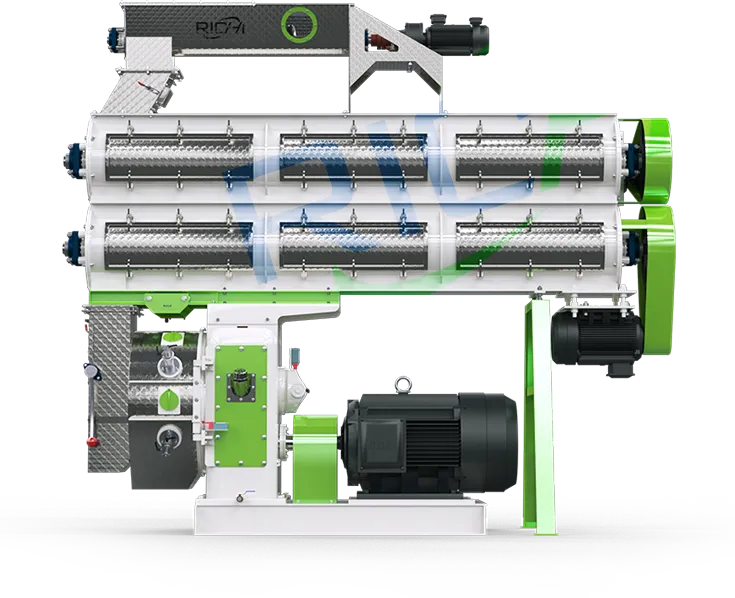

SMALL ANIMAL FEED PELLET MACHINE

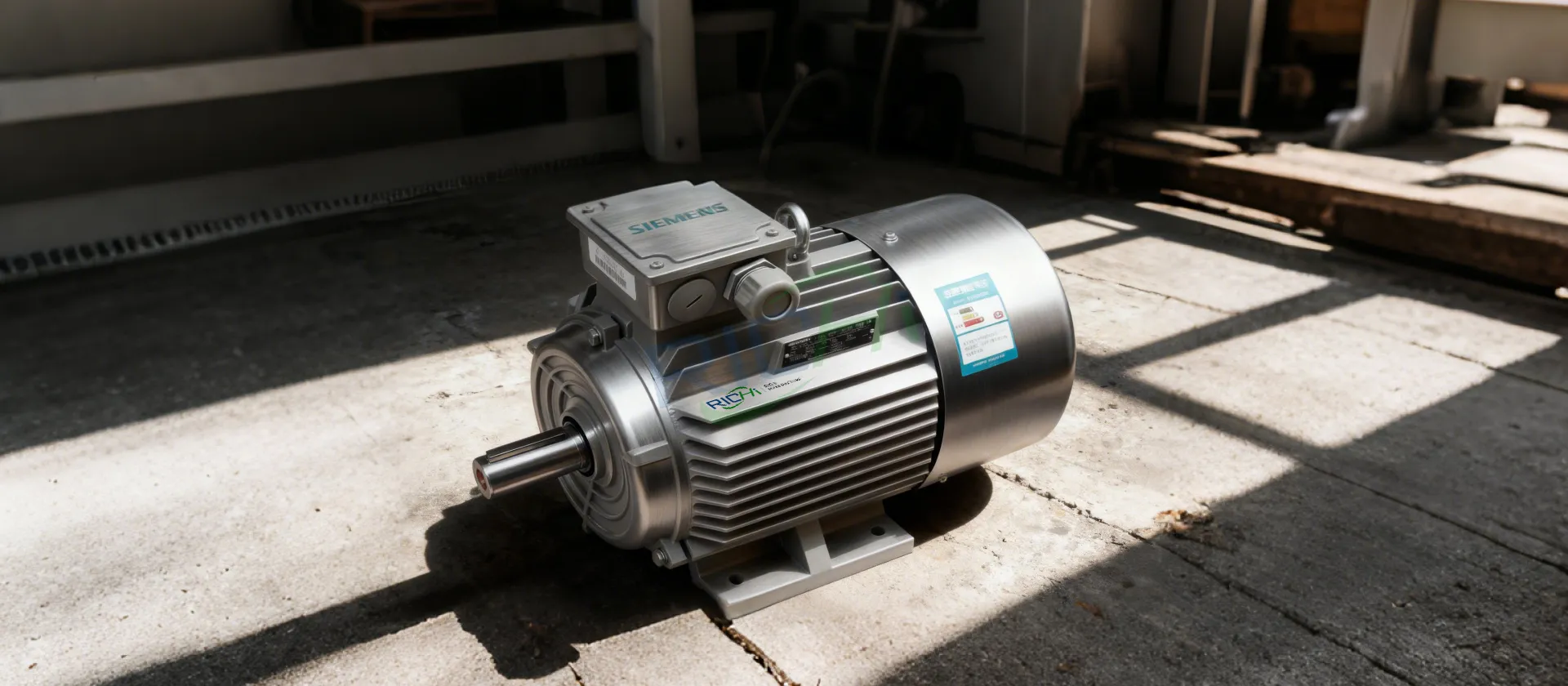

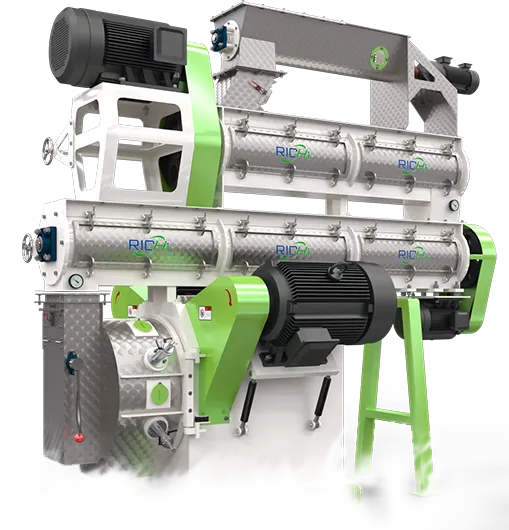

Achieve 1-2t/h production with ease. Our small animal feed pellet machine delivers durable, uniform pellets—efficiently and reliably. This small animal feed pellet machine is RICHI’s smallest ring die model, transforming corn, soybean, grass, and other various raw materials into nutritious pellets at small capacity.

