FEED PELLET GRANULATOR

Meet the SZLH678 feed pellet granulator – engineered for high-capacity commercial feed milling. This robust ring die pellet mill delivers a consistent output of 30-33 tons per hour, making it the core machine for large-scale production of poultry, cattle, fish, shrimp, livestock, pig, chicken, and sheep feed. Designed for reliability and efficiency, it is the industrial-grade solution to meet your specific operational demands. Explore custom configuration options to tailor this feed pellet granulator precisely to your plant’s needs.

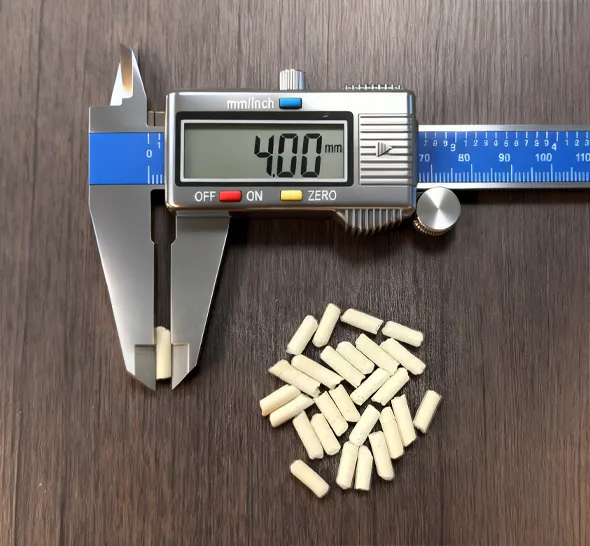

Pellet Size: 2~12mm

Price: $65,000 – $70,000

Model

SZLH678

Production Capacity

30-33T/H

Versatile Applications for Every Feed Type

The SZLH678 feed pellet granulator is engineered to be the central workhorse in modern feed pellet production lines. Its robust ring-die design and powerful processing capability make it perfectly suited for high-output operations within large-scale animal feed mill plants and major integrated farming enterprises. This machine transforms a wide range of raw mash into dense, durable pellets, optimizing nutrition, improving feed conversion rates, and streamlining logistics for bulk buyers and producers.

As a specialized feed equipment manufacturer, we understand that different animal nutrition requires specific pellet formulations and characteristics. The SZLH678 feed pellet granulator excels across the board. To meet these distinct needs, we offer optimized configurations of this premier model, categorizing them primarily by the feed type they are designed to produce most efficiently:

Ideal for producing high-volume feed for chickens, layers, broilers, and turkeys.

Built to create nutrient-dense pellets for cattle, pigs, sheep, and other farm animals.

Engineered for stable, water-resistant pellets for fish, shrimp, and aquatic species.

Tailored Conditioning Technology for Superior Pellets

Beyond feed type classification, the true precision of the SZLH678 feed pellet granulator lies in its conditioning system. As a core manufacturer, we offer this high-capacity machine with three levels of advanced conditioner configurations. Our standard and extended-length, large-diameter conditioners ensure thorough starch gelatinization and uniform liquid blending for optimal pellet durability and digestibility. Each level is designed to unlock specific feed quality and meet distinct customer production goals.

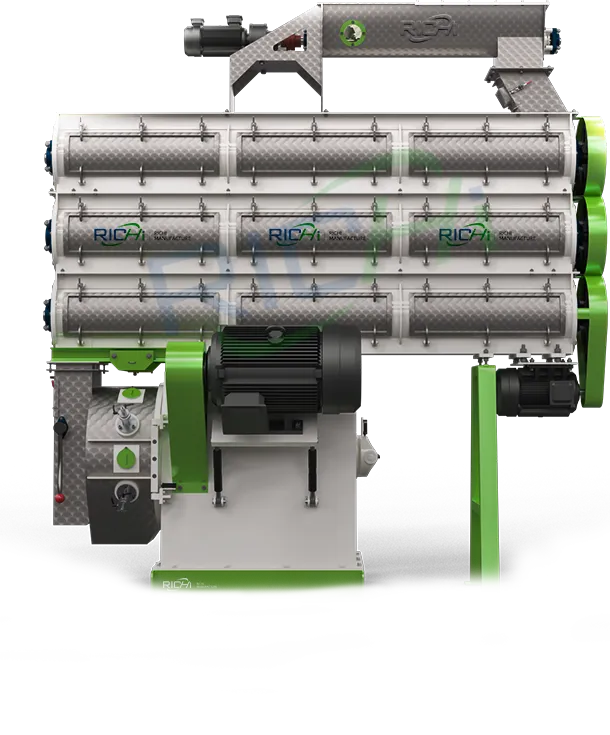

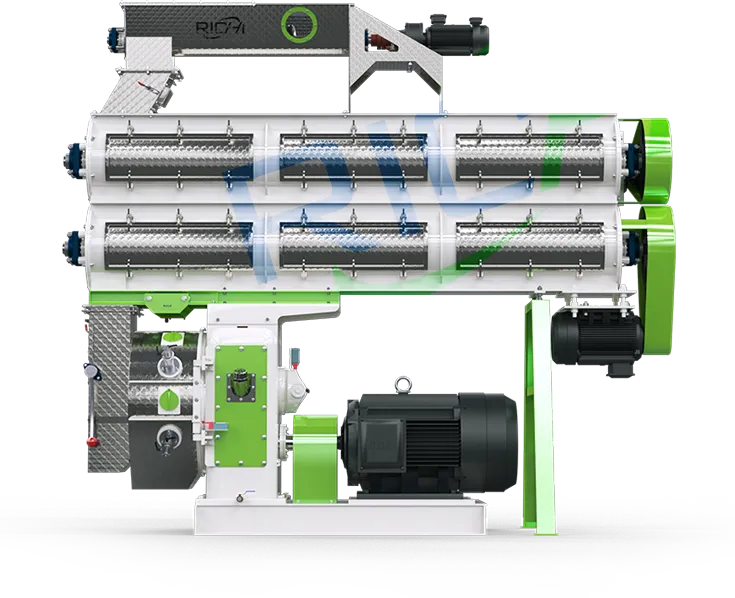

Single-Layer Conditioner feed pellet granulator

This configuration is the industry-standard workhorse. It is ideal for producing common poultry and livestock feed pellets. When equipped with an optional forced feeder, it effectively handles various fibrous feeds containing grass or hay. It is the perfect, cost-efficient choice for feed mills and large farms focused on mainstream animal nutrition.

Double-Layer Conditioner feed pellet granulator

Engineered for higher-grade feed production. The two-stage conditioning process provides superior heat and moisture control. This allows for the production of premium livestock feed and standard sinking fish feed pellets with enhanced stability. It is the recommended solution for producers targeting value-added feed markets and diversified operations.

Triple-Layer Conditioner feed pellet granulator

This is our top-tier configuration for the most demanding applications. The triple-stage, extended conditioning ensures maximum ingredient plasticity and cooking. It is specifically designed to manufacture high-quality, water-stable floating or slow-sinking pellets for shrimp and premium fish feed. This system is essential for specialized aquaculture feed manufacturers.

Broad Raw Material Compatibility

Our SZLH678 feed pellet granulator is built to handle the diverse composition of modern feed formulas. As a leading manufacturer, we engineer our equipment to process a comprehensive range of raw materials, from common grains to specialized additives. This ensures you can produce pellets for any animal nutrition profile. Beyond standard ingredients, the robust design of this feed pellet granulator is also well-suited for integrating processed forms of fresh forages like pasture grass or aquatic plants, as well as fermented silages.

Energy Ingredients

These staples, like corn, wheat, and barley, provide carbohydrates. Our granulator efficiently compacts them into the base of high-energy pellets.

Protein Ingredients

Essential for growth, including soybean meal, fish meal, and rapeseed meal. The machine’s conditioning ensures even distribution and binding within the pellet structure.

Roughages Ingredients

Fibrous materials such as alfalfa, straw, or bran. With optional configurations, our granulator effectively processes these for balanced ruminant and livestock feed.

Feed Additives

Vitamins, minerals, amino acids, and premixes. Precise conditioning in the SZLH678 helps uniformly blend these critical micro-ingredients into every pellet.

See the SZLH678 in Action

Experience the power and reliability of our SZLH678 feed pellet granulator beyond words. The videos below showcase real-world installations and operation across different production environments. These highlights demonstrate the machine’s robust performance in processing various feed formulas with consistent, high-volume output. Witness firsthand how our engineering translates into durable pellets for poultry, livestock, and aquaculture operations worldwide.

Uzbekistan Animal Feed Pelletizing Project

Oman Animal Feed Pelletizing Project

Afghanistan Animal Feed Pelletizing Project

Uganda Animal Feed Pelletizing Project

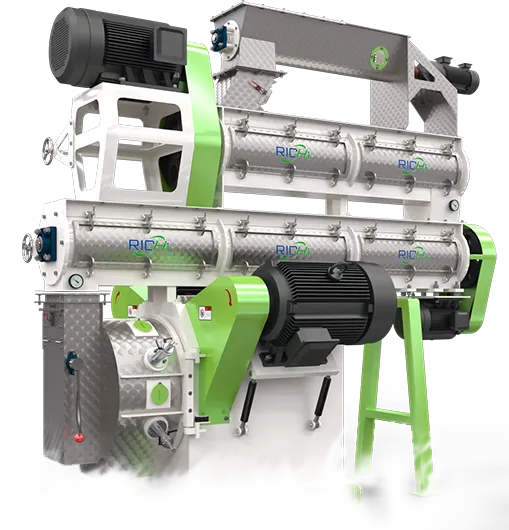

Core Components & Advantages

The superior performance of the SZLH678 feed pellet granulator stems from its meticulously engineered core components. Each part is designed and selected for maximum durability, efficiency, and control, ensuring this machine delivers consistent, high-quality output with minimal downtime. Below, we detail the key structural features that set our granulator apart and demonstrate RICHI’s commitment to manufacturing excellence.

Built for High Output & Lasting Value

The SZLH678 feed pellet granulator is engineered to be more than just machinery; it’s a productivity and profitability solution for large-scale operations. Each advantage is designed to deliver tangible benefits—superior pellet quality, maximized uptime, and a lower total cost of ownership—showcasing our deep expertise as a leading manufacturer.

Superior Conditioning for Unmatched Pellet Integrity

Our integrated, modular conditioning system combines feeding, precise steam infusion, and extended retention in one unit. This advanced design ensures optimal starch gelatinization and liquid absorption for exceptional pellet durability and water stability. The result is superior feed hygiene, faster steam conditioning response, and a significant boost in both pellet quality and overall line productivity.

