ANIMAL FEED GRANULATOR

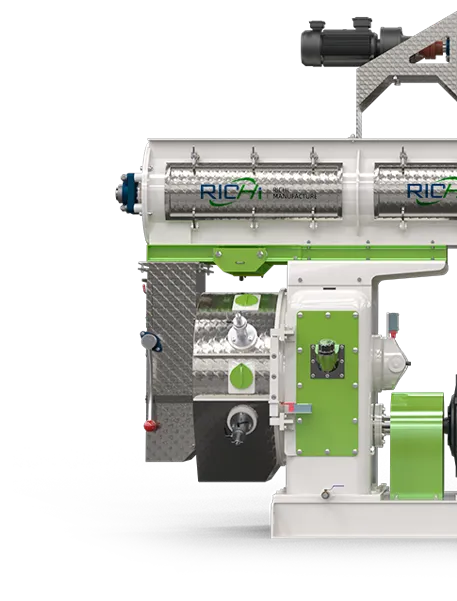

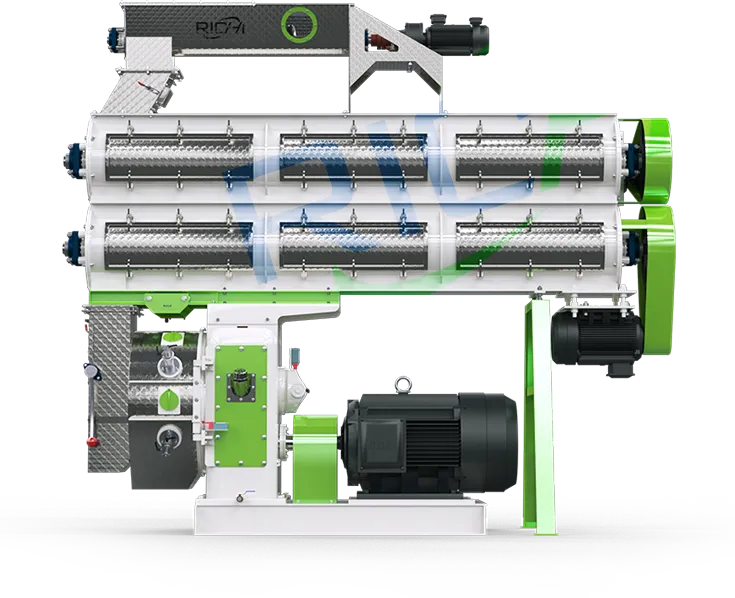

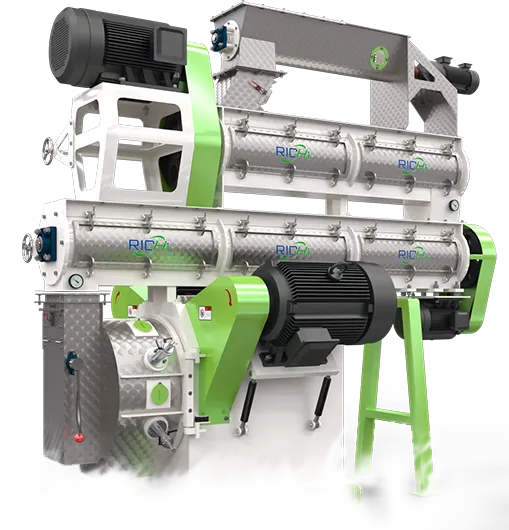

Animal feed granulator machine is the most important equipment during feed mill pelletizing process. Our SZLH 320 animal feed granulator comes in a new fine-tuned design and ensures highly efficient feed pelleting. It combines the best of current pellet mill technology with the proven features from our long-established family of gear-driven pellet mills and offers the highest output per kWh in its class.

Pellet Size: 2~12mm

Price: 15,000-18,000 $

Model

SZLH320

Production Capacity

3-4T/H

VOne Granulator, Multiple Solutions

Our SZLH 320 animal feed granulator is engineered for broad application across the modern agricultural field. It expertly processes feed pellets for diverse livestock, including cattle, sheep, pigs, chickens, ducks, as well as aquatic species like fish and shrimp. The resulting pellets are clean, convenient for the feedlot, easy to transport, and more palatable to animals. By producing strong pellets with a smooth surface, this high-quality feeding stuff cuber enhances feed efficiency and handling for operations of all sizes, from integrated farming enterprises to commercial feed mills.

To meet specific nutritional and physical requirements, feed pelleting machines are categorized by animal type. Our robust animal feed granulator platform is expertly adapted into specialized configurations:

Ideal for producing highly digestible feed for chickens, ducks, and other poultry, ensuring optimal growth and egg production.

Built to create durable, nutrient-rich pellets for cattle, sheep, and pigs, supporting robust health and efficient weight gain.

Precisely engineered for sinking type feed pellets essential for fish and shrimp farming, maximizing feed conversion and yield.

Precision-Conditioning Options

Beyond animal-specific designs, our SZLH 320 animal feed granulator is engineered with modular conditioning technology. We feature a standard, large-diameter, extended-length conditioner for superior steam penetration and uniform starch gelatinization. We offer customization of the conditioner itself. Modifications can be made to its internal paddle configuration, retention time, and steam injection points. This core design is then precisely configured into three levels to meet distinct feed formulation and quality goals, demonstrating our capacity to cover the entire spectrum of feed processing.

Single-Stage Conditioning Granulator

This is our most versatile and widely adopted animal feed granulator. It is ideal for producing standard poultry and livestock pellets efficiently. When equipped with an optional forced feeder, it reliably processes various fibrous feeds containing grass or hay. This model is the optimal, cost-effective choice for general feed mills and farms requiring flexible, everyday production.

Dual-Stage Conditioning Granulator

Our two-layer system subjects ingredients to prolonged, controlled heat and moisture. This advanced conditioning is essential for manufacturing premium livestock feed and standard sinking aquatic pellets. The process enhances digestibility and pellet durability. This configuration is designed for producers targeting higher-value markets where feed quality directly impacts animal performance and farm profitability.

Triple-Stage Conditioning Granulator

This represents the pinnacle of conditioning technology for the most demanding applications. The three-stage process ensures ultra-thorough cook and expansion of starches. It is specifically engineered to produce high-stability, floating or slow-sinking feeds for premium fish and shrimp diets. This animal feed granulator is the definitive solution for specialized aquafeed manufacturers and large-scale commercial hatcheries.

