and electronic equipment safe.

bucket elevator conveyor

A bucket elevator, also called a grain leg, is a mechanism for hauling flowable bulk materials (most often feed, pellet or grain) vertically.

screw conveyor machine

Screw conveyor is ideal for limited space applications, feed, powder, particle, small chips, various types of material, and wet or dry applications.

scraper conveyor

Scraper conveyor is a type of material handling equipment designed to transport bulk materials, such as feed, pellet, coal, sand, or grain, etc.

Grease adding equipment

Liquid adding machine is suitable for intermittently adding various nutrients such as oils and fats into the mixer.

Steam Boiler

A steam boiler is a steam producing heating system; it produces energy by heating water to create steam.

storage silos

RICHI supplies grain storage silos and temporary bin in galvanized steel and stainless steel. Different sizes can be customized.

RICHI MACHINERY

1-2T/H Fish feed processing line configuration

A fish feed processing line uses a lot of equipment. How to configure these equipment into an efficient fish feed processing system is a professional matter. Because the equipment configuration depends on the process design of the production line, a full set of equipment can be configured after the process is determined. Here are the main equipment and models of a 1-2t/h twin screw type fish feed line for you.

| Name | Model |

| Drum type precleaner | SCY63 |

| Permanent magnetic sleeve | TCXT20 |

| Screw conveyor | TLSS20 |

| fish feed Hammer mill | SFSP66*60 |

| Pulse dust collector | TBLMa.24A |

| Bucket Elevator | TDTG36/18 |

| fish feed Mixing machine | SLHY1.0A |

| DDC-conditioner | DC400*300-244 |

| Twin screw fish feed extruder | RCPH120*2 |

| fish feed Drying machine | DHG-2000Q |

| fish feed Coating machine | RISP-2000 |

| fish feed Cooling machine | SKLN17*17 |

| fish feed Vibrating screener | TDZS80 |

| Auto-packing machine | DCS-50 |

| Sewing + belt conveyor | / |

| MCC Control Center ;Mimic control panel (power range from 22 kw for star triangle start, main electric components are Siemens brand) | |

Fish feed processing line construction——RICHI MACHINERY

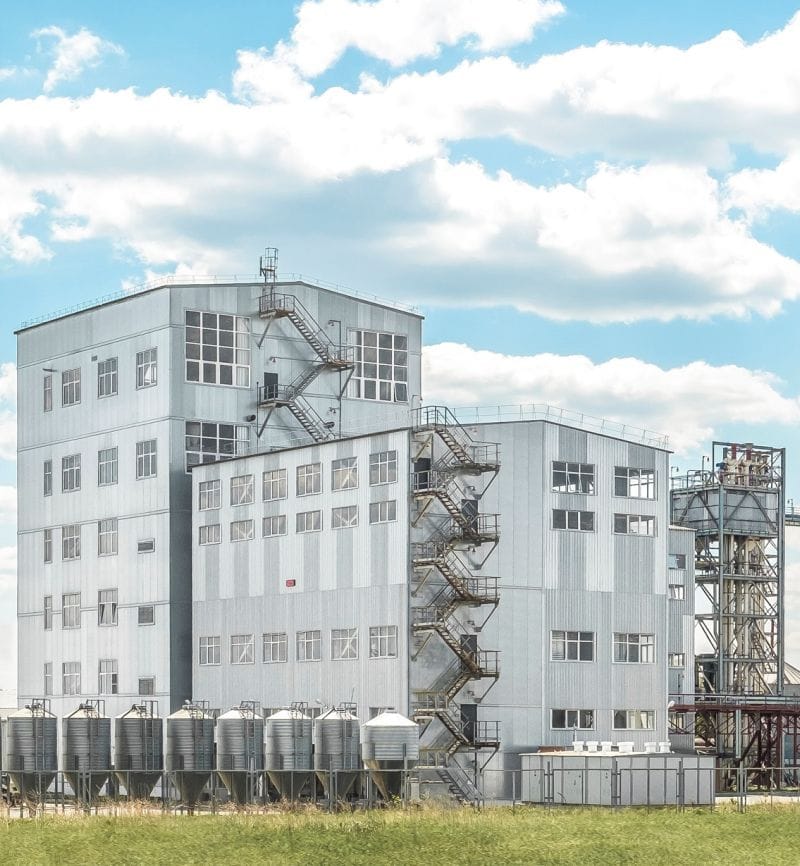

We have on-site engineers that work with our installation team to make sure there is little room for miscommunication and error. We custom design your fish feed production system, implement the software and train your team to be self-sufficient. We set up a communication system for when the project is complete. We’re always just a phone call away!

