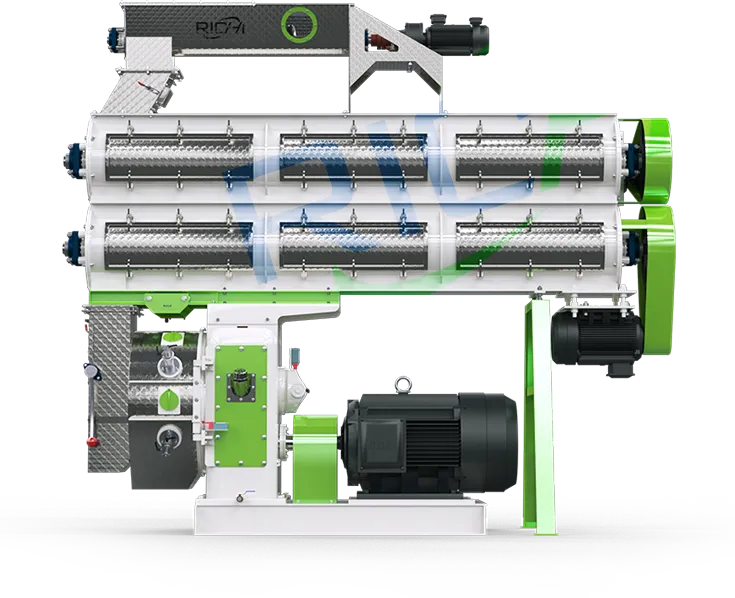

FEED GRANULATOR MACHINE

Meet the core of your feed mill: the SZLH558 feed granulator machine. Designed for the demanding pelleting section, it processes a wide spectrum of formulas—from chicken, pig, and cattle to sheep, rabbit, fish, shrimp, and horse feed—into durable pellets of various sizes. Our advanced system operates at controlled temperatures to preserve vital nutrients and enzymes, guaranteeing consistent pellet quality batch after batch. Built for robust, high-output production, the SZLH558 is your reliable partner for scalable and efficient feed manufacturing.

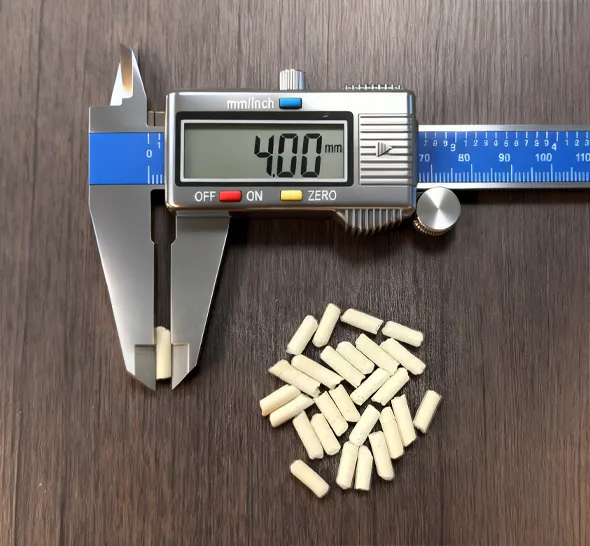

Pellet Size: 2~12mm

Price: $48,000 – $52,000

Model

SZLH558

Production Capacity

20-22T/H

Versatile Classifications & Broad Applications

As a cornerstone of modern feed production, the SZLH558 feed granulator machine is engineered to meet the diverse demands of animal feed mill plants and large-scale farming operations worldwide. This robust system is specifically designed for processing a comprehensive range of animal nutrition into high-quality pellets, serving as essential equipment in commercial feed manufacturing plants, integrated livestock farms, and aquaculture facilities. Its precision and adaptability make it the preferred choice for professionals aiming to optimize their feed processing efficiency and output.

Our expertise as a leading feed equipment manufacturer allows us to tailor the SZLH558’s performance across key feed classifications. Each configuration ensures optimal nutrient preservation and pellet integrity for its specific application.

Produces highly digestible and uniform pellets for chickens, ducks, and turkeys, supporting optimal growth and egg production.

Creates dense and durable pellets for cattle, pigs, sheep, and horses, enhancing feed intake and overall herd health.

Engineered for sinking pellets with superior water stability, essential for fish and shrimp farming nutrition.

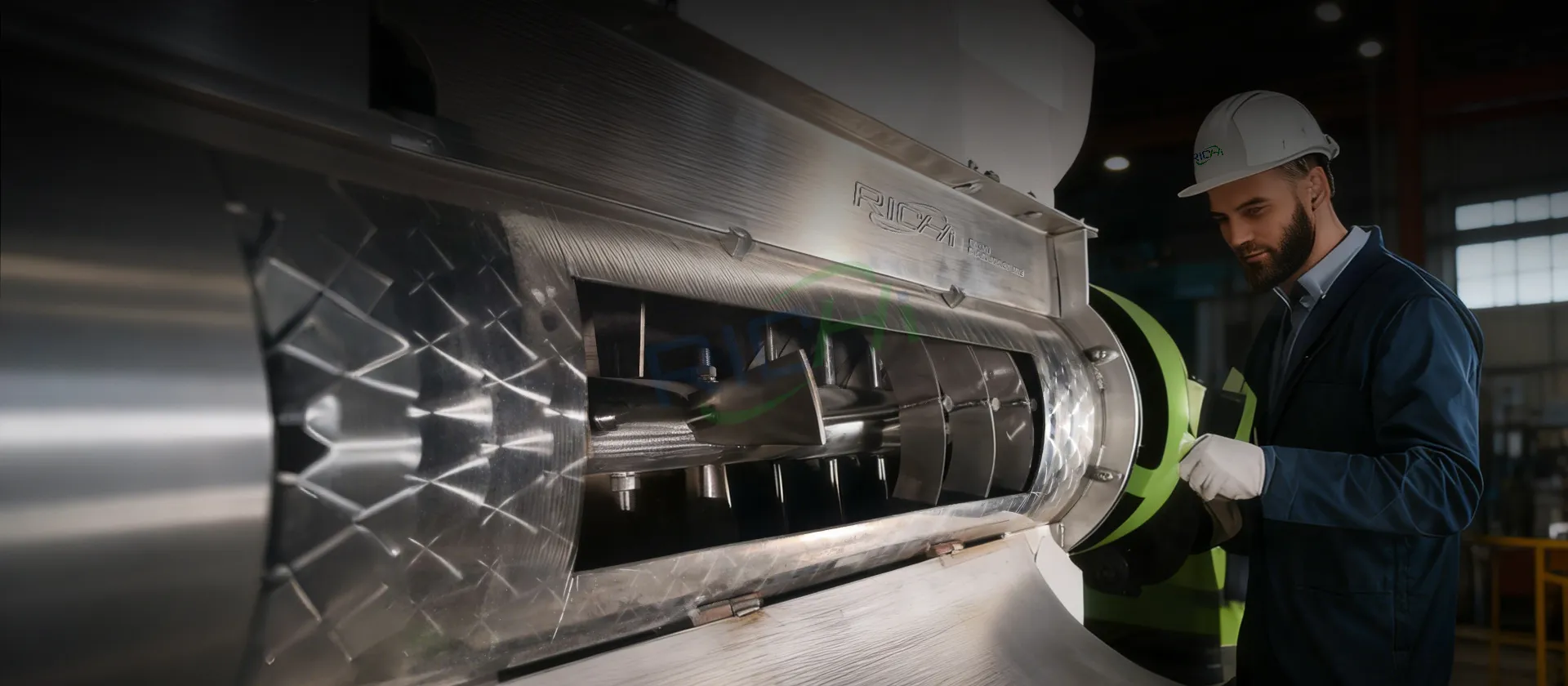

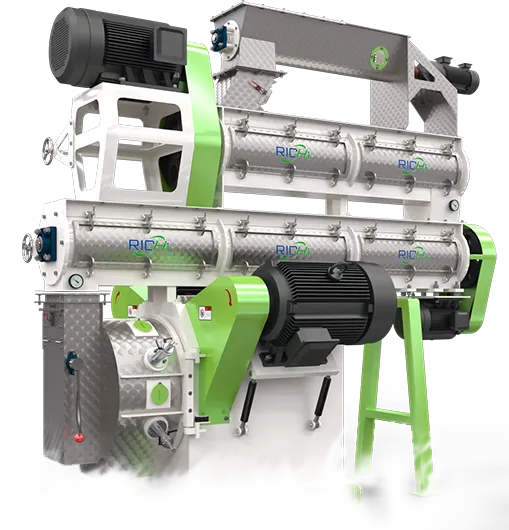

Our Conditioning Technology

The performance of a feed granulator machine hinges on its conditioning system. We offer the SZLH558 in three distinct configurations, defined by the number of conditioning stages. Each features our proprietary, extended-length, large-diameter conditioner for superior starch gelatinization and uniform moisture penetration. This modular design, fully customizable in shaft style, paddle angle, and steam injection points, allows us to match your exact recipe needs and showcase our manufacturing depth in covering all feed types.

Single-Stage Conditioner feed granulator machine

For producers targeting higher-grade outputs, this feed granulator machine adds a second conditioning layer. The extended retention time and enhanced mixing significantly improve digestibility and pellet durability. It excels in producing premium livestock poultry feed and standard sinking aqua feed for species like catfish. Choose this model if you manufacture high-value feeds that demand superior nutritional quality and physical stability.

Dual-Layer Conditioner feed granulator machine

This represents our peak conditioning technology for the most demanding applications. The three-stage process ensures maximum nutrient retention and creates exceptional water stability. This feed granulator machine is specifically engineered for producing high-performance floating or sinking feeds for sensitive aquatic species like shrimp and high-value fish. It is the essential choice for specialized aqua feed manufacturers where premium pellet integrity is non-negotiable.

Triple-Layer Conditioner feed granulator machine

This represents our pinnacle of conditioning technology. Three stages provide maximum control over time, temperature, and moisture. It is essential for manufacturing high-stability, floating or slow-sinking feeds for sensitive species like shrimp and high-value fish. This machine is built for specialized aquaculture feed plants and producers demanding the absolute highest pellet durability and water stability.

