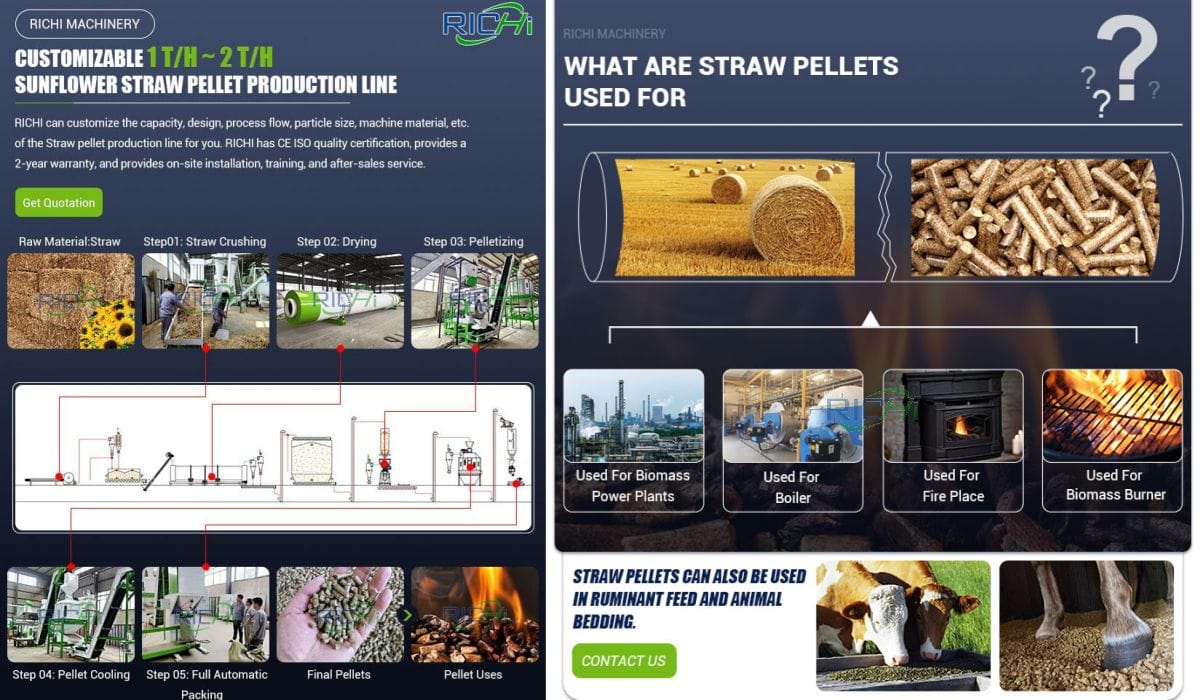

Complete crop straw Pellet Plant For Biofuel Pellets

1-90 T/H Straw fuel pellets production

1-90 T/H straw pellet plant technology uses crop straw as the main raw material, which has the characteristics of easy acquisition of raw materials, low price, continuous and stable supply, and is conducive to enterprises to maintain continuous production. (If you want to making straw pellet feed for livestock, visit our straw pellet production line for details)

Cost: 40,000-3,000,000 USD

Complete straw pellet plant Solution

- Raw material: The straw pellet plant is suitable for pressing various crop straws such as wheat straw, rice straw, corn straw, rape straw, cotton straw, sugarcane straw, peanut shell, rice husk, etc. It is also suitable for bark, branches, wood chips, sawdust, construction Templates and other agricultural and forestry waste.

- Applicable customers: Agricultural resource companies, large furniture factories, wood processing factories, rice factories, oil mills and other users who have advantages in raw materials.

Because straw fuel has high volatile content, less ash, less moisture, and is flammable, its combustion efficiency is as high as 95%. Under the same conditions, the thermal efficiency is increased by more than 7% compared with coal-fired, and the energy saving is about 10%.

How to build a 1-90 t/h straw pellet plant?

- Are there any preferential policies for external environment; subsidy for electricity tax? Attitude towards biomass pellet fuel? Is there any relevant official document published?

- Inspect the quality, price, and quantity of raw materials, and also consider the factors of long-term supply (that is, long-term control), so that we can plan the configuration of the straw pellet production line and analyze the cost according to the raw materials.

- After determining the raw materials, it is necessary to determine the factory building. The construction or finding of the factory building is generally close to the raw material or a place with convenient transportation. It is best to have both.

- Transformers. The biomass granulation industry consumes a lot of electricity. After determining the production capacity, choose to purchase a transformer that matches the production capacity according to the equipment power provided by the equipment manufacturer.

- Purchasing equipment, you must first understand the product quality of the equipment manufacturer before purchasing equipment. It is often difficult to distinguish good or bad product quality in the network environment. Try to visit the straw pellet plant machine manufacturer on the spot and don’t be fooled by the low price.

- Equipment installation and commissioning, RICHI Machinery will send technicians to guide the installation and commissioning training for free.