Versatile Raw Material Processing

Our SZLH 320 animal feed granulator is engineered to process a comprehensive range of raw materials into high-quality pellets. Beyond the core categories of energy feeds, protein sources, roughage, and additives, our robust machine is also fully capable of handling practical配方 components like fresh green forage (pasture grasses, aquatic plants) and fermented silage. This versatility ensures you can produce nutritionally complete and palatable feed tailored to any livestock or aquaculture requirement, solidifying our position as a manufacturer that masters complete feed processing solutions.

Energy Ingredients

These staples, like corn and wheat, provide the essential carbohydrates for animal vitality. Our granulator effectively binds these materials into durable, energy-dense pellets.

Protein Ingredients

Soybean meal, fish meal, and other protein sources are crucial for growth and development. The machine’s conditioning process ensures even blending and gelatinization for optimal nutrient utilization.

Roughages Ingredients

Fibrous materials like alfalfa and hay add necessary bulk and aid digestion. The machine’s powerful compression handles these ingredients, producing structured pellets ideal for ruminants.

Feed Additives

Vitamins, minerals, and premixes are homogenously incorporated during the pelleting process. This guarantees each pellet delivers a consistent, balanced nutritional profile.

See It In Action: Real-World Pellet Production

Experience the durability and efficiency of our SZLH 320 animal feed granulator beyond specifications. The video demonstrations below showcase its robust performance across diverse feed formulations and real production environments. Witness how this machine delivers consistent, high-quality pellets—proof of the reliable engineering and manufacturing strength we build into every unit.

Argentina cattle feed granulator project

Tanzania cow pig feed granulator project

Zimbabwe chicken feed granulator project

Uzbekistan fish broiler feed granulator project

Core Components That Deliver Performance

The superior output and reliability of our SZLH 320 animal feed granulator are rooted in its meticulously engineered components. Every critical part is designed and selected for maximum durability, efficiency, and operational safety, reflecting RICHI’s commitment to building industrial-grade machinery for demanding feed mill environments.

Advantages That Power Your Production

The SZLH 320 animal feed granulator is engineered not just for performance, but to deliver practical, tangible benefits to your operation. It integrates intelligent design with robust construction, offering a solution that increases output, simplifies maintenance, and adapts to your specific needs.

High-Density Output in a Compact Footprint

This granulator delivers exceptional efficiency. It produces nearly 1.2 times the capacity of conventional mills within the same floor space. With a throughput of up to 2-4 t/h, it perfectly matches the needs of small to mid-sized commercial feed mills or farms seeking to expand production without expanding their facility.

Engineered for Simple Operation & Hygiene

Designed with the operator in mind, it ensures easy access and upkeep. The large, openable doors provide 360-degree access to the pelleting chamber for straightforward die and roller changes. A hygienic design with stainless steel contact surfaces allows for quick cleaning, minimizing downtime and cross-contamination.

Robust Build for Reliable, Low-Maintenance Service

Built for longevity, its core features a heavy-duty cast gearbox and efficient direct gear drive, eliminating complex transmission maintenance. Key safety components like accessible shear pins and interlocked safety switches protect both the machine and the operator, ensuring reliable, worry-free daily operation.

Flexible Customization for Your Exact Needs

We tailor the SZLH 320 to your process. Beyond standard models, we offer customized options such as specific motor power ratings, specialized ring die hole sizes and compression ratios, multi-stage conditioners for aquatic feed, and optional configurations like forced feeders for fibrous materials. This animal feed granulator adapts to you.

How It Works: Precision Engineering from raw material to Pellet

First, a variable-speed feeder transfers material into the conditioner, where precise steam or water is added. This crucial step softens the mix, improving starch binding for durable, digestible pellets.

The conditioned mash is then fed into the pelleting chamber. Here, two heavy-duty rollers compress it against a rotating ring die, forcing the material through the die holes under high pressure to form solid strands.

Finally, external cutters instantly trim the strands to your exact specified length, delivering ready-to-use pellets. This streamlined operation makes our animal feed granulator a reliable core of your production line.

Technical Specifications

View the core specifications for the SZLH 320 animal feed granulator below. If your production requires a different capacity, we offer a complete series of seven other models. Click on any to explore its detailed profile and find the perfect fit for your animal feed mill.

PARAMETERS OF SZLH320 (3-4T/H)

Main motor power

37kW

Feeder power

1.5kW

Conditioner power

4kW

Ring die inner diameter

320mm

Finished pellet diameter

2-12mm

Tailored Parameters for Every Feed

Our deep expertise ensures the SZLH 320 animal feed granulator isn’t just a machine—it’s a precision-tuned solution. Optimal pellet quality depends on adjusting key parameters like conditioning time, die specifications, and temperature for each feed type. Below, we outline recommended process guidelines for common feed categories. Please note that exact outputs and settings depend on your specific formulation; the following are typical references for the SZLH 320.

Processing Parameters for Poultry Chicken Feed

For high-volume poultry feed production, this animal feed granulator is typically configured with a high-compression die (ratio 1:10-1:13) to produce dense, 2-4mm diameter pellets. Effective conditioning at around 85-90°C for 60-120 seconds is key to achieving good starch gelatinization and durability, supporting a stable output suited for automated feeding systems.

Processing Parameters for Ruminant Feed (Cattle/Sheep)

Producing robust pellets for cattle and sheep requires a different approach. We recommend using a die with a lower compression ratio (1:6-1:9) to form larger 6-12mm diameter pellets that withstand rumination. A shorter, intense conditioning phase (30-60 seconds at high temperature) helps bind coarse ingredients like forage, ensuring pellet integrity without over-processing.

Processing Parameters for Pig/Swine Feed

Swine feed pellets balance nutrition and palatability. A moderate die compression ratio (1:3.5-1:5) is used to create 2-4mm pellets that are easily consumed. Adequate conditioning time (60-120 seconds) at optimal temperature ensures proper binding of often finely ground ingredients, improving feed conversion and reducing waste.

Processing Parameters for Sinking Fish Feed

Achieving water-stable sinking feed demands precise process control. This requires a die with a high compression ratio (1:16-1:18) and extended, multi-stage conditioning (90-180 seconds). This ensures thorough gelatinization for maximum pellet durability in water, minimizing nutrient leaching. Output is adjusted to accommodate this longer conditioning and higher compression.

