Auxiliary equipment

While pellet mills and extruders form the heart of your operation, it’s the auxiliary equipment that ensures uninterrupted performance and optimal output. Our specialized support systems—from raw material intake to automated packaging—are engineered to integrate seamlessly with your core machinery, eliminating bottlenecks and maximizing throughput. With 30+ years of field experience, we design each component to handle your specific challenges, whether processing feed, biomass, fertilizer, cat litter or other product.

AUXILARY EOUIPMENT

Richi Machinery develops and supplies allkinds of auxliary equipment for feed mllplant, biomass pellet plant fertiizer pellet plant and

crushing

mixing

batching

drying

screening

Conveying

Cooling

spraying

Packaging

other

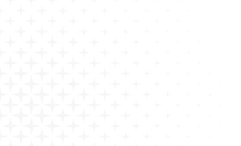

CRUSHING EQUIPMENT

RICHI crusher machine range is always at the very front of the product preparation chain, used for the rapid, powerful crushing and pre-crushing of medium-hard, hard, brittle and tough materials.

Our available equipment includes slicers, shredders, ultra-fine grinders, hammer mill feed grinders, template crushers, organic fertilizer crushers, forage straw crushers, wood chip crushers, micro pulverizer, biomass crushers, wood pellet hammer mill, wood pallet crusher, and more. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants.

hammer mill

Grinds materials ≤5cm into fine powder. Final output can be adjusted between 0.5–20mm by changing the screen.

Capacity:

0.5-50T/H

Power:

37-220KW

drum chipper

Processes logs, branches, and wood strips into wood chips sized 20–40mm. Screen sizes are customizable.

Model:

XPJ

Power:

75-200

Disc Bale Breaker

Designed for coarse crushing of large-diameter baled or loose agricultural waste such as straw and alfalfa into 20–30mm pieces.

Model:

YPPK

Power:

55-90KW

shredder machine

Performs primary crushing of irregularly shaped agricultural/ forestry/ urban waste. Output size is approximately 3cm.

Model:

SSJ

Power:

30-150KW

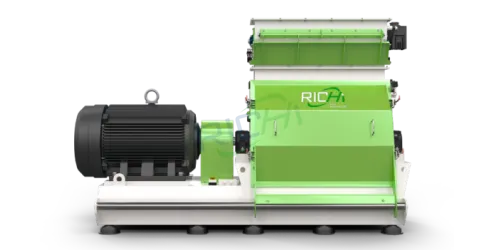

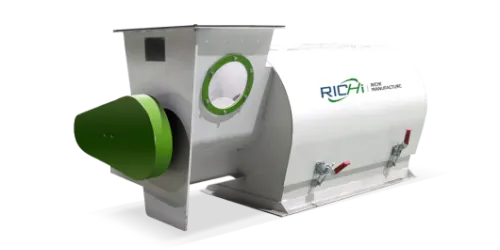

MIXING EQUIPMENT

Offering both standard and custom mixing solutions to meet diverse customer processing needs. Our mixers are designed to efficiently blend powders, granules, flakes, fibrous materials, and viscous substances.

The product portfolio includes poultry feed mixers, cattle feed mixer, fish feed mixer, paddle mixers, ribbon mixers, drum mixers, molasses mixers, biomass mixers, organic fertilizer mixers, manure mixers, NPK blenders, premix mixers and grain mixers, providing reliable and adaptable mixing performance for various applications.

Discover the different feed mixer machines made by RICHI Machinery. Effective, reliable and strong. Mainly used in animal feed mill plants.

Capacity

8-25 MWth

Capacity

8-25 MWth

It is a paddle mixer which has been designed in order to mix homogeneously raw materials, vitamins, minerals and compounds. Mainly used in premix feed mills.

Drum Mixer

Primarily used in feed mills for manually preparing small batches of additive premixes and premix production. Features low investment cost and user-friendly operation.

Capacity (KG/Batch): 100-500

Power (kw): 2.2-3+4

Molasses Mixer

Designed for adding molasses to ruminant feed. Typically installed above the pellet mill, effectively addressing challenges such as molasses viscosity and mixing difficulties.