Engineered for Maximum Operational Efficiency

The SZLH678 is built to sustain its high 30-33 t/h output. Its direct-gear drive transmission eliminates belt slippage, delivering more power with 15% higher efficiency. Components like the forged alloy steel ring die and high-wear resistance rollers are selected for longevity. This robust engineering minimizes unexpected downtime and ensures your production reaches its full profit potential, day after day.

Deep Manufacturer Support & Lifecycle Services

Your investment is protected by our direct factory expertise. Beyond installation, we offer critical support services like professional die refurbishment, which can double your die’s service life at a fraction of the replacement cost. This service helps maintain peak throughput and pellet quality, ensuring you consistently get the most out of your feed pellet granulator for years to come.

Tailored Solutions Through Advanced Customization

We understand that one size does not fit all. The SZLH678 feed pellet granulator can be precisely configured to your needs. This includes customizing the conditioner (single, double, or triple-layer), adapting the feeder for specific raw materials, selecting specialized ring die specifications, and integrating with your existing plant automation. This flexibility ensures the machine perfectly aligns with your specific feed type and production goals.

How It Transforms Mash into Premium Pellets

The exceptional output of the SZLH678 feed pellet granulator is driven by a refined and efficient mechanical process. Our design integrates advanced conditioning with high-pressure extrusion to consistently produce durable, nutritionally optimized feed pellets. Understanding this principle highlights the technical expertise built into every machine we manufacture.

The precision working process of the SZLH678 feed pellet granulator follows three key stages: Advanced Conditioning & Mixing, High-Pressure Extrusion & Forming, Precision Cutting & Discharge. The finished pellets are then discharged, ready for cooling and packaging. This seamless, controlled process is why the SZLH678 feed pellet granulator delivers such consistent quality and high tonnage output for operations worldwide.

Technical Specifications: The SZLH678 in Detail

Review the detailed technical specifications of the SZLH678 feed pellet granulator below. This data sheet provides the precise metrics on power, capacity, and dimensions that define its high-output performance. It confirms why this model is engineered for demanding, large-scale feed mill engineerings.

Have a specific technical requirement? Our team can verify compatibility.

SZLH678 Technical Specification

Main motor power

250kW

Feeder power

1.5kW

Conditioner power

11kW

Ring die inner diameter

673mm

Finished pellet diameter

2-12mm

Expert Process Configurations for Different Feeds

The SZLH678 feed pellet granulator excels across diverse feed types because its operation is optimized for specific nutritional and physical requirements. Our deep manufacturing expertise allows us to provide precise guidelines on throughput, conditioning, and die selection. The parameters below illustrate how this single, versatile machine is expertly configured to produce the ideal pellet for each species.

Chicken Feed Pelletizing Parameters

When configured for poultry, the SZLH678 chicken feed pellet machine achieves its maximum throughput of 23-33 tons per hour. For optimal pellet quality, raw materials should be finely ground to 2.0-3.0mm. A conditioning temperature of around 85-90°C with a 60-120 second retention time is recommended, often using a single or double-layer conditioner. The ring die compression ratio is typically set between 1:10 and 1:13 to form durable 2-4mm diameter pellets, which are then cut to a length of 4-8mm.

Cattle & Sheep Feed Pelletizing Parameters

For ruminant feed, the focus shifts to producing dense, large pellets that withstand rumination. The SZLH678 sheep cattle feed pellet machine is configured for a capacity of 28-38 t/h. Raw materials are coarser (3-5mm), and a shorter conditioning time of 30-60 seconds is typically sufficient. The ring die uses a lower compression ratio (1:6 to 1:9) to create 6-12mm diameter pellets, cut to 12-18mm in length. A single-layer conditioner is commonly used to effectively bind these fibrous formulations.

Pig Feed Pelletizing Parameters

Swine feed production balances nutrition with palatability. The SZLH678 pig feed pellet machine delivers high output of 25-35 t/h for pig feed. Raw materials are finely ground to 2-3mm. Conditioning at 85-90°C for 60-120 seconds with a single or double-layer system ensures optimal starch gelatinization. A moderate ring die compression ratio (1:3.5 to 1:5) is used to produce softer, yet stable, 2-4mm diameter pellets, typically cut to 3-8mm in length.

Sinking Fish Feed Pelletizing Parameters

Producing water-stable sinking pellets requires precise process control. For this application, the SZLH678 fish feed pellet making machine operates at 15-20 t/h. Raw materials must be very fine (1.0-2.0mm). A double or triple-layer conditioner is essential to achieve a longer conditioning time of 90-180 seconds at high temperature and moisture, ensuring binding. A high compression ratio (1:16 to 1:18) is critical to form dense 2-6mm pellets that sink rapidly and maintain integrity in water.

Shrimp Feed Pelletizing Parameters

Shrimp feed represents the pinnacle of aquafeed pelleting technology. The SZLH678 shrimp feed pellet machine is configured for a specialized capacity of 3-5 t/h to produce micro-pellets. Raw material fineness is critical, with 95% passing through an 80-mesh screen. A triple-layer conditioner provides an extended conditioning time of 120-180 seconds. The highest compression ratio (1:20 to 1:25) is used to form extremely dense and water-stable 1.2-2.0mm pellets, cut to 1.8-4mm, which are essential for shrimp feeding.

Our Projects Around the World

Our expertise as a feed equipment manufacturer is proven by our global footprint. We have successfully exported complete animal feed pellet production lines to every continent. These projects showcase our ability to deliver not just a standalone feed pellet granulator, but integrated solutions for diverse companies, farms, and feed mill sizes, processing a vast range of feed types.

feed pellet granulator for sale United States

A large-scale commercial feed mill integrated our high-capacity line to produce premium poultry feed. The system processes corn and soybean meal into uniform 3-5mm pellets for broiler operations.

Feed type: Poultry feed

Pellet size: 3-5mm

feed pellet granulator for sale Russia

Feed type: Pig feed

Pellet size: 2.5-4mm

feed pellet granulator for sale Vietnam

Feed type: Shrimp feed

Pellet size: 1.5-2.0mm

A major integrated aquaculture company chose our triple-layer conditioning system for specialized shrimp feed. The line manufactures micro-pellets from finely ground fishmeal and wheat flour.

feed pellet granulator for sale Colombia

Feed type: Poultry feed (broiler)

Pellet size: 4-5mm

feed pellet granulator for sale Mexico

Feed type: Fish feed (tilapia)

Pellet size: 2-4mm

feed pellet granulator for sale Indonesia

A growing livestock farm invested in our equipment to achieve self-sufficiency in feed production. They now process locally sourced cassava and bran into nutritious 4-6mm pellets for their cattle.

Feed type: Cattle feed

Pellet size: 4-6mm

feed pellet granulator for sale Thailand

Feed type: Livestock feed

Pellet size: 4-10mm

Trusted by Industry Leaders Worldwide

Our partners range from family-owned farms to multinational feed producers. Their trust is built on our commitment to delivering complete, high-performance solutions.

As a professional manufacturer, we provide more than a machine; we deliver a full production ecosystem. From individual feed pellet granulator units to fully automated turnkey lines—including hammer mills, feed mixer machines, coolers, and packaging systems—we engineer solutions that enhance your productivity and product quality. Our team supports you from design and commissioning to after-sales service, ensuring your investment delivers lasting value.

What Our Partners Say

Our reputation is built on tangible results in our clients’ facilities. From technical design to on-site service, our comprehensive approach has earned consistent praise from feed producers worldwide. These testimonials reflect the real-world impact of our reliable machinery and expert collaboration.

Egypt Client

Feed type: Dairy cattle feed

Pellet size: 6-8mm

Operating in a demanding desert environment, we needed a robust line for our dairy cattle operation. RICHI’s team engineered a solution that efficiently processes our local alfalfa and cottonseed meal into highly durable pellets. The consistent quality has significantly improved our herd’s feed intake and milk yield.

Turkey Client

Feed type: Poultry broiler feed

Pellet size: 3-4mm

As a major poultry integrator, uptime is everything. We run two SZLH678 lines 24/7 for broiler feed production. RICHI’s granulator delivers exceptional stability and output. Their engineers’ deep understanding of feed formulation and precise temperature control during conditioning were key to our success.

Iran Client

Feed type: Sheep & goat feed

Pellet size: 4-6mm

Our feed mill specializes in high-fiber sheep and goat feed using local barley straw. RICHI customized the conditioner and die specification to handle this challenging material. The pellets are now perfectly formed, reducing waste and improving our nutritional delivery to flocks.

Philippines Client

Feed type: Sinking fish feed

Pellet size: 2-3mm

Starting our own aquafeed production was a major step. RICHI provided the complete sinking fish feed line, from grinding to packaging. Their triple-layer conditioner and technical training were invaluable in helping us produce stable, water-resistant pellets that our local tilapia farmers trust.

Bangladesh Client

Feed type: Poultry (broiler) feed

Pellet size: 4mm

Space in our urban feed mill is limited. RICHI’s compact yet powerful pellet mill line was the perfect fit. It allows us to produce high-quality broiler feed with excellent pellet durability from a variety of local and imported ingredients, maximizing our production footprint.

Kenya Client

Feed type: Dairy cattle feed

Pellet size: 8-10mm

We supply feed to smallholder dairy farms across the region. Reliability and ease of maintenance were our top priorities. RICHI’s equipment has performed flawlessly, turning our maize and forage mix into uniform pellets. Their local spare parts support gives us complete peace of mind.

Matching Size to Application

The diameter of a feed pellet is not arbitrary; it is a critical design parameter that directly affects animal feed intake, growth performance, and production efficiency. As an experienced manufacturer, we engineer our feed pellet granulator and select the precise ring die specifications to match your target pellet size and species requirement. Below is a guide to the most common pellet diameters and the technical considerations for producing them.

