WOOD PELLET EXTRUDER MACHINE

When your operation demands unmatched robustness and reliability, the MZLH350 series wood pellet extruder machine stands as the leading pellet equipment for the global wood pellet production industry. Engineered by RICHI, this wood pellet extruder machine is built for high production performance, delivering the best quality output at the lowest cost per ton.

Model – MZLH350

Capacity – 0.3-0.5T/H

Who Uses Our Wood Pellet Extruder Machine?

From sawmills and furniture plants to large farms and power companies, our wood pellet extruder machine serves a global clientele. If you work with wood, we have a solution for you. No matter your industry, if you have raw material, our wood pellet extruder machine is built for you. We help you transform waste into wealth.

One Machine, Endless Possibilities

Fertilizer Pellets

Cat Litter Pellets

Wood fuel pellets

Ask Us Anything

Your RICHI wood pellet extruder machine creates more than just fuel. Our clients globally produce premium wood pellets for home heating and industrial power plants. They also make specialized absorbent pellets for cat litter and animal bedding. Others produce dense fertilizer pellets for agriculture and gardening. From clean-burning fuel for schools and hospitals to valuable products for the pet and farm industries, your application defines the final product. With our wood pellet extruder machine, you serve diverse global markets with one robust solution.

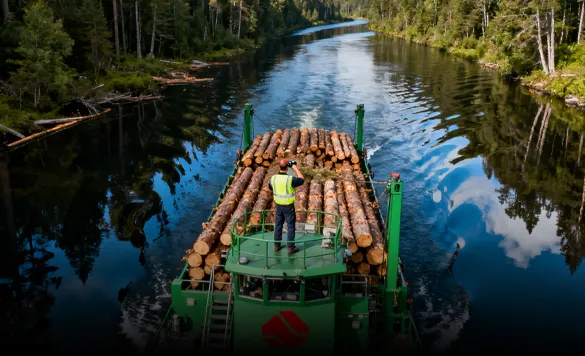

AVAILABLE RAW MATERIALS

Our wood pellet extruder machine is built for versatility. It efficiently processes virtually any wood-based material into high-value fuel. From raw forestry products like logs, stumps, and branches to industrial residues including sawdust, wood chips, and bark. It handles hardwood, softwood, and species like eucalyptus or acacia. It also converts waste streams like used pallets, construction timber, MDF waste, and even furniture factory scraps into consistent, dense pellets. Beyond wood, it processes many agricultural wastes. If you have biomass, our wood pellet extruder machine can turn it into profit.

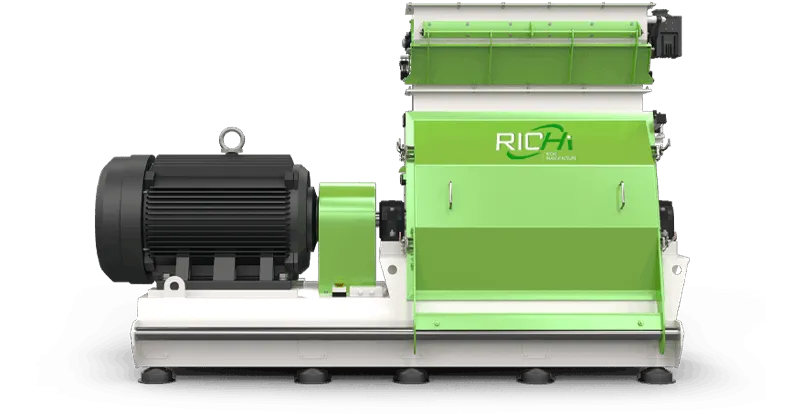

Key Features & Advantages

Our wood pellet extruder machine is built to deliver unmatched reliability and output. It transforms a wide range of raw materials into high-density, premium pellets with the lowest cost per ton, maximizing your profitability from start to finish. Our wood pellet extruder machine is engineered for non-stop performance. It combines a heavy-duty structure with advanced features to deliver the highest quality pellets at the lowest operating cost, guaranteeing your long-term profitability.

Heavy-Duty Gearbox

Designed for 24-hour operation. Provides reliable power transmission, ensuring your wood pellet extruder machine runs without stop.

Compact & Robust Design

Saves floor space while being built to last. This strong structure translates to the lowest maintenance costs over time.

Wear-Resistant Main Shaft

Engineered for durability. Guarantees the production of wood pellets with a smooth, consistent surface for a premium product.

Built-in Cooling System

Features a fan blower to cool the pelletizing area. Ensures continuous high-quality output and protects critical parts.

Siemens Electric Motor

Ensures powerful, reliable, and energy-efficient operation for your wood pellet extruder machine, reducing your power costs.

Anti-Bridging Hopper

Effectively breaks up material in the feed hopper. Eliminates stoppages for true 24/7 operation with less maintenance.

Forced Feeder System

Actively pushes material into the compression zone. Prevents blockages and ensures smooth, continuous high production performance.

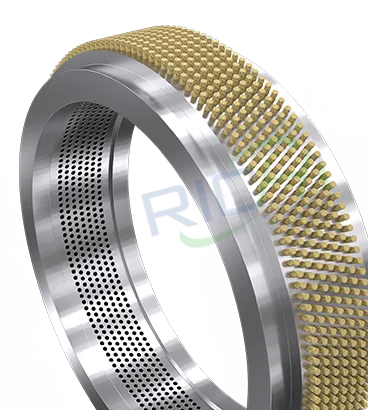

Enhanced Alloy Steel Ring Die

Provides a long service life of 1000-1500 hours. Ensures high capacity with less power and excellent heat dissipation.

WORKING PRINCIPLE

The RICHI wood pellet extruder machine works by forcing material through a hardened ring die. Rollers press biomass against the die, forming dense pellets under high pressure and heat.

Technical Specifications

The MZLH350 wood pellet extruder machine combines robust construction with precision engineering to deliver unmatched reliability. Designed for 24/7 operation, its specifications reflect a focus on high capacity, energy efficiency, and minimal maintenance for the most demanding applications.

MZLH350 Wood Pellet Extruder Machine parameters

Need a different configuration? We can customize this wood pellet extruder machine to match your specific raw materials and production targets.

Capacity:

0.3-0.5 T/H

Main Motor Power:

37 kw

Arch-Breaking Feeder Power:

2.2 kw

Forced Feeder Power:

0.75 kw

Finished Pellet Diameter:

4~12 mm

A Machine for Every Scale

The MZLH350 is just one model in our complete range. We offer a series of robust wood pellet extruder machines with single-unit outputs spanning from 0.2 to 4 tons per hour. Explore five additional models below to find the exact capacity for your operation. For requirements exceeding 4t/h, we provide expert solutions utilizing multiple wood pellet extruder machines for synchronized, high-volume production.

Global Success Stories

From single machines to complete lines, our projects power diverse industries worldwide.

A leading biomass pellet plant uses our wood pellet extruder machine to process 50,000 tons of mixed wood waste annually, powering over 10,000 local homes.

