POULTRY FEED MILL PROJECT

At RICHI, we understand poultry feed production isn’t just about grinding and mixing—it’s about delivering consistent, nutrient-rich feed that optimizes growth and flock health. With hundreds of successful poultry feed mills operating worldwide, we specialize in turnkey solutions tailored to your exact production needs.

Whether you’re producing starter, grower, or layer feed, we design mills that maximize output and minimize downtime. Explore our global poultry feed projects—each engineered to meet regional ingredient variations, strict safety standards, and your profitability goals.

460+

Construction Projects

Three decades of hands-on experience have equipped us to build poultry feed mills that deliver results. From broiler to layer feed production, our 460+ successful installations prove we understand what makes poultry operations profitable.

US$400 million+

Total Sales

That’s the value poultry producers across 120+ countries have put in our equipment. Not just machinery, but complete feed solutions that maximize feed conversion ratios and flock performance season after season.

120+

Covering countries

Whether you’re running an integrated poultry operation in Brazil or a mid-sized feed mill in Vietnam, we’ve been there. Our poultry feed systems are adapted to local ingredients, climate conditions and production needs – because one formula doesn’t fit all in poultry nutrition.

Poultry feed mill projects world wide

We know poultry feed isn’t just about equipment – it’s about creating solutions that help your birds perform better. That’s why every project starts by understanding. With hundreds of successful poultry feed mills under our belt, we’ve seen – and solved – every production challenge imaginable. The projects below show how we’ve helped producers like you optimize their feed operations, reduce waste.

poultry feed mill project report with different Capacity

equipment for poultry feed plant project

Whether producing layer feed, broiler feed, or specialized breeder feed, a comprehensive poultry feed mill project must address three key issues: raw material grinding fineness, mixing uniformity, and pellet durability.

Drawing on 30 years of global project experience, we’ve compiled the essential equipment below. From processing common raw materials like corn and soybean meal to adding specialized premixes, each piece of poultry feed mill equipment directly impacts final feed quality and farming profitability.

Mxing equipment

Crushing equipment

Pelleting equipment

Extrusion equipment

poultry feed mill project videos

The project videos below showcase our proven ability to execute everything from small specialty feed systems to high-volume commercial operations – each one customized to help your poultry perform at their best.

Our approach combines global expertise with local adaptability, ensuring your poultry feed mill is optimized for your specific ingredients, climate conditions, and production goals. Let’s discuss how we can put this experience to work for your operation.

cost to start poultry feed mill project

The total cost of setting up a poultry feed mill project can range from $10,000 to $3 million, depending on factors like production scale, automation level, and storage solutions. The cost of processing poultry pellet feed is higher than that of processing poultry mash feed. The equipment investment for processing poultry premix feed is higher than that for processing poultry compound feed.

To help you estimate your budget, we’ve outlined typical investment ranges for different capacities—from small (1-2 T/H) to large (80-100 T/H)—along with facility needs, timelines, and ROI expectations.

Below is a breakdown of key cost ranges and requirements for various production capacities, allowing you to assess feasibility, space needs, and potential returns based on your project scope.

| Production Scale | Total Power | Project Site Requirements | Production cycle | Installation cycle | Investment Cost(USD) | Profit cycle |

| 1-2T/H | 47-75KW | 300-500m² | 20 Days | 7-15 Days | 10,000-50,000 | 1-3 Year |

| 3-4T/H | 53-165KW | 300-700m² | 20 Days | 15-20Days | 50,000-120,000 | |

| 5-7T/H | 68-259KW | 400-800m² | 20-30 Days | 20-40Days | 70,000-250,000 | |

| 8-10T/H | 125-410KW | 800-2000m² | 30-40 Days | 45-60 Days | 150,000-300,000 | |

| 12-20T/H | 358-620KW | 1500-3000m² | 40-50 Days | 60-90 Days | 250,000-580,000 | |

| 25-40T/H | 545-870KW | 2000-4000m² | 50-60 Days | 90-120Days | 450,000-850,000 | |

| 50-60T/H | 710-1120KW | 3000-5000m² | 60-70 Days | 100-140 Days | 900,000-1,400,000 | |

| 60-80T/H | 815-1370KW | 5000-8000m² | 70-90 Days | 130-160 Days | 1,450,000-1,800,000 | |

| 80-100T/H | 1230-1700KW | 8000-20000m² | 90-120 Days | 160 -190Days | 2,000,000-3,000,000 |

The key to profitability of poultry feed mill project

Using precise nutritional formulas, we reduce the proportion of high-cost raw materials like soybean meal and fish meal. Substitutions (such as miscellaneous meal and amino acid balance) reduce costs by 5-15%, while maintaining feed conversion efficiency.