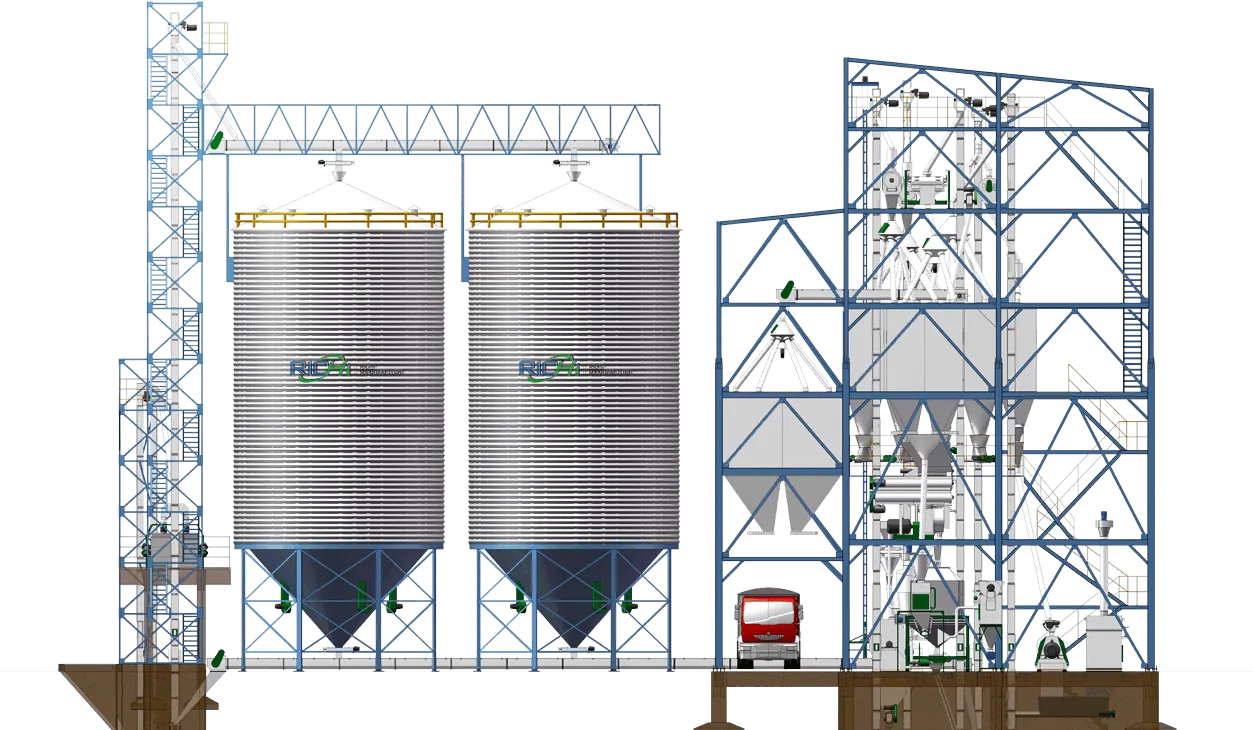

Your Complete Feed Line, Engineered for Your Success

A high-performing feed pellet granulator is the heart of a production line, but its full potential is only unlocked by a perfectly integrated system. We go beyond supplying a single machine; we partner with you to design, engineer, and install a complete, customized feed pellet production line. Every project is unique—varying in raw materials, specific formulas, target pellet size and quality, facility constraints, and investment goals. Our solutions are tailored accordingly. From initial consultation and plant layout to manufacturing, installation, commissioning, and operator training, we provide end-to-end support and lifelong service throughout the entire lifecycle of your equipment.

Silo

Cleaning

Grinding

Mixing

Batching

Pelleting

Cooling

Screening

Packaging

Precision Granulation

This is where

raw, conditioned mash

is transformed into high-value,

commercial feed pellets.

Beyond the Pellet Mill: Your Full-Process Equipment Partner

storage silo equipment

01

cleaning equipment

02

grinding equipment

03

mixing equipment

04

cooling equipment

05

screening equipment

06

packaging equipment

07

A reliable feed pellet granulator is the core of your production, but true efficiency is built on a fully integrated line. As a comprehensive feed machinery manufacturer, we supply all auxiliary equipment required for a complete animal feed processing plant—from raw material intake and storage to the final bagged pellet. Our expertise lies in selecting and configuring the right combination of machines to match your specific process flow and feed type, ensuring seamless operation and maximum return on investment.

We provide the full spectrum of feed processing equipment, including but not limited to: Pre-Processing System, Batching & Mixing System, Conditioning & Pelleting System, Post-Pelleting System, Handling & Automation System. Our engineering team designs the system, ensuring each component—from a simple conveyor to the main mixer—is optimally sized and synchronized for your plant’s capacity and quality goals.

Targeted Solutions for Every Feed Segment

Different animals require distinct nutrition and pellet characteristics. At RICHI, we don’t offer one-size-fits-all lines; we engineer specialized solutions. For each major feed category, we recommend specific feed pellet granulator configurations and tailor the entire process flow—from raw material handling to finished pellet cooling—to maximize nutritional value, production efficiency, and pellet quality.

Feed Pellet Granulator FAQ

We have supplied over a thousand custom feed pellet production lines to clients across six continents. Based on our extensive experience, we have compiled answers to the most common questions our clients have before investing in a ring die feed pellet granulator. This section addresses practical concerns about selection, application, and integration to help you make an informed decision.

What is the price range for a RICHI feed pellet granulator?

+

The feed pellet granulator price varies significantly based on the model’s capacity, motor power, and construction. As a professional manufacturer, we offer a complete range to match different production scales. It is important to understand that the feed pellet granulator cost is an investment that correlates directly with output capability and long-term reliability.

To give you a clear reference, here are the FOB price ranges for some of our core ring die models, which are most commonly used for animal feed production:

- For Small-Scale Farms & Startups:

- SZLH250 Model: With an output of 1-2 tons per hour, the price typically ranges from $6,500 to $9,500.

- SZLH320 Model: With an output of 3-4 tons per hour, the price typically ranges from $14,000 to $19,000.

- For Medium-Sized Feed Mills:

- SZLH350 Model: With an output of 5-6 tons per hour, the price typically ranges from $26,000 to $33,000.

- SZLH420 Model: With an output of 8-12 tons per hour, the price typically ranges from $27,000 to $35,000.

- SZLH508 Model: With an output of 15-16 tons per hour, the price typically ranges from $39,000 to $46,000.

- For Large Commercial Feed Plants:

- SZLH558 Model: With an output of 20-22 tons per hour, the price typically ranges from $47,000 to $54,000.

- SZLH678 Model (Featured on this page): With an output of 30-33 tons per hour, the price typically ranges from $64,000 to $72,000.

- SZLH768 Model: With an output of 38-42 tons per hour, the price typically ranges from $77,000 to $85,000.

The models listed above represent our primary range for standard animal feed production, but they are not our only offerings. The final feed pellet granulator price for your project can be influenced by several customization factors, including the type of conditioner (single, double, or triple-layer), the specification of the ring die and rollers, the choice of motor brand, and the level of automation.

To get an accurate and detailed quotation tailored to your specific raw materials, desired pellet type, and production goals, please contact our sales team with your requirements. We will provide a comprehensive feed pellet granulator cost analysis for the machine and any recommended auxiliary equipment for a complete line.

We are a cattle cooperative in Argentina looking to produce 15 t/h of dairy feed pellets. What model do you recommend, and can it handle a high percentage of local alfalfa?

+

For a 15 t/h output of dairy feed, we recommend the SZLH508 ring die feed pellet granulator. This model provides the ideal balance of power and efficiency for your scale. Handling high-fiber ingredients like alfalfa is a core strength of our design.

We would configure this machine with a heavy-duty, low-compression ring die specifically engineered for fibrous materials, ensuring the formation of dense, durable pellets that withstand handling and promote proper rumination. Our conditioning system can be adjusted to apply optimal steam and retention time to soften the alfalfa, improving pellet binding without compromising nutritional value.

Our feed mill in Nigeria currently produces 8 t/h of poultry feed. We want to upgrade to a 20 t/h line. Can your granulator be integrated with our existing mixers and cooler?

+

Yes, integration with existing equipment is a common and successful part of our project engineering. The SZLH558 model, with a 20-22 t/h capacity, would be the ideal feed pellet granulator for your upgrade. Our technical team would first conduct a detailed assessment of your current mixer’s batch size and cycle time, as well as your pellet cooler machine‘s airflow and capacity.

We then design the interface, which often includes custom conveying solutions and control system modifications, to ensure the new pellet mill works in perfect synchronization with your legacy equipment, maximizing your overall line efficiency without requiring a full plant rebuild.

For a new shrimp feed plant in Ecuador targeting 12 t/h, what is the difference in cost and performance between a standard and a triple-layer conditioner model?

+

For high-value shrimp feed, the conditioning stage is paramount. A standard single-layer conditioner is insufficient for the micro-pellets and ultra-fine powders used in shrimp feed.

A triple-layer conditioner, while representing a higher initial investment, provides vastly superior performance. It ensures precise, multi-stage steam infusion and extended retention time (120-180 seconds), which is non-negotiable for achieving full starch gelatinization and producing pellets with exceptional water stability.

The performance difference translates directly to less fines, better feed conversion ratios, and higher market value for your product. For a 12 t/h shrimp feed line, we would integrate a specialized floating fish feed extruder machine or a high-compression ring die pellet mill for sinking varieties, paired with the triple-layer conditioner.

We are pig farmers in Poland. Is it possible to get one machine that can produce both 3mm grower feed and 8mm sow feed pellets at around 10 t/h, or do we need different dies?

+

Absolutely. A single feed pellet granulator, specifically our SZLH420 model, can efficiently produce both pellet sizes at your target output. The key is having two different ring dies: one with 3mm holes and a standard compression ratio for grower feed, and another with 8mm holes and a lower compression ratio for sow feed.

Our machines feature a quick-release ring die clamping system, allowing for a die change in a matter of hours. The same conditioner and motor are perfectly capable of handling both formulations. We would provide detailed operating parameters for each recipe to ensure optimal pellet quality in both scenarios.

What is the real energy consumption (kWh per ton) for your 25 t/h model when producing standard broiler feed? We need to calculate our operating costs in Vietnam precisely.

+

For our SZLH558 feed pellet granulator producing standard broiler feed (3-4mm pellets), you can expect an average specific energy consumption between 18 and 22 kWh per ton of pellets. This figure is influenced by factors such as the exact formula (fineness of grind, fat content), the conditioning temperature achieved, and the ring die’s condition.

Our direct gear drive system is significantly more efficient than belt-driven systems, contributing directly to these lower operating costs. For a precise calculation for your Vietnam plant, we would need your specific formula details to model the energy requirement accurately.

For a 30 t/h cattle feed project in Texas, USA, what are your standard delivery and commissioning timelines from the port of Qingdao?

+

For a complete 30 t/h line centered on the SZLH678 feed pellet granulator, standard delivery time (FOB Qingdao) is approximately 45-60 working days after order confirmation, depending on the level of customization. Sea freight to the US Gulf Coast typically takes 30-35 days.

Upon arrival, our engineer would travel to your site for commissioning, which generally requires 2-3 weeks for mechanical installation, electrical connection, parameter tuning, and operator training. The entire process from order to operational plant usually takes 4-5 months. We provide a detailed project timeline with each quotation.

