WOOD PELLETIZER FOR SALE

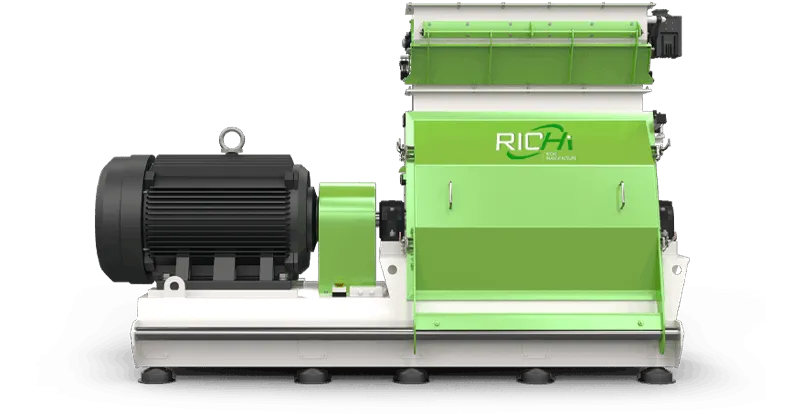

Looking for a reliable wood pelletizer for sale? The MZLH678 from Richi Machinery handles even the toughest materials with ease. It processes timber residues, straw waste, palm fiber, rice husk, and various shells effortlessly. This machine is built for challenging biomass, making it a versatile solution for many industries.

Model – MZLH678

Capacity – 2.5-3.0T/H

Who Uses Our Wood Pelletizer?

From sawmills to power plants, our wood pelletizer for sale serves a global clientele. It is the ideal choice for any business with wood residues. This includes sawmills, wood processing plants, and furniture makers. It also suits board plants like those for particleboard and plywood. Forestry companies, biomass pellet producers, and recycling centers use it. Landscaping firms, municipalities, and large farms benefit too. Energy companies, CHP plants, and large heating users like schools and hospitals are perfect customers. No matter your industry, if you have raw material, our wood pelletizer can turn it into profit.

Pellets for Every Purpose

Fertilizer Pellets

Cat Litter Pellets

Wood Fuel Pellets

Ask Us Anything

Our wood pelletizer for sale creates versatile pellets for a global market. Your primary output will be premium fuel pellets for heating and power generation. Beyond energy, many clients produce highly absorbent wood-based cat litter. Others manufacture organic fertilizer pellets for agriculture. We also serve industries making bedding pellets for animal farms and specialized pellets for industrial processes. This wide range of applications means your business can adapt and thrive. No matter your target market, our machine provides the professional-grade results you need.

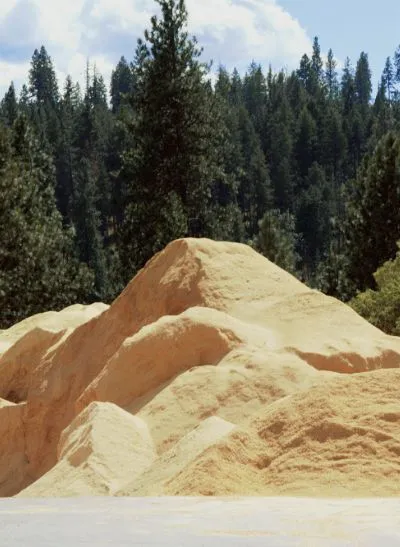

Make Pellets from Almost Any Material

Wondering what you can pelletize? Our wood pelletizer for sale turns a huge range of materials into valuable fuel. It processes all wood forms: sawdust, chips, shavings, bark, and even whole branches or stumps. It handles both hardwood and softwood. Use logging residues, forest thinnings, or reclaimed wood like pallets and construction waste. It also works with sawmill and furniture factory waste, including MDF and chipboard. Even specific species like rubber wood, eucalyptus, and fruit tree wood are no problem. Beyond wood, it efficiently processes many agricultural wastes. This machine turns your leftover materials into profit.

Engineered for Superior Performance

Discover the efficiency of our MZLH wood pelletizer for sale. Our MZLH678 wood pelletizer for sale is built to outperform. It transforms various materials into high-density pellets with exceptional efficiency. This machine combines robust construction with intelligent design for non-stop operation. It delivers higher output with lower energy consumption. Choose reliability, choose power, choose our professional wood pelletizer.

Modular Compact Design

Offers great flexibility for various production lines and is user-friendly for maintenance.

Automatic Lubrication System

Provides continuous oiling to key bearings during operation, reducing wear and maintenance.

Heavy Cast Iron Base

Eliminates machine vibration for stable performance and a longer overall lifespan.

Shear Pin Protection

Safeguards the pressing unit from damage caused by foreign objects or metal overloads.

Siemens Electric Motor

Guarantees reliable power and high energy efficiency for your wood pelletizer.

Arch-breaking Feeder Bin

Prevents material clumping and blockages in the hopper for smooth, continuous operation.

Forced Feeder System

Ensures a consistent and even material flow into the pressing chamber for optimal output.

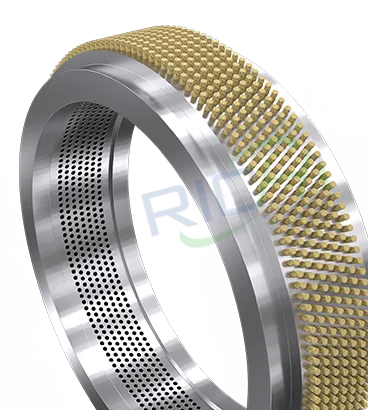

Reinforced Ring Die

Crafted from high-alloy steel for extended service life and stable pellet formation.

WORKING PRINCIPLE

Our wood pelletizer for sale uses a ring die and rollers to compress material through small holes. This process forms uniform pellets from various raw materials. See the machine in action – watch the video on the right to view the complete process.

Technical Specifications: MZLH678 Wood Pelletizer

Find the detailed technical specifications for the MZLH678 wood pelletizer for sale below. This overview provides the key metrics you need to evaluate its capacity and integration into your operation. For a deeper analysis or to discuss how these specs meet your specific production goals, our engineering team is ready to assist.

MZLH678 Wood Pelletizer Parameter Table

Precision Engineering for Maximum Output

Capacity:

2.5-3.0 T/H

Main Motor Power:

185 kw

Arch-Breaking Feeder Power:

3 kw

Forced Feeder Power:

1.5 kw

Finished Pellet Diameter:

4~12 mm

Other Models & Specifications

The MZLH678 is just one option in our complete line of wood pelletizer for sale. We offer five additional models to match your specific output needs. Our machines cover a wide capacity range from 0.2 to 4 tons per hour. For production demands exceeding 4t/h, a multi-unit system can be configured. Explore the full specifications of all our models below to find your ideal solution.