Utilizing automated crushing, mixing, and pelleting equipment reduces manual labor, reduces energy consumption by 20%, increases production capacity by 30%, and reduces per-ton production costs by over 10%.

A modular design shortens the production cycle. Steam conditioning and expansion processes improve pellet durability (PDI ≥ 95%), reduce transportation losses, and increase customer premiums by 8-12%.

Interested in our projects?

After comprehensive optimization, the payback period for small and medium-sized plants can be controlled within 1.5-3 years. Planning to invest in a poultry feed mill project? Click here to get professional plant construction solutions and start your profitable feed production business!

Custom Poultry Feed Solutions for Maximum Flock Performance

At RICHI, we don’t just build feed mills – we create complete poultry nutrition systems tailored to your specific operation. Whether you’re producing starter feed for chicks, grower rations for broilers, or high-calcium layer diets, our team works closely with you to design solutions that address:

- Your exact production capacity needs

- Optimal feed formulation requirements

- Preferred processing methods (pelleting, crumbling, or mash)

- Unique facility layout constraints

- Future expansion plans

With hands-on experience across every major poultry market, we understand what it takes to build poultry feed mills that deliver consistent quality, improved FCR, and maximum profitability.

DISCOVER MORE

When it comes to building a poultry feed mill, you probably have a lot of questions: investment cost? Energy consumption? How to configure equipment? How to determine the production scale? … Feel free to contact RICHI MACHINERY for service and technical support.

What types of poultry feed mill projects are there? What services do you provide?

+

Currently, the poultry feed mill projects we can undertake and have done include the following categories:

- Chicken feed mill plant project

- Broiler feed mill project

- Hen feed plant project

- Bird food factory project

- Layer feed mill project

- Duck feed mill project

- Goose feed mill project

- Quail feed mill project

- Pigeon feed mill project

- Cattle & Poultry feed plant project

- Aqua Fish & Poultry feed plant project

- Pig & Poultry feed plant project

- Ruminant & Poultry feed plant project

- Livestock & Poultry feed plant project

- …

As the poultry feed industry becomes more prosperous, its trends in scale, automation, and intelligence are becoming more and more obvious. It requires equipment manufacturers to provide more comprehensive and systematic solutions.

RICHI provides comprehensive solutions in factory layout design, engineering design, machinery manufacturing, factory construction and automation control systems.

RICHI adopts advanced design concepts and technologies, has a senior design elite team, a skilled construction team and rich engineering project implementation experience, and has successfully cooperated with well-known manufacturers from various countries.

- Poultry feed mill project investment cost: 10,000-2,800,000 USD

- Business type: new construction, reconstruction, expansion

Advantages of RICHI poultry feed mill project

+

High-quality poultry feed production projects are based on RICHI’s strong technical advantages:

- The poultry feed crusher adopts a multi-cavity patented design and is equipped with a special air net to achieve good crushing fineness and high output. It can also reduce the loss of raw material moisture caused by crushing;

- The conditioner has multiple points of steam inlet, so that the materials are fully in contact with the steam, and the curing effect is good, which promotes animal digestion and absorption;

- The quality of the granulator is better and the efficiency is increased by 15%;

- RICHI’s unique feed quality optimization system can control the moisture content of finished products online in real time, making every drop of water valuable!

- Comprehensive use of three-dimensional digital design: factory layout, equipment layout, precise planning, all in one step! 360° visual design of workshop details completely eliminates design errors!

- Can be equipped with granulator, crusher automatic control system, remote monitoring and alarm, automatic palletizing equipment, etc. to improve production efficiency and reduce labor costs.

How to build a poultry feed mill project?What is the Construction process?

+

Setting up a poultry feed mill project is a complex and important process that requires many steps and considerations.

Generally speaking, the process of building a feed factory includes inspecting the market sales channels to determine the type of feed to be produced; applying for a production license and business license, and completing an environmental impact assessment; designing the production process based on time output and production performance.

And purchasing materials that meet the quality of the feed produced. Feed processing equipment; constructing unit frames and floors; during installation, some machines, various types of silos, pipelines, and supporting pneumatic, steam, and power facilities can be manufactured; general production processes are equipped with PLC automatic batching and automatic control.

Below is a detailed guide on the nine-step process of how to set up a poultry feed plant project.

