Compost Pellet Making Machine

FZLH320 compost pellet making machine is suitable for 2-3 t/h scale organic fertilizer processing. This equipment is commonly used in organic fertilizer factory, compound fertilizer factory, chemical fertilizer factory, breeding farm, farm, plantation, sugar factory, sewage treatment plant, waste disposal site, food processing plant, slaughterhouse, etc.

what’s FZLH320 compost pellet making machine ?

A compost granulator is a machine specifically designed to compress and squeeze powdered or crumb compost into small, uniform pellets. It processes compost that has already completed its fermentation and decomposition process.

RICHI FZLH320 compost pelleting machine is an all-purpose granulation equipment. It is applicable for you to make both organic manure fertilizer and compound fertilizer in 2-3 tons per hour produciton capacity.

Compost pelleting is a process that transforms raw material into fine product. By changing its physical form, it offers significant advantages, including cost reduction, ease of use, increased value, and improved efficiency. It is a key step in achieving the commercialization, scale, and efficiency of compost production.

Applicable Raw Materials

All livestock and poultry manure, agricultural waste, municipal and garden waste, organic waste from the food industry, and some other recyclable waste can be used as raw materials for compost pellets. However, when selecting raw materials, it is necessary to pay attention to the pretreatment of the raw materials and avoid using hazardous waste materials.

There’s Always Something New to Meet Your Fertilizer Production Demands. Whatever Your Raw Materials, Finish the Job with RICHI Pellet Machine

Why process compost into pellets?

Technological advantages

Compost pellet making machine is a kind of mechanical equipment used to process organicwaste (such as animal and poultry manure, straw, food waste, etc.) or fermented organic materials into granular fertilizer, it converts loose and wet organic raw materials into uniform and dry granules through physical extrusion and granulation, which is convenient for storage transportation and application.

high efficiency and energy saving

Our Siemens motor and high-precision gear transmission system provide you with 15% higher transmission efficiency than its competitors, delivering powerful power and lower energy consumption.

Iron-clad, stable and durable

Core components utilize reinforced technology, improve its wear resistance and fatigue strength and imported bearings to ensure long-term, stable operation even in harsh conditions, minimizing maintenance costs.

Intelligent protection, clean production

From intelligent overload protection to all-stainless steel construction in key components, we comprehensively safeguard equipment safety and fertilizer cleanliness, protecting your product quality and brand reputation.

convenient production improvement

The unique crack-resistant ring die design and quick-release structure not only directly increase your hourly and total output, but also save time and effort in replacement and maintenance.

WORKING

PRINCIPLE

The compost pellet making machine is a precision-engineered pressure system. A Siemens motor provides reliable power, a feeding system ensures uniform material supply, and the “twin” components of the ring die and rollers work together to shape the material under extreme pressure and wear, ultimately producing high-quality fertilizer pellets.

Technical Parameters of FZLH320 compost pellet making machine

For complete technical specifications, please contact us directly online.

Main Motor Power

22kw

Forced Feeder Power

0.75kw

Finished Pellet Diameter

4~12mm

Capacity

2-3T/H

Ring Die Diameter

320mm

Additional Features

The ring die compost pellet making machine, with its excellent industrial design, can efficiently convert loose compost into high-value granular fertilizer. It not only greatly improves the commercial value and storage convenience of the product, but also becomes a reliable cornerstone for large-scale fertilizer production with its sturdy and durable quality.

Adaptive Conditioning System Optimizes Formation Rate

It automatically adjusts to the optimal pelletizing conditions based on the different organic fertilizer raw material formulations, significantly improving pellet formation rate, smoothness, and hardness, while effectively killing harmful microorganisms.

Low-Energy, Continuous Operation Design

The machine’s power system and transmission structure have been meticulously optimized to maintain strong extrusion pressure while achieving low specific energy consumption. Unique flow-balanced feeding technology ensures 24-hour continuous and stable operation, even under high-load production conditions, saving customers significant electricity costs.

Modular Design, Multi-Purpose Machine

Can produce organic fertilizer, compound fertilizer, or feed pellets of varying sizes (e.g., 4mm, 6mm, and 8mm) by quickly replacing ring dies and rollers with different apertures and compression ratios. This allows for “multi-purpose use” of the same machine, significantly expanding customers’ business scope and ROI.

Intelligent Control and Remote Operation and Maintenance

An optional integrated PLC intelligent control system monitors key data such as main motor current, bearing temperature, and output in real time. This system proactively identifies potential problems, provides maintenance guidance, and minimizes unplanned downtime, making production management smarter and more worry-free.

Matching Your Different Capacity Needs

There’s no “one-size-fits-all” machine, only the most suitable solution. We understand the pelletizing needs of different scales and raw materials, and therefore offer a comprehensive range of ring die pelletizers, with capacities ranging from 1 to 26 tons/hour. Above we have provided the parameter model of FZLH320 compost pellet machine. Here, we will provide you with the technical parameter information of other models of equipment in the same series.