Master Diverse Formulations

Our SZLH558 feed granulator machine is engineered to handle the full spectrum of modern feed ingredients. From staple commodities to specialized additives, this robust system ensures consistent pelleting across diverse formulations. This includes not only the core categories below but also practical ingredients like fresh forages, aquatic plants, and fermented silages. Our expertise ensures your feed granulator machine adapts to your specific recipe, showcasing our capability to deliver solutions for any production need.

Energy Ingredients

Provide the fundamental calories for animal maintenance and growth. Our granulator expertly processes grains like corn and wheat into digestible pellets.

Protein Ingredients

Essential for muscle development and metabolic functions. This machine consistently incorporates oilseed meals, such as soybean and rapeseed meal, into uniform feed pellets.

Roughages Ingredients

Add crucial fiber for digestive health. Equipped to handle fibrous materials like alfalfa meal and certain hulls, supporting robust pellet structure.

Feed Additives

Integrate vital vitamins, minerals, and premixes with precision. Our conditioning technology ensures even distribution within every pellet for optimal nutrition.

Proven Performance Around the Globe

Witness the robust capability of our SZLH558 feed granulator machine. The videos below showcase four real-world installations, delivering premium pellets. From durable livestock feed to specialized aqua diets, see how our engineering provides reliable, high-output performance for leading producers worldwide. This is the tangible proof of our commitment as your expert manufacturing partner.

Uzbekistan feed granulator machine Project

Oman feed granulator machine Project

Afghanistan feed granulator machine Project

Uganda feed granulator machine Project

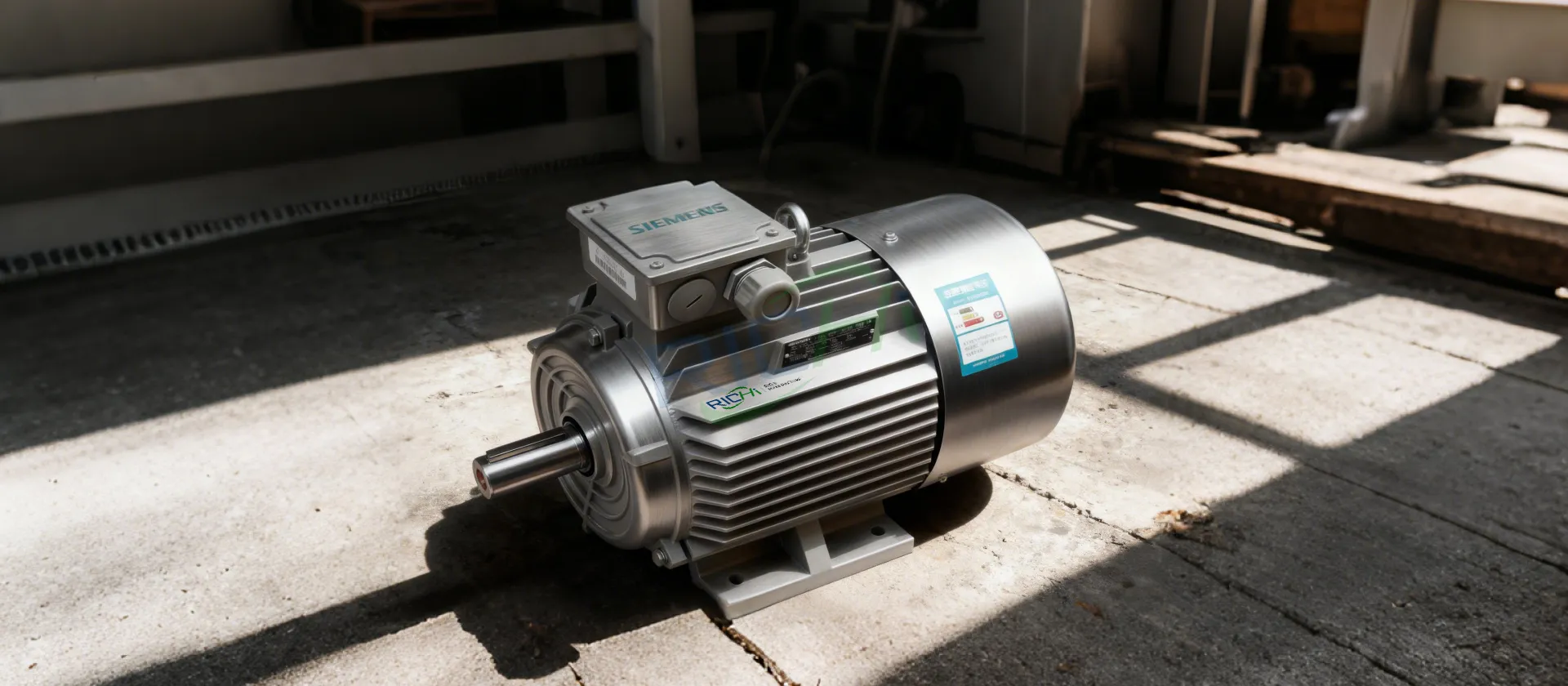

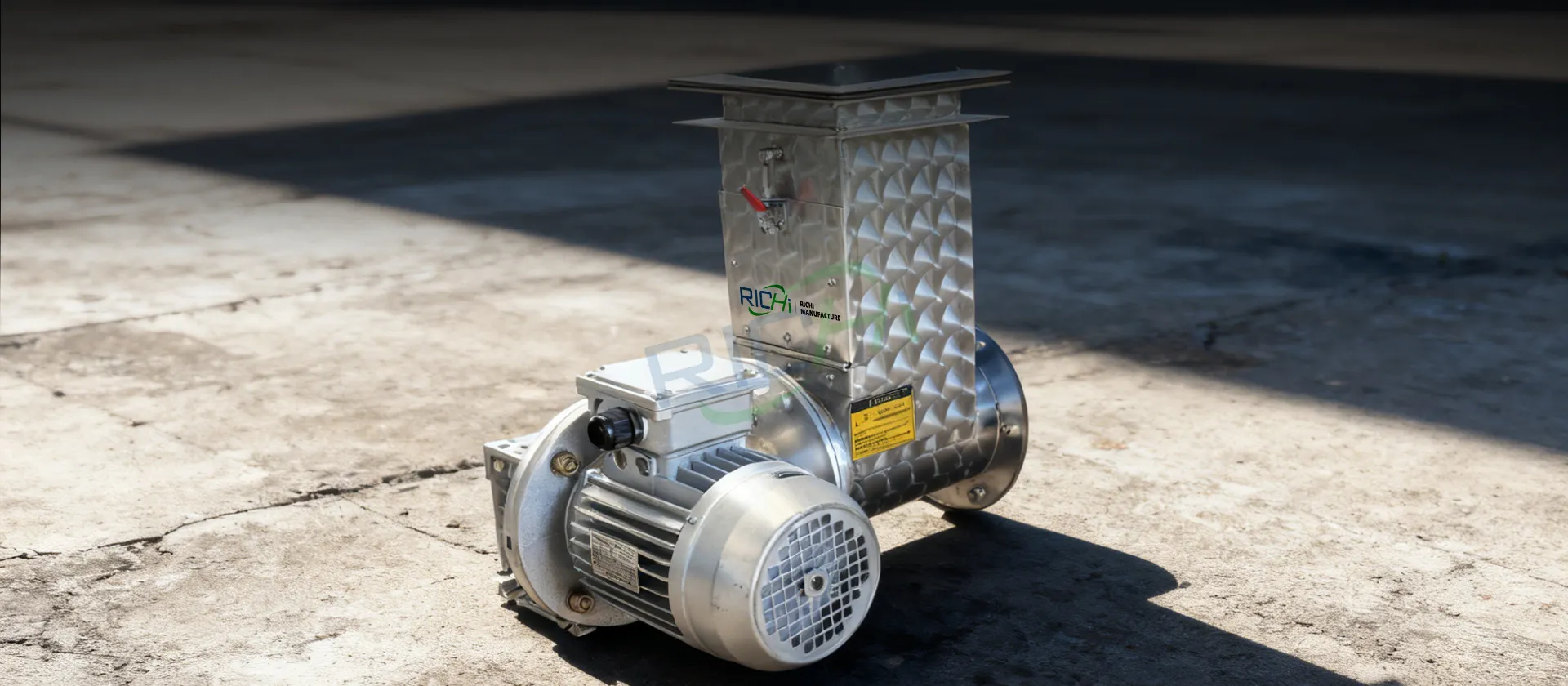

Built for Reliability and Performance

At the heart of every RICHI feed granulator machine lies a commitment to durability and efficiency. Each structural component is engineered with precision to withstand demanding 20-22 t/h operations, reduce long-term costs, and deliver superior pellet quality. Below, we detail the key features that set our SZLH558 apart, showcasing the technical strength that makes us a trusted manufacturer of industrial pelleting solutions.

Engineered Advantages for Unmatched Performance

The RICHI SZLH558 feed granulator machine is more than just durable hardware; it’s a system packed with intelligent features designed to maximize uptime, simplify operation, and optimize pellet quality. These advantages translate directly to lower operating costs and higher return on investment for your animal feed production plant.

Maximized Component Lifespan & Smart Protection

A key advantage of this feed granulator machine is its intelligent design that actively protects core parts. By synchronizing the feeder with the roller position, the rollers automatically retract during idle periods. This simple innovation, combined with high-alloy materials, reduces unnecessary wear, extending the life of dies and rollers by up to 30%.

Precision Control for Optimal Pellet Quality

Operators gain unparalleled control with motorized roller adjustment and active roller slip control. You can fine-tune the roller gap to the die during operation for precise recipe-based settings. The system also automatically detects and corrects roller slip, eliminating related downtime and allowing you to confidently experiment with settings to boost both feed quality and production efficiency.

Enhanced Cleanability & Operational Simplicity

Designed for real-world production, this machine prioritizes easy maintenance. A dedicated die-cleaning mode removes residual material after a batch, preventing caking and ensuring quick, clean restarts. Furthermore, critical components feature an easy-to-clean coating, significantly reducing cleaning time and effort for your crew.