- Step 1: Determine business goals and product positioning

Before setting up a poultry feed mill project, business goals and product positioning need to be clear. Determine what products the factory produces, what the target market is, and the desired sales volume and profitability. - Step 2: Site Selection and Land Purchase

Site selection is a very important step, taking into account factors such as convenience of factory operations, availability of transportation, energy and labor. At the same time, land of appropriate size needs to be purchased for building the factory. - Step 3: Planning and Design

Plan and design the factory based on business goals and product positioning. Determine the layout of the production line, the selection and investment of equipment, and the architectural and engineering design of the plant. - Step 4: Apply for relevant permits and licenses

Before building a poultry feed mill project, you need to apply for and obtain necessary permits and licenses from relevant government departments, including factory construction licenses, environmental protection licenses, safety production licenses, etc. - Step 5: Equipment Procurement and Installation

Procurement and installation of equipment according to planning and design requirements. The quality and price of the equipment need to be considered and ensure that the equipment can meet the production needs of the factory. - Step 6: Building Construction and Equipment Commissioning

After purchasing the poultry feed equipment, carry out the construction of the factory building and debugging of the equipment. Ensure the safety and stability of factory buildings and equipment, as well as the smooth start of production. - Step 7: Recruit and train staff

Before a factory can start operating, staff needs to be recruited and trained. According to the size and needs of the factory, determine the appropriate number of personnel and positions, and conduct training and skill improvement. - Step 8: Production and Operations

Once everything is ready, production and operations work begins. According to product positioning and business goals, formulate production plans and marketing strategies, and ensure product quality and production efficiency. - Step 9: Monitor and improve

After the poultry feed mill project is established, continuous monitoring and improvement work is required. By monitoring production data, market feedback and customer needs, we continuously optimize the production process and improve product quality.

Setting up a poultry feed mill project is a tedious and complex process that requires considerations and decisions in many aspects, from the determination of business goals to the purchase and installation of factory buildings and equipment.

Only careful planning and orderly implementation can ensure the smooth establishment and operation of the poultry feed factory. At the same time, as the factory operates, continuous monitoring and improvement work is required to adapt to changes in market demand and improve competitiveness.

What is the poultry feed mill project Construction cost?

+

The poultry feed plant project cost generally ranges from US$10,000 to US$ 5 million. The cost of starting a poultry feed production factory is closely related to:

- Production output and degree of automation

- Factory layout design and poultry feed production process flow design

- Cost of raw material and poultry feed machinery

- Cost of labor, etc.

Some projects have large output, but the price is not necessarily high; some projects have small output, but the price is not necessarily low. All project prices are determined by customer needs, program design and equipment configuration. If you have any questions, please contact us for professional technical support!

If you are planning to establish a poultry feed mill project and start your poultry feed processing business, you have to know about the local feed market and also have a clear understanding of how to develop a customized business plan for your feed factory, so that to make the best poultry feed mill project plan with low investment and low production cost.