From flexible options for entrepreneurial farms to powerhouses for industrial continuous production, each model embodies our unwavering commitment to efficiency and quality. Whether your goal is to improve pellet quality, overcome production bottlenecks, or optimize overall energy efficiency, we have a specialized machine that precisely fits your production plan and helps you seize market opportunities. If you are not sure about your production capacity, you can provide your raw materials or budget information and we will recommend the right equipment based on your actual situation.

compost pellet making machine project

Our technology has a global reach, providing reliable compost granulation support to numerous renowned companies and farms worldwide. Whether it’s municipal sewage sludge, agricultural waste, or food processing residues, we efficiently transform them into high-value commercial organic fertilizer.

From environmental projects with an annual output of 1,000 tons to large-scale industrial fertilizer production facilities, our successfully delivered granulation lines cover a wide range of production capacities, from 1 t/h to 20 t/h. More importantly, in the vast majority of projects, we deliver not just a single piece of equipment but a complete solution, encompassing project consulting, process design, full-line manufacturing, installation and commissioning, personnel training, and a lifetime supply of spare parts. We are committed to being your trusted, long-term partner, ensuring your success.

Canada

poultry manure compost pelleting machine

Serving a large-scale intensive poultry farming group in Canada.

Romania

chicken manure compost pellet machine

Supporting a leading vertically integrated agribusiness in Romania.

Thailand

Cassava bagasse compost pellet mill

Recycle waste from a large-scale cassava starch processing plant

Argentina

cattle manure compost pellet making machine

Installed at a large-scale beef cattle ranch and agribusiness.

Spain

food waste compost pellet making machine

Serving a municipal organic waste processing center in Spain.

United States

livestock manure compost pellet making machine

Providing solutions for an integrated livestock farming cooperative.

Malaysia

Dewatered sludge compost pellet press

Used by a municipal wastewater treatment and recycled water company.

Türkiye

agricultural waste compost pellet machine

Used to process residues for a regional fruit and vegetable cooperative.

South Africa

animal manure compost pelleting machine

Used by a diversified commercial livestock farm in South Africa.

Your full-cycle compost pelleting partner

We’re more than just a manufacturer of composting pellet equipment; we’re your complete partner, from raw materials to finished compost pellets. We specialize in providing a comprehensive line of ring die compost pellet making machines with capacities ranging from 1 to 26 tons/hour, along with proven complete production lines and lifelong support. Whether you’re processing livestock manure, municipal sludge, or agricultural and forestry waste, we have proven technical solutions and global project experience to ensure you receive a high-yield, stable, and consistently profitable industrial production line.

Trust and Testimonials from Global

Our technology, equipment, and service system have been repeatedly proven in actual production around the world, earning wide recognition and praise from customers in diverse countries and using a variety of raw materials.

Customer from Kazakhstan

This compost pellet machine has completely changed the way we handle farm waste. The equipment is well-suited to our extreme climate, produces stable yields, and produces high-strength granular fertilizer, which has become a significant source of revenue.

Customer from India

Raw Materials: Bagasse and Chicken Manure

Efficient production within a limited space was our primary requirement. The supplier’s compact production line design and localized technical support perfectly met our requirements, ensuring smooth operation and easy maintenance.

Customer from Senegal

We were struggling with pelletizing high-salt raw materials. The company’s professional solutions and corrosion-resistant equipment successfully resolved the issue. The service team’s professionalism is truly admirable.

Customer from Vietnam

Raw material: A mixture of coffee grounds & livestock manure

From single equipment installations to complete production line upgrades, they have always been our reliable partner. The new production line is highly automated, significantly reducing labor costs and resulting in highly competitive pellet product quality in the market.