Tailored Solutions Through Customization

As your expert manufacturing partner, we offer deep customization for your feed granulator machine. Beyond choosing the number of conditioner stages, we tailor solutions based on your specific feed formulas. This includes custom die specifications (hole size, pattern, material), specialized feeder configurations for challenging ingredients, and integration of specific automation controls to match your plant’s workflow perfectly.

How feed granulator machine Works

Understanding the core process highlights why our SZLH558 stands apart. This feed granulator machine transforms powdered mash into dense, uniform pellets through a controlled, mechanical force. It’s a reliable system engineered for consistency at a high 20-22 ton per hour rate, demonstrating our focus on efficient, industrial-grade solutions.

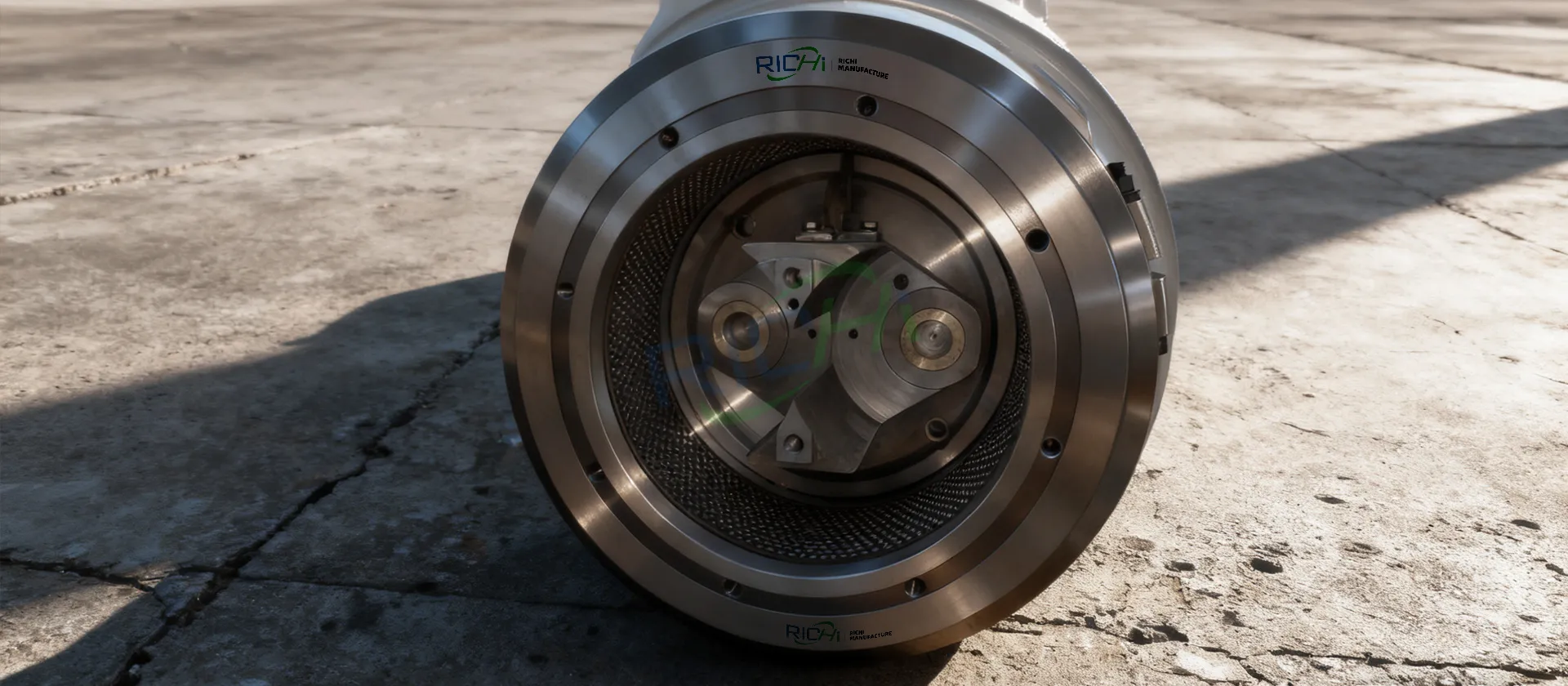

The process begins as conditioned mash is fed into the pelleting chamber. Here, two hardened rollers forcefully press the material through a rotating, precision-drilled ring die. The intense pressure generates heat, naturally binding the ingredients. Finally, adjustable external knives cut the extruded strands to your exact pellet length. This direct, robust mechanism is the foundation of our machine’s reliable output and superior pellet quality.

Technical Specifications & Performance Data

Explore the precise engineering behind the SZLH558 feed granulator machine. The detailed specifications below highlight its robust 20-22 t/h capacity and the technical choices that ensure reliable, high-output performance. As a leading manufacturer, we offer a comprehensive range of pellet mills. If your requirements differ, discover seven additional models tailored for various production scales.

Need detailed specifications in a different format? Contact our team.

SZLH558 (20-22T/H) Technical Specification

Main motor power

185kW

Feeder power

1.5kW

Conditioner power

11kW

Ring die inner diameter

558mm

Finished pellet diameter

2-12mm

Process Tuning for Optimal Pellet Quality

Every feed formula demands specific processing parameters to achieve its ideal nutritional and physical properties. The versatility of the SZLH558 feed granulator machine lies in its precise control over these variables. Below, we detail the key production settings for five major feed types, showcasing our deep expertise in tailoring the pelleting process for maximum performance.

Poultry Feed Pelleting Parameters

Our feed granulator machine achieves an output of 18-23 tons per hour for high-volume poultry diets. The conditioner is set to reach approximately 150°C, with an extended conditioning time of 60-120 seconds to ensure proper starch gelatinization. Pellets are typically sized between 2-4mm in diameter, requiring a die compression ratio of 1:10 to 1:13 to create durable, uniform crumble or finished pellets ideal for chickens.

Ruminant Feed Pelleting Parameters

For cattle and sheep feed, the SZLH558 ruminant cattle feed pellet machine is tuned for denser, larger pellets. Output ranges from 22 to 28 t/h, processing a coarser grind (3-5mm). To form the required 6-12mm diameter pellets effectively, a lower compression ratio of 1:6 to 1:9 is used. Conditioning is robust yet efficient, maintaining a high temperature of 150°C for a shorter 30-60 second duration, optimizing production of high-fiber feeds.

Pig Swine Feed Pelleting Parameters

Producing premium pig feed, this pig feed pellet machine operates at its full 20-25 t/h capacity. Conditioning is critical, with temperatures at 150°C and a 60-120 second dwell time to enhance digestibility. The machine forms smaller pellets (2-4mm diameter) using a moderate compression ratio between 1:3.5 and 1:5. This balance ensures optimal feed conversion with excellent pellet durability for handling.

Sinking Fish Feed Pelleting Parameters

Manufacturing high-stability aqua feed requires precise adjustments. Output is calibrated between 12 and 15 t/h to allow for thorough processing. The raw material is finely ground (1.0-2.0mm) and conditioned for 90-180 seconds at high heat to achieve maximum water stability. A high compression ratio of 1:16 to 1:18 in the fish feed pellet making machine is essential to form the dense 2-6mm pellets that sink reliably.

Shrimp Feed Pelleting Parameters

This represents the most specialized application for the shrimp feed pellet machine. It requires ultra-fine grinding (95% ≥80 mesh) and a very slow, controlled output of 1.5-2.5 t/h. Extended conditioning of 120-180 seconds is vital. The system utilizes the highest compression ratio, from 1:20 to 1:25, to form extremely dense and water-stable micro-pellets, typically 1.2-2.0mm in diameter, crucial for shrimp nutrition.

Global Project Portfolio

Our feed granulator machine is a proven component in animal feed pellet plants operating worldwide. We have successfully delivered complete production solutions to every major continent. These projects range from single machines for specialized farms to fully automated lines for multinational feed producers, processing a vast array of feed types at various capacities. In most cases, we supply not just a standalone feed granulator machine, but the entire integrated pelleting line tailored to the client’s exact needs.

Feed granulator machine for sale Kazakhstan

A large-scale commercial feed mill integrated our feed granulator machine into a new line for cattle feed production. They process local grains into uniform 4-6mm pellets to supply regional dairy and beef farms.

Feed type: Cattle Feed

Pellet size: 4-6mm

Feed granulator machine for sale Indonesia

Feed type: Cattle Feed

Pellet size: 6mm

Feed granulator machine for sale Russia

Feed type: Poultry feed

Pellet size: 3-4mm

A poultry integrator selected our system to manufacture high-volume chicken feed. The chicken feed mill plant is engineered to produce durable 3-4mm pellets from a mix of corn, soybean meal, and essential premixes.

Feed granulator machine for sale Iran

Feed type: Broiler Feed

Pellet size: 2.5mm

Feed granulator machine in Algeria

Feed type: Sheep Feed

Pellet size: 8mm

Feed granulator machine for sale Thailand

We equipped a dedicated aqua feed plant with a specialized feed granulator machine. This setup produces sinking fish feed with pellet sizes of 2mm and 4mm, using precise formulations for tilapia and catfish.

Feed type: Fish Feed

Pellet size: 2-4mm

Feed granulator machine for sale France

Feed type: Horse Feed

Pellet size: 10mm

Trusted by Industry Leaders

We partner with feed producers of all sizes to build reliable, high-output solutions. Our expertise extends beyond manufacturing a superior feed granulator machine to designing and supporting complete pelletizing lines—from raw material handling and grinding to final cooling and packaging. Let us help you build a system that grows with your business.

Global Client Voices

Our commitment to engineering excellence and tailored solutions is validated by clients worldwide. Their feedback on our technology, equipment designs, and comprehensive services highlights the real-world performance and reliability we deliver across diverse feed industries and production environments.