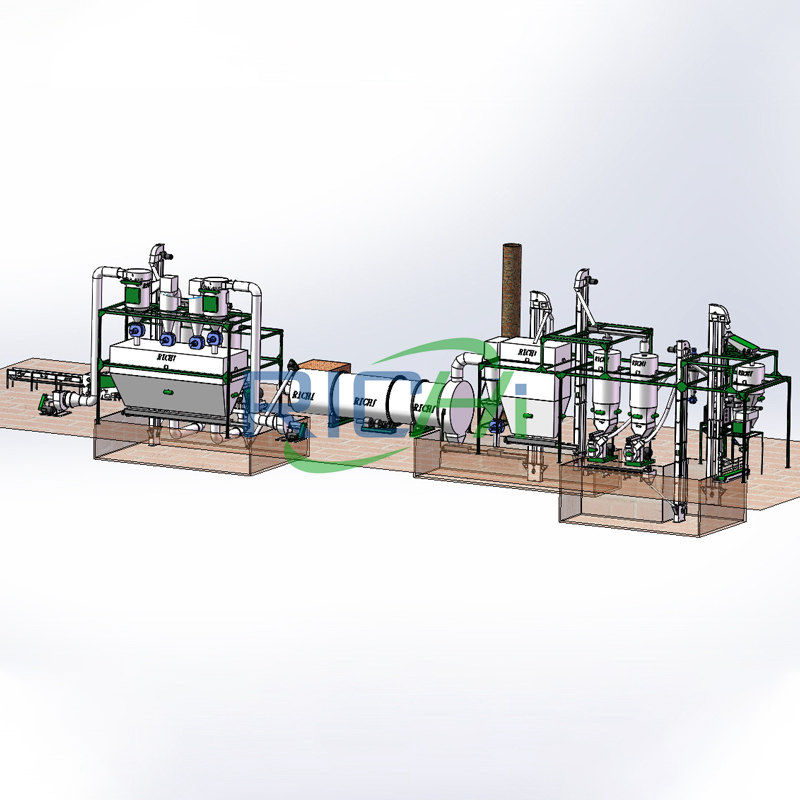

straw pellet plant process design

The preparation method of straw pellet fuel is:

Use corn straw as raw material, after natural drying (moisture content ≤ 16%), use a pulverizer to crush it into powder (particle size ≤ 8 mm), then use a straw pellet machine to extrudate and then cool, screen, and pack or later recycling. The processing flow is: collection – drying – crushing – batching – dust removal – hot compression – forming – cooling – screening-bagging.

Main equipment used in straw pellet plant

Bale breaker

Capacity:

1-15T/H

Main Power:

30-150KW

straw crusher Machine

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

Hammer Mill crusher

Capacity:

3-25T/H

Main Power:

30-160KW

straw pellet plant Projects

corn straw pellet plant in Russia

- project date: 2020.09.01

- Pellet Size: 6mm

wheat straw pellet plant in Canada

- project date: 2021.9.28

- Pellet Size: 6-8mm

wheat straw pellet plant in USA

- project date: 2020.10.10

- Pellet Size: 6-8mm

corn straw pellet plant in Argentina

- project date: 2020.06.18

- Pellet Size: 8-10mm

wheat straw pellet plant in France

- project date: 2023.06.19

- Pellet Size: 6-10mm

rice straw pellets plant in Egypt

- project date: 2020.07.23

- Pellet Size: 8-10mm

rice straw pellet plant in Thailand

- project date: 2019.05.14

- Pellet Size: 8mm

corn straw pelleting plant in India

- project date: 2022.07.30

- Pellet Size: 8-10mm

straw pellet plant Project Report

There are huge business potentials to start straw biomass pellet production line. Not only can one outsource to individuals or small communities, but also big corporations and industries. The selection of the right straw pellet equipment and technology for a straw pelleting plant is critical when establish your own biomass fuel straw pellet manufacturing business.

Next, I will list two straw pellet production plant projects we have done for you, hoping to help you.

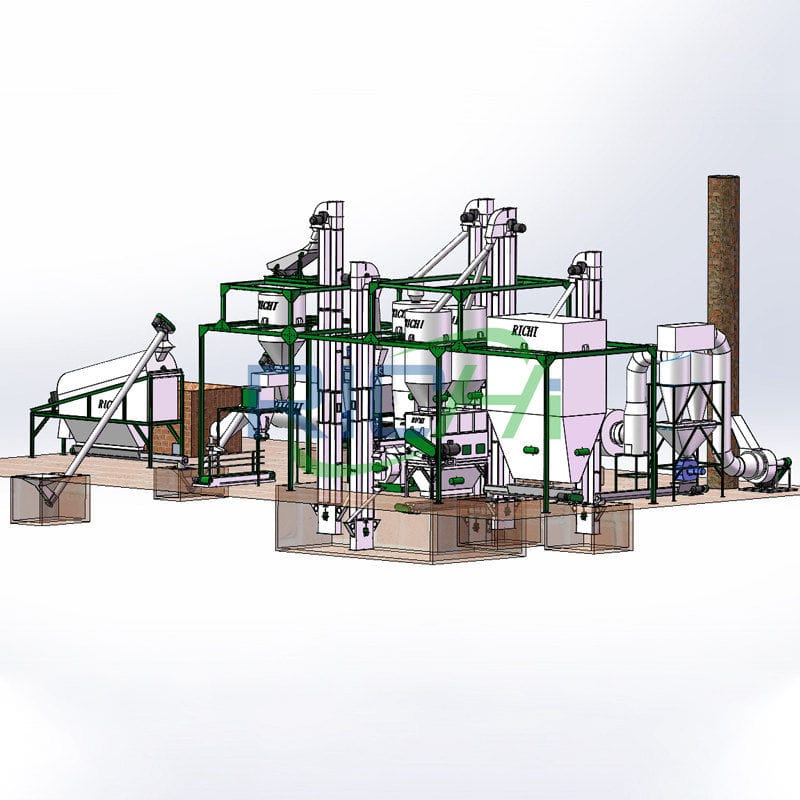

[Case 1] 2 t/h straw pellet plant project

Origin of the project

In recent years, due to the characteristics of low sulfur content and low pollution, biomass pellet fuel has been well known by more and more consumers and has a good market prospect.

After full market research and combined with its own reality, the company decided to invest $550,000 to build a biomass pellet production and processing project with an annual output of 4,000 tons (constructed in two phases, of which the first phase project-1# production line is 2,000 tons, and the second phase project- 2 # production line with an annual output of 2,000 tons).

- Nature of construction: newly built

- The project covers an area of 10 acres, with a new factory building of 2,000 square meters.