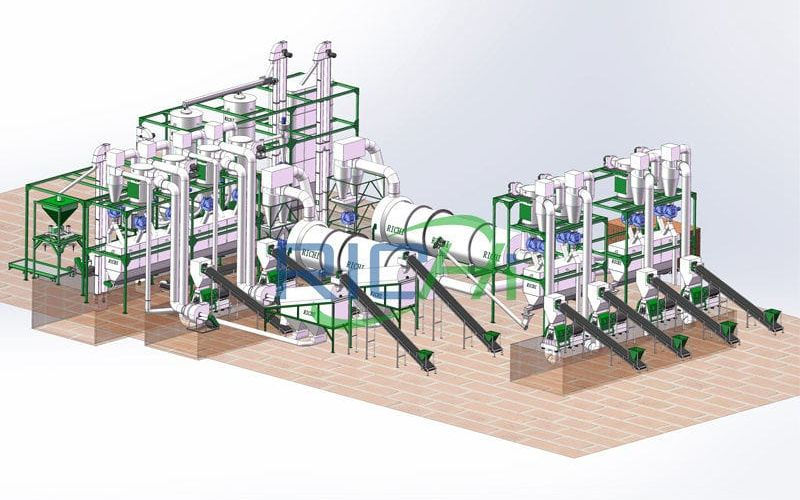

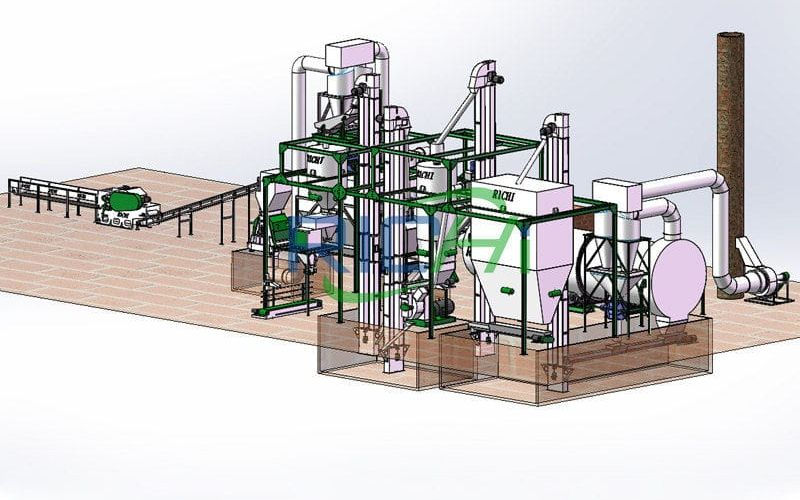

Complete compost pellet line solutions covering the world

We understand that a high-performance pelletizer is the core, but far from the whole, of success. Therefore, we go beyond simply providing equipment; we offer complete turnkey compost pellet production line solutions, from initial site planning and process design to installation and commissioning, and technical training.

Our specialized process begins with your raw material characteristics and culminates in your market goals: First, the raw materials undergo scientific pretreatment (crushing, mixing, and composting), followed by the core pelletizing, drying, and cooling stages. Finally, efficient screening and packaging yield high-value commercial fertilizer pellets.

Compost Pelletizing System

Efficiently convert

fermented compost

into high-value commodity pellets

Each step reflects our precise control over efficiency and cost, ensuring the delivery of a stable, high-yield, and sustainably profitable compost pellet production line.

Beyond the value of compost pellet machine

While an excellent compost pellet making machine is the core, an efficient and stable production line relies even more on the perfect coordination of all equipment components. We not only provide the core pelletizing unit, but also ensure you receive a complete suite of process equipment, from fermentation, pretreatment, molding, to post-processing.

Whether it’s efficient turning and crushing devices, precise mixing and conditioning systems, or reliable drying, cooling, and finished product screening equipment, we integrate them all to ensure optimal coordination and maximized efficiency across the entire line, completely eliminating the compatibility risks associated with patchwork.

Compost Pellet machine FAQs

When investing in compost pelletizing equipment, we understand you have many considerations. Whether it’s equipment performance, raw material compatibility, or return on investment, these are crucial factors in your decision. To this end, we’ve compiled the most pressing questions from our global customers and provided expert answers to help you make the most informed choice.

What is the price of FZLH320 compost pellet making machine?

+

The price of FZLH320 fertilizer granulation equipment is generally 10,000-25,000 USD.

Since the compost pelleting machine is a commonly used processing equipment in the organic fertilizer industry, it is common for organic fertilizer companies to purchase organic fertilizer granulators. However, with the continuous upgrading of manufacturers’ equipment, the price difference is also very large.

What factors will affect the price of compost pellet machine?

- Types of machines: There are many types of compost pellet mills, such as ring die granulators, disc granulators, etc. Each type of compost pellet machine has its unique functions and price.

- Production capacity: The production capacity of the organic fertilizer granulator is an important factor affecting its price. The greater the production capacity, the higher the price.

- Raw materials: The raw materials of the organic fertilizer pellet mill machine will also affect its price. High-quality raw materials can improve the service life and performance of the organic fertilizer granulator, so the price will be higher.

- Manufacturing process: The manufacturing process has a great influence on the price of compost pellet making machine. Advanced manufacturing processes can improve the performance and reliability of organic fertilizer granulators, so the price will be higher.

- Brand: Brand is also one of the factors that affects the price of compost pellet making machine. Well-known brands of organic fertilizer granulators are usually more expensive because they have better quality and after-sales service.

- After-sales service: The after-sales service of the compost pellet mill will also affect its price. Good after-sales service can ensure the normal operation of the organic fertilizer granulator, so the price will be higher.

To sum up, the price of compost making machine is affected by many factors. When purchasing an organic fertilizercompost pellet machine, you should consider these factors comprehensively and choose a suitable fertilizer granulator according to your needs.