RICHI MACHINERY

customized fish feed processing line design

The supported adjustment sites are as follows. You can choose to use the “multi-language site” template that comes with the

01

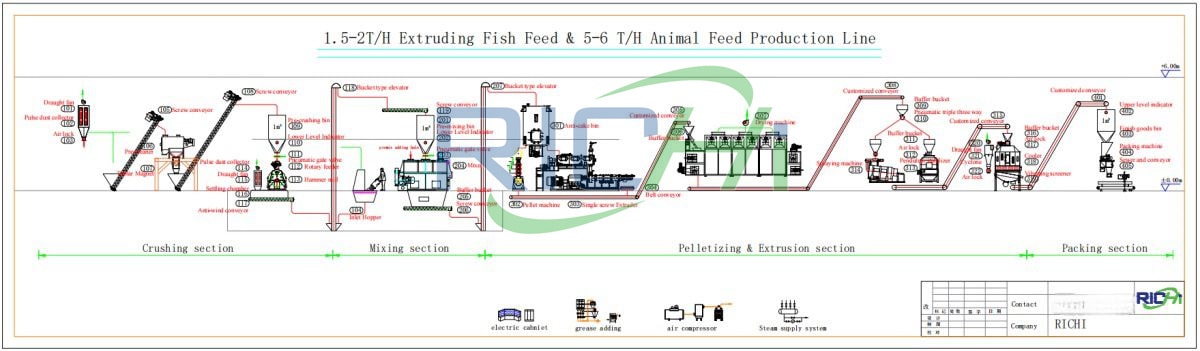

1.5-2T/H extruded fish feed processing line design (Brazil Project)

This project comes from one of our Brazil fish feed processing line projects. The project mainly produces 1.5-2t/h floating fish feed and 5-6t/h animal feed production lines.

The plant height of this project is limited, so in terms of design, it is necessary to dig a pit to lower the height of the entire production line. The main processes of this project are: feeding – crushing – mixing – extrusion (fish feed) – drying – coating – granulation (animal feed) – cooling – crumbling – screening – packaging

02

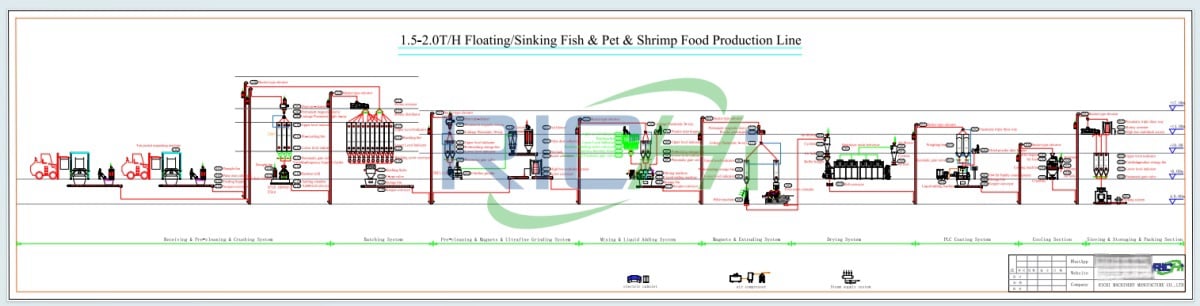

1.5-2T/H floating fish & sinking fish feed processing line (Russia Project)

This is our latest high-end fish feed processing line project exported to Russia. The project mainly processes 1.5-2t/h floating fish feed & sinking fish feed & shrimp feed & pet feed.

The configuration of this processing line is very high. It adopts a fully automatic batching system. Since the plant of this project was newly built after the production line process was determined, there was no restriction on the height and structure of the plant when designing the production line, and the site was very sufficient.

03

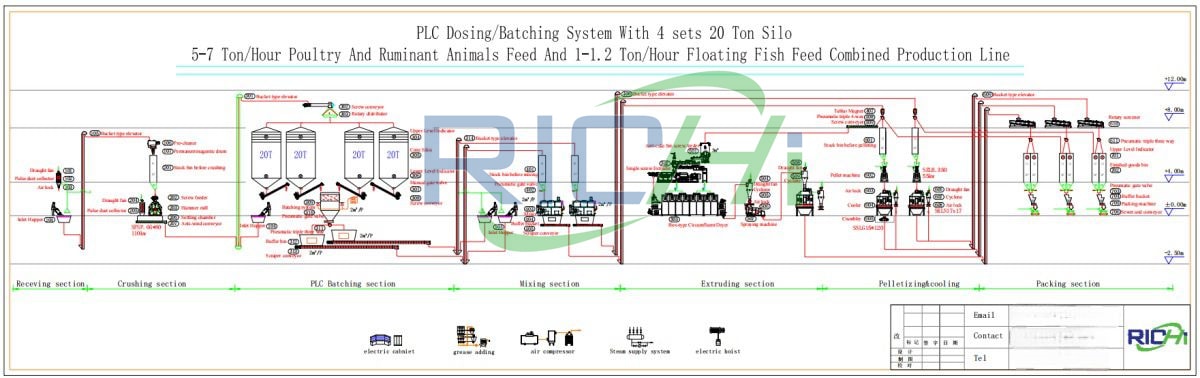

1-1.2T/H floating fish feed processing line design (India project)

This is a fish feed manufacturing project with an hourly output of 1-1.2 tons. This is also a composite production line, processing 5-7 tons of poultry and ruminant cattle feed at the same time.