Capacity (KG/Batch): 15-30

Power (kw): 30-45

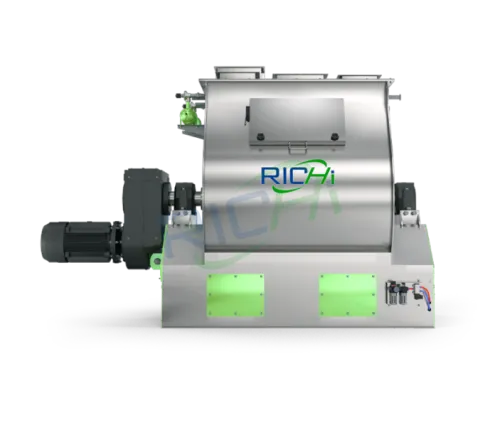

batching equipment

RICHI supplies a complete range of high-accuracy batching equipment to meet the needs of various production processes. Our product line includes batching scales, screw feeders, fully automated computer-based batching systems, micro-ingredient dosing systems, PLC-controlled weighing and batching systems, as well as specialized solutions for organic fertilizer, premixes, NPK blends, powder coatings, and detergent production.

From small additive doses to large-volume bulk materials, our systems integrate seamlessly with mixing and process lines to guarantee formula consistency and end-product quality.

Automatic Dosage Scale

The automatic batching scale is used for weighing and proportioning different materials in formulas.

Model:

PLC

Volume:

1-4 m³

PLC weighing and dosage system

Designed for fully automated production lines, suitable for batching multiple types of materials.

Model:

PLC

Volume:

0.25-3T

trace element Dosage system

Precisely weighs, batches, transports, and feeds powdered or granular micro materials into silos.

Model:

ZFC

Volume:

0.2-10 m³

organic fertilizer Dosing system

Ideal for fertilizer production lines, handles NPK, biomass, municipal waste, and other materials.

Model:

FPL

Volume:

1-8 m³

drying equipment

RICHI offers high-performance drying systems including Rotary Dryers and Belt Dryers, supported by complementary burners and hot air furnaces.

Designed for efficiency and low energy consumption, our dryers effectively remove moisture from materials in a wide range of industries such as fish feed, pet food, grain, food, biomass energy, wood processing, straw, chips, sawdust, grass, pellets, chemicals, organic fertilizer, manure, cat litter, and animal bedding. We provide customized drying solutions tailored to meet specific customer requirements.

Engineered for continuous drying of various materials including aquatic feed, pet food, and agricultural products. Ideal for heat-sensitive materials requiring gentle drying processing.

Model: DHG

Drying Area (㎡): 13-58

Drum Dryer

Designed for high-capacity drying of biomass, organic fertilizers, and municipal waste. Utilizes tumbling action and counter-flow heat exchange for efficient moisture removal.

Diameter(m): 0.6-1.8

Length (m): 6-24

Hot Air Stove

Incorporates flame arrestor and efficient heat exchanger technology. Rapidly heats ambient air to precise temperatures required for drying processes.

Model: RFL

Diameter (m): 1.6-2

Biomass Burner

Operates on wood chips, sawdust, or pellets to generate stable flames for thermal processes. Equipped with automatic feeding and combustion control systems.

Model: MRSJ

Power(KW): 1.5-12

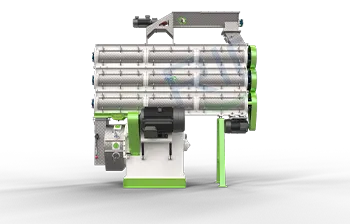

Cleaning & screening equipment

RICHI provides high-performance screening and cleaning solutions for a wide range of materials including pellets, powders, compost, aggregates, and recycled wastes. Our industrial screeners ensure precise sifting and efficient particle size separation, from small-scale tasks to heavy-duty applications.

Designed for reliability, hygiene, and cost-effectiveness, RICHI screening equipment is the ideal choice for pellet production and processing lines. Contact us to customize a solution for your needs.

Precisely classifies pelletized materials into three distinct size categories (large/medium/small) through multi-deck screening technology. Features adjustable amplitude and frequency for optimal separation efficiency in pellet lines.

Capacity:

3-40 T/H

Power:

1.5-5.5 KW

drum cleaning sieve

Performs simultaneous sizing and cleaning operations to deliver multiple graded products in single processing stage. Features modular drum design with replaceable screen segments for various material classification requirements.

Capacity:

3-20 T/H

Power:

3-5.5 KW

cylinder primary sieve

Effectively removes heavy impurities (stones, sand, metal fragments) from granular materials using centrifugal separation principles. Constructed with abrasion-resistant steel screens for extended service life in harsh operating conditions.

Capacity:

15-50 T/H

Power:

0.75-1.5 KW

powder cleaning sieve

Specialized for impurity removal in powdery materials utilizing high-frequency vibration and airflow separation. Equipped with anti-blinding screen meshes to ensure continuous operation in fertilizer powder processing applications.