RICHI Machinery is trustworthy. If you have any questions, please feel free to consult us directly online. Our technical manager will answer your questions online.

How to process pelletized compost? 2-3T/H Complete pellet compost process flow

+

Detailed explanation of compost pellet processing technology:

1.Preliminary preparation and raw material processing

The raw materials of compost pellet fertilizer are mainly various types of agricultural waste, green plant waste and other organic substances. Before processing, the raw materials need to be processed, such as removing impurities, making them into small pieces, applying bacterial agents, etc.

2.Mixture preparation

The processed raw materials are mixed according to a certain proportion of ingredients, and then organic bacteria and biological starters are added for full fermentation. This step is an important step in the production of granular organic fertilizer and determines the subsequent quality.

3.Pellet production

The fermented organic fertilizer mixture needs to be pressed and cut by a compost pellet making machine to form granular organic fertilizer that meets standards.

4.Drying treatment

Pelletized compost organic fertilizer needs to be dried to reduce its moisture content during production to increase its stability and storage life. Drying is usually done using an oven or tumble dryer.

5.Packaging and storage

The dried pelletized compost is packaged according to a certain weight and packaging form, usually in plastic bags or cloth bags. When storing, it needs to be placed in a ventilated and dry place, away from direct sunlight and high temperature and humidity.

Generally speaking, the pelletized compost processing technology involves multiple steps of the operation process, among which mixture preparation, granulation production and drying are the core steps in the organic fertilizer production line.

It is recommended that during processing, the production process specifications should be strictly followed to improve the quality and grade of organic fertilizer.

What are the characteristics of pelletized compost?

+

The compost pellets processed by the compost pellet making machine are small granular solids and an important fertilizer in agricultural production. This kind of fertilizer has many advantages, such as being easy to store, transport and use, improving soil fertility, promoting plant growth, increasing crop yields, etc., so it is widely used.

Organic fertilizer compost pellets have many advantages over traditional organic fertilizers.

- First of all, compost pellets have uniform particle size and shape, which is easy to use and does not require secondary crushing.

- Secondly, compost pellets have high fertilizer efficiency, which can improve soil fertility and promote plant growth.

- In addition, compost pellets also have high stability and are not prone to volatilization and loss, which can reduce fertilizer waste and environmental pollution.

In short, compost pellets are a very good organic fertilizer. Its production method is simple, it is widely used, and it has many advantages. In the future agricultural production, organic fertilizer particles will be increasingly favored by farmers and make greater contributions to agricultural production.

he moisture content of our raw materials is unstable. Does your compost pellet making machine have strict requirements for moisture content fluctuations?

+

Our compost pellet making machine is equipped with an intelligent conditioning system that can accommodate raw material moisture content fluctuations within a range of 25%-40%. When the moisture content is high, the system automatically adds dry auxiliary materials to adjust; when the moisture content is low, steam is used to humidify the pellets. This flexible design ensures a high pellet yield even with unstable moisture content. We recommend that customers try to control the moisture content within the ideal range of 30%-35% during the pretreatment stage to achieve optimal pelletizing results.

If small stones or metal pieces occasionally get mixed into the material, will the equipment be easily damaged?

+

Our designed compost pellet making machine incorporates a triple protection mechanism: first, a screen at the feed inlet; second, a permanent magnetic iron remover in the conveyor section; and most importantly, a hydraulic overload protection system. If unbreakable material is encountered, the ring die automatically disengages and stops operation, effectively preventing damage to core components such as the main shaft and rollers. However, we still recommend strengthening impurity separation during front-end processing as a best practice for long-term equipment operation.

What is the typical lifespan of a ring die? How much does a replacement cost?

+

The lifespan of a ring die depends on the material and operating conditions. Our standard ring dies are carburized alloy steel and can produce 8,000-12,000 tons of pellets under normal operating conditions. For highly corrosive materials, we offer stainless steel ring dies as an option. Replacement costs range from $2,000 to $8,000, depending on the specification. To extend the lifespan, we have developed a ring die maintenance program, with free maintenance guidance provided to customers.

What is the expected pelletizing rate for the entire process, from powdered compost to pellets?

+

Through process optimization, our compost pellet making machine boasts a stable pelletizing rate of 95%-97%. Unformed powder is automatically recycled back to the pre-treatment stage through a recycling system, ensuring a comprehensive raw material utilization rate of over 99%. This figure is based on statistics from over 200 projects worldwide. Actual pelletizing rates may fluctuate slightly depending on raw material composition and operational performance.

What is the required plant area for a compost pellet production line? Are there any special height requirements?

+

The standard production line layout requires an operating area of 15m x 8m, of which the compost pellet making machine occupies approximately 4m x 2m. The clear height of the plant must be at least 4.5 meters to accommodate the lifting equipment and dust removal system. We offer free plant layout planning services and can customize the design based on the customer’s specific site conditions to minimize space requirements.