- Total investment: 130,000 USD

- Work system: 8 hours a day, 225 working days a year;

- Employees: 5 people;

Main construction content and scale

The 2t/h straw pellet plant project will be constructed in two phases:

- The first phase of the new straw biomass pellet manufacturing plant covers an area of 1,100 square meters, using straw as raw material, purchasing 1 straw crusher, 1 hot stove, 1 dryer, 2 wheat straw pellet machines, etc., using “crushing, screening, drying, granulating “Production technology, construction of a biomass pellet production line project with an annual production of 2,000 tons of straw pellets;

- The second phase of the new factory building is 990 square meters, using straw as raw material, purchasing 1 crusher, 1 hot air stove, and 1 straw dryer, and using 2 straw pellet machines in the first phase, also using “crushing, screening, drying, granulation” production process, and build a production line project with an annual production of 2,000 tons of material granules.

Plane layout of straw pellet plant

| Building Name | Footprint (m²) | Building Area (m²) | Remarks |

|---|---|---|---|

| 1 # workshop | 350 | 350 | Constructed (Phase 1) |

| 2 # workshop | 660 | 660 | Constructed (Phase 1) |

| 3 #workshop | 990 | 990 | To be built (phase 2) |

| Total | 6666.7 | 2000 | – |

Product plan

| Product name | Design scale (t/a) | Running time (h/a) |

|---|---|---|

| Biomass pellets | Phase I: 2000; Phase II: 2000; after the completion of the second phase, the whole factory will be 4000 | 1800 |

Consumption of main raw and auxiliary materials

Straw (moisture content about 25%)

- Phase 1 consumption (t/a): 2355.025

- Phase II consumption (t/a): 2355.025

- Amount used in the whole plant (t/a): 4710.05

Main equipment in straw pellet plant

Conveyor, Pulverizer, Induced Fan*30KW, Cyclone Dust Collector, Bag Dust Collector, Hot Air Stove, Screening Machine, Dryer, Feeder, rice straw pellet making machine, etc.

A total of 2 crushing and drying production lines are set up; 1 # production line is located in 1 # workshop, only the dried scrap storage area is located in 2 # workshop, and 2 # production line is located in 3 # workshop. The production capacity and time of the two production lines are the same.

The granulation section is located in 2 # workshop. The granulation section of the second-phase project relies on the granulation system of the first-phase project, and the granulation sections of the first-phase and second-phase projects cannot run at the same time.

straw pellet plant production process

- 【Feeding and transportation】: The purchased straw is fed into the feeder by the loader, and then transported to the straw crusher through the conveyor belt. (The volume and humidity of straw, corn stalks, wheat straw and other straws are relatively large (about 25%))

- 【Crushing and cyclone separation】: Due to the large volume of straw, corn stalks, wheat straw and other straws, they need to be crushed by a grinder first, and the particle size of the crushed particles is 21mm. The discharge port at the tail of the straw pulverizer is connected to the cyclone dust collector, and the material is separated by the principle of material rotation dust removal.

- 【Conveying and storage】: The crushed material after cyclone separation falls into the conveyor belt from the bottom of the cone of the cyclone dust collector, and is transported to the broken material storage area by the conveyor belt for storage.

- 【Feeding and conveying】: After the stored crushed materials are fed into the feeder by the loader, they are conveyed to the screening machine through the conveyor belt.

- 【Sieving, airtight transportation】: Since the crushed straw may contain insufficiently crushed fragments, the crushed fragments are sent to a sieving machine (filter mesh diameter 15mm×15mm) for screening, and the crushed straw with a particle size greater than 15mm The material is manually cleaned and returned to the crushing process, and the crushed material with a particle size of less than 15mm is directly transported to the dryer through a closed auger conveyor.

(The crushed material screening process of this 2t/h straw pellet plant project will produce unqualified crushed materials, about 100t/a of unqualified crushed materials (50t/a in the first phase), and the generated unqualified crushed materials will be returned to the crusher for re-grinding.) - 【Drying】: Biomass straw pellets have strict requirements on the moisture content of raw materials. Due to the different sources of purchase, the purchased straw and straw have a high moisture content (about 25%) due to rain or irregular stacking.

In order to ensure product quality, this 2t/h straw biomass pellet making plant project uses a straw dryer (using the flue gas produced by the biomass hot stove to directly heat and dry, the drying temperature is 280~450℃), so that the moisture content can meet the granulation requirements (about 10%). - 【Conveying and storage】: The broken material after cyclone separation falls into the conveyor belt from the bottom of the cone of the cyclone dust collector, and is transported to the broken material storage area by the conveyor belt for storage.

- 【Feeding and conveying】: The dried crushed material is fed into the feeder by the loader, and then conveyed to the straw granulator through the conveyor belt.

- 【Pelleting and forming】: The dried crushed material is fed into the extrusion chamber of the straw pellet machine by the loader, and the crushed material is squeezed into the inner hole of the mold by the pressing roller, and is formed by hot extrusion of the mold.

(During the compression molding process, the friction of the material generates heat (about 40℃), and the extruded material is cut into cylindrical pellets at the outlet of the straw pellet mill. The whole process is a physical extrusion molding without adding any binder. - 【Conveying and packaging】: After the finished product comes out of the discharge port, after cooling naturally, it is transported to the finished product hopper through the conveyor belt, and then sold after manual packaging.

[Case 2] Biomass fuel 2 t/h straw pellet plant project

Origin of the project

In the 21st century, straw is regarded as a green and renewable energy with a large scale of development and utilization. Crop straw contains a variety of effective components that can be used.

In addition to the vast majority of carbon, it also contains potassium, silicon, nitrogen, calcium, magnesium, phosphorus and other elements as well as cellulose, hemicellulose, lignin, protein, Amino acids and other organic components.

Research by the International Energy Agency shows that straw is a good clean and renewable energy source.

After the straw has been hot-pressed to a certain density and then burned, it can increase the combustion temperature and heat utilization rate, reduce the pollution of the air environment, and the burning speed is fast, saving time, making the straw a high-grade energy product and protecting the ecological environment.

The use of straw fuel in rural energy can provide high-quality fuel for life and production in urban and rural areas, which is an important measure to save fossil energy consumption and improve the ecological environment, and is of great significance to the sustainable development of the global economy.

Project overview

- Nature of construction: newly built.

- Total investment: $220,000.

