BIOMASS WOOD PELLET MACHINE

Overview & Global Applications

The biomass wood pellet machine is a versatile core equipment for transforming various raw materials into uniform, high-density pellets. Its primary uses span across creating fuel for energy, feed for animals, and specialized pellets for industrial and environmental solutions. It is essential for farmers, forestry managers, recycling facilities, and entrepreneurs in the renewable energy and circular economy sectors.

Our pellet machines are proven worldwide, serving diverse industries from biomass power generation and animal husbandry to waste recycling and soil remediation. Whether the goal is to produce fuel, feed, organic fertilizer, cat litter, or advanced materials like biochar and RDF pellets, our technology delivers.

Romania Project

Processing local timber residues into premium wood pellets for heating. It showcases efficient use of European forest resources.

Malaysia Project

Utilizing empty fruit bunches and palm kernel shells from palm oil mills. This turns agricultural waste into valuable biomass fuel.

Argentina Project

Producing nutritious animal feed from alfalfa grass. This line supports Argentina’s large-scale livestock and dairy farming.

Bangladesh Project

Converting rice straw and husk into clean-burning fuel pellets. It addresses crop residue management and provides local energy.

Vast Raw Material Compatibility

Our biomass wood pellet machine is engineered for remarkable flexibility. It processes a comprehensive range of materials, from common agricultural residues to more specialized industrial byproducts. The core raw materials include various agricultural & forestry wastes (straw, sawdust, EFB), industrial & municipal wastes (RDF, sludge, paper), energy crops, and even select inorganic materials like bentonite for binding. These inputs come from farms, forests, factories, processing plants, and urban centers worldwide.

Whether your primary material is a single type or a mixture of two or more, our machine handles it efficiently. You can combine, for example, rice husk with wood chips, or blend paper sludge with agricultural waste to create customized pellets. This versatility ensures that virtually any organic feedstock and many inorganic additives can be transformed into high-value, dense pellets.

Process Almost Any Material Into Pellets

The finished pellets serve countless purposes, from renewable fuel and animal bedding to soil enhancers and industrial adsorbents.

The pellets produced serve a multitude of purposes across different industries. Depending on the raw materials used, they become clean fuel for heating or power generation, nutritious animal feed, effective soil amendments, or specialized industrial pellets for adsorption and environmental remediation.

Have specific raw materials? Our experts will tailor a solution for you.

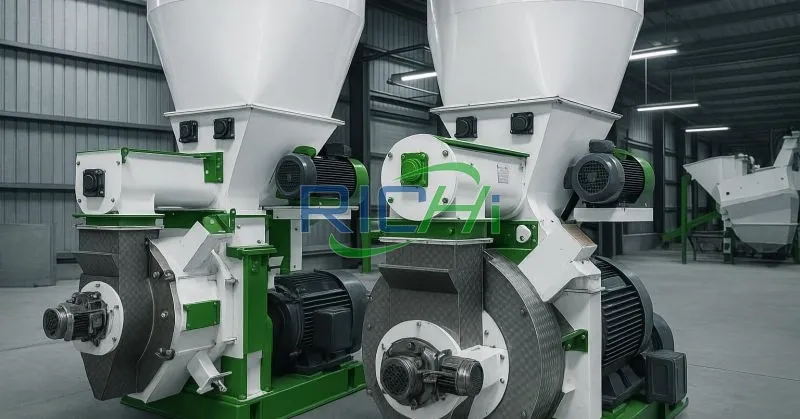

Superior Components & Engineering

The performance of a biomass wood pellet machine is defined by its core components. The MZLH768 is built with premium parts and intelligent design, ensuring high output, durability, and smooth operation for processing diverse biomass materials into quality pellets.

How It Works & Key Advantages

Watch Our Biomass Pellet Machine Video

The biomass wood pellet machine utilizes continuous extrusion molding technology. Material is fed into the chamber where powerful rollers force it through a hardened ring die, creating dense, uniform pellets without the need for additives. die, forcing biomass material through the die holes where it is cut into uniform pellets by an adjustable cutter.

Superior Pellet Quality & Environmental Benefit

Our machines produce high-density, high-strength pellets that meet premium standards. Crucially, the process requires no added binders; the natural lignin in the biomass acts as the sole adhesive, ensuring a clean, sustainable biofuel pellet.

Robust Construction for Maximum Durability

Built with wear-resistant and high-temperature resistant materials in key areas, our bio pellet machine is designed for longevity. This robust construction ensures consistent performance and reduces long-term maintenance costs, even under continuous, heavy-duty operation.

High Output with Remarkable Efficiency

Engineered for productivity, this biomass wood pellet machine delivers impressive output rates. This high efficiency, combined with a compact and stable design, translates into a lower operational cost per ton, ensuring a faster return on your investment.

Exceptional Return on Investment (ROI)

We design solutions for profitability. Clients typically see a cost recovery on the machine in 1-3 months, with full project investment often recouped within a year. Our efficient biofuel pellet machine is engineered to be a reliable profit center for your operation.

Certified Quality & Comprehensive Support

Every bio pellet machine undergoes strict testing and holds international certifications like ISO and CE. We back our quality with a full one-year warranty, professional installation guidance, operator training, and lifelong technical support for complete peace of mind.

Flexible Customization & Tailored Solutions

We understand every biomass pellet project is unique. Our experts provide complete customization, tailoring the biomass wood pellet machine configuration based on your specific raw materials, desired output (3.0-8.0 t/h), finished pellet size, and plant layout for optimal results.

Technical Specifications

Below are the detailed specifications for the MZLH768 biomass wood pellet machine. This data will help you evaluate the machine’s capacity and power requirements for your specific production plans.

Capacity

3.0-8.0T/H

Main Motor Power

315KW

Forced Feeder Power

1.5KW

Broken Arch Feeder Power

4KW

Ring Die Diameter

762mm

Finished Pellet Diameter

4~12mm

Ring Die Material

42CrMo

Door of Pelleting Room

6mm /SUS304

Gear Box

HT250

Gear/Gear Shaft/Spindle

42CrMo

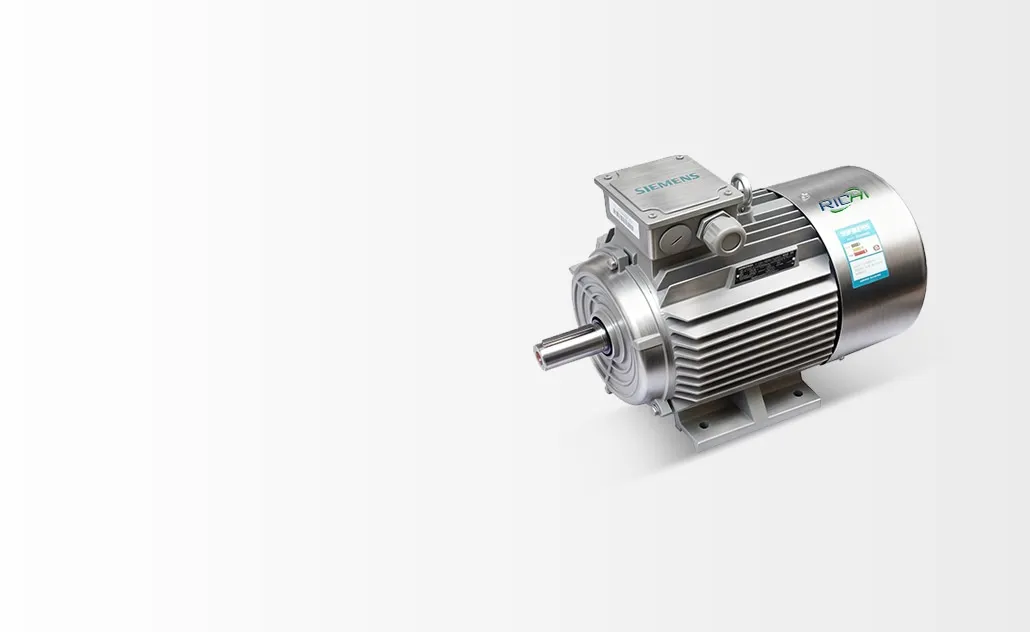

Main motor series

8P

Forced feeding

Worm gear reducer

Motor

Siemens

Oil seal

Germany/Taiwan

Overload mechanical protection

safety pin

Lubrication system

automatic oil injection

Explore More Models for Your Capacity

Our range of biomass wood pellet machines offers capacities from 0.2 to 8 t/h, providing the perfect match for projects of all scales—from pilot plants and farms to large industrial facilities. The right model for you depends on your specific raw material type, formulation, and final pellet application. To determine your precise output, share your material details and goals with our engineers.