Is the equipment noisy and dusty during operation? Does it meet environmental production standards?

+

Our compost pellet making machine features a fully enclosed design, keeping operating noise below 75 decibels. Equipped with a pulse dust removal system, the dust concentration in the workshop is below 10mg/m³, fully compliant with ISO14001 environmental management system standards. When exporting to EU countries, the equipment can be equipped with an optional higher-level dust and noise reduction module to meet the most stringent environmental requirements.

We primarily process pig manure and corn straw. Are there any successful examples using similar raw materials that we can reference?

+

We have successful experience pelletizing pig manure and corn straw in several countries, including China, Vietnam, and the United States. In particular, a project in Iowa, USA, uses our compost pellet making machine to mix pig manure with corn straw in a 6:4 ratio, achieving an hourly output of 3.5 tons, with an organic matter content exceeding 45%. We can arrange a site visit or video conference with existing customers.

What brand of bearings are used in the core components?

+

The main shaft bearings are Swedish SKF or German FAG, while the roller bearings are reinforced tapered roller bearings from Japanese NSK. These world-class brands ensure our compost pellet making machine can withstand continuous, high-intensity operation and have a designed service life of over 20,000 hours.

How to choose FZLH320 compost pellet making machine?

+

1. Equipment productivity

The productivity of equipment is generally measured by indicators such as equipment power and efficiency. Some equipment is also measured by product output per unit time. When an enterprise selects equipment, it must adapt the productivity of the equipment to the enterprise’s production tasks.

Calculating production tasks should not only combine the company’s current production and operation conditions and analyze the market share of the product, but also consider the company’s long-term rules and predict market changes and development trends.

2. Equipment reliability

The reliability of equipment essentially reflects the maintenance of compost fertilizer making machine performance or accuracy and the stability of operation. These two aspects are very important to ensure product quality and improve compost pellet making machine production efficiency.

When selecting equipment, it is necessary to carefully analyze and study the relevant information provided by the manufacturer, and demonstrate the indicators reflecting the reliability of the equipment.

3. Equipment maintainability

The maintainability of equipment refers to the degree and nature of maintenance of systems, equipment, parts, etc. that need to be repaired. The compost fertilizer machine should be easy to repair and disassemble, and have good interchangeability, which can shorten maintenance time, improve equipment utilization and reduce maintenance costs.

When selecting equipment, the ease of repair of the equipment structure should be considered, as well as the manufacturer’s supply of accessories and the possibility of providing maintenance services.

4. Equipment durability

The durability of equipment refers to the service life of the compost making equipment, which is generally expressed in terms of the service life of the equipment. The longer the service life of the equipment, the less depreciation will be amortized each year.

When enterprises select equipment, they must not only focus on the natural life span, but also consider factors such as invisible wear and tear, and appropriately select equipment with long durability.

5. Device security

The safety of equipment refers to the degree to which the compost pellet making machine guarantees production safety. Equipment safety includes personal safety and environmental protection. For example, whether the selected manure pellet mill equipment has safety protection devices, measures to remove and prevent “three wastes” pollution, etc.

6. Equipment energy saving

The energy saving of compost pellet making machine refers to the ability of the fertilizer granulation equipment to save energy. Good energy saving of equipment can greatly reduce the cost of equipment use and improve the economic effect during the life cycle.

7. Equipment completeness

The complete set of equipment is a prerequisite for forming an enterprise’s production capacity. Especially when choosing foreign equipment, purchasing a complete set is often more appropriate than purchasing the main engine and auxiliary equipment separately, which can save investment costs and foreign exchange.

8. Equipment economy

The economy of equipment is a comprehensive indicator for selecting equipment.

It not only considers the investment cost of the equipment (self-made equipment includes research, design, and manufacturing costs, and purchased equipment includes purchase costs, transportation costs, installation and commissioning costs), but also examines the usage costs of the equipment throughout its life cycle (including maintenance costs , insurance premiums, energy consumption fees, etc.).

The total cost is the lowest and the specified tasks can be completed. Such equipment has good comprehensive benefits and the best economy.

9. Environmental protection of equipment

The environmental protection of compost pellet making machine refers to the performance of the equipment in protecting the environment. Environmental protection is generally expressed in terms of the degree of environmental pollution caused by the noise of equipment and the harmful substances emitted by the equipment. When selecting equipment, you should choose equipment whose noise is controlled within the hygienic standards for protecting human health.

10. Equipment flexibility

The flexibility of compost granulating machine refers to the adaptability of equipment to different working conditions, operating uses and general versatility. Flexibility includes:

- first, under the condition that the work object is fixed, the equipment can adapt to different working conditions and environments, and the operation and use are relatively flexible and convenient;

- second, for processing equipment with variable work objects, it is required to be able to adapt to a variety of processing performance. It has strong versatility;

- thirdly, it has compact structure, light weight and small size.