Romania Client

Feed type: Poultry Feed

Pellet size: 3-4mm

Setting up a new poultry feed line in a limited factory space was a challenge. RICHI’s compact yet high-output SZLH558 system was the perfect fit. The precise control over conditioning temperature and time has been crucial for producing consistent, high-quality 3-4mm broiler pellets. Their team’s installation support ensured a smooth launch.

South Africa Client

Feed type: Cattle Feed

Pellet size: 6mm

Our large-scale cattle operation relies on producing high-volume, nutritious feed. The durability of RICHI’s feed granulator machine is outstanding. It consistently processes our local maize and protein blends into dense 6mm pellets, with minimal downtime. This reliability is essential for our commercial feed mill’s daily output.

Brazil Client

Feed type: Pig Feed

Pellet size: 3-4mm

For our integrated swine production, pellet quality directly impacts growth rates. The RICHI granulator’s motorized roller adjustment lets us optimize the gap for different formulas on the fly. We now produce superior 3-4mm pig feed pellets with perfect hardness, enhancing overall feed conversion efficiency in our operations.

Afghanistan Client

Feed type: Sheep & Goat Feed

Pellet size: 8mm

In our region, maximizing nutrition from available forage like alfalfa and crop residues is key. RICHI’s machine, equipped with a forced feeder, handles these fibrous materials perfectly to produce 8mm pellets. It has significantly improved feed efficiency for our flocks, proving robust enough for our demanding conditions.

India Client

Feed type: Aqua Feed (Sinking)

Pellet size: 2mm & 4mm

As a growing aqua feed producer, we needed a machine capable of fine-tuning for different fish species. RICHI’s dual-layer conditioner and adjustable parameters allow us to produce both 2mm and 4mm sinking pellets with excellent water stability. Their technical guidance on recipe adaptation was invaluable.

A Guide to Precision in Feed Manufacturing

Achieving the optimal pellet size is not just a matter of output—it’s a critical factor influencing feed intake, digestibility, and overall animal performance. Different species and growth stages require specific pellet dimensions to maximize nutritional efficiency. This guide outlines the common pellet sizes produced on our advanced feed granulator machine, detailing the appropriate animal applications and the technical considerations in machine configuration for each specification.

Integrated Feed Production Line Solutions

We understand that a high-performance feed granulator machine is the core of a successful operation, but it is only one component of a complete system. We provide comprehensive, turnkey production line solutions—from initial design and engineering to installation, commissioning, and lifecycle support.

Every feed type, from standard poultry pellets to high-stability aquatic feed, requires a distinct processing flow. Our engineers customize the entire line—including grinding, mixing, conditioning, pelleting, cooling, crumbling, and packaging—based on your specific raw materials, target pellet size and quality, recipe, plant layout, and investment goals.

Silo

Cleaning

Grinding

Mixing

Batching

Pelleting

Cooling

Screening

Packaging

Precision Pelleting

The feed granulator is the

critical core where your

recipe is transformed.

Complete Feed Processing Equipment & Integration

storage silo equipment

01

cleaning equipment

02

grinding equipment

03

mixing equipment

04

cooling equipment

05

screening equipment

06

packaging equipment

07

Your feed pellet mill is the heart of the operation, but it requires a fully integrated system to perform at its best. We provide more than just granulators; we engineer and supply the complete spectrum of processing equipment. From the initial intake and storage of raw materials to the final bagging of finished pellets, we ensure every component—from grinders and feed mixer machines to coolers, conveyors, and automated packing lines—is correctly specified and configured for your specific feed type and production goals.

Our capabilities include complete systems for grinding, mixing, conditioning, pelleting, cooling, crumbling, screening, drying, extrusion, conveying, dust collection, automated batching, and palletizing. We don’t just sell individual machines; we design cohesive production lines where every piece of equipment is optimized to work seamlessly with the others, guaranteeing efficiency, consistency, and reliability.

Tailored Solutions for Every Feed Type

No single feed formula is the same, and neither should your production line be. We design and configure complete pelleting systems based on the specific nutritional, physical, and economic requirements of each feed category. Below are our targeted solutions for major animal sectors, detailing the recommended core pellet mill specifications and the standard process flow we engineer for optimal results.

Your Questions on Feed Granulation Answered

When investing in a high-capacity feed production system, you need clear, practical answers. Below, we address the most common inquiries we receive from feed mill managers, farm owners, and project developers worldwide about our ring die feed granulator machine and its integration.

What is the price of a feed granulator machine?

+

The cost of a feed granulator machine varies significantly based on its model, capacity, motor power, and configuration. As a leading manufacturer, we offer a comprehensive range of ring die feed pellet machines to meet different production scales and budgets.

The following provides a general overview of pricing for our standard single ring die feed pellet machine models, quoted on an FOB basis. Please note these are reference price ranges and the final cost can be influenced by specific technical requirements, optional features, and market conditions.

- SZLH250 (22KW): With a capacity of 1-2 tons per hour, this entry-level model is ideal for small farms or pilot plants. The estimated price range is $6,500 – $9,500.

- SZLH320 (37KW): Suitable for medium-scale startup operations, this 3-4 t/h machine typically falls in the range of $14,000 – $19,000.

- SZLH350 (55KW): Designed for steady production of 5-6 t/h, the cost for this reliable workhorse model is approximately $26,000 – $33,000.

- SZLH420 (110KW): A popular choice for growing feed mills requiring 8-12 t/h output, its price generally ranges from $27,000 – $35,000.

- SZLH508 (160KW): For high-capacity production of 15-16 t/h, this robust machine is priced between $38,000 – $47,000.

- SZLH558 (185KW): Our featured model, delivering 20-22 t/h, is engineered for large-scale commercial production. The investment for this unit is typically in the range of $46,000 – $54,000.

- SZLH678 (250KW): For outputs of 30-33 t/h, this industrial-grade machine represents a higher capital investment, usually from $63,000 – $72,000.

- SZLH768 (315KW): Our highest capacity standard model, producing 38-42 t/h, has a price range of approximately $76,000 – $85,000.

The models listed above represent our core series of feed granulator machines but are not an exhaustive list. We provide pellet mills specifically engineered for animal feed processing across poultry, livestock, and aquaculture applications.

It is important to understand that the final feed granulator machine price is highly customized. Factors that influence the cost of a feed granulator machine include:

- Customization: Number of conditioner stages (single, double, triple), specific die specifications, or special coatings.

- Application: Specific requirements for producing poultry, cattle, pig, or high-stability aquatic feed can dictate different configurations.

- Ancillary Equipment: Integration with specific feeding systems, lubrication stations, or control panels.

- Project Scope: Whether the machine is part of a larger turnkey feed production line for a project in, for example, Vietnam, Nigeria, or Chile.

To receive an accurate and detailed quotation tailored to your specific raw materials, desired pellet size, production goals, and location, please contact our sales team with your requirements. We will provide a comprehensive proposal that outlines the optimal machine specification and its corresponding investment.

Our feed mill in Turkey is expanding. For your 20-22 t/h model, what are the exact foundation and space requirements for installation, including the cooler and auxiliary equipment?

+

For a successful installation of the SZLH558 feed granulator machine in a facility like yours in Turkey, we provide a detailed foundation and layout plan during the project engineering phase. Typically, you should allocate a reinforced concrete foundation capable of supporting approximately 8-10 metric tons.

The total footprint for the pelleting section, including the granulator, its matching counter-flow cooler, and necessary clearance for operation and maintenance, is generally around 8 meters in length by 5 meters in width. However, these are approximate figures. Richi Machinery’s project engineers will conduct a specific review based on your existing plant layout to design an optimal, space-efficient integration plan that ensures smooth material flow and safe access.

We run a large pig farm in Mexico. Can this specific machine reliably process high-fiber diets with wheat bran and DDGS into durable 3.5mm pellets without frequent clogging?

+

Absolutely. The SZLH558 feed granulator machine is engineered to handle challenging formulations, including those with high percentages of wheat bran and DDGS common in modern swine diets. The key lies in the configuration.

For such recipes, we recommend equipping the machine with a forced feeder to ensure consistent material flow into the conditioning chamber and a ring die with an optimized compression ratio and release channels for fibrous materials.

Our engineers have extensive experience formulating these specifications for pig feed producers in the Americas. With the correct setup, you can achieve excellent pellet durability (PDI) for 3.5mm pellets, minimizing fines and preventing die clogging.

In Nigeria, we face frequent power fluctuations. What motor starter and electrical protection options do you offer to protect the feed granulator machine from damage?

+

We understand the critical importance of electrical stability in regions like Nigeria. To protect your investment in the SZLH558 feed granulator machine, we strongly recommend and can supply a complete motor control center (MCC) panel equipped with a soft starter or a Variable Frequency Drive (VFD).

A VFD offers superior protection by providing a soft start (reducing mechanical stress), compensating for minor voltage sags, and allowing for precise speed adjustment of the feeder and conditioner.

The panel will include high-quality circuit breakers, overload relays, and phase-failure protection devices specifically calibrated for the 185KW main motor. This integrated electrical package from Richi Machinery is designed to shield the machine’s critical components from damage due to power anomalies.

For a new aqua feed plant in Ecuador targeting tilapia, what is the recommended conditioner configuration to achieve proper water stability for 4mm sinking pellets with this machine?

+

For producing high-quality, water-stable sinking feed for tilapia in Ecuador, a double-layer (two-stage) conditioner is the recommended configuration for the SZLH558.

This setup provides the extended retention time (adjustable up to 90-180 seconds) necessary for sufficient steam penetration and starch gelatinization, which is the foundation of water stability. The first stage pre-heats and moisturizes the mix, while the second stage applies precise heat and steam for optimal cook.

Combined with a high-compression ring die (typically a ratio of 1:16 to 1:18 for 4mm pellets) and a precise post-pelleting drying/cooling process, this system from Richi Machinery delivers pellets with excellent durability and minimal disintegration in water.

What is the expected hourly energy consumption (kWh) for the SZLH558 model under full load when producing standard poultry feed, and how does that impact our operating cost in Poland?

+

Under full load producing standard poultry feed, the SZLH558 feed granulator machine’s main 185KW motor will consume approximately 185 kWh per hour at full draw.