MORERELATED CASES

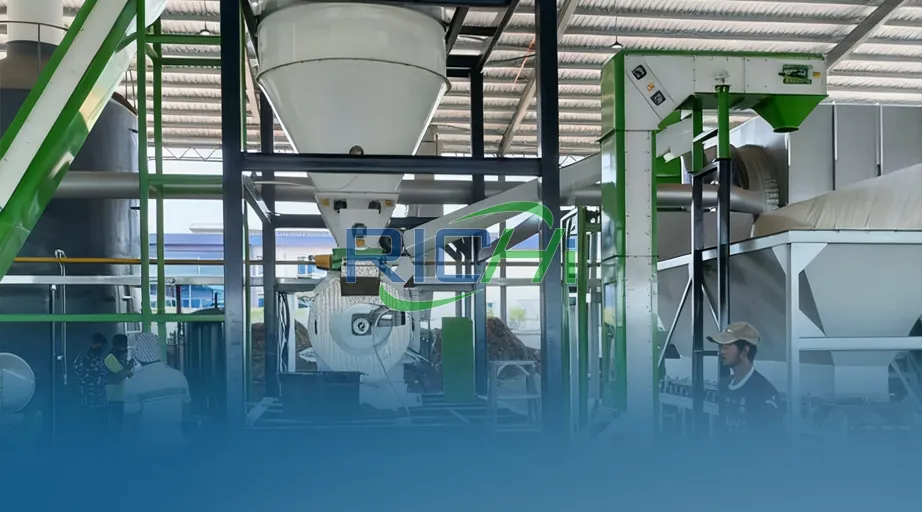

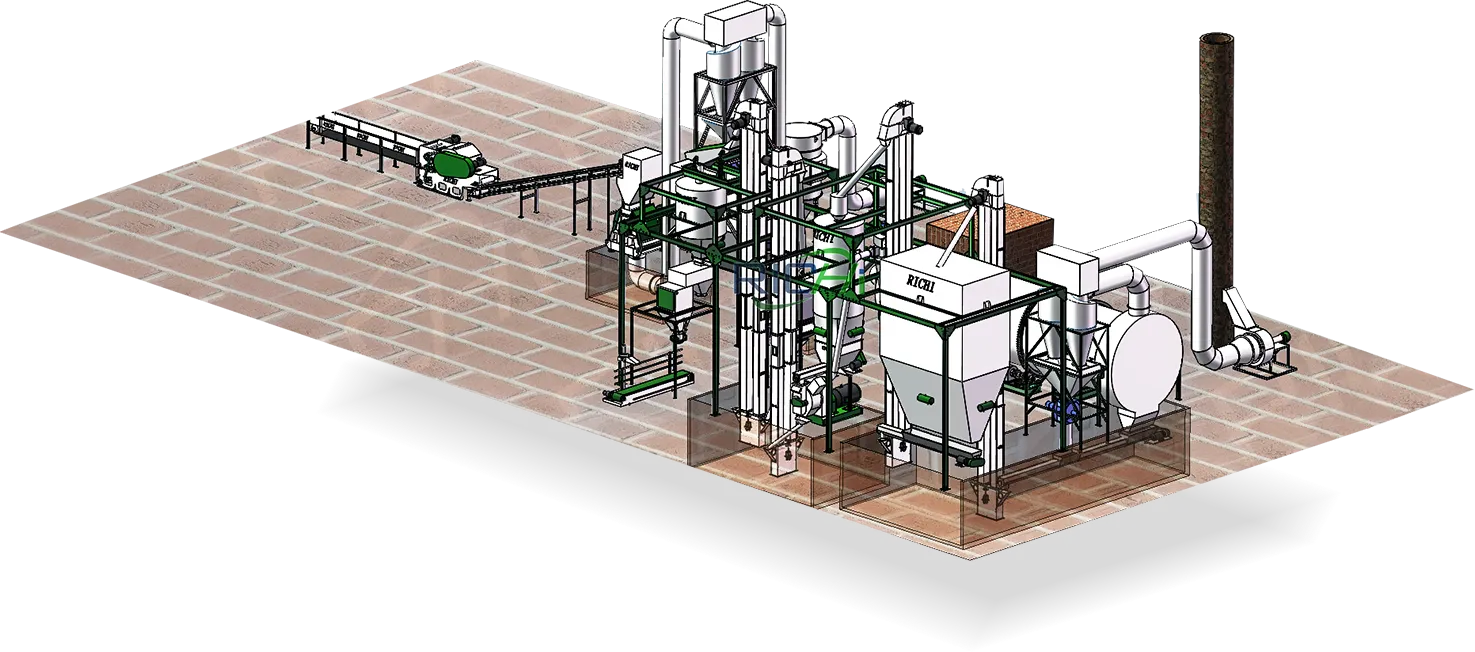

Your Complete Pellet Line, Expertly Engineered

We deliver more than just a wood pellet extruder machine; we provide a fully customized production line. Your process is uniquely designed around your raw material, factory layout, and budget. Based on your needs, we integrate systems for mixing, cleaning, dust removal, and storage. From initial consultation to manufacturing, installation, and lifelong support, we manage your entire project lifecycle.

01.Size Reduction

Large wood waste is chipped and shredded to a uniform size.

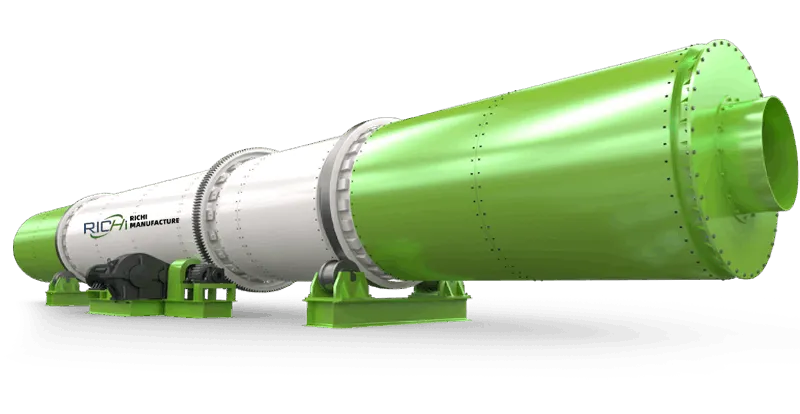

02.Drying Control

Moisture content is precisely adjusted for optimal pelletizing.

03.Pelletizing

The heart of the line—our wood pellet extruder machine forms dense, stable pellets..

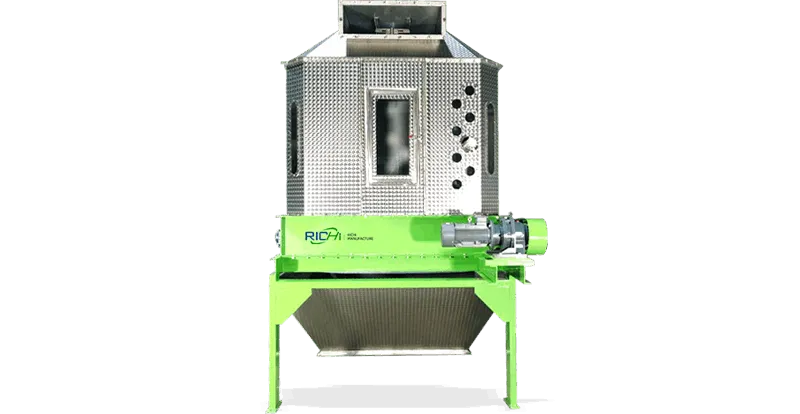

04.Cooling

Pellets are cooled to strengthen and preserve quality.