- Labor quota and work system: 10 employees, 16 hours a day, 300 days of annual production

- Project scale and product plan: The 2t/h straw pellet plant project covers an area of 7,000 square meters, including one office, two warehouses and one workshop.

There is no canteen construction content in this biomass pellet line project. The designed production scale of this straw biomass pellet plant project is 15,000 tons of straw per year and 10,000 tons of straw pellets per year.

Project composition

- Workshop: one, equipped with two biomass pellet machines, with an annual output of 10,000 tons of straw pellets.

- Office: one, for employees to rest and work.

- Warehouse: two, used to store products.

Raw materials and energy consumption

| Name | Annual usage |

|---|---|

| Straw | 15000 tons |

| Water | 180 tons |

| Electricity | 60000kW |

Main Straw Pellet Production equipment

| Device name | QTY |

|---|---|

| Straw shredder | 1 |

| Straw pellet machine | 2 |

| Conveyor | 1 |

| Fan | 1 |

straw pellet plant process flow

- Raw material straw: The biomass raw material is temporarily stored in the storage yard.

- Crushing and screening: Due to the large size of crop straws, they cannot be directly used for molding processing. The main task of the crushing process is to crush the larger straws into short and fine granular raw materials with a straw crusher.

- Biomass pellet machine molding: the raw material is extruded by a biomass pellet machine. The crushed material is fed into the biomass pellet machine. In the biomass straw pellet making machine, the crushed material is heated.

And the heat source comes from the heat generated by the friction between the mold and the material and the heat generated by the friction between the materials due to the compression volume shrinkage.

Under the action of a certain temperature and huge pressure, the lignin in the crushed material is melted into a “glue”, and the raw material is pressed and glued into a solid object, which is extruded from the ring die hole of the straw pellet mill and extruded into this product. Project product – solidified fuel.

The cylindrical solidified fuel is continuously extruded from the corn stalk pellet machine, and cut into the required length by the cutting machine according to the market demand. The cut solidified fuel is conveyed to the packaging section, and the solidified fuel is naturally cooled during the transportation process. - Packaged finished product: The solidified fuel that is cooled during the transportation process is measured, packaged, and sealed in sequence before being stored in the warehouse.

Public works

(1) Water supply works

The water used in this 2t/h straw pellet plant project is mainly domestic water used by staff. The project has a total of 10 employees, and the domestic water consumption is calculated as 60L/d per person, and the water consumption is 180t/a.

The domestic sewage produced is calculated as 85% of the water consumption, so the domestic sewage production is 0.51t/d, 153t/a. A new well was built in the factory with a depth of 60 meters and a water output capacity of 20m³/h, which can meet the water demand of this project.

(2) Drainage works

There is no production wastewater discharge in this straw biomass pelletizing plant project. The wastewater of the project is mainly domestic sewage. The sewage discharge is calculated according to 85% of the water consumption. The sewage generated is 0.51t/d, 153t/a. Take it out and use it as farmyard manure.

(3) Heating

The office is heated by electric heating in winter, and the production workshop does not provide heating. There is no canteen construction in this project.

(4) Power supply

The power supply of this project is provided by the local power grid, which can meet the electricity demand of this 2t/h straw pellet plant project.

[Case 3] 3.5 t/h straw pellet plant project

The client of this project is entering the biomass energy industry for the first time, investing USD 420,000 to build a straw pellet plant. The project labor quota is 10 people, working 300 days a year, one shift per day, each shift is 8 hours.

At present, for many countries, the relative shortage of energy, the irrationality of the energy structure and the storage area of energy resources, and the energy waste and environmental pollution caused by the low efficiency in the process of energy development and utilization have become economic and social problems. important factor for sustainable development.

Therefore, exploiting agricultural and forestry wastes in rural areas to turn them into resources and energy, and implementing strategies to promote the development of biomass energy play an important role in economic development. If you also see the promise of this industry, why not take a deeper look?

Construction content

The 3.5 t/h straw pellet plant project covers an area of 4000m², with a construction area of 2493.6m². The buildings mainly include workshops and offices.

The gate of the project is located on the north side of the factory area, workshop 1 is located on the west side of the factory area, workshop 2 and the raw material warehouse are located on the south side of the factory area, and the office is located on the north side of the factory area.

- Production workshop: used to produce biomass pellets, located on the west side of the factory area, with a building area of 378m².

- Raw material warehouse: located on the south side of the factory area, with a construction area of 816m².

- Office: Located on the north side of the factory area, with a construction area of 75.6m².

Consumption of raw materials

| Main raw and auxiliary materials | Consumption (t/a) |

|---|---|

| Cotton Straw | 3000 |

| Corn stalk | 2500 |

| Sawdust and other waste | 2500 |

3.5 t/h straw pellet plant process design

- Crushing: The purchased dry cotton stalks, corn stalks, wood chips, etc. are sent to chippers and shredders for crushing.

- Screening: The crushed material is transported to the trommel screen for screening through the belt conveyor, and the material with a larger particle size is returned to the crushing process, and the material conveying process is sealed.

- Pelletization: The material with qualified particle size is transported to the biomass straw pellet machine by belt conveyor to make the material into granules, and the material conveying process is sealed.

- Packaging of finished products: The finished products are packaged and stored for sale.

Main equipment and parameters

| Name | QTY | Parameter | Model |

|---|---|---|---|

| Straw Wood Biomass Chipper | 1 | 60kW | TPQ216 |

| Wood Straw Crusher | 1 | 55kW | TPQ65 |

| Drum sieve | 1 | / | / |

| Straw Pellet Machine | 1 | 90kW | MZLH520 |

| Conveyor | 2 | / | / |

Product plan

| Product name | Design scale (t/a) | Running time (h/a) |

|---|---|---|

| Biomass pellets | Phase I: 2000; Phase II: 2000; after the completion of the second phase, the whole factory will be 4000 | 1800 |

Public works

- Heating: The production area does not need to be heated in winter, and the office area is heated by air conditioning in winter, which can meet the heating needs of the project.