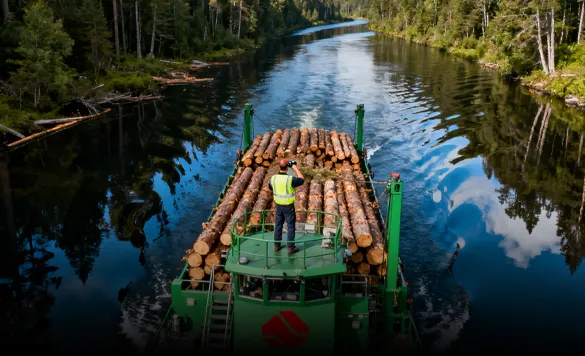

Global Project Gallery

Our wood pelletizer for sale has delivered success worldwide. From individual machines to complete lines, we help diverse industries transform various materials.

USA Hardwood Pellet Plant

A turnkey project for a biomass energy company, processing local oak and maple residues into premium heating pellets.

See Our Wood Pelletizers in Action

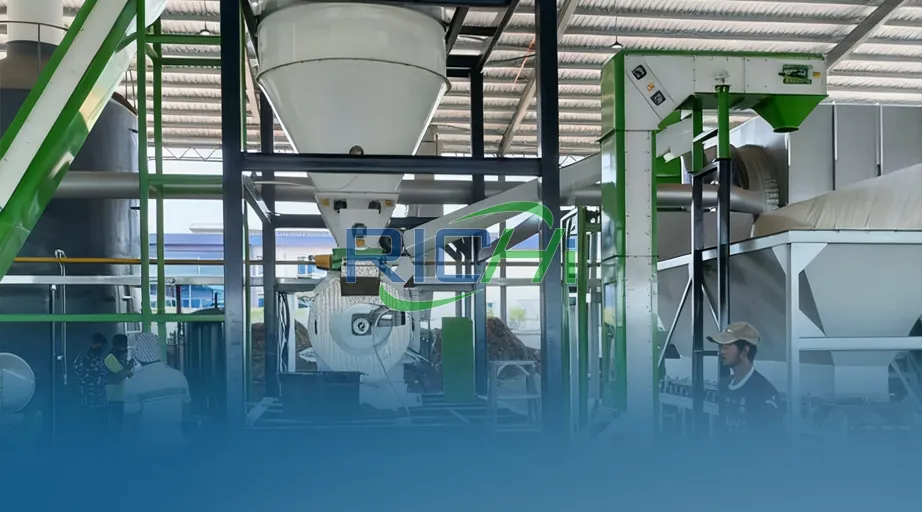

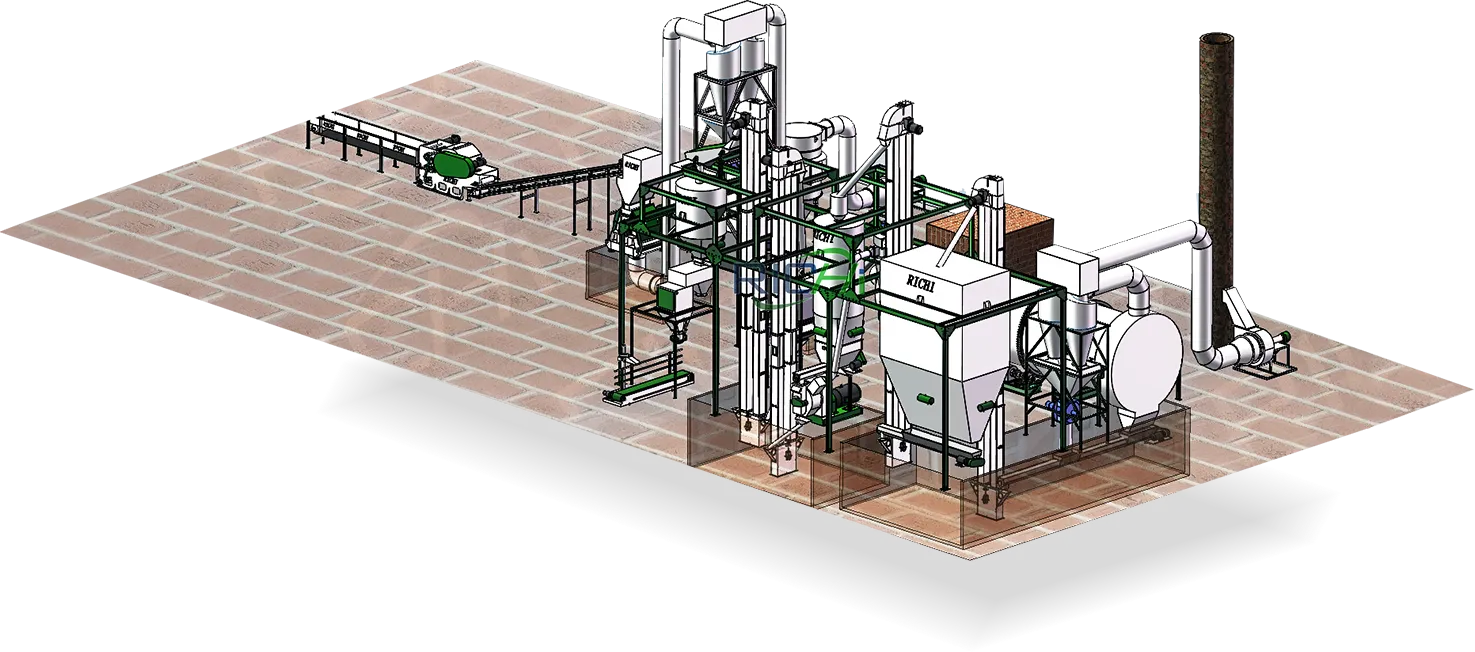

Your Complete Pellet Production Partner

We deliver more than just a wood pelletizer for sale; we provide complete, custom-engineered solutions. Your production line is uniquely designed based on your raw material type, moisture content, factory layout, and budget. Depending on your needs, we integrate optional systems like mixing, drying, or dust removal. We support you from initial consultation to manufacturing, installation, and lifelong service.

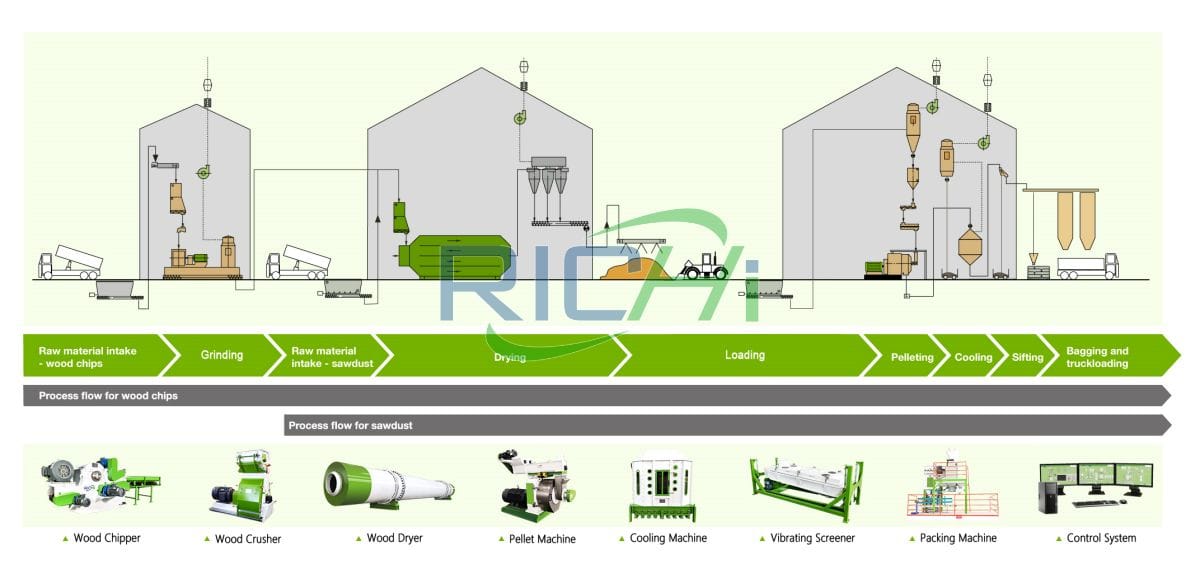

01.Size Reduction

Size Reduction prepares large wood pieces.