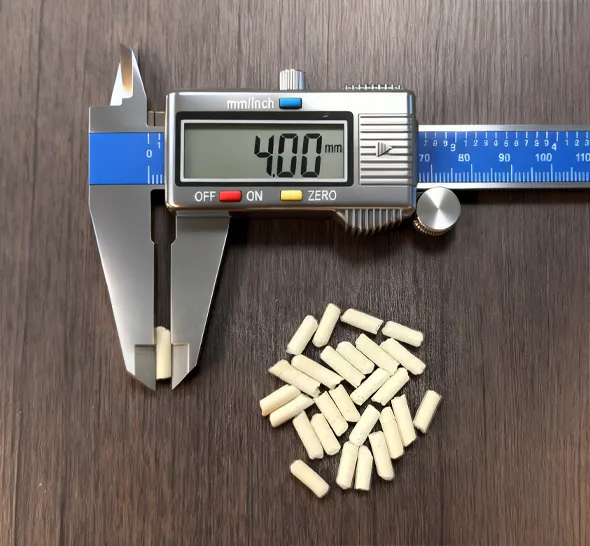

Processing Parameters for Shrimp Feed

Manufacturing micro-aquafeed for shrimp represents the pinnacle of pelleting technology. It requires ultra-fine grinding (95% over 80 mesh), a very high-compression die (1:20-1:25), and prolonged, multi-stage conditioning (120-180 seconds). This meticulous process, managed by our specialized animal feed granulator setup, is essential for producing the water-stable, slow-sinking 1.2-2.0mm pellets critical for shrimp health and growth.

Our Global Projects

We don’t just sell a single machine; we deliver proven animal feed production solutions. Our SZLH 320 animal feed granulator is the reliable core of complete pelleting lines we have successfully exported across six continents. These projects showcase our expertise in configuring systems for diverse raw materials, feed types (from poultry to aquaculture), and production scales—from family-run farms to large commercial feed mills.

Animal feed granulator in Malaysia

A leading integrated poultry farm selected our animal feed granulator for their on-site feed mill. The system processes corn and soybean meal into 3-4mm broiler feed pellets, ensuring a consistent, cost-effective supply.

Feed type: Poultry feed

Pellet size: 3-4mm

Animal feed granulator in Kazakhstan

Feed type: Grass/alfalfa feed

Pellet size: 10mm

Animal feed granulator in Peru

Feed type: Sinking fish feed

Pellet size: 4mm

We supplied a complete line to an aquafeed company specializing in trout farming. The project focused on producing high-density, 4mm sinking pellets using precise formulations of fish meal and grains.

Animal feed granulator Machine in Russia

Feed type: Pig feed

Pellet size: 3mm

Shrimp feed granulator in Indonesia

Feed type: Shrimp feed

Pellet size: 1.5mm

Animal feed granulator in Tanzania

A growing livestock cooperative invested in our equipment to process local maize and sunflower cake. The granulator produces durable 6mm pellets for cattle, improving feed efficiency for their member farms.

Feed type: Cattle feed

Pellet size: 6mm

Animal feed granulator in Mexico

Feed type: Poultry & cattle feed

Pellet size: 2mm & 8mm

Trusted by Industry Leaders Worldwide

Our partners range from local agribusinesses to international feed producers. Their trust is built on our commitment to delivering not just an animal feed granulator, but a total solution—including custom engineering, auxiliary equipment, and professional support for your complete feed pelleting line.

Client Testimonial

Our commitment to technical excellence and tailored engineering is validated by partners worldwide. From large commercial mills to specialized farming operations, customers rely on our solutions for reliable performance, consistent quality, and robust after-sales support.

Argentina Client

Feed type: cattle feed

Pellet size: 4mm

As a major beef producer, we needed a durable line to process our local soybean meal and maize into high-energy feed. RICHI’s team designed a layout that fit our existing facility perfectly. The granulator runs smoothly, producing very consistent 4mm pellets that our cattle thrive on.

Romania Client

Feed type: Poultry feed

Pellet size: 3mm

Our goal was vertical integration and feed cost control. We chose RICHI for their complete poultry feed line, from grinding to pelleting. The equipment is robust, and their engineers provided excellent training. Now we produce all our own 3mm broiler feed pellets with great efficiency.

Tunisia Client

Feed type: Sheep/Goat feed

Pellet size: 6mm

Operating in a region with variable raw material quality, we required a flexible and sturdy machine. RICHI’s granulator handles our mix of barley, bran, and local forage by-products superbly, producing strong 6mm pellets. The service support has been exceptional.

Thailand Client

Feed type: sinking fish feed

Pellet size: 2mm

Producing sinking fish feed requires precise conditioning and durability. RICHI’s triple-layer conditioner and high-compression ring die were key for our 2mm pellets. Their technical team understood our specific needs for a high-stability product, and the results speak for themselves.

Precision in Every Pellet: Matching Size to Application

Pellet size is a critical factor in feed efficiency and animal performance. It directly influences palatability, nutrient intake, and digestion. Selecting the correct ring die specifications is essential for producing pellets with the target diameter, density, and durability. Explore the seven most common sizes below and the technical considerations for achieving them with your animal feed granulator.

Your Complete Line, Engineered from the Ground Up

We go beyond supplying a stand-alone animal feed granulator. Our core expertise lies in designing, engineering, and delivering complete, custom-fitted production lines. We understand that no two feed mills are the same—different raw materials, target pellet specifications, nutritional formulas, and site constraints demand tailored solutions. Our process begins with your specific goals, and we provide comprehensive support through consulting, manufacturing, installation, commissioning, training, and lifetime spare parts supply, ensuring your line’s success through its entire lifecycle.

Silo

Cleaning

Grinding

Mixing

Batching

Pelleting

Cooling

Screening

Packaging

Pelletizing System

This crucial stage transforms

conditioned mash into

durable, precise pellets.

Your Complete Equipment Partner

storage silo equipment

01

cleaning equipment

02

grinding equipment

03

mixing equipment

04

cooling equipment

05

screening equipment

06

packaging equipment

07

A high-performance animal feed granulator is the core of your line, but it’s only one part of a fully integrated system. We provide the complete range of auxiliary equipment needed for a turnkey animal feed mill plant, from raw material intake and storage to the final bagged pellet.

Our expertise ensures every component—from hammer mill feed grinders and feed mixer machines to coolers and packaging systems—is correctly specified and seamlessly integrated to match your specific feed type and production process. With our single-source capability, you gain a cohesive, efficient plant designed for reliability and optimal output.

Tailored Solutions for Every Animal Feed Type

Different animals and aquatic species have distinct nutritional and physical feed requirements. RICHI specializes in engineering complete production lines that are optimized for each specific category. Below, we outline our recommended standard configurations—from the core animal feed granulator specifications to auxiliary equipment—to deliver the ideal pellet quality, durability, and nutritional integrity for your target market.