Beyond the MZLH768, we offer five other proven models. For production needs exceeding 8 t/h, we design efficient multi-machine lines.

Key Factors for Perfect biomass Pellet Quality

Achieving optimal results with a biomass wood pellet machine depends on mastering several critical process variables. Different raw materials behave uniquely under pressure and heat. Our expertise, drawn from hundreds of global projects, allows us to guide you in fine-tuning these parameters for your specific feedstock and pellet application.

The core challenge in pelleting is balancing material properties with machine settings. A one-size-fits-all approach does not work. Success hinges on adjusting the process to the unique characteristics of your biomass.

Raw Material

Particle Size

Feedstock

Moisture Content

Pelletizing

Temperature

Ring Die

Compression Ratio

Every project has its unique formula. These factors are interconnected; changing one affects the others. The true test of a equipment supplier is not just selling a machine, but providing the process knowledge to make it perform. Share your material details with us, and we’ll provide data-driven recommendations to optimize your entire production line.

Proven biomass Pellet Projects

biomass wood pellet machine in Kenya

A cooperative of coffee and macadamia farmers needed to manage growing volumes of processing waste. Our compact, efficient biomass wood pellet machine line converts coffee husks and macadamia shells into clean-burning cooking fuel pellets.

biomass wood pellet machine in Russia

A large agricultural processor in Southern Russia sought to utilize sunflower seed hulls from its oil extraction plant. We engineered a heavy-duty pelleting line that handles this voluminous byproduct, producing solid biofuel for their own processing facility’s thermal needs.

Poland

biomass wood pellet machine in Poland

Raw materials : Wood Chips, Sawdust

A large sawmill partnered with us to utilize its excess wood chips and sawdust, aiming to create a new revenue stream while achieving zero wood waste.

Get Quote

Germany

biomass wood pellet machine in Germany

Raw materials : Beech/Oak Wood Waste

Our precision-engineered biomass wood pellet machine processes local beech and oak wood waste into high-density pellets that meet stringent DINplus certification standards.

Customize

Mexico

biomass wood pellet machine in Mexico

Raw materials : Agave Bagasse, Corn Stover

An agribusiness in Jalisco aimed to solve the disposal problem of agave bagasse left over from tequila production. We designed a robust system to process this fibrous material mixed with corn stover, producing biomass fuel pellets for local industrial boilers and creating value from waste.

Get A Plan

Thailand

biomass wood pellet machine in Thailand

Raw materials : Rice Husk

A Thai investor capitalized on the abundant rice husk from local mills to address regional energy costs. We provided a complete plant that processes this challenging, abrasive material into uniform pellets.

Start Project

A one-size-fits-all approach doesn’t work in biomass processing. Different materials have unique properties that require tailored engineering. Beyond our standard high-output biomass wood pellet machine, we offer specialized solutions optimized for specific feedstocks to ensure maximum efficiency, quality, and durability for your business. Selecting the right equipment is the first step to a profitable operation. Explore our range of machines engineered for particular materials.

Specialized biomass wood Pelletizing Solutions

Featured Pellet Machine Types

Looking for equipment for other materials? We provide dedicated solutions for all categories of agricultural waste, industrial by-products, and municipal solid waste.

husk pellet machine

Forestry/Agricultural/Industrial/Urban Waste Pelletizer

Investing in biomass processing requires clear and realistic financial planning. The total project cost depends on your specific materials, desired output, and plant configuration. Below, we address the most common questions about equipment and production line pricing to help you build an accurate budget.

What is the price of the MZLH768 biomass wood pellet machine?

+

The MZLH768 model, with a 3.0-8.0 T/H capacity, has an FOB price range of approximately $75,000 – $85,000. This base price typically includes the pelletizer with a 315KW motor, anti-bridging feeder, forced feeder, and a control cabinet. The final biomass wood pellet machine cost can vary slightly based on chosen optional accessories or specific electrical configurations.

Other models offer different capacities and price points to match various project scales:

- MZLH320 (22KW): 1.5-2.5 T/H | $15,000 – $18,000

- MZLH350 (37KW): 0.3-1.2 T/H | $18,000 – $25,000

- MZLH420 (90KW): 2.0-3.0 T/H | $26,000 – $32,000

- MZLH520 (132KW): 1.5-3.0 T/H | $43,000 – $50,000

- MZLH678 (200KW): 2.5-5.0 T/H | $64,000 – $70,000

How much does a complete biomass wood pellet plant cost?

+

A complete plant investment is significantly more than a single machine. The total biomass wood pellet plant cost varies greatly based on required pre-processing steps (like crushing and drying) and your raw material’s condition (moisture, shape, size). As a reference, here are typical FOB investment ranges for complete production lines:

- 0.2-0.3 T/H: $20,000 – $140,000

- 1.0-1.2 T/H: $39,000 – $220,000

- 2.5-3.0 T/H: $78,000 – $350,000

- 5.0-6.0 T/H: $160,000 – $570,000

- 6.0-8.0 T/H: $190,000 – $690,000

- 10-12 T/H: $280,000 – $1,100,000

- …

What factors cause the wide price range for a complete plant?

+

The final cost is not determined by capacity alone. Two key factors create this range:

- Raw Material Characteristics: High moisture content requires a dryer; large logs need a powerful crusher. Each pre-processing step adds equipment and cost.

- Automation & Quality Level: A basic manual line costs less than one with full automation, advanced cooling, screening, and packing systems. We tailor the design to your exact budget and quality goals.

Do you have local agents or distributors?

+

No, we do not work through third-party agents or distributors. All our biomass wood pellet machines and complete plants are manufactured in our own factory. This direct-to-client model ensures you receive the best possible price, consistent quality control, and direct technical support from our engineering team. Equipment is shipped directly from our factory.

Can you provide a firm quotation without detailed project information?

+

We cannot provide an accurate fixed quote without understanding your project specifics. A meaningful quotation requires details about your raw material type, initial moisture content and size, desired final pellet specification, and target hourly output. With this information, we can engineer a cost-effective solution that truly fits your needs and avoids unnecessary expense.

Understanding Your Investment

Complete Turnkey Pellet Plant Solutions

We provide full-scale engineering support for biomass pellet plants of every size, from compact 0.2 T/H setups to large industrial complexes exceeding 10 T/H. Our approach moves beyond simply selling a biomass wood pellet machine; we design, manufacture, and commission the complete system around your specific material, space, and budget.

A standard process involves raw material preparation (cleaning, crushing, drying), pelleting, cooling, screening, and packing. However, your real-world needs—material type, local regulations, available space—determine the final layout. We integrate additional stages like blending, impurity removal, dust control, and silo storage to create your ideal production flow.

Biomass Pellet Mill

Find Your Capacity Solution

Select your target output range to explore typical plant layouts and configurations designed for that production scale.

Material-Specific Plant Engineering

Processing different types of biomass requires specialized engineering. A solution optimized for wood waste will not perform efficiently for straw or husks. We design your complete pellet line around your specific raw material’s characteristics—its size, moisture, abrasiveness, and fiber content—to ensure optimal efficiency, pellet quality, and equipment longevity.

Wood Pellet Production Line

Our systems for processing clean wood chips, sawdust, and shavings are engineered for high durability and continuous output. The design focuses on efficient size reduction and robust pelleting to produce premium-grade fuel pellets, often incorporating advanced drying when needed.

Sawdust

Wood Chips

Forest Thinnings

Pallets

Wood Shavings

Bark

Straw Pellet Production Line

Straw is bulky and requires significant compaction. We design lines with heavy-duty shredders, high-capacity dryers, and our most forceful biomass wood pellet machine configurations to transform rice, wheat, or corn straw into solid fuel pellets.

Wheat Straw

Rice Straw

Corn Stalk

Cotton Stalk

Barley Straw

Oat Straw

Husk Pellet Production Line

Abrasive materials like rice husk or coconut shell demand wear-resistant components. Our plants are built with hardened surfaces in key areas and are often paired with specific hammer mill designs to handle these tough feedstocks efficiently.

Grass Pellet Production Line

Processing fibrous and low-density materials like alfalfa or grass requires specialized feeding and conditioning. Our solutions include powerful fine-grinding and precise moisture control to produce dense, durable pellets ideal for feed or fuel markets.