Our raw material in Kenya includes a lot of sunflower cake and mill dust. Which ring die compression ratio and pellet mill configuration do you suggest for a 15 t/h line to ensure pellet durability?

+

Sunflower cake and mill dust can be challenging due to lower natural binding properties and varying particle sizes. For a robust 15 t/h line in Kenya, we recommend the SZLH508 feed pellet granulator. We would configure it with a ring die featuring a medium-to-high compression ratio (e.g., 1:10 to 1:12) to create sufficient friction and pressure for binding.

Crucially, we would specify a heavy-duty, extended stainless steel conditioner to allow for thorough steaming and hydration of the mix. Often, adding a small percentage of a natural binder like cassava starch to the formula, combined with this optimized conditioning, will dramatically improve pellet durability from these ingredients.

Do you provide the full CAD layout and electrical schematics for the granulator’s installation in our new factory in Bangladesh? We need it for our local engineering team.

+

Yes. As part of our comprehensive engineering service, we provide complete technical documentation for all major projects. This includes detailed foundation CAD drawings showing load points and bolt positions, overall equipment layout drawings for plant integration, single-line electrical schematics for connection to your power supply, and a full list of recommended cables and breakers.

These documents are essential for your local team in Bangladesh to prepare the site correctly before the machine arrives, ensuring a smooth and fast installation process.

We plan to produce both sinking fish feed (2mm) and floating fish feed (4mm) at a total of 18 t/h in our plant in Egypt. Can one granulator model handle both with quick changeover?

+

For this application in Egypt, you would typically need two different processing lines. Sinking fish feed (2mm) can be efficiently produced with a high-compression ring die feed pellet granulator like our SZLH558 with a double-layer conditioner. However, true floating fish feed (4mm) requires expansion through a single or twin-screw extruder, which is a different technology. We manufacture both types of equipment.

A practical solution is to install a ring die fish feed production line for sinking feed and an extruder line for floating feed. They can share some upstream (grinding, mixing) and downstream (cooling, drying) equipment. True “quick changeover” on a single machine between these fundamentally different pellet types is not feasible.

What certifications (like CE) do your 22 t/h feed pellet granulators have for export to the European Union? We need documentation for customs clearance in Italy.

+

Our SZLH558 (22 t/h) feed pellet granulator is fully CE marked in compliance with the EU Machinery Directive (2006/42/EC). The certification covers all relevant health, safety, and environmental protection requirements.

For export to Italy, we provide the complete CE documentation package, including the Declaration of Conformity, technical construction file, detailed user manuals in English (or other requested languages), and all necessary test reports. This ensures smooth customs clearance and compliance with EU market regulations.

For a 28 t/h broiler feed production in Thailand, what is the recommended spare parts package we should keep on hand to minimize downtime?

+

For your 28 t/h broiler feed operation in Thailand using the SZLH678, we recommend maintaining a critical spare parts inventory. This should include at least one set of press rollers with bearings, a set of main drive gearbox seals and gaskets, a feeder conveyor belt, several conditioner shaft paddles, a supply of die clamping bolts, and a set of V-belts for the conditioner drive (if applicable).

Most importantly, we advise keeping a spare ring die on hand. While our dies have a long life, having a spare allows for immediate changeover when maintenance is due, eliminating production stoppages. We can provide a customized spare parts list based on your specific operating hours.

We have a tight factory space in Chile. What are the floor space requirements for your 10 t/h feed pellet granulator, including the necessary clearance for maintenance?

+

The SZLH420 feed pellet granulator (10 t/h) has a compact footprint. The machine itself requires approximately 3.5m (L) x 2.2m (W). However, for safe operation and maintenance, you should plan for a total area of about 6m x 4m. This space allows for easy access to all sides for daily inspection, ring die removal (which requires space in front of the machine), and access to the gearbox and motor at the rear. We can provide detailed layout drawings to help you optimize your Chile plant’s floor plan, including integrating the necessary feeder above and discharge conveyor below.

Can your 18 t/h machine be configured for a fully automated line with remote monitoring and control? We are building a modern feed mill in Saudi Arabia.

+

Yes, our SZLH508 (18 t/h) feed pellet granulator is designed for integration into fully automated lines, which is ideal for a modern plant in Saudi Arabia. We can equip it with sensors for monitoring bearing temperature, vibration, main motor load (amperage), and conditioner temperature/moisture.

This data can be fed into a central PLC/SCADA system. We can provide the pellet mill with a local control panel that interfaces with your plant-wide automation, allowing for remote start/stop, recipe selection (adjusting feeder speed and conditioner steam), and real-time performance monitoring from a central control room, enabling predictive maintenance.

What is the warranty period and what does it cover for the main gearbox and ring die on your 30-33 t/h model? Do you have local service agents in Mexico?

+

Our standard warranty for the SZLH678 (30-33 t/h) feed pellet granulator is 12 months from the date of commissioning or 18 months from the date of shipment, whichever comes first. This warranty covers defects in material and workmanship for the main gearbox casting and internal gears.

The ring die is covered for 6 months under normal operating conditions against manufacturing defects. We have trusted technical partners and service agents in major industrial regions across Mexico who can provide local support for spare parts and basic troubleshooting. For major issues, our engineers are available for on-site support.

We are new to feed manufacturing in Australia and want to start with a 5-6 t/h line for poultry. Do you offer full operator training on-site after installation?

+

Yes, comprehensive training is a standard part of our commissioning service for all clients, especially those new to feed manufacturing. For your 5-6 t/h poultry line in Australia based on the SZLH350 feed pellet granulator, our commissioning engineer will spend 1-2 weeks on-site after installation.

Training covers safe operation, daily startup/shutdown procedures, routine maintenance (greasing, inspection), how to change the ring die and rollers, basic troubleshooting for common issues, and guidance on optimizing conditioner parameters for your specific recipe. We also provide detailed operation and maintenance manuals.

We run a mid-sized poultry feed pellet granulator line in India but struggle with fines in our broiler feed. What adjustments can be made to our ring die feed pellet granulator to improve pellet durability?

+

Improving pellet durability often centers on conditioning and die specification. First, check that your conditioning achieves a consistent mash temperature of 82-88°C with proper steam saturation; insufficient heat is a common culprit for fines. For your ring die feed pellet granulator, the die itself is critical.

We recommend a die with a balanced compression ratio (typically 1:10 to 1:13 for broiler feed) and ensure the raw mash has a uniform particle size. Our engineers can review your current setup and may suggest a precision-machined ring die from our factory, which often increases pellet durability by over 20% by ensuring consistent pressure and extrusion.

I’m setting up a feed pellet granulator for a cattle ranch in Australia processing native grasses. What’s the most affordable feed pellet granulator that can handle high fiber content at around 5 t/h?

+

For a 5 t/h operation processing fibrous native grasses, our SZLH350 model offers the best value. It’s engineered with a robust gearbox and a heavy-duty design that handles abrasive, high-fiber materials better than lighter machines.

We configure it with a deep-hole, low-compression ring die (around 1:6 to 1:8) specifically for roughage and an extended conditioner to allow more time for steam to penetrate and soften the fibers. This affordable feed pellet granulator provides the necessary strength and features for ranching applications without the cost of an industrial-scale model.

As a feed pellet granulator supplier, what is the key difference between a standard machine and a high efficiency feed pellet granulator in terms of long-term operating costs for a 15 t/h plant?

+

The long-term cost difference is substantial. A standard feed pellet granulator may have a lower purchase price, but a high-efficiency model like our SZLH508 reduces operating costs significantly. The key differences are in the direct gear drive system, which transmits over 98% of motor power compared to belt drive losses, and the use of high-efficiency (IE3/IE4) motors.

This can lower energy consumption by 15-20% per ton. For a 15 t/h plant running 20 hours a day, this saves thousands of dollars annually in electricity. Additionally, high-efficiency models use premium bearings and sealing systems, reducing maintenance frequency and downtime, which is a major hidden cost.

Our organic chicken farm in France needs a complete feed pellet granulator system that can process high-moisture grains. Do you offer a feed pellet granulator with steam injection that’s suitable for organic feed production?

+

Absolutely. For organic production in France, we provide complete systems with food-grade stainless steel contact parts in the conditioner and feeder to meet hygiene standards. Our feed pellet granulator with precise steam injection is ideal for high-moisture grains.

The system uses indirect steam heating in the conditioner to gently raise the temperature without adding moisture directly, which is crucial for controlling the consistency of organic mash. We can integrate a dryer post-pelleting if needed. The entire line can be certified for organic processing, ensuring no cross-contamination.

For a new shrimp feed pellet granulator line in Vietnam targeting 8 t/h, is it better to invest in a dedicated machine or a commercial feed pellet granulator that can also make poultry feed?

+

For 8 t/h of shrimp feed, a dedicated system is strongly recommended. Shrimp feed requires ultra-fine grinding, multi-stage conditioning, and very high die compression ratios (1:20+) for water stability. A standard commercial feed pellet granulator for poultry cannot achieve this.

We would propose a specialized line featuring a micro-grinder, a triple-layer conditioner, and a high-compression ring die pellet mill. While it represents a higher initial investment, the pellet quality, survival rate, and market price for dedicated shrimp feed far outweigh the savings from a multi-purpose machine, which would compromise on shrimp feed quality.

We are feed pellet granulator manufacturers in Brazil looking to source a reliable industrial feed pellet granulator for our expansion. What are your lead times and do you provide the feed pellet granulator design drawings for local certification?

+

As fellow manufacturers, we understand the need for reliable partners. For industrial models like the SZLH678 (30-33 t/h), standard lead time is 50-60 working days from deposit, subject to configuration.

We provide comprehensive design documentation for local certification in Brazil, including detailed General Arrangement drawings, foundation load diagrams, electrical schematics, and pneumatic layouts.

All our heavy-duty feed pellet granulators come with full CE certification packages, and we can assist with any additional documentation required by Brazilian authorities for industrial equipment installation.

What feed pellet granulator parts experience the most wear when producing high protein feed for trout, and what is your recommended maintenance schedule to avoid downtime?

+

In high-protein aquafeed production for trout, the most wear occurs on the ring die and press rollers due to the abrasive nature of fine fishmeal and minerals. The conditioner paddles also experience wear from the corrosive mix. Our recommended schedule is proactive: inspect roller shells for scoring every 300-400 operating hours and check die hole smoothness weekly.

We advise keeping a calibrated spare set of rollers and a spare ring die on hand. Using our factory-original, carburized and hardened rollers and dies made from high-chromium alloy steel can extend this service life by up to 40% compared to standard parts.