05.Screening

Fines are removed to ensure a clean, premium final product.

06.Packing

Pellets are automatically weighed and packaged.

Your Single-Source Pellet Plant Partner

A high-performance wood pellet extruder machine is the core of your operation, but it’s only one part of the complete system. We supply and expertly configure the full range of auxiliary equipment—from raw material preparation to final packaging—ensuring every component works in perfect harmony for maximum efficiency.

Frequently Asked Questions

Have questions about our compact wood pellet extruder machine? Find expert answers below on raw material suitability, machine capabilities, and setup for small-scale production.

Can this small wood pellet extruder handle a mix of 50% sawdust and 50% wood shavings from my furniture workshop?

+

Absolutely. Our ring die wood pellet extruder machine is specifically engineered to process mixed biomass materials like your sawdust and wood shavings. The forced feeder system and precisely engineered die holes ensure uniform compression and excellent pellet formation from blended feedstocks. Many of our clients in the furniture industry successfully use this model for similar material combinations.

What’s the estimated wood pellet extruder price for a MZLH model that processes MDF dust and chipboard waste?

+

The wood pellet extruder machine price varies depending on the specific configuration needed for your materials. Processing MDF and chipboard waste may require specific alloy die designs for optimal wear resistance. We provide detailed quotations that include any necessary customizations to ensure your wood pellet extruder production line handles these materials efficiently and reliably.

Prices of different models of wood pellet extruders:

- MZLH320 (22KW) : 0.2-3T/H & 15,000-18,000 $

- MZLH350 (37KW) : 0.3-0.5T/H & 18,000-25,000 $

- MZLH420: (90KW) : 1-1.2T/H & 26,000-32,000 $

- MZLH520 (132KW) : 1.5-2T/H & 43,000-50,000 $

- MZLH678 (200KW) : 2.5-3T/H & 64,000-70,000 $

- MZLH768 (315KW) : 3-4T/H & 75,000-85,000 $

- …

What wood pellet extruder machine projects have you worked on?

+

1. Germany – Small-scale Wood Pellet Extruder Project

Customer Background:

A medium-sized family-owned biomass energy company in Bavaria, Germany. The company focuses on producing clean energy pellets for residential heating. They have been active in renewable energy solutions for 15 years and wanted to expand into higher-quality wood pellet production.

Project Overview:

The customer purchased an MZLH320 wood pellet extruder machine. The system is designed for small-scale production with high efficiency and low energy consumption.

Details:

- Production capacity: 300 kg/h

- Raw materials: Sawdust and wood shavings, particle size <5 mm, moisture 12–15%

- Pellet use: Residential heating and biomass boilers

- Finished pellet size: 6 mm

2. Poland – Medium-scale Pellet Line

Customer Background:

A biomass fuel distributor based in Wielkopolska, Poland, supplying pellets to local households and industrial users. They aimed to diversify their product line with more compact and efficient pellets.

Project Overview:

Purchased an MZLH350 wood pellet extruder machine. The client needed a reliable machine with moderate throughput.

Details:

- Production capacity: 400–500 kg/h

- Raw materials: Pine sawdust, particle size 3–8 mm, moisture 13%

- Pellet use: Home heating and small-scale commercial boilers

- Finished pellet size: 8 mm

3. Sweden – Small Biomass Heating Plant

Customer Background:

A newly established sustainable energy startup in southern Sweden focused on district heating solutions. They wanted to produce premium pellets for local heating networks.

Project Overview:

Installed MZLH320 wood pellet extruder machine to produce consistent quality pellets.

Details:

- Production capacity: 300 kg/h

- Raw materials: Mixed hardwood sawdust, <6 mm, moisture 14%

- Pellet use: District heating

- Finished pellet size: 6–8 mm

4. Brazil – Agroforestry Wood Pellet Plant

Customer Background:

A forestry cooperative in Paraná, Brazil, managing small eucalyptus plantations. They sought to convert residues into high-quality energy pellets for domestic and export markets.

Project Overview:

Adopted MZLH420 wood pellet extruder machine to achieve higher throughput.

Details:

- Production capacity: 1.2 T/h

- Raw materials: Eucalyptus and pine sawdust, 5–10 mm, moisture 12%

- Pellet use: Industrial boilers and small-scale power plants

- Finished pellet size: 8–10 mm

5. Vietnam – Compact Pellet Production

Customer Background:

A small biomass processing enterprise in Ho Chi Minh City, producing pellets for local households and restaurants. The company emphasizes low-emission biomass fuels.

Project Overview:

Installed MZLH350 wood pellet extruder machine for continuous pellet production.

Details:

- Production capacity: 0.4 T/h

- Raw materials: Mixed hardwood and bamboo sawdust, <5 mm, moisture 13–15%

- Pellet use: Cooking and heating

- Finished pellet size: 6 mm

6. India – Rural Energy Pellet Project

Customer Background:

A renewable energy NGO in Uttar Pradesh, India, promoting sustainable biomass fuel for rural households. They wanted a small-scale line to serve local villages.

Project Overview:

Purchased MZLH320 wood pellet extruder machine for pilot production.

Details:

- Production capacity: 0.3 T/h

- Raw materials: Rice husks mixed with hardwood sawdust, particle size <5 mm, moisture 12%

- Pellet use: Household cooking stoves

- Finished pellet size: 6 mm

7. Italy – Furniture Residue Pellet Line

Customer Background:

A furniture manufacturer in Tuscany, Italy, looking to utilize sawdust waste efficiently and produce pellets for sale to energy plants.

Project Overview:

Purchased MZLH420 wood pellet extruder machine.

Details:

- Production capacity: 1.1 T/h

- Raw materials: Hardwood and softwood sawdust, <8 mm, moisture 13%

- Pellet use: Industrial heating

- Finished pellet size: 8 mm

8. Canada – Small Pellet Plant for Local Market

Customer Background:

A Canadian start-up in Ontario, producing wood pellets for home heating. They focused on environmentally friendly small-scale production.

Project Overview:

Installed MZLH350 wood pellet extruder machine for continuous operation.

Details:

- Production capacity: 0.5 T/h

- Raw materials: Softwood sawdust, 3–6 mm, moisture 12–14%

- Pellet use: Residential heating

- Finished pellet size: 6–8 mm

9. Thailand – Bamboo and Wood Residue Project

Customer Background:

A biomass energy company in northern Thailand specializing in bamboo-based energy products. They wanted to produce high-quality pellets from bamboo waste and wood residues.

Project Overview:

Adopted MZLH420 wood pellet extruder machine for high efficiency.

Details:

- Production capacity: 1.2 T/h

- Raw materials: Bamboo dust and hardwood sawdust, 3–8 mm, moisture 12–15%

- Pellet use: Industrial boilers

- Finished pellet size: 8–10 mm

10. Australia – Rural Energy Project

Customer Background:

A renewable energy cooperative in Queensland, Australia, focused on producing biomass pellets for farms and small communities.

Project Overview:

Installed MZLH350 wood pellet extruder machine.