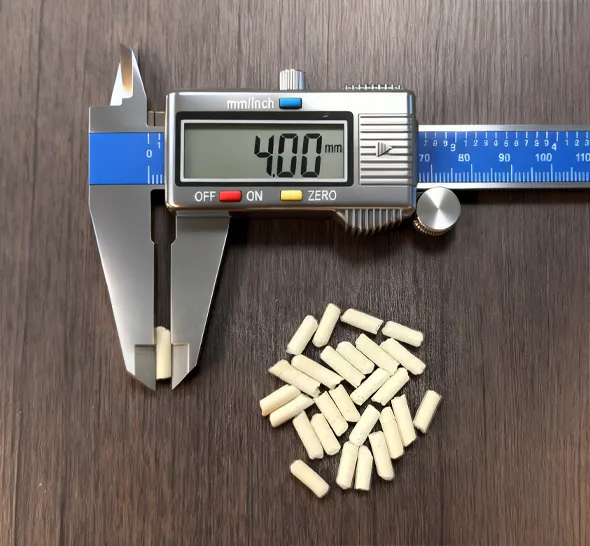

Pellet Size: 2~12mm

Price: 7000-8000 $

Model

SZLH250

Production Capacity

1-2T/H

Versatile Application for All Your Feed Needs

Our small animal feed pellet machine is the core of modern feed production. Designed as a true ring die system, it is the most compact and efficient model in the RICHI lineup. It expertly processes diverse raw materials into high-quality pellets, serving as the ideal solution for animal feed mills, farms, poultry operations, and small to medium-sized agricultural businesses seeking reliable, in-house feed production.

By adapting to different formulas, this single model effectively functions as specialized equipment for poultry, livestock, and aquatic feed production.

Ideal for producing high-nutrition feed for chickens, ducks, and geese to support optimal growth and egg production.

Engineered to create durable and digestible pellets for pigs, cattle, and other livestock animals to promote efficient weight gain.

Specializes in producing water-stable pellets that are essential for the health and growth of sinking fish and shrimp.

Choose Your Conditioning Level

Our core small animal feed pellet machine is offered with three levels of conditioning technology to precisely match your feed formula goals. All models feature our signature extended-length, large-diameter conditioner for superior steam penetration and starch gelatinization. This flexibility, coupled with fully customizable conditioners, allows us to cover all feed types, demonstrating our strength as a complete feed equipment manufacturer.

Single-Layer Conditioner Pellet Mill

This is the most widely used and cost-effective configuration. It is perfectly suited for processing standard poultry and livestock feed pellets. Ideal for small to medium farms and feed mills starting with general animal nutrition.

Dual-Layer Conditioner Pellet Mill

The two-stage conditioning process provides enhanced heat and moisture control. This makes it excellent for producing premium livestock feeds and standard sinking fish feeds. Choose this for operations focused on higher-quality livestock feed or basic aquaculture.

Triple-Layer Conditioner Pellet Mill

Our top-tier system delivers maximum conditioning time for complex formulas. It is specifically engineered for manufacturing high-grade, water-stable fish and shrimp pellets. This is the choice for specialized aquatic feed producers and manufacturers of high-performance feeds.

Our Machine Handles All Your Raw Materials

The versatility of our small animal feed pellet machine is unmatched. It expertly processes the full spectrum of feed ingredients. The foundation includes energy feeds, protein feeds, roughages, and feed additives. Beyond these core categories, our robust pellet mill is also fully capable of handling fresh green fodder and fermented silage, providing a complete solution for any feed formula you need to produce.

Energy Ingredients

Corn, wheat, and barley provide essential carbohydrates. Our machine perfectly cooks and bonds these starches for optimal digestible energy.

Protein Ingredients

Soybean meal, fish meal, and sunflower meal supply vital amino acids. We ensure these ingredients are uniformly blended and pelleted for balanced nutrition.

Roughages Ingredients

Grass, hay, alfalfa, hemp and straw add necessary fiber. Our powerful ring die system compacts these bulky materials into dense, durable pellets.

Feed Additives

Vitamins, minerals, and premixes for health and growth. Precise conditioning ensures these micro-ingredients are evenly distributed in every pellet.

See Our Machine in Action

Witness the real-world performance and reliability of our small animal feed pellet machine. The videos below showcase our equipment operating in diverse customer facilities, from feed mills to working farms. See for yourself how our engineering translates into efficient, high-quality pellet production.

Bangladesh SZLH250 Poultry Feed Pelletizer Project

Indonesia SZLH250 Chicken Fish Feed Pelletizer Project

Uzbekistan SZLH250 Cattle Feed Pellet Mill Project

New Type SZLH250 Double Belt Feed Pelletizer Showcase

Superior Components, Unmatched Performance

Our small animal feed pellet machine is built with robust structural features designed for continuous, high-yield operation. From the heavy-duty housing to the precision drive system, every component is engineered for durability, stability, and ease of control, ensuring your animal feed production line runs smoothly for decades.

Why Our Pellet Mill Outperforms

Our small animal feed pellet machine combines robust engineering with intelligent design to deliver unmatched reliability and output quality. Engineered for continuous 24/7 operation, it meets the stringent standards of modern feed production, offering safety, hygiene, and stability comparable to top European and American models.

Engineered for Continuous, Stable Operation

Designed for 24-hour continuous duty. Featuring SKF bearings, a heavy-duty gear drive, and an advanced steam conditioning system with auto-adjusting feed and steam intake, it ensures non-stop, efficient production of superior poultry, livestock, and aquatic feed.

Superior Conditioning for Excellent Pellet Quality

Equipped with a large-volume, stainless steel conditioner (Ø1800mm). This enhanced design provides superior steam penetration and material maturation, directly contributing to improved feed digestibility, durability, and overall nutritional quality.

Enhanced Safety, Hygiene & Accessibility

Built with operator safety and ease of maintenance in mind. Features side access doors for quick inspection and cleaning, ensuring a hygienic production process and minimizing downtime for routine service.

Flexible Customization to Match Your Needs

We tailor the machine to your specific operation. Customization options include the conditioner configuration (single to triple layer), ring die specifications, motor power, and control system integration, ensuring the perfect fit for your feed formula and production goals.