- Power supply: The 3.5t/h straw pellet plant project uses about 500,000 kW•h/a of electricity, which is supplied by the local power grid, and the pull wires are drawn from nearby substations, which can meet the electricity demand for project production.

- Water supply: provided by the local water supply network, the water quality and quantity meet the water demand of the project. The fresh water consumption of the project is 360 m³/a, mainly water for dust suppression and domestic water for employees.

Environmental engineering

- Wastewater: All water for dust suppression in the project is evaporated, and no production wastewater is produced; the wastewater is mainly the domestic sewage of employees, with a volume of 0.32m³/d (96m³/a). Cleaning, no discharge, no waste water discharge in the whole plant.

- Exhaust gas: Waste gas in the process of feeding, crushing, screening, and granulation of biomass pellets: gas collection hood + bag filter (sub-meter meter) + 15m high exhaust pipe, while the workshop is sealed and the equipment is sprayed Sprinkler device.

Material loading and unloading process (unorganized): the material is stored in the raw material warehouse, and a sprinkler device is installed to sprinkle water to reduce dust during material loading and unloading; the material conveying process is airtight; set up a fog cannon to reduce dust in the factory. - Noise: The mechanical noise generated during the operation of production equipment, select low-noise equipment, foundation vibration reduction, workshop sound insulation, etc.

- Solid waste: leftovers and dust are classified and collected and reused in production; waste packaging materials are collected and sold; domestic waste is regularly cleared and transported by the sanitation department.

[Case 4] 3 t/h straw pellet plant project

Basic overview

- Project nature: newly built

- Project investment: a total investment of 180,000 US dollars

- Occupied area: The total area of the project is 666.7m² (about 1.0 mu), and the total construction area is 460m², 1 new workshop.

- Construction scale: After the project is completed, 9,000 tons of biomass fuel pellets will be processed.

- Labor quota and work system: The labor quota of this project is 3 people, and a shift system is implemented, with 10 hours of work per shift and 300 days of work in a year.

- The project covers an area of 666.67 m², and only builds one production workshop with a construction area of 460 m².

Main raw materials

- Raw material: straw

- Consumption: 9010t/a

- Storage capacity: 5t/a

- Packing form: Bulk

- Storage location: workshop raw material area

Equipment for 3 t/h straw pellet plant

- 1 set of crushing system: straw grinder, silo;

- 1 set of granulation system: straw pellet press, finished product warehouse;

3T/H straw pellet production process flow

The customer’s straw raw material moisture is less than 15%, and has been chopped and sliced, so there is no need to configure hay cutters, slicers and straw dryer.

The process flow we design for customers is as follows:

The purchased raw materials are transported to the factory area by a transport vehicle covered with a tarpaulin, and crushed by a straw pulverizer. The crushed straw powder enters the raw material warehouse through negative pressure suction for storage, and the raw material is transported to the straw pellet machine by a fully enclosed screw for extrusion.

Compression forming, the formed pellets are transported to the finished product silo through a fully enclosed conveyor belt for temporary storage, and after the pellets are naturally cooled, they are manually packed in tons of bags and wait for sale.

Public works

Water supply

The water for this 3 t/h straw pellet plant project is uniformly supplied by the water supply station where the project is located, and the water quantity and quality can meet the water demand of the project. The water used in this project is mainly domestic water and fog cannon water, with a total water consumption of 8.84m³/d.

- Production water: This project is mainly used for dust suppression during raw material loading and unloading. This project uses a fog cannon machine for dust suppression. The water consumption of the fog cannon machine is 1.5m³/d, which is centrally supplied by the water supply system where the project is located.

- Domestic water: This project has a labor quota of 3 people, all of whom are nearby residents. They do not have board and lodging in the factory area. RThe domestic water consumption of employees is 50L/ Calculated by people•d, domestic water consumption is 0.15m³/d.

Drainage

The rain and sewage diversion system is adopted for the drainage of the project, and the rainwater is collected separately and discharged outside. The daily spraying water of the fog cannon machine is taken away with evaporation, and no production wastewater is generated.

The amount of domestic wastewater generated is calculated based on 80% of the water consumption, so the amount of domestic wastewater generated is 0.12m³/d, mainly washing wastewater, and the amount of wastewater generated is small, which is directly used for dust suppression in the factory area.

Heating and cooling

This 3 t/h straw pellet plant project has no production heat. Electric heaters or air conditioners are used for heating in winter, and coal-fired boilers are not used; air conditioners are used for cooling in summer.

Power supply

The power consumption of this project is connected to the local power supply pipeline network, and the power and voltage can meet the power demand of this project.

Since the project site has strict environmental protection requirements, in order to further reduce the amount of fugitive dust, the main measures to be taken in this project are as follows:

- Minimize the generation of dust in production in terms of process design, and choose more advanced production equipment in this industry, which can reduce the phenomenon of dust running and emitting;

- Raw material transportation vehicles should adopt closed body as far as possible, and ensure that the materials are not spilled or leaked.

- In the process of sieving and granulating, try to use closed equipment;

- Minimize the drop of the material at the material outlet to reduce the escape of dust;

- The workshop and dry powder spare room shall be airtight.

- Clean and collect dust deposited on the ground or workbench regularly.

- Strengthen the collection and management of unorganized emissions from the 3 t/h straw pellet plant workshop, and install workshop dust purifiers in the workshop material loading process and dry material standby powder room to reduce workshop dust emissions.

Why use straw to process biomass pellet energy?

Biomass energy is an important part of energy resources. Its development and utilization can alleviate my country’s energy shortage, provide clean and high-quality energy, and can partially replace coal, oil and natural gas. As biomass energy, it has the advantages of no public harm, renewable and beneficial to environmental protection.

Many countries are very rich in biomass energy. The development of biomass solid fuels and the implementation of coal substitution can significantly reduce carbon dioxide and sulfur dioxide emissions and produce huge environmental benefits.

Especially in recent years, the government and the public have paid more and more attention to the impact of agricultural residues residues on environmental pollution, and put forward higher requirements for the resource utilization and harmless treatment of agricultural residues.