02.Fine Grinding

Fine Grinding creates a consistent powder.

03.Pelletizing

Pelletizing in our machine forms the pellets.

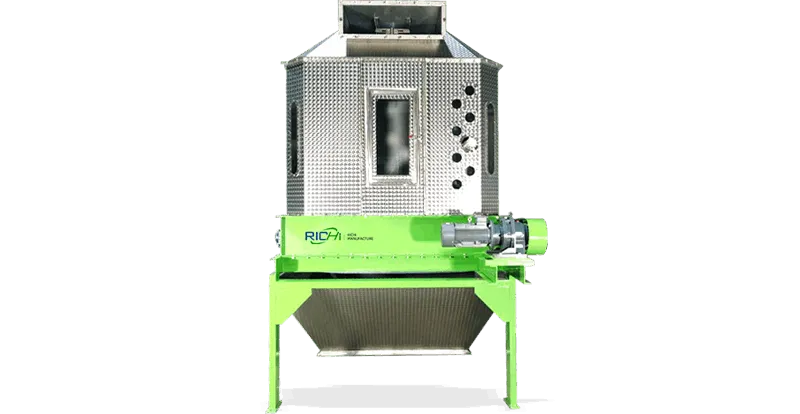

04.Cooling

Cooling solidifies them for storage.

05.Screening

Screening removes fines.

06.Packing

Packing prepares for market.

Your Full-Line Pellet Plant Partner

We provide more than just a high-quality wood pelletizer for sale. As your single-source supplier, we deliver the complete set of equipment for a fully functional pellet plant. Our experts select and configure all auxiliary machines to match your specific process requirements and material characteristics, ensuring optimal performance from raw material to finished bag.

Frequently Asked Questions

Have questions about our wood pelletizer for sale? We have answers. Below are real questions from our global clients about machine capabilities, material suitability, and setting up their pellet production. Find the insights you need to make a confident decision.

Can you provide a detailed wood pelletizer pricelist for different models and their capacities?

+

Of course. Providing a clear wood pelletizer price for each model helps you make an informed decision. Below is a reference pricelist for our core MZLH series ring die wood pelletizer for sale. Please note that these prices are for the pellet mill unit itself and can vary based on specific configuration options. A complete wood pelletizer line with all auxiliary equipment will be priced as a custom package.

- MZLH320 (22KW): Capacity 0.2-0.3T/H | Price: $15,000-18,000

- MZLH350 (37KW): Capacity 0.3-0.5T/H | Price: $18,000-25,000

- MZLH420 (90KW): Capacity 1-1.2T/H | Price: $26,000-32,000

- MZLH520 (132KW): Capacity 1.5-2T/H | Price: $43,000-50,000

- MZLH678 (200KW): Capacity 2.5-3T/H | Price: $64,000-70,000

- MZLH768 (315KW): Capacity 3-4T/H | Price: $75,000-85,000

The final wood pelletizer price is influenced by the motor brand, the specific alloy of the ring die, and optional features like an automatic lubrication system.

For a precise quotation tailored to your raw material and production goals, we recommend contacting our sales team. They can provide a comprehensive wood pelletizer pricelist that includes the optimal model and any necessary auxiliary equipment for a successful operation.

We have both softwood and hardwood sawdust – will the same wood pelletizer machine handle both types effectively?

+

Yes, absolutely. Our ring die wood pelletizer for sale is specifically engineered to handle both softwood and hardwood sawdust efficiently. The key is in the customizable compression ratio of the ring die. For softwoods like pine, which are more fibrous and compress easily, we typically recommend a die with a lower compression ratio.

For hardwoods like oak or maple, which have higher lignin content but are less fibrous, we use a die with a higher compression ratio to achieve the necessary pressure for forming durable pellets.

When you consult with our engineers, we analyze your specific wood mix to supply the perfect ring die configuration. This flexibility makes our industrial wood pelletizer for sale a versatile solution for facilities processing various wood types.

What’s the minimum production capacity you offer for a small woodworking shop looking to recycle their waste?

+

For small workshops, our MZLH320 model is an ideal wood pelletizer for sale, with a capacity starting at 300-500 kg per hour. This compact, electric wood pelletizer is designed for smaller operations that want to efficiently convert their wood shavings, sawdust, and small off-cuts into valuable pellets.

It maintains the same robust ring die principle as our larger models but in a footprint that fits a standard workshop. This allows you to produce fuel for heating or bedding pellets for local farms, effectively turning waste into a new revenue stream with a manageable investment in a commercial wood pelletizer.

Our main materials are construction wood waste and pallets – what special configuration would your wood pelletizer for sale need for this application?

+

Processing construction waste and pallets requires a specifically configured complete wood pelletizer line. The primary challenge is contaminants like nails, screws, and sand. Our standard proposal for such materials includes a heavy-duty crusher to break down the wood, a powerful magnetic separator to remove ferrous metals, and a dedicated cleaner to remove dust and sand.

The core of the system, our heavy duty wood pelletizer, is then fitted with a specially hardened alloy steel ring die and rollers to withstand the abrasive nature of recycled wood. This comprehensive turnkey wood pelletizer system ensures protection for the pellet mill and guarantees a consistent, quality final product from challenging feedstock.

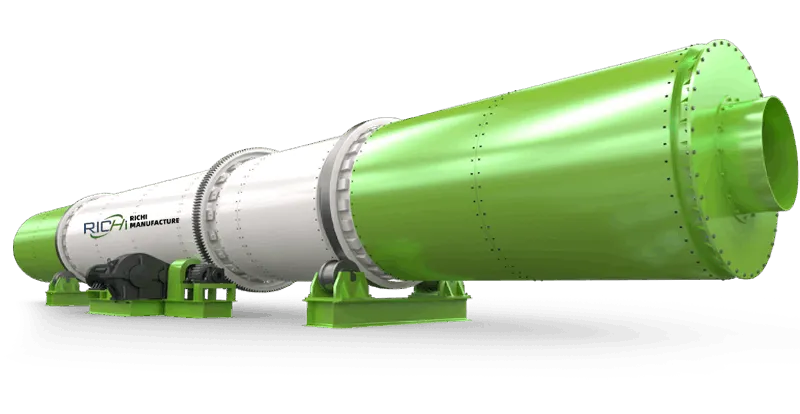

Can your equipment process wet materials like fresh wood chips without pre-drying?