Frequently Asked Questions

Purchasing a new animal feed granulator is a significant investment, and we want you to have all the information you need. Below, we’ve answered some of the most common questions our customers ask about equipment selection, operation, and processing capabilities for a 3-4 t/h ring die feed pellet machine.

How much does an animal feed granulator cost?

+

The animal feed granulator price varies significantly based on its size, capacity, motor power, and specific configuration. As a leading manufacturer, Richi Machinery offers a complete range of ring die pellet mills to suit operations from small farms to large industrial feed mills. The cost is primarily driven by the machine’s throughput (tons per hour) and the robustness of its construction.

For the model highlighted on this page, the SZLH320 animal feed granulator (37KW motor, 3-4 t/h capacity) typically has a FOB price range between $15,000 and $18,000. This model offers an excellent balance of output and investment for small to medium-sized commercial feed producers.

Our broader product line includes other popular models with corresponding price ranges:

- SZLH250 (22KW): 2-3 t/h | $7,000 – $9,000

- SZLH350 (55KW): 5-6 t/h | $27,000 – $32,000

- SZLH420 (110KW): 8-12 t/h | $29,000 – $35,000

- SZLH508 (160KW): 14-16 t/h | $40,000 – $47,000

- SZLH558 (185KW): 18-22 t/h | $48,000 – $55,000

- SZLH678 (250KW): 28-32 t/h | $62,000 – $72,000

- SZLH768 (315KW): 38-42 t/h | $75,000 – $86,000

The models listed above represent our core series of animal feed granulators, but they are not the full extent of what we offer. We engineer and provide pellet mills for virtually every segment of the animal feed processing industry. The final price for your project is never off-the-shelf. It will be influenced by critical customizations such as the type and number of conditioners (single, double, or triple-layer), the specification of the ring die (material, compression ratio, hole size), the choice of ancillary components like forced feeders, and the selection of optional automation features.

The price of an animal feed granulating machine is affected by many factors, mainly including the following aspects:

- Model and specification: The price of feed granulator of different models and specifications varies greatly. Generally speaking, the larger the specification, the higher the price.

- Material: The animal feed pellet price of different materials also varies greatly. The better the material and the longer the service life, the more expensive the supporting equipment.

- Brand: The granulator of big brands is generally more expensive, but the quality is more reliable and maintenance is more convenient.

- Performance: The better the performance of the animal feed pellet mill, the higher the animal feed pellet machine price.

- Production cost: The level of production cost will also affect the price of animal feed pellet machine.

In summary, animal feed granulator is a very common feed equipment and is inseparable from supporting equipment. For feed processors, how to choose suitable supporting equipment is not an easy task, and it requires comprehensive consideration of multiple factors.

At the same time, the price of animal pellet granulator is also affected by many factors and needs to be selected according to actual conditions.

To receive an accurate and competitive quote tailored to your specific raw materials, target pellet specifications, and desired production capacity, please contact our sales team with your detailed requirements. We will provide a comprehensive proposal that outlines the optimal animal feed granulator and line configuration for your investment.

Can you provide some real-world project examples and costs for installing an SZLH320 animal feed granulator in different countries?

+

Absolutely. Providing concrete project references is one of the best ways to demonstrate the global versatility and value of our SZLH320 animal feed granulator. The following examples illustrate how this specific model serves as the reliable core of complete feed production lines worldwide, tailored to meet diverse regional needs and budgets.

The “project cost” reflects the total investment for a complete, functional feed milling line—including auxiliary equipment like hammer mills, mixers, coolers, and electrical controls—with the SZLH320 animal feed granulator as the central pelleting unit.

Here are several recent project references:

- Romania: A commercial feed mill invested approximately $150,000 in a complete line centered on the SZLH320 animal feed granulator to produce high-quality 2-4mm poultry and pig feed pellets for the local market.

- Cambodia: An expanding agribusiness chose the SZLH320 for its flexibility, installing a $160,000 line capable of producing a range of pellet sizes from 2mm to 8mm for poultry, livestock, and tilapia feed.

- Russia: A large-scale farm operation implemented a cost-effective, streamlined feed production system for $97,160. Their SZLH320-based cattle pig feed mill efficiently produces durable pellets from 2mm to 10mm to support their diverse cattle and swine herds.

- Uzbekistan & Cameroon: In both countries, projects with budgets around $82,000 utilized the SZLH320 animal feed granulator to create robust lines for producing 2-8mm pellets, effectively processing local grains and oilcakes into balanced ruminant and poultry feed.

- Madagascar: A strategic investment of $58,000 established a foundational feed mill. The SZLH320 animal feed granulator at its heart allows the production of 2-10mm pellets, supporting the local poultry and livestock sector with essential, affordable nutrition.

- Chad: A significant $124,500 project deployed the SZLH320 chicken cattle feed pellet machine within a more extensive and automated system. This line is engineered to produce 2-10mm pellets with high consistency, designed for higher-volume commercial feed sales.

- Cameroon & Uzbekistan (Second Example): Another project pairing, with an investment of $130,820, highlighted the granulator’s application in more specialized aquafeed and starter feed production, with pellet sizes ranging from a fine 1.5mm up to 6mm.

- Iraq: A poultry-focused feed mill was established for $99,070. This efficient chicken feed mill plant, built around the dependable SZLH320 chicken feed pellet machine, is dedicated to producing premium 2-3mm broiler feed pellets.

These examples underscore why the SZLH320 is a globally trusted choice. The variation in total project cost is not due to the animal feed granulator itself, but to the extensive customization of the surrounding line—including the scale of raw material handling, the level of automation, the choice of ancillary machinery brand and capacity, and specific construction requirements.

At Richi Machinery, our engineers excel at designing these tailored solutions. We consider your local raw material availability, target animal species, desired pellet specifications, and budget to provide a complete system that delivers maximum return on investment, no matter where in the world you are located.

What is the main difference between your SZLH series granulator and a standard belt-driven model for my feed mill?

+

The core difference lies in the drive system and the resulting reliability for high-volume production. Our SZLH ring die animal feed granulator utilizes a heavy-duty, all-gear transmission housed in a cast-iron gearbox. This design delivers power more directly and efficiently than belt drives, which can slip and stretch over time.

You gain about 15% higher mechanical efficiency, which translates to more consistent output and lower energy costs per ton of feed. For a feed mill running multiple shifts, this reliability is crucial to avoid unplanned downtime and maintain pellet quality. The gear drive in our granulator also operates with less noise and vibration, contributing to a better working environment and longer overall component life.

We plan to produce both poultry and cattle feed. Can one granulator handle both, or do we need two separate machines?

