ANIMAL FEED

FACTORY PROJECT

For years, RICHI has been redefining what’s possible in animal feed production. We don’t just follow industry standards—we set them. From groundbreaking automation to smarter plant layouts, our innovations have helped hundreds of feed producers boost output, cut waste, and run more efficiently. And we’re not slowing down—because your success demands constant improvement.

1000+

Construction Projects

For three decades, RICHI has been at the forefront of feed machinery innovation, delivering over 1,000 successful feed plant installations worldwide. Our hands-on experience across diverse markets makes us a trusted partner for industrial feed production.

USD $1.8 billion+

Total Sales

We don’t just sell feed factory equipment—we build complete feed manufacturing systems. With $2.3+ billion in global project value, our team handles everything from design to commissioning, ensuring your facility operates at peak efficiency from day one.

120+

Covering countries

Our machinery operates in 120+ countries, adapting to regional raw materials, regulations, and production needs. Whether you’re expanding or building new, we bring tested animal feed factory project solutions tailored to your market’s unique demands.

Proven Projects – Delivering Results Worldwide

No two animal feed factories are the same. That’s why we don’t believe in one-size-fits-all solutions. Whether you’re building new, expanding, or modernizing, we start by listening. How many tons per hour? What mix of pellets, mash, or extruded feed? Bagging, bulk storage, or both? Your answers shape the design—not the other way around.

Animal feed factory project report

Animal feed factory projects worldwide

In animal feed factory projects, the choice of equipment directly affects production efficiency, finished product quality and operating costs. We provide you with full-process feed production equipment, including raw material cleaning, crushing, ingredient mixing, granulation (or puffing), cooling and screening, packaging and automatic control systems.

Each feed factory equipment is based on the design concept of high capacity, low energy consumption and easy maintenance, and can be customized according to your raw material characteristics, production scale and product requirements.

Mixing Equipment

Crushing Equipment

Pelleting Equipment

Extrusion Equipment

animal feed Project Video

Want to know how modern animal feed factories operate efficiently? We have selected three typical project videos to take you to RICHI turnkey project sites of different sizes to provide a real reference for your future investment. Click on the video below to start your feed factory planning journey!

RlCHl Machinery offers a diverse expertise to prgvide solutions for your feed factory constructionrenovations, design/build, upgrades and engineering projects. We begin with our customers keydesian criteria in mind. These include feed mill production

cost to start animal feed factory project

The cost of investing in a feed mill is usually between $10,000 and $3 million, depending on the scale of production, process complexity, equipment configuration level, and whether a silo system is configured. To help you better plan your investment, we have compiled typical investment data for different production capacity scales, including key parameters such as site requirements, installation cycle, and payback period for your reference:

The following table lists in detail the investment cost range and related supporting requirements for feed production lines with different capacities from 1-2 tons/hour to 80-100 tons/hour, helping you evaluate the budget and payback period based on actual needs.

| Production Scale | Total Power | Project Site Requirements | Production cycle | Installation cycle | Investment Cost(USD) | Profit cycle |

| 1-2T/H | 47-75KW | 300-500m² | 20 Days | 7-15 Days | 10,000-50,000 | 1-3 Year |

| 3-4T/H | 53-165KW | 300-700m² | 20 Days | 15-20Days | 50,000-120,000 | |

| 5-7T/H | 68-259KW | 400-800m² | 20-30 Days | 20-40Days | 70,000-250,000 | |

| 8-10T/H | 125-410KW | 800-2000m² | 30-40 Days | 45-60 Days | 150,000-300,000 | |

| 12-20T/H | 358-620KW | 1500-3000m² | 40-50 Days | 60-90 Days | 250,000-580,000 | |

| 25-40T/H | 545-870KW | 2000-4000m² | 50-60 Days | 90-120Days | 450,000-850,000 | |

| 50-60T/H | 710-1120KW | 3000-5000m² | 60-70 Days | 100-140 Days | 900,000-1,400,000 | |

| 60-80T/H | 815-1370KW | 5000-8000m² | 70-90 Days | 130-160 Days | 1,450,000-1,800,000 | |

| 80-100T/H | 1230-1700KW | 8000-20000m² | 90-120 Days | 160 -190Days | 2,000,000-3,000,000 |

The key to profitability of animal feed factory project

The price difference between raw materials and finished products is the basis of profit. There are significant differences in the purchase price of raw materials such as corn and soybean meal and the selling price of feed in different regions, which directly determines your profit margin. For example, the market price difference between Southeast Asian aquatic feed and European poultry feed can reach more than 30%.