Since the customer did not intend to invest too much, he did not choose a fully automatic batching system, but a more economical PLC batching system. In addition, the plant height of this project is sufficient, and there is no need to dig a pit. The entire processing line is a horizontal structure.

1-2 t/h fish feed processing line project

— Richi Machinery —

At present, we have established fish feed production lines in 80 countries around the world, and have established fish feed systems with an hourly output of 1-2 tons in more than 40 countries. These countries include major aquaculture countries such as India, Russia, Indonesia, USA, Brazil, Ecuador, Vietnam, Bangladesh, Egypt, Chile and Philippines.

1.5-2 t/h fish feed processing line in iran

Feed type: Floating fish, shrimp, livestock and poultry

After the completion of this compound animal pet aqua fish food processing line, it mainly produces extruded feed for floating fish, feed for sinking fish and shrimp, but at the same time, the possibility of producing pet feed, poultry feed, chicken feed, cattle feed and goat feed is reserved in the future.

- Cost: approximately $330,000

- Production cycle: 60 days

- Delivery time: by sea, 40 days

- Installation period: 90 days

- Number of employees: 12

- Working system: single shift, 8 hours per shift, 250 days per year

- Project voltage: 380V/50HZ/3P

1.5-2 t/h fish feed processing line in russia

Feed type: floating fish feed

This customer runs a large aquaculture farm, and all the processed fish feed will be used in its own fish farm. The original intention of the customer to build a fish feed production line was to save feed costs. When designing the production line, the customer said that he wanted to reserve 2-5 t/h of expansion capacity. According to the customer’s needs, RICH engineers customized a suitable solution for it and reserved space for capacity expansion.

- Cost: approximately $260,000

- Production cycle: 30 days

- Delivery time: by sea, 20 days

- Installation period: 30 days

- Number of employees: 8

- Working system: single shift, 8 hours per shift, 330 days per year

- Project voltage: 380V/50HZ/3P

1-2 t/h fish feed processing line in india

Feed type: floating fish feed & shrimp feed

This client is an investor who, based on the booming aquaculture in India, invested in building a 1-2 ton fish feed processing system. The system processes a variety of fish feeds and shrimp feeds, and is equipped with a twin-screw extruder and a shrimp feed pelletizer.

- Cost: approximately $360,000

- Production cycle: 30 days

- Delivery time: by sea, 40 days

- Installation period: 50 days

- Number of employees: 14

- Working system: single shift, 8 hours per shift, 320 days per year

- Project voltage: 380V/50HZ/3P

1-1.2 t/h fish feed processing line in Qatar

Feed type: floating fish & bird & camel

This is a project that uses extrusion technology to process fish feed, bird feed and camel feed, with feed sizes ranging from 1 to 12 mm. The customer uses dry extrusion technology, which has a relatively low investment cost. The project does not have a packaging system. The feed particles enter the manual packaging section after screening, and then the feed is sold.

- Cost: approximately $70,000

- Production cycle: 20 days

- Delivery time: by sea, 40 days

- Installation period: 23 days

- Number of employees: 4

- Working system: single shift, 6 hours per shift, 300 days per year

- Project voltage: 380V/50HZ/3P

1-2 t/h fish feed processing line in indonesia

Feed type: floating fish feed & sinking fish feed

This customer is a well-known local feed company in Indonesia, mainly processing livestock and poultry feed and shrimp feed. In 2023, the customer wants to build a 1-2t/h fish feed production line. Through personalized customization, this project of using twin-screw extrusion technology to process both floating fish and sinking fish feed was realized.

- Cost: approximately $560,000

- Production cycle: 40 days

- Delivery time: by sea, 25 days

- Installation period: 30 days

- Number of employees: 16

- Working system: single shift, 10 hours per shift, 310 days per year

- Project voltage: 380V/50HZ/3P

1-2 t/h fish feed processing line in Ecuador

Feed type: floating fish feed & shrimp feed

This Ecuadorian customer is an old customer of ours. The customer once purchased a 3-4t/h livestock and poultry feed production line and a 1t/h shrimp feed production line from us. As the previous project was very profitable, in 2023, they contacted us again to invest in this project.