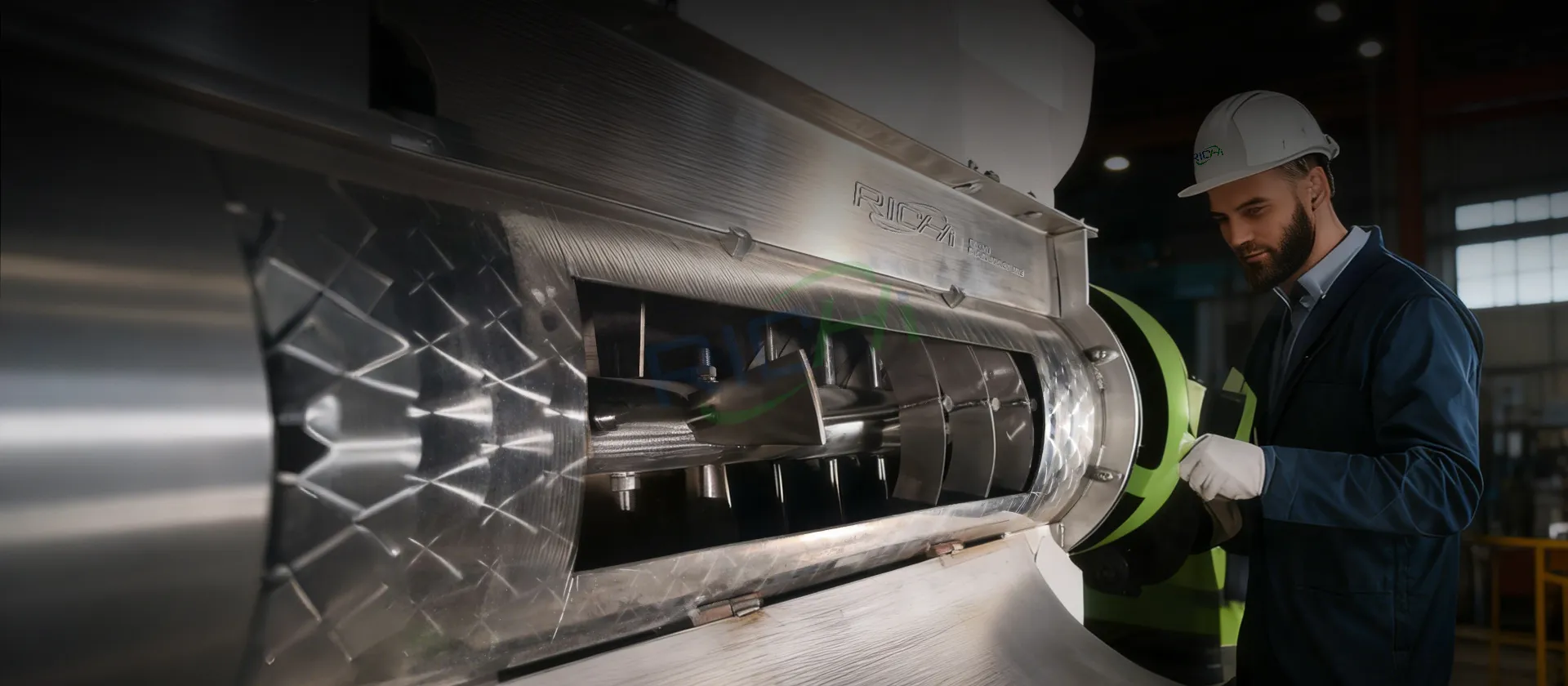

Precision Pelletizing from Raw Material to Finished Feed

Our small animal feed pellet machine transforms loose feed mixtures into uniform, dense pellets through a precise and efficient mechanical process. This reliable operation is the result of our deep engineering expertise in feed production technology, ensuring consistent quality in every batch.

The process begins in the large-volume conditioner, where raw materials are evenly mixed with steam. This critical step gelatinizes starches, improving digestibility.

The conditioned mash is then fed between a rotating ring die and heavy-duty press rollers. Under high pressure, the material is forced through the die holes, forming solid strands that are cleanly cut to the desired length by adjustable knives. The result is durable, high-quality feed ready for cooling and packing.

Technical Specifications

Below are the detailed specifications for our robust small animal feed pellet machine. This model is engineered for high performance and durability, reflecting our commitment to manufacturing excellence. If your needs require a different capacity or configuration, we also offer a complete range of seven additional ring die pellet mill models. You can click on any model to explore its dedicated product page.

PARAMETERS OF SZLH250 (1-2T/H)

Main motor power

22kW

Feeder power

1.1kW

Conditioner power

1.5kW

Ring die inner diameter

250mm

Finished pellet diameter

2-12mm

Optimizing Process for Every Feed Type

Our expertise goes beyond machinery – we understand the precise pelleting parameters required for different feed formulas. The following data demonstrates how our versatile small animal feed pellet machine can be configured to deliver optimal results across various species, showcasing our in-depth knowledge of feed processing technology.

Chicken Feed Pelletizing Parameters

Our small animal feed pellet machine is expertly configured for efficient poultry nutrition. It produces 1-2 T/H of 2-4mm pellets with a compression ratio of 1:10 to 1:13. A one or two-layer conditioner heats the finely ground mash (2-3mm) to 85°C for 60-120 seconds, ensuring optimal starch gelatinization for high-quality broiler and layer feed.

Cattle & Sheep Feed Pelletizing Parameters

For durable ruminant pellets, this machine delivers 1.5-2.5 T/H. It forms larger 6-12mm pellets using a lower 1:6 to 1:9 compression ratio. A single-layer conditioner processes coarser material (3-5mm) at 85°C for 30-60 seconds, creating dense, slow-digesting feed that meets the nutritional needs of cattle and sheep.

Pig Feed Pelletizing Parameters

Configured for swine nutrition, the machine outputs 1-2 T/H of 2-4mm pellets. A medium compression ratio (1:3.5 to 1:5) is used with medium-fine grinding (2-3mm). Conditioned at 85°C for 60-120 seconds in one or two layers, this process enhances palatability and digestibility for optimal pig growth.