+

No, it cannot process wet materials effectively, and no reputable manufacturer should claim otherwise. The pelletizing process requires a consistent moisture content of around 12-15%. Feeding fresh, wet wood chips into any wood pelletizer machine, including our high-capacity models, will not form pellets and will likely cause a blockage.

For wet materials, a dryer is an essential component of the complete wood pelletizer line. We offer a range of rotary and belt dryers that can be integrated into your system. Our engineers will calculate the necessary drying capacity based on your initial moisture content to ensure your complete biomass pelletizer plant operates smoothly from the start.

What’s the typical price range for a complete wood pelletizer plant capable of processing 5 tons per hour?

+

Providing a fixed price for a 5 t/h complete wood pelletizer plant is difficult as it is highly customized. The wood pelletizer price for a system this size depends on several factors: the specific characteristics of your raw material (size, moisture, abrasiveness), the level of automation you require, and the auxiliary equipment needed (e.g., type of dryer, crusher, cooling system).

A basic line might start in the range of $150,000 to $200,000, but a fully automated turnkey wood pelletizer system with all components can be higher. We strongly recommend you share your project details with us for a precise wood pelletizer pricelist and a solution tailored to your budget and output goals.

What wood pelletizer projects have you worked on?

+

Our wood pelletizers for sale have been trusted by clients worldwide for over two decades. From small family-run farms to large industrial energy producers, we have successfully delivered and installed thousands of machines across six continents. Each project is a testament to our commitment to providing reliable, customized solutions that turn local biomass resources into sustainable value. The following cases highlight the diversity of our global footprint and the adaptability of our equipment.

1. Wood Pelletizer for Sale USA

A sawmill in Oregon sought to reduce disposal costs and create a new revenue stream. They purchased an MZLH520 pelletizer to process their mixed softwood sawdust and shavings. The raw material, with a consistent 12% moisture content, is now transformed into 6mm premium heating pellets for the local residential market, producing about 1.8 tons per hour.

2. Wood Pelletizer for Sale Canada

A forestry cooperative in British Columbia needed to manage logging residues. They invested in an MZLH678 system to process a mix of spruce and pine chips from forest thinnings. The final 8mm wood pellets are used in a community heating system, with the plant steadily operating at 2.8 tons per hour.

3. Wood Pelletizer for Sale UK

A large arable farm in England purchased an MZLH420 to diversify its income. They use a blend of wheat straw and miscanthus from their own land. After bale breaking and milling, the material is pelletized into 6mm fuel pellets, which are sold under a brand to local schools and hospitals, achieving an output of just over 1 ton per hour.

4. Wood Pelletizer for Sale Australia

A timber company in Tasmania specializing in hardwood processing installed an MZLH768. They use it to pelletize dry eucalyptus and oak sawdust and sander dust. The highly durable 6mm pellets are exported to Asia for industrial power generation, with the line consistently hitting its 3.5-ton-per-hour capacity.

5. Wood Pelletizer for Sale Germany

A medium-sized energy provider in Bavaria chose an MZLH520 for a CHP plant. They process clean, untreated pallet waste and planing shavings. The resulting 8mm pellets are used directly in their gasification system to produce both power and heat for a local district, consuming roughly 1.7 tons of material per hour.

6. Wood Pelletizer for Sale Brazil

A sugarcane processing plant invested in an MZLH420 to handle its waste stream. They pelletize a mixture of sugarcane bagasse and eucalyptus bark. The 6mm pellets, produced at a rate of 1.1 t/h, are used as boiler fuel within their own facility, significantly reducing their reliance on fossil fuels.

7. Wood Pelletizer for Sale South Africa

A fruit farm in the Western Cape purchased an MZLH350 to manage orchard waste. They pelletize prunings from apple and pear trees. The 8mm pellets are sold as high-value smoking pellets for the braai (barbecue) market, with the small-scale line producing a steady 0.4 tons per hour.

8. Wood Pelletizer for Sale Vietnam

A furniture manufacturer near Hanoi installed an MZLH520 to recycle production waste. They process a mix of rubberwood sawdust, shavings, and a small percentage of MDF dust. The 6mm pellets are sold as industrial fuel to a nearby brick factory, with production averaging 1.6 tons per hour.

9. Wood Pelletizer for Sale Poland

A large pig farm integrated an MZLH320 into its operation. They use it to pelletize wheat straw and dried manure. The 8mm pellets are used as advanced, absorbent bedding material for the livestock, improving animal welfare and farm hygiene, with a modest output of 0.25 t/h.

10. Wood Pelletizer for Sale Mexico

An agribusiness in Jalisco purchased an MZLH420 to address agricultural waste. They process blue agave fiber and corn stover. The resulting 6mm pellets are used for local small-scale power generation, providing a reliable 1-ton-per-hour supply of biomass fuel.

11. Wood Pelletizer for Sale Thailand

A rubber wood processor installed an MZLH678 to utilize all mill residues. The line processes rubberwood sawdust and chips. The 6mm pellets are primarily for export as industrial boiler fuel, with the plant operating efficiently at 2.7 tons per hour.

12. Wood Pelletizer for Sale Italy

A vineyard in Tuscany chose an MZLH350 for a circular economy project. They pelletize prunings from their Sangiovese grapevines. The unique 8mm pellets are packaged and sold as specialty grilling pellets for the culinary market, producing about 0.35 tons per hour.

13. Wood Pelletizer for Sale Argentina

A pine plantation in Patagonia invested in an MZLH768 to manage its timber operations. They process pine logs and branches from thinnings. The 8mm pellets are shipped to urban centers for residential heating, with the large-capacity line producing 3.2 tons per hour.

14. Wood Pelletizer for Sale Turkey

A hazelnut producer on the Black Sea coast purchased an MZLH420. They pelletize hazelnut shells and branches from orchard maintenance. The high-energy 6mm pellets are sold as fuel, creating a new income from what was previously waste, at a rate of 1 ton per hour.

15. Wood Pelletizer for Sale Indonesia

A palm oil mill in Sumatra integrated an MZLH678 to handle biomass waste. They process empty palm fruit bunches and palm kernel shells. The 8mm pellets are used in the mill’s own boiler to generate process steam, achieving an output of 2.5 tons per hour.

16. Wood Pelletizer for Sale Spain

An olive oil cooperative in Andalusia installed an MZLH520. They process olive pits and prunings from olive groves. The very hard and high-energy 6mm pellets are sold as premium heating fuel, with production running at 1.8 tons per hour.

17. Wood Pelletizer for Sale Philippines

A coconut processing plant purchased an MZLH420 to utilize waste. They process coconut husks and shells. The final 8mm pellets are used for local industrial heating and are also sold as activated carbon feedstock, producing about 1.1 tons per hour.

18. Wood Pelletizer for Sale Egypt

A date palm farm invested in an MZLH350 to manage agricultural waste. They pelletize fronds and other biomass from palm maintenance. The 6mm pellets are used in local bakeries and restaurants as a cheap cooking fuel, producing 0.4 tons per hour.