- Cost: approximately $310,000

- Production cycle: 40 days

- Delivery time: by sea, 40 days

- Installation period: 30 days

- Number of employees: 10

- Working system: single shift, 8 hours per shift, 300 days per year

- Project voltage: 380V/50HZ/3P

fish fed processing line cost

— Richi Machinery —

The equipment price of a 1-2t/h fish feed processing line is usually between 100,000 – 560,000 USD. This price range is based on a large number of our production line quotations. However, there are always many special custom designs and equipment configurations, and the price may be higher or lower than this range. So this price range is for most cases, not for all projects.

If you want to get an accurate equipment quotation and process design, please contact us directly and tell us your needs. Our engineers will customize a satisfactory solution for you.

| Production Scale | Cost(USD) | Total Power(KW) | Project Site Requirements (m²) | installation cycle (Days) |

| 100-150 kg/H | 30,000-50,000 | 47-75 | 100-200 | 7-10 |

| 200-400 KG/H | 40,000-80,000 | 53-100 | 100-250 | 7-20 |

| 500-600 KG/H | 50,000-100,000 | 135-180 | 200-300 | 10-20 |

| 800-1000 KG/H | 70,000-170,000 | 164-200 | 300-500 | 15-30 |

| 1.0-2.0 T/h | 100,000 – 560,000 | 182-250 | 500-700 | 20-40 |

| 3.0-4.0 T/H | 230,000 – 650,000 | 223-310 | 800-2000 | 30-60 |

| 5.0-6.0 T/H | 470,000 – 840,000 | 247-420 | 1000-3000 | 40-80 |

| 8.0-10.0 T/H | 580,000 – 1,200,000 | 345-580 | 1500-4000 | 45-90 |

Richi Machinery

Meeting Your Needs, Creating A Plan

In order to produce high-quality aquafeed, perfect aquafeed processing technology and suitable aquafeed processing equipment are the key, because different process designs and processing equipment often produce different effects.

Richi Machinery has always insisted on innovating our products and processes around the needs of customers, and has successively developed a series of core aquatic equipment, such as 75×2, 125×2, 155×2 and other specifications of the twin-screw extruder for aquatic products; 500, 1000, 2000 and other specifications of vertical vacuum spraying machine; natural gas type, steam type horizontal fish feed dryer machine, etc.

In addition, we have also developed a variety of high-quality equipment such as a special hammer mill feed grinder for aquatic products, a special high-efficiency granulator for shrimp feed, etc.

case studies

Perhaps the above content has not fully understood our projects. Here, RICHI will introduce you to our two projects in detail, one is the American fish feed line project with an output of 1.5 tons per hour, and the other is the Vietnamese fish feed processing line project with an output of 2 tons per hour. We hope you can have a deeper understanding of the construction of fish feed processing projects.

1.5 t/h floating fish feed processing line in united states

The client of this 1.5t/h floating fish feed processing line project is mainly engaged in the processing, manufacturing and sales of aquatic feed and livestock feed. In order to meet the needs of market development, this expansion project plans to adjust the production scale.

The customer carried out technical transformation of the feed production line of the original project, dismantled all the original production lines, optimized the scale and composition of the products, and renovated the 1.5t/h floating fish feed making machine project in the already built workshop, and built a new warehouse and a workshop.

Among them, Richi Machinery has contracted to build an aquafeed production line with an annual output of 4,000 tons. Aquatic feed production equipment includes: 14 scraper conveyors, 3 bucket elevators, 1 fish feed extruder machine, 1 fish food dryer, 1 superfine pulverizer, 1 spraying machine, 2 grading sieves, baler 1 set, 2 cylinder warehouses. Before the expansion of the project, the annual output of various feeds is about 120,000 tons/year.

After the expansion, it is expected to increase the aquatic feed by 4,000 tons, reduce the scale of livestock feed by 2,000 tons, and the total scale will increase by 2,000 tons/year. The plant is equipped with two boilers, the main boiler is a 5t/h natural gas-fired steam boiler, and the standby boiler is a 1t/h natural gas-fired steam boiler.

- Project Nature: Reconstruction & Expansion

- Project products: tilapia feed, grass carp feed, fork fish feed

- Working system: 8 hours a day, about 300 days a year. The USA fish feed processing line project sets up a staff canteen, which provides 2 meals a day for employees, and does not set up staff dormitories.