Capacity:

10-50 T/H

Power:

5.5-7.5 KW

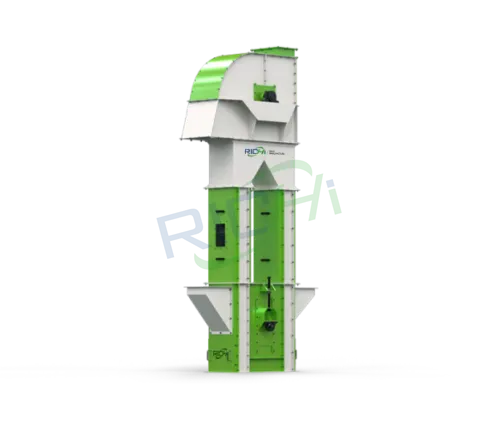

Conveying equipment

RICHI offers a full range of powered and gravity conveyor systems in various sizes and capacities, designed to replace manual handling and enhance operational reliability, ergonomics, and organization.

Suitable for use in feed mills, biomass and wood pellet plants, fertilizer production, cat litter factories, food processing, and more, our conveyors help automate transporting, sorting, loading, palletizing, and other processes. They integrate easily as standalone units or within larger automated systems, helping increase throughput, reduce bottlenecks, and maximize labor productivity.

Modular and tailored to your business needs, bucket elevator conveyor can be leveraged to create efficiencies throughout your warehouse, distribution center or production facility.

Capacity: 1-100T/H

Model: TDTG/ZDTJ

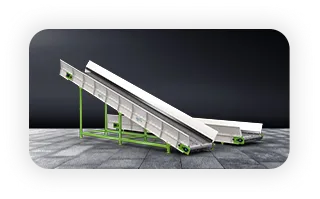

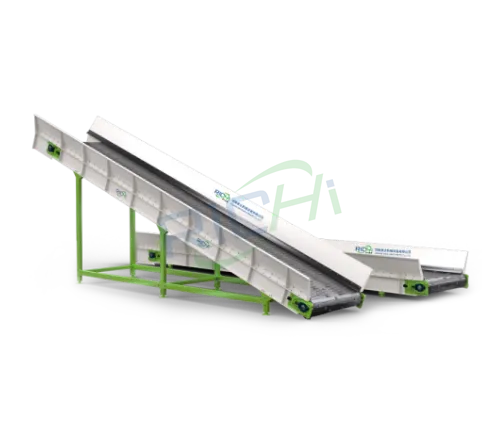

belt conveyor machine

Belt Conveyors are the most versatile and simplest material handling systems, ideal for gentle horizontal conveying of bulk materials such as e.g. grain, pellets, and seed… RICHI Belt Conveyor, designed for excellence.

Belt Width: 500-1500 mm

Model: PDS

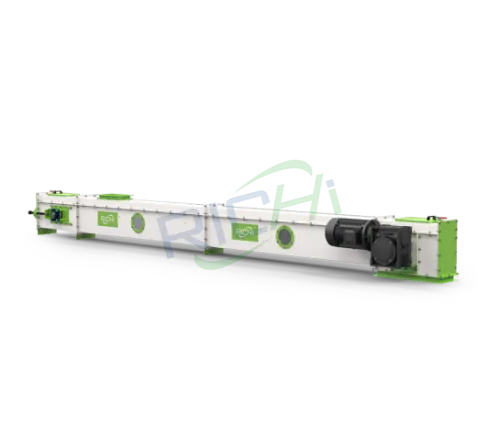

A scraper conveyor equipment is a type of flight conveyor. It consists of a trough in which a continuous driven chain with flights is running. Learn how Richi Machinery can help improve your operations today.

Capacity: 15-210 m³/h

Model: TGSS/TGSU

Our experts have access to a variety of technologies and design tools to find the best solution to support your goals. Discover screw conveyors, known for their longevity and careful handling of goods.

Capacity: 8-80 m³/h

Model: TLSS/TLSU

Cooling & crumbling equipment

RICHI provides efficient cooling and crumbling solutions essential for feed, biomass, fertilizer, wood, and other pellet production lines. Our counterflow pellet cooler machines rapidly reduce pellet temperature within minutes, offering robust performance with built-in efficiency and durability.

The product range includes double- and triple-roller pellet crumbler machines, as well as flap-type and impeller-type counterflow coolers, delivering reliable post-processing performance for various pellet applications.