19. Wood Pelletizer for Sale Chile

A radiata pine sawmill installed an MZLH768 to expand its product line. They process a mix of pine sawdust and shavings. The 6mm and 8mm pellets are produced for both the domestic heating market and export, with the line capable of 3.8 tons per hour.

20. Wood Pelletizer for Sale New Zealand

A dairy farm in Waikato purchased an MZLH320 for on-farm efficiency. They pelletize a mixture of pasture grass and barley straw. The 8mm pellets are used as supplemental feed and bedding for the herd, creating a closed-loop system that produces 0.3 tons per hour.

….

Do you offer different models specifically designed for softwood versus hardwood pellet production?

+

We don’t offer entirely separate model lines, but we expertly customize our core wood pelletizer for sale for each application. The fundamental machine structure is robust enough for both. The critical difference lies in the ring die specification. For softwood pelletizers, we use a die with a lower compression ratio that leverages the material’s natural fibers.

For hardwood pelletizers, we specify a higher compression ratio die to compact the denser material effectively. When you order a professional wood pelletizer from us, our technical team will specify the correct die and may also adjust the feeder speed and motor power settings to optimize it for your primary material, ensuring you get a high efficiency wood pelletizer for your specific needs.

How does your wood pelletizer design handle abrasive materials like MDF and particleboard dust?

+

Our wood pelletizer design incorporates several features to handle abrasive materials.

- Firstly, we use ring dies and rollers made from high-chromium alloy steel, which has superior wear resistance compared to standard materials.

- Secondly, we can configure a die with a specific hole design and a thicker face to extend its service life under abrasive conditions.

- Furthermore, the forced feeder ensures a consistent, non-slip material flow, which prevents the accelerated wear that can occur with uneven feeding.

This robust design makes our industrial wood pelletizer for sale a reliable choice for processing challenging industrial waste like MDF and particleboard.

We need to produce both 6mm and 8mm pellets – can we easily switch between sizes on your machine?

+

Yes, switching between pellet sizes is a standard feature of our professional wood pelletizer for sale. The process involves changing the ring die to one with the desired hole diameter, typically 6mm or 8mm.

With proper training and the use of a simple hoist, this changeover can be completed by your operators in a few hours. We supply different dies and provide full guidance on the procedure. Many of our clients who serve multiple markets regularly switch sizes on their wood pelletizer machine to meet varying customer demands for fuel pellets, animal bedding, or other applications.

What kind of pre-processing equipment is needed for tree branches and logging residues?

+

For raw materials like tree branches and logging residues, a complete pre-processing system is essential before the material reaches the wood pelletizer mill. We recommend a two-stage size reduction process.

- First, a wood chipper processes the branches and residues into uniform chips.

- Second, a high-power hammer mill grinds these chips into a fine powder suitable for pelletizing.

This setup is a core part of our complete wood pelletizer line for forestry biomass. We integrate all this equipment, including conveyors, to create a seamless, high-output forestry residue pelletizer system.

Can your system handle mixed materials including agricultural residues like rice husk and wood chips?

+

Certainly. Our biomass wood pelletizer is excellent for processing mixed materials. In fact, combining wood chips with agricultural residues like rice husk can often improve pellet quality due to the different binding properties.

For such mixtures, we would typically include a vertical mixer in the complete wood pelletizer line to ensure a homogeneous blend before pelletizing. The key is to determine the optimal mix ratio and then customize the ring die’s compression ratio and the conditioning system to suit that specific recipe, ensuring our high output wood pelletizer produces strong, durable pellets.

What safety features are included in your industrial wood pelletizer for sale?

+

Safety is a core part of our wood pelletizer design. Our industrial wood pelletizer for sale includes multiple safety features: an emergency stop button on the control panel, a mechanical safety device (like a shear pin) that protects the gearbox from overloads caused by foreign objects, and an electrical overload protection system for the main motor.

The belt guard and other moving parts are fully covered. Furthermore, our automatic wood pelletizer models can be equipped with interlocking systems that prevent the machine from starting if the door is open, ensuring operator safety.

How much floor space is required for a complete 3 t/h wood pellet production line?

+

A typical complete wood pelletizer line for 3 t/h output, including raw material storage, crushing, drying (if needed), pelletizing, cooling, and packaging, requires approximately 300 to 400 square meters. The exact footprint depends on the layout and the specific equipment configuration.

For instance, a vertical cooler uses less space than a horizontal one. When you work with Richi Machinery, our engineering team will provide a detailed plant layout diagram optimized for your available space, ensuring the industrial wood pelletizer line is both efficient and space-effective.

Do you provide installation supervision and operator training with your wood pelletizer equipment?

+

Yes, we highly recommend and provide both installation supervision and comprehensive operator training. When you purchase a wood pelletizer for sale from us, our experienced engineers can travel to your site to supervise the equipment installation, ensuring it is done correctly.

They will then conduct detailed training for your production team, covering everything from daily operation and routine maintenance to troubleshooting common issues. This service is part of our commitment to ensuring your complete biomass pelletizer plant achieves its designed performance from day one.

What is the typical lifespan of the ring die and rollers in your heavy duty wood pelletizer?

+

The lifespan of the ring die and rollers in our heavy duty wood pelletizer varies significantly based on the material being processed. For non-abrasive softwood sawdust, a ring die can last 800 to 1,200 hours. For more abrasive materials like hardwood or recycled wood, the lifespan may be 400-600 hours. The rollers typically last for about half the lifespan of the die.

Using our genuine, high-alloy wear parts and following proper maintenance schedules is crucial for achieving these service life expectations and protecting your investment in the wood pelletizer machine.

Can your automatic wood pelletizer be integrated with existing crushing and drying equipment?

+

Yes, our professional automatic wood pelletizer is designed for easy integration with existing equipment. We can design and supply the necessary interfacing components, such as conveyors or pneumatic transfer systems, and adapt our control system to communicate with your existing machinery.

Our engineers will need the specifications of your current crushing and drying equipment to ensure compatibility and a seamless workflow for your upgraded wood pelletizer production line.

What power requirements are needed for your 2 t/h electric wood pelletizer?

+

Our standard 2 t/h electric wood pelletizer, a key model in our wood pelletizer for sale range, is typically powered by a 90 kW electric motor. The total connected power for the entire pelletizing unit, including the forced feeder and lubrication system, is approximately 95-100 kW.

For the complete wood pelletizer plant with crusher, conveyor, and cooler, the total power requirement will be higher. We provide detailed power load lists with our proposals to help you prepare your electrical infrastructure.

How does your biomass wood pelletizer handle materials with different moisture contents?

+

Our biomass wood pelletizer itself requires a consistent moisture content of 12-15% at the feeder inlet to produce quality pellets. The machine itself cannot compensate for varying moisture levels. This is why a key part of our complete wood pelletizer line is a reliable dryer with an automatic moisture control system.

This dryer ensures that regardless of the incoming moisture fluctuation from the raw material pile, the feedstock entering the pellet mill is consistently within the optimal range, allowing the high efficiency wood pelletizer to operate stably and produce premium pellets.