- Annual power consumption: 5010000 kwh/a

- Annual water consumption: 3250m3/a

- Gas consumption (natural gas): 900,000 m3/a

- The annual consumption of raw materials: 47260t/a

- Project raw materials: corn, bran, soybean meal, fish meal, stone meal, cotton meal, soybean oil, lard, flour, fish oil, corn gluten meal, corn germ meal, rice bran, rapeseed meal, calcium dihydrogen phosphate, bacterial protein powder, Corn gluten feed, lysine, peanut meal, other ingredients (vitamins, minerals, trace elements)

Expansion content

- Production workshop: There is 1 existing production workshop, and a new 1.5t/h floating fish feed line is added. It is located in the production workshop, with a construction area of 2378.8m2;

- Raw material warehouse and finished product warehouse: There are 1 livestock and poultry raw material warehouse, 1 livestock and poultry finished product warehouse and 1 finished aquatic feed warehouse. Based on the existing project, two new cylindrical warehouses are added at the same time.

fish feed processing line design

The production of 1.5t/h floating fish food processing line adopts primary mixing, primary crushing, secondary crushing and secondary batching to complete the processing of extruded pellet feed and powdery raw materials. The main floating fish feed manufacturing processes are as follows:

- Feeding—— Materials are fed in two ways: Large-size materials such as corn are directly fed into the feeding chamber by trucks for closed feeding; The bagged raw materials such as fish meal are fed by manual feeding (there are two feeding ports), and the dust generated by feeding is treated by two bag filter and then discharged through the 8m exhaust pipe.

- Crushing: The pulverization process is carried out in the basement. After the pulverization is completed, the materials are sent to the upper level by suction to carry out simple classification and batching of various raw and auxiliary materials. After the first mixing, it needs to be pulverized by an ultrafine pulverizer for the second time.

- Conditioning: It is mainly to continue to add trace additives and water to the mixed ingredients.

- Extrusion: The mixed feed is made into a specific granular form, and the material is cooked for a period of time under high temperature (temperature between 120 and 130℃), high humidity and high pressure, during which the physical and chemical properties of the material change drastically (Mainly starch gelatinization, protein denaturation), the instantaneous pressure dropped from the die hole, the water in the feed is converted from liquid to gas, and it is emitted from the feed to cause the material to expand.

- Drying and spraying: After the material is extruded by the twin screw extruder, it forms moist and soft particles, which are released from the floating fish extruder. Enter the dryer for drying, reduce the moisture, and then use the air pressure of the air compressor to spray the fish oil and other additives on the surface of the feed.

- Cooling & screening & packing: After the fish feed passes through the external spraying system, it needs to be cooled and screened, and finally packaged into products.

2T/H fish feed line in Vietnam

The client of this 2t/h fish feed processing line project is a technology-based joint-stock enterprise integrating feed research and development, production and sales. At present, complete compound feeds for livestock, poultry and aquatic products have been developed and developed, with a total of 117 varieties in more than ten series, which are widely used in the breeding of livestock, poultry, aquatic products and other agricultural products.

During this period, the company has formed a competitive advantage by putting into use of Richi Machinery’s fish extruder and shrimp feed pelletizer stand-alone products and molds. This time, the 2t/h fish feed production project is a small eel feed production line newly built by the customer – a number of RICHI fish feed pulverizers and fish feed mixers have been put into use.

The total investment of the 2t/h fish feed making project is 110,000 US dollars, covering an area of 4,056 square meters. The use of RICHI high-efficiency fish food processing machine also indicates that the product quality will further improve the market competitiveness, and its coverage will become more and more extensive.

- Project nature: New construction. To rent an industrial plant, you only need to install the production equipment.

- Project product: eel feed

- Annual output: 5000 tons

- Product shape: powder

- Power consumption: 100,000 kWh/year

- Water consumption: 120m³/a

- Main workshop: the area is 25 m×20 m, and the height is about 12 m

- Working system: 10 employees, 300 working days a year, 8 hours a day, 8:00-12:00, 14:00-18:00. There are no canteens and staff dormitories in the project site.

- Project investment: 110,000 USD

Main raw materials

| Raw material | Usage (t/a) | Raw material | Usage (t/a) |

|---|---|---|---|

| Fish meal | 3250 | Starch | 1250 |

| Vitamin | 80 | brewer’s yeast | 250 |

| Citric acid | 30 | Table salt | 20 |

| Choline | 50 | Soybean lecithin | 70 |

Composition

- Main workshop: Approx. 500 m², 1 for eel feed processing such as crushing, mixing and packaging;

- Office: Approx. 300 m2, 1 for daily office use;

- Warehouse: Approx. 3256 m², 2 for storing product and raw materials;

- Power Distribution System: Supply electricity for production and office life;

- Water and drainage system: The source of water supply is municipal tap water, and the domestic sewage is treated by an independent domestic sewage treatment facility and discharged into nearby rivers;

- Separate domestic sewage treatment facility: Sewage Treatment

- Bag Dust Collector: The crushing and batching equipment is equipped with bag dust removal device.

