ANIMAL FEED PELLET MAKING MACHINE FOR SALE

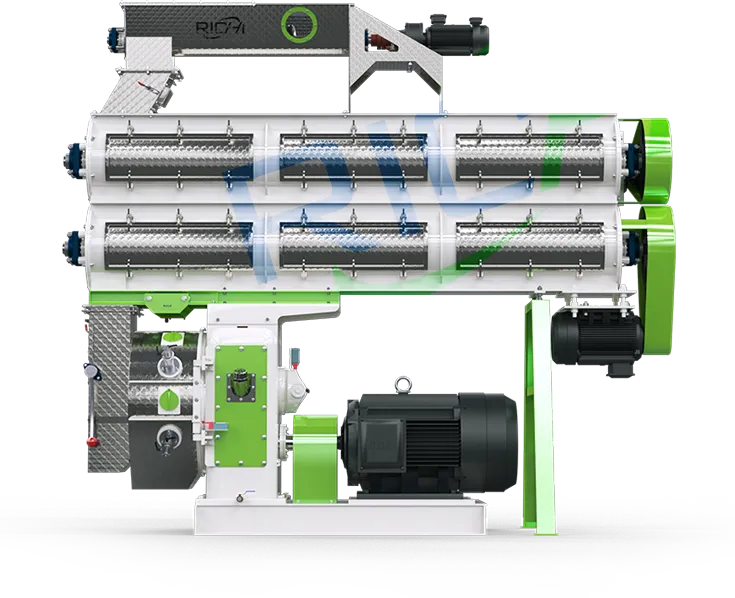

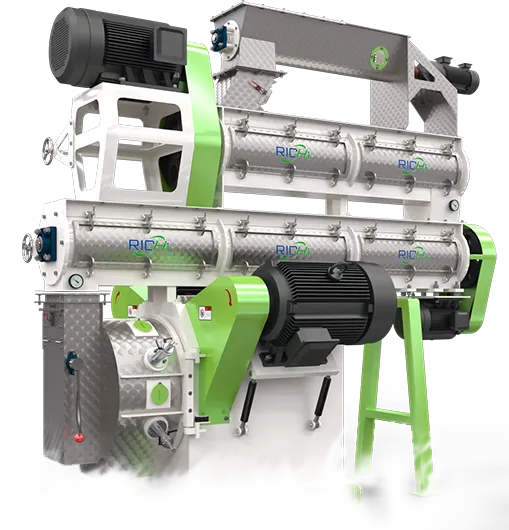

Ring Die Animal Feed Pellet Making Machine for Sale – Engineered for Impact. From morning eggs to dinner-time steak, you help feed the animals that feed the world. With the SZLH508 series, achieve reliable production of 15-16 tons per hour in facilities of any scale. RICHI delivers this robust animal feed pellet making machine for sale worldwide, ensuring optimal capacity tailored to your operation. When your role is essential, never settle for second best.

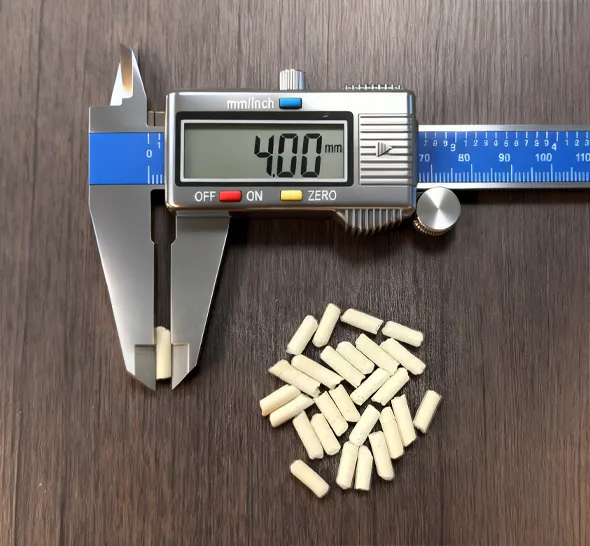

Pellet Size: 2~12mm

Price: $40,000 – $45,000

Model

SZLH508

Production Capacity

15-16T/H

Precision-Engineered for Every Feed Type

For over 30 years, RICHI has perfected equipment design to provide comprehensive solutions for your unique ingredients and requirements. This expertise is built into our core animal feed pellet making machine for sale, a versatile powerhouse engineered to deliver optimal performance across the three primary feed categories. Trusted by operations on every continent—from massive animal feed mill plants to specialized production lines—this single model adapts seamlessly to produce high-quality pellets for poultry, livestock, and aquaculture.

Our robust 15-16 t/h machine is engineered to process a wide range of formulations into durable, nutritional pellets. It is the ideal core equipment for commercial feed manufacturing plants, integrated livestock and poultry farms, and dedicated aquaculture feed production facilities. Wherever consistent, high-volume pellet output is critical, this machine provides the reliable performance that global producers depend on.

Produces highly digestible pellets for broilers, layers, and turkeys to optimize growth rates and egg production.

Creates dense, uniform pellets for cattle, pigs, and sheep to enhance feed efficiency and herd health.

Engineered to produce water-stable pellets for fish and shrimp, supporting sustainable aquatic farming.

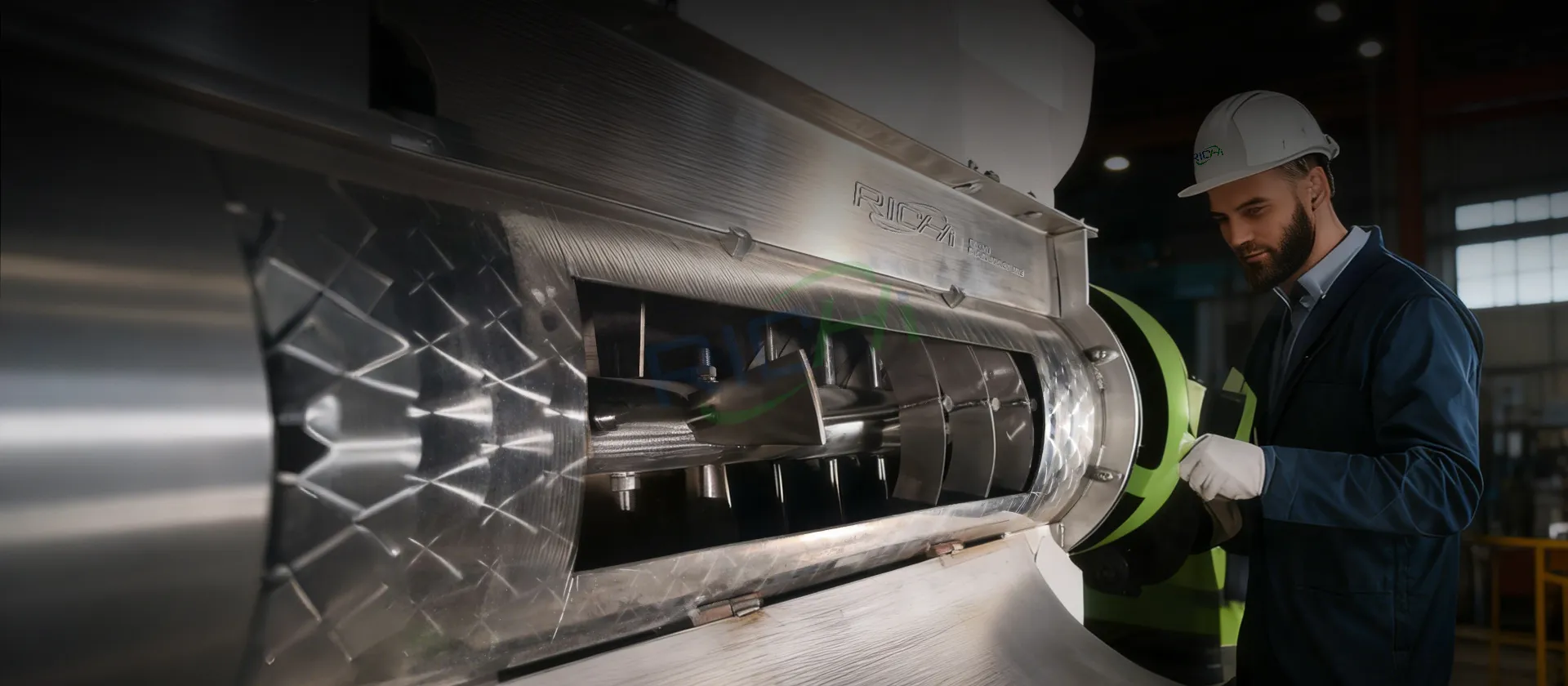

Modular Conditioning Technology

Our expertise extends beyond animal types to the core of pellet quality: conditioning. Every animal feed pellet making machine for sale from RICHI features our superior, large-diameter, elongated conditioner. This design ensures thorough steam penetration and uniform starch gelatinization. The best part? This critical component is fully customizable in length and configuration to match your specific formula. We offer three specialized variants to cover the complete spectrum of feed production, from standard to high-end.

Single-Stage Conditioner feed pellet making machine

This robust and versatile model is the industry’s most widely used workhorse. It is perfectly suited for producing standard poultry and livestock feed pellets with high efficiency. For clients processing fibrous materials, we integrate a forced feeder to reliably pelletize various grass-containing feeds. It is the ideal, cost-effective choice for general animal feed production plants and integrated farms.