However, the total connected load for the entire pelleting station, including the forced feeder, conditioner motors, and lubrication system, is typically around 210-220 KW. Actual energy cost in Poland depends on your local industrial electricity rate.

For a precise operating cost analysis, our engineers can factor in your specific tariff, expected annual operating hours, and the machine’s efficiency.

It’s important to note that the gear-driven transmission of our granulator is more energy-efficient than belt-driven systems, converting more power directly into pelleting force, which helps optimize energy use per ton of output.

We currently produce cattle feed but plan to add poultry lines next year. How difficult and costly is it to change the ring die and adjust settings on this machine to switch between producing 8mm cattle pellets and 3mm broiler pellets?

+

Switching between such different pellet specifications is a standard operational change for a well-designed feed granulator machine like the SZLH558. The primary task is changing the ring die and rollers, which is a straightforward mechanical process for trained personnel and can often be completed within a few hours.

The cost involves owning two sets of consumables: an 8mm die with a lower compression ratio for cattle feed and a 3mm die with a higher compression ratio for broiler feed. Additionally, you will need to adjust the conditioner parameters (steam, retention time), the roller-to-die gap, and the knife position.

Richi Machinery provides comprehensive operational training and manuals to empower your team to make these changes efficiently, maximizing your plant’s flexibility.

For a cooperative in Kenya processing local maize and sunflower meal, what is the typical percentage of fine particles (fines) we can expect after pelleting and cooling with your system?

+

With a properly configured and operated Richi Machinery SZLH558 line, you can expect a fines generation rate of less than 5% after the cooler, and often as low as 2-3% for well-conditioned maize and sunflower meal formulations.

Achieving this low level depends on several factors our engineers optimize: precise grinding size of the maize, sufficient conditioning temperature and time to activate binding agents in the sunflower meal, using the correct die specification for your formula, and properly adjusting the pellet cooler to avoid thermal shock and cracking.

We focus on the entire process to deliver whole, durable pellets that maximize your yield.

What is the standard delivery lead time for the SZLH558 to a port in Vietnam, and what key spare parts should we plan to keep in stock to minimize downtime?

+

The standard lead time for manufacturing, testing, and preparing shipment of an SZLH558 feed granulator machine to a port like Hai Phong in Vietnam is approximately 60-75 days after order confirmation. To ensure maximum uptime, we advise all customers to maintain a critical spare parts kit.

For the SZLH558, this should include: a set of pellet mill rollers (2 pieces), a set of main drive belt(s) (if applicable), key bearing seals and gaskets, and a supply of die-specific relief pins.

For long-term planning, having a spare ring die is also highly recommended. Richi Machinery provides a recommended spare parts list tailored to your planned operating hours and can support fast replenishment of parts from our warehouse.

Can your 20-22 t/h feed granulator machine be integrated with an existing older mixing and grinding line from a different European manufacturer, and what interface challenges should we anticipate?

+

Yes, integration with existing equipment is a common and strength of our engineering services. The SZLH558 can be integrated with older European lines. The primary interface challenges we expertly address are:

- 1) Material Flow Matching: Ensuring the throughput of your existing grinder and mixer matches the 20-22 t/h capacity of the new granulator. We may recommend buffer bins or control system adjustments.

- 2) Control System Interface: Bridging between different PLC or control systems to ensure seamless start/stop sequences and safety interlocking.

- 3) Physical Connection: Designing and fabricating custom chutes, air systems, and supports to connect the new machine to your existing layout.

Richi Machinery’s project team handles all these aspects to ensure a smooth, functional integration.

We are a feed producer in the Philippines with high humidity. What specific anti-corrosion treatments or paint systems do you use on the machine to ensure longevity?

+

For the challenging high-humidity and salty air environments common in the Philippines, Richi Machinery uses an enhanced protective coating system. Critical structural components, like the main housing and conditioner, are sandblasted to a clean surface and then treated with a high-quality epoxy zinc-rich primer.

This is followed by multiple coats of polyurethane topcoat paint, which offers excellent resistance to moisture, chemicals, and UV radiation. For areas with the highest wear or exposure, such as the feeder, we can apply stainless steel cladding upon request.

This robust paint system is a standard part of our commitment to delivering a durable, long-lasting feed granulator machine.

What is the recommended routine daily and weekly maintenance checklist for operators to follow on this high-capacity machine?

+

A disciplined maintenance routine is key to the longevity of your feed granulator machine. Our comprehensive manual provides full details, but key daily tasks include: checking and greasing all bearing points (per the lubrication chart), inspecting V-belt tension, checking for oil leaks at the gearbox and lubrication station, and ensuring the roller-to-die gap is correct.

Weekly tasks involve a more thorough inspection: checking wear on the rollers and die, cleaning the magnet and feed intake area, verifying the condition of the knife blades, and ensuring all safety guards and interlocks are functional.

Richi Machinery’s training ensures your operators are fully equipped to perform this care.

For a project in Egypt, do you offer remote monitoring and support capabilities for the granulator?

+

Yes, for projects in Egypt and globally, Richi Machinery offers advanced remote support solutions.

We can equip the SZLH558 feed granulator machine with IoT-enabled sensors and a gateway that transmits key operational data (motor load, bearing temperature, production rate) to a secure platform.

This allows our engineers in China to perform preliminary diagnostics, monitor performance trends, and provide proactive support. For direct assistance, we utilize secure remote desktop connections to your plant’s HMI/SCADA system for real-time troubleshooting, significantly reducing potential downtime.

When processing high-fat broiler feed formulas, what is the maximum fat percentage that this machine can handle effectively?

+

The SZLH558 feed granulator machine can effectively process broiler feed with up to 6-8% added fat (post-conditioning, total fat content typically 8-10%). Success with high-fat formulas depends on strategic fat application.

We recommend adding a portion of the fat (1-3%) in the conditioner for lubrication and binding, with the remaining fat applied via a precise post-pelleting liquid coating (PLC) system.

This prevents the fat from overly lubricating the die during extrusion, which can cause slippage and poor pellet formation. Richi Machinery can supply the complete integrated system, including the granulator and PLC, optimized for high-fat diets.

What is the noise level of the SZLH558 during operation, and are there optional enclosures available?

+

During normal operation, the SZLH558 feed granulator machine produces a sound pressure level of approximately 85-90 dB(A) at a distance of 1 meter, primarily from the gear transmission and pelleting action.

To meet strict workplace regulations like those in Germany, Richi Machinery offers an optional acoustic enclosure kit.

This custom-fitted enclosure, made of sound-dampening panels, can reduce the operational noise to below 80 dB(A), ensuring a safer and more comfortable working environment for your operators while maintaining full accessibility for maintenance.

For a new dairy feed production line in Uruguay, what is the scope of your technical support for commissioning and training?

+

Our support for your dairy feed line in Uruguay is comprehensive. The scope includes:

- 1) Pre-commissioning: Remote guidance on foundation and utility preparation.

- 2) On-site Commissioning: Sending 1-2 experienced engineers to Uruguay for 7-10 days to supervise installation, perform mechanical and electrical checks, conduct test runs with your actual materials, and fine-tune the system to produce perfect 6-8mm cattle pellets.

- 3) Training: Hands-on operational training for your production and maintenance teams, covering daily operation, routine maintenance, troubleshooting, and safety procedures.

- 4) Post-Commissioning Support: Providing a detailed commissioning report and remaining available for ongoing technical consultation.

Our goal is to ensure your team is confident and your line is productive from day one.

We are planning to install a commercial feed granulator machine for our broiler operation in Thailand. What’s the ideal pellet size for different growth stages, and can one machine handle all sizes efficiently?

+

For a broiler operation in Thailand, pellet size is crucial for feed conversion. Starter feed typically requires 2.0mm to 2.5mm pellets, grower feed uses 3.0mm, and finisher feed can be 3.5mm to 4.0mm. A single, well-configured ring die feed granulator machine from Richi Machinery, like our SZLH series, can absolutely handle this range.

The key is quick-change die technology and adjustable knife systems. We supply the machine with multiple ring dies (e.g., 2mm, 3mm, 4mm compression ratios) and train your operators on the efficient changeover procedure, which can be completed in a matter of hours.

This allows one high-performance unit to serve your entire production cycle, maximizing your investment.

Our dairy farm cooperative in New Zealand needs a high-performance feed granulator machine to process local forage mixes. How do we ensure the machine produces uniform size pellets that are durable enough for automated feeding systems?

+

For New Zealand dairy feed with high forage content, pellet durability and uniformity are non-negotiable for automated TMR systems. The solution lies in a robust feed granulator machine specifically configured for fibrous materials.

At Richi Machinery, we recommend a model equipped with a heavy-duty gearbox for high torque, a forced feeder to ensure consistent material flow, and a ring die with a lower compression ratio and deeper relief to prevent clogging. The precise roller-to-die gap adjustment, a standard feature on our machines, is critical for achieving uniform pellet density and size (typically 6mm or 8mm).

Combined with proper conditioning to activate natural binders, this setup from Richi delivers the hard, consistent pellets required for your automated feeding infrastructure.

I’m setting up a small-scale aquafeed plant in Indonesia focusing on tilapia. Should I choose a floating fish feed granulator machine or a slow-sinking model, and what are the key differences in the conditioning process?

+

For tilapia feed in Indonesia, the choice between floating and slow-sinking feed depends on farming practice, but slow-sinking is very common. It’s important to clarify the technology: a standard ring die feed granulator machine produces dense pellets and is ideal for sinking feed.

For true floating fish feed, a different technology—a single or twin screw extruder—is required, which we also supply. For your slow-sinking tilapia feed using a ring die machine, the conditioning process is paramount. We configure the machine with a double-layer conditioner to provide extended retention time (up to 180 seconds) and high-temperature steam (85-95°C).

This ensures thorough starch gelatinization, which is the foundation for good water stability and controlled sinking rates. Our engineers will specify the exact conditioner setup and die compression ratio for your specific formula.