Main fish feed production Equipment

The 2t/h fish feed processing equipment is tightly connected by pipelines, and the feed mixer and feed pulverizer belong to the integrated production equipment.

| Device name | QTY |

|---|---|

| Fish feed mixer | 4 |

| Fish feed crushers | 2 |

Process flow of 2 t/h fish feed processing line project

The production process of this 2t/h fish feed processing plant project is relatively simple. In the project, the purchased raw and auxiliary materials such as fish meal, starch and vitamins are put into the suction trough of the fish food pulverizer according to a certain proportion. It is then transported to the mixer through the pipeline to mix evenly, and manually packaged according to certain specifications. After sealing and packaging, it can become a product.

The 2t/h fish feed line project adopts integrated equipment, 2 crushing and batching lines, of which 1 line is equipped with 2 feed mixers and 1 pulverizer, and the other line is equipped with 1 mixer and 1 pulverizer. A total of 5 feeding ports are set in the project, which are equipped with 5 bag dust collectors to process the dust. After processing, the dust is led to the pulverizer.

The pulverized dust is processed by the bag dust collector. The 2t/h fish feed processing project arranges personnel to clean the bag dust regularly and reuse it directly. A small amount of dust is discharged through the 15m high exhaust pipe.

The 2t/h fish feed processing line project adopts an integrated automatic batching ultra-fine pulverizer. The large-sized materials absorbed to the upper layer by the exhaust air need to be crushed into powder by the pulverizer, and a small amount of dust will be generated during crushing and mixing.

During the 2t/h fish feed production process, the powder does not need to be puffed, granulated, nor does it need to use raw and auxiliary materials such as allicin.

Fish feed processing line design with different capacity

We offer a wide range of products and are able to meet your specific needs for any aqua shrimp fish feed processing. With decades of experience in designing grinding, milling, mixing, extrusion & pelleting equipment for any aqua feed plant, you can rely on our expertise to get you the solution best suited for you.

RICHI Machinery process and project engineers have the skills and experience to define the best fish feed processing line solution, making us the perfect partner at every stage of your project, from initial design to completion as well as maintenance for the lifetime of your fish feed plant.

floating fish feed mill

Used for processing various fish extruded feed pellets. Either a twin-screw extrusion process or a single-screw extrusion process can be used.

sinking fish feed production line

Used for processing various pelletized fish feed. The extrusion process or the pellet mill process can be used.

RICHI MACHINERY

how to build a fish feed processing line?

The specific steps and procedures for building a fish feed processing line are as follows (different countries may have differences):

- Understand industry regulations and standards:

Before preparing a fish feed line, you first need to have a deep understanding of the regulations and standards of the feed industry, including the national and local laws and regulations on feed production, sales, quality control, etc., as well as the quality standards and safety requirements of feed products. - Apply for relevant certificates and procedures:

- Business license: Prove the legal operation of the enterprise.

- Tax registration certificate: Ensure that taxes are paid in accordance with the law.

- Production license: According to relevant laws and regulations, a production license is required to produce feed.

- Environmental protection license: Ensure that the feed factory meets environmental protection requirements during production and processing.

- Sewage discharge license: Treat wastewater, waste gas and other pollutants generated during feed production.

- Special equipment operator certificate: If the feed factory involves special equipment (such as boilers), the relevant operators need to hold the corresponding certificates.

- Fire safety certificate: Ensure that the feed factory meets fire safety requirements.

- Technical Supervision Bureau filing certificate: Prove the legality of the enterprise and the quality of the product.

- Bank account opening license: Permission to open an account in a bank.

- Trademark registration certificate: Proof of trademark ownership.

- Safety production license: If the feed mill involves the production of hazardous chemicals, a safety production license is required.

- Conduct environmental assessment:

Before opening a fish feed mill, an environmental impact assessment is required to assess the possible impact of the fish feed processing line on the environment. This usually includes assessments of air, water, and soil, and is submitted to the local environmental protection department for review. - Site selection and construction:

Choose a suitable business site, register for a lease, or obtain a property certificate. Bring relevant documents to the government department to apply for a business license. After completing the business license application, apply for official seal approval and seal engraving, apply for an organization code certificate, tax registration, and pay the corresponding taxes and fees. - Equipment procurement and installation:

Find a suitable fish feed equipment manufacturer, who can carry out fish feed process design, equipment manufacturing, and project cases. Purchase necessary production equipment according to production needs, and install and debug it in accordance with specifications.

● RICHI MACHINERY

Service

Richi Machinery is always based on market trends and customer needs, constantly seeking changes and improving, timely innovation, and relying on standard floating fish feed processing line solutions, flexible and reasonable configuration of fish feed processing equipment, to achieve stable performance and mature customized design.

If you have any needs or questions about the construction of fish food processing line, please leave a message and we will reply to you as soon as possible after receiving it! You can also contact us directly via WhatsApp (+86 138 3838 9622)!