Agricultural Waste Pellet Line

This category covers diverse farm byproducts. We provide flexible, modular designs that can be adapted to process mixed or seasonal agricultural wastes, often incorporating pre-cleaning and versatile conditioning systems.

Industrial & Municipal Waste Pellet Line

For non-traditional materials like RDF, sludge, or paper waste, we engineer complete systems with critical pre-processing stages. This includes shredding, sorting, drying, and sometimes additive dosing to produce consistent fuel or industrial pellets.e fuel production.

Expert Answers to Your biomass Pellet Production Questions

You have questions, we have real-world solutions. Based on thousands of biomass pellet projects, we’ve compiled answers to the most common technical, operational, and business questions about setting up and running a successful pellet production line.

Can your biomass wood pellet machine handle 100% pine sawdust with 50% moisture?

+

Yes, but it requires a complete system approach. A biomass wood pellet machine cannot process material with 50% moisture directly. For such wet pine sawdust, you would need a robust drying system upstream to reduce moisture to the optimal 12-18% range before pelleting.

Our engineers would design a line integrating a high-capacity drum dryer, ensuring the dried sawdust is consistently fed into our heavy-duty MZLH series pellet mill. This ensures stable pellet formation and prevents damage to the ring die and rollers from steam pressure and poor compaction.

What is the best machine for rice husk and straw mixed 50/50 for a 2 t/h plant?

+

For a 2 t/h plant processing a 50/50 mix of abrasive rice husk and fibrous straw, we recommend the MZLH520 or MZLH678 model, depending on your exact material preparation. This mix requires a machine with strong torque and a wear-resistant ring die.

The MZLH520 (132KW) is an excellent choice for 1.5-3.0 T/H capacity. We would specify a ring die with a suitable compression ratio and material (e.g., high-chrome alloy) to handle the abrasiveness of the husk while effectively compacting the straw. A preconditioning step to add slight moisture/steam can greatly improve the binding of the straw fibers.

Do I need a special die for making 10mm diameter fuel pellets from oak wood chips?

+

Yes, producing high-quality 10mm pellets from dense hardwood like oak requires a specially configured ring die. The die would have 10mm holes with a specific compression ratio (length-to-diameter ratio) calculated to create enough friction and pressure to properly soften the oak’s lignin and form a durable pellet.

Using a standard die for softer woods would likely produce crumbly pellets from oak. Our technical team will determine the optimal die specification based on your oak chip particle size and moisture content to ensure high output and pellet integrity.

We have almond shells and olive pits. Can one line process both?

+

Absolutely, but with careful system design. Both are extremely hard and abrasive. A single production line can be designed to process them, either separately or in a blend.

The key is the preparation stage: a heavy-duty hammer mill with replaceable, hardened hammers and screens is essential to reduce them to a consistent, small particle size (e.g., below 3mm).

The core biomass wood pellet machine, such as the MZLH768, must be equipped with a super-hardened ring die (like a stainless steel or high-chrome alloy) and matching rollers. The same line can process both by adjusting the mill screen size and potentially the die specification for optimal results with each material.

What pre-treatment is needed for wet coffee husks before pelleting??

+

Wet coffee husks require drying and fine grinding.

Fresh coffee husks have high moisture. The first step is drying them down to 12-15% moisture using a rotary dryer. After drying, they become brittle but still fibrous. A secondary fine grinding step using a hammer mill with a small screen (e.g., 2-3mm) is crucial to break down the fibers and create a uniform powder.

This fine, dry material will then pelletize efficiently in a biomass wood pellet machine, producing dense, high-energy fuel pellets. We design complete lines that integrate drying, grinding, and pelleting seamlessly for coffee processing waste.

How fine should we grind bamboo for optimal pellet durability?

+

For optimal bamboo pellet durability, the material should be ground to a particle size where most of it passes through a 3-4mm screen, with a good distribution of finer particles.

Bamboo is fibrous, so fine grinding is essential to break the long fibers, allowing for better interlocking and binding during the compression in the biomass wood pellet machine. Too coarse, and the pellets will be weak and prone to breaking.

Our recommended process uses a two-stage size reduction: a chipper followed by a hammer mill with the appropriate screen to achieve this ideal particle size distribution for strong pellets.

Can your system process municipal green waste (leaves, branches) into fuel pellets?

+

Yes, we provide complete systems for processing municipal green waste (MGV) into RDF (Refuse-Derived Fuel) or SRF (Solid Recovered Fuel) pellets.

The process is more complex than clean wood. It requires robust pre-processing: primary shredding, magnetic separation to remove metals, often screening to remove fines or sand, and efficient drying due to high moisture.

The prepared, cleaned material is then fed into a heavy-duty biomass wood pellet machine like the MZLH768. We engineer these lines with durability and contamination tolerance in mind, ensuring reliable operation with heterogeneous feedstock.

What’s the minimum moisture for pelleting wheat straw without a dryer?

+

You can typically pellet wheat straw without an active dryer if its natural moisture content is between 12% and 16%. Straw below 10% moisture becomes too dry and brittle, leading to poor binding and excessive dust. If your straw is harvested and stored under cover, it may naturally fall within this range.

However, for consistent year-round production, integrating a dryer provides control. Our engineers can assess your specific straw supply chain. If moisture is consistently suitable, we can design a line focusing on fine grinding and effective conditioning to optimize the natural moisture for the biomass wood pellet machine.

Do you have a solution for making 6mm cat litter pellets from bentonite and sawdust?

+

Yes, we have specialized solutions for composite pellets like cat litter. A mixture of bentonite (clay) and sawdust requires precise proportioning and mixing.

We would design a cat litter production line with a weigh-batching system, a paddle mixer to homogeneously blend the dry materials, and potentially a small conditioner to add a precise amount of moisture or binding agent.

The blend is then fed into a biomass wood pellet machine fitted with a 6mm ring die. The key is balancing the recipe and the die’s compression ratio to produce pellets that are firm yet highly absorbent and have low dust. We offer complete plant designs for such specialized products.

How does the process change for making animal feed pellets (alfalfa) vs. fuel pellets?

+

The core pelleting principle is similar, but critical differences exist. For animal feed pellets (e.g., alfalfa):

1) Conditioning is Vital: A high-shear conditioner adds precise steam to cook the starch/proteins, improving digestibility and binding.

2) Die Specification: Dies for feed often have a different compression ratio optimized for nutritional quality over pure density.

3) Post-Processing: Feed pellets require faster, more gentle cooling to prevent nutrient degradation and often a coating system.

4) Hygiene Standards: Equipment design considers easier cleaning. For fuel pellets, conditioning is simpler (often just moisture adjustment), and the focus is on density and durability.

Our engineering team tailors the entire line design—from grinding to cooling—based on the pellet’s end use.

What capacity machine do I need for 500 tons of wood chips per month?

+

To process 500 tons per month, we assume about 20 operating days per month, which is 25 tons per day. For an 8-hour shift, that’s approximately 3.1 tons per hour. For a 16-hour shift, it’s about 1.55 tons per hour.

Considering efficiency and downtime, we would recommend a biomass wood pellet machine with a capacity of 3-4 T/H for single-shift operation (e.g., MZLH678 or MZLH768) or a 1.5-2.5 T/H machine (e.g., MZLH420 or MZLH520) for double-shift operation.

The final choice depends on your chip moisture, species, and desired pellet quality. A Richi Machinery engineer can provide a precise recommendation based on your specific parameters.

Can we make pellets from 100% shredded paper and cardboard?

+

Yes, 100% shredded paper and cardboard can be pelletized into excellent fuel pellets. The key challenges are low bulk density and potential for high ash content (from inks, coatings). The process requires a powerful shredder/coarse grinder first, followed by a fine hammer mill to create a fluffy material.

A densification feeder may be needed before the pellet mill. The biomass wood pellet machine must generate significant pressure to compress the material; models like the MZLH520 or MZLH678 are well-suited. The natural lignin in paper acts as a binder when heated by friction. The resulting pellets have high calorific value and are ideal for industrial boilers or RDF applications.

Is a conditioner needed for making hay pellets for horses?

+

For high-quality, durable hay pellets for horses (feed grade), a conditioner is highly recommended and often essential. Steam conditioning accomplishes several things: it softens the tough hay fibers, partially gelatinizes starches (if any grains are present), increases moisture uniformly, and kills potential pathogens and mold spores.