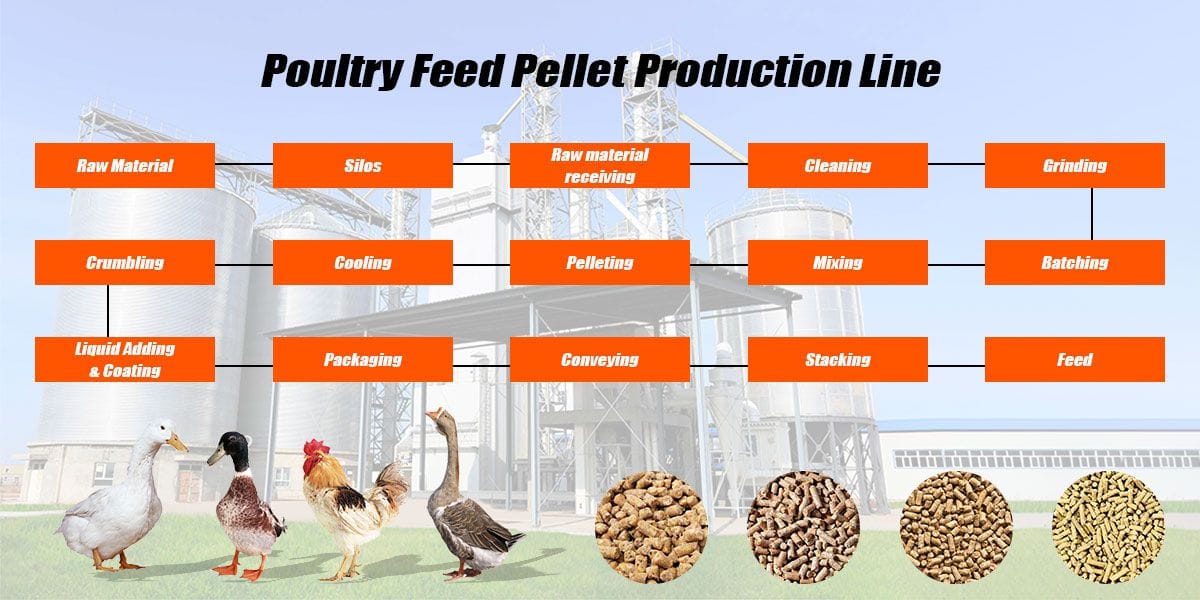

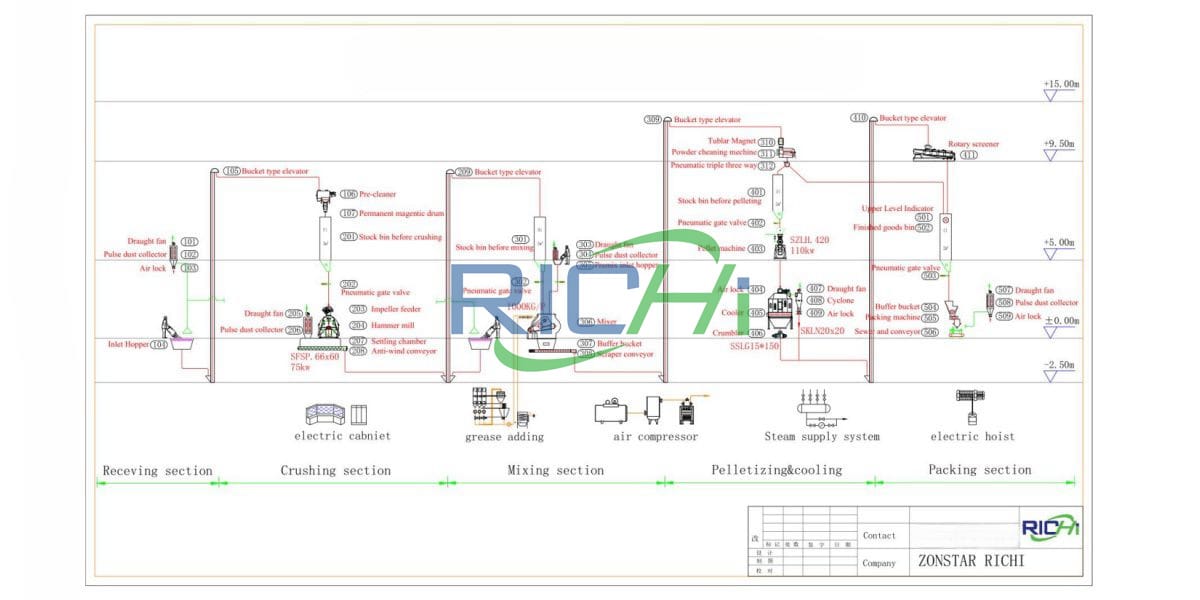

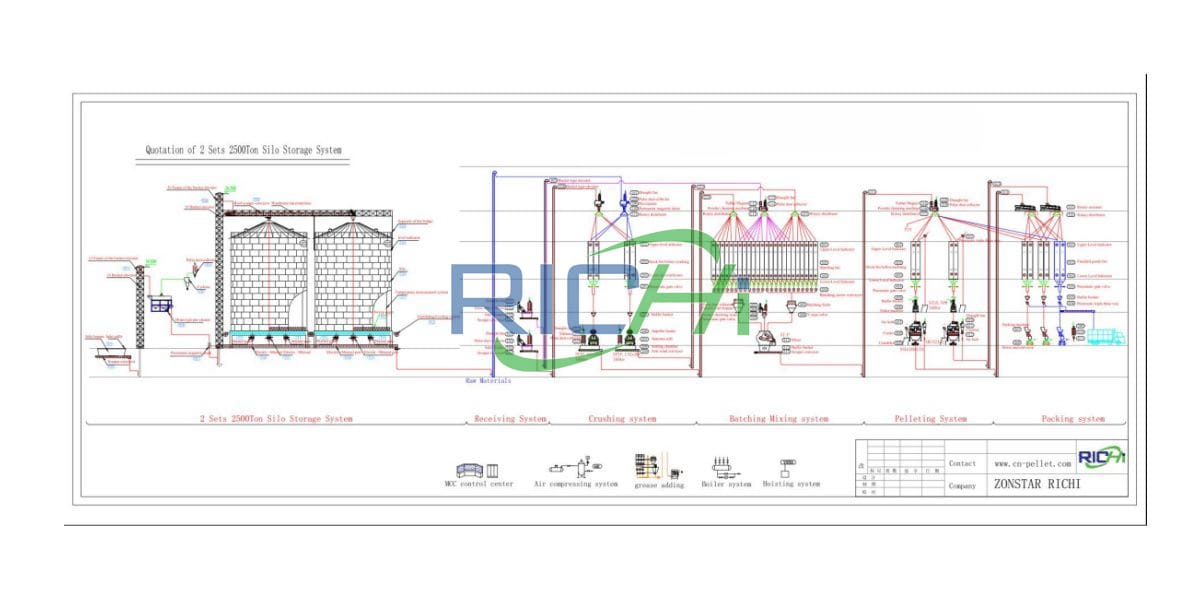

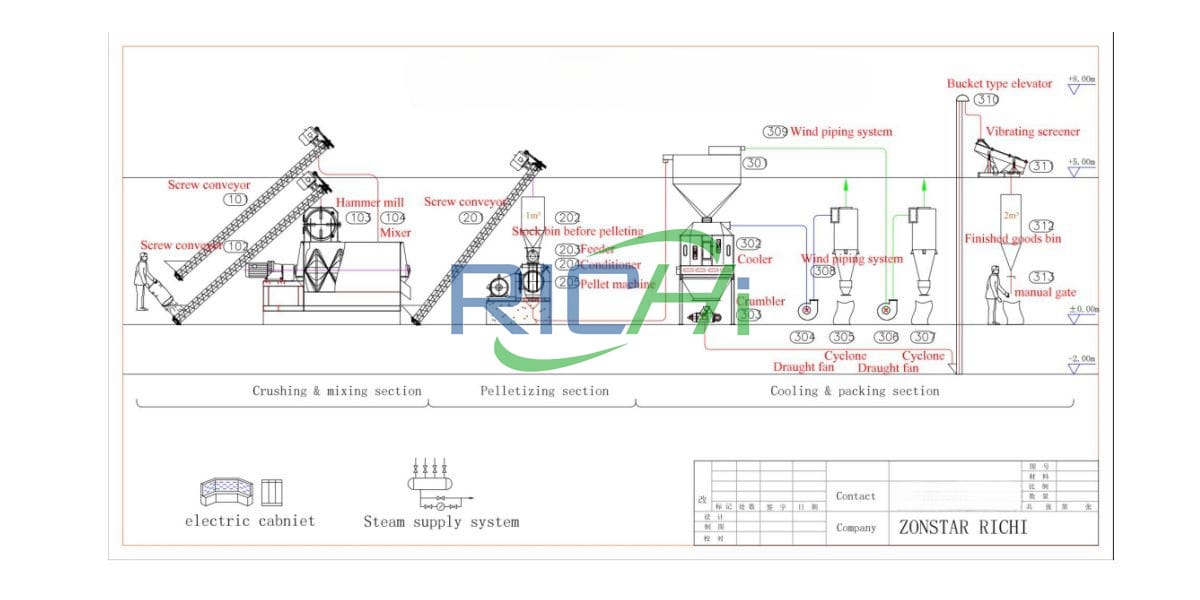

Process flow design of poultry feed mill project

+

Based on the physiological characteristics, nutritional needs and raw material characteristics of poultry, combined with practical experience in engineering construction and production, RICHI provides excellent production technology and engineering design services to the world.

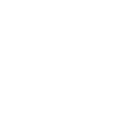

Generally speaking, the standard process flow of a poultry feed production line is: cleaning – crushing – batching – mixing – granulation – cooling – crushing – screening – spraying – packaging. (Even with the same capacity, the final process design and equipment configuration are different depending on the customer’s needs, budget, product type, degree of automation, and equipment configuration level.)

The following is what we provide for different customers Customized process flows for some poultry feed projects designed:

10 t/h chicken feed mill project process design

20 t/h broiler & layer feed mill project process design

50-60 t/h poultry feed pellet plant project process design

1 t/h poultry feed mill project process design

Equipment needed to start poultry feed mill project

+

Whether you are looking for broiler feed making machine, hen feed making machine, duck feed machine, goose feed equipment, pigeon feed equipment, bird feed machine, RICHI can provide you with a series of technical support such as feed mill equipment design, manufacturing, installation, debugging, and training.

poultry Feed Grinder machine

Used in poultry feed materials crushing section.