Details:

- Production capacity: 0.5 T/h

- Raw materials: Pine and eucalyptus sawdust, 4–7 mm, moisture 12%

- Pellet use: Farm heating

- Finished pellet size: 6–8 mm

11. Norway – Small District Heating Line

Customer Background:

A cooperative in Oslo, Norway, focused on producing clean biomass pellets for residential district heating.

Project Overview:

Purchased MZLH320 wood pellet extruder machine.

Details:

- Production capacity: 0.3 T/h

- Raw materials: Pine sawdust, <5 mm, moisture 13%

- Pellet use: Residential district heating

- Finished pellet size: 6 mm

12. South Africa – Agricultural Residue Pellet Plant

Customer Background:

A South African agricultural cooperative in Gauteng, converting forestry and sugarcane residues into biomass pellets.

Project Overview:

Installed MZLH420 wood pellet extruder machine.

Details:

- Production capacity: 1.1 T/h

- Raw materials: Sugarcane bagasse mixed with hardwood sawdust, 4–10 mm, moisture 12–14%

- Pellet use: Industrial boilers

- Finished pellet size: 8 mm

13. Japan – Small-scale Residential Pellets line

Customer Background:

A Japanese eco-startup in Hokkaido, producing pellets for home heating and small biomass stoves.

Project Overview:

Purchased MZLH320 wood pellet extruder machine.

Details:

- Production capacity: 0.3 T/h

- Raw materials: Softwood sawdust, <5 mm, moisture 13%

- Pellet use: Home stoves

- Finished pellet size: 6 mm

14. Mexico – Bamboo Residue Pellet Line

Customer Background:

A Mexican company in Chiapas producing bamboo pellets for both local and regional markets.

Project Overview:

Installed MZLH350 wood pellet extruder machine.

Details:

- Production capacity: 0.5 T/h

- Raw materials: Bamboo shavings, 3–8 mm, moisture 12–15%

- Pellet use: Residential and commercial heating

- Finished pellet size: 8 mm

15. France – Small Pellet Line for Furniture Waste

Customer Background:

A French furniture company in Brittany converting sawdust into high-quality pellets for industrial boilers.

Project Overview:

Purchased MZLH420 wood pellet extruder machine.

Details:

- Production capacity: 1.2 T/h

- Raw materials: Mixed hardwood sawdust, 5–10 mm, moisture 12–14%

- Pellet use: Industrial heating

- Finished pellet size: 8–10 mm

16. UK – Compact Wood Pellet Plant

Customer Background:

A UK renewable energy company in Scotland producing small batches of pellets for households and local businesses.

Project Overview:

Installed MZLH350 wood pellet extruder machine.

Details:

- Production capacity: 0.4 T/h

- Raw materials: Softwood sawdust, <6 mm, moisture 12–13%

- Pellet use: Residential heating

- Finished pellet size: 6–8 mm

17. Russia – Small Pine Pellet Line

Customer Background:

A Russian biomass startup in Siberia producing wood pellets for winter heating in local villages.

Project Overview:

Purchased MZLH350 wood pellet extruder machine.

Details:

- Production capacity: 0.5 T/h

- Raw materials: Pine sawdust, 4–7 mm, moisture 13%

- Pellet use: Home heating

- Finished pellet size: 8 mm

18. Egypt – Agro-forestry Pellet Project

Customer Background:

An Egyptian energy company in Upper Egypt producing pellets from wood and agricultural residues.

Project Overview:

Installed MZLH420 wood pellet extruder machine.

Details:

- Production capacity: 1.1 T/h

- Raw materials: Palm wood residues and sawdust, 4–10 mm, moisture 12–14%

- Pellet use: Industrial biomass boilers

- Finished pellet size: 8–10 mm

19. Indonesia – Bamboo & Wood Pellet Plant

Customer Background:

A biomass company in Java, Indonesia, producing pellets from bamboo and wood residues for local power plants.

Project Overview:

Purchased MZLH420 wood pellet extruder machine.

Details:

- Production capacity: 1.2 T/h

- Raw materials: Bamboo sawdust and hardwood residues, 5–8 mm, moisture 12–15%

- Pellet use: Industrial boilers and power generation

- Finished pellet size: 8–10 mm

20. Turkey – Small Industrial Pellet Line

Customer Background:

A small Turkish biomass producer in Marmara region, specializing in producing pellets for industrial clients and local heating systems.

Project Overview:

Installed MZLH420 wood pellet extruder machine.

Details:

- Finished pellet size: 8 mm

- Production capacity: 1.2 T/h

- Raw materials: Mixed hardwood sawdust, 5–10 mm, moisture 12–14%

- Pellet use: Industrial boilers and commercial heating

21. Chile – Medium Industrial Pellet Plant

Customer Background:

A forestry cooperative in southern Chile, managing pine and eucalyptus plantations. The cooperative converts logging residues into high-quality energy pellets for local industry and export.

Project Overview:

Purchased MZLH520 wood pellet extruder machine to upgrade production and improve pellet quality.

Details:

- Production capacity: 1.8–2.0 T/h

- Raw materials: Pine and eucalyptus sawdust, particle size 6–12 mm, moisture 13%

- Pellet use: Industrial boilers and small-scale power plants

- Finished pellet size: 8–10 mm

22. Argentina – Large Biomass Export Plant

Customer Background:

An agribusiness company in Entre Ríos, Argentina, focusing on agroforestry residues and wood pellets for European export.

Project Overview:

Installed MZLH678 wood pellet extruder machine for high-volume production.

Details:

- Production capacity: 2.8–3.0 T/h

- Raw materials: Hardwood residues, <10 mm, moisture 12%

- Pellet use: Export industrial fuel

- Finished pellet size: 10 mm

23. South Korea – Industrial Heating Pellet Line

Customer Background:

A renewable energy company in Gyeonggi Province, South Korea, producing wood pellets for commercial heating networks.

Project Overview:

Selected MZLH520 wood pellet extruder machine for continuous production.

Details:

- Production capacity: 1.7 T/h

- Raw materials: Mixed hardwood sawdust, 5–8 mm, moisture 12–14%

- Pellet use: Commercial and industrial boilers

- Finished pellet size: 8 mm

24. Morocco – Agroforestry Residue Pellet Plant

Customer Background:

A Moroccan biomass startup in Rabat, utilizing cedar and pine residues to produce energy pellets for local factories.

Project Overview:

Purchased MZLH678 wood pellet extruder machine for higher capacity production.

Details:

- Production capacity: 2.7 T/h

- Raw materials: Cedar and pine sawdust, particle size 6–12 mm, moisture 13%

- Pellet use: Industrial biomass boilers

- Finished pellet size: 10 mm

25. Turkey – High-capacity Pellet Line

Customer Background:

A biomass energy company in Marmara, Turkey, producing pellets for industrial heating and export.

Project Overview:

Installed MZLH768 wood pellet extruder machine to increase throughput.

Details:

- Production capacity: 3.5 T/h

- Raw materials: Mixed hardwood sawdust, 6–12 mm, moisture 12–14%

- Pellet use: Industrial boilers and energy plants

- Finished pellet size: 10–12 mm

26. Kenya – Agroforestry Pellet Plant

Customer Background:

A biomass enterprise in Rift Valley, Kenya, using eucalyptus and acacia residues to produce wood pellets for local industry.