Dual-Layer Conditioner animal feed pellet making machine

Engineered for enhanced nutritional quality, this model features two sequential conditioning chambers. The extended retention time and dual-stage steam application are crucial for producing premium livestock feeds and standard sinking aquatic pellets. It is designed for complete feed mill plants targeting higher digestibility and for operators entering the aquaculture market with standard fish feed requirements.

Triple-Layer Conditioner animal feed pellet making machine

This represents our pinnacle of conditioning technology. Three stages provide maximum control over time, temperature, and moisture. It is essential for manufacturing high-stability, floating or slow-sinking feeds for sensitive species like shrimp and high-value fish. This machine is built for specialized aquaculture feed plants and producers demanding the absolute highest pellet durability and water stability.

Process Over 50+ Raw Materials

The true capability of our animal feed pellet making machine for sale is defined by the diversity of raw materials it can process efficiently. Whether you’re working with traditional grains, specialized protein sources, fibrous roughages, or precise additive blends, this model handles them all. It is also expertly engineered to process challenging materials like fresh green forages and fermented silages, ensuring a complete feed solution tailored to modern, complex formulations.

Energy Ingredients

Provide the foundational calories for animal growth and maintenance. Our machine ensures perfect gelatinization of starches from grains like corn and wheat for optimal digestibility.

Protein Ingredients

Crucial for muscle development and overall health. From soybean meal to fishmeal, our conditioning process preserves nutritional integrity while creating durable pellets.

Roughages Ingredients

Add essential fiber for ruminant and livestock digestive health. Our robust design, with optional forced feeders, effectively processes fibrous materials like alfalfa and straw.

Feed Additives

Enable precise inclusion of vitamins, minerals, and premixes. Uniform mixing and gentle conditioning ensure even distribution within every pellet for consistent animal nutrition.

See Our Global Installations at Work

Talk is one thing, but real-world performance is everything. For over 30 years, our animal feed pellet making machine for sale has proven its reliability in demanding operations worldwide. The video case studies below demonstrate our machine’s robust performance across different continents and applications—from large-scale commercial mills to specialized production facilities. See for yourself how our engineering delivers consistent, high-capacity output and stands up to the task, day after day.

Uzbekistan Animal Feed Pelletizing Project

Oman Animal Feed Pelletizing Project

Afghanistan Animal Feed Pelletizing Project

Uganda Animal Feed Pelletizing Project

Core Design & Technical Superiority

The outstanding performance of our animal feed pellet making machine for sale is built on a foundation of superior engineering and precision components. Every structural element is designed for durability, efficiency, and unparalleled reliability in high-capacity production. Below are the key features that make this machine a low-fault model, engineered to exceed industry standards and deliver a higher return on your investment.

Key Advantages

Our animal feed pellet making machine for sale is designed to deliver more than just high output—it provides intelligent, reliable, and adaptable performance. Built upon decades of industry experience, this model incorporates advanced features that directly address the core challenges of modern feed production: quality consistency, operational efficiency, and flexible application.

Variable Die Speed for Formula-Specific Precision

Gain precise control over pellet density and texture. Our system allows you to adjust the die’s circumferential speed without changing the die itself. This versatility lets you perfectly tune the machine for each unique feed formulation, from broiler starter to high-fat aquafeed, ensuring consistent, top-tier pellet quality across all your recipes.

Automated Roller Gap Adjustment & Anti-Blocking

Maximize productivity while protecting your investment. The machine features automatic roller gap adjustment during operation, maintaining optimal pressure for uniform pellets without stopping. Combined with our Anti-Blocking System (ABS), it prevents roll slippage and material jams. This allows you to operate safely at peak capacity, significantly reducing unplanned downtime and wear on critical parts.

Tailored Customization for Your Specific Needs

We build solutions, not just machines. Beyond our standard model, your animal feed pellet making machine for sale can be extensively customized. This includes selecting the optimal conditioner type (single, double, or triple-stage), configuring specific die and roller specifications, integrating tailored automation levels, and adapting auxiliary systems like forced feeders for fibrous materials. We engineer the machine to fit your plant, not the other way around.

Scalable Automation for Future-Ready Operations

Start simple and expand seamlessly. The machine serves as the reliable core of your production line. We offer a full spectrum of automation solutions, from basic machine control panels to comprehensive smart factory integrations with production monitoring and data analytics. This ensures your investment is protected and can grow alongside your business.

The Precision Behind the Pellet: How It Works

Understanding the engineering inside our animal feed pellet making machine for sale reveals why it delivers such consistent, high-volume output. The process is a masterful blend of mechanical force and precise control, transforming conditioned mash into uniform, durable pellets. It’s a continuous, efficient operation perfected over 30 years of building robust feed mill engineering solutions.

Here’s a straightforward look at the core process:

First, the optimally conditioned feed mash is fed into the machine’s chamber. Centrifugal force from the rotating ring die, assisted by internal scrapers, distributes the material evenly. The mash enters the compression zone between the rotating die and the heavy-duty press rollers.

Here, immense pressure forces the material through the precisely drilled holes in the hardened steel ring die. This extrusion process compacts the mash, creating dense, column-shaped strands. Finally, an external adjustable cutter slices these strands into precise, uniform pellets of your required length, ready for cooling and packing.

Technical Specifications & Model Comparison

Review the detailed engineering parameters of our flagship animal feed pellet making machine for sale below. This table confirms the robust performance and precise specifications that deliver reliable 15-16 t/h output for professional animal feed production plants. For operations with different capacity requirements, we offer a complete series of seven additional pellet mill models. Explore the full range to find the perfect match for your production scale.

Need precise specifications for your planning?

SZLH508 Technical Specification

Main motor power

160kW

Feeder power

1.5kW

Conditioner power

7.5kW

Ring die inner diameter

508mm

Finished pellet diameter

2-12mm

Optimized Process for Every Feed Type

Achieving perfect pellets requires more than just a machine—it demands precise process tuning for each specific feed formula. Our deep understanding of feed science is built into every animal feed pellet making machine for sale. Below are the key production parameters we recommend for major feed categories, demonstrating how our single, robust model is expertly configured to meet diverse processing requirements.

Chicken Feed Pelletizing Parameters

Our machine is expertly set for high-volume poultry operations. For broiler and layer feeds, we target a high capacity of 10-15 t/h chicken feed pellet machine. Pellets are typically 2-4mm in diameter with a compression ratio of 1:10 to 1:13. Conditioning is critical; we recommend a temperature of 150°C and an extended retention time of 60-120 seconds in a one or two-layer conditioner to ensure optimal starch gelatinization and durability for high feed intake.

Cattle & Sheep Feed Pelletizing Parameters

Processing ruminant feed requires handling coarser ingredients. Here, capacity is adjusted to 12-18 t/h for denser materials. Our cattle feed pellet machine produce larger 6-12mm diameter pellets with a lower compression ratio (1:6 to 1:9) to maintain proper rumen function. Conditioning at 150°C for a shorter 30-60 seconds in a single-layer conditioner is sufficient to bind the pellet without over-processing fibrous components.

Pig Feed Pelletizing Parameters

For swine nutrition, our pig feed pellet machine balances high output with digestibility. Operating at 12-18 t/h, it produces 2-4mm pellets. A moderate compression ratio of 1:3.5 to 1:5 creates a slightly softer pellet that is preferable for pigs. Similar to poultry, thorough conditioning at 150°C for 60-120 seconds (using one or two layers) is applied to enhance palatability and nutrient availability.

Sinking Fish Feed Pelletizing Parameters

Manufacturing aquatic feed demands precision for water stability. Capacity is calibrated to 7-10 t/h to accommodate finer grind (1.0-2.0mm) and complex binders. Producing 2-6mm pellets requires a high compression ratio (1:16 to 1:18). A two or three-layer conditioner sinking fish feed machine is essential, maintaining 150°C for 90-180 seconds to achieve the necessary starch gelatinization and pellet integrity for submerged feeding.

Shrimp Feed Pelletizing Parameters

This represents the pinnacle of feed pelleting technology. For ultra-fine (95% ≥ 80 mesh) shrimp feed, the animal feed pellet making machine for sale is configured for a precise 2-2.2 t/h output. It forms small 1.2-2.0mm pellets using an extremely high compression ratio (1:20 to 1:25). A three-layer conditioner is mandatory, providing prolonged conditioning at 150°C for 120-180 seconds to create the highly water-stable, slow-sinking pellets critical for shrimp farming.

Our Global Projects: From Machine to Complete Line

Our expertise is proven worldwide. We have delivered not just single machines, but complete animal feed pellet production lines to every continent. These projects span diverse scales—from family-run farms to major industrial mills—processing a vast range of feed types. For most clients, the animal feed pellet making machine for sale serves as the reliable core of their custom-engineered production system.

animal feed pellet making machine for sale USA

A mid-western feed cooperative integrated our system to produce high-quality dairy feed. The line processes corn, soybean meal, and mineral premixes into uniform 4-6mm pellets for enhanced milk production.

Feed type: Dairy cattle feed

Pellet size: 4-6mm

Animal feed pellet making machine for sale Algeria

Feed type: Sheep feed

Pellet size: 8mm

Animal feed pellet making machine for sale Indonesia

Feed type: Poultry (broiler) feed

Pellet size: 3mm

An integrated poultry operation chose our complete line for its reliability. It efficiently turns local corn and protein mixes into durable 3mm broiler feed pellets, supporting their high-volume farming needs.