What after-sales support do you provide for your wood pelletizer for sale?

+

Richi Machinery provides comprehensive after-sales support for every wood pelletizer for sale. This includes a 12-month warranty on the machine, lifelong technical support via phone, email, and video call, and a reliable supply of genuine spare parts.

We maintain a large inventory of commonly needed parts like ring dies, rollers, and bearings, ensuring fast shipping to minimize your downtime. Our support team is always ready to help you troubleshoot any operational issues with your wood pelletizer equipment.

Can your machine produce pellets from 100% bark material?

+

Producing pellets from 100% bark is challenging but possible with the right configuration. Bark is very fibrous and has low lignin content, making it difficult to bind. Our wood bark pelletizer solution involves using a ring die with a very high compression ratio and often includes a high-temperature conditioning system to help activate the natural binders.

We have successfully implemented several such specialized projects. We recommend testing your specific bark material in our facility to confirm the pellet quality and finalize the optimal machine configuration for your wood pelletizer plant.

What’s the lead time for a custom-configured complete biomass pelletizer plant?

+

For a custom-configured complete biomass pelletizer plant, the standard lead time is 30 to 45 working days after the order confirmation. This period allows for the engineering design, manufacturing, factory assembly, and testing of the entire system, including the wood pelletizer with crusher and other auxiliaries.

For more complex or large scale wood pelletizer projects exceeding 5 t/h, the lead time may extend to 60 days. We keep you updated throughout the process to ensure timely delivery of your turnkey wood pelletizer system.

Have you ever worked on a 2.5t/h wood pelletizer plant project?

+

Yes, we have. Below, we’ll show you one of our 2.5t/h pellet plant projects.

This 2.5t/h complete wood pellets plant project is to make use of waste resources, process waste resources (wood scraps, sawdust) into shaped biomass particles, shaped biomass particles are easy to store, transport, easy to use, without any harmful additives, high combustion efficiency and clean and environmentally friendly.

After the wood pelletizer plant project is completed and put into production, it will solve the problem of discarding waste materials such as wood processing waste, increase employment opportunities, protect the environment, and promote local economic development, with good economic and social benefits.

Biomass fuels are generally made of agricultural and forestry wastes (such as straw, sawdust, bagasse, rice bran and other crops containing wood fibers) as raw materials, and are made into various shapes (such as blocks) through crushing, mixing, extrusion, drying and other processes. Shape, granular, etc.), a new type of clean fuel that can be burned directly. Its diameter is generally 3-8 mm, and its length is 4-5 times of its diameter, the broken rate is less than 1.5%-2.0%, the dry basis moisture content is less than 10%-15%, the ash content is less than 1.5%, the sulfur content and chlorine content are both less than 0.07%, and the nitrogen content is less than 0.5%.

TECHNICAL SERVICE

The client of this 2.5tph wood pelleting line project has an existing standardized factory building and rents another 1824m² factory building. The plant is divided into raw material area, crushing area, drying area, product area of 1800m², and office room of 24m². Renovate the original factory buildings, purchase equipment such as wood shredders and drying equipment, and build 2 complete wood pellet production lines with an annual output of 6,000 tons of woody biomass pellets.

- Project product: Biomass wood fuel pellets

- Annual output: 6000t/a

- Production per hour: 2.5T/H

- Biomass molding fuel standards: total moisture ≤ 13%, ash ≤ 5%, volatile content ≥ 70%, total sulfur ≤ 0.1%, nitrogen ≤ 0.5%, chlorine ≤ 0.8%, low calorific value ≥ 13.4MJ/kg

- Production plan: 20t in 8h a day, 300d in a year, 2400h in a year, 2 wood pellet production lines, 6000t of biomass wood pellets per year. Among them, 100d is dried by a hot air stove, about 800h, which is only used in winter or rainy and snowy weather, and not used in sunny days in summer.

- Total project investment: 280,000 US dollars

As a manufacturer focusing on the wood pelletizer for sale, Richi Machinery insists on summarizing and summarizing the details of wood pellets manufacturing process, product improvement, on-site process layout, etc., digging deep into customer needs in multiple forms, and always taking technological innovation as the main driver We strive to do a good job in products and services, and continuously improve our production capacity and market influence.

Construction content and scale

The construction 2.5t/h wood pellet line project covers an area of 1824m². Mainly arrange the production workshop, storage workshop and raw material warehouse, etc.

- Production Workshop (built) : Leased production plant 1, with a total construction area of 1824m², divided into crushing and screening area, drying area, granulation area, and 2 production lines. Form an annual production capacity of 6,000 tons of woody biomass pellets.

- Material area (built) : is located on the north side of the factory building, covering an area of about 720m², for stacking raw materials.

- Finished product area (Created) : Located on the south side of the factory building, it covers an area of about 150m² and is used for stacking finished products.

- Office (Created) :The prefabricated house is located on the southwest side of the production plant, covering an area of about 24m².

Wood pellet Equipment List

| Device Name | QTY | Specification Model |

|---|---|---|

| Crusher | 1 | BL218 |

| Sieving machine | 1 | / |

| Wood chip dryer | 1 | / |

| Wood pelletizer | 1 | MZLH678 |

| Belt Conveyor | 2 | / |

| Loader | 1 | / |

| Hot stove | 1 | 1.5t/h |

| Pulse bag filter | 3 | / |

When choosing a wood pelleting machine or a manufacturer who focus on wood pelletizer for sale, you should purchase the corresponding supporting equipment and determine the model and quantity of the supporting equipment.

Main Raw and Auxiliary Materials

| Name | Annual consumption (t/a) | Remarks |

|---|---|---|

| Shavings | 1000 | Outsourcing |

| Sawdust | 2000 | Outsourcing |

| Wood scraps | 4000 | Outsourcing |

Energy consumption

| Name | Annual usage |

|---|---|

| Electricity (KWh/a) | 550,000 |

| Natural gas (Nm³/a) | 100000 |

Public works of 2.5T/h wood pelletizer plant

- Water supply: Mainly domestic water, the annual water consumption is about 150m3/a, and the water supply comes from the municipal water supply pipe network.

- Drainage: rain and sewage diversion system, rainwater is discharged to the ditches outside the factory through the drainage system in the factory; the wastewater of the project is mainly domestic sewage, with a daily discharge of 0.4m³/d and an annual discharge of 120m³/a. After the septic tank is treated, it is connected to the municipal sewage pipe network and imported to the Gao’an sewage treatment plant for treatment, without being discharged outside.

- Power supply: The electricity used by the project comes from the local power supply network, which can meet the needs of the project during the operation period, and the annual electricity consumption is about 550,000 KWh.

- Production organization and labor employment The project works 300 days a year, with single-shift production, 8 hours per shift, and 2400 hours per year. The project labor quota is 10 people, including 2 managers.

Richi Machinery specialize in wood pelletizer for sale, according to the resource characteristics of different countries and regions, on-site operating environment and climatic conditions, to provide corresponding customized solutions for product and wood ppelletizing factory design, so that customers have more protection in comprehensive investment.