Sinking Fish Feed Pelletizing Parameters

Producing 0.6-1.2 T/H of water-stable feed, this setup requires finer raw material (1-2mm) and a high compression ratio (1:16 to 1:18). A two or three-layer conditioner provides extended 90-180 seconds of conditioning at 85°C, creating the dense, slow-sinking pellets essential for many fish species.

Shrimp Feed Pelletizing Parameters

For the most demanding micro-pellets, the machine produces 0.1-0.2 T/H. It requires super-fine mash (95% over 80 mesh) and uses the highest compression ratio (1:20 to 1:25) to form tiny 1.2-2.0mm pellets. A triple-layer conditioner ensures a long 120-180 second retention at 85°C, achieving the extreme water stability critical for shrimp feed.

Our Machines Are Working Worldwide

Our expertise extends globally, with reliable feed production systems operating across continents. We have successfully delivered solutions from single small animal feed pellet machine units to complete turnkey animal feed pellet plants. Our projects span diverse clients, from family-owned farms to large commercial feed mills, processing a wide range of feed types at various production scales.

Small animal feed pellet machine in Indonesia

A poultry integrator chose our pelleting system for their feed mill. The plant produces high-quality 3mm chicken feed pellets primarily from corn and soybean meal.

Feed type: chicken feed

Pellet size: 3mm

Small animal feed pellet machine in Australia

Feed type: dairy cattle feed

Pellet size: 12mm

Small feed pellet machine in Angola

Feed type: cattle feed

Pellet size: 8mm

A commercial livestock farm invested in our equipment to achieve feed self-sufficiency. The machine processes local maize and grass into 8mm pellets for cattle.

Small feed pelletizer in Tanzania

Feed type: broiler feed

Pellet size: 3.5mm

Small feed pelletizer in Oman

Feed type: ruminant feed

Pellet size: 6mm

Small animal feed pellet machine in Thailand

A regional feed cooperative utilizes our robust small animal feed pelleting solution, manufacturing durable pellets from a mix of grains and protein concentrates.

Feed type: pig feed

Pellet size: 4mm

Small animal feed pellet machine in Bangladesh

Feed type: poultry & livestock feed

Pellet size: 3-5mm

Proven Solutions for Global Feed Producers

From a single small animal feed pellet machine to complete automated production lines, we provide tailored feed processing solutions. Our expertise covers every step—from material handling and grinding to precise pelleting and cooling—ensuring you receive a fully integrated system designed for efficiency, durability, and consistent output quality.

Client Testimonial

Our technical expertise, reliable equipment, and tailored engineering solutions have earned the trust of feed manufacturers across diverse global markets. These testimonials reflect our commitment to delivering performance that meets the specific demands of every operation., crab feed).

Argentina Client

Feed type: cattle feed

Pellet size: 8mm

As a large-scale beef producer, we needed a line that could handle local alfalfa and corn silage efficiently. RICHI provided not just a reliable pellet machine, but a complete crushing and conditioning system. Their team designed a layout that maximized our existing warehouse space. The pellet durability is excellent for our feedlot operation.

Romania Client

Feed type: pig feed

Pellet size: 4mm

Our integrated farm required a compact yet high-output solution for swine nutrition. RICHI’s small animal feed pellet machine was the perfect core of our new premix and pelleting line. It processes our wheat-barley-soybean mix consistently. The energy efficiency has significantly lowered our monthly operating costs.

Tunisia Client

Feed type: poultry feed

Pellet size: 3mm

Operating in a region with high summer temperatures, equipment stability is critical. We chose RICHI for their robust cooler and conditioner design. The pellet mill runs smoothly with our local corn and sunflower meal blend. Their after-sales support team provided excellent local technician training.

Iraq Client

Feed type: dairy cattle feed

Pellet size: 12mm

Water scarcity here means we rely on imported hay and date by-products. We needed a machine strong enough to pelletize these fibrous materials. RICHI engineers customized the ring die compression ratio for our recipe. The pellet quality has improved our herd’s feed intake and milk yield.

Matching Pellet Size to Your Feed Formula

The optimal pellet size directly impacts animal growth, feed conversion, and production efficiency. Below is a guide to common pellet diameters, their primary applications, and the key technical considerations for configuring your small animal feed pellet machine to achieve consistent, high-quality results.

From Raw Materials to Finished feed Pellets: Your Complete Line Solution

We are more than just a machine supplier; we are your engineering partner for complete feed production. Understanding that every feed type—from poultry to aquaculture—requires a distinct process, we design and deliver fully customized production lines.

Our solutions are tailored around your specific raw materials, target pellet size, nutritional formula, plant layout, and investment goals. We provide comprehensive support from initial consultation and system design to manufacturing, installation, commissioning, operator training, and lifelong spare parts supply.

Silo

Cleaning

Grinding

Mixing

Batching

Pelleting

Cooling

Screening

Packaging

06.Pelletizing System

This is where your formulated

mash transforms into

high-quality, durable

feed pellets.

Auxiliary Machinery list

storage silo equipment

01

cleaning equipment

02

grinding equipment

03

mixing equipment

04

cooling equipment

05

screening equipment

06

packaging equipment

07

As your turnkey solutions partner, we supply every essential component for a fully operational feed production line. Our scope extends beyond the core pellet mill to include the complete ecosystem of equipment—from receiving and cleaning raw materials.

This integrated offering includes hammer mill feed grinders, feed mixer machines, counterflow pellet cooler machines, animal feed dryers, feed extruders, conveyors, dust collectors, and automated packing systems, all selected and configured to create a seamless, efficient process tailored to your specific feed type and capacity. This integrated approach ensures your entire operation runs smoothly, maximizing throughput, consistency, and your return on investment.

Tailored pelletizing Solutions for Every Feed Type

We design specialized pelleting systems for distinct animal nutrition requirements. Below are our standard recommendations for key feed categories, detailing the optimal machine configuration and process flow we engineer for each. Every solution is built around a robust ring die feed pellet machine, precisely matched with auxiliary equipment to maximize feed quality and production efficiency.

Frequently Asked Questions

Have questions about integrating a pellet mill into your operation? Below are answers to the most common inquiries we receive from animal feed mill plants and farms considering our 1-2 t/h small animal feed pellet machine.

What is the typical price range for a 1-2 ton per hour ring die small animal feed pellet machine, and how does it compare to other models?