This results in pellets that are more digestible for the horse, have a longer shelf life, and are much harder and less prone to crumbling during handling and transport. A standard biomass wood pellet machine can be paired with an appropriate feed-grade conditioner in our complete plant design.

What is the expected pellet output using 100% sunflower hulls?

+

The output using 100% sunflower hulls in a given biomass wood pellet machine will be slightly lower than with clean wood sawdust due to their abrasive nature and lower natural binding properties.

For example, our MZLH768, which can produce 3-8 T/H with wood, might achieve 3-6 T/H with sunflower hulls, depending on their moisture content and fineness.

To maximize output, the hulls must be finely ground and have optimal moisture (12-15%). We select a ring die with a compression ratio tailored for oilseed shells to ensure good pellet quality without excessively slowing down production or causing undue wear.

How do we adjust the process for very abrasive materials like palm kernel shell (PKS)?

+

Processing highly abrasive materials like PKS requires adjustments focused on wear resistance and preparation.

1) Grinding: Use a hammer mill with tungsten carbide-tipped hammers and hardened screens.

2) Pellet Mill Components: The biomass wood pellet machine must be fitted with a ring die and pressure rollers made from the most wear-resistant alloys available (e.g., high-chrome steel).

3) Die Specification: A slightly lower compression ratio can sometimes help reduce extreme friction and wear, while still making a good pellet.

4) Maintenance Plan: Factor in more frequent inspection and replacement of wear parts.

Our proposals for PKS lines always highlight these specialized, durable components.

Can your biomass wood pellet machine in Vietnam handle acacia wood with high sap content?

+

Yes, our biomass wood pellet machines supplied to Vietnam and other regions are well-suited for acacia wood, which often has higher sap/resin content. The sap can act as a natural binder, which is beneficial. However, it can also cause material to stick in the feeder or die if not managed.

We address this by ensuring our forced feeder system is designed to handle slightly sticky materials and by selecting a ring die with an appropriate hole pattern and surface finish to promote smooth release. Proper drying of the acacia to around 12% moisture is also critical to control the sap’s behavior during pelleting.

What’s the recommended compression ratio for softwood vs. hardwood?

+

As a general rule, softwoods (like pine, fir) require a higher compression ratio die than hardwoods (like oak, maple). Softwoods are less dense and have longer fibers, so they need more compression length within the die hole to create enough friction and heat to melt the lignin and form a firm pellet.

Hardwoods are denser and can form pellets under slightly less compression. For example, pine might need a compression ratio of 1:6 to 1:8, while oak might work well with 1:5 to 1:7. At Richi Machinery, we test your specific material sample to recommend the precise ring die specification for your biomass wood pellet machine.

Is a hammer mill or crusher better for preparing vineyard prunings?

+

For vineyard prunings, which are stringy and fibrous, a two-stage process is often best.

- First, a wood crusher or chipper is used for primary size reduction, breaking the long branches into smaller chips (20-30mm).

- Then, a hammer mill is essential for secondary fine grinding to reduce the chips to the optimal 3-6mm size for pelleting. The hammer mill’s beating action is effective at breaking apart the fibrous structure.

Using only a crusher may not achieve fine enough particles, leading to poor pellet quality. Our plant designs often include both a crusher and a hammer mill in series for such fibrous biomass.

Can we produce 8mm pellets from a mix of sawdust and rice husk?

+

Yes, producing 8mm pellets from a sawdust and rice husk mix is very feasible. You will need a biomass wood pellet machine fitted with an 8mm ring die. The die’s compression ratio must be chosen to balance the binding properties of the sawdust with the abrasive, less cohesive nature of the rice husk.

A uniform mix and consistent particle size (both materials finely ground) are crucial. The rice husk content will increase wear on the die and rollers, so we recommend specifying wear-resistant alloy parts for such applications to maintain productivity and pellet quality over time.

How much does particle size of corn stover affect the final pellet quality?s?

+

Particle size of corn stover dramatically affects final pellet quality. If the stover particles are too large (>6mm), the pellets will be weak, have a rough surface, and may break apart easily due to poor interlocking.

If ground too fine into almost dust (<1mm), it can be difficult to feed consistently into the die and may require more binding agent. The ideal is a graded mix, with most particles between 1mm and 4mm.

This allows smaller particles to fill the voids between larger ones, creating a dense, solid pellet in the biomass wood pellet machine. Proper grinding is the single most important pre-processing step for corn stover.

What auxiliary equipment is essential for a 5 t/h wood pellet line?

+

A complete 5 T/H wood pellet line requires several essential auxiliary pieces beyond the core biomass wood pellet machine:

1) Hammer Mill: For grinding raw material to correct size.

2) Dryer: Likely a rotary drum dryer to reduce moisture to 12-15%.

3) Cyclone & Dust Collector: For material transfer and workshop air quality.

4) Bucket Elevators/Belt Conveyors: For material transport between machines.

5) Counterflow Cooler: To cool hot pellets after the mill.

6) Rotary Screener: To remove fines from finished pellets.

7) Storage Silos & Bins: For raw material and finished product buffer.

8) Electrical Control Cabinet: To coordinate the entire system.

Richi Machinery supplies all these components as a synchronized turnkey plant.

Can the line be designed to switch between making fuel pellets and feed pellets?

+

Designing a line to switch between fuel and feed pellets is complex but possible with significant upfront planning and investment. It requires a versatile conditioning system that can switch between steam addition for feed and simple moisture adjustment for fuel.

The biomass wood pellet machine itself can be the same, but you would need interchangeable ring dies with different compression ratios and hole sizes optimized for each product. The cooling, screening, and possibly bagging systems would need to handle different pellet characteristics.

Crucially, for feed production, the line must be designed to meet higher hygiene standards, with easy-clean surfaces. This is a highly customized project our engineers can explore with you.

How is the process different for producing RDF pellets from municipal waste?

+

Producing RDF pellets from municipal solid waste (MSW) involves extensive pre-processing not needed for clean biomass. Key differences:

1) Sorting & Shredding: MSW requires primary shredding, magnetic separation (for metals), and often air classification or screening to remove non-combustibles like glass, stones, and high-chlorine materials.

2) Secondary Shredding: Refined waste is shredded again to a uniform size.

3) Drying: Essential due to high and variable moisture.

4) Pelleting: The prepared RDF fluff is pelleted in a heavy-duty biomass wood pellet machine built to handle contaminants and varying material composition. The focus is on producing a consistent, marketable fuel from a highly variable feedstock.

What safety features are needed for processing dusty materials like bagasse?

+

Processing dusty materials like dry bagasse requires integrated safety features to prevent fire and dust explosions:

1) Dust Collection: A high-efficiency cyclone and bag filter system must be installed at every dust generation point (hammer mill, cooler, screener, transfer points).

2) Explosion Venting: Dust collectors and silos should have explosion vents or suppression systems.

3) Electrical Equipment: All motors, starters, and control cabinets should have a high protection rating (e.g., IP65) or be placed outside dusty areas.

4) Grounding: All equipment must be properly grounded to prevent static spark ignition.

5) Fire Detection: Thermal sensors in dryers and dust collectors. Our plant designs for dusty materials always prioritize these safety systems.

Do you offer solutions for integrating a boiler with the pellet line for internal heat use?

+

Yes, we offer integrated energy solutions. A very efficient setup is to use a biomass-fired boiler to generate the hot air for your raw material dryer and provide space heating for your plant. The fuel for the boiler can be your own production fines (screenings), low-quality feedstock, or a portion of your pellets.

We can design the thermal system, specifying the boiler and integrating the hot air ducting with the dryer. This significantly reduces your operational energy costs and creates a closed-loop, sustainable production model. Our engineering covers the entire process, including such energy integration optimizations.

How long does the ring die typically last when processing eucalyptus bark?

+

Eucalyptus bark is very abrasive due to its high silica content. The lifespan of a standard alloy ring die processing 100% eucalyptus bark could be as low as 300-400 hours.

However, by using our premium-grade, high-chrome or tungsten carbide alloy ring dies specifically designed for abrasive materials, you can extend this lifespan to 600-800 hours or more, depending on the bark’s purity and your machine maintenance.

Regular die rotation and using matched, high-quality rollers are also essential to maximize life. We provide specific wear-part recommendations for challenging materials like eucalyptus bark.

What is the power consumption for a 3 t/h line using mixed agricultural waste?