Capacity:

3-25 T/H

Main Power:

30-160 KW

poultry Feed Mixer machine

Used in poultry feed raw materials mixing section.

Capacity:

250-2000 KG

Main Power:

4-55 KW

poultry feed pellet machine

Used in poultry feed raw materials pelleting section.

Capacity:

1-48 T/H

Main Power:

22-315 KW

poultry Feed Extruder

Used in extruded poultry feed production process.

Capacity:

1-12 T/H

Main Power:

0.75-355 KW

Pellet Cooler Machine

Used in poultry feed pellet cooling section.

Capacity:

3-25 T/H

Main Power:

30-160 KW

vibrating screening machine

Used in poultry feed pellet screening section.

Capacity:

3-20 T/h

Main Power:

1.5-5.5 KW

Automatic Bagging Machine

Used in poultry feed pellet and mash packing section.

Capacity:

6-12 Bags/Min

Main Power:

1.1-5 KW

Professional production technology can ensure the freshness of raw materials and efficient and balanced nutrition; high-performance feed mill equipment and accessories can reduce operating costs of poultry feed mill project, reduce residues and avoid cross-contamination; and excellent control technology can achieve automation, intelligence and traceability of production, ensure feed safety.

Raw material storage design, automatic warehousing of bagged raw materials, automated design of small material systems, automatic control of stand-alone equipment, and the use of automatic packaging and palletizing devices reduce the use of labor.

Highly comprehensive solutions and high-quality equipment that can operate trouble-free for a long time are always our pursuit. Contact Richi Machinery for details!

What featured cases have you worked on?

+

RICHI has won the recognition of customers from many countries around the world with its professional technology and reliable quality. So far, RICHI series products and complete sets of projects have covered all continents around the world.

Complete sets of feed processing equipment are exported to Europe, America, Southeast Asia, the Middle East, Africa and other countries and regions. area.

The following poultry feed plant projects are just simple displays. If you want to know more about our projects, please contact us directly to get project information or solutions for poultry feed mill projects.

poultry feed mill project in Canada

- Output: 3-4T/H

- Feed type: broiler Feed

- Workshop size: 9m*7m*13m

- Main feed mill equipment: 1.37KW ring die chicken feed pellet making machine; 2.37KW chicken food hammer mill machine; 3. 500kg/batch poultry chicken feed mixing machine; 4. SSLG1580 pellet crumbler machine; 5. SKLN1414 Counter-flow Cooler;6.Automatic bagging machine,etc.

- Installation time: 30 Days

- Project price: FOB $60,000

poultry feed plant For Sale Venezuela

- Output: 5T/H

- Feed type: laying hen Feed

- Workshop size: 11m*5m*15m

- Main equipment of the project: 1. feed Hammer mill * 37 kw; 2. feed Mixing machine * 1000kg/batch; 3. Cooling machine* 1.5kw; 4. screen machine*1.5kw, 5.auto packing machine and other subsidiary equipment, It’s one set full automatic contral system.

- Installation time: 25 Days

- Project price: FOB $110,000

poultry feed mill project in Senegal

- Output: 6-8T/H

- Feed type: layer & broiler feed

- Workshop size: 19m*16m*12m

- Main equipment of the project: 1.Feed Grinder*37KW; 2.Feed Mixing Machine*500kg/batch; 3.chicken Feed Pellet Machine*37KW; 4. Cooling Machine*SKLH14*14; 5. Pellet Crumbler*SSLG15*80; 6.Vibrating Screen; 7.Packing Machine

- Installation time: 45 Days

- Project price: FOB $250,000

poultry feed factory project in Kyrgyzstan

- Output: 25T/H

- Feed type: chicken & duck & goose feed

- Project Area: 3120m2

- Main equipment of the project: poultry feed pellet mill machine, Poultry feed grinder, Poultry feed mixer, Pellet cooler, Baler, Manipulator, Natural gas boiler, Oil storage tank, Molasses jar, Filter tank, Weighing tank, etc.

- Installation time: 80 Days

- Project price: 320,000 USD

poultry feed factory project in Ecuador

- Output: 30T/H

- Feed type: chicken & pig feed

- Project Area: 4482m2

- Main equipment of the project: Pulse dust collector, Rotary distributor, 2T/H Boiler, High efficiency mixer, Hammer crusher, Animal feed pellet machine, screw conveyor, Counterflow Cooler, Bucket elevator, Cooling fan, Belt feeding double bucket packaging scale, silo systems, etc.