Project Overview:

Purchased MZLH520 wood pellet extruder machine to scale up production.

Details:

- Production capacity: 1.6 T/h

- Raw materials: Eucalyptus and acacia sawdust, 5–8 mm, moisture 12–15%

- Pellet use: Industrial boilers and small power plants

- Finished pellet size: 8 mm

27. Colombia – Bamboo and Hardwood Pellet Line

Customer Background:

A Colombian biomass startup in Antioquia producing pellets from bamboo and hardwood residues for domestic industry.

Project Overview:

Installed MZLH678 wood pellet extruder machine for higher capacity and mixed raw materials.

Details:

- Production capacity: 2.9 T/h

- Raw materials: Bamboo dust and hardwood sawdust, 6–12 mm, moisture 13–15%

- Pellet use: Industrial boilers and commercial heating

- Finished pellet size: 10 mm

28. Philippines – Industrial Pellet Plant

Customer Background:

A Philippine energy company in Luzon, using tropical hardwood residues for pellet production supplying industrial boilers.

Project Overview:

Selected MZLH520 wood pellet extruder machine for moderate-scale production.

Details:

- Production capacity: 1.8 T/h

- Raw materials: Mahogany and mixed hardwood sawdust, 5–10 mm, moisture 13%

- Pellet use: Industrial biomass boilers

- Finished pellet size: 8 mm

29. New Zealand – Large Wood Pellet Plant

Customer Background:

A forestry company in North Island, New Zealand, producing pellets from pine and radiata residues for export.

Project Overview:

Installed MZLH768 wood pellet extruder machine to achieve high-capacity production for export markets.

Details:

- Production capacity: 3.8 T/h

- Raw materials: Pine sawdust, 6–12 mm, moisture 12%

- Pellet use: Export industrial fuel

- Finished pellet size: 10–12 mm

30. Saudi Arabia – Industrial Pellet Plant

Customer Background:

A Saudi biomass energy company in Riyadh producing pellets from imported hardwood residues for factories.

Project Overview:

Purchased MZLH678 wood pellet extruder machine to supply high-quality pellets for industrial clients.

Details:

- Production capacity: 2.6–3.0 T/h

- Raw materials: Hardwood sawdust, 6–10 mm, moisture 12–13%

- Pellet use: Industrial boilers and energy plants

- Finished pellet size: 10 mm

I have old pallets and construction timber. Do I need a separate crusher before your wood pellet extruder machine?

+

Yes, for pallets and construction timber, a crusher or shredder is an essential pre-processing step. The feed material for our wood pellet extruder press must be uniformly sized below 5mm. We can include a suitable wood hammer mill in your complete wood pellet extruder line to prepare these raw materials, ensuring smooth operation and high-quality pellet output.

My main material is logging residues with bark. Will this affect the pellet quality from your biomass wood pellet extruder?

+

Our biomass wood pellet extruder is designed to handle logging residues including bark. The bark’s lignin content can actually act as a natural binder. However, high bark content may require slight adjustments to the moisture content and compression settings. Our engineers will provide specific guidance to optimize your wood pellet extruder system for this feedstock.

Is your China-made wood pellet extruder machine CE certified for export to Europe?

+

Yes, all our wood pellet extruder equipment is fully CE certified, meeting all essential health and safety requirements for the European market. As a leading China wood pellet extruder machine manufacturer, we ensure all our machines, including the small wood pellet extruder machine models, comply with international standards for seamless export and operation.

Can I produce fertilizer pellets from mixed wood waste using this equipment?

+

While our wood pellet extruder machine is primarily for fuel pellets, it can produce biomass-based fertilizer pellets when combined with organic fertilizers. The key is achieving the correct binder-to-fiber ratio. Our technical team can advise on the feasibility and any necessary modifications to the wood pellet extruder production line for your specific fertilizer application.

What is the power consumption of your electric wood pellet extruder for 0.25t/h output?

+

Our high efficiency wood pellet extruder in the 0.2-0.3t/h range typically operates on a 22-30kW motor. The exact power consumption of this electric wood pellet extruder depends on the specific raw material’s hardness and fiber structure. We focus on designing low energy consumption wood pellet extruder models to maximize your profitability.

How does your ring die wood pellet extruder handle different materials like hardwood and softwood mixtures?

+

The ring die wood pellet extruder excels with mixed hardwoods and softwoods. The robust gearbox and roller assembly maintain consistent pressure through varying material densities. We select the optimal die compression ratio and roller gap settings for your specific mixture, ensuring this industrial wood pellet extruder delivers consistent pellet density and quality.

Do you offer a complete wood pellet extruder line including a hammer mill and cooler for this capacity?

+

Yes, Richi Machinery specializes in complete wood pellet extruder plant solutions. For a 0.2-0.3t/h output, we can supply an integrated system including a hammer mill, dryer (if needed), the pellet extruder with built-in cooling, and packaging equipment. This comprehensive wood pellet extruder line ensures optimal performance from raw material to finished product.

What’s the minimum workshop size needed for this small wood pellet extruder machine and auxiliary equipment?

+

A space of approximately 8m x 5m is typically sufficient for the small wood pellet extruder machine and essential auxiliary equipment. However, as a professional wood pellet extruder supplier, we provide customized layout drawings based on your specific equipment selection and workflow to maximize space efficiency in your facility.

Can your extruder process wet materials like fresh wood chips without a dryer?

+

No, the wood pellet extruder machine requires material moisture content between 12-20% for optimal pelletizing. Fresh wood chips typically contain 40-50% moisture and would require drying first. We can include an appropriate wood chip dryer in your wood pellet extruder system configuration to properly condition your raw materials.

How long does delivery take for a wood pellet extruder from your China factory to Indonesia?

+

Delivery for a standard wood pellet extruder machine to Indonesia typically takes 25-35 days after order confirmation. As an experienced China wood pellet extruder machine supplier for Southeast Asian markets, we have established reliable shipping routes to ensure timely delivery of your pellet production equipment.

Is professional installation included when I buy a wood pellet extruder plant from you?

+

Yes, Richi Machinery includes professional installation and commissioning services with every wood pellet extruder plant purchase. Our experienced engineers will travel to your site to supervise installation, conduct operator training, and ensure your wood pellet extruder production line starts up smoothly and efficiently.

Can this machine produce both 6mm and 8mm diameter pellets for different markets?

+

Yes, our ring die wood pellet extruder press can be configured with interchangeable dies to produce both 6mm and 8mm pellets. We can supply multiple dies with your machine, allowing you to switch between pellet sizes to meet different market requirements with the same wood pellet extruder equipment.

Have you ever worked on an 800 kg/h wood pellet extruder line project?

+

Yes, here’s a sample of an 800 kg/h pellet plant project we’ve completed.

The 800kg/h wood pelletizing plant project mainly carries out the processing of biomass fuel. The project purchases equipment such as pulverizers, wood pellet maker machines, packaging machines, and conveyor belts. With the purchased raw materials such as wood chips, branches, bark, straw, and corn husks, the processing of biomass fuels is after crushing, molding, and packaging. The wood pelleting plant project rents a site for production, and the workshop in the site has been built.