+

Absolutely, one of the key strengths of our SZLH 320 animal feed granulator is its versatility. A single machine can efficiently produce feed for multiple species. The primary adjustment required is switching the ring die. For poultry feed, you would use a die with smaller holes (e.g., 3-4mm) and a higher compression ratio to create dense, durable pellets.

For cattle feed, you would switch to a die with larger holes (e.g., 6-8mm) and a lower compression ratio suitable for coarser, fibrous ingredients. We design our granulators with a user-friendly, clamp-type die attachment system that allows for this changeover in under an hour. Many of our customers operate this way, and Richi Machinery can supply a set of customized dies and provide training for your team on the efficient changeover process.

Our main raw material is grass/alfalfa for ruminant feed. Will your standard model handle high-fiber content without clogging?

+

Processing high-fiber materials like grass and alfalfa is a common application, but it requires the correct configuration. The standard animal feed granulator can be successfully used for this purpose when equipped with an optional forced feeder system. This accessory acts as a positive displacement pump, pushing the bulky, low-density fibrous material uniformly into the pelleting chamber.

This prevents the material from “bridging” or arching over the feed inlet, which is a common cause of clogging and inconsistent production. Additionally, we would recommend specifying a ring die with a lower compression ratio and larger hole diameter specifically engineered for roughage. Our engineers have extensive experience setting up lines for hay and silage pelleting and can ensure your system is optimized from the start.

What is the recommended moisture content of the mash before it enters the pelleting chamber for optimal results?

+

Achieving the correct mash moisture is critical for pellet quality and machine efficiency. For most standard formulations entering our animal feed granulator, the ideal conditioned mash moisture content is between 16% and 18%. This level provides sufficient lubrication for the material to flow through the die holes smoothly while allowing starch to gelatinize properly for binding.

Our conditioning system, with its extended retention time and efficient steam injection, is designed to bring your mixture to this precise window consistently. If the mash is too dry, it causes excessive wear on the die and rollers, high power consumption, and produces weak, crumbly pellets. If it’s too wet, it can lead to clogging and unstable pellets. During commissioning, our technicians will calibrate your system to achieve this optimal moisture for your specific recipe.

How long does it typically take to change a ring die on your machine, and how many people are needed?

+

We have engineered our animal feed granulator for maintainability. With the standard clamp-type ring die fixation system, a standard die change can be performed by two trained maintenance personnel in approximately 30 to 45 minutes. The process does not require specialized pulling tools or excessive force.

The design allows for the die to be loosened, slid forward, and replaced without major dismantling of other components. This feature is highly valued by our customers as it directly minimizes production downtime during product changeovers or routine die maintenance. Richi Machinery provides detailed manuals and we can include die-change procedure training during your installation and commissioning service.

We are a small farm looking to produce our own feed. Is the 3-4 t/h model too large for a starter operation?

+

This is an excellent and common consideration. While the 3-4 t/h animal feed granulator is a robust, commercial-grade machine, it is often a smart choice for forward-thinking farms. You do not need to run it 24 hours a day. Its advantage is that it allows you to produce a week’s or month’s worth of feed in concentrated, efficient batches, freeing up labor for other tasks. This capacity also provides immediate room for growth if you expand your herd or decide to sell feed to neighbors.

Many small to medium-sized farms find this model to be the perfect balance of capability and investment. Our team at Richi Machinery can help you analyze your consumption and design a batch production schedule that makes this machine a cost-effective centerpiece of your operation.

For producing sinking fish feed, what special configuration does the granulator need?

+

Producing high-quality sinking fish feed requires specific engineering to achieve the necessary pellet density and water stability. The core of this solution is still our robust animal feed granulator, but it must be configured with key features.

- First, it requires a dual or, preferably, a triple-layer conditioner. This provides extended retention time (90-180 seconds) for thorough steam penetration and starch cooking, which is essential for binding.

- Second, a high-compression ring die (with a ratio such as 1:16 to 1:18) is mandatory to compress the fine mash into an extremely dense pellet that will sink. The process also relies on super-fine grinding upstream.

Richi Machinery designs complete sinking fish feed production lines that integrate these specialized granulator settings with precise grinding, fat coating, and cooling systems.

What kind of after-sales support and warranty do you provide with the granulator?

+

Richi Machinery stands behind every animal feed granulator we sell with a comprehensive support package. We offer a standard 12-month warranty on the machine, covering defects in materials and workmanship. Our support begins with detailed installation guidance and on-site commissioning by our engineers, who will train your operators. Post-installation, we provide lifelong technical support via phone, email, and video call.

We maintain a large inventory of wear parts and components at our factory, ensuring fast shipment. Furthermore, we offer customized service contracts for regular inspections and preventive maintenance to maximize your equipment’s lifespan and performance. Our goal is to be your long-term partner in production.

Can the production line be automated, and how do we integrate your granulator with our existing mixer and cooler?

+

Yes, full or semi-automation is a standard offering. Our animal feed granulator is designed to be the intelligent heart of an automated line. It comes equipped with standard PLC control interfaces that can communicate with upstream and downstream equipment. We can supply the complete feed mill plant—including conveyors, elevators, and control panels—or we can engineer a solution to integrate the granulator seamlessly into your existing setup.

Our project engineers will analyze your current mixer, cooler, and other equipment to design the proper mechanical linkages and control logic, ensuring a smooth, synchronized material flow from ingredient intake to finished pellet bagging with minimal manual intervention.

What is the power consumption (kWh per ton) of this model when producing standard chicken feed pellets?

+

The specific energy consumption is a key metric of efficiency. For our SZLH 320 animal feed granulator producing standard corn-soy based chicken feed pellets (3-4mm), you can expect an average power consumption in the range of 18 to 22 kWh per metric ton.

This industry-leading efficiency is a result of the high-efficiency gear drive, precision-balanced rotor assembly, and optimized die/roller design. It’s important to note that the actual figure can vary by about 10-15% based on your specific formula (higher fat or fiber can influence it), the exact compression ratio of the die, and the conditioning parameters. Our technicians will fine-tune these variables during commissioning to help you achieve the most efficient operation for your recipe.

How do we control the pellet length, and can it be adjusted during operation?

+

Pellet length is controlled externally by one or two adjustable cutter assemblies mounted just outside the ring die. As the strands of extruded feed emerge from the die holes, these rotating cutters slice them to the desired length. A significant advantage of our animal feed granulator design is that this adjustment can be made “on-the-fly.”

By simply turning a handwheel or adjusting a bolt, the distance of the cutter blades from the die face can be changed, altering the pellet length without stopping the machine. This allows for great flexibility and quick adjustments between batches or if you notice the initial pellet length is not perfect.