Therefore, investing in the establishment of a straw pellet plant will be supported by the government.

Hazards of incineration of straw and other agricultural, rural and agricultural residues:

- Pollution of the air environment, endangering human health. When burning straw, the three pollution indexes of sulfur dioxide, nitrogen dioxide, and inhalable particulate matter in the atmosphere reached their peaks, among which the concentration of sulfur dioxide was twice as high as usual, and the concentration of nitrogen dioxide and inhalable particulate matter was three times higher than usual.

Equivalent to the fifth level of daily average concentration. When the concentration of inhalable particles reaches a certain level, it will greatly irritate the mucous membranes of the eyes, nose and throat, and cause coughing, chest tightness, and tears in mild cases, and may cause bronchitis in severe cases.

- Cause a fire, threatening the safety of people’s life and property. Straw burning is very easy to ignite the surrounding combustibles, especially near the mountains and forests. Once a fire is triggered, the consequences will be disastrous.

- Cause traffic accidents, affecting road traffic and aviation safety. Since there is a large amount of farmland on both sides of most expressways, the smog formed by burning straw will cause air visibility to decrease, and the visible range will be reduced, which will easily lead to traffic accidents.

- Destroy the soil structure and cause the quality of farmland to decline. The burning of straw causes the ground temperature to rise sharply, which can directly burn and scald the beneficial microorganisms in the soil, affect the full absorption of soil nutrients by crops, directly affect the yield and quality of farmland crops, and affect agricultural income.

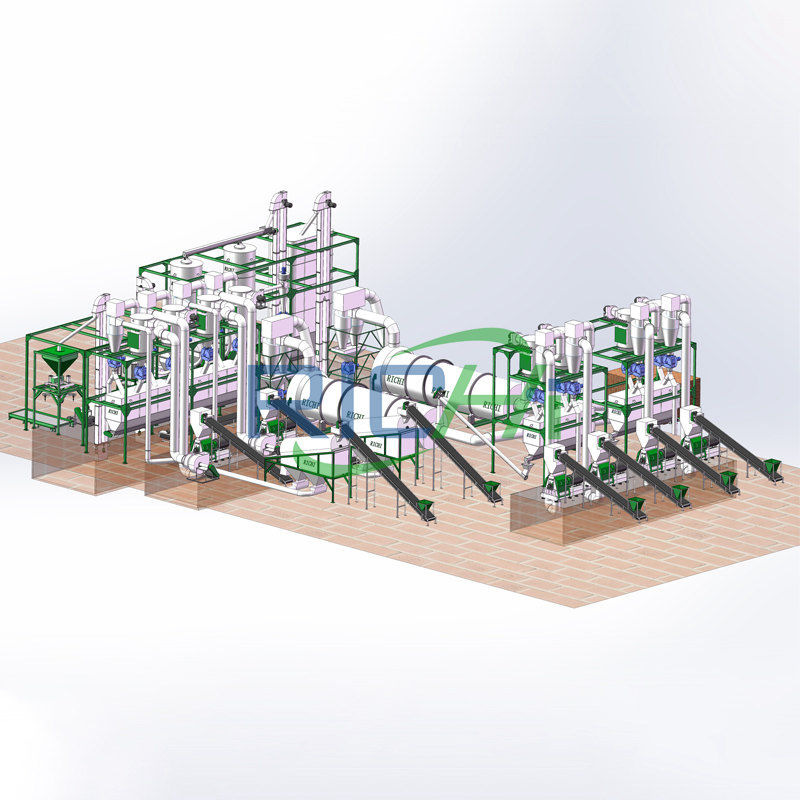

[Case 5] 4 t/h straw pellet production project

Origin of project

Biomass energy is a renewable resource and the only renewable carbon source. The development of biomass energy is a strategic measure to promote energy conservation and emission reduction.

It is an important aspect of promoting the development of circular agriculture and building modern agriculture. It is also an effective way to protect the ecological environment and use agricultural resources rationally and effectively. Among them, straw is the most common agricultural waste for most countries.

The burning of coal and oil has caused a certain degree of pollution to the environment. Choosing biomass pellet fuel instead of burning coal and oil can meet environmental protection requirements and is affordable. In view of this, the client seized the market opportunity and built a new local 4t/h straw pellets plant project with an annual output of 10,000 tons.

- Nature of construction: newly built

- Total investment: USD 450,000

- Main construction content and scale: The project covers an area of 10,000m², with a total construction area of 1,700m². It is mainly divided into production workshops, warehouses, and comprehensive office buildings. After the project is fully completed, it can produce 10,000t/a of biomass pellets.

- Labor quota and working system: The project has a quota of 15 people, and the annual production days are about 300 days. The enterprise working system is 8-hour production in one shift, and no production at night.

- Project progress: The project is expected to be completed and put into operation in October 2018.

Main construction content

- Production workshop: 1F, steel structure, construction area 500m², equipped with 1 straw pulverizer, straw pellet mills, and 5 conveyors.

- Warehouse: 1F, steel structure, construction area 1000m². It is used to store raw materials and finished products, with a storage capacity of more than 10,000 tons.

- Comprehensive office: 1F, steel structure, building area 200m².

Raw materials and energy consumption

The main raw materials required for the production of this 4t/h straw pelletizing plant project are solid wastes such as crop stalks, straw, and rice husks.

| Name of raw material | Annual consumption | purpose |

|---|---|---|

| Crop solid waste | 10000t/a | Ingredients |

| Electricity | 100000kwh/a | Production life |

Main equipment to start 4 t/h straw pellet plant

| Device Name | Specification Model | QTY |

|---|---|---|

| Forklift | / | 2 |

| MZLH420 Straw pellet machine | / | 4 |

| Straw grinder | / | 1 |

| Conveyor belt | Length 24m | 1 |

| Conveyor belt | Length 30m | 1 |

| Conveyor belt | Length 35m | 1 |

| Conveyor belt | Length 18m | 1 |

| Conveyor belt | Length 15m | 1 |

| Bag filter | / | 1 |

Straw biomass fuel processing process

- Loading and unloading: The wood chips and straw transported by cars from the surrounding area are loaded and unloaded in the warehouse. There is no boiler in this 4t/h straw pellet plant project, and the raw materials are stacked in the workshop instead of outside.