Impeller type Counterflow Cooler

Incorporates rotating vane assembly that gently moves materials against cooling airflow. Provides consistent retention time for complete thermal stabilization of pellets. You can deliver superior performance and reliability.

Capacity:

1-40 T/H

Model:

SKLY

Flap-Type Counterflow Cooler

Features modular flap gates that create optimized cooling zones for gradual temperature reduction. Ensures uniform cooling across full bed depth while minimizing energy consumption and lowest maintenance costs.

Capacity:

1-40T/H

Model:

SKLF

Dual-Roller Pellet Crumbler

Utilizes counter-rotating rollers with precision-grooved surfaces to break oversized pellets into uniform granules. Maintains particle integrity while achieving desired size reduction with minimal fines generation.

Model:

SSLG

Power:

4-11 KW

Triple-Roller Pellet Crumbler

This pellet crumbler machine employs three-stage roller system for progressive size reduction, ensuring superior control over final particle distribution. Ideal for heat-sensitive materials requiring gentle processing.

Model:

SSLG

Power:

11-18.5 KW

liquid adding and spraying equipment

RICHI offers a complete range of liquid application systems including liquid weighing systems, storage tanks, paddle mixers, rotary coaters, vacuum sprayers, and basic spraying units. Designed for precise and uniform liquid distribution, our equipment is widely used in aquafeed, pet food, cat litter, fertilizer processing, and other industries requiring accurate liquid blending and coating.

Vacuum spraying System

Enables high-capacity liquid infusion (up to 36% oil content) through vacuum impregnation technology. Ensures deep penetration without compromising particle structural integrity.

Capacity: 1-15T/H

Model: XYPLC

Roller spraying System

Applies liquid coatings to extruded/pelleted materials through precision roller technology. Maintains coating uniformity while preserving heat-sensitive additive integrity.

Capacity: 1-15T/H

Model: SYPL

Liquid Weighing System

Precisely measures, stores, and heats viscous liquids (oils, molasses, phospholipids) with ±0.5% dosing accuracy. Features temperature-controlled tanks and CIP cleaning for continuous production cycles.

Adding Flow Rate (L/Min): 100-200

Model: SYTC

Simple Spraying System

This basic spraying system can provides economical surface coating for pellets/extrudates using nozzle-based application. Suitable for standard production requirements with manual control options.

Capacity: ≤500-1000

Model: PTJ

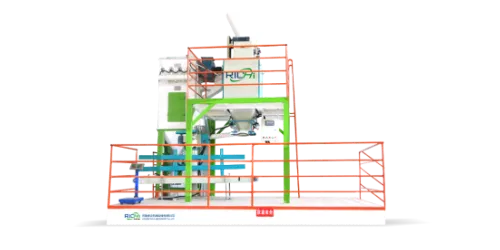

Packaging & storage equipment

RICHI supplies efficient and versatile packaging and storage solutions, including automatic bagging scales, bulk bag fillers, assembly silos, storage systems, and custom hoppers.

Our all-electric bagging equipment enables quick setup with minimal maintenance, handling powders, pellets, and bulk materials with precision. Ideal for feed, biomass pellets, cat litter, fertilizer, food, and chemical industries.

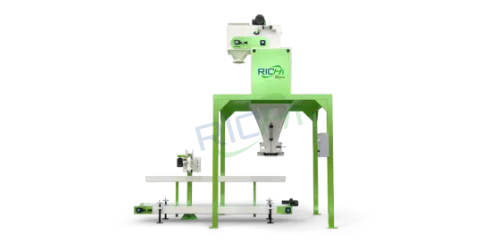

Ton bag weighing

It is designed for bulk material handling with capacity ranging from 500-2000kg per bag. Features automatic bag hanging, dust-free filling, and precision weighing controls. Includes optional compression and palletizing functions for streamlined logistics.

Speed:

2-8 bag/min

Model:

DCS

Precisely measures and packages various materials with multiple sealing options including heat-sealing, thread-stitching, or combined methods. It ensures ±0.2% weighing accuracy and integrates seamlessly with conveyor systems for continuous operation.

Speed:

15-20 bag/min

Model:

DSC

Provides storage solutions from 150 to 12,000 tons capacity with diameters ranging 1.12-32 meters. Engineered for both granular and powdered materials with cone angles optimized for complete discharge. Customizable with level monitoring and aeration systems.

Diameter:

5.5-27.5 m

Volume:

222-13382 m³

Unloading system

Automatically handles various bag types including woven PP and paper bags. Equipped with dust containment system and residual material recovery. Features sharp object detection and bag compaction functionality for efficient waste management.