Operating cost control is crucial. Let us do the math for you: Taking a pellet feed line with an output of 10 tons per hour as an example, the power consumption per ton is about 35-50 degrees (depending on the energy efficiency of the equipment), and the annual replacement cost of wearing parts accounts for about 2-3% of the equipment investment. Choosing our high-efficiency and energy-saving models can reduce energy consumption by more than 15% compared with ordinary equipment.

The most important thing is the level of the management team. For the same equipment, a professional operation team can increase production capacity by 20% and reduce the failure rate by 50%. We not only provide equipment, but also train core technicians for you and recommend proven production management solutions.

Interested in our projects?

Planning to invest in an animal feed factory? Click here to get professional plant construction solutions and start your profitable feed production business!

Prospects of investing in animal feed factory project

As the global population grows and the demand for meat consumption continues to rise, the feed industry is entering a period of stable growth. The rapid development of the aquaculture industry in emerging markets such as Southeast Asia and Africa has created a large demand for feed production capacity; while mature markets in Europe and the United States focus on equipment upgrades and green production transformation, creating new opportunities for efficient and energy-saving feed mills.

Currently, investing in feed processing plants has significant advantages: the globalization of raw material procurement has reduced production costs, the popularization of automation technology has improved operational efficiency, and the high added value trend of special feeds (aquatic products, pet food, etc.) has increased profit margins. Whether it is to meet local market demand or to lay out an international supply chain, modern feed mills are agricultural investment projects with great potential.

Maybe you have questions

When investing in a feed factory or purchasing animal feed plant machinery, have you encountered these questions: How much investment is needed to build a factory? How long will it take to get back the investment? What equipment configuration should be selected for different production capacities? How to reduce energy consumption and increase production? ….RICHI engineer team will answer your questions and provide technical support.

animal feed factory project types ?

+

At present, the animal feed plant projects we have done are mainly divided into the following categories:

- Poultry feed plant project

- Cattle feed plant project

- Fish feed mill project

- Pig feed mill project

- Pet feed mill factory project

- Sheep feed factory project

- aqua feed factory project

- Shrimp feed mill factory project

- Livestock feed factory project

- Premix feed mill factory project

- fermented feed factory project

- Compound feed factory project

- ruminant feed factory project

- mash feed plant project

- …

RICHI provides 1-160 t/h feed mill factory projects to global customers, including comprehensive technical services including factory layout, process design, equipment manufacturing, installation, commissioning, electrical control and operation training, and technical formulation.

At present, RICHI’s animal feed factory projects have been built in more than 130 countries around the world, and various complete sets of feed factory machines have been successfully exported to Russia, Iran, Indonesia, the United States, India, South Africa, Thailand, the United Kingdom, Germany, France, Canada, Brazil, Algeria, Argentina, Peru, Egypt, Poland, Romania, Australia, Egypt, Kenya, Kazakhstan, Afghanistan, Iraq and many other countries and regions.

How to build animal feed factory project?

+

The basic procedures for feed mill engineering project construction usually include the following stages:

- Project proposal stage: This is the preliminary stage of project startup, which requires preliminary research and planning for the project.

- Feasibility report stage: At this stage, a more detailed feasibility study of the project is required, including market analysis, technical solutions, investment estimates, etc.

- Design stage: Based on the preliminary research, carry out detailed design work, including process flow design, equipment selection, architectural scheme design, etc.

- Construction preparation stage: In this stage, preparations such as site leveling, construction drawing design, equipment procurement, and construction team bidding need to be carried out.

- Construction implementation stage: This is the substantive stage of project construction, including civil construction, equipment installation, pipeline laying, etc.

- Completion acceptance phase: After the project is completed, completion acceptance is required to ensure that all projects meet the design requirements and relevant quality standards.

In addition, the construction of a complete feed mill plant may also involve some special links, such as the procurement and storage of raw materials, monitoring and quality control of the production process, etc. During the production process, attention must also be paid to the crushing and granulation of raw materials to ensure the quality and safety of the feed.

For the construction of animal feed factory projects, environmental protection and safety requirements also need to be taken into consideration, such as providing environmental protection certificates if there are environmental protection requirements.

Different Animal feed factory project, Different process design?