Animal feed pellet making machine for sale Iraq

Feed type: Poultry feed

Pellet size: 4.5mm

Animal feed pellet making machine for sale in Uganda

Feed type: Cattle feed

Pellet size: 6mm

Animal feed pellet making machine for sale Oman

We supplied a turnkey project to a new aquaculture venture. The plant specializes in producing slow-sinking 2mm shrimp feed from finely-ground fishmeal and specialized binders for optimal water stability.

Feed type: Shrimp feed

Pellet size: 2mm

Animal feed pellet making machine for sale the Philippines

Feed type: Swine feed

Pellet size: 2-3mm

Trusted by Industry Leaders Worldwide

From standalone machines to fully automated factories, we are a professional partner for feed producers at any scale. Our solutions are backed by deep technical expertise in designing systems that process every feed type efficiently and reliably. Whether you need a core animal feed pellet making machine for sale or a complete plant, we engineer for your success.

Global Clients, Proven Results

Our commitment to engineering excellence and reliable performance is validated by our clients worldwide. From technical design to project execution and service, RICHI solutions consistently meet the diverse and demanding needs of feed producers across the globe.

Argentina Client

Feed type: Beef cattle feed

Pellet size: 8mm

The RICHI line transformed our beef cattle operation. It handles our local alfalfa and corn silage mix perfectly, producing dense 8mm pellets that maintain their form. Our herd’s feed efficiency has noticeably improved since the switch.

Russia Client

Feed type: Dairy cattle TMR feed

Pellet size: 6mm

We needed a robust machine capable of running in cold conditions and processing high-fiber ingredients for our dairy consortium. RICHI’s pellet mill delivers consistent 6mm TMR pellets without blockage, which is crucial for our large-scale winter feeding program.

Thailand Client

Feed type: Shrimp feed

Pellet size: 2mm

For our integrated shrimp farming business, pellet water stability is everything. The three-layer conditioner on our RICHI machine makes all the difference. We now produce superior 2mm shrimp feed with less than 1% fines in water after two hours.

Afghanistan Client

Feed type: Sheep feed

Pellet size: 4mm

As a medium-sized sheep feed mill, we required a simple, durable line. RICHI provided a straightforward, easy-to-maintain system that processes our local barley and cottonseed cake into uniform 4mm pellets. It runs flawlessly with minimal technical support needed.

Zimbabwe Client

Feed type: Poultry (broiler) feed

Pellet size: 3mm

Starting our poultry feed company was a major investment. RICHI didn’t just sell us a machine; they provided a full layout design for our small facility. Their pellet mill produces excellent 3mm broiler feed, giving us a competitive edge in the local market.

Matching Pellet Size to Animal Nutrition

Selecting the correct pellet diameter is critical for feed efficiency, animal health, and optimal production. The precision of your animal feed pellet making machine for sale directly determines this key parameter. Below is a technical guide to the seven most common pellet sizes, detailing their primary applications and the specific machine configurations required to produce them consistently.

Your Complete Line, Your Specific Process

RICHI provides far more than a standalone machine; we deliver comprehensive production solutions from initial design to final commissioning. We understand there is no universal process. Pelletizing poultry feed differs fundamentally from creating water-stable aquafeed.

Therefore, every line we engineer is customized, meticulously matching your specific raw materials, target pellet specifications, available plant layout, and investment goals. Our partnership extends through the entire lifecycle of your operation, encompassing consultation, manufacturing, installation, commissioning, training, and ongoing spare parts support.

Silo

Cleaning

Grinding

Mixing

Batching

Pelleting

Cooling

Screening

Packaging

Precision Pelleting

The pellet mill is the

critical core where your

recipe is transformed.

Complete Support for Every Processing Stage

storage silo equipment

01

cleaning equipment

02

grinding equipment

03

mixing equipment

04

cooling equipment

05

screening equipment

06

packaging equipment

07

A successful feed operation relies on a perfectly synchronized line, not just a single machine. At RICHI, we provide the full spectrum of processing equipment to cover every critical stage—from raw material intake and storage to the final bagged pellet. Our expertise ensures each component, from hammer mill feed grinders and mixers to coolers, graders, and automated packing systems, is optimally selected and configured for your specific feed type and production goals.

Optimized Solutions for Every Animal Feed Type

Each animal species requires a unique nutritional approach and processing strategy. RICHI specializes in designing tailored pelletizing lines that meet the specific demands of different feed categories. From equipment selection to process flow, we engineer solutions that maximize feed quality, efficiency, and return on investment for your target market.

Your Questions, Our Expertise

Purchasing a high-capacity pellet mill is a significant investment, and having clear, technical answers is crucial. Below, we address the most common questions from feed mill managers, farm owners, and investors about our ring die animal feed pellet making machine for sale. Our goal is to provide the transparency and detailed information you need to make a confident decision for your operation.

How much does a SZLH508 animal feed pellet making machine cost?

+

The cost of an animal feed pellet making machine for sale is not a single figure, as it varies significantly based on capacity, power, construction, and included features. As a professional manufacturer, Richi Machinery offers a complete series to meet different production scales. The price primarily reflects the machine’s capability and durability.

For reference, here is a general price range for our standard ring die pellet mill series (FOB prices):

For Small Farms & Startups:

- SZLH250 Series: With a 22KW motor and an output of 1-2 tons per hour, this entry-level model is priced between $6,500 and $9,500. It’s an ideal solution for small poultry or livestock farms aiming to produce their own feed.

- SZLH320 Series: Featuring a 37KW motor for 3-4 t/h output, this model offers a step up in capacity, with prices ranging from $14,000 to $19,000.

For Medium-Sized Feed Mills:

- SZLH350 Series: A 55KW machine producing 5-6 t/h, suitable for expanding operations. The investment typically falls between $26,000 and $33,000.

- SZLH420 Series: This 110KW model is a robust workhorse capable of 8-12 t/h. Its price range is $27,000 to $35,000, representing a strong balance of output and value.

For Large Commercial Production Lines:

- SZLH508 Series: The 160KW model you are considering, with a 15-16 t/h capacity, is priced from $39,000 to $46,000. This animal feed pellet making machine for sale is built for continuous, high-volume operation with premium components for minimal downtime.

- SZLH558 Series: At 185KW and 20-22 t/h, this unit costs between $47,000 and $53,000.

- SZLH678 & SZLH768 Series: For the highest output demands, our 250KW (30-32 t/h) and 315KW (38-40 t/h) models are priced from $64,000 to $71,000 and $77,000 to $84,000, respectively.

The above represents pricing for our main standard models, but it is not an exhaustive list. We provide a full range of pellet mills tailored for animal feed processing.

It is crucial to understand that the final price for your animal feed pellet making machine for sale can be affected by several customization factors, including the type of conditioner (single, double, or triple-layer), the specification of the ring die and rollers, the level of automation (from basic control to full PLC), and the choice of ancillary equipment.

Therefore, the most accurate way to get a quote is to share your specific production requirements with us. Please contact our sales team with details about your target feed type, desired capacity, raw materials, and available facility space so we can provide a tailored solution and a precise, competitive quotation.

What is the total connected power load for the entire pelleting line built around this machine?

+

A complete 15-16 t/h line centered on our ring die animal feed pellet making machine for sale typically has a total connected load between 350 kW to 450 kW. This includes the main pellet mill motor (approx. 220-250 kW), the hammer mill, feed mixer machine, conveyor systems, cooler fans, and control systems.

During the initial design phase, Richi Machinery engineers will calculate the exact peak and average demand for your specific configuration to ensure your electrical infrastructure is sufficient and to optimize energy efficiency.

Can this specific model efficiently pelletize high-roughage feeds containing 20-30% alfalfa or grass meal?

+

Absolutely. This is a common requirement for ruminant feed producers. Our animal feed pellet making machine for sale is specifically configured for such challenges. We integrate a heavy-duty forced feeder to ensure consistent material flow into the conditioning chamber.

Furthermore, we specify a ring die with a lower compression ratio and larger inlet holes to prevent bridging and blockage. Combined with our extended conditioner for proper moisture and heat treatment of the fibrous material, the system produces dense, durable pellets from high-roughage formulas.

How does the output and pellet quality differ when switching from making 2mm shrimp feed to 8mm cattle feed on the same machine?

+

The output and quality are directly controlled by the die specification and process parameters. Switching from 2mm shrimp to 8mm cattle feed requires a complete die change. The shrimp feed die will have a very high compression ratio (e.g., 1:20) and small holes, resulting in lower output (potentially 0.8-1.2 t/h) but maximum pellet durability for water stability.

The cattle feed die has a low compression ratio (e.g., 1:7) and large holes, allowing the machine to run at its full 15-16 t/h capacity. The pellet quality—hardness for cattle, water stability for shrimp—is engineered into each specific die.

Our process experts provide clear parameters for conditioning time and temperature for each formula to ensure optimal results after the changeover.

What is the lead time from order to delivery for this animal feed pellet making machine for sale, and what does shipping typically involve?

+

The standard lead time for a single 15-16 t/h pellet mill is 30-45 days after order confirmation and receipt of deposit. For a complete customized production line, lead time ranges from 60 to 90 days, depending on complexity. Shipping is typically via sea freight (FOB or CIF terms) from our port.