These factors mentioned above are interrelated and restrict each other. Therefore, when enterprises choose compost pellet making machine, they must take into account various factors, weigh the pros and cons, make a comprehensive evaluation, and choose the optimal solution for purchasing equipment.

What features does your compost pellet making machine project have? What raw materials can be used?

+

Below are some of the compost pellet making machine projects we have worked on recently.

compost pellet making machine In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: industrial waste

- project price: 80,000 USD

compost pellet making machine In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: livestock manure

- project price: US$110,000

compost pellet making machine In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: poultry litter

- project price: US$430,000

compost pellet making machine In Lithuania

- Country: Lithuania

- Production: 35,000 T/A

- Ingredients: food waste

- project price: 410,000USD

compost pellet making machine In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: chicken manure, cow manure

- project cost: 570,000 USD

compost pellet making machine In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- project cost: 190,000 USD

compost pellet making machine In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: livestock manure, poultry manure

- project cost: $160,000

compost pellet making machine In Pakistan

project cost: $385,000 USD

Country: Pakistan

Production: 30,000 T/A

Ingredients: cow manure, Bagasse

What are the characteristics of the structural components of your compost pellet making machine?

+

- The main transmission adopts high-precision gear rotation, and the efficiency is increased by about 15% compared with the belt transmission type, and the ring mold adopts the quick-release type hoop type;

- High-quality imported bearings and oil seals are used in the transmission part of the whole machine to ensure efficient, stable and low noise;

- The international advanced level compensation serpentine spring coupling has the characteristics of novel structure, compact, safe, low failure and so on;

- Strengthen the working strength of the main working parts from the materials, heat treatment and other processes to meet the granulation requirements of biomass particles;

- There are a number of innovative designs on the ring die, mainly to improve the problems of the ring die to prevent cracking, increase in output and increase in total output;

- Configured with overload protection device to increase the service life of equipment;

- Door is made by stainless steel material, durable use.

How does the FZLH320 compost pellet making machine work?

+

The working principle of the FZLH320 compost pellet making machine mainly involves material conveying, extrusion and cutting processes. details as follows:

- Material transportation. Powdered materials first enter through the feeder and then enter the granulation chamber through the chute.

- Squeeze. In the granulation chamber, the material is distributed between the rotating ring die and the pressure roller. The pressure roller and the ring die exert pressure on the material. The material is squeezed and extruded through the die hole on the ring die to form a certain shape. Particles.

- Cutting. The extruded material is cut by a cutter to form pellets of a specific length.

- Adjustment of pellet length and shape. The length of the pellets can be controlled by adjusting the position of the cutter, while the shape of the pellets mainly depends on the design of the ring die.

Different types of organic fertilizer pellet making machines (such as dry granulators) may have different working principles, but the basic process is similar, involving the conveying, modulation, extrusion and final cutting of materials.

Could you provide more detailed parameter information of this FZLH320 compost pellet making machine?

+

| Model | FZLH320 |

| Output (t/h) | 2-3 |

| Main motor power (kw) | 22 |

| Main motor series | 8P |

| Ring die diameter (mm) | 320 |

| Finished pellet diameter (mm) | 4-12mm |

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

How to choose compost pellet making machine manufacturer?

+

The application of compost pellet making machines has gradually become popular in the organic fertilizer processing industry. The performance and quality of organic fertilizer granulation also have a vital impact on the quality and efficiency of the product.

- When purchasing a compost pelleting machine, you first need to consider the production scale, process flow, production capacity and other demand information of your own company (the above three points will directly affect the price) and customize the equipment according to actual needs.

- The second is the operation and maintenance of thecompost pellet machine (reliable compost pellet production line merchants will provide professional training). Only by understanding the principle and structure of the equipment can you comply with the precautions for the use of the equipment during use. Through regular Maintenance extends the stability and service life of equipment operation.

- There are many compost pellet making machine manufacturers on the market. There is no standard for non-standard customized products to directly judge whether they are good or bad. It is easy for everyone to be confused.

In fact, a brand with high brand awareness and strong technical strength will be more worthy of trust and choice. The main reference is whether the company is the source manufacturer, and whether the product case involves a wide range of industries and professional capabilities. What is the company’s strength? - A reliable compost pelleting machine company will have a professional R&D and production team to customize different organic fertilizer granulators according to customer needs to meet the different needs of customers.

In terms of operations, we will continue to introduce professional talents to focus on R&D, design, and production to expand the company’s hard power. For details, you can refer to the company’s patent situation to get the company’s R&D strength.