2T/H wood pellet production plant process flow

01 Screening and crushing

The raw materials of the project are shavings, sawdust, wood scraps, etc., and the raw materials are crushed into Ø3-8 mm particles by a crusher, and then screened by a screen machine to be the raw materials for the wood pelletizer.

02 Drying

The moisture content of the pellets in the raw material is relatively high, and the process requires a moisture content of less than 10%, so the pellets need to be dried. The dryer used in this project is a drum dryer, which is mainly composed of a hot blast stove, a feeding device, a wood chip dryer, a discharging device, a cyclone separator, and an induced draft fan. The project is only used in winter or rainy and snowy days, about 100d throughout the year.

The outlet of the screening machine is connected to the dryer through a conveyor belt, and the screened raw materials are transported to the drying cylinder of the dryer by the conveyor belt. Natural gas is combusted to generate high-temperature gas flow.

The high-temperature air flow enters the drying cylinder together with the pellets, and the water in the pellets is evaporated during the high-speed hot air flow, and the pellets are discharged from the discharge port at the tail of the drying cylinder to obtain dry pellets;

The water and the waste gas produced by drying enter the cyclone separator, and the tail of the outlet of the drying cylinder is connected to the cyclone separator. Use electricity or gas as a clean fuel as an energy source.

03 Granulation

The dried product is put into the wood peleltizer mill by a forklift. Driven by the motor, the propeller rotates at a high speed, and uses its own screw to bring the raw material into the forming cylinder.

The forming cylinder is heated by the heating ring to make the raw material lignin components in the pellets are softened, the bonding ability is enhanced, coupled with the high-strength extrusion of the propeller head screw, and finally high-density and high-hardness shaped biomass is obtained.

04 Product inspection

Products that pass the inspection are put into storage and wait for delivery.

2.5 t/H wood pellet plant Layout

The production area is arranged in the southeast of the 2.5t/h pellet making plant project, and the raw material storage yard, crushing area, screening area, drying area, and granulation area are arranged in sequence from south to north, and the office is located in the northwest of the factory area.

The layout of the wood pellet factory area is conducive to the production collaboration of various departments in the process of project production and operation, and improves production efficiency. Generally speaking, the general layout of the project is basically reasonable.

Richi Machinery focuses on wood fuel pellet mill plant and wood pelletizer for sale, as a professional waste wood pelletizer supplier, in fact, Richi Machinery does not only regard wood pellet plant as a “turnkey project”, we hope it is a key to entering the new model of whole fuel pellet plant project management, and jointly maintain the stable and healthy development of the market.

Do you offer different payment terms for large wood pelletizer orders?

+

Yes, for large orders of our industrial wood pelletizer for sale, we offer flexible payment terms to facilitate your investment. While standard terms involve a deposit with order and balance before shipment, for substantial projects, we can negotiate terms such as a 30% deposit, 40% against shipment copies, and 30% after commissioning or against a bank guarantee. We understand that a complete wood pelletizer line is a major investment and we work with our clients to find a mutually agreeable financial solution.

How does your continuous feed wood pelletizer maintain consistent pellet quality?

+

Our continuous feed wood pelletizer maintains consistent quality through its stable mechanical design and intelligent control system. The heart of the system is the robust gearbox and main shaft that ensure the ring die rotates at a constant, powerful speed.

This is complemented by a forced feeder that delivers a uniform layer of material into the pelletizing chamber at a controlled rate, preventing overload or starvation. In our automatic wood pelletizer models, the feeder speed can be linked to the main motor load, automatically adjusting the feed rate to maintain optimal conditions and consistent pellet density and durability.

What makes your China wood pelletizer different from European brands?

+

Our China wood pelletizer from Richi Machinery offers a superior value proposition. While European brands are known for quality, our wood pelletizer for sale delivers comparable performance and durability at a more competitive price point.

We achieve this through advanced manufacturing in our own modern facilities, strict quality control of components like the gearbox and bearings, and a direct-to-customer sales model that eliminates middleman costs. Furthermore, we provide a level of customization and responsive service that is often challenging for larger European manufacturers to match, making us a preferred partner for a custom complete wood pelletizer line.

Can your system be upgraded to higher capacity in the future?

+

The modular design of our wood pelletizer equipment allows for some degree of future upgrades. For instance, you could start with a basic 1 t/h wood pelletizer system and later add a larger dryer, additional coolers, or automated packaging lines to increase overall plant throughput.

However, upgrading the pellet mill itself from, say, a 2 t/h to a 3 t/h model typically requires replacing the main machine. We advise clients to discuss their long-term plans during the initial consultation so we can design a wood pelletizer production line with future expansion in mind, potentially saving significant cost and effort down the line.

What certification does your CE approved wood pelletizer carry for international sales?

+

Our CE approved wood pelletizer carries the full CE marking, demonstrating compliance with European health, safety, and environmental protection standards. This certification covers the essential requirements of the Machinery Directive 2006/42/EC.

For clients in other international markets, we can also provide relevant documentation to support customs clearance and local regulatory requirements. This certification is a testament to our commitment to producing safe, reliable, and high-quality wood pelletizer machines for the global market.

How to making wood pellets with complete wood pellet plant?

+

Producing wood pellets seems to be the new rage, with new large capacity plants being announced in every news publication on a weekly basis. This summary will attempt to help you determine if this is an industry you want to invest in.

Wood Pellet Production Process:

- Typically any raw material will require some form of processing prior to being pelletized. This can range from debarking if using whole logs (round wood) to shredding or grinding of pallets, agricultural waste. Once the product is shredded or ground, it could require further processing through a hammer mill, depending on how it was received.

- If the raw material is wet (over 15%) it will need to be dried. After sizing and drying if needed, the product is now ready to be pelletized by wood pelletizer. Pellets can be made in a wide range of diameters and bulk densities, which is typically determined by the end use of the pellet.

The pellet machine die specifications can be changed, allowing for multiple sizes to be produced from the same mill. In most cases pellets will exit the wood pellet mill hot (100-170 degrees) and must be cooled. This is done with a pellet cooler by pulling ambient air through the pellets. - Once the pellet is cooled to ambient temperature, the pellets are screened to remove any fines that may have been created during the process. The pellets are now ready to be packaged by automatic bagging machine, stored or sold in bulk.

RICHI has exported wood pelletizer for sale the world, and has reached cooperative relations with more than 1,000 customers in more than 120 countries and regions, providing them with complete pellet line solutions and services covering the entire product life cycle.

What raw materials can your wood pelletizer machine process?

+

Our wood pelletizer for sale is engineered for remarkable versatility in handling a vast range of raw materials. The core principle is that any lignocellulosic biomass can typically be densified into pellets with the correct preparation and machine settings. We’ve successfully configured our machines for clients processing everything from primary forestry products to complex industrial waste streams.

The list of suitable materials is extensive. It includes all forms of virgin wood such as wood chips, shavings, sawdust, bark, and even whole tree components like branches, trunks, and stumps. This also covers forestry by-products like logging residues and forest thinnings. A significant application for our industrial wood pelletizer for sale is in recycling wood waste. This includes pallet wood, construction waste wood, reclaimed timber from demolition, and port timbers. For sawmills and woodworking plants, all their residues are ideal feedstock.