+

The total power consumption for a complete 3 T/H line processing mixed agricultural waste (straw, stalks, etc.) is typically in the range of 220-280 kW. This includes: the main biomass wood pellet machine motor (~132-160 kW for a MZLH520/678), the hammer mill (~55-75 kW), the dryer fan and burner system (~15-30 kW), conveyors, cooler, screener, and dust collectors (~20-40 kW).

The exact figure depends on the moisture content (drying load), the hardness of the waste, and the level of automation. Richi Machinery provides detailed power load lists with our proposals for accurate electrical planning.

Can your machine produce square or other shaped pellets?

+

Standard ring die biomass wood pellet machines produce cylindrical pellets. Producing square or other shaped briquettes (like hexagons) requires a different type of machine called a briquetting press or extruder, which uses molds to form the shape under high pressure.

While we specialize in ring die pellet machines, we can advise on briquetting technology for specific applications where shape is a market requirement. For most fuel and feed applications, the cylindrical pellet is the standard due to its excellent handling, burning, and storage characteristics.

What cooling method is best for high-capacity (10 t/h) wood pellet production?

+

For high-capacity lines (8-15 T/H), a vertical counterflow cooler is the industry standard and most efficient method. Pellets enter the top of a tall column and cool gradually as they descend against a stream of ambient air drawn upwards by a fan.

This design is space-efficient, provides uniform cooling, and minimizes pellet breakage compared to horizontal rotary coolers. It effectively reduces pellet temperature from 70-90°C out of the biomass wood pellet machine down to within 5-10°C of ambient temperature, stabilizing them for storage and preventing condensation in bags.

How do we control the density of the final pellet?

+

Pellet density is controlled by several interconnected factors in the biomass wood pellet machine process:

1) Raw Material: The inherent density of the biomass.

2) Particle Size: Finer grinding generally allows for higher compaction.

3) Moisture Content: Optimal moisture (12-18%) allows lignin to plasticize.

4) Die Specification: The compression ratio (L/D ratio) of the ring die is the primary mechanical control—a higher ratio creates denser pellets.

5) Die-to-Roller Gap: A properly adjusted, small gap ensures full pressure is applied.

6) Feed Rate: A consistent, optimal feed rate maintains steady pressure. Our process engineers help you balance these variables for your target density.

Is a silo and automated feeding system necessary for a 1 t/h plant?

+

For a 1 T/H plant, while not strictly “necessary,” a small raw material storage silo (e.g., 20-30 cubic meters) and an automated feeding system (screw conveyor from silo to hammer mill) are highly recommended investments.

They provide several benefits: buffer storage to ensure continuous operation even when raw material delivery is intermittent, reduced manual labor, more consistent feed rate to the hammer mill and dryer (which improves overall system stability), and better control over material flow into the biomass wood pellet machine.

They significantly improve the professionalism, efficiency, and reliability of even a small-scale operation.

What dust collection system do you recommend for a straw pelleting plant?

+

For a straw pelleting plant, we recommend a centralized dust collection system. This consists of dust hoods at all major emission points (hammer mill inlet/outlet, straw dryer discharge, cooler discharge, screener, transfer points), connected via ducting to a high-capacity pulse-jet baghouse filter.

Straw dust is very fine and combustible, so the filter should have explosion venting. The clean air is exhausted, and the collected dust can be automatically returned to the process (e.g., before the pellet mill) to maximize yield. Proper dust control is critical for operator health, safety, and equipment longevity in a straw plant.

Can the production line be fully automated from raw material intake to bagging?

+

Yes, we design and deliver fully automated biomass pellet plants.

Automation can include: raw material intake via conveyor from truck dump, automated batching and mixing, process control via PLC (Programmable Logic Controller) with touchscreen HMI, automatic adjustment of dryer temperature based on moisture sensors, synchronized speed control of all conveyors and the biomass wood pellet machine, and automated weighing and bagging (into big bags or 25kg sacks).

The level of automation is tailored to your budget and labor strategy, but we can provide solutions ranging from semi-automatic to fully lights-out production facilities.

What is the typical waste percentage (fines) after screening that can be recycled?

+

After screening, typically 3% to 8% of the total pellet production may be fines (broken pellets and dust). This percentage depends on pellet durability, handling, and the screener efficiency. The great news is that 100% of these fines can and should be recycled.

They are typically fed back into the process, either directly into the conditioner ahead of the biomass wood pellet machine or mixed with fresh raw material. Recycling fines improves overall yield, reduces waste, and because they are already dry and finely divided, they can actually improve the pelleting process. Our system designs always include fines recycling loops.

How do you prevent corrosion when processing materials with high chlorine content (like some straw)?

+

Materials with high chlorine (e.g., wheat straw from certain regions, MSW) can cause corrosion when combined with moisture, particularly in the dryer and exhaust systems. We combat this by:

1) Material Selection: Using stainless steel or special coatings for critical parts of the dryer, ducting, and cyclone contacting hot, wet gases.

2) Temperature Control: Operating the dryer at temperatures that minimize acid dew point corrosion.

3) Rapid Cooling & Drying: Quickly drying and cooling the pellets to minimize the time they release corrosive vapors.

4) Ventilation: Ensuring good general ventilation in the production hall. This is a key consideration in our corrosion-resistant plant designs.

What is the best way to add a binder (like starch) to the mix if needed?

+

The most effective way to add a dry powder binder like starch is via a continuous dosing system. This consists of a small storage hopper for the binder, a precision screw feeder (loss-in-weight feeder is best), and a injection point into a paddle mixer or conditioner before the biomass wood pellet machine.

The binder must be thoroughly and uniformly mixed with the biomass for it to be effective. For liquid binders, a precise metering pump and spray nozzle system are used. We integrate these dosing systems into our plant designs when binders are required for specific materials or to meet premium pellet quality standards.

Can your biomass wood pellet machine in Indonesia process a mix of EFB and wood waste?

+

Yes, our biomass wood pellet machines installed in Indonesia and elsewhere are excellent for processing mixes of Empty Fruit Bunch (EFB) fibers and wood waste. This is a common and logical mix. The wood waste provides density and natural binding lignin, while the EFB utilizes a major waste stream. The EFB must be shredded and dried thoroughly.

The mix ratio can be adjusted to optimize pellet quality and machine wear. A model like the MZLH768 is well-suited for such high-volume, industrial-scale production in the palm oil region, and we equip it with components to handle the abrasive nature of the EFB fibers.

How do we calculate the required dryer capacity based on our raw material’s initial moisture?

+

Dryer capacity is calculated based on the amount of water that needs to be evaporated per hour. The formula is: Evaporation (kg/h) = Throughput (kg/h) x [(Initial Moisture% – Final Moisture%) / (100 – Final Moisture%)].

For example, to dry 2000 kg/h of wet sawdust from 50% to 15% moisture: Evaporation = 2000 x [(50-15)/(100-15)] = 2000 x (35/85) ≈ 824 kg of water per hour.

You would then select a dryer (e.g., rotary drum) rated for at least 900-1000 kg/h evaporation to provide a safety margin. Our engineers perform this calculation as part of the complete system design for your biomass wood pellet plant.

What is the difference between a flat die and ring die machine for small-scale farm use?

+

For small-scale farm use (<500 kg/h), the choice is often between flat die and small ring die machines.

Flat Die:

The die is a flat disk with holes; rollers press material down through it.

- Pros: Simpler, cheaper, easier to maintain.

- Cons: Generally lower output, less durable for abrasive materials, pellet quality can be less consistent.

Small Ring Die:

The die is a rotating ring; stationary rollers press material outward through it.

- Pros: Higher efficiency, better pellet quality and durability, more suitable for continuous operation.

- Cons: Higher initial cost, slightly more complex maintenance.

For a serious farm operation aiming for consistent quality, a small ring die biomass wood pellet machine like our MZLH350 is often the better long-term investment.

Can you design a mobile or containerized pellet production unit?

+

Yes, we design and manufacture mobile and containerized pellet production units. These are ideal for demonstration, pilot projects, or processing biomass in remote locations.

Key components like the hammer mill, biomass wood pellet machine (e.g., MZLH420), cooler, and control system are integrated into one or two standard shipping containers or onto a heavy-duty trailer.

These units are pre-assembled and tested at our factory, requiring only basic utility connections on-site. They offer a quick-start, flexible solution for specific projects where a permanent building is not feasible or for testing feedstock viability before building a full-scale plant.