What are the most common wear parts, and what is their typical service life?

+

The primary wear parts in any ring die animal feed granulator are the ring die itself and the two pressure rollers. In our machines, the service life of these components depends heavily on the abrasiveness of your raw materials. For standard poultry or livestock feed with common grains, a high-quality alloy steel ring die from Richi Machinery can typically last between 1,000 to 1,800 operating hours before needing replacement or re-boring. The pressure rollers generally have a similar lifespan.

For more abrasive feeds (those containing minerals or certain by-products), the life will be shorter. We use specially hardened and treated alloys to maximize wear resistance and provide detailed guidance on monitoring wear to help you plan maintenance and spare parts inventory effectively.

Do you offer a trial or test run using our own raw material formula before purchase?

+

Absolutely. At Richi Machinery, we strongly believe in proving performance. We operate a fully-equipped testing center at our factory where prospective customers can send samples of their raw material formula (typically 500-1000 kg). Our technicians will run your material through the appropriate animal feed granulator configuration.

You will receive a detailed report including the actual pellet quality, production rate, power consumption, and samples of the finished pellets. This “test-before-you-invest” service eliminates uncertainty and allows us to recommend the exact machine specifications and process settings you will need for success.

How to choose animal feed granulator?

+

- Select equipment according to production needs: Select suitable equipment according to the product needs and production scale of the animal feed mill factory. The technical parameters, quality, performance, etc. of the equipment should be comprehensively considered.

- Consider the maintenance cost of the equipment: When selecting animal feed granulator equipment, the feed factory should also consider the later maintenance cost, including the service life of the equipment, maintenance and replacement of accessories, etc.

- Select a manufacturer with high credibility: Selecting an equipment manufacturer or agent with high credibility can better guarantee the quality of the animal feeds granulator equipment.

- Whether there is corresponding technical support: Before selecting equipment, you should also understand the technical support, maintenance guarantee and other services provided by the relevant manufacturer.

- The intelligence and automation level of the equipment: Selecting equipment with high intelligence and automation level according to production needs can improve production efficiency and reduce labor costs.

Feed mill factories have very high requirements for feed mill equipment. Choosing a suitable equipment for feed factories requires comprehensive consideration of multiple factors.

Correct selection and use of animal feed granulator will help improve the production efficiency and product quality of feed factories.

What safety features are built into the machine to protect operators?

+

Operator safety is paramount in our design. Our animal feed granulator incorporates multiple layers of protection.

- Firstly, an overload shear pin is fitted to the main drive; if a metal object enters or the chamber is overloaded, this pin shears, protecting the gearbox and motor from catastrophic damage.

- Secondly, all access doors and panels are fitted with safety limit switches. If a door is opened during operation, it immediately cuts power to the main motor and feeder, bringing the machine to a safe stop.

- Thirdly, all rotating transmission parts (gears, shafts) are fully enclosed in guards. These features, combined with proper training, create a safe working environment around the equipment.

For producing pig feed, is a single-layer conditioner sufficient, or do you recommend a double-layer?

+

The choice depends on your quality targets and formula complexity. For many standard grower/finisher pig feeds, a single-layer conditioner on the animal feed granulator is perfectly adequate and cost-effective. It provides sufficient steam addition and mixing for good pellet durability.

However, we often recommend a double-layer conditioner for several key scenarios: if you are producing starter feeds for piglets where digestibility is critical, if your formula includes high levels of fat or liquid additives that need better distribution, or if you are aiming for premium pellet quality with very low fines and high hardness.

The double-layer system provides longer, more controlled conditioning time, leading to better starch cooking and pellet integrity. Our sales engineers can help you weigh the benefits against the investment for your specific operation.

How is the SZLH 320 animal feed granulator typically used in a complete feed production line?

+

The SZLH 320 animal feed granulator is most commonly applied as the core pelleting unit in a complete 3-4 ton per hour feed production line. This specific capacity makes it an ideal, balanced choice for small to medium-sized commercial animal feed pellet plants, cooperative processing centers, and large-scale integrated farms. For operations requiring larger output, multiple SZLH 320 granulators can be efficiently integrated in parallel within a single, larger processing system, offering scalability and redundancy.

A complete animal feed pellet production line is a sophisticated, integrated process designed to transform a wide array of raw materials—including cereals, agricultural by-products, oils, molasses, vitamins, fats, and minerals—into a nutritionally complete and balanced final feed. The process is expertly tailored to produce feed that meets the precise dietary requirements of different animal species across their various life stages, thereby optimizing health, growth, and overall productivity.

A standard, high-efficiency feed production line featuring our animal feed granulator follows this optimized processing flow:

- Raw Material Reception & Cleaning

- Feed Grinding (to achieve optimal particle size)

- Feed Mixing (for homogeneous distribution of all ingredients and micro-additives)

- Feed Pelletizing (the core stage performed by the SZLH 320 animal feed granulator)

- Pellet Cooling (to stabilize and harden pellets)

- Pellet Crumbling (for starter feeds, if required)

- Screening & Grading (to remove fines and ensure uniform pellet size)

- Pellet Packing (for storage and distribution)

At Richi Machinery, we don’t just supply a standalone animal feed granulator. Our strength lies in engineering the entire animal feed production line around it. Each stage is carefully selected and configured based on your specific raw material profile, target feed formulas, and desired final pellet specifications. Our project engineers will design a solution that ensures seamless integration, maximum efficiency, and consistent output of high-quality feed.

What are the key material and component specifications in the configuration of the SZLH 320 animal feed granulator?

+

The performance, durability, and reliability of a feed granulator are directly determined by the quality of its core components. The configuration of our SZLH 320 animal feed granulator is engineered with premium materials and proven industrial components to ensure it withstands the high-pressure, abrasive environment of continuous feed production.

This careful selection is what separates a commercial-grade machine from lesser alternatives and underpins our reputation for building long-lasting equipment.

Here is a detailed breakdown of the key specifications that define the robust configuration of the SZLH 320 animal feed granulator:

- Critical Contact Parts & Hygiene: All surfaces that directly touch the feed are designed for durability and cleanliness. The ring die is constructed from wear-resistant alloy steel, and crucial housings like the door cover of the granulation chamber (6mm thick) and the feed chute are made from SUS304 stainless steel. This prevents corrosion, avoids material contamination, and simplifies cleaning.

- Power Transmission & Gearbox: The heart of the drive system is a heavy-duty gearbox cast from HT250, a high-tensile iron known for its strength and vibration-dampening properties. The critical gears and shafts (including the main spindle and empty shaft) are forged from high-grade alloy steels like 42CrMo and 20CrMnTi. These materials are heat-treated to achieve exceptional hardness and fatigue resistance, ensuring smooth power transfer and a long operational life.