For a swine feed production line in Canada that must include medicated premixes, what special features should we look for in a feed granulator machine to ensure accurate dosing and prevent cross-contamination between batches?

+

Handling medicated feed in Canada requires a strict focus on feed mill hygiene and batch integrity. For the feed granulator machine itself, we recommend a model with a highly cleanable design.

Key features include stainless steel contact surfaces in the feeder and conditioner, quick-release doors for inspection, and an effective die-cleaning mode that uses specialized granules to purge residual material. More importantly, the solution is systemic.

Richi Machinery designs the entire production line segment around this need, incorporating dedicated batch mixers, sequenced flushing systems for conveyors, and sometimes a dedicated pellet mill for medication-only production.

Our control systems can log and trace each batch from mixing through pelleting, ensuring compliance with CFIA regulations.

We operate a horse stable network in Argentina and want to produce our own high-fiber feed. What type of ring die granulator for feed is best suited for processing long-stem hay and oats into palatable pellets?

+

Producing high-quality horse feed from ingredients like long-stem hay in Argentina requires a feed granulator machine built for challenge. The primary hurdle is the fibrous, low-starch nature of the raw material, which lacks natural binding agents.

We recommend a heavy-duty model with a wide-diameter, deep-conditioning chamber to allow sufficient time for steam penetration and moisture uptake. It must be equipped with a powerful forced feeder to push the bulky material into the pelleting chamber consistently.

The ring die will have a very low compression ratio (e.g., 1:5) and large hole diameters (10mm, 12mm) to form the pellets without excessive pressure that can cause overheating.

Richi Machinery has extensive experience configuring systems for equine nutrition that produce durable, palatable pellets without damaging heat-sensitive nutrients.

As a feed mill in South Africa looking to upgrade, how does an industrial feed granulator machine with a conditioning system differ from a basic powder to pellet model in terms of final pellet quality and nutrient retention?

+

This is a fundamental question about feed quality. A basic powder-to-pellet machine applies mechanical pressure only, resulting in pellets that are often crumbly, have high fines, and offer poor nutrient digestibility.

An industrial feed granulator machine with an integrated conditioning system, like those from Richi Machinery, is a game-changer. The conditioner uses precise steam and time to cook the mash before pelleting.

This gelatinizes starches, which act as a natural binder for superior pellet durability (lower fines). More importantly, this thermal process improves nutrient availability, destroys anti-nutritional factors, and allows for better fat and enzyme integration.

The result is not just a physical pellet, but a nutritionally enhanced feed that directly improves feed conversion ratios (FCR) for your customers in South Africa.

For shrimp feed production in Vietnam, what makes a dedicated shrimp feed granulator machine different from a standard aquafeed model, particularly in achieving the required low-fines micro-pellet quality?

+

Shrimp feed represents the pinnacle of aquafeed pelleting, especially in a competitive market like Vietnam. The core difference for a shrimp feed granulator machine is its ability to handle ultra-fine grind (95% through 80 mesh) and achieve extremely high compression.

Our dedicated machines feature a triple-layer, micro-retention conditioner for maximum starch cook and binder activation. They use precisely machined, thin dies with very small hole diameters (1.0mm to 2.0mm) and exceptionally high compression ratios (1:25 or higher).

This combination, powered by a stable and powerful transmission, creates the dense, water-stable micro-pellets with a glassy surface that shrimp require.

Achieving “low-fines” output is a result of this entire optimized system—proper conditioning, exact die specification, and gentle post-pellet drying—all of which Richi Machinery engineers design into the complete line.

What regular maintenance does a large capacity feed granulator machine require to maintain consistent output, and what are the most critical spare parts we should keep in stock for our operation in Saudi Arabia?

+

Consistent output from a large-capacity machine in Saudi Arabia depends on disciplined preventative maintenance. A daily routine includes checking oil levels in the gearbox and lubrication station, greasing all bearing points per the chart, inspecting V-belt tension, and listening for unusual noises.

Weekly, operators should check and adjust the roller-to-die gap and inspect wear on the rollers and die inner surface. To minimize downtime, we advise keeping these critical spare parts on hand: a full set of pellet mill rollers (2 or 3 pieces), a set of main drive belts, key oil seals and gaskets for the gearbox and main shaft, and a stock of die-specific release pins.

For long-term security, investing in a spare ring die is highly recommended. Richi Machinery provides detailed maintenance manuals and can help you establish a tailored spare parts inventory plan.

When comparing different feed granulator machine brands for our new poultry feed pellet line in Poland, what technical specifications should we prioritize to ensure energy efficiency and low operating costs?

+

For a cost-conscious operation in Poland, focusing on total cost of ownership is key.

Beyond the purchase price, prioritize these technical specs for efficiency:

- Transmission Type: A gear-driven system (like ours) is more energy-efficient and durable than belt-driven, translating directly to lower kWh per ton.

- Motor Quality & Efficiency Class: Insist on high-efficiency (IE3 or IE4) motors from reputable brands.

- Conditioner Insulation: A well-insulated conditioner reduces heat loss, saving steam energy.

- Lubrication System: An automatic, recirculating oil lubrication system with cooling protects bearings and reduces friction losses compared to manual greasing.

At Richi Machinery, we design our feed granulator machines with these efficiency principles in mind, providing you with detailed power consumption data for an accurate operating cost forecast for your Polish facility.

For a ruminant feed granulator machine that will process high-roughage diets in Australia, what features are necessary to prevent die clogging and ensure smooth operation with ingredients like alfalfa and cottonseed hulls?

+

Processing high-roughage diets in Australia’s robust livestock sector demands a specifically ruggedized feed granulator machine. To prevent die clogging, the machine must have a forced feeder (a non-negotiable feature) to positively displace the fluffy, low-density material into the die.

The ring die should have larger hole diameters (6mm, 8mm, 10mm) with a wider inlet angle and deeper relief to guide the fiber in and allow it to compress without jamming. Furthermore, a variable speed drive on the feeder allows the operator to perfectly match the feed rate to the density of the formula.

Richi Machinery’s ruminant feed systems are built around these features, ensuring smooth, continuous operation with challenging ingredients like alfalfa and cottonseed hulls, maximizing uptime for your Australian operation.

We need to produce both complete feed pellets and supplements for our integrated livestock operation in Kenya. Can one professional feed granulator machine be easily adjusted to switch between producing concentrate feed pellets and full ration pellets?

+

Yes, a versatile professional feed granulator machine from Richi Machinery can be configured for this dual purpose on an integrated farm in Kenya. The adjustment is primarily in the die specification and conditioning parameters.

For dense, high-protein concentrate pellets (e.g., 4mm), a die with a higher compression ratio is used. For full ration pellets containing more fiber and grain (e.g., 6mm), a die with a lower compression ratio is optimal. Switching involves changing the ring die and rollers, a standard procedure we train your staff to perform.

Additionally, the conditioner steam and retention time settings are adjusted based on the starch content of each formula. With proper planning and our guidance, one machine can efficiently serve both production needs.

What are the advantages of choosing an automatic feed granulator machine with PLC controls for a high-volume feed production facility in Brazil, compared to manually operated models?

+

For a high-volume facility in Brazil, the advantages of a PLC-controlled automatic feed granulator machine are transformative for productivity and consistency.

- Operational Advantages: The PLC allows for recipe-based saving of all parameters (feeder speed, conditioner steam, motor load targets). With a single button, the machine adjusts itself for a new feed type, eliminating human error and reducing changeover time.

- Quality & Safety: The system provides real-time monitoring and automatic adjustments to maintain pellet quality. It also integrates safety interlocks (e.g., preventing start-up if a guard is open) and generates production reports for traceability.

- Labor Efficiency: It enables one operator to manage multiple machines and reduces the skill level required for day-to-day operation.

Richi Machinery’s advanced control systems are designed to integrate seamlessly into modern Brazilian feed mills, driving efficiency and profitability.

For pet food production in the United States, what modifications are needed to a standard livestock feed granulator machine to safely process high-fat recipes and achieve the precise shapes required for premium pet food?

+

For premium pet food production in the competitive U.S. market, a standard livestock feed granulator machine is not suitable. Pet food requires extrusion technology, specifically a twin-screw feed extruder.

This is because pet food formulas are very high in fat and protein, require precise shaping (stars, bones, etc.), and often need high levels of starch gelatinization for digestibility. A twin-screw extruder provides the necessary cooking, mixing, and forming capabilities under controlled temperature and pressure.

Richi Machinery supplies state-of-the-art pet food extrusion lines that include preconditioners, twin-screw pet food extruder machines with specialized dies, animal feed dryers/oilers, and coolers tailored to produce the exact shapes, textures, and nutritional profiles demanded by the U.S. pet food industry.

When installing a new feed granulator machine in an existing feed mill in India, what are the most common integration challenges with upstream mixing and downstream cooling systems, and how can they be addressed?

+

Integrating a new feed granulator machine into an existing Indian feed mill factory is common, and the challenges are predictable.

- Upstream with Mixing: The main issue is capacity matching. The new granulator’s throughput (e.g., 20 t/h) must be matched by the batch cycle time of the existing mixer. The solution often involves adding a surge or buffer bin between the mixer and the granulator feeder to ensure a continuous, steady supply of mash.

- Downstream with Cooling: The existing pellet cooler machine must have sufficient capacity to handle the increased output and remove the heat from the new machine. Sometimes, adding a second cooler in series or upgrading the fan capacity is needed.

Richi Machinery’s engineers specialize in these retrofit projects. We conduct a full audit of your existing line and design the integration—including custom chutes, supports, and control system interfacing—to ensure the new machine works in perfect harmony with your old equipment.

As a new entrant in the Nigerian market looking to establish a feed mill, what capacity range would you recommend starting with to balance initial investment with growth potential?

+

For a new entrant in the dynamic Nigerian market, we recommend a scalable approach. Starting with a machine that is too small limits growth, while one that is too large strains cash flow. Based on market analysis, we often advise beginning with a commercial feed granulator machine in the 8-12 tons per hour range (like our SZLH420 model).