- Project output: 800kg/h

- Project investment: 300,000 US dollars

- Working system: The project employs 6 employees, implements 3 shifts, 8 hours per shift, and works 300 days a year.

800 kg/h Wood pellet extruder plant Equipment List

| Section | Equipment | QTY |

|---|---|---|

| Crushing | Wood pellet hammer mill | 2 |

| Pelletizing | MZLH350 wood pellet extruder machine | 2 |

| Packaging | Packing machine | 2 |

| Transport | Belt Conveyor | 2 |

Main buildings of the project

| Building name | Number of layers | Building area (m²) |

|---|---|---|

| Workshop | 1 | 900 |

| Office area | 1 | 300 |

composition of 800 kg/h wood pellet extruder machine plant

- Workshop: The workshop covers an area of about 900 square meters. The workshop is arranged with 2 production lines from north to south. Each line includes a shredder, a molding machine, a packaging machine, and a set of conveyor belts.

- Raw material area: Located on the north side of the workshop, it is mainly used for temporary storage of raw materials such as straw, ginger seedlings, branches, corn husks, etc., covering an area of about 200 square meters.

- Finished product area: Located on the south side of the workshop, it is mainly used for temporary storage of packaged biomass fuel products, covering an area of about 150 square meters.

- Office area: Located on the northeast side of the production workshop, it covers an area of about 300 square meters.

- Water use: The water used in the wood pellet extruder machine project is mainly domestic water, which is provided by the local water supply network. The annual fresh water volume is about 72m³.

- Electricity consumption: The annual electricity consumption of this project is 100,000 kWh, which is provided by the local power supply network. There is a transformer in the factory.

- Heating: The production process of the 800kg/h wood pellet production plant project does not require heating. The project workshop is heated by electric air conditioner. The production process of the project does not require heating; the workshop uses electric air conditioners for heating, and no coal-fired (oil) boilers are built; workers use electric heaters for drinking water, and no coal-fired tea stoves are built.

Process flow of 800 kg/h wood pellet mill plant

01 Crushing

The project purchases materials such as corn husks, straws, ginger seedlings, branches, etc., and puts them into a grinder for crushing until they are granulated. The crushing process is a closed process, and particles will only be produced when the crushing is discharged.

02 Pelleting

The crushed material is sent to the wood pellet extruder machine by the conveyor belt. The conveyor belt is airtight, and the transmission process is an airtight process. The material is compacted by the wood pellet pressing machine, and the finished biomass fuel is obtained after pressing to the corresponding standard.

03 Packing

The finished product is packed by a packing machine.

As a manufacturer focusing on the wood pellet extruder machine, Richi Machinery insists on summarizing and summarizing the details of pellet equipment manufacturing process, product improvement, on-site process layout, etc., digging deep into customer needs in multiple forms, and always taking technological innovation as the main driver We strive to do a good job in products and services, and continuously improve our production capacity and market influence.

What’s the typical lifespan of the ring die in your wood pellet extruder press?

+

The ring die lifespan in our wood pellet extruder machine varies based on material abrasiveness and maintenance, but typically ranges from 800 to 1,500 operating hours. Using hardened alloy steel and specialized heat treatment, our dies offer extended service life, reducing your long-term operating costs for the wood pellet extruder production line.

Do you provide videos of your wood pellet extruder machine processing furniture factory waste?

+

Yes, we have multiple videos demonstrating our wood pellet extruder equipment processing various materials including furniture factory waste. Contact our sales team to receive specific video footage showing the complete process from raw material to finished pellets using our industrial wood pellet extruder.

How much noise does your automatic wood pellet extruder produce during operation?

+

Our wood pellet extruder machine operates at approximately 75-80 dB, which is typical for industrial pellet equipment. The machine features a heavy-duty construction that minimizes vibration noise. For installations in noise-sensitive areas, we can recommend additional sound-proofing solutions for your wood pellet extruder system.

Can your system handle materials with nails or stones from reclaimed timber?

+

While our wood pellet extruder equipment is robust, metals and stones can cause severe damage. We strongly recommend using a magnetic separator and screening system before the pellet extruder when processing reclaimed timber. We can include these protective devices in your complete wood pellet extruder line to prevent damage to the die and rollers.

What’s the cost difference between your electric wood pellet extruder and diesel models?

+

The electric wood pellet extruder typically has a lower initial cost compared to diesel-powered versions of equivalent capacity. However, operational costs depend heavily on your local electricity and diesel fuel prices. As your wood pellet extruder supplier, we can help analyze the total cost of ownership for both options based on your specific situation.

How often does the roller assembly need replacement in your wood pellet extruder equipment?

+

The roller assembly in our wood pellet extruder machine typically lasts 400-800 hours depending on material abrasiveness. Our rollers feature replaceable shells, which significantly reduces maintenance costs. Regular lubrication and proper adjustment extend service life in this critical component of the wood pellet extruder press.

Do you have clients using your 0.3t/h wood pellet extruder for bamboo pellet production?

+

Yes, we have several clients successfully using our wood pellet extruder machine for bamboo pellet production. Bamboo’s unique fiber structure requires specific compression settings, which our engineers can optimize. The ring die wood pellet extruder handles bamboo efficiently, producing high-density pellets suitable for both fuel and animal bedding applications.

What moisture content is ideal for pine wood shavings in your pellet extruder?

+

For pine wood shavings, the ideal moisture content for our wood pellet extruder machine is between 12-15%. This range allows the natural lignins to activate properly as binders while ensuring the pellets maintain structural integrity after compression in the wood pellet extruder press.

Can I get a wood pellet extruder machine that includes dust collection systems?

+

Absolutely. We can integrate efficient dust collection systems into your wood pellet extruder plant design. Proper dust control is essential for both operational safety and product quality. Our engineers will specify the appropriate dust collection solution based on your specific wood pellet extruder line configuration and local regulations.

How does your horizontal wood pellet extruder compare to vertical models for mixed biomass?

+

Our horizontal wood pellet extruder machine offers significant advantages for mixed biomass materials. The gravity-assisted feeding system provides more consistent material flow to the die, while the robust gearbox handles varying material densities more effectively than typical vertical designs. This results in higher stability and production efficiency for your wood pellet extruder system.

What’s your warranty policy for the wood pellet extruder machine’s main components?

+

Richi Machinery provides a comprehensive 12-month warranty for the main components of our wood pellet extruder equipment, including the gearbox, main shaft, and bearing assembly. The ring die and rollers are covered under a 6-month warranty against manufacturing defects. As a reliable wood pellet extruder manufacturer, we also provide lifelong technical support and readily available spare parts.

How does a wood pellet extruder machine work?

+

The crushed wood material is transported to the feed port manually or by a transmission mechanism, and then transported to the sprinkling nozzle through the feeding screw rod. The sprinkling nozzle rotates at the same speed as the pressure roller, and the wood waste material is under the action of centrifugal force. The bottom is thrown and distributed to the inner wall of the ring die cavity.

The pressure roller starts to squeeze the material, and the loose material starts to become compact. The material enters the pressure-holding straight hole through the funnel-shaped material guide hole, and the air between the materials is gradually discharged, and plastic flow and extension begin to occur under huge pressure, the materials become more and more compact.