● Consulting

Customer Consultation

We want to have a deep understanding of your industrial process, to know your exact needs of feed, wood, biomass, fertilizer or other pellet processing.

● Design

fish feed line Design

Based on your unique situation and industrial process, we will tailor complete fish feed processing line you need, and inform you of every additional detail that could facilitate operation, minimize total cost.

● Manufacturing

Equipment Manufacturing

The critical components of the of the complete pellet production line equipment are built in our own workshops in Asia. Additional equipment is manufactured by our worldwide network of reliable partners.

● Testing

Quality Inspection & Testing

Before leaving the factory, all auqa feed mill equipment will be inspected by the quality inspection department. We can also provide customers with testing services from a single machine to a complete pellet plant system, and provide you with real actual data for “worry-free use.”

● Delivery

Equipment Delivery

In equipment boxing and packaging, we adopt professional packaging and modular solutions to ensure the safe and non-destructive delivery of fish feed plant equipment.

● Installation

Installation & Commissioning

Whether you choose your own subcontractor for the erection phase or you want to install everything together with us, a Richi supervisor will be around to make sure everything is mounted in a safe and thorough way.

● Training

Staff Training

We provide comprehensive training for the technicians of each fish feed processing line project. We can also continue to provide support for the technicians during latter project operation.

● After-sales

Project Follow-Up

When everything is up and running our Richiers will help you further whenever needed. We are ready to answer your call 24/7.We’ll also visit you regularly to learn about your needs.

Fish feed ingredients and formulations

— Richi Machinery —

Fish feed raw materials usually include fish meal, soybean meal, corn, cottonseed meal, peanut cake, soybean cake, vegetable cake, minerals, vitamins, additives, etc.

The feed formula of extruded floating fish feed should be designed according to the nutritional needs of various fish species and the characteristics of fish feed processing line extruding. It should ensure that more than 20% of the starch raw materials are in the raw material ratio. The additives should be selected to withstand high temperature, especially vitamins, high-resistant varieties should be used or the dosage should be increased.

The ratio of raw materials, starch content and moisture content in the raw materials, extrusion temperature and pressure, and the rotation speed of the fish feed extruder machine all affect the quality of extrusion, especially the starch content and moisture content in the raw materials and the extrusion temperature. These factors should be comprehensively adjusted in fish food processing line to produce extruded floating feed with better quality.

Amberjack

catfish

Cod

Char

tilapia

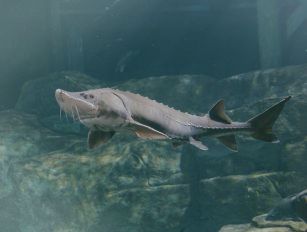

Sturgeon

Frequently Ask Question

FAQ of fish feed processing line

What is the grinding particle size and equipment required for fish feed processing line?

Generally, in the production of ordinary aquatic feed (such as carp, grass carp and silver carp, etc.), the particle size of raw materials before pelleting is 40-60 mesh, but when producing special aquatic feed (such as shrimp, eel, soft-shelled turtle, etc.), before pelleting, the crushing particle size of raw materials must reach 80 mesh or more.

The pulverized particle size of the raw material determines the surface area of the feed composition. The finer the particle size, the larger the surface area. It has a strong ability to absorb water in steam before extrusion, which is beneficial to conditioning and extruded pellet forming, so that the pellets have good water stability, and at the same time prolong the residence time of feed in aquatic animals.

In order to achieve the ideal crushing particle size, the common hammer mill used in the past is difficult to adapt to the crushing particle size required for the production of fish feed. Therefore, it is required to choose better crushing equipment. At present, the popular “drop-type” hammer mill pulverizer at home and abroad uses a unique design idea.

One fish feed pulverizer can form two kinds of hammer-screen gaps, which are suitable for ordinary pulverization and fine pulverization respectively. According to the requirements of fish feed production, the power consumption per ton of feed is low, which can reduce the fish feed processing line production cost.

If special aquatic feeds such as prawns, eels, soft-shelled turtles, and crabs are produced, the crushing particle size is required to be finer. In the past, the micro-grinding of aquatic feeds often used a secondary grinding process, that is, coarse grinding and then micro-grinding. The second-step micro-grinding generally used a micro-grinder and a micro-classifier to achieve the required grinding particle size.

This fish feed processing line process occupies a large area, and the size of the crushing size needs to be achieved by replacing the sieve plates with different apertures and adjusting the air volume of the system, and it is easy to cause the temperature of the crushed material to rise sharply, the nutrients are destroyed, and the phenomenon of sieve blocking often occurs, resulting in equipment wear and high energy consumption and other issues.

If a sieveless pulverizer can be used, the influence of the sieve plate can be eliminated, and the pulverizer with its own classifier can be omitted. The return material treatment has low material temperature, low power consumption, high output, and the thickness can be adjusted according to needs, there is no need to separately support the micro-classification machine.