+

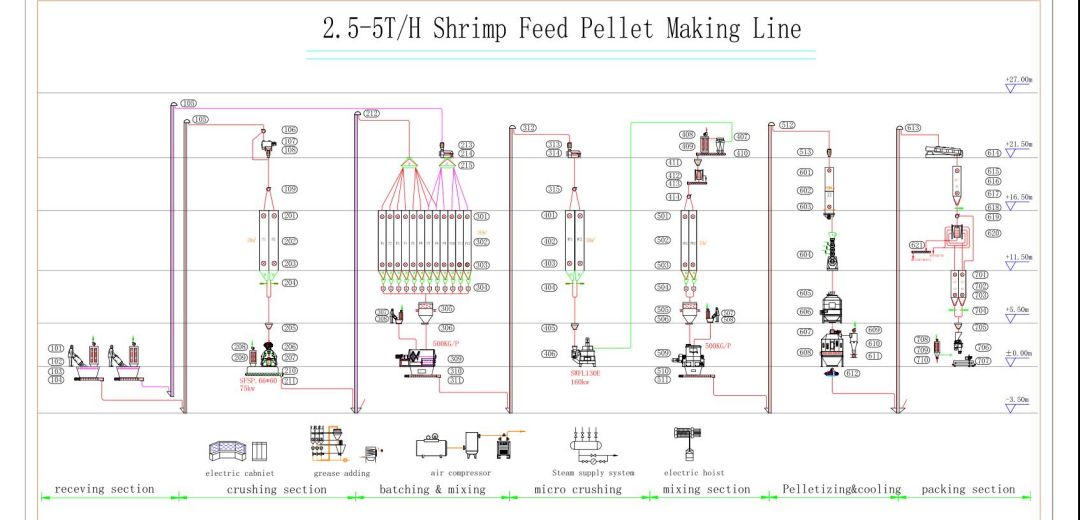

Different types of feed processing techniques are different. It is mainly divided into poultry feed processing, livestock feed processing, grass feed processing, fermented feed processing, aquatic feed processing, and pet feed processing.

- Livestock and poultry feed processing process: cleaning – crushing – ingredients – mixing – granulation – cooling – crushing – screening – packaging

- Aquatic feed processing process: cleaning – ingredients – mixing – crushing – micro-crushing – extrusion – drying – grading – spraying – cooling – screening – packaging

- Pet feed processing process: feeding – ingredients – mixing – crushing – ultrafine grinding – mixing – extrusion – drying – spraying – cooling – screening – packaging

- Ruminant feed processing process: cleaning – crushing – mixing – pelleting – cooling – grading – packaging