+

Thank you for your inquiry. As a professional manufacturer, Richi Machinery offers a comprehensive range of feed pellet mills to meet different scales of operation. The price is determined by the machine’s capacity, motor power, build specifications, and included features.

For a compact production line, farm, or startup feed mill, our small animal feed pellet machine in the 1-2 ton per hour (t/h) range, such as the SZLH250 model, is the most popular entry point. The FOB price for this reliable and efficient core machine typically falls within the range of $6,500 to $8,500. This model balances upfront investment with robust performance for producing high-quality pellets for poultry, livestock, and other small animals.

For operations requiring higher output, we provide a series of larger ring die pellet mills. The price scales with the increased capacity, power, and structural robustness. Below is a reference list of our other standard models and their indicative FOB price ranges:

- SZLH320 (3-4 t/h): Approximate price range: $15,000 – $18,000

- SZLH350 (5-6 t/h): Approximate price range: $26,000 – $32,000

- SZLH420 (10 t/h): Approximate price range: $28,000 – $34,000

- SZLH508 (15 t/h): Approximate price range: $39,000 – $46,000

- SZLH558 (20 t/h): Approximate price range: $46,000 – $55,000

- SZLH678 (30 t/h): Approximate price range: $62,000 – $73,000

- SZLH768 (40 t/h): Approximate price range: $74,000 – $87,000

The above represents our primary series of standard ring die pellet mills for animal feed processing. Please note that this is not an exhaustive list, and the final price for your project is highly customized. Factors that can influence the final quotation include:

- The specific feed type you will be producing (e.g., poultry, aqua, ruminant).

- The choice and configuration of the conditioner (single, double, or triple layer).

- The material specifications of critical wear parts like the ring die and rollers.

- The level of automation and control system integration (e.g., PLC panels).

- Requirements for auxiliary equipment to form a complete production line.

A small animal feed pellet machine is an investment in your operation’s efficiency and product quality. To receive a precise and detailed quotation tailored to your raw materials, target capacity, and plant layout, please contact our sales team with your specific requirements. We will provide a comprehensive proposal that ensures you get the right machine at a competitive price.

What are the typical applications for the SZLH250 small animal feed pellet machine? ?

+

The RICHI Machinery SZLH250 small animal feed pellet machine is an exceptionally versatile and robust piece of core equipment, engineered as the ideal solution for entry-level and mid-scale feed production. Its primary application is as the heart of a 1-2 ton per hour feed processing line, making it perfectly suited for a wide array of operations that require reliable, in-house pellet production.

This machine finds extensive use across diverse sectors of the animal husbandry and aquaculture industries. It is commonly installed in small to medium-sized feed processing plants, as well as integrated directly into working farms.

Specific applications include dedicated production lines for pig feed, poultry feed (for chickens and broilers), cattle and livestock feed, and fish feed. You will find our small animal feed pellet machine operating efficiently in chicken feed mill plants, broiler feed mills, cattle feed production lines, fish feed production plants, and on livestock farms, poultry farms, and aquaculture farms worldwide.

Understanding that every business has unique needs, RICHI Machinery offers more than just industrial-scale solutions. We specialize in providing compact, turnkey 1-2 t/h small animal feed pellet machine production lines. These systems are designed with a small footprint, making them very suitable for on-farm use or for entrepreneurs starting a feed production business.

Furthermore, our service extends beyond hardware. To help our customers enter and succeed in the feed pelletizing industry, we also offer customized business plan consulting. This holistic approach—combining a reliable machine, a complete compact line, and strategic guidance—demonstrates our commitment to being your true partner in feed production, from concept to profitable operation.

Can you provide examples of recent global projects using your 1-2 t/h small animal feed pellet machine??

+

Absolutely. Our compact yet robust SZLH250 small animal feed pellet machine is a cornerstone of successful feed operations worldwide, chosen for its reliability and adaptability.

The following are real project examples that demonstrate its versatility across different continents, feed types, and customer budgets. These projects highlight that the total investment encompasses not just the pellet mill itself, but a complete, customized production line designed by Richi Machinery engineers.

- Colombia, Fish Feed Production Plant: A client selected the SZLH250 small sinking fish feed machine as the core of their new aquatic feed line. Configured to produce 2-4mm sinking pellets, the complete turnkey project, including grinding, mixing, conditioning, and cooling systems, represented an investment of approximately $59,000.

- Uzbekistan, Livestock Feed Production Line: For a diversified farm, we supplied a complete feed manufacturing solution centered on the small animal feed pellet machine. The system was engineered to produce durable 4-8mm pellets for cattle and sheep. The total project cost for this efficient, on-farm line was about $42,000.

- Peru, Poultry Feed Production Line: A growing agribusiness implemented our compact solution to achieve feed self-sufficiency. Utilizing the reliable SZLH250 small chicken feed pellet machine, the line produces 3-6mm pellets for layers and broilers. This cost-effective project totaled approximately $25,000.

- Algeria, Cattle Feed Production Line: A commercial dairy operation needed a system to process local forages and concentrates. Our solution, built around the durable small animal feed pellet machine, delivers consistent 4-8mm pellets. The complete installation was valued at around $50,000.

- Russia, Chicken Feed Mill Plant: For a small-scale poultry producer, we provided an essential production setup. The heart of the system is the SZLH250 small animal feed pellet machine, configured for 2-4mm broiler feed. This streamlined project had an investment cost of roughly $13,600.

- Ecuador, Broiler Feed Mill: A regional farm cooperative invested in a dedicated feed line to improve efficiency. The project, featuring our small animal feed pellet machine, is designed for high-output production of 2-4mm broiler pellets. The total project value was approximately $27,300.

- Malaysia, Poultry Feed Pellet Plant: An integrated farm sought to modernize its feed production. The implemented system, with the SZLH250 small animal feed pellet machine at its core, produces high-quality 2-4mm pellets. This comprehensive project amounted to an investment of about $38,600.

- Zimbabwe, Chicken Feed Pellet Plant: To support local poultry farming, a feed mill was established using our technology. The flexible small animal feed pellet machine is set up to produce a range of 1-4mm pellets for different growth stages. The total project cost was approximately $46,900.