What are the key considerations for setting up a biomass wood pellet machine in Russia for sawmill waste?

+

Key considerations for Russia:

1) Climate: The plant building must be insulated, and equipment must be rated for low-temperature operation (e.g., proper hydraulic oils). Raw material storage must prevent freezing.

2) Raw Material: Abundant softwood (pine, spruce) sawmill waste is ideal. The process must handle potential bark content and variable moisture from snow/ice.

3) Power: Standard 380V/50Hz industrial power is available.

4) Market: Pellets are primarily for domestic heating and export to Europe. The biomass wood pellet machine and line must produce ENplus A1 quality pellets.

5) Service: We provide comprehensive documentation in Russian and have established spare parts logistics for the region to ensure reliable operation.

Are your machines suitable for the high-humidity conditions in a biomass wood pellet plant in Vietnam?

+

Yes, our machines are well-suited for high-humidity environments like Vietnam. We take specific measures:

1) Corrosion Protection: We use high-quality paints and, where necessary, stainless steel components on external surfaces and in critical areas prone to moisture.

2) Electrical Systems: All motors and control cabinets have a high IP (Ingress Protection) rating (e.g., IP55 or higher) to resist moisture and dust.

3) Process Design: We account for the ambient humidity in the drying system calculations, as it affects dryer efficiency.

4) Spare Parts: We advise on proper storage of spare parts (like dies and rollers) to prevent rust in the humid climate. Our installations in Southeast Asia are designed for these conditions.

Do you have local service support for a biomass wood pellet machine in Germany?

+

While Richi Machinery is based in China, we provide comprehensive direct service support for our biomass wood pellet machines in Germany and across Europe. This includes:

1) Remote Support: 24/7 technical support via email, phone, and video call.

2) On-Site Commissioning & Training: Our engineers travel to your site for installation supervision, commissioning, and operator training.

3) Spare Parts: We maintain a strategic stock of critical spare parts (rings dies, rollers, bearings) in a European warehouse for fast delivery, often within 3-5 working days.

4) Service Partners: We work with trusted local mechanical and electrical service companies for urgent on-site interventions if needed.

What is the typical feedstock used for projects with your biomass wood pellet equipment in Poland?

+

In Poland, the most common feedstocks for our biomass wood pellet equipment are:

1) Softwood Sawdust & Shavings: From the large furniture and timber industry, primarily pine and spruce.

2) Agricultural Straw: Wheat and rye straw, often used in larger industrial plants.

3) Miscanthus: An energy grass increasingly cultivated for biomass.

4) Sunflower Hulls: From the local oilseed industry.

5) Clean Post-Consumer Wood Waste.

The Polish market demands high-quality ENplus pellets, so our lines there are designed for precise drying, grinding, and pelleting to meet these strict standards consistently.

Can you supply a complete biomass wood pellet plant in Brazil for sugarcane bagasse?

+

Absolutely. Brazil is a key market for us, especially for sugarcane bagasse processing. We supply complete turnkey plants designed specifically for bagasse’s characteristics: high initial moisture, high fiber, and abrasiveness.

Our solution includes: high-capacity rotary dryers, specialized hammer mills for fibrous material, and robust biomass wood pellet machines like the MZLH768 fitted with wear-resistant dies. The pellets are used for industrial boiler fuel (often at the sugar mill itself) or for export.

We understand the local regulations and can manage the entire project from design to commissioning on the ground in Brazil.

What export documentation do you provide for shipping a biomass wood pellet machine to South Africa?

+

Shipping industrial equipment internationally requires precise documentation to ensure smooth customs clearance and compliance with both Chinese export and South African import regulations. At Richi Machinery, we handle this process professionally for every shipment.

When you purchase a biomass wood pellet machine or a complete plant destined for South Africa, we provide a comprehensive set of export documents, which typically includes:

1. Core Commercial & Shipping Documents:

- Commercial Invoice: A detailed invoice stating the accurate description of the goods (e.g., “MZLH768 Ring Die Biomass Pellet Machine”), unit prices, total value, and terms of trade (e.g., FOB Qingdao). This is the primary document for customs valuation.

- Packing List: A meticulous list specifying the contents of each crate or container, including dimensions, gross/net weights, and itemized components. This helps South African customs verify the shipment and is essential for freight handling.

- Bill of Lading (B/L) or Air Waybill: The original title document issued by the shipping carrier. It serves as a contract of carriage and a receipt of goods. We ensure it is correctly marked with consignee details and shipping instructions.

2. Certifications and Technical Documentation:

- Certificate of Origin (COO): We provide a standard Certificate of Origin, often issued by the Chamber of Commerce, declaring the country of manufacture as China. This document may be required for tariff assessment in South Africa.

- Technical Data Sheets & Detailed Equipment Manuals: These are provided in English and include specifications, electrical diagrams, installation guidelines, and parts lists for the biomass wood pellet machine and all ancillary equipment.

- Test and Inspection Reports: For major components, we can provide factory test reports for motors, gearboxes, etc. For complete plants, we often provide a pre-shipment inspection report and photos/videos of the assembled line undergoing a factory acceptance test (FAT).

- Declaration of Conformity: We provide a manufacturer’s declaration stating that the biomass wood pellet machine and its electrical control systems are manufactured according to relevant safety standards.

3. Support for South African Specific Requirements:

- While we ensure our core documentation is robust, specific South African regulatory requirements (such as a possible Letter of Authority (LOA) for certain electrical components) are typically managed by the importer or their appointed clearing agent, as they have the local accreditation. However, we provide all necessary underlying manufacturer’s data and test certificates to support your agent in obtaining these local approvals.

- We are experienced in preparing documentation for the South African Revenue Service (SARS) and are familiar with the need for accurate HS Code classification. We will advise on the correct HS Code for the biomass wood pellet machine to facilitate smooth declaration.

Our Process and Partnership:

We don’t just hand over a stack of papers. Our logistics team works closely with your nominated freight forwarder or agent to ensure all documents are accurate, consistent, and submitted in a timely manner. We understand that incomplete or incorrect documentation is a primary cause of port delays.

By providing a complete, professional dossier, we minimize this risk, ensuring your biomass wood pellet machine clears customs efficiently and reaches your project site with minimal administrative hassle. This end-to-end documentary support is an integral part of our service as a reliable international supplier.

Are your machines certified for use in the European Union (CE) for export to Italy?

+

Yes, our core biomass wood pellet machines and their integrated electrical control systems are fully CE marked in compliance with the European Machinery Directive (2006/42/EC) and relevant Electromagnetic Compatibility (EMC) and Low Voltage Directives. This certification is mandatory for legal sale and operation within Italy and the entire European Union.

We provide the complete Technical Documentation File and the legally required EU Declaration of Conformity with each shipment to Italy. This documentation confirms that the machine meets the essential health, safety, and environmental protection requirements of the EU, ensuring smooth customs clearance and a safe, compliant foundation for your operation.

What is the lead time for delivering a biomass wood pellet machine to the USA?

+

The lead time depends on whether you are ordering a standard model or a fully customized production line. For a core machine like the MZLH768 biomass wood pellet machine, the standard manufacturing cycle is 25-35 working days after order confirmation and deposit receipt.

Shipping via sea freight from our port (e.g., Qingdao) to a major US West Coast port (like Los Angeles or Long Beach) typically takes 18-25 days. Inland freight within the USA to your site adds further time.

For a complete, customized pellet plant, the lead time is longer due to the integration of multiple equipment units (dryer, hammer mill, cooler, etc.), typically ranging from 45-70 working days for production.

We provide a detailed project timeline with each formal quotation, but you should generally plan for a 3 to 4-month timeline from order to delivery at a US port for a standard machine.

Do you have experience with the regulatory standards for pellet plants in South Korea?

+

Yes, we have extensive experience supplying biomass wood pellet plant equipment to South Korea and understand the key regulatory landscape. The most critical aspects involve:

Industrial Safety & Noise: Compliance with the Korean Industrial Safety and Health Act (KOSHA) guidelines for machine guarding, noise levels, and operational safety is crucial. We design our equipment with safety guards, emergency stops, and consider noise reduction to align with these requirements.

We work collaboratively with our Korean partners or the client’s engineering team to ensure the overall plant design and documentation support a smooth approval process with local authorities.

Air Emissions & Dust Control: Korean air pollution control laws (Clean Air Conservation Act) require efficient dust collection systems for dryers, hammer mills, and pellet coolers. Our plant designs integrate high-efficiency cyclones and bag filter dust collectors to meet these standards.