- Premix process: cleaning – crushing – ingredients – mixing – packaging

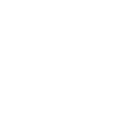

40-50 T/H poultry chicken feed factory project design

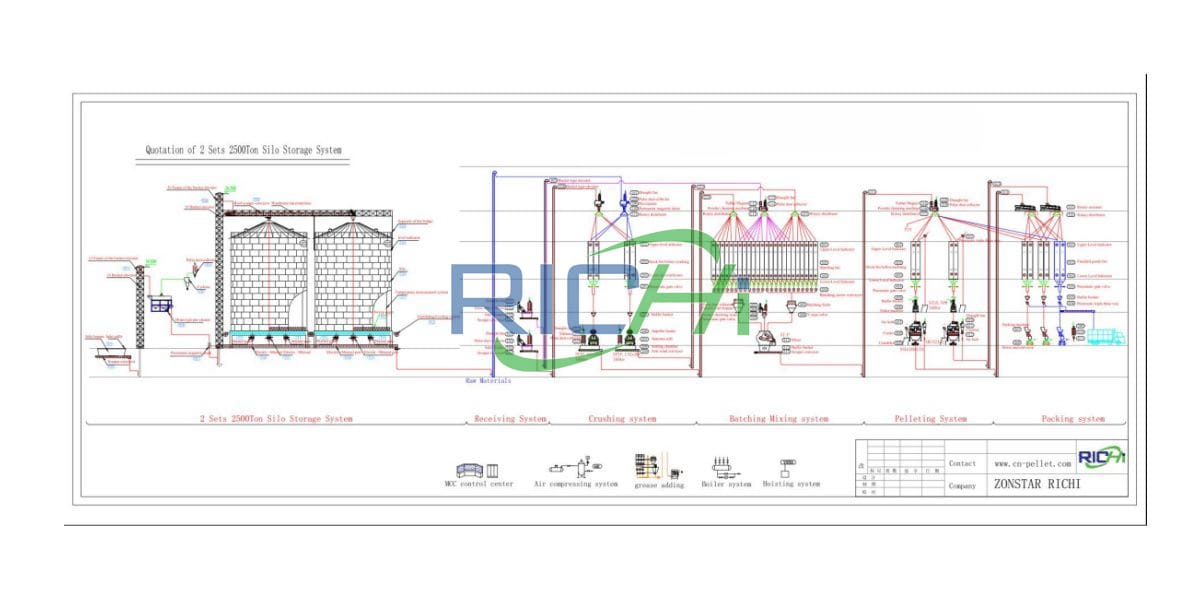

10 T/H livestock cattle feed factory project design

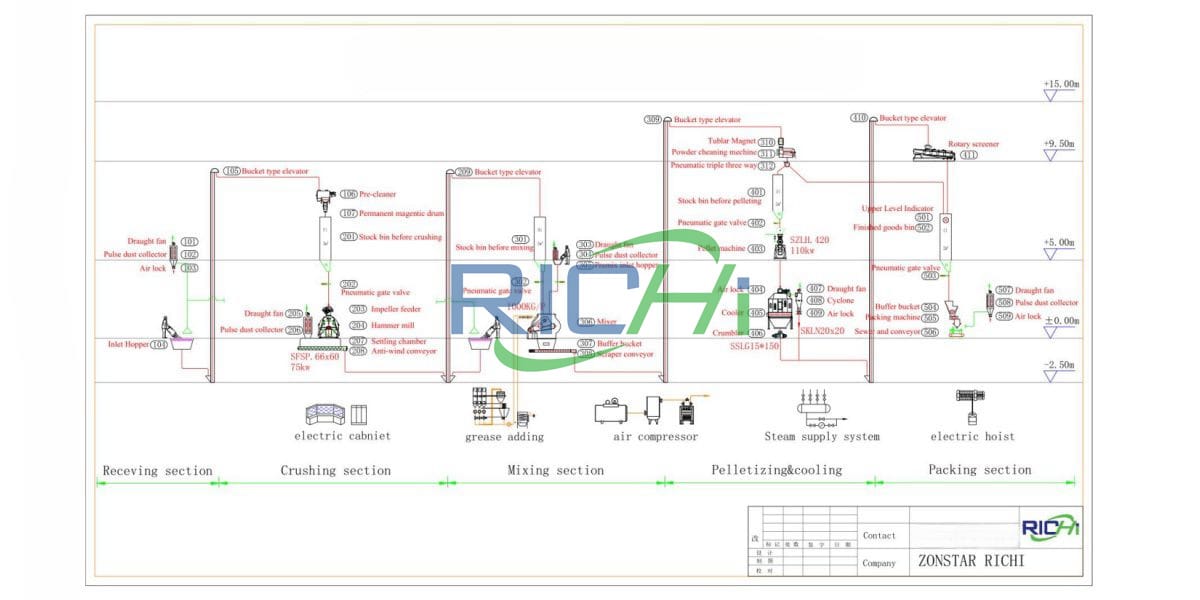

shrimp & fish feed factory project process design

shrimp aqua feed factory project process design

In addition to the processing of the above feed types, our customized animal feed factory projects are also suitable for fermented feed and special biomass raw material feed processing (such as peanut shell feed, bagasse feed, rice husk feed, etc.).

Many commercial feed mill processes need to be customized. They may need to expand raw materials, use a vacuum spraying system, or configure a robot palletizing system… As long as you have needs, our team of senior engineers can design industry-leading feed mill solutions and provide a complete set of feed mill equipment for you.

If you have any needs or questions, contact us for professional technical support!

Equipment needed to start animal feed factory project?

+

Different types of animal feed preparation plants require different feed equipment:

For general sinking fish feed and shrimp feed processing, hammer mills, ultrafine grinders, feed mixers, shrimp feed granulators, shrimp feed extruders, oil adding equipment, spraying equipment, and feed cooling are mainly needed equipment, cubic sieve, automatic packaging scale, silo system, fully automatic control system, etc. can also be configured.

- For poultry and livestock feed production projects, the main equipment required includes feed crushers, feed mixers, feed granulators, feed coolers, feed screening machines, feed packaging machines, etc. Silos, automatic control systems, etc. can also be configured.

- For the processing of grass animal feed, in addition to the above equipment, it is also necessary to configure forage crushers, hay cutters, bale breakers and other equipment.

- For the processing of puffed aquatic products and pet feed, hammer mills, ultrafine pulverizers, feed mixers, twin-screw extruders, single-screw extruders, grease adding equipment, spraying equipment, and feed cooling equipment are mainly needed , screening equipment, packaging equipment, and can also be equipped with silo systems, automatic palletizing equipment, fully automatic control systems, etc.

hammer mill feed grinder

Used in animal feed materials crushing section.

- Capacity: 3-25 T/H

- Main Power: 30-160 KW

Feed Mixer machine

Used in animal feed raw materials mixing section.