Model:

CBJ

Speed:

20-40 bag/h

other equipment

RICHI supplies a comprehensive range of essential auxiliary equipment designed to save energy and reduce material consumption. Our product line includes pulse dust collectors, magnetic separators, de-ironers, compost turners, rotary distributors, boilers, air compressors, spray systems, and more.

Ideal for feed, pellet, fertilizer, cat litter, and environmental applications, we provide guaranteed performance, expert technical support, and complete turnkey solutions—so you can focus on production with confidence.

Efficiently captures and filters production line dust through high-pressure pulse cleaning, maintaining workshop air quality and equipment integrity.

Dust Removal Efficiency: ≥99.8%

Model: TBLMa

Rotary distributor

Precisely directs bulk materials to multiple storage bins with self-cleaning design to prevent cross-contamination and residue buildup.

Power: 0.75 KW

Model: TFPX

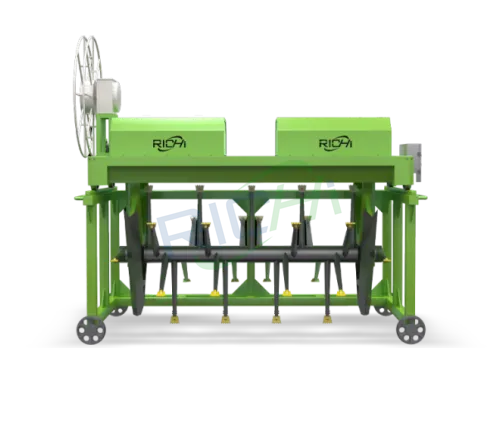

Fermentation throwing machine

Automatically turns and aerates fermentation materials with adjustable frequency control for optimized biodegradation processing.

Fermentation Tank Width: 3-6 m

Model: FPJ

Permanent magnet cylinder

Removes ferrous impurities from material streams through powerful magnetic separation, ensuring product purity and equipment protection.

Capacity: 25-70 T/H

Model: TCXT

top selling equipment

With our owner Lee ji (Chief Mechanical Engineer, RCIHI), actively involved in our day-to-day operations, you will find no company from the top on down more committed to our quality of machinery as well as customer satisfaction.

These machines are our “babies” at Richi Machinery made with our own hands, and we truly think of our customers as our extended “pelletizer family”. We are very proud to say our expertise in finding and maintaining the most cost effective and efficient solution to your pelleting & extrusion needs is unsurpassed here at Richi Machinery!

Engineered for high-nutrition poultry feed production with precise conditioning and pelleting for optimal digestibility and growth performance.

Complete turnkey solutions for animal feed production, featuring advanced grinding, mixing, and pelleting technologies for uniform feed quality.

Specialized extrusion and sinking pellet systems for aquatic feeds, ensuring water stability and nutrient retention for fish and shrimp.

Industrial-grade pelletizers for wood processing, producing high-density biomass pellets with low energy consumption and consistent quality.

Versatile pellet production for agricultural residues and energy crops, designed for high throughput and wear-resistant operation.

fertilizer granulation equipment

Organic and NPK fertilizer granulators with precision drum or extrusion technology for uniform particle size and slow-release properties.

Dedicated pelletizers for clumping and non-clumping litter products, featuring odor-control additive systems and low-dust output.

60000 +

Backed by a 60,000 m² advanced production complex

140 +

Global footprint extends across 140+ international markets

2000 +

Over 2,000 successful pellet production system installations

2013

RICHI MANUFACTURE

Established in 1995, RICHI MACHINERY has grown from a medium-sized enterprise to become China’s largest pellet production line manufacturer. With two major manufacturing bases spanning hundreds of thousands of square meters, we specialize in custom pellet machines and complete plant solutions, handling every production stage in-house—from R&D to delivery.

Our vertically integrated facilities (including dedicated sections for production, testing, and logistics) ensure premium quality, environmental responsibility, and operational reliability for feed, biomass, and fertilizer industries worldwide. For nearly three decades, we’ve partnered with clients to enhance productivity, minimize risks, and achieve sustainable outcomes through innovative engineering.

Zhengzhou Headquarters

R&D, global operations and strategic management converge

Jiaozuo New Production Base (2025)

Featuring automated production lines and Industry 4.0 technologies

Kaifeng Original Complex (Since 1995)

Our manufacturing legacy began and quality traditions endure

Certifications & Patents

As a world-leading pellet plant equipment manufacturer, RICHI Machinery demonstrates its engineering prowess through internationally recognized certifications and proprietary innovations.