The lignin in the material begins to soften under the high temperature generated by friction, and works together with the cellulose to gradually bond the material together, and finally solidifies and forms.

The longer the material stays in the pressure-holding straight hole, the denser and more stable the structure will be, and finally it will be discharged from the die hole through the decompression discharge hole, and cut into the required length by a knife.

From customized non-standard models to multi-combination standard models, Richi Machinery not only focus on wood pellet extruder machine for sale, but always in accordance with market trends and customer needs, constantly seeking changes and improving, timely innovation, and adjusting according to customers’ actual processes.

What raw materials can the wood pellet extruder machine process?

+

Our ring die wood pellet extruder machine is engineered for exceptional material versatility across the wood processing industry. It efficiently processes a comprehensive range of raw materials, which can be broadly categorized as follows:

- Primary Wood Products: This includes all forms of timber such as tree trunks, tree stumps, and full-length logs.

- Forestry By-Products: We can effectively utilize all logging residues, forest thinnings, tree branches, and wood bark.

- Wood Processing Mill Residues: The machine is ideal for sawmill by-products like sawdust, wood chips, and wood shavings, as well as materials from board plants such as MDF and chipboard waste.

- Post-Consumer & Reclaimed Wood: Our extruder handles challenging materials including construction waste wood, reclaimed timber, pallet wood, and port or wharf timber.

- Specific Wood Species: It works excellently with various species including hardwood (oak, maple, birch), softwood (pine, fir, spruce), and fast-growing types like rubber wood, eucalyptus, acacia, poplar, and willow. Fruit tree wood and processed driftwood are also suitable.

The key to processing this diverse range in our wood pellet extruder machine lies in proper material preparation—primarily achieving a uniform particle size below 5mm and controlling moisture content between 12-15%. For larger pieces like logs, stumps, or pallets, we integrate crushers and shredders into the complete wood pellet extruder line to prepare the feedstock.

This demonstrates the core advantage of our system: we don’t just sell a machine; we provide a customized solution tailored to transform your specific raw materials into high-value pellets.

What is the compression ratio of a wood pellet extruder machine?

+

The compression ratio is a fundamental engineering parameter in a ring die wood pellet extruder machine, specifically referring to the ratio of the ring die’s effective thickness to the diameter of its die holes. This critical design element directly determines the compression force and residence time of the biomass material inside the die channels, ultimately defining pellet density, durability, and overall production quality.

As the most vital and easily worn component, the ring die’s quality and its correctly specified compression ratio are what separate amateur equipment from professional-grade wood pellet extruder equipment. There is no universal compression ratio that works for all materials. The optimal ratio must be carefully selected based on the specific raw material’s fiber structure, lignin content, and the desired pellet quality.

Our extensive experience at Richi Machinery has allowed us to build a comprehensive database of material-specific compression profiles. For instance:

- Dense hardwoods like Mahogany perform best with a ratio of 1:4 to 1:4.5.

- Softwoods like Pine, with higher natural lignin, require greater compression, around 1:5 to 1:6.

- Fibrous agricultural wastes like Grass demand a very high ratio of 1:9 to 1:10 to form stable pellets.

Crucially, these figures are a starting point. We firmly believe that the final compression ratio for any wood pellet extruder machine must be validated through real-world testing with your exact feedstock. This is where our expertise shines.

Our engineers don’t just sell you a machine; we conduct material tests and customize the ring die specification to ensure your wood pellet extruder press delivers the highest output and the most durable pellets at the lowest operational cost. This commitment to custom engineering, not just off-the-shelf solutions, is why clients globally trust Richi Machinery as a professional wood pellet extruder manufacturer.

Are you looking for a wood pellet extruder machine optimized for your specific material? Contact Richi Machinery for a detailed consultation and material test analysis.

What other wood pellet extruder machine models do you offer besides the MZLH350?

+

Beyond the MZLH350, Richi Machinery provides a comprehensive range of industrial ring die wood pellet extruder machines designed to meet any production scale. Our full series, from compact to heavy-duty models, maintains the same commitment to robustness, high output, and the lowest operating cost per ton that defines our brand.

Here is our complete lineup of wood pellet extruder equipment:

1. MZLH320 Wood Pellet Extruder Machine

A proven and reliable entry-level model, the MZLH320 is a robust and easy-to-maintain biomass pellet mill. It’s engineered for small to medium-sized operations requiring high performance and low operating costs.

- Capacity: 0.2-0.3 T/H

- Main Motor Power: 22 KW

- Ring Die Inner Diameter: 320 mm

- Pellet Size: 4-12 mm

2. MZLH350 Wood Pellet Extruder Machine

This model builds on the MZLH320 with increased power and output, serving as a leading solution for the global wood pellet production industry where a balance of footprint and capacity is key.

- Capacity: 0.3-0.5 T/H

- Main Motor Power: 37 KW

- Ring Die Inner Diameter: 350 mm

- Pellet Size: 4-12 mm

3. MZLH420 Wood Pellet Extruder Machine

With a unique design proven on hundreds of machines worldwide, the MZLH420 offers a significant step up in output. It is a robust, high-capacity mill known for its reliability and ease of maintenance.

- Capacity: 1.0-1.2 T/H

- Main Motor Power: 90 KW

- Ring Die Inner Diameter: 420 mm

- Pellet Size: 4-12 mm

4. MZLH520 Wood Pellet Extruder Machine

Featuring a rugged design and a dual-reduction drive gearbox, the MZLH520 performs reliably under the most challenging conditions. It is engineered to deliver higher performance at the industry’s lowest operating costs for medium-to-large-scale production.

- Capacity: 1.5-2.0 T/H

- Main Motor Power: 132 KW

- Ring Die Inner Diameter: 520 mm

- Pellet Size: 4-12 mm

5. MZLH678 Wood Pellet Extruder Machine

This model represents the shift into high-volume production. With increased power and a larger ring die, the MZLH678 is built for continuous, heavy-duty operation, delivering exceptional output for large-scale pellet plants.

- Capacity: 2.5-3.0 T/H

- Main Motor Power: 185 KW

- Ring Die Inner Diameter: 673 mm

- Pellet Size: 4-12 mm

6. MZLH768 Wood Pellet Extruder Machine

As our top-tier model, the gear-driven MZLH768 is made for the most demanding high-capacity tasks. It runs smoother and quieter while experiencing less wear, producing pellets at the absolute minimum cost per ton for maximum profitability.

- Capacity: 3.0-4.0 T/H

- Main Motor Power: 250 KW

- Ring Die Inner Diameter: 762 mm

- Pellet Size: 4-12 mm

Every model in the RICHI wood pellet extruder machine series is designed for versatility across all biomass materials and backed by our engineering team’s expertise in customizing solutions for your specific raw material and production goals.

How to Start Your Own Wood Pellet Extrusion Plant & Customize Your Processing System?

+

Starting a successful wood pellet extrusion plant requires careful planning, the right equipment selection, and expert guidance. At RICHI Machinery, we don’t just sell a wood pellet extruder machine; we partner with you to design, build, and optimize a complete production line tailored to your specific raw materials and output goals.