We handle all export documentation, crating, and loading. For larger projects, we can arrange door-to-door delivery and customs clearance assistance in the destination country. We provide a detailed shipping schedule and tracking information at every step.

Do you offer a trial or testing service where we can send our own raw material mix to verify pellet quality before purchase?

+

Yes, we strongly encourage this. Richi Machinery operates a fully-equipped pilot plant at our facility. You can send your specific raw material formula. Our engineers will run it through the relevant process—grinding, mixing, conditioning, and pelleting—on a comparable smaller-scale animal feed pellet making machine for sale.

We will provide you with a detailed report including pellet durability index (PDI), production rate observations, and recommendations for die specification and process settings. This service minimizes your investment risk.

What is the recommended annual maintenance schedule and cost for critical wear parts like the ring die and rollers?

+

Proper maintenance is key to longevity. We recommend a daily check of roller and die gap, and a weekly inspection of all bearings and gearbox oil. The ring die and rollers are consumable parts. Their lifespan depends entirely on the abrasiveness of your materials.

For standard corn-soy poultry feed, a high-quality alloy steel die can last 18,000-22,000 tons, while rollers last 8,000-10,000 tons. For more abrasive diets, life is shorter. We provide a transparent spare parts price list.

As a guideline, budgeting 1-3% of the machine’s initial cost annually for routine wear parts (dies, rollers, seals, scrapers) is a prudent practice for a busy mill.

For a new feed mill startup, what level of automation do you recommend—basic manual control or full PLC—for this capacity?

+

For a 15-16 t/h greenfield plant, we strongly recommend a PLC-based control system. At this capacity, the efficiency gains and error reduction far outweigh the initial cost. A basic PLC system for the pellet mill line allows for automated startup/shutdown sequences, monitoring of motor load and temperature, and centralized control of feeders and conditioners.

This prevents operator error that can damage the animal feed pellet making machine for sale. For larger investments, we can integrate full SCADA systems with production data tracking and recipe management. We design scalable automation that grows with your business.

How does the pellet durability (PDI) from your machine compare to other major brands when processing standard broiler feed?

+

When configured with the correct die and proper conditioning, our animal feed pellet making machine for sale consistently produces broiler feed pellets with a PDI exceeding 95%.

The key differentiators are our heavy-duty, precision-ground gear drive that ensures absolutely stable roller pressure, and our customizable, elongated conditioners that achieve superior starch cook.

We have numerous clients who switched from other brands and reported an immediate 3-5% increase in PDI, directly reducing feed waste and fines in transport. We welcome comparative trials with your material as proof.

We have voltage fluctuations. Are the motors and electrical components on your animal feed pellet making machine for sale protected?

+

Yes, protection is standard. All our main drives for this capacity are equipped with premium soft starters or variable frequency drives (VFDs) that provide smooth acceleration and protect against current surges.

The control panel includes under-voltage, over-voltage, and phase-loss protection relays. For regions with severe grid instability, such as parts of India or Nigeria, we can specify a wider tolerance range for components and recommend the installation of a dedicated voltage stabilizer or generator system for the entire line.

What safety features are built into the machine to protect operators, especially during cleaning or unclogging procedures?

+

Operator safety is paramount. Our animal feed pellet making machine for sale includes multiple mechanical and electrical safety interlocks. The main access doors are equipped with limit switches that cut power to the main motor and conditioner when opened.

The machine cannot be started remotely if a door is open. For clearing blockages, we provide specially designed safety tools. Furthermore, all rotating shafts are fully guarded. Our commissioning engineers provide mandatory safety training for your operational team.

Can the machine’s control system be integrated with our existing plant-wide SCADA or monitoring software?

+

In most cases, yes. The PLC system we install in our pellet mill line supports standard industrial communication protocols such as Profibus, Modbus TCP/IP, or Ethernet/IP.

We can work with your plant’s automation provider to establish a communication link, allowing your central SCADA system to monitor key parameters like motor load, production rates, and temperatures from our animal feed pellet making machine for sale. This is a common requirement for large, modern feed mill factory expanding their capacity.

What is the noise level during operation, and are there specific recommendations for sound insulation in an indoor facility?

+

The pellet mill itself operates at approximately 85-90 dB(A) at 1 meter, which is typical for heavy industrial machinery. We recommend installing the machine in a dedicated room or area.

Effective measures include mounting the machine on a vibration-damping base, using flexible connections for all ducts and spouts, and lining walls with acoustic panels. For the hammer mill, which is louder, we offer sound-insulated enclosures. We provide foundational and layout drawings that account for noise control considerations.

How many skilled operators are required to run this animal feed pellet making machine for sale effectively per shift?

+

For a well-automated 15-16 t/h line, one skilled operator stationed at the main control panel is sufficient to monitor and control the pelleting process from conditioning to the pellet cooler machine discharge.

However, you will also need personnel for raw material handling, bagging, and general floor supervision. Therefore, we recommend a minimum of 2-3 personnel per shift for the entire pelleting section. Our training program ensures your lead operator understands all aspects of running and troubleshooting the machine.

What are the most common operational mistakes that lead to premature wear or damage, and how can we train our staff to avoid them?

+

The top three mistakes are:

- 1) Running with an incorrect roller-to-die gap, causing rapid wear and poor pellet quality.

- 2) Starting the machine with a clogged die or without proper steam in the conditioner, leading to extreme load and potential breakage.

- 3) Using the wrong die specification (compression ratio) for the formula, causing low output and high power consumption.

Richi Machinery’s comprehensive on-site training specifically focuses on these operational best practices. We provide detailed manuals and quick-reference guides in your local language to reinforce proper daily procedures and prevent costly errors.

Does your warranty cover both parts and labor, and what is the typical response time for technical support in our region?

+

Our standard warranty is 12 months from commissioning for major components like the gearbox, main shaft, and body, and 6 months for electrical components, excluding consumable wear parts. The warranty covers replacement parts and the labor for our engineer’s time if the issue is due to manufacturing defects.

For technical support, we offer 24/7 remote assistance via phone and video call. For critical on-site issues, we have service engineers in key regions like Southeast Asia, the Middle East, and Africa, with a target response time of 48-72 hours. In other regions, we dispatch engineers from our headquarters, typically within 5-7 working days. Our goal is to minimize your downtime.

We are setting up a commercial poultry operation in Texas. What features make your machine the best animal feed pellet making machine for sale for high-volume broiler and layer feed?

+

For a US-based commercial poultry operation, our ring die animal feed pellet making machine for sale is engineered for consistency and durability. The key features include a high-precision gear drive for stable operation, customizable double-layer conditioners for optimal starch gelatinization, and wear-resistant alloy steel dies that maintain precise pellet dimensions for automated feeding systems. These elements combine to deliver the consistent quality and high uptime required for profitable poultry production.

As a cattle farm in Canada looking to produce our own feed, what should we look for in an affordable animal feed pellet making machine for sale that can handle roughage?

+

For Canadian cattle operations, an affordable animal feed pellet making machine for sale must balance cost with rugged capability.

Focus on machines with forced feeder systems that prevent bridging with fibrous materials, dies with lower compression ratios suitable for hay and silage inclusion, and simple, robust construction that withstands cold weather operation.

Our value-oriented models offer these essentials without unnecessary automation, keeping operational costs low while ensuring reliable pellet production from your farm-grown roughage.

Our feed mill in Nigeria needs to produce both floating fish feed and poultry pellets. Can one commercial grade animal feed pellet making machine for sale handle both applications effectively?

+

A true commercial grade animal feed pellet making machine for sale must offer versatility. While the core machine is the same, producing both floating fish feed and poultry pellets requires different configurations.

For floating fish feed, a high-compression extruder system is needed. For poultry, a standard die and conditioning suffice.

We provide the robust base machine and the technical guidance for quick changeovers, making it a cost-effective multi-purpose solution for diversified mills in markets like Nigeria.

For a startup pig farm in the Philippines, is a small animal feed pellet making machine for sale sufficient, or should we invest in a higher-capacity system?

+

For a startup pig farm, a small animal feed pellet making machine for sale is often the perfect initial investment. It allows you to control feed quality, utilize local by-products, and reduce costs without excessive capital outlay.

Choose a model with a capacity that matches your current herd size but from a manufacturer that offers larger models. This ensures you can source compatible spare parts and potentially upgrade smoothly as your farm grows, protecting your initial investment.

What is the key difference between a standard feed pellet making machine and an automatic animal feed pellet making machine for sale for a large layer operation in Australia?

+

The key difference lies in labor efficiency and batch consistency. A standard machine requires manual adjustment of feeders, conditioners, and the die/roller gap. An automatic animal feed pellet making machine for sale for a large Australian layer operation would include a PLC control system.

This automates the startup sequence, maintains consistent conditioning temperature and steam flow, and can even adjust parameters based on the specific feed formula being run. This automation maximizes output per shift, ensures uniform pellet quality for flock health, and reduces the risk of operational errors.

We are an agricultural cooperative in India looking to produce goat and sheep feed. What specifications are critical in a livestock feed pellet making machine for sale for small ruminants?

+

For an Indian cooperative producing small ruminant feed, the critical specifications in a livestock feed pellet making machine for sale are durability and flexibility. The machine must withstand abrasive dust from grains and pulses common in local rations.

A die with a medium compression ratio is ideal to create a firm pellet that withstands handling but does not over-process fibrous ingredients like groundnut haulms. Easy access for maintenance and local availability of spare parts are also crucial for cooperative success.