These examples illustrate that while the core small animal feed pellet machine remains constant, the final project scope and cost are fully customized. Factors like raw material type, desired pellet size, automation level, and local infrastructure directly influence the design and investment. For a precise quotation tailored to your specific feed type, capacity, and operational goals, please contact our engineering team with your detailed requirements.

What’s the main difference between your ring die machine and a cheaper flat die model for a small farm?

+

Our ring die small animal feed pellet machine is engineered for continuous, commercial-grade production, offering superior durability and consistent pellet quality that flat die models cannot match. While flat die mills may have a lower initial cost, they are typically suited for very low-volume or experimental use.

Our ring die system features a more robust gear-driven transmission, higher production efficiency (1-2 t/h), and significantly longer wear life for the die and rollers. For any farm or small feed mill planning consistent daily output and seeking a reliable return on investment, the ring die machine from Richi Machinery is the professional choice that minimizes long-term operating costs and downtime.

Can this small animal feed pellet machine handle high-fiber materials like alfalfa or straw for cattle feed?

+

Absolutely. Our small animal feed pellet machine is specifically designed with a heavy-duty gearbox and high-torque drive to compact fibrous materials effectively. For feeds high in alfalfa or straw, we recommend configuring the machine with a ring die that has a lower compression ratio and thicker walls.

Combined with proper conditioning to soften the fibers, our machine consistently produces dense, durable pellets for cattle and other ruminants. We advise consulting with our engineers to tailor the conditioning time and die specification to your exact raw material mix for optimal results.

What’s the typical power requirement (kW) for the 1-2 t/h model, and will my existing electrical setup support it?

+

The main drive motor for our 1-2 t/h ring die small animal feed pellet machine typically ranges from 55kW to 75kW, depending on the specific feed formula and desired pellet hardness. The complete production line, including grinder, mixer, conditioner, cooler, and conveyors, will have additional power needs.

We strongly recommend a site evaluation by our technical team. They can assess your current electrical capacity and provide a detailed power load plan to ensure safe and efficient operation, often suggesting phased startups or system optimizations if needed.

We produce feed for both poultry and pigs. Can one machine efficiently make 3mm chicken feed and 4mm pig feed, or do we need different dies?

+

Yes, a single Richi Machinery small animal feed pellet machine can efficiently produce both. The key is to have interchangeable ring dies. You would use one die with a specific hole diameter (e.g., 3mm) and compression ratio optimized for high-starch poultry feed, and another die (e.g., 4mm) with a different ratio for the higher-fat, fibrous pig feed.

Our machines are built for quick die changes, and our engineers will help you select the perfect pair of dies for your formulas. This flexibility makes our machine an excellent core asset for diversified feed producers.

How often do the ring die and rollers need to be replaced, and what is the approximate cost of these spare parts?

+

Lifespan varies greatly based on the abrasiveness of your raw materials (e.g., minerals in feed add wear). Under normal conditions with standard corn/soy-based feeds, our high-alloy ring dies and rollers can last 800 to 1,200 production hours. For highly abrasive materials, life may be shorter.

We provide wear estimates during the project planning phase. As for cost, we offer transparent pricing for genuine Richi Machinery spare parts. Investing in our original parts guarantees perfect fitment and preserves your machine’s warranty, ultimately protecting your productivity and pellet quality.

Is the steam conditioner mandatory, or can we run the small animal feed pellet machine without it for certain simple feeds?

+

While the machine can technically operate without steam conditioning for some simple, dry mixes, we do not recommend it. Conditioning is critical for efficiency and quality. Steam gelatinizes starches, which acts as a natural binder, dramatically increasing pellet durability (PDI) and reducing energy consumption during pelleting. It also improves digestibility.

For simple feeds, you can operate the conditioner at a lower temperature or moisture addition, but bypassing it entirely will lead to poor pellet quality, high fines, excessive wear on the die, and higher power use. Our system is designed for integrated conditioning for optimal results.

What’s the expected pellet durability (PDI) for standard poultry feed from this machine, and how can we improve it?

+

With proper conditioning and the correct die selection, our small animal feed pellet machine can consistently achieve Pellet Durability Index (PDI) values above 95% for standard poultry feed.

To reach and maintain this level, ensure your mash is finely and uniformly ground, use adequate steam (80-85°C) in our enhanced conditioner, and select a ring die with the appropriate compression ratio (we’ll specify this). Our experts can also advise on potential natural binders or process adjustments if your specific recipe presents challenges.

We have a batch mixer. How do we ensure a consistent and continuous feed rate into the pellet mill to prevent blocking?

+

The transition from batch mixing to continuous pelleting is a common engineering challenge we solve. The solution is a surge hopper or buffer bin with a live-bottom discharge feeder installed between the mixer and the pellet mill’s conditioner. This system holds several batches of mixed mash and provides a steady, metered flow into the conditioner.

Richi Machinery includes the design and integration of this crucial interface in our complete feed line proposals, ensuring seamless operation and preventing the blockages and pressure fluctuations that damage equipment and pellet quality.

Can this machine produce floating fish feed, or is it only suitable for sinking pellets?

+

Our ring die small animal feed pellet machine is engineered specifically for producing dense, sinking aquatic feeds. True floating fish feed requires a different process involving high-temperature, high-shear cooking and expansion, which is achieved with a twin-screw or single screw floating fish feed extruder machine.

However, Richi Machinery is a complete solution provider. While this particular pellet mill produces excellent sinking pellets, we also manufacture and supply full floating feed extrusion lines. Our team can help you determine the right technology—or combination of technologies—for your aquaculture feed product portfolio.

What kind of after-sales support do you offer? Do you provide installation supervision and operator training on-site?

+

Our support is comprehensive and begins the moment you place an order. It includes detailed installation drawings, foundation plans, and a full parts list. We offer optional on-site installation supervision by our experienced engineers to ensure correct assembly.

Mandatory on-site operator and maintenance training is provided to teach your team how to run, adjust, and perform basic maintenance on the small animal feed pellet machine. We maintain a global network of technical support agents and offer long-term supply of genuine spare parts. Remote diagnostic support is also available.

For a start-up feed mill, what auxiliary equipment is absolutely essential to run with the small animal feed pellet machine?

+

The absolute essential auxiliaries form a “basic line”:

- 1) A hammer mill to grind raw materials to the correct particle size.