This capacity is sufficient to supply several large poultry farms or a respectable number of smaller customers, establishing your presence. Crucially, when you design your plant layout with Richi Machinery, we plan for future expansion.

The foundation, electrical supply, and material handling can be pre-designed to allow for a straightforward upgrade to a 20-22 t/h machine later, protecting your initial investment and enabling seamless growth as your business and the Nigerian market develop.

Can you share some real project examples of your feed granulator machine in use globally, including the cost?

+

Yes, absolutely. Sharing project details helps potential clients understand how our SZLH558 feed granulator machine is applied in diverse markets and the investment scope for a complete pelleting solution.

It’s important to note that the “project cost” reflects the total value of a customized animal feed production line supplied, which always centers on the feed granulator machine but includes many other critical components like hammer mills, mixers, conditioners, coolers, conveyors, electrical control systems, and installation engineering.

The final cost varies based on line capacity, automation level, and local requirements. Below are several real references from our project database.

1. Poultry & Livestock Feed Line in Argentina

- Client Needs: A large agribusiness required a versatile line to produce feed for multiple species.

- Our Solution: We supplied a turnkey line featuring the SZLH558 feed granulator machine, configured to produce a wide range of pellet sizes from 2mm to 10mm. This flexibility allows them to manufacture feed for broilers, layers, and cattle from a single production line.

- Project Investment: The total installed project cost was approximately $370,000 USD.

2. High-Capacity Commercial Feed Mill in Afghanistan

- Client Needs: Establishing a major complete feed mill plant to supply the growing domestic poultry and aquaculture sectors.

- Our Solution: The project involved a complete, high-tech feed manufacturing plant. The core SZLH558 feed granulator machine was selected for its 20-22 t/h output and ability to produce precise pellets from 1.5mm (shrimp/starter) up to 6mm (larger fish/livestock), demonstrating its broad application range.

- Project Investment: The comprehensive project cost was about $790,000 USD.

3. Specialized Pig Feed Production in Mexico

- Client Needs: A swine integrator needed a dedicated line for high-quality, uniform pig feed pellets.

- Our Solution: We engineered a line optimized for swine nutrition. The SZLH558 feed granulator machine was fine-tuned with specific conditioning and die parameters to produce highly durable 2-3mm pellets that are ideal for piglet and grower diets, maximizing feed efficiency.

- Project Investment: The tailored line had a project cost of $559,700 USD.

4. Integrated Feed Mill for Local Farms in Indonesia

- Client Needs: A cooperative sought to produce various feeds for local chicken, duck, and fish farms.

- Our Solution: We provided a robust and flexible production line. The SZLH558 feed granulator machine serves as the reliable heart of the operation, capable of switching between 2mm poultry feed and 10mm cattle feed pellets with quick die changes, serving a diverse customer base.

- Project Investment: The complete mill project was valued at $550,000 USD.

5. Modern Sheep & Cattle Feed Plant in Algeria

- Client Needs: To produce nutritious pelleted feed for the region’s significant sheep and cattle herds.

- Our Solution: The line was designed for efficiency with local raw materials. The SZLH558 feed granulator machine is configured with a forced feeder to handle fibrous ingredients, producing dense 2-6mm pellets that improve feed intake and digestibility for ruminants.

- Project Investment: The total project cost came to $320,000 USD.

6. Poultry Feed Expansion in Uzbekistan

- Client Needs: An existing feed preparation plant aimed to expand capacity and improve pellet quality.

- Our Solution: We integrated a new SZLH558 feed granulator machine into their facility. The machine’s precise control over conditioning and pelleting now produces superior 2-5mm broiler and layer feed pellets, leading to better growth performance for their customers.

- Project Investment: The expansion and equipment package cost $420,000 USD.

7. Premium Dairy Feed Production in the United States

- Client Needs: A dairy feed manufacturer required a high-efficiency line to produce consistent, high-density pellets for dairy cows.

- Our Solution: We supplied a state-of-the-art line featuring the SZLH558 feed granulator machine with advanced automation. It is calibrated to produce uniform 3-6mm pellets that withstand handling and promote rumen health, meeting the high standards of the U.S. market.

- Project Investment: This advanced project had an investment of $750,000 USD.

8. Aqua & Poultry Feed Facility in Malaysia

- Client Needs: A new facility targeting both the vibrant poultry and aquaculture industries.

- Our Solution: This dual-purpose plant uses the versatile SZLH558 fish chicken feed pellet machine as its core. With different die sets and conditioning setups, it efficiently produces 2-4mm pellets suitable for both fast-growing chickens and various fish species, showcasing the machine’s adaptability.

- Project Investment: The complete facility project cost was $650,000 USD.

These examples illustrate that while the SZLH558 feed granulator machine is a constant, high-performance centerpiece, every Richi Machinery project is uniquely engineered. The final cost depends on your specific goals for pellet size, formula complexity, desired automation, and annual capacity. We recommend contacting our engineers for a custom quotation based on your detailed production plans.

Can you explain the key components and how a ring die feed granulator machine works?

+

Understanding the internal mechanics of a feed granulator machine provides insight into its reliability and ability to produce high-quality pellets.

At its core, a ring die granulator is a robust system that transforms conditioned mash into uniform pellets through mechanical pressure. Below is a breakdown of the main components and the principle behind our high-performance SZLH series machines.

Core Components & Their Role:

- The Ring Die: This is the heart of the feed granulator machine and the most critical element defining pellet quality. Richi Machinery uses high-chromium alloy steel dies, known for superior wear resistance compared to standard stainless steel, extending service life significantly. The die is precision-drilled with thousands of holes of a specific diameter and shape. The compression ratio (the effective length to the hole diameter) of each hole is carefully engineered based on the target feed type—higher for aqua feed, lower for fibrous cattle feed. It is within these holes that the raw material is formed under immense pressure into dense pellets.

- The Press Rollers (or Pellet Mills Rolls): These are the driving force. Typically, two rollers rotate within the stationary ring die. At Richi Machinery, we use high-quality, case-hardened rollers that provide an optimal balance of durability and grip. The rollers do not touch the die; a precise, micron-level gap is maintained and can be adjusted even during operation on our advanced models. This “roller-to-die gap” is critical; too wide reduces output, too close causes excessive wear. Our engineers specify the optimal roller diameter and surface pattern (smooth or corrugated) based on your primary raw materials to ensure efficient material capture and consistent pressure.

- The Feeder: This is the gatekeeper of consistency. Our feed granulator machines are equipped with a variable-speed, forced feeder (often a screw type) that delivers a steady, controllable flow of conditioned mash from the conditioner into the extrusion chamber. This ensures the rollers and die are consistently and evenly loaded, which is fundamental to achieving stable motor load, uniform pellet density, and preventing clogging or slippage.

- The Cutter: Positioned externally on the die housing, adjustable knives slice the continuous strands of extruded material into precise pellets. The distance of the knife from the die face directly determines pellet length. Our systems allow for quick external adjustment, enabling operators to change from short crumbles to long pellets in minutes without stopping production.

- Lubrication & Drive Systems: These are the unsung heroes of durability. Richi Machinery granulators feature a centralized, automatic lubrication system that continuously feeds clean oil to critical bearings, reducing friction, heat, and wear. The main drive is a heavy-duty gearbox coupled with a high-efficiency motor, providing the powerful, steady torque required for continuous 20-22 t/h operation with minimal energy loss.

What are the key material and component specifications for the SZLH558 feed granulator machine?

+

The superior performance and durability of our SZLH558 feed granulator machine are a direct result of its premium material selection and component engineering. We build this industrial workhorse to withstand continuous, high-capacity operation while minimizing long-term maintenance costs. Here is a detailed look at the critical configuration that defines its quality.

Core Specifications & Component Origin:

- Ring Die Material: While standard options include high-alloy steel, we primarily manufacture ring dies from high-grade stainless steel for clients requiring superior corrosion resistance, especially for aqua feed or high-moisture applications. This extends die life significantly under challenging conditions.

- Hygienic & Durable Construction: The door cover of the granulation chamber is constructed from 6mm thick SUS304 stainless steel, ensuring robustness and easy cleaning. The internal feed chute is also made from 3mm SUS304 stainless steel to prevent material adhesion and corrosion, which is critical for maintaining feed hygiene and simplifying maintenance.

- High-Strength Power Transmission:

- Gearbox: The main housing is a heavy-duty casting (HT250 grade), providing exceptional stability and vibration damping.

- Gears: The main drive gears are precision-machined from 42CrMo alloy steel, a material chosen for its excellent strength, toughness, and wear resistance under heavy loads.

- Gear Shaft: The critical gear shafts are made from 20CrMnTi, a carburizing steel known for its hard, wear-resistant surface and tough core, ensuring long-term reliability.

- Premium Bearing & Sealing System: To guarantee smooth operation and prevent breakdowns, we use imported high-precision bearings (from brands like SKF or NSK) in all critical positions. These are paired with high-quality oil seals from German or Taiwanese manufacturers, renowned for their reliability in preventing lubricant leakage and contaminant ingress.

- Reliable Drive & Protection:

- Coupling: The machine utilizes a serpentine spring coupling for power transmission. This design effectively absorbs shock loads and compensates for minor misalignments, protecting both the motor and the gearbox.

- Motor: It is powered by a Siemens industrial-grade motor, ensuring efficient, reliable, and consistent power delivery.

- Overload Protection: In addition to electrical protections, the system includes a mechanical shear pin (safety pin) overload protection device. In the event of a severe jam, this pin shears instantly, physically disconnecting the drive and preventing catastrophic damage to the gearbox or other core components.

Why This Configuration Matters for Your Feed Production:

This specification sheet is not just a list of parts; it reflects a philosophy of building for the long term. The use of SUS304 stainless steel in key contact areas speaks to our commitment to hygiene and durability, which is vital for producing safe feed.

The selection of specific alloy steels (42CrMo, 20CrMnTi) for gears and shafts is an engineering decision that directly translates to the machine’s ability to maintain precise alignment and deliver consistent power over thousands of hours, a necessity for achieving uniform pellet quality. By integrating top-tier imported bearings and seals with a robust mechanical design, we minimize unplanned downtime—the single biggest cost in feed production.