For a shrimp farm in Vietnam, why is a specialized shrimp feed pellet making machine for sale necessary compared to a standard pellet mill?

+

Shrimp feed requires extreme durability and water stability. A standard pellet mill cannot achieve the necessary starch gelatinization and binding. A specialized shrimp feed pellet making machine for sale includes a triple-layer, extended-length conditioner for prolonged, precise cooking.

It uses a very high-compression die for ultra-dense pellets and is paired with a post-pelleting dryer. This integrated system is essential in Vietnam’s competitive market to produce feed that minimizes nutrient leaching and water pollution.

As a dealer in the UK sourcing equipment for diverse farms, what should I verify about the animal feed pellet making machine for sale manufacturer before stocking their products?

+

As a UK dealer, you must verify the manufacturer’s commitment to quality and support. Ensure they use internationally-sourced, premium components (bearings, gears, motors) for reliability.

Confirm they provide comprehensive technical documentation, readily available spare parts, and responsive after-sales support.

The manufacturer should offer a range of models and be willing to provide machine customization, making you a one-stop solution for your clients’ varied needs, from small horse farms to large dairy operations.

What does a complete animal feed pellet production line for sale typically include beyond the main pellet making machine?

+

A complete animal feed pellet production line for sale is a turnkey system. Beyond the core pellet mill, it includes raw material receiving and storage, grinding (hammer mill), precise batching and mixing, conditioning, pelleting, cooling, screening to remove fines, and automated weighing and bagging.

For aquatic feed, it also includes micro-grinding and drying stages. We design and supply all interconnected components—conveyors, elevators, bins, and dust control systems—ensuring seamless, efficient operation from raw material to finished bag.

For a customer in Mexico with variable grain quality, how does the conditioner in your feed pellet making machine for sale with conditioner ensure consistent pellet quality?

+

The conditioner is vital for managing variable raw materials. In our feed pellet making machine for sale with conditioner, the extended retention time in the conditioner allows for thorough blending of steam and moisture. This process gelatinizes starches, which acts as a natural binder.

Even if grain starch content varies, our system’s adjustable steam injection and mixing paddles ensure each particle is uniformly treated. This compensates for ingredient inconsistency, producing strong, durable pellets batch after batch, which is crucial for maintaining feed quality in the Mexican market.

What are the key structural components and functions of a commercial-grade ring die pellet mill like your SZLH508 model?

+

Understanding the robust engineering behind a pellet mill is crucial for making an informed investment. Our SZLH508 animal feed pellet making machine for sale is a prime example of heavy-duty, purpose-built design. It consists of four primary systems that work in precise harmony to ensure reliable, high-output pelleting for diverse feed formulas.

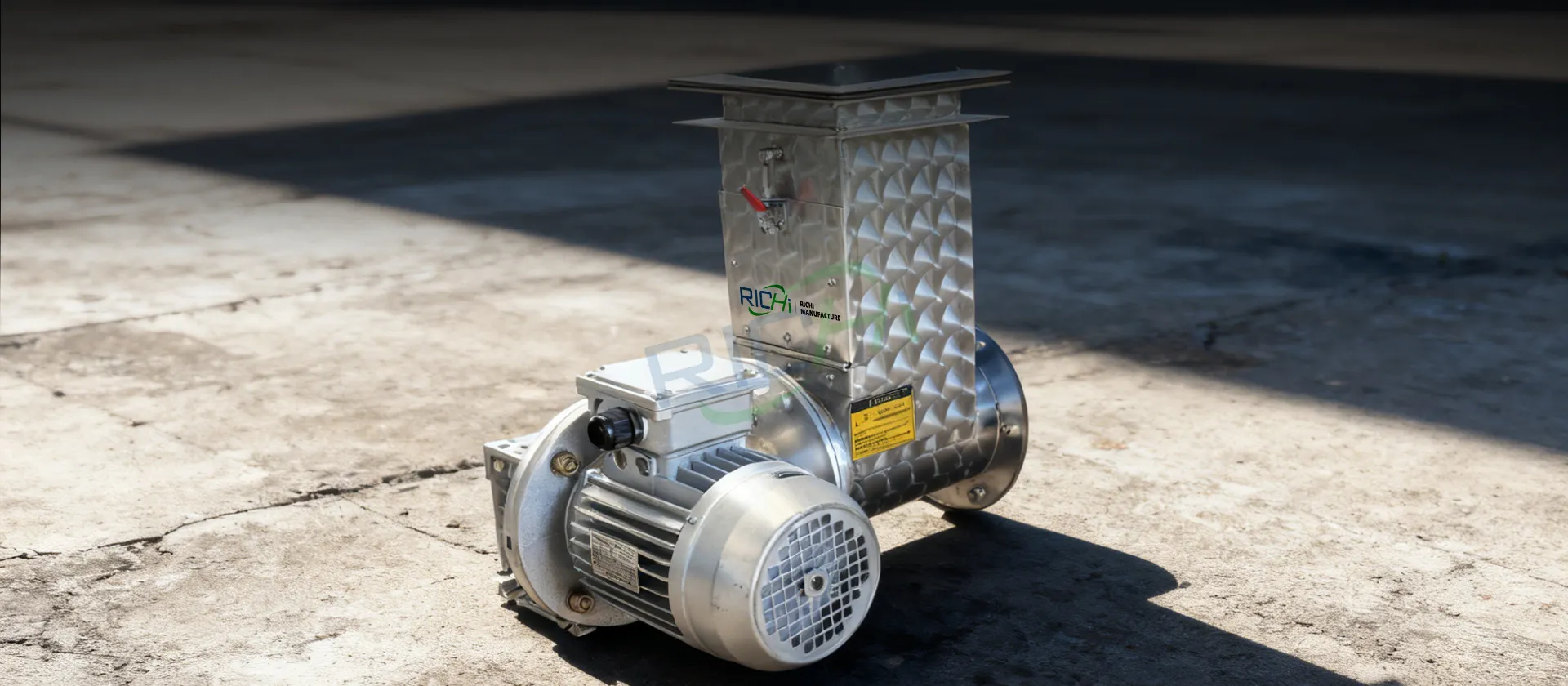

1. The Precision Feeding Mechanism

This system is the first point of control and consists of the inlet hopper, a forced feeder, and a regulating valve. The forced feeder is critical; it actively pushes material—whether it’s a fine mash for shrimp feed or a fibrous cattle ration—into the conditioning and pressing zone.

This prevents bridging and ensures a consistent, controllable flow of raw material into the machine, which is the foundation for stable operation and uniform pellet quality.

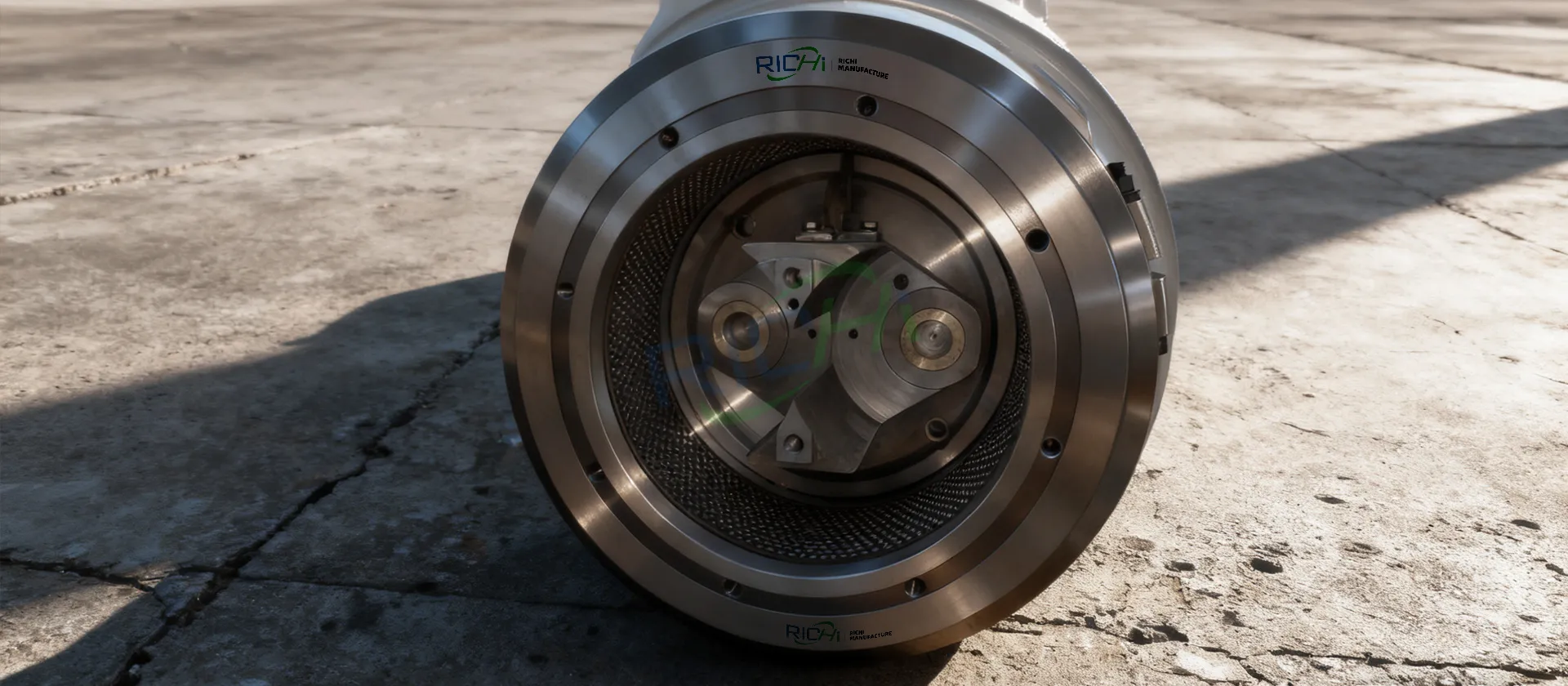

2. The High-Durability Pressure Roller & Die Assembly

This is the true heart of the animal feed pellet making machine for sale. The assembly includes the hardened alloy steel ring die, the heavy-duty pressure rollers (typically two), their shafts, and the robust housing. The rollers, driven by a high-torque gear system, press the conditioned material through the precisely machined holes in the stationary ring die.