- Precision Bearings & Seals: To maintain alignment and minimize friction under heavy loads, we utilize imported high-precision bearings. These are paired with high-quality oil seals from German or Taiwanese manufacturers to effectively retain grease and prevent contamination, a common point of failure in less robust machines.

- Safety & Drive Protection: The machine incorporates a reliable overload mechanical protection system via a shear safety pin. This simple yet effective design protects the entire gear train and motor from catastrophic damage if an overload occurs. Power is transmitted from the motor via a serpentine spring coupling, which absorbs shock loads and compensates for minor misalignments, reducing stress on the drivetrain.

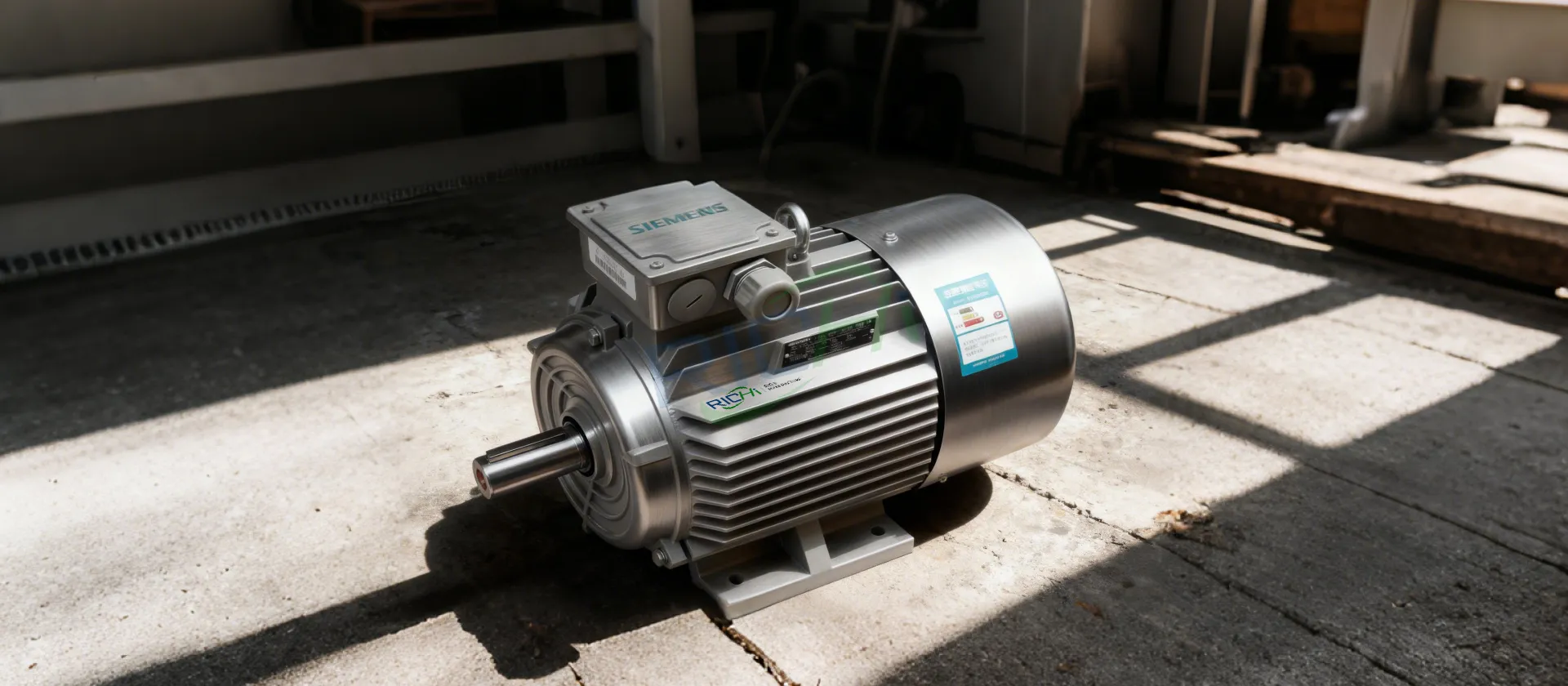

- Prime Mover: The animal feed granulator is typically driven by a Siemens electric motor, a global benchmark for efficiency, reliability, and consistent power delivery.

This configuration is not arbitrary; it is the result of decades of engineering experience at Richi Machinery. We specify these materials because we understand the demands of processing everything from fine poultry mash to coarse, fibrous ruminant diets. By investing in this level of component quality, we ensure that the SZLH 320 animal feed granulator delivers not just high output, but also unmatched operational stability and a lower total cost of ownership through reduced downtime and maintenance.

Can you explain the main structural components and working mechanisms of the SZLH320 animal feed granulator?

+

Understanding the core structure of a pellet mill is key to appreciating its reliability and capability. The SZLH320 animal feed granulator is built around a robust, logically designed mechanical system where each component plays a critical role in transforming powdered feed into dense, uniform pellets. Its design reflects decades of engineering refinement by Richi Machinery to handle a vast spectrum of feed formulas with precision and efficiency.