Can a single heavy duty feed pellet granulator effectively produce both 2mm sinking fish feed pellets and 4mm layer feed pellets, or are two separate machines recommended for a farm in Egypt?

+

A single heavy-duty feed pellet granulator, like our SZLH558, can produce both, but it requires a dual-die strategy and process adjustments. You would need two different ring dies: a high-compression 2mm die for sinking feed and a standard-compression 4mm die for layer feed.

The changeover takes 4-6 hours. The main challenge is conditioning; fish feed needs longer, hotter conditioning. For a farm in Egypt with moderate volume for each type, one machine is cost-effective. For high-volume dedicated production, two separate lines are better. We can provide a custom configuration with quick-change die clamps to facilitate this switch.

Looking for a small feed pellet granulator for a pig farm in Poland (approx. 3 t/h). Is an electric feed pellet granulator powerful enough, or is a diesel model necessary for consistent pig feed pellet quality?

+

For a 3 t/h operation on a pig farm in Poland, an electric feed pellet granulator is absolutely sufficient and preferable. Our SZLH320 model (37KW) is designed for this exact scale and provides stable, consistent power for high-quality pig feed pellets.

Electric models offer smoother operation, easier speed control, lower noise, and significantly lower long-term fuel costs compared to diesel. They are ideal for farms with reliable grid power. Diesel models are only necessary for remote locations without stable three-phase electricity. The electric model will deliver excellent pellet consistency for your grower and finisher diets.

When comparing your best feed pellet granulator models, what specific features should I look for to ensure it can handle custom feed blends with varying ingredient densities for my mixing business in South Africa?

+

For custom blends with varying densities, look for a feed pellet granulator with a robust, variable-speed feeder and a wide-range conditioning system. Key features include a forced feeder (auger) to prevent bridging of fluffy or dense mixes, and a conditioner with adjustable paddle angles and steam injection zones to adapt to different recipes.

The ring die feed pellet machine should also have a quick-release die clamp to allow for easy changes between dies with different compression ratios suited to high-protein or high-fiber blends. Our models for the South African market are often specified with these flexibility features for precisely this reason.

We need a feed pellet granulator with a crumbler to produce starter feed for our poultry operation in Mexico. Can this attachment be added later, or must it be included in the initial feed pellet granulator plant design?

+

The pellet crumbler machine can be added later, but planning for it initially is far more efficient. If retrofitted, you must ensure your cooler discharge height allows for the crumbler’s installation underneath and that there is adequate power available. It also requires integrating a screening system to separate the desired crumble size.

We strongly recommend including it in the initial feed pellet granulator plant design for Mexico. This allows for optimal placement in the flow, correct sizing of conveyors and elevators, and integrated controls, resulting in a smoother, more automated process for your starter feed production.

As a first-time buyer, how to choose a feed pellet granulator for a dairy feed operation in New Zealand? What are the top three specifications I should prioritize beyond capacity?

+

For a dairy feed operation in New Zealand, prioritize these three specifications beyond hourly capacity:

- First, Motor Power and Drive Type: Ensure it has a powerful enough motor (e.g., 90KW+ for 5-6 t/h) with a direct gear drive for efficient energy use with fibrous feeds.

- Second, Conditioner Size and Type: Opt for an extended, single or double-layer stainless steel conditioner to properly cook grains and soften forages like hay or straw.

- Third, Ring Die Specifications: Choose a die with a low compression ratio (1:6-1:9) and large hole diameter (6-10mm) suitable for dense ruminant pellets. A durable, low-compression die is more important than high capacity for dairy feed quality.

Your feed pellet granulator video shows smooth operation, but what is the realistic noise level of a high capacity feed pellet granulator (25 t/h) in an enclosed feed mill setting?

+

A high-capacity feed pellet granulator like our SZLH558 (20-22 t/h) or SZLH678 (30-33 t/h) generates significant operational noise, primarily from the gear drive and pellet extrusion. In an enclosed feed mill, without acoustic treatment, sound levels at the operator position typically range from 85 to 92 dB(A).

We address this through design: our machines use helical gears for smoother, quieter transmission and precision-balanced rotors. We also offer optional acoustic enclosures or panels that can reduce perceived noise by up to 15 dB(A), bringing it closer to 75 dB(A), which is a much safer and more comfortable working environment for your staff in a mill.

For medicated feed pellet production in the USA, are there specific feed pellet granulator designs or protocols (like clean-out procedures) you recommend to prevent cross-contamination between batches?

+

For medicated feed production in the USA, following FDA guidelines is paramount. We design feed pellet granulators with cleanability in mind: smooth, stainless steel surfaces in the conditioner and feeder, minimal ledges, and easy-access panels.

We recommend specific protocols: running a substantial batch of non-medicated carrier material (like cornmeal) as a flush after a medicated batch. Our machines can be equipped with air purge systems for the conditioner. Most critically, we advise using dedicated tooling (dies and rollers) for medicated lines to eliminate any risk of residue, a practice our US clients in the feed industry strictly follow.

We produce high fat feed for energy-dense ruminant feed. What special modifications does your cattle feed pellet granulator require to prevent clogging and ensure proper pelleting with fat levels above 8%?

+

High fat content (above 8%) lubricates the die, reducing friction and making pelleting difficult, often leading to clogging. For our cattle feed pellet granulator, we implement several modifications:

- First, we use a ring die with a very low compression ratio and a “release” hole pattern to counteract the lubricating effect.

- Second, we install a forced feeder to ensure positive material flow into the die.

- Third, we often recommend adding the fat in a post-pelleting coating system rather than in the mixer, which is the most effective solution.

If fat must be included pre-pelleting, we adjust the conditioning to slightly lower moisture and higher temperature to compensate.

Considering a feed pellet granulator with mixer for our integrated farm in Kenya. Does an integrated system compromise on mixing quality or pellet mill power compared to standalone units?

+

A feed pellet granulator with an integrated horizontal paddle mixer does not compromise quality if properly engineered. In our SKJ series combi machines, the mixer is designed for short, intensive mixing (60-120 seconds) which is sufficient for most farm formulations. The pellet mill section uses the same heavy-duty gearbox as our standalone models.

The advantage for an integrated farm in Kenya is space and cost savings, and reduced material handling. The potential compromise is slightly lower overall throughput compared to a dedicated large mixer feeding a separate mill, but for on-farm use up to 3-4 t/h, it provides excellent efficiency and simplicity.

What is the typical lifespan of the feed pellet granulator die and roller when producing abrasive aquafeed pellets, and what material do you use to maximize it?

+

Producing abrasive aquafeed pellets is extremely demanding. Using standard carbon steel dies and rollers, lifespan can be as short as 400-600 tons. To maximize it, Richi Machinery uses premium materials: Ring dies are made from high-chromium alloy steel (like 20CrMnTi) and undergo deep-hole carburizing and hardening to achieve a surface hardness of HRC 56-60.

The rollers use a similar hardened alloy steel shell. With this specification, producing standard sinking fish feed, clients typically achieve 1,200 to 1,800 tons per die set. For highly abrasive formulas with high mineral content, we offer even more wear-resistant tungsten carbide-lined dies, which can last 3-4 times longer.

We are an exporter looking for a reliable feed pellet granulator exporter to supply feed pellet granulator equipment to Nigeria. Do you provide regional spare parts support and technician training?

+

Yes, as a leading feed pellet granulator exporter, we have established a strong supply chain and support network for Nigeria. We maintain a core inventory of critical spare parts (rollers, dies, bearings, shafts) with our local partner in Lagos to ensure fast delivery.

We provide comprehensive technician training, which can be conducted at our factory in China or on-site in Nigeria during commissioning. The training covers operation, maintenance, troubleshooting, and die changing. We also provide detailed manuals and online support to ensure the long-term success of your clients’ operations.

For a feed pellet granulator for pet food production in Italy making grain-free recipes, how does the pelleting process differ from standard livestock feed, and what machine adjustments are needed?

+

Grain-free pet food, often high in meat meals, fats, and starches like potato or pea, behaves very differently from grain-based livestock feed. The main differences are in binding and fat content. The process requires significant adjustments: a lower conditioning temperature (70-80°C) to prevent protein denaturation, longer conditioning time to hydrate binders, and often the use of a pre-conditioner.

The feed pellet granulator must be configured with a very specific die compression ratio to handle the sticky, dense mash. We often recommend using a twin screw extruder for certain grain-free textures, but for dry expanded pellets, a specialized ring die mill with precise thermal control is essential.

Is it practical to use a mash feed pellet granulator to also produce pellets from concentrate feed powders without significant recipe modification, or are two different processing lines necessary?

+

It is practical to use the same mash feed pellet granulator for both, but it requires careful recipe formulation and process adjustment, not necessarily a second line. Concentrate powders are denser and may have different binding properties. The key is in the conditioning stage: you may need to adjust steam addition and retention time to properly gelatinize the starch in the concentrate base. The same ring die can often be used if the overall pellet size target is similar.

The main requirement is a skilled operator who can fine-tune the conditioner parameters based on the mash. For large-scale, dedicated production of each type, separate lines are more efficient, but for many integrated farms, one well-operated machine suffices.

We are upgrading our feed pellet granulator production line in Canada to include a feed pellet granulator with cooler for improved pellet stability. What are the integration requirements with our existing ring die feed pellet granulator?

+

Integrating a cooler with your existing ring die feed pellet granulator in Canada requires matching a few key parameters.

- First, we need the discharge height and pellet temperature from your granulator. The cooler must be positioned to receive hot pellets directly, usually via a conveyor or chute.

- Second, the cooler’s capacity (in tons per hour) must match or exceed your granulator’s output.

- Third, we need to connect the cooler’s electrical controls to your main panel.

Our engineering team can provide a retrofit kit that includes the mounting frame, transition spouting, and control integration instructions, ensuring the new cooler works seamlessly with your current setup to stabilize and harden pellets effectively.

As a cooperative in the Philippines, we need a versatile feed pellet granulator for custom feed blends that can switch between producing horse feed pellets and rabbit feed pellets weekly. What’s the changeover process for dies and settings?

+

For weekly switching between horse feed (typically 8-12mm) and rabbit feed (3-4mm), the changeover process on a versatile feed pellet granulator like our SZLH420 is manageable. The main task is changing the ring die and possibly the rollers for optimal wear. With our quick-release die clamp, this takes 2-3 hours.

You will also need to adjust the knife to cut the pellets to the new length. The process settings that change significantly are the conditioner steam (more for rabbit feed’s finer grind) and the feeder speed. We provide clients like your cooperative with detailed changeover checklists and parameter sheets for each recipe to standardize the process and minimize downtime between production runs.