The quality of these components—specifically the metallurgy of the die and the bearing design of the rollers—directly determines the machine’s output, pellet durability, and longevity. Our use of premium materials and advanced heat treatment here is what separates our machine from lower-cost alternatives.

3. The Versatile Speed & Gap Adjustment System

This system provides the operational flexibility needed for different feed types. It allows operators to finely adjust two key parameters: the rotational speed of the feeder and conditioner to control material retention time, and the gap between the rollers and the die.

Correct gap adjustment is vital—too wide and pellets won’t form; too narrow and it causes excessive wear and power consumption. Our design allows for smooth, reliable adjustments to optimize performance for anything from low-density floating fish feed to high-density cattle pellets.

4. The Intelligent Electronic Control & Drive System

Modern production demands modern control. This system integrates the main motor, frequency converter (VFD), and the centralized control panel. The VFD allows for soft-starting the motor to reduce mechanical stress and enables precise speed control of the main shaft.

Advanced panels feature ammeters to monitor motor load (a key indicator of correct operation), temperature displays, and safety interlocks. For a true commercial grade animal feed pellet making machine for sale, this level of control is not a luxury but a necessity for efficiency and safety.

In summary, the SZLH508 exemplifies how thoughtful design in these four core systems—feeding, pressing, adjustment, and control—creates a reliable, versatile production asset.

This integrated architecture, backed by Richi Machinery’s engineering expertise, ensures that our animal feed pellet making machine for sale can be precisely configured to handle your specific raw material challenges and feed formulation goals, delivering consistent performance year after year.

What are the key material and component specifications that ensure the durability and reliability of your SZLH508 pellet mill?

+

The long-term performance and return on investment of a pellet mill are determined by the quality of its core materials and components. Our SZLH508 animal feed pellet making machine for sale is engineered with premium specifications to withstand the high stress and abrasion of 24/7 commercial feed production. Below is a breakdown of the critical configurations that define its superior build:

1. Critical Wear Parts & Contact Surfaces:

- Ring Die & Contact Parts: The ring die is crafted from high-grade alloy steel, not stainless steel, to provide the optimal balance of hardness and toughness for long life. For corrosion resistance in key hygiene areas, we use SUS304 stainless steel for the granulation chamber door cover (6mm thick) and the feed chute (3mm thick), ensuring easy cleaning and preventing contamination.

- Gearbox & Drive Train: The gearbox housing is made from HT250 cast iron for exceptional strength and vibration damping. The gears and main gear shaft are forged from 42CrMo alloy steel, then carburized and hardened to withstand immense, continuous torque loads.

2. Core Shafting & Precision Components:

- Main Spindle & Hollow Shaft: Both the main spindle and the hollow shaft are manufactured from 42CrMo, a high-strength chromium-molybdenum alloy known for its excellent fatigue resistance. This is crucial for maintaining alignment and preventing deflection under load, which directly protects pellet quality.

- Bearings & Seals: We exclusively use imported, heavy-duty bearings (from brands like SKF or FAG) to support the main shafts, ensuring smooth operation and extended service life. Critical oil seals are sourced from German or Taiwanese manufacturers, renowned for their reliability in preventing grease leakage and dust ingress.

3. Safety & Power Transmission:

- Overload Protection: The machine incorporates a shear-pin type mechanical overload protection system. In the event of a severe blockage, a calibrated safety pin shears, instantly disengaging the drive and preventing catastrophic damage to the gearbox or shafts—a simple yet highly effective failsafe.

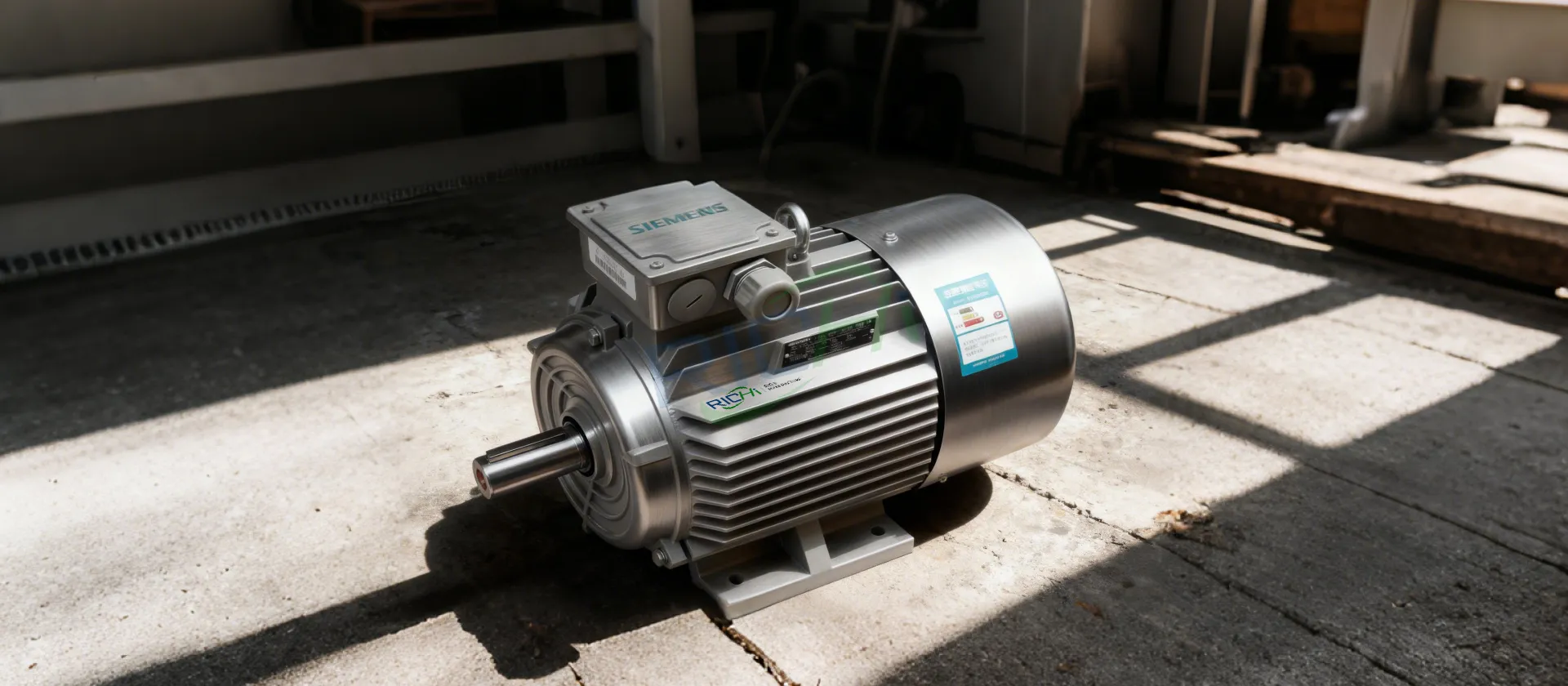

- Coupling & Motor: Power is transmitted via a durable serpentine spring coupling, which absorbs shock loads and compensates for minor misalignments. The drive is powered by a genuine Siemens motor, guaranteeing high efficiency, reliable starting torque, and consistent power delivery under fluctuating loads.

Why This Configuration Matters for Your Operation:

This detailed specification sheet is not just a list of parts; it is a commitment to uptime. By selecting 42CrMo for high-stress components, imported bearings for precision, and a Siemens motor for dependable power, we build a commercial animal feed pellet making machine for sale that minimizes unplanned downtime.

This robust configuration allows the SZLH508 to consistently process a vast range of feed types—from abrasive cattle feed with minerals to high-fat aquafeed—without compromising performance.

It is this engineering philosophy that allows us to offer customized solutions with confidence, knowing the core machine is built to handle your specific formulation challenges for years to come.

Can you provide examples of recent global projects using the SZLH508 model, and how does its configuration adapt to different regional needs?

+

Absolutely. The widespread adoption of our SZLH508 model across diverse markets is the strongest testament to its versatility and reliability. Richi Machinery has successfully commissioned projects in over 130 countries, including the United States, Canada, Brazil, Russia, Saudi Arabia, South Africa, Vietnam, India, Australia, and across Europe.

The core animal feed pellet making machine for sale remains the robust SZLH508, but each installation is uniquely customized to meet local feed formulations, raw material profiles, and production goals. Below are specific examples illustrating this global adaptability:

1. United States – Commercial Poultry & Livestock Integration

- Configuration: SZLH508 with high-automation PLC control and fat-coating system.