- Installation time: 4 months

- Project price: 850,000 USD

poultry feed factory project in Morocco

- Output: 5-7T/H

- Feed type: chicken duck bird & livestock cattle sheep feed

- Project Area: 800m2

- Main equipment of the project: poultry feed Crusher, Bucket elevator, Cooler, Animal feed granulator, Silo, Pulse bag dust collector, Bag filter, Cyclone, 2T/H gas boiler, screening machine, automatic packing machine, etc.

- Installation time: 2 months

- Project price: 230,000 USD

poultry feed mill project in Angola

- Output: 15-20 T/H

- Feed type: poultry & fish feed

- Project Area: 1830m2

- Main equipment of the project: Feed grinder, Animal feed pellet machine, poultry Feed mixer, fish Feed dryer machine, Fish feed extruder machine, Pellet cooler, Initial cleaning and screening, Bucket elevator, Packing Machine, Sprayer, Gas boiler (3 t/h), etc.

- Installation time: 4 months

- Project price: 580,000 USD (Without silo)

poultry feed mill project in Côte d’Ivoire

- Output: 8-10T/H

- Feed type: Poultry & stock & sinking fish eed

- Project Area: 2,000m2

- Main equipment of the project: Scraper conveyor, Bucket elevator, Rotating sifter, Micro pulverizer, Hammer mill crusher, Twin-shaft paddle mixer, animal feed pellet press, Counter flow pellet cooler, Rotary grading screen, Packaging scale, Biomass fuel boiler, etc.

- Installation time: 90 Days

- Project price: 330,000 US dollars

poultry feed mill project in Libya

- Output: 1-2T/H

- Feed type: mash feed and pellet feed

- Workshop size: 13m*4m*8m

- Main equipment of the project: 1. Hammer mill feed grinder* 11 kw; 2. Mixer * 250kg/batch; 3. Pellet machine * 22 kw; 4. Cooling machine* 0.93 kw; 5. crumbler machine*5.5kw; 6. screen machine*0.25 kw and other subsidiary equipment, it’s one set full automatic control system.

- Installation time: 15 Days

- Project price: FOB $27,000

poultry feed plant project in russia

- Output: 50 T/H

- Feed type: chicken & duck feed

- Project area: 4600m²

- Main equipment of the project: 3 Grinding lines consisting of 3 sets poultry animal feed hammer mill grinders, Poultry chicken manure grinder machine, 1 feed crumbling line with above double-roller mill, 3 pelleting lines with 4 sets poultry feed pelleting presses, etc.

- Installation time: Total 180 days

- Project price: 2,100,000USD (Turnkey price)

poultry feed factory project in Chile

- Output: 20 T/H

- Feed type: Broiler feed pellets

- Project area: 3762m²

- Main equipment of the project: Corn grinder for chicken broiler feed, ring die chicken animal feed pellet making machine, feed mixer machine for chicken, rotary grading screen, premix mixer, automatic packaging machine, silo systems, etc.

- Installation time: 3 Months

- Project price: 790,000 USD

poultry feed mill project in Tunisia

- Output: 15 T/H

- Feed type: chicken & cattle feed

- Project Area: 5,335m2

- Main equipment: Bag pulse dust removal, Pulse dust collector, Chicken feed grinder, Bucket elevator, Rotary distributor, Automatic batching system, packaging, feed mixer, crumbler, Air compressor, Chicken feed pellet mill, Automatic bag sewing label machine, etc.

- Installation time: 150 Days

- Project price: FOB $ 360,000

We have done hundreds of poultry feed projects so far. If you are interested in our project, or want to customize your own poultry feed mill engineering solution, contact us to get professional technical support and free solution design services!

What raw materials and formulas are the nominal capacity of the production line (such as 10T/H) based on? How big is the difference in actual output between different formulas (such as high-protein poultry feed vs. energy feed)?

+

- The nominal capacity is usually based on a corn-soybean meal basic formula (moisture ≤12%, bulk density 0.6-0.7g/cm³).

- High-fiber formulas (such as 30% bran) may cause a 15-20% drop in capacity, and high-fat formulas (added oil>5%) require an enhanced conditioner.

A raw material adaptability test report is required, focusing on the grinding fineness (such as chicken feed requires a 2.0-3.0mm screen) and the conditioning temperature (85-90℃ is optimal).

What is the power consumption per ton of feed for poultry feed mill projects? Which equipment is the main cause of power consumption (such as crusher vs pelletizer)?