- Capacity: 250-2000 KG

- Main Power:

- 4-55 KW

poultry livestock Pellet mill

Used in poultry & lievstock feed raw materials pelleting section.

- Capacity: 1-48 T/H

- Main Power: 22-315 KW

animal Feed Extruder

Used in extruded animal feed production process, especially aquatic feed and pet feed.

- Capacity: 0.5-12 T/H

- Main Power: 0.75-355 KW

Sinking fish feed machine

Used in sinking fish feed raw materials pelleting section.

- Capacity: 0.6-27T/H

- Main Power: 22-315KW

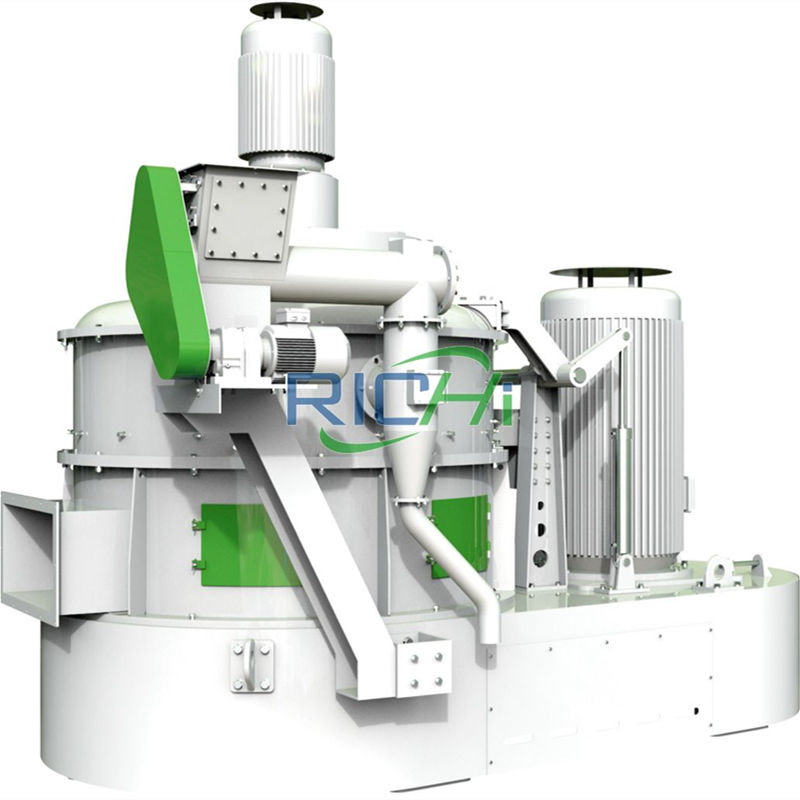

shrimp feed pellet machine

Used in fish & shrimp feed raw materials pelleting section.

- Capacity: 0.1-6T/H

- Main Power: 22-315KW

animal Feed Dryer

Used in the drying section of feed mills, especially aquatic feed and pet feed.

- Capacity: 2-12T/H

- Main Power: 44.3-71.8KW

Spraying Machine

Used in the spraying section of animal feed mill plants

- Capacity: 3-15T/H

- Main Power: 22KW

Micro Pulverizer

Mainly used in the crushing section of aquatic products and pet feed factories.

- Capacity: 1-12T/H

- Main Power: 90-220KW

grass dryer machine

Used in the drying stage of feed processing containing grass and agri raw materials.

- Capacity: Customizable

- Rotate speed: 3-8 R/Min

Bale breaker

For grass-containing animal ruminant and livestock feed production.

- Capacity: 1-20 T/H

- Main Power: 30-90 KW

Grass crusher

Mainly used for crushing grass, straw, hay and related feed raw materials.

- Capacity: 0.3-3 T/H

- Main Power: 22-93 KW

Pellet Cooler Machine

Used in animal feed pellet cooling section.

- Capacity: 3-25 T/H

- Main Power: 30-160 KW

pellet crumbler machine

Used to reduce the pellet size of finished feed pellets.

- Capacity: 2-20 T/H

- Roller: 2-3

vibrating screening machine

Used in animal feed pellet grading section.

- Capacity: 3-20 T/h

- Main Power: 1.5-5.5 KW

Automatic Bagging Machine

Used in animal pellet & mash feed packing section.

- Capacity: 6-12 Bags/Min

- Main Power: 1.1-5 KW

The above equipment is only the main equipment of a feed factory. The operation of a feed factory also requires cleaning equipment, dust removal equipment, silo systems, palletizing systems, automated control equipment and systems, etc.