Vertical shaft micro-grinder is a micro-grinding equipment that integrates grinding, screening and separation, which can meet the requirements of grinding particle size for producing special aquatic feed.

Since the crushing chamber and the grading chamber are located in the same body, the equipment can simultaneously complete the processes of crushing, air screening, separation and re-crushing, which can effectively prevent over crushing.

Built-in high-precision micron-level wind classification, the crushing particle size can reach 60-200 mesh, and can be adjusted arbitrarily as needed. The temperature rise of the crushed material is low, especially suitable for the crushing of heat-sensitive materials.

The whole fish feed processing line process has compact structure, small footprint, low power consumption per ton of material, uniform particle size and high output after crushing. It is an ideal micro-grinding equipment for producing special aquatic feed.

What are the characteristics of the mixing process of the fish feed processing line and what equipment is needed?

In addition to the raw material particle size requirements for aquatic feed, attention should also be paid to the selection of mixing process and feed mixing machine, because the performance of the mixer and the effect of use directly affect the production efficiency and product quality of the fish feed processing line. Most of the aquatic feed processing adopts the secondary mixing process.

Since the second crushing is carried out after batching and mixing, and the crushed materials are conveyed by wind (or other conveying methods), the possibility of classification of the materials increases, so the materials are granulated. Mixing should be added again before, and trace additives or liquid additives should be added during the second mixing.

In order to ensure product quality, the CV value of the coefficient of variation of the mixing uniformity of the powder before extrusion should be less than 7%.

In general, a horizontal ribbon mixer can be used for the first mixing, and a double-shaft paddle high-efficiency mixer must be used for the second mixing. The mixing uniformity coefficient of variation CV of the mixer is less than or equal to 5%.

In order to ensure that the mixing time does not exceed the pulverizing time, and can be equal to or similar to the batching cycle of the batching scale, the selected fish feed mixer machine is required to mix the materials evenly in a relatively short period of time.

The double-shaft paddle high-efficiency mixer uses a new mixing mechanism to achieve the required mixing uniformity. The coefficient of variation of the mixing uniformity is CV≤5%, and the best can reach 3%. The mixing time of each batch is 30-120s, which is significantly shortened. Mixing cycles to improve production efficiency.

The mixing process of the equipment is mild, without segregation, and the material is discharged quickly and without residue. The machine is equipped with a liquid addition tube, which can add oil and other liquids.

What are the characteristics of the extrusion process of the fish feed processing line and what equipment is needed?

Feed extruding technology is mainly used in the production of aquatic floating fish feed, pet feed and other animal feed.

The conversion rate of extruded feed is higher than that of pelleted feed, mainly because the raw materials are processed at high temperature and high pressure in the extrusion process, starch gelatinization and protein denaturation are more sufficient, which can effectively prevent animal digestive tract diseases and improve the digestion and absorption of feeding animals. Generally, it can improve the digestion and absorption rate by 10% to 35%.

The feed extruding technology of floating fish feed processing line has strong applicability and is not only suitable for extruding materials with high starch and fat content, but also can extrude a wider range of feed resources.

It is precisely because of the advantages of puffing that more and more floating fish feed production lines have begun to apply them to the processing of special aquatic feeds, pet feeds and other animal feeds. In many countries, it has been used on a large scale, and it will definitely become a major development direction of the entire feed industry.

At present, the extruder selected by the fish feed line is mainly a twin-screw extruder. The floating fish feed extruder machine consists of a feeding system, a transmission system, an extrusion and kneading system, a discharging die and an electric control system.

Since puffing has many advantages, the application of puffing technology in fish feed processing line has gradually increased, and will be favored by more feed manufacturers. The extruding process can be used to produce floating, sinking, slow sinking or semi-moist aquafeed on demand.

The feed is processed by extrusion, which reduces bacterial content and improves storage stability. To produce high-quality feeds required by the majority of farmers, especially aquatic feeds and special feeds of different varieties, each floating fish feed processing unit and floating fish feed enterprise should choose the appropriate fish food processing machine according to its own product requirements.

Who we are

RICHI Machinery is one of the world’s leading suppliers of technology and services for the animal feed, aqua feed and pet food industries, also the largest pellet production line manufacturer in China.

Since 1995, RICHI’s vision to build a first-class enterprise, to foster first-class employees, and to make first-class contributions to society has never wavered.

In the past three decades, we have expanded our business to a wide range of areas, including animal feed mill equipment, aqua feed equipment, pet feed equipment, biomass pellet equipment, fertilizer equipment, cat litter equipment, municipal solid waste pellets equipment, etc.

1995

RICHI Established

2000+

Serving More Than 2000 Customers

120+

RICHI Employees

140+

Exported To 140 Countries