Ultimately, the configuration of the SZLH558 feed granulator machine is designed to provide a stable, reliable, and hygienic pelleting core for your feed line, capable of processing everything from high-fat poultry diets to abrasive cattle feed with unwavering consistency. This commitment to quality components is what separates a Richi Machinery granulator from a commodity machine.

What is the typical application and capacity range for the SZLH558 feed granulator machine, and what kind of production line does it support?

+

The SZLH558 feed granulator machine is engineered as the core pelleting unit for medium to large-scale commercial animal feed production, specifically designed for operations targeting a continuous output of 15 tons per hour or more. Its robust construction and high-power drive make it the ideal choice for animal feed processing plants supplying large farms, cooperatives, or regional distributors.

Primary Application & Animal Range:

This industrial-grade machine is the central component in complete feed pellet production lines. These lines are designed to manufacture nutritionally optimized, durable pellets for an extensive range of animals, including but not limited to:

- Poultry: Chicken (broilers & layers), duck, goose, quail, pigeon.

- Livestock: Cattle (beef & dairy), pigs, sheep, goats, rabbits, horses.

- Aquaculture: Fish (e.g., tilapia, catfish, trout), shrimp.

The versatility of the SZLH558 feed granulator machine lies in its adjustable operational parameters. By changing the ring die specification (hole size and compression ratio) and fine-tuning the conditioning process, the same machine can efficiently switch between producing, for example, 2.5mm broiler feed and 8mm cattle feed, making it a highly flexible asset for multi-species feed producers.

Integration into a Complete Feed Production Line:

A feed pellet production line is a sophisticated, integrated system where each stage is critical to final product quality. The feed granulator machine is the pivotal stage in this process. A typical line designed around the SZLH558 includes:

- Raw Material Receiving & Storage

- Grinding (to achieve the correct particle size)

- Batching & Mixing (for precise formula accuracy)

- Conditioning & Pelleting (The core function of the feed granulator machine)

- Cooling & Screening (to stabilize and remove fines from pellets)

- Crumbling (if required for starter feeds)

- Coating & Packaging

As a leading manufacturer of both feed granulator machines and complete turnkey plants, Richi Machinery has a proven track record of successfully engineering and commissioning such lines for investors worldwide. We understand that every project is unique, defined by local raw material availability, target animal species, market size, and budget.

Therefore, we do not offer a one-size-fits-all solution. Whether your goal is a 15 t/h line or a much larger facility, our engineers provide fully customized production line designs. This includes a detailed process flow, tailored equipment configuration list, and factory layout—all backed by comprehensive technical support, installation supervision, and operator training to ensure your plant operates at peak efficiency and stability from day one.

For investors serious about establishing or expanding a feed production operation with a capacity exceeding 15 tons per hour, the SZLH558 feed granulator machine from Richi Machinery represents a reliable and high-performance starting point for building a profitable and sustainable business.

What are the main factors that determine the price of a feed granulator machine, and how should a company evaluate its investment?

+

This is an excellent and crucial question for any business planning to invest in feed production capacity. The price of a feed granulator machine is not arbitrary; it reflects a combination of engineering specifications, material quality, and manufacturing standards.

At Richi Machinery, we believe in transparent value. Understanding these factors will help you make an informed decision that balances initial investment with long-term operational reliability and profitability.

Key Factors Influencing Feed Granulator Machine Price:

- Specifications, Capacity, and Physical Size:

This is the most direct factor. The SZLH558, as a 20-22 ton/hour industrial machine, commands a higher price than our 5 t/h SZLH350 model. Larger machines require significantly more raw material (heavy-duty castings, larger gears, bigger motors), more complex machining, and longer assembly and testing cycles. The price scale directly correlates with the machine’s output potential and its physical robustness to handle continuous high-load operation. - Technical Complexity and Specialized Functions:

Standard machines handle common feed types. However, specific applications demand—and justify—higher technical investment. For instance:- Aqua Feed Production: Requires a triple-layer conditioner for extended retention time and ultra-high compression dies, increasing complexity and cost.

- Special Materials: Processing highly abrasive or corrosive blends may necessitate upgraded stainless steel components (e.g., conditioner liners, feed chutes) or special alloy die/roller materials.

- Automation & Control: A basic machine with manual controls differs vastly in price from one with a full Siemens PLC, touchscreen HMI, automated roller gap adjustment, and remote monitoring capabilities. These features enhance consistency, reduce labor, and prevent errors, offering a rapid return on investment for high-volume producers.

- Material Selection and Component Quality:

The choice of materials fundamentally dictates durability, maintenance intervals, and ultimately, lifetime cost. Our standard SZLH558 uses 42CrMo alloy steel for gears and imported high-precision bearings, which are more expensive than generic alternatives but ensure smooth, reliable power transmission for years. A client can choose a standard high-alloy steel die or opt for a more expensive stainless steel die for corrosive aqua feed, directly affecting the unit price. We guide clients to select materials that match their specific feed formula to avoid both over- and under-engineering. - Manufacturing Process and Quality Assurance:

A lower price often reflects shortcuts in manufacturing. At Richi Machinery, our price includes the cost of advanced processes: precision CNC gear grinding for quiet, efficient operation; automated welding and stress-relieving of frames for longevity; and comprehensive run-in testing of every machine before shipment. Our strict quality control protocols at every stage ensure you receive a feed granulator machine that is reliable from startup, avoiding costly downtime and repairs that erode the value of a cheaper, untested machine.

Market Analysis and Strategic Procurement:

For companies in emerging markets like Nigeria or Indonesia, or established markets like the USA or Brazil, a strategic view is essential. Beyond the machine’s sticker price, consider:

- Total Cost of Ownership (TCO): This includes energy efficiency (gearbox vs. belt drive), expected spare parts consumption, and maintenance labor. A higher-quality, slightly more expensive feed granulator machine often has a lower TCO.

- Supplier Capability: Choose a manufacturer like Richi Machinery that can also supply the entire production line (mixers, coolers, etc.). This ensures seamless integration, single-point accountability, and often better overall project pricing than sourcing piecemeal from multiple vendors.

- Future-Proofing: Consider if your chosen machine can be easily upgraded or adapted for new feed types as your market evolves. The modular design and customization options of our machines protect your investment against future changes in demand.

In summary, while price is a critical entry point, it should be evaluated against specifications, technical features, material quality, and the manufacturer’s reputation for engineering and support.

Richi Machinery works with clients to design a feed granulator machine and production line solution that delivers the optimal balance of performance, durability, and value for their specific business plan and market conditions. We recommend a thorough needs analysis as the first step toward a sound investment.

What are the key factors to consider when choosing the right feed granulator machine for our operation?

+

Selecting the optimal feed granulator machine is a critical decision that impacts your production efficiency, product quality, and long-term profitability.

It’s more than just picking a model number; it’s about matching engineering capabilities to your specific business needs. Based on our decades of experience implementing projects globally, we recommend a structured evaluation focusing on four core pillars.

1. Define Your Requirements: Capacity & Feed Type (The “Equipment Type”)

The first and most crucial step is a clear analysis of your own operation. The model series you mentioned—SZLH250, SZLH320, SZLH350, SZLH420, SZLH508, SZLH558, SZLH678, SZLH768—represent a capacity range from 1-2 t/h to over 40 t/h.

- Capacity: Honestly assess your current daily tonnage needs and 3-5 year growth plan. Choosing a machine that is too small constrains growth, while one that is too large operates inefficiently at low load. For a large-scale feed mill engineering, the SZLH558 (20-22 t/h) is often the ideal backbone.

- Feed Type: Will you produce only poultry feed, or also ruminant, swine, or aqua feed? This dictates the necessary machine configuration. A basic single-conditioner machine works for standard poultry feed, but producing water-stable fish feed requires a double or triple-layer conditioner and different die specs. A versatile machine like the SZLH558 can be configured at purchase to handle this range.

2. Scrutinize Technical Performance & Configuration

Beyond the basic model, delve into the technical specifications that define real-world performance:

- Power & Drive: A gear-driven transmission (standard on Richi machines) offers higher efficiency, durability, and consistent power delivery compared to belt drives, especially under heavy load.

- Conditioning System: This is where pellet quality is made. Evaluate the conditioner size, retention time (aim for 35+ seconds for good starch gelatinization), and the option for multiple stages. Our machines feature extended, large-diameter conditioners.

- Ring Die & Roller Specs: The die compression ratio must match your feed formula. We provide dies with ratios from 1:5 for cattle feed to 1:25 for shrimp feed. Ask about the material (high-chromium alloy steel vs. stainless steel) and hardening process.

- Control & Automation: Consider the level of automation needed. Basic manual controls suffice for some, while others benefit from PLC systems with recipe memory and automatic roller gap adjustment for consistent quality.

3. Evaluate the Manufacturer’s Brand & Engineering Depth

The brand represents a promise of quality and support. Look for a manufacturer, not just a trader.

- Reputation & Track Record: Investigate the company’s project history. Richi Machinery, as a direct manufacturer, has successfully commissioned feed lines on six continents, giving us unparalleled practical experience with diverse raw materials and climates.

- Customization Capability: Can they modify the standard feed granulator machine to suit your unique raw materials (e.g., high palm kernel cake, DDGS) or space constraints? Our engineering team regularly provides such tailored solutions.

- Comprehensive Supply: A supplier who can also provide the hammer mill feed grinder, mixer, cooler, and electrical controls ensures seamless system integration and single-point accountability, simplifying your project immensely.

4. Plan for the Entire Lifecycle: Maintenance & Support

The cheapest machine can become the most expensive due to downtime and repair costs.

- Ease of Maintenance: Ask about access points for greasing, the simplicity of die/roller changes, and the availability of maintenance manuals. Our machines are designed with serviceability in mind.

- Spare Parts Policy & Availability: Ensure critical spare parts (rollers, bearings, dies) are readily available. Richi Machinery maintains a large inventory and offers recommended spare parts lists for different operating schedules.