Whether it is a small or medium-sized feed processing plant or a large modern production line, our mature process solutions and reliable equipment performance can ensure the stable operation of your project and create long-term value. If you want to build a feed factory, contact us, we Our professional consultants will configure the optimal performance feed production line solution for you.

What 1-2 t/h animal feed mill cases have you worked on?

+

1-2T/H small scale feed mill project is suitable for small feed processing businesses and farms. Currently, projects and equipment with this output have been exported to Belgium, the Netherlands, Moldova, Russia, Indonesia, Vietnam, Saudi Arabia, Qatar, and Uzbekistan Nearly 100 countries including Stan, Kazakhstan, Cuba, Chile, Australia, and Algeria

1-2T/H animal feed factory project price: 10,000-50,000 USD

animal feed factory project In Ethiopia

- Output: 1-2T/H

- Feed type: Broiler chicken feed

- Workshop size:10m*4m*5m

- Main equipment: Animal food hammer mill machine * 11 kw; Feed Mixer * 250kg/batch; Chicken feed pellet machine * 22 kw; Cooling machine* 0.93 kw; pellet crumbler machine*5.5kw; screen machine*0.25kw, etc.

- Installation time: 15 Days

- Project price: FOB $41,000

animal feed factory project In Qatar

- Output: 1-1.2T/H

- Feed Type: Bird And Camel feed

- Workshop size: 10m*5m*12m

- Main equipment of the project: feed hammer mill*11KW; feed mixer*250kg/batch; feed pellet extruder*22kw; cooling machine; packing machine and other auxiliary equipment, It’s one set full automatic control system .

- Installation time: 26 Days

- Project price: FOB $39,000

animal feed factory project In Nigeria

- Output: 2T/H

- Feed type: chicken and pig feed

- Workshop size: 15M*9.5M*8M

- Main equipment of the project: 37KW hammer mill, 2.500kg/batch mixer, 22KW Poultry pig feed pellet machine, SKLN11*11 cooler, vibrating shifter, etc.

- Installation time: 30 Days

- Project price: FOB $33,000

What are the 3-4 tons animal feed plant projects you have built?

+

The 3-4 t/h animal feed production plant project is suitable for investors in small and medium-sized farms, breeding farms and small feed processing businesses. Currently, our 3-4 tons animal feed plants have been exported to Indonesia, New Zealand, Canada, South Africa, Ethiopia, Australia, Algeria, Zimbabwe, Vietnam, Cambodia, Tanzania, Russia, Senegal, India, Ghana, Nigeria, Philippines, Pakistan and other countries

3-4 T/H animal feed factory project cost: 5,0000-12,0000 USD

animal feed project in the Philippines

- Output: 4T/H

- Feed type: Pig feed & chicken pellets

- Project area: 1200m²

- Main equipment of the project: Animal livestock feed pellet machine, Animal livestock feed mixer, Animal livestock feed grinding machine, Powder cleaning screen, Pulse bag dust collector, Rotating sieve, Bucket elevator, Scraper conveyor, Pellet cooler, etc.

- Installation time: 1 Month

- Project price: 63,000 USD

animal feed factory project in Uzbekistan

- Output: 3-4T/H

- Feed type: sheep and cattle feed pellets

- Workshop size: 7m*6m*8m

- Main equipment of the project: 37KW SZLH320 cattle feed pellet machine; 37KW cow food grinding mill; 3. Good quality 500kg/batch cattle feed mixer equipment; 4. Grass dryer; 5. SKLN1414 Counter-flow Cooler; 6. Automatic bagging machine, etc.

- Installation time: 30 Days

- Project price: 79,000 USD

animal feed factory project in Tanzania

- Output: 3-4T/H

- Feed type: broiler Feed

- Workshop size: 12m*12m*25m

- Main equipment of the project: Feed Grinder Machine*110KW; Batching Scale*1000KG/Batch; Feed Mixing Machine*1000KG/Batch; Pellet Making Machine*110KW; Cooling Machine*SKLN2020; Pellet Crumbler*SSLG15150; Screen and Packing Machine; Other Auxiliary Equipment

- Installation time: 40 Days

- Project price: FOB $70,000

What 5-7 ton animal feed factory projects have you worked on ?

+

The 5-7 t/h animal feed factory project is very suitable for medium and large-scale breeding farms and some medium-sized feed processing business investors. Currently, our 5-7t/h animal feed projects have been exported to Germany, Russia, the United States, the United Kingdom, Indonesia, Oman, India, Pakistan, the United Arab Emirates, Uzbekistan, Kazakhstan, El Salvador, Algeria, Tanzania, Somalia, Senegal, and New Zealand , Zimbabwe and other countries.