For a large-scale livestock feed pellet granulator operation in Turkey focusing on swine feed, what’s the minimum required floor space for your automatic feed pellet granulator system, including maintenance access?

+

For a large-scale automatic livestock feed pellet granulator system producing swine feed in Turkey, such as our 25 t/h SZLH678 line with automated weighing and mixing, you should plan for a dedicated pelleting bay. The machine itself needs about 4m x 3m floor space.

However, with proper maintenance access (at least 1 meter on all sides for die removal and servicing), included conveyor infeed and discharge, and space for the control panel, a total area of 8m (length) x 6m (width) x 5m (height) is a safe minimum. This allows for safe operation, use of lifting tools for die changes, and access to all service points. We provide detailed layout drawings during the project planning phase.

I’ve seen many cheap feed pellet granulator options online. As a feed pellet granulator factory, what are the hidden costs or risks we should consider before purchasing equipment for our startup in Colombia?

+

The hidden costs of a cheap feed pellet granulator can cripple a startup in Colombia.

- First is energy inefficiency: poor gear design and low-quality motors can increase your power cost by 30%.

- Second is downtime: thin metal frames, inferior bearings, and soft gears fail frequently. The cost of lost production and emergency repairs far exceeds machine savings.

- Third is poor pellet quality: inconsistent dies and weak rollers produce high fines, wasting 5-10% of your raw materials.

- Fourth is no technical support: you’re left alone when problems arise.

As a factory, we see clients ultimately pay 2-3 times the cheap machine’s price in these hidden costs within two years. Investing in a robust machine from a proven manufacturer protects your business.

When evaluating feed pellet granulator manufacturers for our new fish farming operation in Greece, what specific certifications should we require for equipment operating in high-humidity coastal environments?

+

For a fish farming operation in Greece’s coastal environment, prioritize these certifications:

- 1. CE Marking: Mandatory for the EU, ensuring basic health, safety, and environmental standards.

- 2. IP (Ingress Protection) Rating: Look for an electrical panel rating of at least IP55, which protects against dust and water jets, crucial for humidity and wash-downs.

- 3. Material Certificates: Require certificates for stainless steel (e.g., 304 or 316 grade) used in the conditioner and feeder to prove corrosion resistance.

- 4. Motor Certificates: Motors should have an insulation class of F or H and a high protection rating (IP55/IP65).

Reputable feed pellet granulator manufacturers like Richi Machinery provide full certification packages to meet these stringent requirements for harsh environments.

For high moisture feed pellet granulator applications in Indonesia using fresh by-products, what additional preprocessing equipment is necessary before the mash enters the feed pellet granulator mill?

+

Using fresh, high-moisture by-products in Indonesia requires preprocessing to create a stable mash. Before the feed pellet granulator mill, you will likely need:

- 1. A Dewatering Press or Screw Press: To reduce the moisture content from perhaps 70-80% down to 50-60%.

- 2. A Coarse Crusher or Grinder: To break down the pressed cake into smaller particles.

- 3. A Batch Mixer: To blend the moist by-product with dry ingredients (like bran, meal) to achieve a uniform mash with a total moisture content suitable for conditioning (typically 16-18%).

Trying to pelletize very wet material directly will clog the die and produce mushy pellets. We design integrated systems that include this preprocessing to handle local by-products effectively.

We operate a feed pellet granulator for poultry farm in Morocco and want to add molasses coating. Can your feed pellet granulator press be equipped with a post-pelleting liquid application system?

+

Yes, absolutely. Adding molasses coating is an excellent way to increase energy density. Our feed pellet granulator systems can be equipped with a post-pelleting liquid application system, typically a rotating drum coater installed after the cooler. The cool, hard pellets enter the coater, where a fine mist of molasses (or fat) is evenly sprayed onto them as they tumble.

The system includes a heated tank and pump for the molasses. This addition requires some extra floor space and integration with your controls. We can provide this as a retrofit or include it in a new line design for your poultry farm in Morocco, significantly enhancing your feed’s value.

What’s the learning curve for operators unfamiliar with how to use a feed pellet granulator? Do you provide multilingual manuals and video guides for our team in Ukraine?

+

For a new operator, the basic learning curve to run a feed pellet granulator safely and produce acceptable pellets is about 5-7 days of hands-on training. Mastering optimization for different recipes may take a few months of experience.

To support your team in Ukraine, we provide comprehensive multilingual support: detailed operation and maintenance manuals in Ukrainian or Russian, instructional videos with subtitles covering startup, shutdown, daily checks, and die change procedures.

Most importantly, our commissioning engineer provides on-site training in English with a local interpreter, ensuring your operators are confident before we leave. We also offer follow-up online training sessions.

When producing starter feed for chicks using a feed powder pellet granulator, what’s the ideal particle size of the powder before pelleting to ensure proper nutrition and pellet formation?

+

For starter feed crumbles, the ideal particle size of the powder before pelleting is a fine and uniform grind. A common target is that 100% of the mash passes through a 2.0mm sieve, with a mean geometric diameter (MGD) around 0.7-0.9mm. This fine grind ensures maximum nutrient availability for the chicks and creates a dense, smooth pellet that can then be crumbled into small, uniform particles.

If the powder is too coarse, the pellet will be weak and crumble into dusty fines. Our feed powder pellet granulator systems are always paired with a high-quality hammer mill feed grinder equipped with the correct screen size to achieve this precise particle size distribution for optimal starter feed quality.

For a dairy feed pellet granulator processing silage in Ireland, how do we calculate the correct feed pellet granulator motor power to handle the variable density of this raw material?

+

Processing silage in a dairy feed pellet granulator requires extra power due to its variable density and fiber. A standard calculation for mixed feed is 15-20 kWh per ton. For silage-based feed, we increase this to 22-28 kWh per ton due to the fiber. So, for a target output (e.g., 5 t/h), you’d need: 5 t/h * 25 kWh/t = 125 kW.

We then add a 15-20% safety margin for peak loads, recommending a 150-160 KW motor. It’s also critical to have a feed pellet granulator with a high-torque gearbox and a forced feeder to manage the silage’s inconsistent flow. Our engineers use these refined calculations to specify the correct motor for reliable Irish silage pelleting.

We need a feed pellet granulator with conditioner for our layer feed production in Chile. What’s the optimal temperature and retention time in the conditioner to maximize nutrient availability without damaging vitamins?

+

For layer feed production, the optimal conditioning balances starch gelatinization with heat-sensitive vitamin preservation. In our feed pellet granulator with conditioner, we target a mash temperature of 78-85°C at the conditioner exit. The retention time should be between 30 and 60 seconds.

This “gentle cooking” range is sufficient to gelatinize most starches in corn and wheat, improving pellet binding and digestibility, while keeping the heat exposure brief enough to minimize the degradation of critical vitamins like A, D3, and some B vitamins. Using a double-layer conditioner allows for more precise control over this temperature ramp, which is ideal for maintaining the nutritional integrity of your layer feed in Chile.

As a feed pellet granulator distributor in Saudi Arabia, what after-sales support package do you offer, including technical assistance and emergency parts supply for your industrial feed pellet granulator models?

+

For our distributors in Saudi Arabia, we offer a partnership-level after-sales support package. This includes:

- Technical Assistance: Priority access to our senior engineers via phone, email, and video call for troubleshooting.

- Emergency Parts Supply: We maintain a “fast-track” inventory of critical parts for industrial models (gears, shafts, main bearings) that can be shipped via air freight within 48 hours of order confirmation.

- Training: We provide regular factory training sessions for your technical staff.

- Marketing & Documentation: We supply high-quality sales materials, specification sheets, and installation manuals in Arabic.

Our goal is to equip you to provide first-class local support to your clients.

When producing high protein feed pellet granulator output for aquaculture in Malaysia, what’s the maximum protein content your standard ring die can handle before we need special die specifications?

+

Our standard ring die for aquafeed is already designed for high-protein formulations, typically handling up to 45-50% protein content effectively. Beyond 50% protein, especially with high levels of fishmeal, the mash becomes very abrasive and can have binding challenges.

At this point, we recommend special die specifications: a die made from a higher grade of wear-resistant alloy steel (like our premium chromium steel) and potentially a specific hole pattern design to manage the unique friction and flow characteristics of ultra-high-protein mash.

For Malaysian clients producing premium shrimp or fish feed, we often start with this premium die specification to ensure longevity and consistent pellet quality from the outset.

For a feed pellet granulator for grower feed production in Peru, what’s the recommended ratio of fines that can be recycled back into the process without affecting the final pellet quality?

+

In a well-tuned feed pellet granulator system for grower feed, you will always have some fines from the cooler and screens. The recommended ratio to recycle is generally between 5% and 15% of the total production flow. Exceeding 15-20% can disrupt the process: the dry, cold fines mix with the fresh conditioned mash, reducing the overall moisture and temperature entering the die, which leads to weaker pellets and can even cause die blockage.

The key is to recycle the fines continuously at a steady, controlled rate back into the mixer, not directly into the conditioner. Our systems include automated recycling conveyors with adjustable speed controls to manage this ratio precisely for operations in Peru.

We’re considering a new feed pellet granulator for our organic feed production in Austria. Are there specific materials used in the construction of your machines that are certified for organic production?

+

Yes, for organic feed production in Austria, we can configure a feed pellet granulator to meet stringent organic certification requirements. The critical contact parts—the conditioner, feeder, and any pre-mixer—are constructed using certified 304 or 316 food-grade stainless steel. All seals and gaskets are made from FDA-approved materials.

Furthermore, we use a food-grade, H1-rated lubricant in the gearbox (where there is any remote possibility of contact) or specify a sealing system that absolutely prevents lubricant leakage. We provide a full declaration of materials for all wetted parts to support your organic certification process with Austrian authorities.

What safety features are standard on your heavy duty feed pellet granulator models, particularly regarding emergency stops and protection against access to moving parts for our workers in Bangladesh?

+

Safety is paramount. Our heavy-duty feed pellet granulator models come with these standard safety features:

- 1. Emergency Stop Buttons: Located at multiple, accessible points on the machine, including the main control panel and near all potential hazard zones.

- 2. Mechanical Safety Guards: Robust, interlocked steel guards cover all moving parts like the main drive, conditioner shaft, and die/roller area. The guards are electrically interlocked; if opened, the machine power is cut.

- 3. Motor Overload Protection. Warning Labels and Signs in English and/or pictograms. For operations in Bangladesh, we ensure all electrical components meet relevant standards and can provide safety documentation to support your compliance with local workplace regulations.

For a feed pellet granulator for finisher feed in hog operations in the United States, what’s the ideal pellet hardness to maximize feed conversion while minimizing equipment wear?