+

Typical poultry animal feed production line power consumption per ton:

- Crushing stage: 18-25kWh/t (depending on the hardness of the raw material)

- Pelletizing stage: 12-18kWh/t (ring die compression ratio 1:8-1:12)

It is recommended to choose variable frequency speed control crusher and high-efficiency permanent magnet electric pelletizer, which can reduce consumption by 10-15%.

What is the design life of wearing parts such as ring die, pressure roller, hammer piece, etc.? Is there a local stock of replacement parts?

+

- Ring die life: Carbon steel material is about 3,000-5,000 tons/die, alloy steel can reach more than 8,000 tons.

- Roller life: usually 50-70% of the ring die (need to be replaced simultaneously).

Require the manufacturer to provide a list of local spare parts and specify the emergency delivery cycle (such as 72 hours of delivery).

How to solve the dust explosion risk in the crushing and feeding process? Does the noise level of the whole line meet the EU (85dB) or OSHA standards?

+

Dust control requires pulse dust collector + explosion-proof motor (concentration <20g/m³), and the investment accounts for about 3-5%.

Key points of noise:

- Add a soundproof cover to the crusher (noise reduction of 10-15dB)

- Pneumatic conveying is replaced by a screw conveyor (from 90dB to 75dB).

How long does it take to switch from broiler feed to laying hen feed (large difference in calcium content)? How to control the residual rate?

+

Quick switching solution:

- The mixer needs to be equipped with a liquid post-spraying system (to reduce heat loss of vitamins)

- Use a double-shaft paddle mixer (residue <0.1%, switching time <5 minutes).

- High calcium formulas require additional anti-arching hoppers.

Can the central control system realize automatic recipe calling and fault alarm? How to connect with MES system?

+

Standard automation package should include:

- PLC automatic batching (error ±0.1%)

- Blockage warning sensor (alarm via SMS/APP)

- Data interface supports OPC UA protocol and can connect to ERP to obtain order data.

Does the manufacturer need to send engineers to install the equipment? How long is the debugging cycle?

+

Usually includes 2 weeks of on-site installation guidance + 1 week of debugging with materials.

Need to confirm:

- Foundation load requirements (such as pelletizers need to bear ≥5t/m²)

- Local power voltage compatibility (such as Africa requires 50Hz/380V adaptation).

Can you provide a ton of feed production cost analysis for similar projects (such as Egypt’s 10T/H poultry feed factory)?

+

Reference data (taking Egypt as an example):

- Ton production cost: $220-260 (including labor $15/ton, electricity consumption $18/ton)

- Payback period: 2.5-3 years (based on local poultry feed profit $50-70/ton).

About RICHI

Since founding in 1995, RICHI MACHINERY has grown to become the world’s leading designer and builder of pellet production line systems. RICHI has delivered over 2000 projects to clients located in more than 140 countries across six continents. Altogether we have over 200 employees, and from start to finish, RICHI can design, manufacture, build and deliver your entire project – there’s no need to manage multiple project partners.

RICHI Technology

Adhering to the R&D tenet of “independent innovation”, Richi Machinery‘s annual R&D investment accounts for more than 3% of total sales. It is supported by CAD, Solidworks and other computer-aided design systems, Ansys, matlab simulation analysis software, and VCC, EasyBuoder8000 and other programming software.

Project Management

For the construction of a complex pellet plant, process design, equipment manufacturing, precise logistical organization, accurate work, a combined installation team of experienced subcontractors are essential, which our company has retained for decades.

Patents & certifications

In the process of our continuous development, exploration and innovation, relying on our strength, we have more than 30 patent technologies, and all products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

Service You Can Count On

When customers need support, our customer service is the solution.

consultation

We assess our client’s long-term development needs, what the products manufactured by it require, what it intends to manufacture and what quantity it wants to produce.

Design

Advanced design technology combined with years of experience, specialist skills and innovative thinking drives advanced, cost-effective and productive solutions for our customers.

manufacturing

The technological equipment and machines comprising the pellet plant are manufactured by our permanent expert staff in continuous consultation with our engineers.

Installation

We offer a range of start-up field services across a variety of industries to get your new equipment set up and running as quickly as possible. Once installed, we test and analyze key operations to maximize performance.

Industrial maintenance

Regular maintenance achieves a longer service life for investments and maximises production efficiency. We are able to react quickly to problem situations and serve you flexibly with a package tailored to your needs.

Accessories

Your pellet plant equipment will require regular maintenance and wear parts will need to be replaced. We have a large parts inventory so you can rely on us to have in stock what you need and be able to get it to you in a timely manner.