5-7 T/H animal feed factory project price: 7,0000-25,0000 USD

animal feed factory project In El Salvador

- Output: 5T/H

- Feed type: premix feed

- Workshop size: 11m*7m*13m

- Main equipment of the project: 1. Stainless steel feed hammer mill*37KW; 2. Stainless steel feed mixer 500kg/batch; 3. Fully automatic stainless steel batching weighing system; 4.packing machine and other equipment, It’s one set full automatic premix feed processing system.

- Installation time: 60 Days

- Project price: FOB $480,000

animal feed pellet plant project in Thailand

- Output: 5-6T/H

- Feed type: poultry Powder And Feed Pellet

- Workshop size: 9m*5m*15m

- Main equipment of the project: 1. 37KW hammer mill; 2. 500kg/hour feed mixing ; 3. 55KW poultry feed pellet making machine; 4. animal feed pellet cooler machine; 5. rotary shifter; 6. manual packing machine, etc.

- Installation time: 40 Days

- Project price: FOB $210,000

animal feed factory project in Argentina

- Output: 5-7T/H

- Feed type: layer hen broiler feed

- Workshop size: 13m*4m*8m

- Main equipment: Hammer mill * 37 kw; Mixer * 500kg/batch; Animal feed pellet press * 37 kw; Cooling machine* 0.93 kw; crumbler*5.5kw; screen machine*0.25 kw and other subsidiary equipment

- Installation time: 50 Days

- Project price: FOB $190,000

What 8-10 ton animal feed processing projects have you worked on?

+

The 8-10T/H animal feed processing plant project is suitable for investors in large farms and medium and large feed processing businesses. Currently, our 8-10t/h feed mill equipment has been exported to South Africa, Saudi Arabia, Iran, the United States, the United Kingdom, Russia, Kazakhstan, Oman, Uzbekistan, Algeria, Zimbabwe, Haiti, India, Indonesia, the Philippines, Thailand, and Malaysia , Bangladesh, Argentina, Brazil, Ecuador and other countries.

8-10 T/H animal feed factory project investment: 150,000-580,000 USD

animal feed factory project in brazil

- Output: 10T/H

- Feed type: poultry duck chicken feed pellets

- Workshop size: 12m*12m*25m

- Main equipment of the project: 1.Feed Grinder Machine*110KW; 2.Batching Scale*1000KG/Batch; 3.Feed Mixing Machine*1000KG/Batch; 4.Animal Feed Pellet Mill*110KW; 5.Pellet Cooler*SKLN2020; 6. Pellet Crumbler*SSLG15150; 7.Screen and Packing Machine, etc.

- Installation time: 60 Days

- Project price: FOB $430,000

animal feed factory project in Iran

- Output: 10T/H

- Feed Type: Pig cattle Mash Feed And Pellet Feed

- Workshop size: 14M*7M*15M

- Main equipment of the project: 1.Feed Grinder Machine*110KW; 2.Feed Mixing Machine*1000KG/Batch; 3.Animal Feed Pellet Making Machine*110KW; 4.Cooling Machine*SKLN2020; 5.Pellet CrumblerSSLG15*150; 6.Screen and Packing Machine; 7.Other Auxiliary Equipment

- Installation time: 30 Days

- Project price: FOB $240,000

animal feed project in New Zealand

- Output: 10-15T/H

- Feed Type: poultry cow Mash And Pellet Feed

- Workshop size: 35m*20m*25m

- Main equipment: Feed Grinder Machine*110KW; Batching Scale*1000KG/Batch; Feed Mixing Machine*1000KG/Batch; Animal Feed Granulator*110KW; Cooling Machine*SKLN2020; Pellet Crumbler; Screen and Packing Machine; Silo System, etc.

- Installation time: 60 Days

- Project price: FOB $580,000

What animal feed mill projects with a capacity of more than 10 t/h have you worked on ?

+

Large-scale animal feed project construction is very suitable for large-scale breeding farms, farms and large-scale feed companies. At present, our feed production line projects of more than 10 tons have been exported to Iran, India, Oman, the United States, Canada, New Zealand, Bangladesh, Uganda, Argentina, Brazil, Mexico, the United Arab Emirates, Vietnam and other countries.

Large animal feed factory project price: 250,000-2,800,000 USD

animal feed factory project in USA

- Output: 25 T/H

- Feed type: Pig & chicken feed

- Project area: 4300m²

- Main equipment of the project: chicken pig feed mixer, Chicken feed grinder hammer mill, Bucket elevator, Automatic batching scale, Chicken feed granulator machine, Dust collector, Rotary grading screen, etc.