- Crushing: The raw materials are crushed according to the process requirements, and the crushed raw materials are less than 5mm. The dust generated by this process is processed through a bag filter, and the generated dust is reused.

- Granulation: The biomass straw pellet fuel pellet machine is the key equipment of the production line. According to the needs of customers, adjust the use of the straw pelletizer The raw material contains a certain amount of lignin and cellulose. The lignin is a structural monomer in the material and is a polymer compound. It has the function of strengthening cell wall and binding cellulose.

Lignin is non-crystalline, the main part is insoluble in any solvent at room temperature, has no melting point, but has a softening point. When the temperature reaches a certain value, the softening cohesive force of lignin increases, and under a certain pressure, the cellulose molecular clusters are dislocated, deformed, and extended. During the granulation process, the temperature should be controlled at 80-100℃. - Transport and cooling: The temperature of the biomass fuel at the outlet of the straw pelleting machine is 80-90℃, and the generated biomass pellets are sealed and sent to the buffer silo through the conveyor belt, and the biomass pellets are naturally cooled during the transmission process.

- Packaged into storage: After cooling, the biomass straw pellets are packaged and stored for sale.

Public works

(1) Water supply and drainage

The source of water supply for this 4t/h straw pellet plant project is the local water supply pipe network.

(2) Power supply

It is connected to the local municipal power grid, which is stable and reliable, and can meet the project requirements.

(3) Heating

Electric heating is used for office heating in winter.

Reasonable location

This project is a newly built project with convenient transportation and superior geographical location. The water and electricity supply capacity can meet the needs of the project. The project location does not involve sensitive areas such as nature reserves, scenic spots, and drinking water sources, and there are no environmental constraints.

General layout rationality

The factory area is generally divided into two parts, the north is the production area, with a straw biomass fuel processing workshop, a warehouse, etc.; the south is the office and living area, with an office.

The general layout design of the 4t/h straw pellet plant project combines the natural conditions of the factory area such as terrain, geology, hydrology, and meteorology to comprehensively and reasonably arrange the buildings and transportation routes of the factory area.

The building layout is compact, the transportation is convenient, and the management is convenient, which is conducive to improving the production efficiency of the enterprise and reducing transportation costs.

The production workshop is about 80 meters away from the nearest residents on the west side, and the production area is located in the crosswind direction of the perennial dominant wind direction (northwest wind), which has little impact on nearby production, office and residents’ lives, and the overall functional division is reasonable. In summary, the layout of the project is reasonable.

[Case 6] 5T/H straw pellet plant

Origin of the project

This straw pellet plant project is a new project, and the customer rented an existing factory building for project production. The plant covers an area of 3.82 mu (2544m²), with a total construction area of 4500m².

According to the actual needs of customers, we have configured crushers, pulverizers, straw biomass pellet mills and other facilities for customers. After being put into operation, it can reach the production capacity of 12,000 tons of pellet fuels per year.

After biomass is compressed and molded, its volume is greatly reduced, which makes it easier to transport, store and use, and solves the key problem of large-scale utilization of biomass.

In view of this, the client is optimistic about the market prospect of crop pellet production, and uses the purchase of wood chips or wood scraps and agricultural and forestry waste from surrounding rural areas as the source of raw materials for this project to achieve comprehensive utilization of resources.

The 5t/h straw pellet plant project uses the purchase of agricultural and forestry waste straw, wood chips or wood scraps from surrounding rural areas as the source of raw materials for this project, and reduces the moisture in the raw materials through natural drying, without using fuel for drying.

- Construction nature: newly built

- Total investment: $350,000

- Product specification: 8mm in diameter, about 1.6-2.4cm in length

- Main raw materials: straw, flue-cured tobacco rods, sawdust or wood scraps, etc.

- Working system: 8 employees, 300 days a year, 8 hours a day, one of them is on duty every day, and the rest of the employees do not live in the factory.

Construction scale

The total area of the project is about 2544m², including 400m² living area, 1944m² processing workshop, 200m² molding workshop and warehouse. The factory building and cement hardened ground have been completed.

During the construction period of the project, decoration and equipment installation will be mainly carried out, and no other buildings will be built.

- Production workshop: The production workshop is 1944m², with a height of about 7m. It uses the built buildings in the leased factory area for decoration and renovation. It is mainly engaged in the production of biomass pellets. After the straw pellet plant project is completed, it can achieve an annual output of 12,000 tons of biomass pellets.

- Warehouse and granulation workshop: covers an area of about 200m². Relying on the built buildings in the project area for decoration and transformation, it is used for the molding of biomass pellets and the stacking of raw materials.

- Office area: The office covers an area of about 400m², using the existing rooms in the site as the office area. (Related solution: 2t/h biomass pellet manufacturing plant)

Raw and auxiliary materials and energy consumption

Biomass pellets are mainly wood chips or wood scraps, agricultural and forestry wastes (mainly straw, flue-cured tobacco rods, etc.), which are extruded into rod-shaped biomass pellet fuels through the pressure of a biomass pelletizer.

The site of this project is small, so it is not suitable for drying a large amount of raw materials. In view of this problem, we suggest that customers control the moisture content of the purchased raw materials to about 20% as much as possible, or rent another site for drying raw materials, and avoid drying in the factory area.

The production of the 5t/h straw pellet plant project does not add any auxiliary materials, and does not use waste wood containing paint. The main raw and auxiliary materials used in the operation process are detailed in the following table:

| Name | Consumption |

|---|---|

| Scrap wood, offcuts, sawdust | 6150.9t/a |

| Agricultural and forestry waste such as straw and flue-cured tobacco stalks | 14352.1t/a |

| electricity | 13000kw•h/a |

| Water | 240t/a |

| Packaging material (bag) | 0.7t/a |

Main product plan

Since the sales target of the product is industrial and civil use, the production of the product will be processed into rods (different in thickness) according to different fuel equipment and scope of use.