- 2) A batch or continuous mixer to blend ingredients uniformly.

- 3) Our machine’s integrated steam conditioner.

- 4) A counterflow pellet cooler to bring pellets to safe storage temperature and moisture levels.

- 5) Simple conveying equipment (screw conveyors, bucket elevators) to link these stages.

Richi Machinery specializes in designing and quoting these cost-effective starter lines for new businesses, ensuring you have a functional and efficient system from day one.

How fine do our raw materials need to be ground before pelleting for different animal feeds (e.g., broiler vs. dairy cow)?

+

Particle size is critical. For broiler feed, a fine grind is needed—typically over 80% of the mash should pass through a 1.5mm screen. This maximizes starch gelatinization and pellet durability. For dairy cow feed, a much coarser grind is used—particles may be 3-5mm—to promote healthy rumen function and slow digestion.

Our small animal feed pellet machine is compatible with both, but the grinding stage must be set up correctly. We will specify the exact hammer mill screen sizes and grinding strategies for each feed type you plan to produce as part of our holistic process design.

We experience high humidity. What precautions are needed for the cooling and storage of pellets after production?

+

In high-humidity environments, proper cooling is even more crucial. Our counterflow coolers are highly effective, using ambient air to remove heat and moisture from pellets. We may specify a slightly larger cooler capacity or extended cooling time for your climate.

For storage, we recommend using sealed silos or bins and potentially integrating a dehumidification system in the storage area. Our post-pellet handling solutions always consider local climate conditions to prevent moisture re-absorption, which can lead to mold and spoilage.

Is automation available? Can the small animal feed pellet machine be integrated with a PLC control system for easier operation?

+

Yes, automation is a key strength. Our small animal feed pellet machine can be fully integrated into a PLC-controlled production line. The PLC can monitor and control motor loads, steam addition to the conditioner, feeder speed, and pellet temperature.

Alarms for blockages or overheating are standard. This allows for consistent, repeatable production with less operator intervention and provides valuable production data. We offer different levels of automation, from basic control panels to full SCADA systems, to match your operational goals and budget.

What are the key factors in choosing the correct ring die hole size and compression ratio for our specific feed formula?

+

The key factors are:

- 1) Target Animal Species & Pellet Size: This determines the hole diameter (e.g., 2mm for shrimp, 4mm for pigs, 12mm for cattle).

- 2) Formula Composition: High-starch formulas (poultry) need higher compression ratios (e.g., 1:12) for binding. High-fiber or high-fat formulas (ruminants, swine) need lower ratios (e.g., 1:6) to avoid excessive heat and blocking.

- 3) Desired Pellet Hardness: A higher ratio generally increases durability but also energy use.

There is no one-size-fits-all answer. This is where Richi Machinery’s expertise is invaluable. Our engineers analyze your recipe, recommend the optimal die specifications, and often provide a test run at our facility to confirm performance before delivery.

What are the key factors that influence the price of an animal feed pellet mill?

+

The market price of a feed pellet mill can indeed vary significantly. As an important industrial investment, understanding what drives these costs is essential for making an informed purchase that balances budget with long-term value.

The small animal feed pellet machine price is not arbitrary; it is determined by a combination of tangible engineering specifications, brand reputation, and market dynamics. Below, we break down the primary factors to help you navigate your purchasing decision effectively.

1. Power, Capacity, and Core Engineering.

The most fundamental cost drivers are the machine’s motor power (kW) and its guaranteed production output (tons per hour). A small animal feed pellet machine rated for 1-2 t/h, like our SZLH250 model, is engineered with a specific gearbox, bearing assembly, and main shaft to deliver that capacity reliably.

Higher-powered models for greater output require more robust components, superior metallurgy, and advanced manufacturing processes, which naturally increase the cost.

Investing in a machine matched precisely to your actual needs—neither underpowered nor excessively oversized—is the first step in cost optimization. RICHI Machinery provides transparent specifications to ensure you select a model that delivers optimal efficiency for your target volume.

2. Brand Heritage, Quality, and Technological Level.

The manufacturer’s brand represents a promise of quality, reliability, and technological advancement. Established brands like RICHI Machinery invest heavily in research and development, precision manufacturing, and rigorous quality control (backed by certifications like ISO 9001 and CE).

This results in a small animal feed pellet machine with higher pellet durability, longer component life, and greater stability over years of operation. While the initial price may be higher than unknown brands, this investment protects you from the hidden costs of frequent breakdowns, poor pellet quality, and premature failure.

Our reputation is built on delivering machines that perform consistently in diverse global applications, from poultry farms to aquaculture feed plants.

3. Configuration, Customization, and Critical Accessories.

The base price of a small animal feed pellet machine can be significantly affected by its configuration and optional accessories. Standard features on our machines, like heavy-duty ring dies and reliable gear drives, ensure core performance. However, specific enhancements add value and cost:

- Conditioning System: A standard single-layer conditioner differs in price and capability from a customized double or triple-layer conditioner, which is essential for producing high-quality aquatic or ruminant feed.

- Feeding System: An advanced variable-frequency drive (VFD) feeder allows for precise control, improving efficiency and pellet quality.

- Component Material: Choices like stainless steel contact parts for corrosion resistance or specially hardened alloys for abrasive feeds affect the price.

At RICHI, we view these not as mere extras but as opportunities for customization. Our engineers work with you to specify only the configurations that your specific feed formula and process require, ensuring you pay for performance you will actually use.

4. Market Forces, Supply Chain, and Logistics.

Broader market factors, including raw material costs (e.g., steel), component availability, and global shipping logistics, influence the final price. As a major manufacturer with an integrated supply chain, RICHI Machinery can often mitigate extreme fluctuations, providing more stable and predictable pricing.

Furthermore, our global project experience allows us to efficiently manage transportation and logistics costs, ensuring your complete feed production line arrives as planned.

In conclusion, the price of a small animal feed pellet machine is a reflection of its engineering, quality, customization, and the support behind it. The most cost-effective choice is rarely the cheapest initial ticket price.

It is the machine that minimizes your cost per ton of high-quality pellet over its entire operational life. By partnering with a professional manufacturer like RICHI Machinery, you gain not just a machine, but a customized solution and the engineering expertise to ensure it becomes a profitable asset for your business.