Furthermore, we have extensive experience with specialized materials. This includes furniture factory waste comprising mixed wood species, MDF, and chipboard dust. We also process specific tree species like rubber wood, eucalyptus, acacia, poplar, and fruit tree wood. The adaptability of our wood pelletizer machine even extends to certain agricultural residues when mixed with wood-based materials to ensure proper binding.

The key to success lies not just in the machine’s robust design but in our expert configuration. We analyze your specific material’s fiber structure, lignin content, and abrasiveness to recommend the perfect ring die compression ratio, feeder settings, and any necessary pre-processing steps. This ensures that when you invest in a wood pelletizer for sale from us, it is fully optimized for your unique raw material, guaranteeing high output, low energy consumption, and durable pellet quality.

What key factors should I consider before purchasing a wood pelletizer mill?

+

This is an excellent and crucial question for anyone looking to invest in a wood pelletizer for sale. Making the right choice upfront ensures long-term profitability and avoids costly mistakes. Based on our decades of experience at Richi Machinery, here is a structured approach to guide your decision.

1. Thoroughly Analyze Your Raw Material.

This is the most critical first step. The type, size, and moisture content of your material—whether it’s wood chips, sawdust, bamboo, rice husks, or more abrasive furniture waste—directly determine the required machine specification.

A professional wood pelletizer for sale must be configured to match your specific feedstock. We always conduct a free material analysis for our clients to recommend the correct ring die compression ratio and pre-processing setup, ensuring optimal pellet quality and machine longevity.

2. Define Your Required Output Capacity.

Be clear about your daily and annual production goals. Capacity needs dictate the size of the wood pelletizer machine and the entire production line. It’s also wise to consider future expansion; sometimes, selecting a slightly larger model or a system that can be easily upgraded is a more cost-effective long-term strategy than replacing the entire unit later.

3. Insist on Testing with Your Own Materials.

Never underestimate the importance of a factory acceptance test. Before finalizing any purchase, you should bring a representative sample of your actual raw materials to the manufacturer’s facility and run it through the wood pelletizer for sale you intend to buy.

This “try before you buy” approach is the only way to verify performance, output quality, and energy consumption. At Richi Machinery, we not only allow this but strongly encourage it, as it builds confidence and ensures the system is perfectly tuned for your needs.

4. Choose a Reputable and Experienced Manufacturer.

The market can be complex, making thorough research essential. Look for a manufacturer with a proven track record, substantial production capacity, and a strong portfolio of global clients. Investigate their after-sales service, availability of spare parts, and technical support capabilities.

A large, established company like Richi Machinery, which specializes in industrial-grade wood pelletizers for sale, invests in advanced manufacturing and engineering expertise. This translates into reliable equipment designed for continuous, heavy-duty operation, backed by a team of engineers who provide customized solutions from design to installation.

By carefully considering these four pillars—Material, Capacity, Testing, and Manufacturer—you can navigate the purchasing process with confidence and invest in a wood pelletizer mill that will become a reliable and profitable asset to your operation for years to come.

Can I get customized equipment for a complete wood pelletizing plant?

+

Absolutely. A truly efficient and profitable operation requires more than just a standalone machine; it demands a fully integrated wood pelletizing plant customized to your specific circumstances. When you invest in a wood pelletizer for sale from a professional manufacturer like us, the core pellet mill is just the heart of a larger system. The supporting equipment is crucial for ensuring consistent quality, high output, and long-term reliability.

A complete, customized line considers every stage of production:

- Size Reduction: It begins with a Wood Chipper to process logs and branches, and a Hammer Mill to finely grind the material into a uniform sawdust, which is essential for high-quality pelletizing.

- Moisture Control: A Rotary Dryer is then critical to consistently reduce the moisture content of your specific raw material to the ideal 12-15% range, a vital step for pellet stability and machine health.

- Pelletizing & Post-Processing: This is where your core industrial wood pelletizer for sale operates, forming the pellets. This is immediately followed by a Pellet Cooler to solidify the pellets and a Screening Machine to remove fines, ensuring a clean, premium product.

- Packaging & Automation: Finally, an Automatic Bagging System packs the finished pellets for market. Beyond these, we can integrate conveyors, silos, mixers, and dust removal systems to create a seamless, automated production line.

The key is that these are not off-the-shelf components. We customize the model and capacity of each machine—from the chipper’s power to the dryer’s throughput—based on your unique raw material type, initial moisture content, desired final output, factory layout, and investment budget. This holistic, engineered approach is what transforms a simple wood pelletizer machine into a turnkey success story, guaranteeing that your entire plant works in harmony from day one.

Why Choose Richi Machinery as Your Customized Wood Pelletizer Plant Supplier?

+

Selecting the right partner for your wood pellet production project is the most critical decision you will make. At Richi Machinery, we are more than just a manufacturer offering a wood pelletizer for sale; we are a full-service EPC (Engineering, Procurement, and Construction) partner dedicated to delivering a completely customized and profitable plant from concept to operation.

Our approach is what sets us apart. We manage your project from A to Z, beginning with a thorough analysis of your project’s profitability and the identification of the right technical solutions.

Our process is structured and comprehensive, encompassing nine key stages to ensure success: Establishing the project basis, Preliminary and Final Design, assisting with Building Permission Applications, creating Execution Drawings, managing the Contract Award process, providing continuous Project Supervision, and delivering complete Project Documentation.

This meticulous, step-by-step methodology guarantees a stress-free experience for you and a plant that is perfectly tailored to your raw materials, local conditions, and production goals.

Our expertise as a customized wood pelletizer plant supplier means that no matter your feedstock—be it wood chips, agricultural waste, or complex industrial residues—we have the engineering prowess to design a suitable wood pellet equipment solution. We don’t just sell you a machine; we deliver a fully functional, optimized production line. When you partner with Richi Machinery for your wood pelletizer for sale and plant needs, you gain a single, accountable partner committed to turning your biomass vision into a thriving, efficient reality.

How does a wood pelletizer work?

+

Ring die wood pelleting machine adopts ring die and roller as the main working parts, and is mainly composed of feeding system, mixing and tempering system, transmission system and forming system.

Working principle of wood pelletizer machine:

The motor drives the ring die to rotate, and due to the effect of friction, the material on the ring die drives the pressure roller to rotate. After the material is fed into the pressing chamber by the forced feeder, it rotates with the ring die and the pressure roller, and the two squeeze each other, and the material sandwiched between them is continuously compressed.

As the internal pressure and density of the material continue to increase, it reaches a certain density. The material is pressed into the die hole of the ring die, and after a period of pressure holding and shaping, the biomass pellet fuel with a certain density is formed.

Due to the small diameter of the pellet fuel and the large compression ratio of the ring die, the requirements for the moisture content of the raw material are relatively high.

Generally, when the moisture content is between 12% and 15%, and the particle size of the raw material is between 1 and 5 mm, it is suitable for molding.

From customized non-standard models to multi-combination standard models, Richi Machinery not only focus on wood pelletizer for sale, but always in accordance with market trends and customer needs, constantly seeking changes and improving, timely innovation, and adjusting according to customers’ actual processes.