Electrical Safety (KC Mark): While our core machinery is CE certified, certain electrical components may require local KC (Korea Certification) marking for market entry. We can either supply components that already bear the KC mark (for standard items) or provide all necessary manufacturer’s test reports and documentation to support our client or their local agent in obtaining the required certifications.

Can your biomass wood pellet machine in Turkey be configured for both local fuel and export-quality pellets?

+

Absolutely. This is a common requirement in markets like Turkey, where domestic heating pellets and export-grade industrial fuel pellets have different specifications. Our biomass wood pellet machine systems are engineered for this flexibility. The key lies in the process control and interchangeable components:

Die Selection: You would maintain two different ring dies—one with a compression ratio and hole size optimized for high-density, low-ash export pellets (often from 100% hardwood), and another for cost-effective domestic fuel from mixed agricultural residues.

Conditioning Parameters: The steam/moisture conditioning system can be adjusted. Export-quality pellets may require precise, lower moisture conditioning, while domestic pellets might utilize a different recipe.

Raw Material Blending: The plant can be designed with a blending system to switch between different feedstock mixes.

The same robust MZLH768 machine can produce both, but the “recipe” – defined by the die, feedstock mix, and conditioning settings – is changed. We provide the technical guidance and control system flexibility to manage this dual-production mode efficiently.

What after-sales support is available for a biomass wood pellet plant in Chile?

+

For our clients in Chile, we provide a comprehensive, multi-tiered after-sales support package designed for long-distance partnership:

Warranty: Standard 12-month warranty on all equipment against manufacturing defects, starting from the date of commissioning.

Remote Technical Support: Lifetime priority access to our engineering team via email, WhatsApp, and video conference (e.g., Zoom) for operational guidance, troubleshooting, and process optimization.

Remote Diagnostics: For plants with PLC control systems, we can perform secure remote diagnostics (with client permission) to quickly identify and resolve electrical or control issues.

Spare Parts Supply: We guarantee the long-term supply of all spare and wear parts. Parts are shipped via air express (DHL/FedEx) for urgent needs (5-7 days delivery) or by sea for cost-effective bulk orders. We maintain an inventory of critical parts like ring dies and rollers.

On-Site Service: We can dispatch our experienced engineers to Chile for major installation supervision, commissioning, training, or complex troubleshooting. Travel and accommodation costs are pre-agreed and billed separately.

Documentation & Training: We provide complete English/Spanish operation and maintenance manuals, and conduct thorough training for your technicians during commissioning.

Are spare parts readily available for your biomass wood pellet equipment in Mexico?

+

Yes, spare parts availability is a cornerstone of our service for clients in Mexico. We have established a reliable logistics chain to ensure prompt delivery:

Factory Inventory: We maintain a strategic stock of high-wear parts—ring dies, rollers, bearings, hammer mill hammers and screens, drive belts, and coupling elements—at our manufacturing base.

Fast Shipping Options: For urgent breakdowns, parts can be shipped via international air express (DHL, FedEx) directly to your facility, typically arriving within 5-7 business days.

Cost-Effective Sea Shipment: For planned maintenance and non-urgent parts, we consolidate shipments via sea freight to major Mexican ports like Manzanillo or Veracruz, which is more economical for larger or heavier items.

Pre-Shipment Support: Upon purchasing a biomass wood pellet machine or plant, we provide a recommended spare parts list to help you plan your initial inventory. Our technical team is always available to help you identify the correct part number and expedite the order process.

What is the most popular capacity range for a biomass wood pellet machine in India?

+

In the diverse and price-sensitive Indian market, the most sought-after capacity range for an industrial biomass wood pellet machine is 1 to 3 tons per hour. This scale is ideal for:

- Medium-scale entrepreneurs and MSMEs (Micro, Small & Medium Enterprises).

- Agro-processing cooperatives managing crop residue.

- Smaller industrial users like brick kilns, food processing plants, or dyeing units seeking captive fuel.

Models like our MZLH420 (2-3 T/H) and MZLH520 (1.5-3.0 T/H) are particularly popular. They are used to process a vast array of locally abundant feedstocks, including rice husk, groundnut and coconut shells, cotton stalks, bamboo dust, sawdust, and sugarcane bagasse.

The pellets are primarily used for industrial thermal applications and are increasingly in demand for co-firing in India’s growing biomass-based power generation sector, driven by government policies.

Can you advise on feedstock sourcing for a new project using a biomass wood pellet machine in Ghana?

+

While we are equipment engineers, our extensive project experience allows us to offer strategic advice on feedstock sourcing in Ghana. The key is to identify abundant, low-cost, and consistent waste streams:

- Primary Focus: Agricultural Residues are the most promising. This includes cocoa pod husks (a major byproduct), rice husk from milling centers, palm kernel shells (PKS) and empty fruit bunches (EFB) from oil palm mills, corn cobs, and coconut shells.

- Sourcing Strategy:

- Direct Agreements with Processors: Establish long-term supply contracts with large-scale palm oil mills, rice mills, or cocoa processing plants. This secures volume and often a stable, low cost.

- Collection Centers: For dispersed residues (like corn cobs), consider setting up or partnering with collection centers in key agricultural regions.

- Sawmill Waste: Partner with timber processors in regions like the Ashanti region for sawdust and wood shavings.

- Our Role: We analyze the physical properties (moisture, abrasiveness, ash content) of your target feedstock samples. This analysis directly informs the design of your biomass wood pellet plant—specifying the necessary drying capacity, the type of hammer mill, and the wear-resistant specifications required for the pellet machine’s ring die and rollers to handle materials like abrasive PKS.

Do you offer financing options for clients purchasing a biomass wood pellet plant in the Philippines?

+

As a manufacturing company, Richi Machinery does not directly provide in-house financing or leasing options. However, we actively support our clients in the Philippines (and globally) to secure financing through established channels:

- Bankable Documentation: We provide all necessary technical specifications, detailed quotations, proforma invoices, and factory certifications that are required to support a loan application with local or international banks.

- Letter of Credit (L/C) Transactions: We are highly experienced in working with Letters of Credit, which is a common and secure method of payment in international trade. We can guide you through the documentation requirements.

- Partnerships with Financial Institutions: We can connect serious buyers with third-party trade finance companies or export credit agencies that have experience financing renewable energy and agricultural equipment.

- Phased Payment Terms: We offer standard and flexible payment terms (e.g., 30% deposit, 70% before shipment) that can help with cash flow management.

We recommend that clients in the Philippines consult with their local banks, development banks (like DBP or LandBank, which may have green energy programs), or international development funds that support sustainable energy projects in Southeast Asia.

What is the routine daily maintenance required for the biomass wood pellet machine?

+

A disciplined daily maintenance routine is critical for preventing breakdowns and ensuring consistent output. For the biomass wood pellet machine, this should include:

- Pre-Startup Inspection: Visually check for any leftover material in the feeder and die chamber. Ensure all safety guards are in place. Check the oil level in the gearbox (if applicable).

- Lubrication: Grease all lubrication points (bearing housings on the main shaft and feeder) according to the manufacturer’s schedule, typically every 8-10 hours of operation. Use only the recommended grease.

- Check Drive Belt Tension: Inspect V-belts for wear and proper tension to prevent slippage and power loss.

- Monitor During Operation: Listen for unusual noises (knocking, grinding) and watch for excessive vibration. Monitor the amperage draw on the main motor; a sudden increase can indicate a feeding problem or mechanical issue.

- Post-Shutdown Cleaning: After stopping, run some dry, soft material (like sawdust) through the machine for a few minutes to “clean” the die holes. This prevents hardened material from clogging the die overnight. Then, open the door and brush out any residual fines.

How many operators are needed to run a 5 t/h complete pellet plant?

+

For a moderately automated 5 T/H complete pellet plant, the typical staffing requirement is 3-4 operators per shift, each with a specific focus:

- Front-End Operator: Manages the raw material intake (feeding the conveyor or silo), monitors the dryer, and oversees the hammer mill. Their role is to ensure consistent, properly sized and dried feedstock is supplied.

- Pellet Mill Operator: This is the key role. This operator monitors and controls the biomass wood pellet machine, the conditioner, and the feeding system. They adjust feed rates, monitor pellet quality at the discharge, and perform the die/roller gap checks.