Check whether the company’s production development direction is characterized by high efficiency, energy conservation and environmental protection, which plays a role in energy conservation and emission reduction, and strives to create higher use value and good experience for customers. - Check whether the organic fertilizer granulator machine company has established a complete quality assurance system and after-sales service system to ensure the stable, reliable and long life of the equipment.

Whether the equipment is equipped with an intelligent control system, real-time monitoring of the status of the equipment can automatically alarm if there is any abnormality, reducing the time of fault investigation can effectively improve the safety and stability of the equipment. - Observe the company’s service concept.

Whether it is before, during or after the sale of equipment, a good company will provide thoughtful services with the goal of safeguarding the interests of customers. We can provide customers with help and suggestions in terms of equipment selection, layout planning, and technical issues.

Whether you already have an organic fertilizer processing business or have just entered this industry, you need to find a professional company to provide you with technical consulting support. After the sale, professional technical engineers will be assigned to provide customers with considerate assistance during equipment installation, debugging and other aspects.

In general, choosing a suitable organic manure making machine manufacturer is an important guarantee for the stable operation of the production line and improving production efficiency. If you have any questions about the organic fertilizer granulator, please feel free to consult RICHI Machinery directly online!

If I want to adjust the pellet diameter later, is the operation complicated?

+

Adjusting the pellet diameter is simple; simply replace the ring die and adjust the cutter position. We offer a variety of ring die options, ranging from 2 to 12 mm. Changing the die takes only 1-2 hours. We’ve also developed a quick die change system that reduces changeover time to under 30 minutes.

Will you send an engineer to provide on-site guidance during installation and commissioning? How is the cost calculated?

+

We offer a complete installation and commissioning service package, which includes on-site guidance by a senior engineer for 5-7 business days, along with full technical training. This service fee is included in the total equipment price; customers only need to cover the engineer’s accommodation, food, and transportation. For overseas projects, we promise that the engineer will arrive on-site within 7 business days.

What are the equipment’s most vulnerable parts? Is routine maintenance complex?

+

The rollers and ring dies are standard vulnerable parts. We have designed a modular maintenance plan, requiring only daily lubrication and per-shift cleaning, with routine inspections every 500 hours. Our remote diagnostic system can predict maintenance needs in advance, greatly simplifying the maintenance process.

What is the power of the motor? How many kilowatt-hours of electricity does the production line consume per hour?

+

The power of the main engine of the compost pellet making machine ranges from 22kW to 315kW, depending on the model. Taking our mid-range model as an example, the entire line, including auxiliary equipment, consumes approximately 35-45 kilowatt-hours per ton of material. Our latest energy-saving version, through an optimized drive system, can further reduce power consumption by 15%.

If there’s a sudden power outage during production, will restarting the machine be difficult?

+

The machine is equipped with a power failure protection system. In the event of a power outage, the hydraulic system automatically maintains pressure to prevent the material from solidifying in the die. Once power is restored, the machine can be restarted with a simple cleaning tool. Under normal circumstances, the time from power outage to resumption of production should not exceed 30 minutes.

Our production volume is small. Are there any recommended models with low production capacity and high cost-effectiveness?

+

We have specially developed the FZLH250 compact series, with an output of 1-1.5 tons per hour and a power of 22kW, making it ideal for start-ups or small farms. This model retains core technology and key features at a competitive price, offering excellent value for money.

Will the organic matter and nutrient content of the final pelletized fertilizer be affected?

+

Under the correct process parameters, the impact of the pelletizing process on organic matter and key nutrients is negligible. Tested data shows that after processing in our compost pellet making machine, organic matter retention exceeds 98%, and nitrogen loss is controlled to less than 2%. We also optimize conditioning temperature and time based on the customer’s raw material characteristics to maximize nutrient retention.

How strong are the compost pellets? Can they withstand long-distance transportation without breaking?

+

The pellets produced by our compost pellet making machine have a hardness exceeding 98N and a crushing rate of less than 5% in a drop test (free fall from a height of 1.5 meters), fully meeting long-distance transportation requirements. We also offer a special surface polishing process to further enhance the pellets’ resistance to breakage.

Besides the equipment itself, can you provide technical guidance on related production processes?

+

We offer comprehensive process support, including raw material formulation optimization, production process specification development, and product quality testing methods. Customers also receive access to our independently developed intelligent production management system, enabling digital monitoring and optimization of the entire production process.

How can I address the rust on the equipment’s exterior? Are key components made of stainless steel?

+

The main body of the equipment is epoxy-coated, and key contact areas, such as the feed auger and conditioner, are constructed of 304 stainless steel. For highly corrosive environments, we offer custom versions constructed entirely of stainless steel, ensuring a long service life even in humid environments.

What equipment is required for a compost pellet making machine system?

+

The standard compost pellet production line includes the complete process steps: crushing → screening → mixing → conditioning → pelletizing → cooling → packaging. We offer modular configurations, allowing customers to flexibly choose based on their budget and needs. For example, they can start with the core pelletizing unit and gradually add automated packaging modules later.