- Application: A major integrated operation produces 2-8mm pellets for both broiler chicken and beef cattle rations. The line handles high corn-soy diets with consistent precision.

- Project Scope: This was a complete, high-efficiency turnkey line.

- Key Adaptation: The system was designed for strict USDA-grade hygiene standards and to integrate seamlessly with the client’s existing grain receiving and storage infrastructure.

2. Australia – Premium Ruminant & Dairy Feed

- Configuration: SZLH508 with heavy-duty forced feeder and extended conditioner.

- Application: Focused on producing 2-6mm high-energy pellets for dairy cows and sheep, often incorporating alfalfa and cereal by-products.

- Project Scope: A large-capacity production line for a national feed supplier.

- Key Adaptation: Built to handle abrasive, fibrous materials common in Australian rations, with a focus on durability to minimize maintenance costs in remote locations.

3. Algeria & Saudi Arabia – Poultry & Aquaculture Development

- Configuration: SZLH508 with options for double or triple-layer conditioning.

- Application: Versatile lines producing 1.5-8mm pellets, ranging from poultry feed to sinking fish feed for tilapia farms.

- Project Scope: Large-scale, government-supported commercial feed mill projects.

- Key Adaptation: Engineered for harsh climate conditions (heat, dust) with enhanced cooling systems and corrosion protection. Configured to process both imported and local raw material blends.

4. Vietnam & Indonesia – Intensive Aquaculture & Swine

- Configuration: SZLH508 optimized for high-compression pelleting.

- Application: Primarily producing 2-4mm high-stability pellets for shrimp and pangasius feed, as well as dense pellets for swine.

- Project Scope: Medium to large-scale feed mills serving integrated farming clusters.

- Key Adaptation: Specific die designs and conditioning parameters to achieve exceptional water stability for aquaculture feed, a critical market requirement in Southeast Asia.

5. Russia & Kazakhstan – Large-Scale Livestock Complexes

- Configuration: SZLH508 with cold-climate package and ruggedized construction.

- Application: Producing a wide range (1-8mm) of pellets for poultry, pigs, and cattle to service vast integrated agro-holdings.

- Project Scope: Major industrial feed production facilities.

- Key Adaptation: Designed for operation in extreme winter temperatures, with pre-insulated panels, heated gearbox oil systems, and controls rated for sub-zero environments.

Why This Global Proof Matters:

The variance in project cost reflects not the core animal feed pellet making machine for sale, but the scale of the complete plant (grinding, mixing, automation, storage) and local logistics. From a compact line in Senegal focusing on poultry to a multi-million-dollar flagship plant in South Africa, the SZLH508 serves as the reliable, high-output heart of the system.

This global portfolio demonstrates our engineering team’s unparalleled expertise in tailoring this proven machine to any regional ingredient, any climate, and any feed formula, ensuring your investment is precisely configured for success in your specific market.

For what scale of feed production is the SZLH508 model designed, and what are the key benefits of building a complete plant around this machine?

+

The RICHI SZLH508 animal feed pellet making machine for sale is engineered as the core component for mid-to-large-scale commercial feed production lines. It is optimally designed for facilities targeting a finished pellet output between 10 and 20 metric tons per hour. Building an advanced feed plant around this reliable pellet mill offers transformative benefits beyond just high capacity.

Primary Application & Scale:

This model is the industry workhorse for feed mills requiring robust, continuous operation. It is perfectly suited for:

- Dedicated commercial feed mills supplying regional poultry, livestock, or aquaculture farms.

- Large integrated farming operations producing feed for their own herds or flocks.

- Cooperative processing plants serving multiple local farmers.

Its design prioritizes stability at this output range, making it the most cost-effective and reliable choice for businesses focused on growth and consistent supply.

Key Advantages of a Complete SZLH508-Based Production Line:

- Enhanced Efficiency & Lower Operational Cost: An advanced plant built around the SZLH508 isn’t just about output; it’s about smart economics. The integration of efficient transmission systems, automated process control, and optimized conditioning technology directly reduces energy consumption per ton of feed produced. Furthermore, the machine’s robust construction and accessible design lower long-term maintenance costs and minimize unplanned downtime.

- Unmatched Flexibility in Feed Production: Our animal feed pellet making machine for sale is the versatile heart of diverse feed plants. By customizing the auxiliary systems—such as the conditioner type (single, double, or triple-layer), die specifications, and cooling technology—the same core SZLH508 machine can drive a cattle feed plant producing 8mm dense pellets, a poultry feed plant making 3-4mm fast-digestion crumbles, or a fish feed plant manufacturing water-stable aquatic pellets. This flexibility protects your investment as market demands shift.

- Automated, Consistent Quality: Our complete animal feed manufacturing plants are designed for automation. From ingredient batching and mixing to conditioning, pelleting, and cooling, the process ensures batch-to-batch consistency. This automated control, centered on the precise operation of the pellet mill, guarantees the physical quality (durability, size, shape) and nutritional integrity of every pellet, which is critical for animal performance and feed conversion ratios.

- Engineered for the Future: Investing in a plant with the SZLH508 means investing in a system. We provide comprehensive solutions that include plant layout design, equipment configuration, installation guidance, and operator training. This holistic approach ensures your 12-20 t/h production line is not just a collection of machines, but a streamlined, profitable asset designed for your specific raw materials and end-product goals.

If you are planning a feed production line within this capacity range, the SZLH508 offers the ideal balance of power, reliability, and adaptability. To receive a detailed solution design, a customized equipment configuration list, and a specific quotation for your project, please contact our engineering team with your production requirements.

Why can the price range for a commercial animal feed pellet making machine for sale vary so significantly between different suppliers and models?

+

This is an excellent and very common question. The price of a commercial-grade animal feed pellet making machine for sale is not determined by a single factor but is a reflection of its total value proposition, which includes engineering, durability, brand support, and production efficiency. Understanding these variables helps in making an investment that delivers long-term profitability, not just a low initial cost.

The primary factors influencing price are:

1. Technical Complexity & Build Quality:

This is the most significant factor. A high-end animal feed pellet making machine for sale, like our SZLH508 series, incorporates advanced technical features that justify its price. These include:

- Precision Drive Systems: A high-torque, hardened gear drive (using alloys like 42CrMo) is far more robust and efficient than a simpler belt-drive system, leading to higher output and lower long-term maintenance, but at a higher initial cost.

- Customization Capability: The ability to customize the conditioner (single, double, or triple-layer), integrate specific die technologies for different feeds (e.g., high-compression for aquafeed), and include advanced automation (PLC controls with load monitoring) adds complexity and value. A machine that can process both fibrous cattle feed and fine shrimp feed requires more sophisticated engineering than a single-purpose unit.

- Component Specifications: The use of imported heavy-duty bearings, German-grade seals, and alloy steel for critical wear parts directly impacts reliability and lifespan, but also cost. A lower-priced machine often uses standard commercial-grade components to hit a price point.

2. Brand Reputation & After-Sales Support:

A reputable brand like Richi Machinery commands a price that reflects over 30 years of engineering experience and a proven global track record. This price includes intangible but critical assets:

- Reliability & Proven Design: Our machines are iterated on based on feedback from thousands of installations worldwide. You are paying for reduced operational risk and proven performance.

- Comprehensive Technical Support: The price includes access to expert engineers for plant design, proper installation guidance, thorough operator training, and responsive after-sales service. A cheaper machine often comes with limited or no real support, transferring the risk and cost of troubleshooting to the buyer.

- Consistent Quality & Warranty: An established brand stakes its reputation on every machine, backing it with a meaningful warranty and guaranteed access to genuine spare parts.

3. Production Scale & Project Scope:

The price is also contextual to your project.

- For a Complete Turnkey Line: The quoted price for the animal feed pellet making machine for sale is part of a larger system including conveyors, mixers, coolers, and automation. Economies of scale apply; a larger, more integrated project allows for optimized design and can improve the overall value.

- For a Standalone Machine: The price is more focused on the unit’s specifications. However, we always advise clients to consider the total cost of ownership. A slightly higher initial investment in a robust, efficient machine from a reliable supplier typically results in far lower costs per ton of feed produced over 5-10 years due to better energy efficiency, higher durability, and less downtime.

Making a Wise Decision:

When evaluating the animal feed pellet making machine for sale price, look beyond the sticker. Assess the technical specifications for your specific feed types, verify the brand’s project history in your region, and calculate the total cost of ownership.

A machine that seems “affordable” but cannot handle your recipe variations, breaks down frequently, or has no local support will ultimately be far more expensive. We encourage clients to share their specific production requirements—raw materials, target capacity, and feed types—so we can provide a transparent, tailored quotation that clearly outlines the value and robustness built into our solution.

How to choose animal feed pellet making machine?

+

1. Recognize the needs

Before purchasing animal feed pellet making machine for sale, you first need to carefully analyze your production needs to determine the type and specifications of the required equipment. Set production goals, determine production capacity indicators, analyze the problems that may be encountered in actual production, and then choose suitable equipment for these problems.

2. Consider quality

For animal food pellet making machines, quality is a crucial factor. A good equipment needs to have excellent performance, stable operation, durable life and other quality guarantees.

Therefore, when choosing a supplier, you should pay attention to the other party’s factory files, production capacity, service level and other factors. Only by choosing excellent equipment can you ensure that production efficiency and product quality are met.