Our ISO quality management system, CE compliance, BV-certified production processes, GOST-R for Russian compliance, ATEX explosion-proof certification for EU safety standards, FDA registration for U.S. market access, and EHEDG hygienic design certification validate our commitment to global standards, while 50+ patented technologies in pellet mills, extruders and automation systems deliver unmatched performance.

When you choose RICHI, you’re selecting globally validated, future-proof solutions backed by the industry’s most comprehensive certification portfolio.

01

Consultation

Our experts provide professional advice to understand your specific pellet production requirements.

02

Design

We develop customized solutions with optimized layouts and equipment configurations for your project.

03

Manufacturing

All feed mill equipment is precision-built using quality materials in our ISO-certified factories.

04

Shipping

We handle secure packaging and global logistics with reliable delivery timelines.

05

Installation

Our engineers supervise on-site assembly and commissioning for smooth operation.

06

Training

Comprehensive operator instruction ensures proper use and maintenance of equipment.

07

After-sales

Dedicated support team provides troubleshooting and technical assistance.

08

Spare Parts

Genuine components are available worldwide with fast delivery service.

FAQs – Your auxiliary Equipment Queries Answered

How do your auxiliary systems improve overall production line efficiency?

+

Our auxiliary equipment is engineered to eliminate bottlenecks and optimize material flow. For example, smart conveyors with variable speed controls maintain consistent feed rates to pellet mills, while precision graders recycle off-spec material back into the process. This integration typically increases overall line efficiency by 15-25% compared to mismatched components.

01

What makes your dust collection systems different from standard solutions?

+

Richi Machinery’s pulse-jet dust collectors feature calculated air-to-cloth ratios and cyclone pre-separation stages that handle 30% more particulate load than conventional systems. Our ATEX-compliant designs include spark detection and suppression systems specifically for combustible biomass dust.

02

Can you customize auxiliary equipment for existing production lines?

+

Absolutely. We’ve retrofitted over 200 existing lines with customized solutions like inclined screw conveyors for space constraints or specialized coolers for heat-sensitive materials. Our engineers first conduct laser scans of your current setup before designing bolt-on modifications.

03

How do your cooling systems prevent pellet degradation?

+

Our counterflow coolers use patented multi-zone temperature control and gentle material handling to prevent thermal shock and minimize fractures. The result is typically <2% fines generation versus 5-8% with conventional coolers.

04

What maintenance advantages do your auxiliary systems offer?

+

operating cWe design for minimal downtime with features like quick-release access panels, standardized components across equipment classes, and remote monitoring capabilities. Many clients report 40% reduction in maintenance hours compared to previous setups.onditions.

05

How accurate are your weighing and batching systems?

+

operating conditioOur microprocessor-controlled weighing systems achieve ±0.1% accuracy through redundant load cells and automatic moisture compensation. The system automatically calibrates itself before each batch and logs all production data for quality tracking.ns.

06

Can your systems handle abrasive materials like rice husk?

+

operating Yes. We use AR400 steel wear plates, ceramic-lined elbows, and replaceable abrasion zones in all equipment handling abrasive materials. For rice husk applications, we typically achieve 3x longer component life than industry standards.conditions.

07

Do you provide automation integration for auxiliary equipment?

+

operating cAll our equipment comes with PLC controls that seamlessly integrate with existing systems. We’ve implemented IIoT solutions that allow real-time monitoring of equipment health and production metrics from anywhere in the world.onditions.

08

What safety features are incorporated into your designs?

+

operating cBeyond standard compliance, we build in layered protection including emergency stop circuits, guard interlocks, pressure relief valves, and explosion venting. All electrical components meet IP65 standards for dust and moisture protection.onditions.

09

Can your drying systems be customized for specific moisture reduction requirements and unique raw materials?

+

operating conditions.Absolutely. Richi Machinery designs tailored drying solutions based on your material characteristics and production goals. For high-moisture materials like fresh wood chips or agricultural waste, we incorporate multi-stage drying with precision moisture sensors that maintain ±0.5% accuracy.

Our systems adjust airflow, temperature, and retention time dynamically – for example, using lower temperatures for heat-sensitive organic materials while maintaining efficiency.

We’ve developed specialized configurations for over 50 different biomass types, including corrosive palm waste and fluffy rice husk. Customizations include corrosion-resistant coatings, indirect heating options, and heat recovery systems that reduce energy consumption by up to 30% compared to standard dryers.

10