What are the key factors to consider when choosing a small animal feed pellet machine?

+

Selecting the right small animal feed pellet machine is a critical investment decision that requires careful consideration of several factors to ensure it meets your production goals, ensures long-term reliability, and delivers a strong return on investment. Based on our extensive experience at RICHI Machinery, here is a comprehensive guide to help you make an informed choice.

1. Evaluate the Machine’s Core Structure & Durability.

The overall construction of the small animal feed pellet machine is paramount. Look for a robust ring die system with a heavy-duty gearbox, as this ensures stable transmission and can handle continuous operation.

The materials used, such as high-alloy steel for the ring die and rollers, directly impact wear life and resistance to abrasive ingredients. A well-built machine from a reputable manufacturer like RICHI Machinery is designed to be durable, safe, and reliable, minimizing unscheduled downtime.

2. Analyze Key Product Performance Metrics.

Beyond the machine itself, assess its performance characteristics. For a small animal feed pellet machine, key metrics include its stated capacity (e.g., 1-2 t/h), power consumption (kW/t), and the resulting Pellet Durability Index (PDI) it can achieve.

The equipment must be reliable and stable under your specific feed formulas. Also, consider its energy efficiency and environmental performance; modern machines with precise conditioning systems use steam more effectively, reducing overall energy costs and waste.

3. Prioritize Ease of Maintenance and Service Support.

Maintenance simplicity is crucial for reducing long-term operational costs. When evaluating a small animal feed pellet machine, check how easily accessible key components like the die and rollers are for replacement.

Furthermore, the manufacturer’s after-sales support is non-negotiable. Ensure they offer comprehensive services: detailed manuals, ready availability of genuine spare parts, operator training, and accessible technical support. RICHI Machinery, for instance, provides full lifecycle support to keep your line running smoothly.

4. Match the Machine’s Advantages to Your Specific Needs.

Different models have different strengths. Some prioritize user-friendly operation, while others offer higher precision for specialized feeds like aquaculture or shrimp feed. You must align the machine’s advantages with your production needs.

Are you producing poultry, cattle, fish, or pet food? The optimal small animal feed pellet machine for a chicken feed factory differs in die specification and conditioning from one designed for a cattle forage operation. This is where RICHI’s engineering expertise is vital—we help you select and customize the machine to excel with your exact recipe and pellet size requirements.

5. Clearly Define Your Usage Scenario and Future Plans.

Finally, be precise about your usage scenario. Are you a farm seeking on-site feed production, or a startup feed mill? The required auxiliary feed mill equipment (grinder, mixer, cooler) and level of automation will differ. A clear understanding of your current and future scale allows for a scalable solution.

The versatility of the RICHI SZLH250 small animal feed pellet machine makes it an excellent foundation, as it can be configured for numerous scenarios—from poultry and livestock farms to small aquafeed plants.

In summary, choosing the right small animal feed pellet machine involves a holistic analysis of build quality, performance data, serviceability, and a precise match to your feed type and operational context.

We recommend thoroughly researching product specifications and, most importantly, partnering with an experienced manufacturer. At RICHI Machinery, we don’t just sell a machine; we provide a consultation to understand your complete process and offer a tailored solution that ensures your success from day one.

How do I select a reliable manufacturer for a small animal feed pellet machine?

+

Choosing the right partner to supply your small animal feed pellet machine is as crucial as selecting the machine itself. A reputable manufacturer ensures you receive a high-quality product, comprehensive technical support, and a solution that delivers long-term value. Based on industry best practices and what discerning customers look for, here are the key factors to evaluate.

1. Verify Manufacturer Credentials and Certifications.

The foundation of trust begins with formal recognition. Always verify that the manufacturer possesses legitimate business licenses and holds internationally recognized certifications. Key certifications to look for include ISO 9001 for quality management systems and CE Marking for compliance with European health, safety, and environmental standards.

These are not just plaques on a wall; they are third-party validations that the company adheres to rigorous production and quality control processes. At Richi Machinery, our certifications are a testament to our commitment to manufacturing reliable and safe small animal feed pellet machine units.

2. Conduct a Thorough Evaluation of Equipment and Capabilities.

Whenever possible, arrange a factory visit. This allows you to inspect the build quality, compare different models of small animal feed pellet machine, and witness the manufacturer’s production capabilities firsthand. During your visit, assess:

- Processing Technology & R&D: Examine the machine’s design, the quality of critical components like the ring die and gearbox, and inquire about their in-house engineering team’s expertise in optimizing machines for different feeds (poultry, cattle, aqua).

- Technical Support & Training: A good manufacturer doesn’t disappear after the sale. Discuss their after-sales service structure, availability of spare parts, and the operator training they provide. The ease of maintenance and operation directly impacts your machine’s uptime and service life.

3. Analyze True Cost-Effectiveness, Not Just Price.

The initial purchase price is only one part of the total cost of ownership. A truly cost-effective small animal feed pellet machine offers superior value over its lifespan. Consider:

- Operating Costs: A more efficient machine with lower energy consumption per ton and higher pellet durability (reducing fines) saves money daily.

- Durability & Longevity: High-quality materials and construction reduce frequency of part replacements and unplanned downtime.

- Return on Investment (ROI): A slightly higher upfront investment in a robust machine from a manufacturer like Richi Machinery often leads to faster ROI through consistent output, lower maintenance, and higher-quality feed that improves animal performance.

4. Research the Manufacturer’s Reputation and Track Record.

A manufacturer’s reputation is built over years of satisfying customers. Investigate their track record:

- Customer Reviews & Case Studies: Look for testimonials and project examples from clients in similar industries or regions. Can they show you proven applications of their small animal feed pellet machine in poultry farms, cattle feed lines, or fish feed plants?

- Market Presence & History: How long have they been in business? A manufacturer with a long history, like Richi Machinery, has refined its designs based on real-world feedback and has the stability to support you for the long haul. Positive word-of-mouth is the ultimate indicator of quality and service reliability.

Selecting a manufacturer requires diligent research. It involves checking credentials, evaluating tangible quality and support, understanding total costs, and trusting proven market reputation. By partnering with an established and professional manufacturer, you secure more than just a machine; you gain a reliable engineering partner dedicated to the success of your feed production operation.