3. Consider cost performance

When choosing animal feed pelletizer, it is not enough to only focus on the price. You should consider the cost performance of the equipment itself, including the initial price and subsequent maintenance costs. We should consider more factors such as equipment performance, quality and life, and choose the right equipment to truly maximize the investment.

4. Consider after-sales service

The after-sales service level of the animal pellet machine has an important impact on production efficiency and equipment life. Therefore, when purchasing equipment, we need to understand the supplier’s after-sales service quality and service response speed.

In order to avoid affecting production efficiency due to after-sales service problems, you must choose a suitable supplier according to your own needs.

Selecting a high-quality animal feed pellet maker plays a vital role in improving production efficiency and product quality. If you have any questions about the selection of a pellet maker for animal feed, you can contact us directly for free technical support!

How to choose animal feed pellet making machine manufacturer?

+

Selecting a suitable manufacturer who specializes in animal feed pellet making machine for sale is crucial to ensuring product quality and improving production efficiency. So, how to choose a reliable feed pellet machine processing manufacturer?

1. Pay attention to the manufacturer’s equipment and technology

Diversified processing equipment and technology are the key to ensuring the quality of pellet making machine for animal feed. When inspecting manufacturers who focus on animal feed pellet machine for sale , pay attention to whether the newness and oldness of their equipment and the technical level meet the industry standards.

Generally speaking, manufacturers with large scale and more equipment have stronger processing and production capabilities, and can better guarantee the quality and precision of animal pellet making machine products.

2. Understand the production strength of manufacturers

Different manufacturers have different production capacities. Some manufacturers who focus on animal feed pellet making machine for sale can only handle small batch orders and produce a single type of feed pellet machine, while some manufacturers have strong feed pellet machine processing capabilities.

They can process multi-diameter, multi-material, and multi-model animal pellet maker products, and can also provide customized processing services for customers. Before choosing a animal feed pellet maker machine processing manufacturer, you must first clarify your own needs and then choose a suitable factory.

3. Inspecting the manufacturer’s service and after-sales service is a guarantee

In addition to the product itself, the manufacturer’s service and after-sales service are equally important. When choosing animal feed pellet making machine manufacturer, you may want to ask about the required product inventory, delivery cycle and delivery method.

Only by understanding these contents can you avoid buck-passing and wrangling in the later cooperation process, making the entire cooperation process smoother.

In short, choosing a suitable manufacturer who rooted in animal food pellet making machine for sale requires comprehensive consideration of the manufacturer’s equipment and technology, production strength, quality and delivery time, as well as service and after-sales. (FInd RICHI on youtube)

We are a new livestock feed cooperative in the Philippines. How do we choose between an affordable animal feed pellet making machine for sale and a model that might be more expensive but claims to be a “best value” option?

+

Your question highlights the most critical decision for a new cooperative. An affordable animal feed pellet making machine for sale typically refers to a model with simplified features, potentially lighter-duty construction, and limited customization. It serves a basic function at a lower upfront cost.

The “best value” animal feed pellet making machine for sale, like our configured SZLH series models, represents a different calculation. It balances initial investment with superior long-term economics through higher durability, greater efficiency, and adaptability.

For a cooperative, “best value” is crucial. It means:

- Lower Cost Per Ton: Higher-quality components (gears, bearings, dies) wear slower and consume less energy, reducing your operating cost for every ton of feed produced for your members.

- Minimized Downtime: Robust construction and reliable performance prevent breakdowns during critical feeding periods, ensuring consistent supply to all cooperative farms.

- Growth Flexibility: A “best value” machine can be reconfigured with different dies and conditioners to produce various feed types (e.g., switching between hog and poultry rations) as your cooperative’s needs evolve, protecting your investment.

We recommend starting with a clear analysis of your most common feed formulas, desired hourly output, and 5-year growth plan. This allows us to propose a “best value” configuration that delivers the right balance of capability, reliability, and cost-effectiveness for your collective success.

As a farm in Kenya looking to make our own dairy cattle feed, what should we prioritize when looking for a feed pellet making machine for sale with delivery and installation service?

+

For a farm in Kenya or across Africa, prioritizing a supplier who offers a complete feed pellet making machine for sale with delivery and installation service is as important as the machine itself. The key priorities should be:

- In-Region Logistics Expertise: The supplier must have proven experience managing freight, customs clearance, and inland transportation to your specific location. They should handle all documentation to prevent costly delays at the port.

- Professional On-Site Installation & Commissioning: The price should include the dispatch of a qualified engineer to supervise installation, ensure the machine is perfectly leveled and connected, and conduct the initial commissioning run with your local materials.

- Comprehensive On-Site Training: The service must include hands-on training for your operators on how to run, maintain, and perform basic troubleshooting on the animal feed pellet making machine for sale. This knowledge transfer is essential for long-term independence.

- After-Sales Support Network: Verify the supplier has a reliable channel for providing technical advice and sourcing genuine spare parts in your region after the installation team leaves.

For your dairy operation, this means we would not only supply a robust machine configured for your roughage-based rations but also manage its entire journey to your farm, set it up for optimal performance, and ensure your team is fully prepared to operate it profitably.

For a commercial layer farm in the UK, is an automatic pellet making machine for animal feed farm sale worth the higher investment compared to a manual system?

+

For a UK-based commercial layer farm, where consistency, labor costs, and traceability are paramount, investing in an automatic pellet making machine for animal feed farm sale is not just an upgrade—it’s a strategic necessity for remaining competitive. Here’s why:

An automatic system centered on a high-quality pellet mill with PLC control delivers:

- Precise Recipe Consistency: Automated batching and conditioning ensure every batch of layer feed has the exact same nutritional profile, which is critical for steady egg production and shell quality.

- Labor Optimization: One operator can manage the entire pelleting process from a control panel, reducing labor costs and minimizing human error in settings like steam addition or die/roller gap.

- Enhanced Feed Quality & Safety: Automated processes maintain optimal conditioning temperatures and times consistently, improving starch gelatinization for better digestibility. The system also provides data logs for full traceability.

- Operational Efficiency: The system can be programmed for automatic start-up and shutdown sequences, optimizing energy use and reducing wear on the animal feed pellet making machine for sale.

The higher initial investment is quickly offset by reduced waste, lower labor costs, improved flock performance, and the ability to produce certified, consistent feed. For a modern UK layer farm, automation is the foundation of efficiency and quality assurance.

What are the advantages of a complete animal feed pellet making machine system for sale over purchasing individual machines separately for a new feed mill in Bangladesh?

+

Building a new feed preparation plant in Bangladesh with a complete animal feed pellet making machine system for sale offers decisive advantages versus piecing together individual machines, which often leads to a “project” fraught with hidden costs and inefficiencies.

Advantages of a Complete, Integrated System:

- Guaranteed Compatibility & Efficiency: Every component—from the hammer mill and mixer to the pellet mill conditioner, cooler, and conveyors—is engineered to work in perfect harmony. This ensures smooth material flow, eliminates bottlenecks, and optimizes the overall energy consumption of the plant.

- Single-Point Accountability & Support: You have one contract and one responsible supplier (like Richi Machinery) for the entire system’s performance, warranty, and after-sales service. This eliminates finger-pointing between different equipment vendors if a problem arises.

- Optimized Plant Design & Layout: We provide the complete system based on a professional plant layout designed for your specific site, ensuring logical workflow, safety, and future expansion potential. This is virtually impossible to achieve when sourcing disparate machines.

- Faster, Smoother Commissioning: A single team from the supplier installs, interconnects, and commissions the entire line, dramatically reducing the startup time and getting you to production—and profitability—much faster.

For a new mill in Bangladesh, this turnkey approach reduces complexity, mitigates risk, and ensures your investment becomes a streamlined, productive asset from day one, rather than a collection of mismatched parts.

When looking at a feed pellet making machine for sale with a full set of accessories, what are the essential accessories that a mid-sized cattle feed plant in Brazil should not overlook?

+

For a mid-sized cattle feed plant in Brazil, purchasing a feed pellet making machine for sale with a full set of accessories is critical for operational readiness and durability. Beyond the core pellet mill, the essential accessories that directly impact productivity and uptime include:

- Forced Feeder: This is non-negotiable for cattle feed. It actively pushes fibrous, sometimes sticky, raw materials (like citrus pulp or soybean hulls common in Brazilian rations) into the conditioner, preventing bridging and ensuring consistent feed rate.

- Spare Ring Die & Roller Set: Having a spare die and set of rollers on-site is the best insurance against unplanned downtime. When the working set needs reconditioning, you can swap them out in hours, not weeks.

- Quick-Release Die Clamping System: This accessory drastically reduces die changeover time from half a day to under two hours, allowing for more flexible production scheduling between different pellet types.

- Liquid Addition System (Molasses Coater): For beef and dairy feeds, a post-pelleting molasses or fat coating system is essential for increasing energy density and palatability. It should be integrated with the cooler discharge.

- Specific Tool Kit & Maintenance Consumables: A factory-provided toolkit with specialized wrenches, torque gauges for roller adjustment, and a stock of high-temperature grease and gear oil ensures proper maintenance can be performed correctly on-site.

Overlooking these accessories would mean your new animal feed pellet making machine for sale arrives without the critical components needed to handle local ingredients efficiently and maintain continuous production in a demanding market like Brazil.