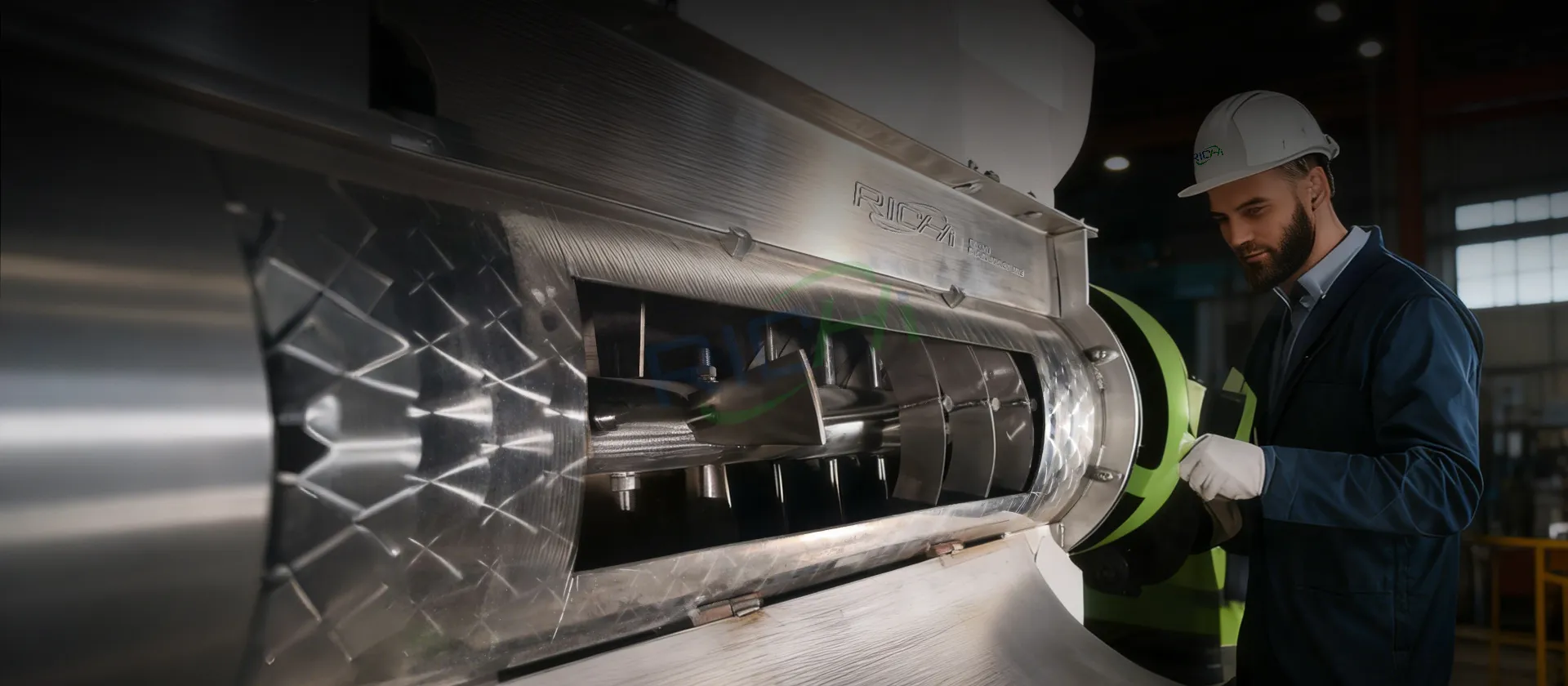

The main structure is founded on a heavy-duty frame that provides absolute stability under high dynamic loads. Power is supplied by a high-torque motor (such as Siemens), which drives the entire system. The core of the machine is the rotor assembly, which houses the pressing mechanism. Contrary to a simple “sieve and valve,” the critical component for controlling pellet size is the perforated ring die and the external adjustable cutters.

The workflow is accomplished through three integrated mechanisms:

1. The Feeding Mechanism

This subsystem ensures consistent and controllable material flow. It consists of a feed hopper and a variable-speed feeder screw (or feed roller). The screw, often driven by a separate geared motor, meters the conditioned mash from the hopper at a precise rate into the conditioning/pelleting chamber. This controlled feeding is vital to prevent choking or underfeeding the next stage, which directly impacts pellet quality and machine stability.

2. The Pressing Roller & Die Structure

This is the absolute heart of the animal feed granulator where pellet formation occurs. Inside the pellet chamber, two or more heavy-duty, free-rotating press rollers are mounted on the rotor. They rotate in close contact with the inner surface of a stationary perforated ring die.

As the conditioned feed is forced between the rollers and the die, tremendous pressure builds, compacting the material and extruding it through the die holes to form solid strands. The compression ratio of the die (the relationship between hole length and diameter) is the primary factor determining pellet density and hardness. By selecting a die with the correct ratio and hole size, operators can produce everything from soft ruminant pellets to ultra-hard aquatic feed.

3. The Adjustment & Control Mechanisms

This refers to the integrated systems that allow for precise operation and product adjustment. Key elements include:

- Feeder Speed Control: An inverter (VFD) allows real-time adjustment of the feeder screw speed to perfectly match the main motor load and desired throughput.

- Conditioning Control: Steam and liquid addition are regulated to achieve the exact mash moisture and temperature for optimal gelatinization.

- Pellet Length Adjustment: This is done via externally mounted, adjustable cutters that slice the extruded strands to the desired length as they exit the die. This adjustment can be made while the machine is running.

- Gap Adjustment: A mechanism allows for fine adjustment of the minimal gap between the press rollers and the die surface, which is crucial for startup and efficient operation.

This sophisticated yet robust structure is why the SZLH320 animal feed granulator is so versatile. The ability to precisely control feeding, conditioning, compression, and cutting allows our customers and our engineers to fine-tune the machine for any feed type—from high-fat poultry starter to fibrous cattle feed or complex sinking aquafeed. It’s not just a machine; it’s a highly tunable production system.

How to choose animal feed granulator manufacturer?

+

There are many feed pellet mill manufacturers, so “how to choose a reliable animal feed granulator manufacturer” is particularly important. Choosing a reliable feed pellet mill manufacturer requires considering many factors. Here are some suggestions:

- Understand the manufacturer’s professional capabilities and experience.

When choosing a manufacturer, you need to understand its professional field, technical strength, project experience, etc. You can understand its professional capabilities and experience by checking the manufacturer’s official website, case display, and the strength of customers who have cooperated. - Confirm the manufacturer’s qualifications and reputation.

Animal feed granulator manufacturers need to have relevant qualifications and certifications, such as ISO9001 quality management system certification, C certification, etc. - Confirm the manufacturer’s R&D and production capabilities.

Animal feed pellets granulator manufacturers need to have strong R&D and production capabilities and be able to provide high-quality and high-performance equipment that meets customer needs. You can evaluate its R&D and production capabilities by visiting the factory and understanding the equipment process. - Confirm the manufacturer’s after-sales service.

Animal feed pellet granulators will inevitably have problems during use. Manufacturers need to provide timely and complete after-sales services, be able to respond quickly to customer needs, and ensure the stability and reliability of the equipment. - Confirm the rationality of the manufacturer’s price and cost-effectiveness.

When choosing a animal feed granulator manufacturer, you need to consider its rationality of price and cost-effectiveness. You need to understand the market situation and the price level of similar products, compare the quotations and equipment performance, service level and other aspects of different manufacturers, and choose a manufacturer with high cost-effectiveness.

Whether you need to grind, condition, pellet, or cool, we can meet the demands of almost every conceivable application. Your entire process is covered from start to finish, and our rock-solid equipment lets you operate your animal feed granulator plant at the lowest possible cost.

Our animal feed granulator and other animal feed mill equipment can handle anything you throw at them, so you can meet the demands of your customers. (FInd RICHI on youtube)