Our Step-by-Step Process for Your Custom Wood Pellet Plant:

- In-Depth Consultation & Material Analysis: We begin by analyzing your specific raw materials—whether logs, sawdust, wood chips, or blended biomass—to determine their moisture content, fiber structure, and unique pelleting characteristics. This critical first step ensures the entire system is designed for your exact feedstock.

- Customized Process Design & Layout: Our engineers create a comprehensive plant layout and process flow that maximizes efficiency in your available space. We design the material flow from raw intake to finished pellets, ensuring smooth operation and worker safety.

- Precise Equipment Selection & Configuration: Based on your material analysis and production targets, we select and configure each component. This includes choosing the optimal ring die wood pellet extruder machine model with the correct compression ratio, plus all auxiliary equipment for a seamless production line.

- Professional Installation & Commissioning: Our experienced technicians supervise the installation and conduct thorough commissioning. We ensure every component, from the initial chipper to the final packaging machine, works in perfect harmony with your wood pellet extruder machine.

- Comprehensive Operator Training & Lifelong Support: We provide hands-on training for your operators and maintenance team. Our support continues long after startup with readily available spare parts and technical assistance to maximize your plant’s uptime and profitability.

Standard Wood Pellet Production Process Flow:

- Chipping: Large wood waste, logs, and branches are reduced to uniform chips using our heavy-duty wood chippers.

- Crushing: Wood chips are further pulverized into fine sawdust (typically <5mm) using our high-efficiency hammer mills, preparing the material for optimal pelletizing.

- Drying: The moisture content is precisely adjusted to 12-15% using our rotary or belt dryers, which is critical for achieving high-quality pellet formation in the wood pellet extruder machine.

- Pelletizing: This is the heart of the process where your prepared material is transformed. Our ring die wood pellet extruder machine applies extreme pressure and heat, activating natural lignins to form dense, durable pellets without chemical binders.

- Cooling: Freshly extruded hot pellets are stabilized and hardened in our counter-flow coolers, making them suitable for storage and transport.

- Screening & Packing: Fines are removed to ensure product quality, and the finished pellets are automatically weighed and packaged for market.

We can also integrate additional systems for mixing, dust removal, and storage based on your specific requirements. From compact 0.3 T/H systems to large-scale 90 T/H plants centered around our robust wood pellet extruder machine, RICHI Machinery provides complete solutions that transform your biomass into profit. Contact us to begin the conversation about your custom wood pellet plant today.

What services do you provide?

+

At Richi Machinery, we provide far more than just a high-quality wood pellet extruder machine. We deliver a comprehensive partnership that supports your investment from initial concept to long-term, profitable operation. Our full spectrum of services is designed to maximize your plant’s uptime, efficiency, and return on investment.

Our Integrated Service Portfolio:

1. Professional Consultation & Custom Plant Design

We begin by analyzing your specific raw materials, production goals, and site conditions. Our engineers then design a complete wood pellet extruder plant layout, selecting the optimal ring die wood pellet extruder machine model and auxiliary equipment tailored for your unique requirements. This ensures a system perfectly configured for your biomass feedstock and output targets.

2. Complete Project Management & Installation

We treat every project as a turnkey solution, managing all stages from equipment manufacturing to installation and commissioning. Our experienced project teams ensure your wood pellet extruder machine and entire production line are installed correctly and operational according to agreed timelines, providing you with a ready-to-produce facility.

3. Comprehensive Operation & Maintenance Support

Understanding that pellet production is a 24/7 operation, we offer extensive support services:

- Technical Assistance: Remote and on-site support to resolve operational issues quickly

- Maintenance Services: Scheduled maintenance and repair services for your wood pellet extruder equipment

- Mechanical Works: Professional servicing of key components like dies and rollers

- Process Optimization: Continuous improvements to maximize your production capacity

4. Professional Staff Training & Development

We conduct comprehensive training programs for your operational team, covering:

- Equipment Operation: Detailed training on operating your wood pellet extruder machine

- Maintenance Best Practices: Proper care and maintenance procedures

- Process Optimization: Techniques to improve production efficiency and pellet quality

- Safety Protocols: Ensuring safe operation of all equipment

5. Continuous Improvement & System Upgrades

Leveraging our extensive experience with hundreds of installations worldwide, we provide:

- System Revamping: Modernization of existing wood pellet extruder plants

- Performance Upgrades: Enhancements to increase production capacity

- Technology Updates: Implementation of latest innovations in pellet production

- Process Optimization: Fine-tuning your operation for maximum profitability

6. Global After-Sales Support Network

With clients in over 120 countries, we maintain a robust support network that ensures:

- Rapid Response: Quick assistance whenever you need it

- Genuine Spare Parts: Immediate access to authentic components

- Technical Expertise: Expert guidance from our specialized engineers

- Lifelong Partnership: Ongoing support throughout your equipment’s lifecycle

Our commitment extends beyond equipment delivery – we become your dedicated partner in operational excellence, ensuring your wood pellet extruder machine and complete production line deliver optimal performance year after year. From 0.3 T/H to 90 T/H capacity plants, we provide the comprehensive support needed to succeed in the competitive biomass pellet industry.

What is the best wood pellet extruder 1t/h for mixed agricultural waste?

+

For consistent 1.0-1.2 ton per hour production using mixed agricultural waste, we recommend the MZLH420 wood pellet extruder machine. Its unique forced feeder system and specially designed ring die handle variable material densities exceptionally well. The machine’s 90KW power plant provides sufficient compression force for challenging materials like straw, husks, and wood mixtures, ensuring stable operation and high pellet quality.

Do you have a wood pellet maker for sale with a 500kg/h capacity?

+

Yes, our MZLH320 model is an ideal wood pellet extruder machine for this production range. This robust and compact machine delivers 300-500kg/h, making it perfect for small to medium-sized operations. It maintains the same heavy-duty construction and precision engineering as our larger models, ensuring high-quality pellet production from various biomass materials at a competitive wood pellet extruder price.

Can your wood pellet extruder 2t/h handle 24/7 continuous operation?

+

Absolutely. The MZLH520 wood pellet extruder machine is specifically engineered for continuous 2t/h production in demanding environments. Featuring a dual-reduction gearbox assembly and advanced cooling systems, this industrial wood pellet extruder maintains stable operation around the clock. Many of our clients operate this model continuously with proper maintenance, achieving the lowest cost per ton in its class.

What makes your wood pellet extruder 3t/h model different from competitors?

+

Our MZLH768 wood pellet extruder machine stands out through its innovative gear-driven design and superior construction. Unlike conventional models, it delivers 3-4t/h with fewer moving parts, resulting in smoother operation, reduced maintenance, and lower energy consumption. The machine’s 762mm ring die and 250KW motor provide exceptional compression force while maintaining industry-leading efficiency for large-scale production.

How do I choose between 500kg/h and 3t/h wood pellet extruder machines?

+

Selection depends on your raw material availability, budget, and business goals. Our 500kg/h MZLH320 wood pellet maker is perfect for startups or specialized applications, while our 3t/h MZLH768 wood pellet extruder machine suits established operations needing high-volume production. Our technical team will analyze your specific requirements and recommend the optimal model, ensuring you get the right capacity wood pellet extruder equipment for your investment.