- Back-End Operator: Manages the cooler, screener, and bagging station. They ensure pellets are properly cooled, screen out fines, and oversee the packaging or bulk loading process.

- Shift Supervisor / Utility (Optional 4th): In some setups, a supervisor may oversee the entire line, perform quality checks, and assist where needed, or this role may be combined in a 3-person team for highly automated lines.

The level of automation (e.g., automated dryer controls, PLC-based material handling) significantly influences labor needs. Our plant designs aim to optimize automation to reduce labor dependency while ensuring control.

What training do you provide for our team on operating and maintaining the line?

+

We provide comprehensive, hands-on training structured in two phases:

Phase 1: Factory Acceptance Test (FAT) Training (Optional but Recommended):

If you visit our factory for the FAT, we conduct theoretical and practical sessions on the assembled equipment, covering principles, safety, and preliminary operation.

Phase 2: On-Site Commissioning & Training (Standard):

This is the core training program conducted at your plant after installation:

- Classroom Session: Overview of the entire process, safety protocols, electrical systems, and control panel (PLC/HMI) operation.

- Hands-On Operational Training: Step-by-step instruction on starting, running, and shutting down each major component (hammer mill, dryer, biomass wood pellet machine, cooler). Focus on daily checks, parameter adjustments (feed rate, conditioner), and responding to common alarms.

- Maintenance Training: Detailed demonstration of routine maintenance tasks: lubrication, belt adjustment, die & roller removal/installation, gap adjustment, and hammer/screen replacement in the crusher.

- Troubleshooting Workshop: We review common problems (low output, poor pellet quality, blockages) and their solutions.

- Documentation: We leave you with detailed, illustrated Operation & Maintenance Manuals in English. Training is conducted until your key personnel are confident in independent operation.

What is your warranty policy on the main biomass wood pellet machine?

+

Our standard warranty policy for the main biomass wood pellet machine (e.g., MZLH768) is as follows:

- Support: During the warranty period, we provide free technical support and guidance. If a covered defect requires part replacement, we supply the part free of charge; the customer is typically responsible for associated labor and inland freight costs.

- Coverage: The warranty covers defects in materials and workmanship under normal use and proper maintenance as per our guidelines. It includes the repair or replacement, at our discretion, of faulty major components such as the gearbox housing, main shaft, and body castings.

- Wear Parts: Components subject to normal wear and tear are not covered under the standard warranty. This includes but is not limited to: the ring die, pressure rollers, roller shells, bearings, V-belts, and hammer mill hammers/screens. These are consumables whose lifespan depends on your feedstock’s abrasiveness and operating hours.

- Conditions: The warranty is valid only if the machine is installed, operated, and maintained according to our provided instructions. It is void in cases of misuse, improper modification, accidents, or use of non-genuine spare parts.

- Warranty Period: 12 months from the date of successful commissioning at the buyer’s site, or 18 months from the date of shipment from our factory, whichever occurs first.

How do I order and what is the typical process from inquiry to installation?

+

The process is a collaborative journey to ensure your project’s success:

- After-Sales Support: Our support begins, including warranty service, spare parts supply, and lifetime technical consultation.

- Initial Inquiry & Needs Analysis: You contact us with your raw material type, target capacity, and pellet use. We have a detailed questionnaire to capture all critical data.

- Feasibility & Quotation: We may request a 1kg material sample for free testing. Based on the analysis and your requirements, our engineers prepare a detailed technical and commercial proposal, including plant layout and equipment list.

- Proforma Invoice & Contract: Upon your review and approval, we issue a Proforma Invoice (PI). After payment of the deposit (typically 30%), a sales contract is signed.

- Detailed Engineering & Manufacturing: Our technical team creates detailed manufacturing and electrical drawings for your approval. Production begins in our factory.

- Factory Acceptance Test (FAT): Before shipment, you (or your representative) are invited to witness the pre-assembled line or key equipment undergoing a test run. This is your chance to verify performance.

- Shipping & Documentation: We arrange export packaging, customs clearance, and sea/air freight as per the agreed Incoterm. All shipping documents are provided.

- Customs Clearance & Delivery: Your agent clears the goods at the destination port. We assist with necessary documents. Equipment is delivered to your site.

- Installation Supervision & Commissioning: We can dispatch engineers to supervise installation (foundation check, equipment placement, connection) and conduct the commissioning and training.

What are the voltage and electrical requirements for installing your biomass wood pellet machine in Saudi Arabia?

+

For installation in Saudi Arabia, our biomass wood pellet machines are configured to match the standard Saudi industrial electrical grid:

- Standard Supply: 380-400 Volts, 3-Phase, 50 Hertz (Hz). This is the prevalent industrial voltage in KSA.

- Motor Specifications: All main drive motors (e.g., the 315KW motor for the MZLH768) and major auxiliary motors are supplied to operate on this 380V/3PH/50Hz supply.

- Control Voltage: The machine’s control cabinet (PLC, relays, sensors) typically operates on a lower, isolated control voltage (e.g., 24V DC or 110V AC) for safety, which is derived internally from the main supply.

- Power Demand: It is crucial that your site’s transformer and electrical distribution panel have sufficient capacity. A MZLH768 wood pellet press machine alone has a 315KW motor with a high starting current. A complete 5 T/H plant may require a total connected load of 450-550 KVA. We provide detailed electrical load lists and single-line diagrams with our proposal for your electrician to design the correct cabling, circuit breakers, and protection devices.

- Certification: While we provide a CE Declaration of Conformity, you should consult with your local consultant regarding any specific Saudi Arabian Standards Organization (SASO) requirements that may apply to the electrical installation on site.

Do you have experience supplying pellet plants that must meet specific emission standards for a biomass wood pellet plant in Japan?

+

Yes, we have significant experience with the stringent environmental regulations in Japan. Key areas of focus for a biomass wood pellet plant there are:

- Dust Emissions (Soot and Dust Regulation Law): Japan has strict limits on particulate matter (PM) emissions. Our plant designs for Japan incorporate high-efficiency pulse-jet baghouse filters (with filtration efficiency >99.9%) on all major dust generation points: the hammer mill, dryer exhaust, cooler, and screening stations. We ensure the filter design meets the required emission concentration (mg/Nm³).

- Dryer Exhaust: The combustion gases from the dryer’s biomass furnace (if used) must be clean. We design the drying system with a complete combustion furnace and often integrate a secondary cyclone or wet scrubber if necessary to meet local limits on NOx and SOx, though these are typically low for biomass combustion.

- Noise Pollution: Japan has strict noise ordinances. We specify low-noise fans, use vibration dampeners on mills, and can design acoustic enclosures for key equipment like the hammer mill.

- Documentation & Testing: We provide detailed technical data on emission control equipment and can support the client in preparing the documentation required for the local environmental permit application. We understand the need for precise, reliable data to satisfy Japanese regulatory scrutiny.

Can your equipment handle the specific blend of agricultural residues commonly found in a biomass wood pellet machine project in Argentina, like wheat straw and sunflower hulls?

+

Absolutely. The combination of wheat straw (fibrous, low density) and sunflower hulls (abrasive, high ash) is a classic yet challenging Argentine feedstock, and our systems are specifically engineered for such blends.

- Process Design: The line requires robust pre-processing. The straw needs a heavy-duty shredder and fine hammer mill to break down fibers. The sunflower hulls require a hard-wearing hammer mill.

- Conditioning Strategy: The blend benefits from precise conditioning. Steam addition can soften the straw’s lignin, while the optimal moisture content (around 14-16%) must be achieved for the whole mix to bind properly under pressure.

- Core Machine Configuration: The biomass wood pellet machine (e.g., MZLH768) must be equipped to handle the mix’s dual nature: it needs high torque for compaction (for the straw) and extreme wear resistance (for the hulls). We specify a high-chrome alloy ring die with a carefully calculated compression ratio that balances pellet durability with production efficiency. The gap between the die and rollers is critical and requires specific operator training.

- Proven Solution: This is not theoretical. We have supplied lines in Argentina processing similar blends. The key is our custom engineering approach—testing the specific ratio of your blend to optimize every parameter of the plant, ensuring it converts this locally abundant residue mix into high-quality, marketable pellets.

What are the main challenges and solutions for operating a biomass wood pellet machine in the high-altitude conditions of Peru?

+

Operating at high altitudes (e.g., in the Andean regions of Peru) presents unique physical challenges that affect equipment performance. Our engineering accounts for these factors: