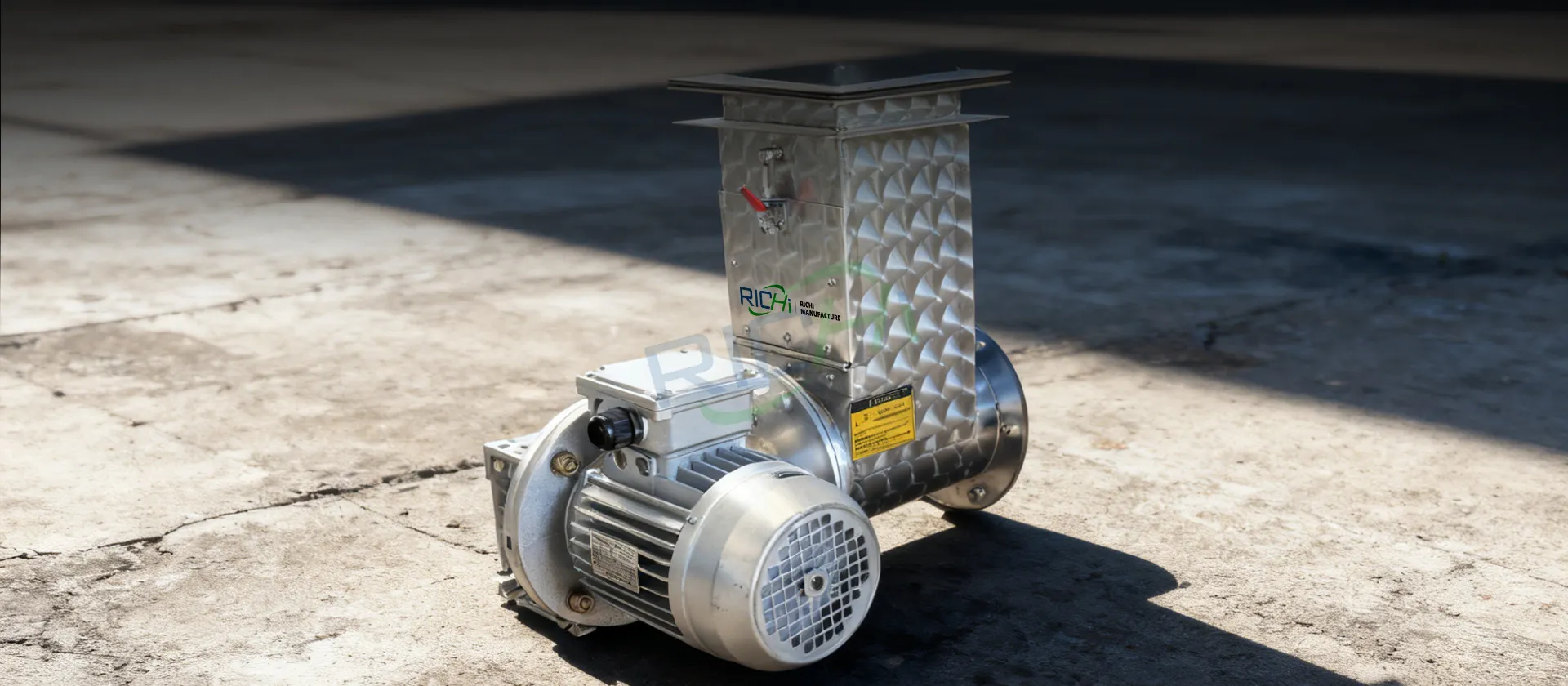

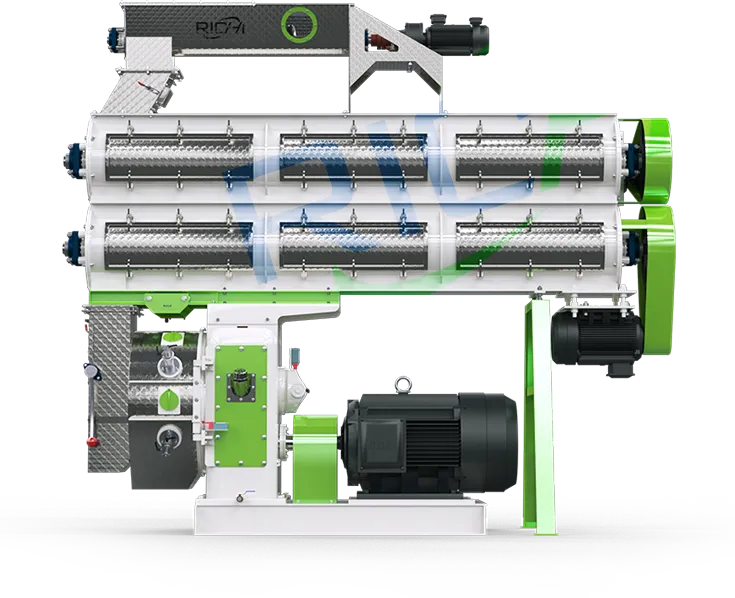

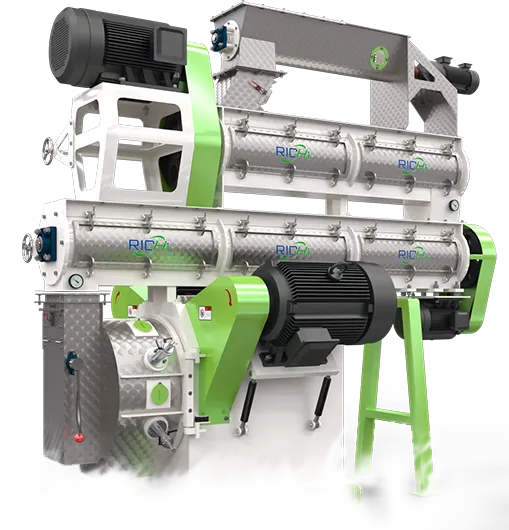

COMMERCIAL FEED PELLET MILL

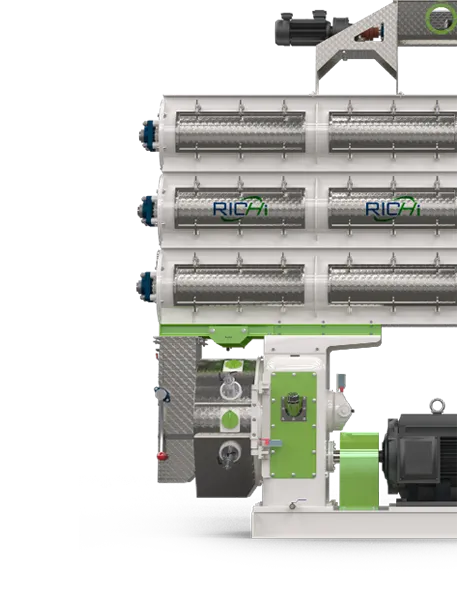

Meet the SZLH768 Commercial Feed Pellet Mill: Engineered for high-capacity pelletizing at 38-40t/h. Its innovative direct drive system removes the traditional transmission, cutting energy use by up to 10% while enhancing operational reliability and easing maintenance. This commercial feed pellet mill is built for performance and efficiency.

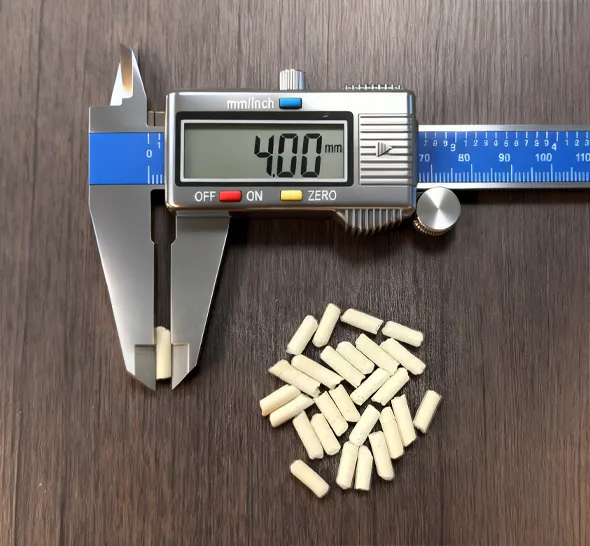

Pellet Size: 2~12mm

Price: $78,000 – $83,000

Model

SZLH768

Production Capacity

38-40T/H

Versatile Applications of the SZLH768 Commercial Feed Pellet Mill

This high-capacity commercial feed pellet mill is engineered to meet the rigorous demands of diverse, large-scale feed production. It is the core machine for processing various nutritional pellet types, commonly installed in integrated feed mill plants and major farming operations to ensure a consistent, high-quality supply. At RICHI Machinery, we leverage our in-house design and engineering expertise to provide complete turnkey systems, ensuring your specific production line – whether for poultry, livestock, or aquaculture – is up and running swiftly and efficiently.

The SZLH768 commercial feed pellet mill is expertly configured for three primary feed categories. Each configuration optimizes pellet density, durability, and nutritional integrity for its target animal group.

Ideal for producing high-volume feed for chickens, layers, and broilers in dedicated feed mills and large poultry farming complexes.

Designed for creating robust pellets for cattle, pigs, and sheep, supporting efficient nutrition management in modern livestock farms and feed production facilities.

Specialized for formulating floating or sinking pellets with high water stability, essential for fish and shrimp feed production plants.

Our Commercial Feed Pellet Mill with Advanced Conditioning Systems

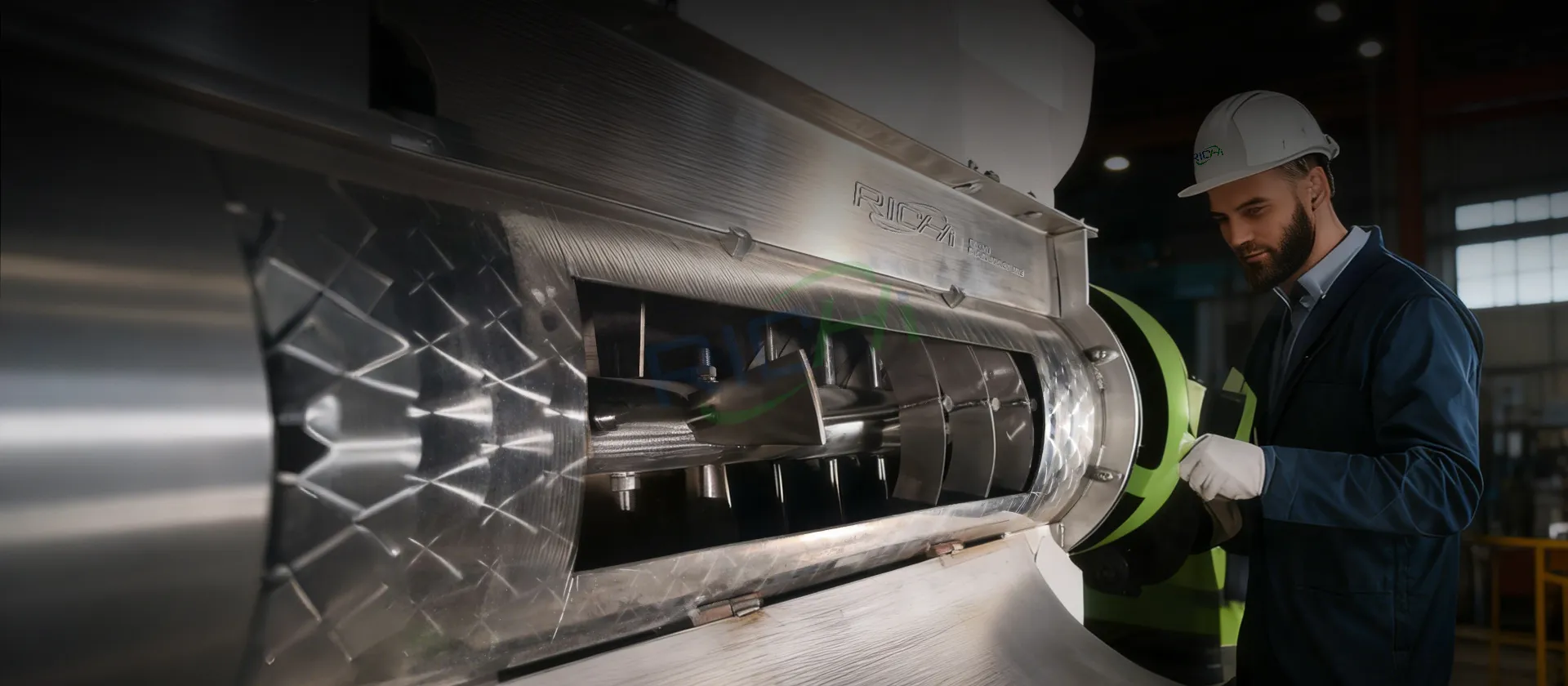

The performance of a commercial feed pellet mill hinges on its conditioning process. That’s why we equip the SZLH768 with our proprietary, large-diameter, extended-length conditioner. This design maximizes steam penetration and ingredient hydration for superior pellet quality. Beyond our standard offering, we provide fully customizable conditioners.

Clients can specify the shell material, internal paddle configuration, steam injection points, and retention time to meet exact recipe requirements. This flexibility ensures our commercial feed pellet mill adapts to your specific needs. We offer the SZLH768 commercial feed pellet mill in three specialized configurations, defined by the number of conditioning stages, to cover the entire spectrum of feed production.

Single-Stage Conditioner commercial feed pellet mill

This robust configuration features one extended conditioner. It is the most versatile and widely used type for standard poultry and livestock feed pellets. When equipped with an optional forced feeder, it effectively processes fibrous feeds containing grass or alfalfa.

Ideal For: Standard animal feed mill plants and farms requiring reliable, high-volume production of common poultry & livestock feed.

Dual-Layer Conditioner commercial feed pellet mill

This system utilizes two sequential conditioning chambers. The double-stage process achieves higher starch gelatinization and moisture uniformity. It is essential for producing premium-grade poultry & livestock pellets with enhanced digestibility and for formulating standard sinking fish feeds.

Ideal For: Producers focusing on high-nutrition livestock feed or entering the aquaculture market with basic sinking fish feed.

Triple-Layer Conditioner commercial feed pellet mill

Our premium configuration incorporates three conditioning stages. It delivers the ultimate control over temperature, moisture, and conditioning time. This is critical for manufacturing highly water-stable, floating or slow-sinking feeds for sensitive species like shrimp and high-value fish.

Ideal For: Specialized aquaculture feed plants and producers targeting the premium aquatic feed sector.

Process the Full Spectrum of Feed Materials with Precision

From traditional grains to innovative formulations, our commercial feed pellet mill is engineered to handle a vast range of feed ingredients. A standard feed formula combines four main categories: energy feeds, protein sources, roughage, and feed additives. In practice, formulations may also include fresh green forage and fermented silage. Our robust commercial feed pellet mill is specifically designed to process these diverse and sometimes challenging materials, delivering consistent, high-quality pellets every time.

Energy Ingredients

These are the foundation, providing carbohydrates and fats for animal energy. Common examples include corn, wheat, barley, and sorghum. Our commercial feed pellet mill effectively processes these grains into digestible, high-calorie pellets.

Protein Ingredients

Essential for growth and development, these ingredients supply critical amino acids. This category includes soybean meal, fish meal, rapeseed meal, and sunflower meal. Our equipment ensures uniform mixing and binding of these vital components.

Roughages Ingredients

This fiber-rich material supports digestive health in ruminants and other livestock. It includes alfalfa meal, grass hay, rice hulls, straw, fresh pasture grasses, aquatic plants, and their fermented silage versions. Our machine’s design is capable of handling these fibrous materials for balanced nutrition.

Feed Additives

These components enhance nutrition, health, and pellet quality. They include vitamins, minerals, enzymes, mold inhibitors, and pellet binders. Our commercial feed pellet mill ensures these micro-ingredients are evenly distributed throughout every pellet.

See Our Commercial Feed Pellet Mill Deliver

Witness the robust performance and global reliability of our commercial feed pellet mill. Below are real-world videos from four distinct customer installations. See firsthand how our machinery achieves high-capacity output, handles diverse materials, and operates with efficiency in various feed production environments. These projects showcase our strength as a manufacturer who delivers proven solutions, from initial design to smooth on-site operation.

Uzbekistan Animal Feed Pelletizing Project

Oman Animal Feed Pelletizing Project

Afghanistan Animal Feed Pelletizing Project

Uganda Animal Feed Pelletizing Project

Core Components of the SZLH768

The outstanding performance and durability of our commercial feed pellet mill begin with its superior engineering. Every critical component is selected and designed for power, precision, and longevity. This focus on core structural integrity ensures the SZLH768 delivers unmatched reliability, higher output, and consistent pellet quality, solidifying RICHI’s position as a manufacturer of high-performance feed machinery.

Why the SZLH768 Leads in Performance & Value

Beyond robust construction, the true measure of a commercial feed pellet mill is its impact on your operation’s efficiency and bottom line. The SZLH768 is engineered to deliver tangible advantages, from unmatched recipe flexibility and significant energy savings to reliable high-capacity output. These benefits are the direct result of RICHI’s integrated design and manufacturing expertise, ensuring you invest in a machine built for real-world productivity.

Exceptional Recipe Versatility

This commercial feed pellet mill is built to handle complex formulations with ease. It consistently processes high-fiber and high-fat recipes that challenge standard machines, giving you unparalleled flexibility in feed design without compromising pellet quality or equipment performance.

Proven High-Capacity Output

Engineered for productivity, the SZLH768 commercial feed pellet mill delivers reliable high-volume production. Its optimized gear drive and reinforced components enable sustained output, ensuring you meet demanding production targets efficiently and dependably.

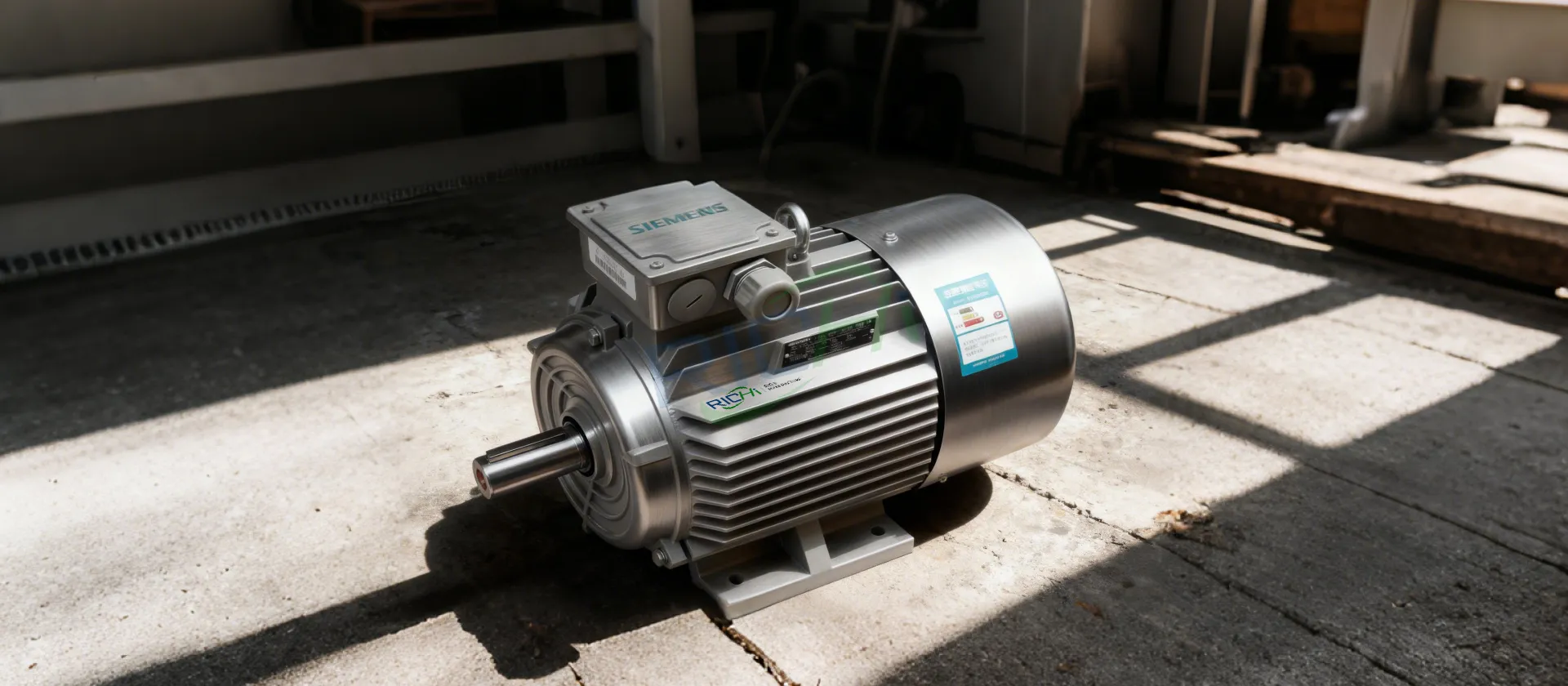

Direct Drive Efficiency

The integrated high-precision gear drive system directly connects the motor to the main shaft, eliminating power loss common in belt-drive systems. This intelligent engineering reduces overall energy consumption by up to 10%, translating directly into lower operating costs for your feed mill.

Tailored Configuration & Customization

We understand that no two production lines are identical. Beyond our standard model, we offer extensive customization for this commercial feed pellet mill. This includes tailoring the conditioner (single, double, or triple stage), configuring specific motor power, adapting the feeder for unique ingredients, and modifying the die & roller assembly for specialized pellet characteristics.

How the SZLH768 Commercial Feed Pellet Mill Operates

Understanding the core process highlights the engineering behind reliable performance. The operation of our commercial feed pellet mill is a precise, continuous cycle of conditioning, formation, and cutting.

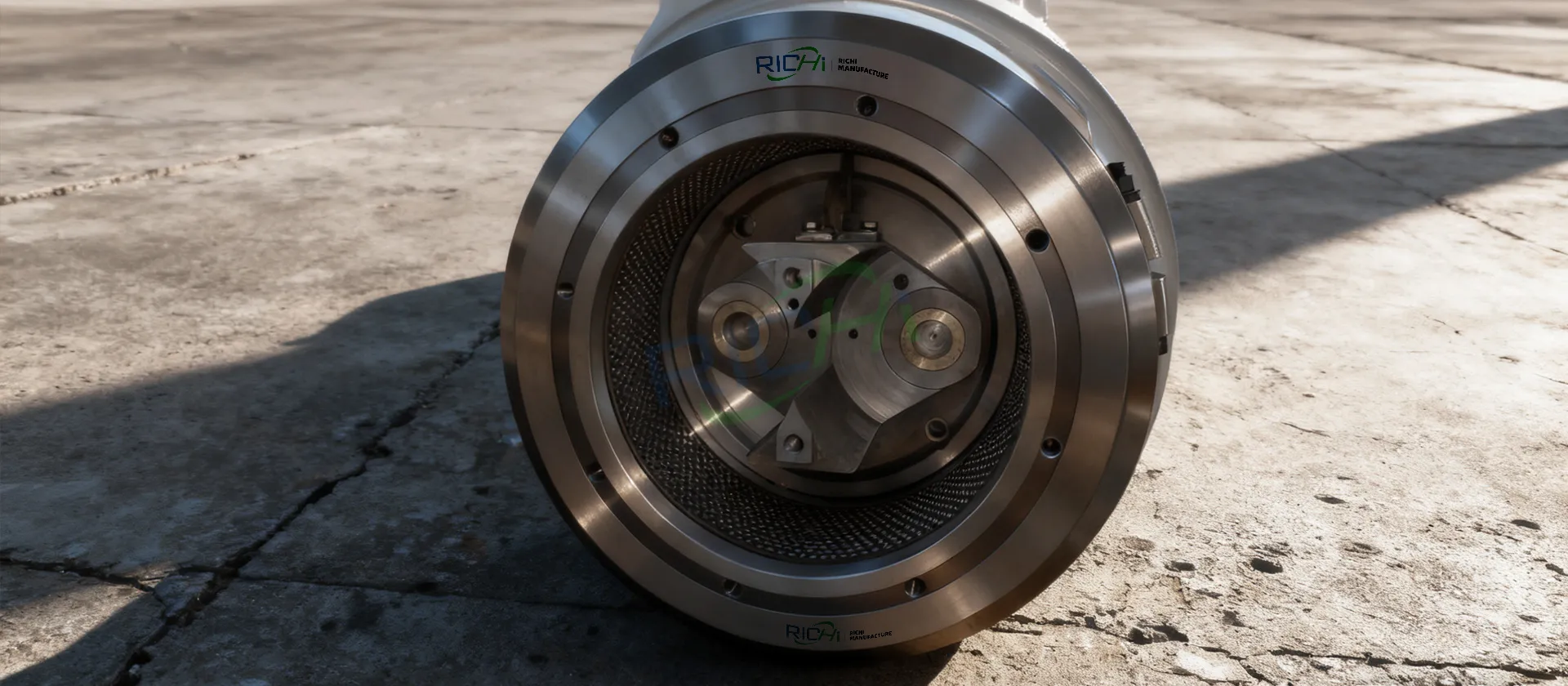

Properly conditioned feed mash enters the mill through the feeder. A rotating distributor ensures the material is evenly fed into the critical space between the heavy-duty ring die and the parallel press rollers.

Here, the powerful rotation of the die draws the material into this gap. The stationary rollers exert extreme pressure, forcing the mash through the precision-drilled holes in the die wall. This action compacts the ingredients, creating firm, continuous strands.

Finally, adjustable high-speed knives, mounted externally, cleanly slice the extruded strands to your exact specified length.

SZLH768 Technical Specifications & Our Full Range

Below you will find the detailed specifications for this high-capacity commercial feed pellet mill, confirming its capabilities and fit for your operation. As a leading manufacturer of comprehensive feed solutions, we offer a complete series of ring die pellet mills. If your production requires a different capacity, explore our seven other reliable models by clicking the links.

Need a different capacity? Compare our full series of commercial feed pellet mills.

SZLH768 Technical Specification

Main motor power

315kW

Feeder power

2.2kW

Conditioner power

11kW

Ring die inner diameter

762mm

Finished pellet diameter

2-12mm

Key Parameters for Different Feeds

Producing superior feed requires more than just a machine; it demands precise control over the pelleting process. The versatility of our commercial feed pellet mill is demonstrated through specific adjustments for each feed type. Below are optimized reference parameters for key species, showcasing our deep application expertise and the machine’s ability to meet diverse requirements.

Processing Chicken Feed with the SZLH768

This high-volume application focuses on achieving high output and consistent pellet durability. Our commercial chicken feed pellet machine operates at 35-42 T/H, producing 2-4mm pellets. Optimal process control involves a conditioning temperature of 150°C and a longer conditioning time of 60-120 seconds, which can be achieved with a single or double-layer conditioner to enhance starch gelatinization.

Processing Cattle & Sheep Feed with the SZLH768

The focus for ruminant feed shifts to creating large, dense pellets that withstand rough handling. Production typically runs at a stable 38-48 T/H, producing larger 6-12mm diameter pellets. A conditioning temperature of 150°C with a shorter 30-60 second dwell time in a single-layer conditioner is often sufficient, using a lower ring die compression ratio to form durable, long-lasting pellets.

Processing Pig Feed with the SZLH768

Pig feed production balances palatability and nutrient availability. The commercial feed pellet mill achieves 35-45 T/H output for smaller 2-4mm pellets. Critical parameters include thorough conditioning at 150°C for 60-120 seconds and the use of a lower ring die compression ratio to produce softer, more digestible pellets, which can be facilitated by one or two conditioning layers.

Processing Sinking Fish Feed with the SZLH768

Producing water-stable sinking feed requires intensive conditioning to bind particles and ensure low disintegration. For this application, output is adjusted to 20-27 T/H to ensure quality. The process demands precise control with a 150°C conditioning temperature and an extended 90-180 second conditioning time, best achieved with a two or three-layer conditioner and a high ring die compression ratio for pellet integrity.

Processing Shrimp Feed with the SZLH768

Shrimp feed represents the highest level of pelleting precision, requiring ultra-fine grind and maximum water stability. Throughput is carefully managed at 4-6 T/H. This critical process requires a high conditioning temperature of 150°C and the longest retention time of 120-180 seconds in a three-layer conditioner, combined with the highest compression ratio to form ultra-dense, slowly soluble pellets from finely ground material.

Our Commercial Feed Pellet Mill at Work Worldwide

Our commercial feed pellet mill and complete animal feed processing plants have been successfully exported and installed across six continents. The projects below demonstrate our equipment’s versatility across different scales, feed types, and regional requirements. In most cases, we deliver not just a single machine, but a fully integrated turnkey solution.

commercial feed pellet mill for sale Thailand

A leading integrated poultry company chose our commercial feed pellet mill to serve its high-capacity needs. It processes corn and soybean meal into 2.0-3.0mm broiler feed pellets for its large-scale farming operations.

Feed type: Broiler feed

Pellet size: 2.0-3.0mm

commercial feed pellet mill for sale Russia

Feed type: Cattle feed

Pellet size: 4mm

commercial feed pellet mill for sale Brazil

Feed type: Cattle feed

Pellet size: 4-6mm

A large-scale cattle ranch invested in our equipment to produce its own nutritious feed on-site. The mill processes locally sourced grains and mineral additives into 4-6mm cattle feed pellets to enhance herd nutrition and operational independence.

commercial feed pellet mill for sale Philippines

Feed type: Pig feed

Pellet size: 3mm

commercial feed pellet mill for sale Turkey

Feed type: Poultry & aqua feed

Pellet size: 2.5mm & 3.5mm

commercial feed pellet mill for sale United States

A U.S.-based producer of premium aquatic feed utilizes our commercial feed pellet mill for a niche market. The system processes high-protein meals into precise 1.5mm shrimp feed pellets, demanding exceptional water stability.

Feed type: Shrimp feed

Pellet size: 1.5mm

commercial feed pellet mill for sale Kazakhstan

Feed type: Livestock feed

Pellet size: 4-6mm

Trusted by Industry Leaders Worldwide

From commercial feed mills and integrated farms to agricultural cooperatives, our partners choose RICHI for reliable, high-performance solutions. We provide more than just a commercial feed pellet mill; we engineer complete feed mill plants—including hammer mill feed grinders, mixers, coolers, and packaging systems—tailored to your specific capacity and nutritional goals.

What Our Global Partners Say

Our engineering solutions are measured by the results they deliver for clients worldwide. From feed quality and operational efficiency to project support, here is what industry leaders have to say about working with RICHI.

France Client

Feed type: Dairy cattle feed

Pellet size: 6mm

Our cooperative needed a reliable system to process local forage and protein concentrates into high-density pellets. RICHI’s team designed a robust line that handles our high-moisture silage mix perfectly. The pellet durability has significantly improved our feeding efficiency.

Mexico Client

Feed type: Broiler feed

Pellet size: 3mm

Running a large-scale poultry operation, consistency is everything. Since installing the RICHI pellet mill, our feed conversion ratios have improved due to the uniform pellet quality. Their engineers provided excellent training for our maintenance crew.

Iran Client

Feed type: Sheep feed

Pellet size: 4mm

In our arid region, optimizing feed from limited local barley and alfalfa is crucial. RICHI configured a system with a heavy-duty conditioner that produces exceptionally durable pellets. This has reduced waste and supported our flock’s nutrition through seasonal changes.

Uzbekistan Client

Feed type: Beef cattle feed

Pellet size: 8mm

We required a system to add value to our cottonseed meal and wheat by-products. RICHI delivered a complete feed preparation plant that transforms these materials into high-energy pellets. The machine’s stability in our climate and the professional installation were key to our success.

Senegal Client

Feed type: Tilapia feed

Pellet size: 2mm

Starting our first commercial fish farm, we needed affordable yet reliable technology. RICHI offered a perfectly scaled line for our floating feed production. The pellets have excellent water stability, and the local service support has been invaluable.

Matching Pellet Dimensions to Animal Needs

The diameter of a feed pellet directly impacts animal intake, digestion efficiency, and production performance. Selecting the correct pellet size—and the right equipment to produce it—is a critical technical decision. The images below showcase the seven most common pellet diameters our commercial feed pellet mill is engineered to produce, along with the specific applications and technical considerations for each.

Your Complete Feed Production Partner

A successful feed operation requires more than just a high-quality pellet mill. At RICHI, we design and deliver fully integrated, custom-engineered feed pellet production lines. We understand that every client’s needs are unique—defined by their specific raw materials, target feed formula, desired pellet specifications, facility layout, and investment goals. Our comprehensive service covers everything from initial consultation and process design to manufacturing, installation, commissioning, operator training, and lifelong after-sales support, ensuring your line is optimized for performance and longevity from day one.

Silo

Cleaning

Grinding

Mixing

Batching

Pelleting

Cooling

Screening

Packaging

Precision Pelleting

The feed pellet mill is the

critical core where your

recipe is transformed.

Your Single Source for a Complete Feed Plant

storage silo equipment

01

cleaning equipment

02

grinding equipment

03

mixing equipment

04

cooling equipment

05

screening equipment

06

packaging equipment

07

A high-performance commercial feed pellet mill is the core of your line, but true efficiency is built around it. At RICHI, we supply the full ecosystem of processing equipment for a seamless, integrated animal feed plant. From raw material intake and storage to final product bagging, we provide every critical component—including hammer mills, ribbon mixers, counterflow coolers, and beyond. Our engineers expertly select and configure ancillary systems like conveyors, dust collectors, automated batching scales, dryers, and packaging lines to match your specific feed type and production goals, ensuring a cohesive and high-output operation.

Specialized Solutions for Every Feed Type

The optimal process and equipment configuration differ significantly across feed types. RICHI designs targeted solutions for each sector, specifying the ideal pellet mill setup and auxiliary machinery to maximize nutrition, durability, and output. Explore our proven engineering approaches for different animal feeds.

Your Commercial Feed Pellet Mill Queries Answered

Considering a commercial feed pellet mill is a major decision with many practical questions. We’ve compiled the most common inquiries from farmers, feed mill operators, and project planners worldwide to help you make an informed choice. Below, you’ll find real-world questions focused on equipment selection, application, and operational needs.

What is the price range for a commercial feed pellet mill? How much does a commercial feed pellet mill cost?

+

$7,000 – $83,000. The commercial feed pellet mill price varies significantly based on the machine’s model, capacity, motor power, and configuration. It’s not a one-size-fits-all investment cost. A standard commercial feed pellet mill machine price is primarily determined by its hourly output (tons per hour).

For your reference, here is a general commercial feed pellet mill price list for some of our popular models, provided as FOB price ranges to give you an idea of the commercial feed pellet mill for sale price.

- Small to Medium Capacity:

- SZLH250 (22KW): Output 1-2 t/h. Price: $7,000 – $9,000

- SZLH320 (37KW): Output 3-4 t/h. Price: $15,000 – $18,000

- SZLH350 (55KW): Output 5-6 t/h. Price: $27,000 – $32,000

- SZLH420 (110KW): Output 8-12 t/h. Price: $28,000 to $34,000

- Medium to Large Capacity:

- SZLH508 (160KW): Output 15-16 t/h. Price: $40,000 – $45,000

- SZLH558 (185KW): Output 20-22 t/h. Price: $48,000 – $52,000

- High-Capacity Models (Including the Featured SZLH768):

- SZLH678 (250KW): Output 30-33 t/h. Price: $65,000 – $70,000

- SZLH768 (315KW): Output 38-42 t/h. Price: $65,000 – $70,000

Please note that the above are base price ranges for our primary single ring die pellet mill types and are not exhaustive. We offer a wider range of pellet mills suitable for all animal feed processing needs.

The final commercial feed pellet mill quotation you receive will be tailored to your specific project. Key factors that influence the final commercial feed pellet mill cost include:

- Customization: Choice of conditioner type (single, double, or triple layer), specific motor brands (e.g., Siemens), feeder type, and die specifications.

- Ancillary Equipment: Integration with hammer mills, feed mixer machines, coolers, and automation systems for a complete line.

- Shipping & Service Terms: Delivery, installation, and commissioning services.

To get an accurate and detailed commercial feed pellet mill investment cost for your operation, please contact our sales team with your specific requirements regarding feed type, desired capacity, and any special processing needs. We will provide a professional and competitive quotation.

We are a dairy cooperative in Poland looking to produce our own high-protein cattle feed. What pellet mill capacity and die specification do you recommend for processing local rapeseed meal and alfalfa?

+

For your dairy cooperative, we typically recommend a mid to high-capacity commercial feed pellet mill, such as our SZLH558 or SZLH678 series, with outputs of 20-22 t/h or 30-33 t/h respectively, depending on your herd size and desired production scale.

Processing a blend of rapeseed meal and alfalfa requires a robust machine. Rapeseed meal can be abrasive, and alfalfa adds fiber. We would specify a ring die with a moderate compression ratio (typically between 1:8 to 1:12) and hard-chromed or alloy steel construction for extended wear life.

The key is pairing this with a long, single or double-layer conditioner to ensure proper steam penetration into the fibrous alfalfa, which is crucial for binding and pellet durability. Our engineers can analyze your exact ingredient percentages to finalize the optimal die specification and conditioner configuration.

Our farm in Nigeria wants to start making poultry feed to reduce costs. Can your pellet mill handle high-cassava meal formulations, and what is the minimum required workshop space?

+

Yes, our commercial feed pellet mill is well-suited for formulations with high cassava meal content. Cassava meal can be challenging due to its high starch content and low protein, which can affect binding. The success lies in the overall process design.

We recommend a comprehensive line starting with fine grinding to ensure a uniform particle size, followed by thorough mixing and conditioning. Our pellet mills, with their adjustable conditioner retention time and precise steam control, are excellent at gelatinizing the cassava starch, which acts as a natural binder.

For a small to medium farm operation, we often suggest our SZLH350 model (5-6 t/h). The minimum workshop space would need to accommodate not just the pellet mill (approximately 3m x 2m footprint), but also the grinder, mixer, and a pellet cooler machine, requiring a clear area of roughly 8m x 10m with adequate height for overhead conveying.

I’m setting up a new feed mill in Vietnam targeting both tilapia and catfish feed. Can the same pellet mill produce both floating and sinking pellets, or do I need two different machines?

+

This is an excellent and common question. The core commercial feed pellet mill can often be the same base machine, such as our SZLH420 or SZLH508 models. However, the process to produce floating (extruded) feed versus sinking (hard-pressed) feed is fundamentally different and requires different peripheral configurations and processing parameters.

For sinking catfish or tilapia feed, our ring die commercial feed pellet mill is perfect. It produces dense, water-stable pellets through high mechanical pressure. You would use a fine-grind formula and often a double-layer conditioner for longer retention and higher temperature conditioning.

For floating fish feed, the process requires a single or twin-screw extruder, not a ring die pellet mill. Extrusion cooks the starch under high pressure and temperature, causing it to expand upon exit, creating buoyancy.

We at Richi Machinery provide both technologies. For an animal feed production plant targeting both products, we design a flexible line where the grinding and mixing sections are shared, but the line splits post-mixing: one stream goes to the commercial feed pellet mill for sinking feed, and another to the extruder for floating feed. This is a classic example of our custom engineering approach.

For a startup pig farm in Chile, is it more cost-effective to buy a complete small feed line from you or just the pellet mill and source other equipment locally?

+

For a startup, we strongly advise purchasing a complete, matched small scale feed mill from us. While sourcing the pellet mill alone and finding local mixers and grinders might seem cheaper initially, it often leads to significant hidden costs and operational headaches.

Incompatibility between equipment (e.g., mismatched capacities, control systems, or safety standards) can cause bottlenecks, inconsistent feed quality, and higher long-term maintenance costs. Our complete “plug-and-play” small lines, such as those built around the SZLH250 or SZLH320 commercial feed pellet mill, are pre-engineered to work seamlessly together.

Every component from the grinder to the cooler is sized and selected for optimal performance with the pellet mill. This ensures you achieve the designed pellet quality and output from day one, with single-source accountability for service and parts. The total investment is often more predictable and delivers a faster return on investment through reliable operation.

We have a by-product of sunflower husks in our processing plant in Ukraine. Can your pellet mill press this fibrous material into fuel pellets, or is it only for animal feed?

+

Our standard commercial feed pellet mill is primarily engineered for animal feed production, which prioritizes nutritional quality and digestibility. While it can handle some fibrous materials, sunflower husks for fuel pellets present a different challenge. Fuel pelleting requires extremely high pressure to ligninate pure biomass without binders like starch.

For dedicated fuel pellet production from sunflower husks or other agro-forestry waste, we manufacture specialized heavy-duty pellet mills with features like force feeders, heavier-duty gearboxes, and dies with specific hole designs for biomass.

We recommend discussing this application separately with our biomass equipment division, as the machine specifications, wear parts, and process flow are tailored for the fuel industry.

What are the main differences between your standard commercial pellet mill and the “heavy-duty” version for a high-volume shrimp feed plant in Ecuador?

+

A high-volume shrimp feed plant requires what we classify as a “premium-grade” or heavy-duty commercial feed pellet mill. The differences from our robust standard models are significant and focused on precision, durability, and process control:

Controls & Instrumentation: It comes with a comprehensive PLC-based control system monitoring and adjusting conditioning temperature, feeder speed, and main motor load to ensure batch-to-batch consistency critical for shrimp feed quality and water stability.

Conditioning: Shrimp feed requires extensive conditioning. The heavy-duty version will feature a triple-stage, stainless steel conditioner with individual steam injection points in each stage for precise thermal control and long retention times (120+ seconds).

Die & Roller Assembly: It will use ultra-fine, high-compression ratio ring dies (e.g., 1:20+) made from premium alloys and manufactured with gun-drilling for perfect hole geometry. The rollers are also of a higher-grade material to withstand the extreme pressure.

Drive System: It incorporates an even more robust gearbox and high-precision bearings to ensure constant, vibration-free operation under continuous high load.

How does the power consumption of your direct-drive pellet mill compare to a traditional belt-driven model for a 10 t/h layer hen feed operation in Italy?

+

Our direct-drive commercial feed pellet mill offers a clear advantage in energy efficiency for a 10 t/h operation, which would typically use a model like our SZLH420. In a traditional belt-drive system, energy is lost through friction in the multiple belts and pulleys, and the system requires constant tensioning to prevent slippage.

Our integrated high-precision gear drive system directly couples the motor to the main shaft, eliminating these parasitic losses. In practical terms, this design can reduce overall energy consumption for the pelleting process by 8-12% compared to an equivalent belt-driven machine. For a mill running 20 hours a day, this represents substantial annual savings on electricity costs, improving your operational economy.

Our existing feed mill in India needs an upgrade. Can we retrofit your new pellet mill’s ring die and conditioner onto our old machine base, or must we replace the entire unit?

+

While we appreciate the desire to upgrade cost-effectively, retrofitting our key components like the ring die and conditioner onto an old, potentially different-brand machine base is generally not recommended and often not feasible.

The performance of a commercial feed pellet mill relies on the precise synergy between all components: the base frame rigidity, the alignment of the gearbox and main shaft, the bearing specifications, and the coupling to the new conditioner. Installing our high-performance parts on an incompatible base risks misalignment, excessive vibration, accelerated wear, and could even be unsafe. It would also void any warranty.

For a reliable and guaranteed upgrade, we recommend replacing the entire pelletizing unit. However, we can certainly assess your current line and propose the most efficient upgrade path, which might involve integrating a new pellet mill while reusing some peripheral equipment like coolers or conveyors.

What is the typical lead time from order placement to shipment from your Qingdao port for a complete 20 t/h feed pellet line bound for South Africa?

+

The lead time for a complete 20 t/h line, centered on a commercial feed pellet mill like the SZLH558, depends on the final configuration and customization level. For a standard line specification with common options, the typical production and assembly time in our factory is approximately 45-60 working days after order confirmation and receipt of deposit.

This includes manufacturing, pre-assembly, and comprehensive factory testing (FAT) of the complete line. Following successful FAT, packing and preparation for sea freight takes about 5-7 days. Shipment from Qingdao Port to major ports in South Africa usually takes 30-40 days by sea.

Therefore, the total timeline from order to arrival at port is roughly 3 to 4 months. We provide detailed project schedules and maintain transparent communication throughout the process.

For a goat and sheep farm in Australia with variable grain quality, how sensitive is your pellet mill to fluctuations in raw material moisture and particle size?

+

Our commercial feed pellet mill is designed with a degree of tolerance, but consistent raw material quality is key to optimal performance and pellet quality. Significant fluctuations in moisture and particle size will affect the pellet mill’s operation:

- Moisture: Grain with too high moisture can lead to clogging in the conditioner and die, producing soft, mushy pellets. Grain that is too dry requires more steam addition in the conditioner, which must be precisely controlled. Our conditioner with variable speed drive (VSD) allows operators to adjust retention time to better manage moisture variance.

- Particle Size: Inconsistent grind size (too coarse or too fine) leads to poor mixing, uneven steam penetration in the conditioner, and ultimately, weak pellets that break apart. The ideal is a uniform particle size distribution.

We strongly recommend including a good quality hammer mill and mixer in your line to standardize the raw materials before they reach the pellet mill. For farms dealing with variable grains, we can also provide guidance on optimal moisture ranges and configure the grinder screen size to ensure a consistent feedstock, making the entire process more stable.

We are concerned about after-sales support in Peru. If a critical spare part like a main bearing fails, what is your guaranteed response and delivery time for replacement parts?

+

We understand the critical importance of after-sales support, especially in remote locations. Richi Machinery has a structured global support system. For critical spare parts like main bearings, which we stock for all our commercial feed pellet mill models, we operate on the following protocol:

- Delivery Logistics: We work with reliable international couriers (DHL, FedEx) for air freight. Door-to-door delivery to major cities in Peru typically takes 5-7 business days after dispatch. We handle all export documentation and provide tracking information. For non-stocked special items, we provide a firm manufacturing lead time immediately. We also maintain a recommended list of local spare parts (standard seals, belts) that clients should keep on hand.

- Initial Response: Within 4 business hours of your service request.

- Parts Dispatch: Once the part is identified and confirmed, for stocked items, we guarantee dispatch from our factory warehouse within 48 hours.

Does your company provide the necessary CE certification and other export documentation for customs clearance in Saudi Arabia for industrial feed machinery?

+

Yes, absolutely. As a manufacturer exporting worldwide, we ensure all our commercial feed pellet mills and complete lines comply with the necessary standards for the target market. For the European Union and many other countries, we provide full CE certification, which includes machinery directive compliance, technical construction file, and the Declaration of Conformity.

For shipment to Saudi Arabia, we provide all commercial documents (Commercial Invoice, Packing List, Certificate of Origin) and can also prepare the required SASO (Saudi Standards, Metrology and Quality Organization) documentation to facilitate smooth customs clearance. Our shipping department is experienced in handling the specific requirements for industrial machinery exports to the Middle East.

For processing broiler feed with added fats in a large integrated operation in the United States, what special features does your pellet mill have to prevent clogging and ensure consistent quality?

+

Processing high-fat broiler feed is a common application for our large-capacity commercial feed pellet mills like the SZLH768. To handle added fats (often post-pelleting spray, but sometimes internal addition), our mills include several key features:

Post-Pelleting Liquid Application: For the highest fat inclusion levels, we often design the process to add the majority of fat in a dedicated coating system after the pellets are cooled. This is the most effective method to prevent pelleting issues and achieve precise fat content.

Optimized Feeder Design: Our feeder is designed to prevent “bridging” or sticking of fatty mixes, ensuring a consistent and even flow of material into the conditioner.

Conditioner Paddle Configuration: The paddles inside our conditioner are arranged to create a positive, forward-moving mix, preventing fat buildup and ensuring uniform heat and moisture distribution before the material enters the pelleting chamber.

Die Specifications: We recommend specific die hole patterns and inlet geometries (e.g., larger inlet cones) that are less prone to clogging when processing formulas with higher fat content internally. The goal is to ensure the fat lubricates the process without impeding extrusion.

Considering the humid climate in Indonesia, what anti-corrosion treatments or material specifications do you recommend for the pellet mill’s exterior and key components?

+

For operation in humid, coastal climates like Indonesia’s, we offer specific build options to enhance corrosion resistance and equipment longevity for our commercial feed pellet mill:

Fasteners & Hardware: We use galvanized or stainless-steel bolts and fasteners in areas prone to moisture exposure. Discussing your specific location during the quotation phase allows us to specify the most appropriate protection package.

Exterior Finish: Standard paint is upgraded to a high-quality epoxy or polyurethane marine-grade paint system, applied in multiple layers over a thorough sandblasting pre-treatment.

Stainless Steel Contact Parts: We can fabricate the entire feeder, conditioner shell, and door assemblies from food-grade stainless steel (304 or 316), which is standard for our aquaculture-grade mills and highly recommended for humid environments.

Internal Protections: Critical internal components, such as the main shaft in the conditioning area, can be coated with special anti-corrosion treatments. Electrical panels are supplied with higher IP (Ingress Protection) ratings and internal dehumidifiers or heaters.

We plan to produce organic feed for a specialty poultry brand in Germany. Can your equipment be thoroughly sanitized between batches of different formulas to prevent cross-contamination?

+

Yes, we can design a commercial feed pellet mill and complete line to meet the stringent hygiene and traceability requirements of organic or specialty feed production. Key features for such applications include:

- Sanitary Design: Smooth, crevice-free surfaces inside the conditioner, feeder, and pellet mill hood. Doors and access panels designed for easy and complete cleaning.

- Material Choice: Extensive use of stainless steel (SS304 or SS316) for all product contact surfaces, which is durable and easy to clean and disinfect.

- Clean-Out Points: Strategic placement of easy-access clean-out ports in conveyors, bins, and above the pellet mill to allow for complete evacuation of residual material between batches.

- Process Isolation: For complete separation, the line can be designed with dedicated legs (e.g., separate mixers or batch bins) for different organic formulas, converging only at the pellet mill, which is then thoroughly purged and cleaned between runs.

We work with organic certifiers and understand the protocols. Our control systems can also assist with batch tracking and documentation to support your certification requirements.

We are planning to set up a commercial feed pellet mill for animal feed production in Kenya. Could you provide commercial feed pellet mill reviews or case studies from similar feed mill projects in East Africa to help us evaluate performance?

+

Richi Machinery has extensive experience in the East African market. We have successfully commissioned several commercial feed pellet mill projects in Kenya, Uganda, and Tanzania, focusing on both poultry and dairy feed production.

For a project similar to yours, we can provide detailed case studies, including client testimonials, specific challenges addressed (such as adapting to local maize and soybean meal variations), and documented performance metrics like pellet durability index (PDI) and production uptime.

Our commercial feed pellet mill installations in the region are known for their robustness in handling local power fluctuations and raw material consistency, which are common considerations. We would be happy to connect you with a reference client, with their permission, to discuss their firsthand experience with our equipment and engineering support.

Our poultry farm in Pakistan requires a commercial poultry feed pellet mill capable of processing mash feed into uniform pellets. What is the recommended ring die specification and conditioner setup for optimal results?

+

For a poultry farm in Pakistan processing standard broiler or layer mash, the optimal setup for our commercial feed pellet mill depends on your target pellet size and formula. For 3mm to 4mm poultry pellets, we typically recommend a ring die with a compression ratio between 1:10 and 1:12. This ensures adequate density without excessive power consumption. The die material should be high-chrome alloy steel for durability against abrasive ingredients. The conditioner is critical for starch gelatinization. A single or double-layer conditioner with a retention time of 45-90 seconds, operating at 75-85°C, is usually sufficient for standard poultry formulations. Proper steam quality is key. Our engineers can specify the exact die hole pattern and conditioner paddle configuration based on your specific mash composition, which directly impacts pellet quality and mill throughput.

We are comparing different commercial feed pellet mill models for a medium feed factory in Bangladesh. Can you provide a detailed commercial feed pellet mill comparison focusing on energy efficiency and maintenance requirements?

+

When comparing commercial feed pellet mill models for a medium-scale factory in Bangladesh, key factors beyond initial price are crucial. At Richi Machinery, our SZLH series, for example, is designed with a direct-gear drive system that eliminates belt losses, improving energy efficiency by 8-12% compared to traditional belt-driven models. This directly reduces your operating costs.

For maintenance, our design philosophy prioritizes accessibility. Features like a quick-release ring die clamp, self-lubricating bearings in key areas, and standardized, readily available spare parts significantly reduce downtime and long-term maintenance complexity.

We provide a detailed comparison chart outlining the specific energy consumption (kW/t), recommended maintenance schedules, and expected wear part life for models like the SZLH420 (8-12 t/h) versus the SZLH508 (15-16 t/h), helping you make a lifecycle cost-based decision, not just a capital cost one.

For a commercial cattle feed pellet mill intended for large scale production in India, what heavy duty features should we prioritize to ensure stable operation and long service life?

+

For large-scale cattle feed production in India, prioritizing heavy-duty features in your commercial feed pellet mill is essential for stability and longevity. The core components require special attention.

- First, the main gearbox must be an industrial-grade, high-torque unit designed for 24/7 operation.

- Second, the main shaft and bearings should be oversized and rated for continuous heavy loads.

- Third, a force feeder is often necessary to ensure consistent, positive feeding of bulky, fibrous cattle feed ingredients into the die chamber, preventing slippage and ensuring stable motor load.

- Fourth, the ring die and rollers must be made from premium alloy steels with deep hardening treatments to withstand the abrasive nature of mineral mixes and fibrous materials.

- Finally, the entire frame should be of heavy-welded construction with vibration-damping elements.

Our SZLH678 and SZLH768 models are specifically engineered with these heavy-duty features to deliver the reliable, long-service life required for high-volume cattle feed operations.

We are looking for a turnkey solution including a commercial feed pellet mill complete plant for animal feed industry operations in Nigeria. What does your EPC project scope typically cover?

+

At Richi Machinery, our EPC (Engineering, Procurement, and Construction) turnkey solution for a commercial feed pellet mill complete plant in Nigeria is comprehensive. Our scope covers everything from initial feasibility and plant layout design to commissioning and operator training.

Specifically, we handle the detailed engineering of the entire process flow: raw material receiving and storage (including silo design), grinding section, batching and mixing, conditioning and pelleting (centered on the commercial feed pellet mill), cooling, screening, fat coating (if required), and finished product packing or bulk loading.

We procure, manufacture, and supply all mechanical equipment, electrical control systems, and piping. Our team supervises the civil work, directs equipment installation, performs rigorous testing, and provides hands-on training for your staff. We manage the project to ensure all components work in harmony, delivering a fully operational plant that meets your specified capacity and quality targets.

Can you recommend a commercial feed pellet mill for compound feed production in Vietnam that supports continuous working and high output for a feed processing plant?

+

For a feed processing plant in Vietnam requiring high-output, continuous compound feed production, we recommend our SZLH558 or SZLH678 commercial feed pellet mill models. These models are built for sustained 20-22 t/h and 30-33 t/h operations, respectively.

The key to continuous, high-output performance lies in the integrated design: a heavy-duty gear drive for consistent power transmission, a large-capacity conditioner with variable speed control to maintain optimal conditioning parameters, and a robust die/roller assembly that maintains calibration under constant load.

For compound feed, which often contains binders and varied ingredients, the precise steam control in our conditioners ensures uniform moisture uptake, which is critical for stable pelleting and high pellet durability during continuous runs. We also advise on ancillary equipment like surge bins and automated controls to create a seamless, uninterrupted production line from mixing to pelleting.

We are a commercial feed pellet mill supplier in the Philippines. Do you offer local technical support and spare parts for commercial feed pellet mill installation projects?

+

Yes, Richi Machinery provides dedicated local technical support and maintains a strategic inventory of critical spare parts for commercial feed pellet mill installation projects in the Philippines. We work with trained local partners who can provide first-line response for operational queries and minor troubleshooting.

For more complex technical issues, our engineers in China provide remote video support and can be on-site if necessary, depending on the service agreement. We understand that downtime is costly, so we keep a stock of high-wear parts like ring dies, rollers, conditioner shafts, and seals specifically for the Southeast Asian market, facilitating faster delivery to major Philippine ports.

We provide detailed parts manuals and maintenance guides to empower your local team and ensure the long-term performance of your investment.

For organic feed production in the USA, what modifications or specific commercial feed pellet mill design features are needed to meet organic certification standards?

+

For organic feed production in the USA, meeting certification standards requires specific design considerations for the commercial feed pellet mill and the entire production line. The primary focus is on material contact surfaces and cleanability.

We recommend constructing the entire preconditioner, feeder, and pellet mill chamber contact areas from food-grade 304 or 316 stainless steel to prevent contamination and allow for thorough cleaning and sanitization between batches. All seals and gaskets should be USDA-approved materials. The design must eliminate material traps and dead zones where residual non-organic feed could linger.

Furthermore, the lubrication system for the main bearings and rollers must be designed with sealed bearings or use food-grade grease with proper drip trays to prevent any contact with the product. Our engineering team is familiar with NOP (National Organic Program) requirements and can design a system that supports your organic certification audit, including documentation of material traceability for all wetted parts.

What is the expected energy saving percentage when using your high efficiency commercial feed pellet mill compared to conventional models in a commercial feed pellet mill system in South Africa?

+

In a complete commercial feed pellet mill system in South Africa, the energy savings from our high-efficiency models are realized primarily in the pelleting unit itself, which is a major power consumer. Our direct-drive, gear-transmission commercial feed pellet mill typically demonstrates 8% to 15% higher energy efficiency compared to conventional belt-driven models of equivalent capacity.

This is because it eliminates slippage and friction losses inherent in belt systems. For a system running 20 hours a day, this translates to substantial annual savings on electricity costs. The exact percentage depends on the specific model, the formula being processed, and the pellet size.

We can provide historical data from similar installations in climates like yours, showing specific energy consumption in kilowatt-hours per ton of output, which gives a more accurate picture of operational cost savings over time.

We are starting a small scale production of aquaculture feed in Indonesia and need a commercial feed pellet mill 3-5 t/h. What type of ring die and conditioner configuration is suitable for floating fish feed?

+

It is important to clarify that floating fish feed is not produced using a standard ring die commercial feed pellet mill. Floating feed requires the expansion of starch, which is achieved through the high temperature, pressure, and shear force of an extruder. For a 3-5 t/h floating fish feed production line in Indonesia, we would recommend a single or twin screw extruder.

However, for sinking aquaculture feed within that capacity range, our commercial feed pellet mill is an excellent choice. For sinking pellets, we would configure a model like the SZLH350 or SZLH420 with a high-compression ratio ring die (e.g., 1:16 to 1:20) to create dense, water-stable pellets.

The conditioner should be a double or triple-pass type to ensure long retention time (90+ seconds) and thorough cookout of the starch for binding, which is crucial for water stability even in sinking feeds.

For a commercial feed pellet mill for sale in Pakistan, what are the key factors to consider when selecting between a single stage conditioner and a multi-stage conditioner for poultry feed production?

+

When selecting a commercial feed pellet mill for poultry feed production in Pakistan, the choice between a single and multi-stage conditioner hinges on feed quality targets and ingredient complexity. A single-stage conditioner is cost-effective and efficient for standard broiler or layer feeds with straightforward formulas (mainly corn and soybean meal). It provides adequate steam conditioning for good pellet durability.

A multi-stage (double-layer) conditioner is recommended if you are producing high-performance feeds, using alternative ingredients (like canola meal or DDGS), or aiming for superior pellet quality with higher PDI. The multi-stage design allows for longer, more controlled retention time and often separate steam injection points, enabling better starch gelatinization and moisture penetration, especially for finer grinds.

For most commercial poultry operations in Pakistan aiming for optimal balance, a double-layer conditioner on a commercial feed pellet mill offers excellent flexibility and quality assurance.

In a commercial feed pellet mill for feed manufacturing in Turkey, how do you ensure low maintenance and stable operation when processing high fiber ingredients like sunflower meal?

+

Processing high-fiber ingredients like sunflower meal in a commercial feed pellet mill in Turkey requires specific design features to ensure low maintenance and stable operation. The abrasiveness of these materials demands extra durability. We use wear-resistant alloys for the conditioner paddles, feeder screws, and most importantly, the ring die and rollers.

The die holes are designed with specific entry angles to facilitate the flow of fibrous material, reducing clogging and back-pressure. To maintain stable operation, a forced feeder is often essential to consistently push the bulky, low-density fiber mix into the die roller gap, preventing surging and amperage spikes on the main motor.

Furthermore, ensuring precise control over conditioning moisture and temperature is key to softening the fibers, making them more pliable for pelleting and reducing the mechanical strain on the machine. Our systems are designed with these parameters in mind to handle challenging ingredients reliably.

Can your commercial feed pellet mill for concentrate feed handle the inclusion of liquid additives like molasses without affecting pellet quality? We are based in Egypt.

+

Yes, our commercial feed pellet mill systems for concentrate feed are well-equipped to handle liquid additives like molasses in operations based in Egypt. The key is proper application and integration into the process. Molasses is typically added in the conditioner section of the commercial feed pellet mill.

We equip our conditioners with precision liquid injection systems that spray the molasses evenly onto the mixed mash as it is being agitated. This ensures uniform coating and absorption before the material enters the pelleting chamber. The conditioning temperature helps to lower the viscosity of the molasses, improving its distribution.

It’s crucial to control the total moisture content; our automated systems monitor and adjust steam and liquid addition to maintain the optimal moisture for pelleting. When correctly applied, molasses can actually improve pellet binding and palatability without negatively affecting the operation of the commercial feed pellet mill or the final pellet hardness.

We are expanding our livestock feed production in Mexico and need a commercial feed pellet mill for commercial use with automatic controls. What level of automation do you recommend for a 10 tph feed plant?

+

For a 10 tph livestock feed plant expansion in Mexico, we recommend an intermediate to high level of automation for your commercial feed pellet mill system to maximize efficiency and consistency. This would typically include: Automated batching and mixing based on recipe recall from a PLC.

For the pelleting line itself, automation should cover the critical control loops. This includes an automated system that adjusts the feeder speed based on the main motor load to keep the commercial feed pellet mill operating at optimal capacity. It should also include automatic control of steam addition to the conditioner based on the temperature setpoint and feed rate.

A touch-screen HMI would provide operators with real-time data on production rates, motor amperage, conditioner temperature, and system alarms. This level of automation reduces operator dependency, ensures consistent pellet quality, protects the equipment from overloads, and provides valuable production data for management.

Are there any specific commercial feed pellet mill models designed for shrimp feed production that you would recommend for a project in Thailand, particularly in terms of ring die durability and pellet water stability?

+

For shrimp feed production in Thailand, where pellet water stability is paramount, a standard commercial feed pellet mill is not suitable. Shrimp feed requires ultra-fine grinding and extensive cooking to achieve the necessary water stability, which is accomplished with a twin-screw extruder.

Richi Machinery supplies specialized shrimp feed extruder lines for this exact purpose. However, for high-quality sinking fish feed, our commercial feed pellet mill can be configured for high performance. For such applications, we recommend models with multi-stage conditioners (often triple-pass) and ultra-high compression ratio ring dies.

The dies for such applications are manufactured from the finest alloys and processed for maximum wear resistance to handle the finely ground, abrasive formulas. While we are a leading supplier of pellet mills, we always guide our clients in Thailand toward the correct technology—extruders for shrimp and floating feed, and highly specialized pellet mills only for premium sinking aqua feeds.

We are looking for a commercial animal feed pellet mill to produce organic feed for our specialty farm in Canada. What certifications and material standards (e.g., food-grade stainless steel) do your machines meet for organic production requirements?

+

For organic feed production on a specialty farm in Canada, Richi Machinery can configure a commercial animal feed pellet mill to meet the stringent requirements of Canadian Organic Standards.

The system can be built using food-grade 304 or 316 stainless steel for all product contact surfaces, including the conditioner, feeder, and pelleting chamber doors. We can provide documentation certifying the materials used.

Furthermore, we design for complete cleanability, with smooth welds, minimal ledges, and accessible clean-out points to prevent cross-contamination between organic batches. Critical for certification is preventing contact between lubricants and feed; we utilize sealed-for-life bearings in key areas and design grease points to be external and shielded.

While the final organic certification is granted to your process and facility, we provide the equipment engineering and material traceability documentation necessary to support your application with certifying bodies like CFIA.

Our commercial feed pellet mill for sale Philippines project requires processing both poultry and swine feed. Can the same commercial pellet machine efficiently handle both feed types with minimal changeover time, and what adjustments are needed?

+

Yes, the same commercial pellet machine from Richi Machinery can efficiently process both poultry and swine feed in the Philippines with relatively quick changeover. The primary adjustments involve the die and the conditioning parameters.

You would need two different ring dies: one with a compression ratio suited for poultry feed (e.g., 1:10-1:12 for 3-4mm pellets) and another for swine feed, which often benefits from a softer pellet made with a slightly lower compression ratio. Changeover involves swapping the die, which our quick-release systems facilitate.

Secondly, the conditioning temperature and retention time may be adjusted slightly via the control system—swine feed might require slightly different steam settings for optimal fat distribution or fiber conditioning. With proper planning, having dedicated dies and saved parameter recipes on the control panel can make changeover a matter of an hour or less, maximizing your mill’s flexibility.

For a commercial feed pellet mill complete plant installation in Nigeria, what are the typical power requirements and infrastructure needs for a 5-10 t/h production line? We need to plan our facility’s electrical and layout design.

+

For a complete 5-10 t/h commercial feed pellet mill plant in Nigeria, careful infrastructure planning is key. The total connected power load will typically range from 150 kW to 250 kW, depending on the specific configuration (grinder size, number of mixers, etc.).

The heart of the line, the commercial feed pellet mill itself (e.g., SZLH420), will require a motor around 90-110 kW. You will need a stable three-phase power supply capable of handling the starting currents of the large motors. We highly recommend a dedicated transformer and proper electrical panels with soft starters or variable frequency drives (VFDs) for major equipment.

For layout, you need a building with a clear height of at least 5-6 meters to accommodate elevators and coolers. The floor plan must allow for a linear process flow: raw material intake -> grinding -> mixing -> pelleting -> cooling -> packing.

Adequate space for bag storage, maintenance access around equipment, and dust collection points are also critical. Our engineering team provides detailed layout drawings and electrical load lists as part of our project planning service.

We’re comparing commercial feed pellet mill brands for our feed mill project in Bangladesh. Beyond the machine price, what should we consider regarding long service life and low maintenance costs in humid climates?

+

When comparing commercial feed pellet mill brands for an animal feed pellet plant in Bangladesh’s humid climate, looking beyond the initial machine price is wise. For long service life and low maintenance, focus on:

- Corrosion Protection: The quality of paint and the use of stainless steel or galvanized components in moisture-prone areas (conditioner, feeders).

- Component Quality: The origin and rating of critical parts like bearings, gears, and motors. Brands using reputable international components often have longer intervals between failures.

- Sealing Systems: Effectiveness of seals on shafts and bearings to prevent moisture and dust ingress, which is crucial in humidity.

- Spare Parts Availability & Cost: The local availability and long-term pricing of wear parts like dies and rollers. A cheaper machine with expensive, hard-to-find parts becomes costly quickly.

- Design for Service: How easy is it to access parts for routine maintenance? Machines designed for easy die changes and bearing inspections reduce downtime costs.

Richi Machinery designs with these factors in mind, using protective coatings, quality seals, and a modular design to minimize your total cost of ownership in challenging environments.

Can you provide a commercial feed pellet mill turnkey solution for a small scale production startup in Pakistan? We need everything from building design to training, and wonder about the estimated timeline from order to operation.

+

Absolutely, Richi Machinery specializes in providing complete turnkey solutions for small-scale production startups in Pakistan. Our scope includes site assessment, factory layout and civil design guidance, supply and installation of the complete line (e.g., centered on a 1-2 t/h or 3-5 t/h commercial feed pellet mill), electrical wiring and control system integration, commissioning, and comprehensive operator training.

The estimated timeline from order confirmation to successful plant operation is typically 4 to 6 months. This breaks down as: equipment manufacturing (8-10 weeks), sea freight to Karachi (4 weeks), and on-site installation, commissioning, and training (4-6 weeks).

We provide a detailed project schedule and maintain constant communication. Our goal is to deliver a fully functional facility where you can start producing quality feed pellets from day one of handover.

When researching best commercial feed pellet mill options for our livestock feed production in Kenya, how important is the ring die material quality? What’s the difference between standard and hardened alloy steel dies?

+

The ring die material quality is arguably the most critical factor for the longevity and consistent performance of your commercial feed pellet mill in Kenya. It is the highest-wear part. The difference between a standard carbon steel die and a hardened alloy steel die is substantial. Standard dies are less expensive initially but wear out much faster, especially when processing abrasive ingredients common in livestock feed (like minerals or certain brans). This leads to frequent replacement costs and downtime. More importantly, as the die holes wear, the pellet quality degrades—pellets become less dense and more fragile. Our hardened alloy steel dies, manufactured using advanced techniques like vacuum furnace heat treatment and deep case hardening, offer 3-5 times longer service life. They maintain their precise hole geometry far longer, ensuring consistent pellet size, density, and quality over time, which translates to lower cost per ton produced and more stable feed quality for your livestock.

We operate a commercial cattle feed pellet mill in Argentina and want to improve efficiency. What energy saving technologies or operational practices do you recommend for reducing our commercial feed pellet mill’s power consumption?

+

To improve the energy efficiency of your commercial cattle feed pellet mill in Argentina, we recommend a combination of technology and practice. Technologically, if your mill is belt-driven, upgrading to a modern direct-drive commercial feed pellet mill can offer immediate savings of 8-12%.

Operationally, the biggest levers are:

- Optimal Die Selection: Using a die with the correct compression ratio for your formula. Too high a ratio wastes energy; too low produces poor pellets.

- Proper Conditioning: Ensuring the mash is properly conditioned with the right moisture and temperature before entering the die. Dry, under-conditioned feed requires significantly more mechanical energy to form into pellets.

- Consistent Feed Rate: Running the mill at its designed capacity, avoiding under-loading, which is inefficient.

- Regular Maintenance: Keeping the die and rollers in good condition. Worn components increase friction and power draw.

- Steam Quality: Using dry, saturated steam at the correct pressure ensures efficient heat transfer in the conditioner.

An audit of your current process by our engineers can pinpoint the most impactful areas for improvement.

For commercial aquaculture feed pellet mill production in Vietnam, what specific features (e.g., conditioning time, die specifications) differentiate machines for fish feed versus shrimp feed manufacturing?

+

For aquaculture feed in Vietnam, it is vital to distinguish between the technologies. A commercial feed pellet mill is used for sinking fish feed (e.g., for pangasius, tilapia). Key features for this include a double or triple-stage conditioner to achieve long retention times (90-180 seconds) for starch cook-out and binding, and a high-compression ratio ring die (1:16 to 1:20+) to create dense, water-stable pellets.

For shrimp feed, which must be floating or slowly sinking with very high water stability, a twin-screw extruder is required, not a pellet mill. The floating fish feed extruder machine provides much higher shear, temperature, and pressure to fully gelatinize starch and create an expanded, porous structure.

While Richi Machinery supplies both technologies, we ensure our clients select the correct one: pellet mills for high-quality sinking fish feed and extruders for shrimp and floating fish feed.

We’re a commercial feed pellet mill supplier in Indonesia and need to source reliable equipment. What after-sales support, including spare parts availability and technician training, do you provide for commercial feed pellet mill installation projects?

+

As a fellow supplier in Indonesia, Richi Machinery understands the critical importance of after-sales support. For our commercial feed pellet mill installation projects, we provide a comprehensive package. This includes detailed installation supervision and commissioning by our engineers. We offer extensive on-site training for your technicians on operation, routine maintenance, and troubleshooting.

For spare parts, we maintain a regional inventory of high-wear components in a strategic location to ensure fast delivery to Indonesia. We provide complete parts manuals and exploded-view drawings. Furthermore, we offer remote diagnostic support and have a 24/7 response channel for urgent technical inquiries. Our goal is to be a long-term partner, ensuring the equipment we supply operates reliably and profitably for your clients, which in turn supports your business reputation.

Our commercial feed pellet mill for animal feed factory in Egypt currently experiences frequent downtime. What are the most common operational issues with commercial feed pellet mills, and how does your design address them for stable operation?

+

Frequent downtime in a commercial feed pellet mill in Egypt often stems from a few common issues:

- 1. Die & Roller Wear/Improper Alignment: Causes poor pelleting, high fines, and power surges. Our mills feature precision-machined housing for perfect alignment and easy-adjustment rollers to maintain the critical gap, ensuring consistent performance.

- 2. Inconsistent Feeding or Conditioning: Leads to blockages and motor overload. Our designs include reliable forced feeders and conditioners with precise steam control to deliver a consistent, well-conditioned mash to the die.

- 3. Bearing Failures: Often due to heat, dust, or misalignment. We use high-grade, sealed bearings in critical positions and design for optimal heat dissipation and dust protection.

- 4. Poor Steam Quality: Wet steam drastically reduces conditioning efficiency.

Our systems include proper steam pipelines and traps. Our commercial feed pellet mill is engineered for stable operation by addressing these root causes through robust design, quality components, and intelligent process integration.

We plan to export pellets from our commercial feed pellet mill for feed production business in South Africa. What pellet quality parameters (durability, moisture content) should we consistently maintain to meet international standards?

+

To export pellets from your commercial feed pellet mill business in South Africa, consistently meeting key quality parameters is essential. The most critical are:

- Pellet Durability Index (PDI): This measures the percentage of whole pellets remaining after a standardized tumbling test. For export-quality feed, a PDI of 95% or higher is typically targeted to minimize fines generated during handling and transport.

- Moisture Content: This should be tightly controlled, usually between 10% and 12%. Too high risks mold growth during shipping; too low can increase brittleness.

- Fines Content: The percentage of material passing through a screen smaller than the pellet diameter after tumbling should be minimal, often below 5%.

- Uniform Size and Diameter: Consistency in appearance is important for customer confidence.

Our commercial feed pellet mill systems, when paired with proper conditioning and cooling, are designed to produce pellets that consistently meet these stringent export standards, supported by process control systems that monitor and record key parameters.

For a commercial poultry feed pellet mill in Turkey processing high-corn diets, what conditioner configurations help prevent die clogging and ensure optimal starch gelatinization for pellet quality?

+

For a commercial poultry feed pellet mill in Turkey processing high-corn diets, effective conditioning is the key to preventing die clogging and unlocking pellet quality. Corn is high in starch, which needs to be gelatinized to act as a natural binder. We recommend a double-layer conditioner for this application.

The first stage can use lower-temperature steam to begin warming and moisturizing the mash uniformly.

The second stage applies higher-temperature steam to achieve the target conditioning temperature of 80-85°C. This two-stage approach ensures thorough, uniform heat penetration without creating localized pockets of over-wet mash that can lead to clogging. The extended retention time (60+ seconds) in the double-layer design allows the starch to fully gelatinize.

This results in a pliable, well-bonded mash that flows smoothly through the die holes, producing strong, durable pellets and keeping the commercial feed pellet mill running smoothly.

Can your commercial feed pellet mill engineering solution include automatic ingredient batching and mixing systems? We want to minimize human error in our commercial feed manufacturing process in Saudi Arabia.

+

Yes, absolutely. Our commercial feed pellet mill engineering solution for Saudi Arabia is most effective when integrated with automated batching and mixing systems. We design and supply complete automated batching lines that precisely weigh out micro and macro ingredients according to digital recipes.

This system typically includes bulk ingredient scales, micro-ingredient weighing hoppers, and a computerized control panel that eliminates manual calculation and scooping errors. The weighed ingredients are then discharged into a high-efficiency mixer (double-shaft or ribbon) for a set mixing time. This perfectly blended mash is then conveyed seamlessly to the conditioner of the commercial feed pellet mill.

This level of automation ensures absolute formula accuracy, consistent raw material cost, and uniform pellet quality batch after batch, which is crucial for modern, high-volume feed manufacturing where human error must be minimized.

We need a commercial feed pellet mill for medium feed factory expansion in India. How do we properly size the machine (like 3-5 tph production line) based on our raw material characteristics and target pellet diameter?

+

Properly sizing a commercial feed pellet mill for a 3-5 tph line expansion in India requires evaluating several factors beyond just the desired throughput. 1. Formula Density: Heavy formulas (high in minerals) produce more tons per hour than light, fibrous ones. 2. Pellet Diameter: Producing 2mm pellets typically has a lower output rate than 4mm pellets from the same die, due to the higher resistance of smaller holes. 3. Conditioning Requirements: If your formula requires long conditioning time, the throughput of the conditioner itself becomes a limiting factor. 4. Grind Size: A finer grind generally improves pelleting efficiency but may reduce throughput slightly. Based on typical Indian poultry or cattle feed formulas, our SZLH350 (55KW) is well-suited for a solid 4-5 tph line with 3-4mm pellets, while the SZLH420 (110KW) can reliably deliver 5-6 tph or more and offers room for growth. Our engineers will analyze your specific formula, pellet size, and desired annual production to recommend the optimal model.

Are there commercial feed pellet mill models specifically designed for high fiber feed production (e.g., dairy rations) in Uruguay? What modifications are needed to handle ingredients like alfalfa hay?

+

Yes, we have commercial feed pellet mill models specifically configured for high-fiber feed production like dairy rations in Uruguay. The primary modifications focus on feeding, conditioning, and die design. 1. Feeding: A force feeder is essential to positively push the low-density, bulky alfalfa hay mix into the die roller gap. 2. Conditioning: A long, single or double-pass conditioner is needed to allow time for steam to penetrate and soften the fibrous material, making it more pliable. Sometimes liquid binders like molasses are added here. 3. Die Design: The ring die requires a lower compression ratio (e.g., 1:5 to 1:8) and larger inlet holes to facilitate the flow of long fibers without excessive pressure build-up and clogging. Models like our SZLH508 or SZLH558 are often chosen for such applications due to their robust construction and power. Proper preparation of the alfalfa (consistent chopping/grinding) is also crucial for success with a commercial feed pellet mill.

What are some recent examples of complete poultry feed plant projects using your high-capacity commercial feed pellet mill, and what are the typical investment ranges in different countries?

+

Richi Machinery has successfully delivered numerous turnkey poultry feed plant projects worldwide, with our flagship commercial feed pellet mill, the SZLH768, serving as the reliable core in many high-volume operations. The total plant cost varies significantly based on the scope of automation, ancillary equipment (grinding, mixing, cooling, packaging systems), and local infrastructure requirements. Below are representative examples from recent engagements, showcasing the versatility of the SZLH768 in producing different pellet sizes for various markets. Please note that all costs are approximate for a complete plant (FOB basis) and are subject to detailed engineering based on your specific requirements.

- Russia: For a commercial feed pellet mill for sale project supplying large integrated farms, we configured an SZLH768-based line producing 1-5mm pellets for versatile poultry rations. The complete plant cost was approximately $650,000 USD.

- Mexico: A major producer selected the SZLH768 for a new broiler feed mill facility, requiring high output of standard 2-4mm broiler feed pellets. The engineered commercial feed pellet machine solution, including advanced automation, had a project value near $750,000 USD.