+

For hog finisher feed in the US, the target pellet hardness (measured by a Kahl hardness tester) is typically in the range of 8 to 12 kg. This level of hardness is durable enough to withstand handling with minimal fines (under 5%), which maximizes feed conversion ratio (FCR) by ensuring pigs consume complete pellets.

At the same time, a hardness above 12-15 kg offers diminishing FCR returns and significantly increases the wear and tear on the feed pellet granulator’s ring die and rollers, as well as power consumption. We help clients fine-tune their conditioning and die selection to consistently hit this 8-12 kg sweet spot, optimizing both animal performance and machine longevity.

When exporting a complete feed pellet granulator line from your factory to South Africa, what documentation and certifications are included to ensure smooth customs clearance at port?

+

We provide a comprehensive export documentation package for South Africa:

- 1. Commercial Documents: Commercial Invoice, Packing List, Bill of Lading.

- 2. Shipping Documents: Certificate of Origin (often Form E for China-ASEAN, but for SA, a standard COO).

- 3. Technical & Certification Documents: CE Certificates, Detailed Equipment Manuals, Factory Test Reports, Material Certificates for major components.

- 4. Customs Documentation: A detailed HS Code declaration for each major machine.

We work closely with your nominated freight forwarder to ensure all paperwork is accurate and complete, facilitating smooth customs clearance at Durban or Cape Town port. We are experienced with the requirements of the South African National Standards (SANS).

How does the pellet quality from a horizontal feed pellet granulator compare to vertical models when producing ruminant feed with long fiber ingredients for our operation in Argentina?

+

For ruminant feed with long fiber ingredients in Argentina, a modern horizontal ring die feed pellet granulator is generally superior to an old-style vertical die machine. The horizontal design allows for a larger, more accessible die and better distribution of two or three rollers, creating more even pressure and producing a more consistent, durable pellet.

It handles long fibers better as the material flow is gravity-assisted into the die area. Vertical models can struggle with bridging of fibrous material. The pellet quality from our horizontal machines, especially in terms of density and durability for handling, is significantly higher, leading to less waste and better animal performance for your pasture-based operation.

We produce specialty medicated feed in small batches. Is there a small feed pellet granulator model that minimizes residual product loss during batch changeovers for our facility in Portugal?

+

For small-batch medicated feed production in Portugal, minimizing residuals is crucial. Our smallest commercial model, the SZLH250 (1-2 t/h), is designed with this in mind. Key features to minimize loss include: a compact conditioner with a steep incline for good material discharge, a slide-gate at the conditioner exit to physically separate batches, and a quick-release die clamp for fast cleaning access.

The total residual mash in the system (conditioner and die chamber) can be as low as 8-10 kg. We also recommend running a small batch of a non-active carrier material (like maize grits) as a flush between medicated batches to fully clean the system, ensuring compliance and minimizing cross-contamination risk.

What are the key benefits of using a feed pellet granulator to process animal feed compared to feeding mash or powder?

+

Utilizing a professional-grade feed pellet granulator transforms feed production, delivering significant advantages that impact everything from animal health to operational efficiency. The pelleting process mechanically shapes finely ground mash into dense, uniform pellets by applying precise moisture, heat, and pressure.

This method has become essential in modern feed manufacturing due to its proven positive effects on animal performance, which are directly tied to the physical quality of the pellet.

A high-quality feed pellet granulator from a seasoned manufacturer like Richi Machinery ensures these benefits are fully realized:

- Reduced Feed Waste: Durable pellets minimize loss during mechanical handling, storage, and feeding, ensuring more of your formulated nutrition reaches the animal.

- Improved Feed Intake: The uniform pellet form is highly palatable, encouraging consistent consumption across all animals, including finicky eaters.

- Enhanced Digestibility: The controlled heat and steam conditioning during pelleting gelatinizes starches, improving nutrient availability and overall feed conversion ratios.

- Nutrient Preservation: Properly engineered conditioning in a modern feed pellet granulator balances cooking with retention, helping to stabilize vitamins and minerals within the pellet matrix, preventing segregation and degradation.

- Superior Storability: Pelleted feed has a lower bulk density and is less prone to caking or spoilage than powdery mash, allowing for longer, safer storage.

The ultimate value depends on preserving this pellet quality from the moment it leaves the feed pellet granulator all the way to the point of consumption. This is why investing in a robustly engineered machine with precise control over conditioning parameters, die specification, and cooling is critical. Our expertise ensures your system is optimized for your specific ingredients—whether for poultry, livestock, or aquaculture—to consistently produce pellets that deliver these operational and nutritional benefits.

What are the main structural components of a ring die feed pellet granulator and what is the function of each?

+

A professional-grade feed pellet granulator is a sophisticated piece of industrial equipment, and its performance hinges on the precise engineering and integration of its core subsystems. Understanding its structural composition is key to appreciating how it delivers consistent, high-quality pellets. Our machines are designed with durability and process control in mind, ensuring each component meets the demands of continuous, high-tonnage production.

Here is a breakdown of the six main systems in a robust ring die feed pellet granulator:

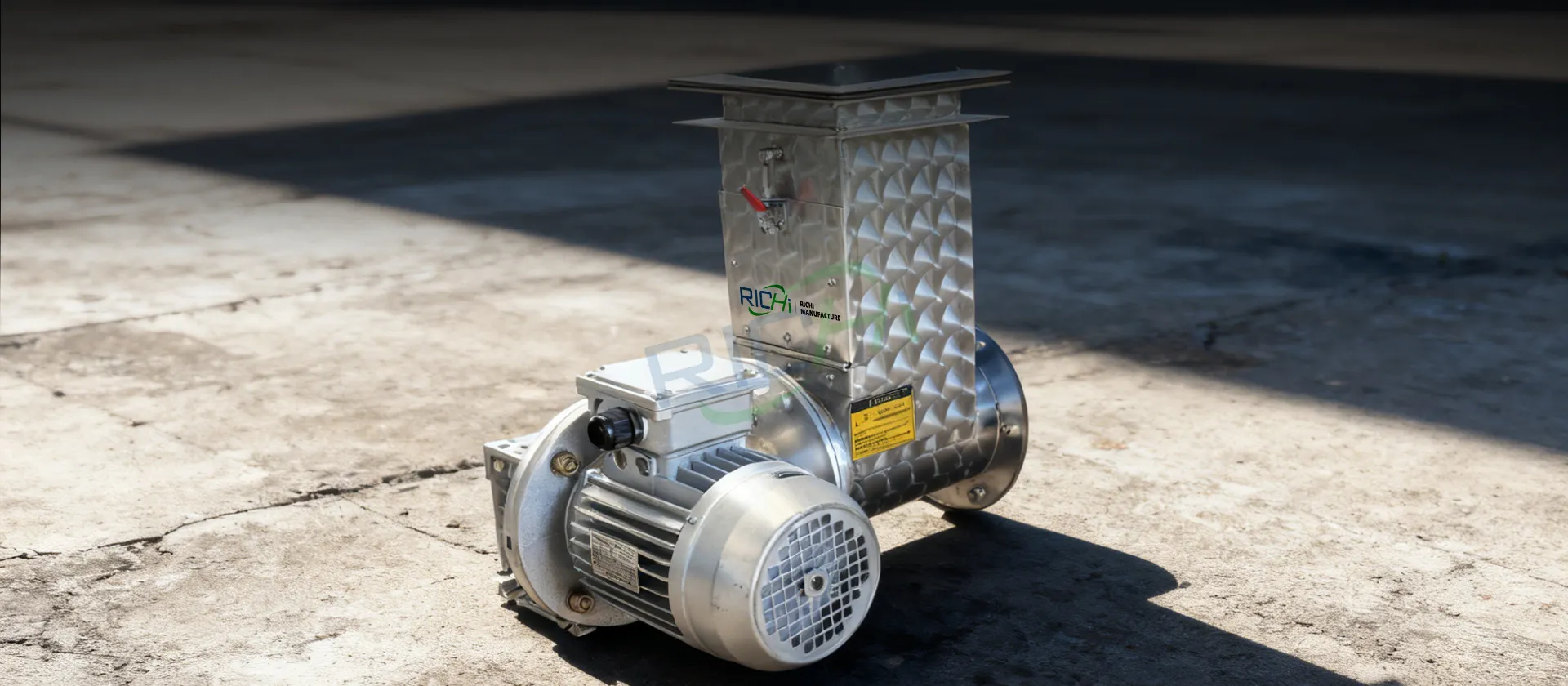

1. Feeding Mechanism

This system ensures a consistent and controllable flow of raw material. It consists of a feed hopper and a variable-speed feeder (typically a screw conveyor). We equip our machines with frequency-controlled feeders for precise, automated regulation of the feed rate, which is critical for maintaining stable conditioning and extrusion pressure, especially when processing diverse raw material blends.