Compost Turner

Turning height:

0.5-2.0 m

Motor:

32-300 KW

Compost Grinder

Capacity:

3-25T/H

Main Power:

30-160KW

organic Fertilizer Mixer

Capacity:

250-2000 kg/P

Main Power:

4-30 KW

organic fertilizer Dryer machine

Capacity:

Customized

Rotate Speed:

3-8 R/Min

compost pellet making machine

Capacity:

1-12T/H

Main Power:

37-280KW

Pellet Cooler Machine

Capacity:

1.5-18T/H

Main Power:

0.75-2.05 KW

vibrating screening machine

Capacity::

3-20T/H

Main Power:

1.5-5.5KW

Automatic Bagging Machine

Speed::

6-12 Bags/Min

Main Power:

1.1-5KW

What is the outlook for the compost fertilizer market?

+

01 Increased demand for organic fertilizers

At present, crop cultivation around the world requires a very large amount of fertilizer. Moreover, with the rapid development of social economy, the development of organic agriculture and ecological agriculture is also gradually increasing. The market prospects for organic fertilizers are very promising.

02 Sufficient supply of organic fertilizers

Organic fertilizer, which is made by compost pellet making machine, mainly derived from plants and animals, is a carbon-containing material that is applied to the soil to provide plant nutrition as its main function.

It is processed from biological materials, animal and plant wastes, and plant residues, eliminating toxic and harmful substances, and is rich in a large number of beneficial substances, including: a variety of organic acids, peptides, and abundant nitrogen, phosphorus, and potassium. of nutrients.

Organic fertilizers are the recycling and reuse part of nutrients in agriculture, so as the amount of chemical fertilizers applied increases and crops are harvested, the amount of organic fertilizers also increases. China’s organic fertilizer industry is in the recovery stage, with an increasing number of participating companies and a gradually expanding production scale. Market demand also continues to grow steadily, and the overall market size of the industry maintains a stable expansion trend.

03 Organic fertilizer meets the requirements of green development

It is of great significance to use organic fertilizers instead of traditional chemical fertilizers to provide a variety of nutrients to crops and improve the quality of agricultural products. Therefore, we should pay attention to the use of organic fertilizers, use organic fertilizers to meet people’s demand for green, pollution-free food, and make organic fertilizers more widely used in agricultural production. (Find RICHI on YouTube)

60000 +

Backed by a 60,000 m² advanced production complex

140 +

Global footprint extends across 140+ international markets

2000 +

Over 2,000 successful production system installations

2013

RICHI MANUFACTURE

Established in 1995, RICHI MACHINERY has grown from a medium-sized enterprise to become China’s largest pellet production line manufacturer. With two major manufacturing bases spanning hundreds of thousands of square meters, we specialize in custom pellet machines and complete plant solutions, handling every production stage in-house—from R&D to delivery.

Our vertically integrated facilities (including dedicated sections for production, testing, and logistics) ensure premium quality, environmental responsibility, and operational reliability for feed, biomass, and fertilizer industries worldwide. For nearly three decades, we’ve partnered with clients to enhance productivity, minimize risks, and achieve sustainable outcomes through innovative engineering.

Zhengzhou Headquarters

R&D, global operations and strategic management converge

Jiaozuo New Production Base (2025)

Featuring automated production lines and Industry 4.0 technologies

Kaifeng Original Complex (Since 1995)

Our manufacturing legacy began and quality traditions endure

Certifications & Patents

As a world-leading feed mill equipment manufacturer, RICHI Machinery demonstrates its engineering prowess through internationally recognized certifications and proprietary innovations.

Our ISO quality management system, CE compliance, BV-certified production processes, GOST-R for Russian compliance, ATEX explosion-proof certification for EU safety standards, FDA registration for U.S. market access, and EHEDG hygienic design certification validate our commitment to global standards, while 50+ patented technologies in pellet mills, extruders and automation systems deliver unmatched performance.

When you choose RICHI, you’re selecting globally validated, future-proof solutions backed by the industry’s most comprehensive certification portfolio.

01

Consultation

Our experts provide professional advice to understand your specific feed production requirements.

02

Design

We develop customized solutions with optimized layouts and equipment configurations for your project.

03

Manufacturing

All feed mill equipment is precision-built using quality materials in our ISO-certified factories.

04

Shipping

We handle secure packaging and global logistics with reliable delivery timelines.

05

Installation

Our engineers supervise on-site assembly and commissioning for smooth operation.

06

Training

Comprehensive operator instruction ensures proper use and maintenance of equipment.

07

After-sales

Dedicated support team provides troubleshooting and technical assistance.

08

Spare Parts

Genuine components are available worldwide with fast delivery service.