- Installation time: 4 Months

- Project price: 650,000 USD

animal feed factory project in Russia

- Output: 80 T/H

- Feed type: Poultry chicken & Fish feed

- Project area: 55 acres

- Main equipment of the project: Poultry feed grinding mill, machine for mixing poultry feed, ring die chicken feed pellet granulator, microcomputer batching systems, bagging machine, liquid adding equipment, etc.

- Installation time: 12 Months

- Project price: 3,500,000 USD

animal feed factory project in Vietnam

- Capacity: 50 T/H

- Feed type: Dairy cow & Goat feed

- Project area: 90 Acres

- Main equipment of the project: Corn receiving system, Corn silo system, Cleaning system, Crushing system, Mixing system, animal cattle fodder ring die feed pellet machine, Finished product packaging system, etc.

- Installation time: 12 Months

- Project price: 1,600,000 USD

The above is just a list of individual projects. If you want to know more about our animal feed factory projects, please contact us directly, or view the details of our cases in various continents:

Why Richi Machinery?

+

At Richi Machinery, we believe there’s no substitute for experience. And we have well over 25 years of it.

We have been in business for 25+ years.

Our long-term business strategy lends stability to our client’s animal feed factory projects.

We are innovators.

We don’t stand still—we are continually finding ways to improve the design and animal feed plant construction process to add value and save you money.

We are a lean organization.

Our clients work with just one project manager and one animal feed factory project superintendent who have the authority to make decisions. This minimizes mistakes and expedites jobs, saving everyone time and money.

We have key employees with significant experience in the industry

Our key employees have an average of 10 years with the company. As a result, we deliver our jobs faster and help our clients get a return on their investment sooner than other companies in our industry.

We understand the importance of communication

We want to make sure our clients know what’s going on at all times. We anticipate problems to minimize client risk, and we listen to ensure that client needs are accurately reflected from proposal to animal feed factory project completion.

We understand customer satisfaction includes being cooperative

We work as a team with the owner, subcontractors, and suppliers. We strive to make the construction process a pleasant experience for the client.

We are committed to quality

We see each animal feed factory project as a reflection of our values and build each one as though it were for ourselves. We strive to do it right the first time, improving the investment value of our client’s property.

We work safely

We have minimal lost time due to injuries and our insurance costs are lower, which saves our clients money.

We work in tough environments

We understand the challenges, maintain flexibility in our work schedule, and minimize errors in order to deliver your animal feed mill equipment on time and on budget.

About RICHI

Since founding in 1995, RICHI MACHINERY has grown to become the world’s leading designer and builder of pellet production line systems. RICHI has delivered over 2000 projects to clients located in more than 140 countries across six continents. Altogether we have over 200 employees, and from start to finish, RICHI can design, manufacture, build and deliver your entire project – there’s no need to manage multiple project partners.

RICHI Technology

Adhering to the R&D tenet of “independent innovation”, Richi Machinery’s annual R&D investment accounts for more than 3% of total sales. It is supported by CAD, Solidworks and other computer-aided design systems, Ansys, matlab simulation analysis software, and VCC, EasyBuoder8000 and other programming software.

Project Management

For the construction of a complex pellet plant, process design, equipment manufacturing, precise logistical organization, accurate work, a combined installation team of experienced subcontractors are essential, which our company has retained for decades.

Patents & certifications

In the process of our continuous development, exploration and innovation, relying on our strength, we have more than 30 patent technologies, and all products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

Service You Can Count On

When customers need support, our customer service is the solution.

consultation

We assess our client’s long-term development needs, what the products manufactured by it require, what it intends to manufacture and what quantity it wants to produce.

Design

Advanced design technology combined with years of experience, specialist skills and innovative thinking drives advanced, cost-effective and productive solutions for our customers.

manufacturing

The technological equipment and machines comprising the pellet plant are manufactured by our permanent expert staff in continuous consultation with our engineers.

Installation

We offer a range of start-up field services across a variety of industries to get your new equipment set up and running as quickly as possible. Once installed, we test and analyze key operations to maximize performance.

Industrial maintenance

Regular maintenance achieves a longer service life for investments and maximises production efficiency. We are able to react quickly to problem situations and serve you flexibly with a package tailored to your needs.

Accessories

Your pellet plant equipment will require regular maintenance and wear parts will need to be replaced. We have a large parts inventory so you can rely on us to have in stock what you need and be able to get it to you in a timely manner.