According to the diameter of 8mm and the length of about 1.6-2.4cm, the process flow and related equipment are designed to be suitable for various boilers and kilns, with an annual output of 12,000 tons.

The process flow is briefly described as follows:

The customer collects agricultural and forestry wastes such as straw and flue-cured tobacco rods at fixed points. When the agricultural and forestry wastes are not enough, the leftovers, sawdust, and waste wood produced by the wood processing plant are purchased as raw materials for production. (Related solution: 1-1.5t/h biomass pellet production line)

They need to be dried, crushed, and crushed according to the moisture content and particle size of the purchased raw materials. After processing, it will be granulated for production.

- Drying: The moisture content of the raw materials that can be directly used for crushing by the crusher is about 15%-20%. If the moisture content of the purchased raw materials cannot reach the standard of 15%-20%, the raw materials will be dried first.

When its moisture content is reduced to between 15% and 20%, it will be crushed. Due to the small size of the project area, the construction unit designed to control the moisture content of the purchased raw materials at about 20%, try to avoid drying raw materials in the factory area, or rent another site for drying raw materials. - Chipping: Use a crusher to cut waste wood, straw, bellflower, etc., and large pieces that cannot be crushed directly into small pieces.

- Crushing: Agricultural and forestry wastes are pulverized by a pulverizer to make the particle size less than 5mm. The biomass pulverizer is only equipped with a material inlet and a material outlet.

After feeding, close the material inlet to reduce dust escape. After the dust generated by the pulverizer is treated by a cyclone dust collector and a bag filter, all the collected dust can be reused in the production line . - Granulation: The crushed materials of the project are made into granular biomass fuel through physical extrusion. The material transportation process is closed transportation, and the materials transported to the granulation workshop are fed to the straw pellet making equipment by a forklift.

The whole process Do not use manual dumping of materials.The project is made into finished products through extrusion. The extrusion process is a physical process, without adding any adhesives, and without chemical reactions. Except for the connection of the feeding auger and the outlet, the equipment is sealed; - Conveying and cooling: The granulated biomass pellets are naturally cooled by conveying, so that their temperature can reach the conditions for packaging and storage, and finally conveyed to the finished product warehouse.

- Packaging: The compressed hot pellets pass through the screening at the end of the conveyor belt, and the qualified biomass pellets fall into the finished product bin. The bottom of the finished product bin is a funnel-shaped discharge port, and the finished product can directly fall into the packaging bag.

After the machine is packaged, it can be stockpiled and sold. After molding, the biomass pellets have been compressed and compacted, and basically no dust will be generated during the bagging process. Unqualified products are discharged and collected and returned to the granulation process.

Equipment for 5 t/h straw pellet plant

| Name | QTY |

|---|---|

| Slicer (crusher) | 1 |

| Straw shredder | 1 |

| Straw pellet machine | 2 |

| Bag filter | 3 |

| Cyclone dust collector | 2 |

| Loader | 1 |

| Forklift | 1 |

| Grabber | 1 |

| Bucket | 1 |

General layout

The entrance and exit of the living area and the production factory area of the project are connected to the road on the south side, so the transportation is convenient. The plant covers an area of 3.82 acres (2544m²), with a total construction area of 4500m². The crushing and crushing workshop of the 5t/h straw pellet plant project is located on the west side of the living area and the southwest of the entire factory area.

In order to reduce the impact of noise on the sensitive points on the east side of the factory boundary during the project operation period, we designed to arrange the crusher and pulverizer on the northwest side of the crushing and crushing workshop, as far away from sensitive points as possible.

The warehouse, granulation and molding workshop are located on the northwest side of the crushing and crushing workshop. About 8m east of the factory boundary is a residential area. There is a living area between the production plant and the residential area. The cement hardened ground in the factory area separates rain and sewage.

While promoting the development of the local economy, the construction of the project can also achieve comprehensive utilization of resources, reduce the occurrence of random stacking and incineration by local farmers, and reduce the generation of air pollutants to a certain extent.

The 5t/h straw pellet plant project continues to use the completed factory buildings for project production, no open-air operations, waste gas and noise are reasonably designed and equipped with disposal facilities, the solid waste disposal rate in the factory area can reach 100%, and waste water is not discharged outside, which minimizes the impact of project production on the surrounding environment Impact.

Why use straw as raw material for biomass pellets?

Straw biomass pellets mainly use corn stalks, cotton stalks, wheat straws, tobacco stalks, etc.) as raw materials, and are extruded into rod-shaped biomass pellet fuels through the pressure of a biomass pellet press.

- It’s renewable energy

Straw is a green plant and a renewable energy source. Biomass fuel can reduce zero emission of CO, which is very beneficial to control climate warming. - It’s a low-pollution fuel

The pellet fuel made of straw as the main component is low-pollution. The oxygen content of straw fuel is 3-4 times larger than that of coal, with less heavy hydrocarbons, good combustion effect, and the blackness of smoke is lower than Ringelman level 1. - The economy is reasonable and the scope of application is wide

The cost of processing straw into pellet fuel is significantly lower than that of diesel and natural gas. The economic advantages of biomass pellet combustion boilers are very prominent.

Substituting fuel oil, gas, and electric heating boilers can save users a lot of operating costs. Compared with coal, although the price is similar, its superior environmental protection performance and renewability are unmatched by coal-fired boilers. - High combustion efficiency, saving energy

Due to the high volatile content of straw fuel, less ash, less moisture, flammability, mechanical, chemical, and smoke exhaust incomplete combustion heat loss is small, and the combustion efficiency is as high as 95%.

Under the same conditions, the thermal efficiency is increased by more than 7% compared with the coal-fired furnace, and the energy saving is about 10%.

If you also want to build your own straw pellet plant, please feel free to consult Richi Machinery! (Find RICHI on YouTube)