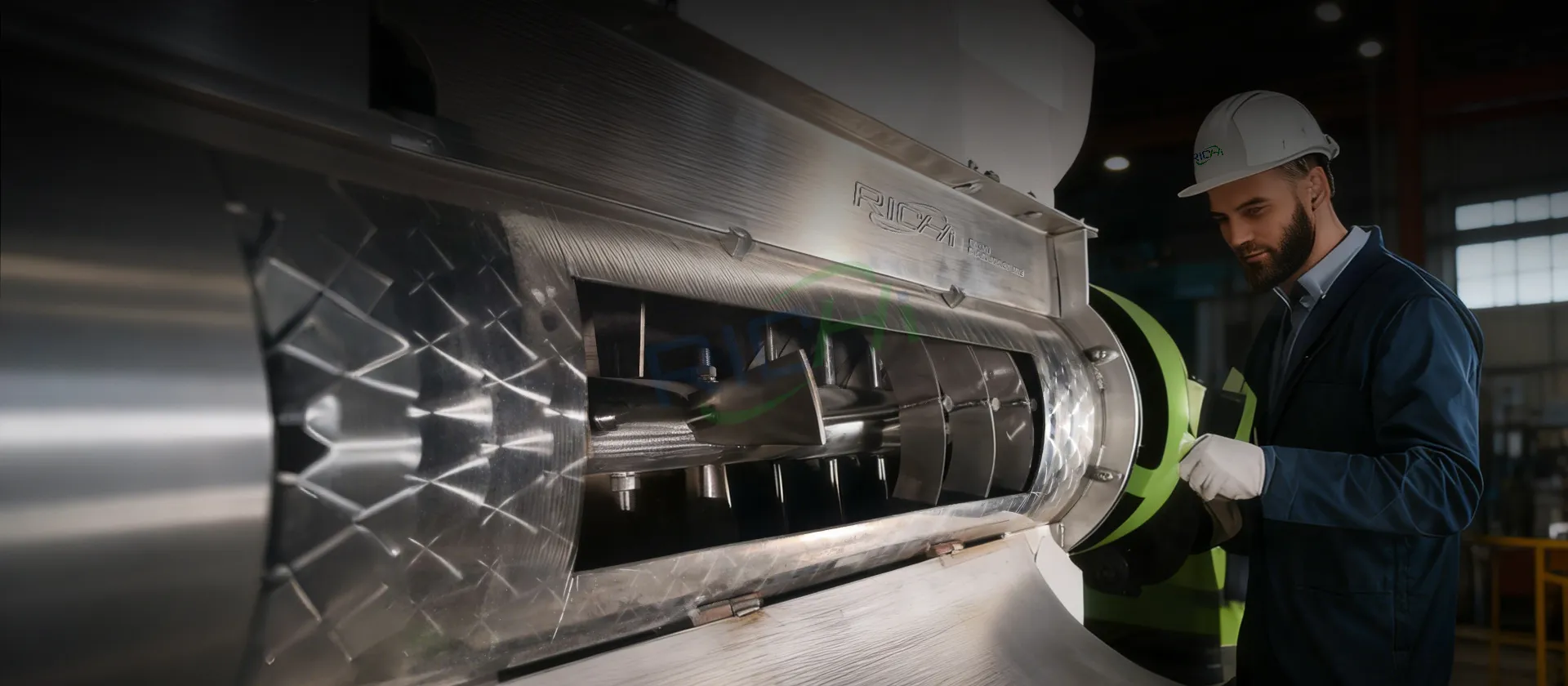

2. Conditioning Mechanism

This is where process transformation begins. The mechanism comprises a conditioning chamber (or cylinders) with rotating shafts fitted with paddles. Steam and sometimes liquid additives are injected here. Our design often features extended, large-diameter stainless steel conditioners—available in single, double, or triple-layer configurations—to provide optimal retention time and thorough heat/moisture penetration. This process gelatinizes starches, improves digestibility, and is fundamental to achieving pellet durability and water stability for various feed types.

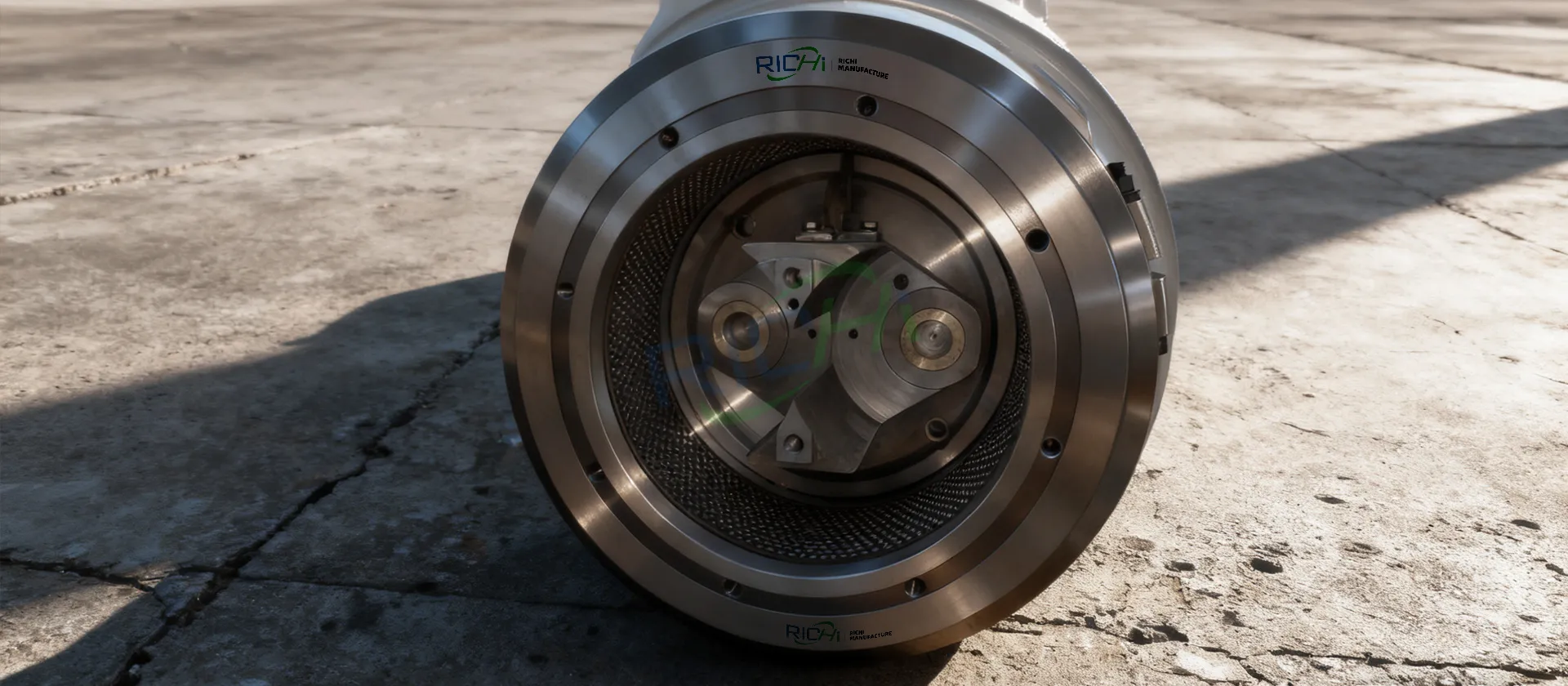

3. Extrusion Mechanism

This is the absolute heart of the feed pellet granulator. It consists of a heavy-duty, precision-machined ring die and two or more hardened press rollers. The conditioned mash is forced into the gap between the rollers and the die. The rollers exert tremendous pressure, squeezing the material through the die holes to form dense, compacted pellets. The quality of the die (material, hole pattern, compression ratio) and the alignment of the rollers are paramount, which is why we manufacture these core components in-house to the highest standards.

4. Temperature Control System

Effective pelleting requires precise thermal management. This system is more comprehensive than just steam injection. It integrates the steam system for conditioning with critical bearing cooling circuits. Our machines often include closed-loop oil circulation systems that cool the main drive bearings and roller shafts. This prevents overheating, ensures consistent viscosity of lubricants, and protects these high-value components during continuous operation, directly contributing to machine longevity and stable pellet quality.

5. Cutting Mechanism

Located just outside the ring die, this mechanism controls the final pellet length. It consists of adjustable knives mounted on a rotating cutter head. The distance of the knives from the die face is easily adjusted to produce pellets of the required length, from micro-crumble to long rods. A well-designed cutter ensures clean, uniform cuts without creating excessive fines.

6. Transmission System

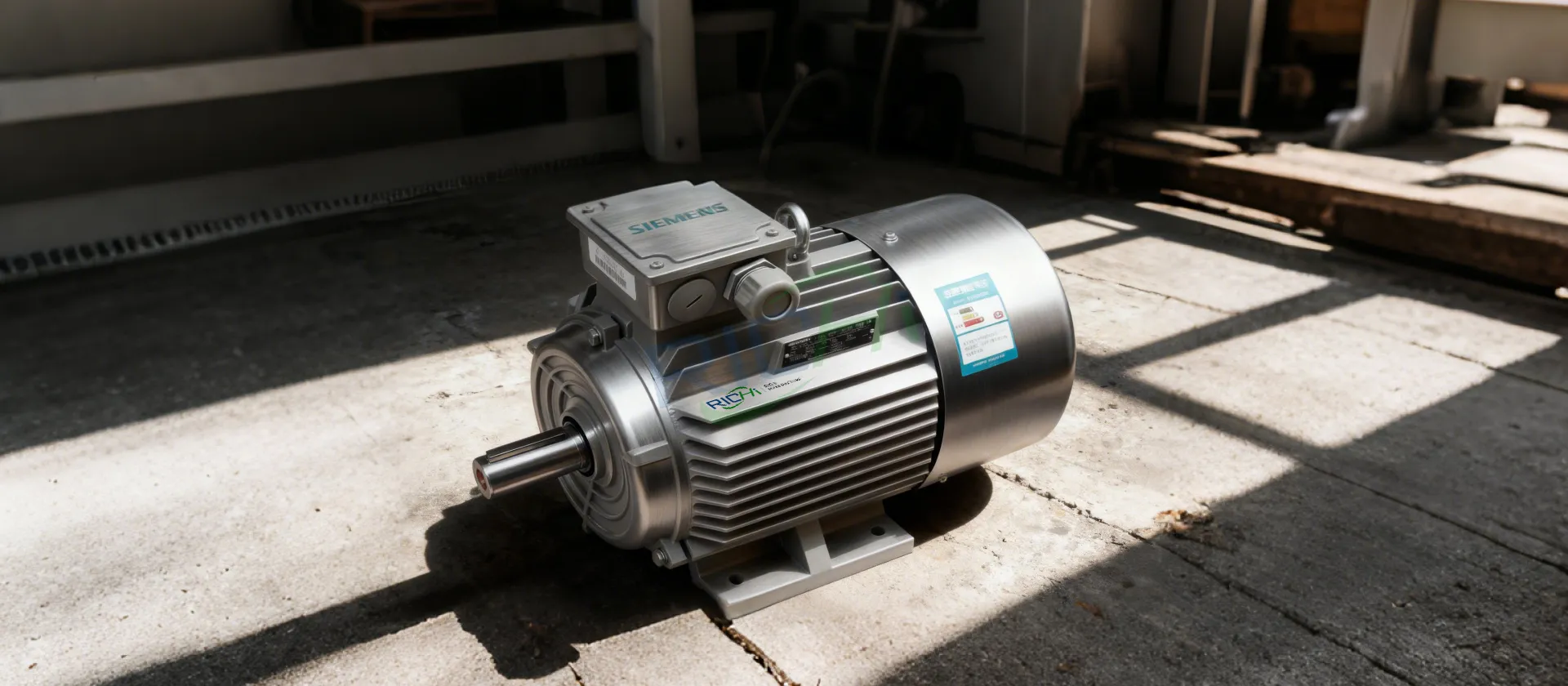

This is the powerhouse, comprising a high-torque main motor (e.g., Siemens or equivalent) and a heavy-duty reduction gearbox. Our feed pellet granulators utilize a direct gear drive system, where the motor couples directly to the gearbox, which then drives the main shaft. This design is vastly more efficient and reliable than belt drives, transmitting maximum power with minimal energy loss, ensuring smooth startup under load, and providing the consistent rotational force needed for stable extrusion 24/7.