ANIMAL FEED PELLET MILL FOR SALE

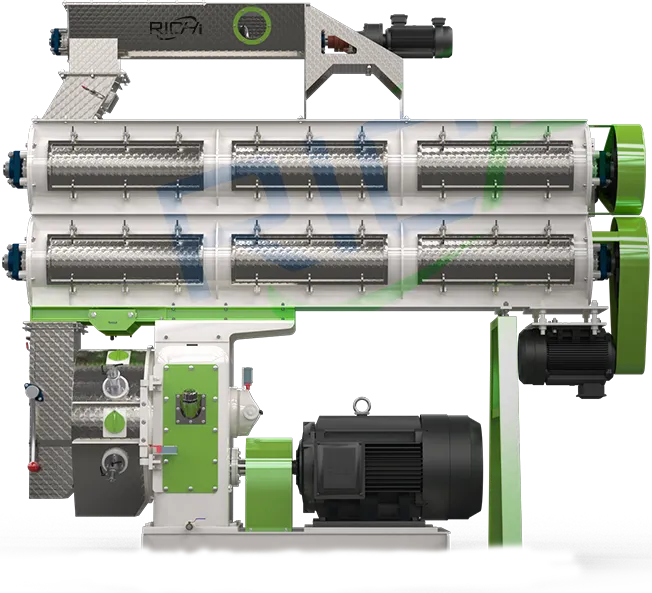

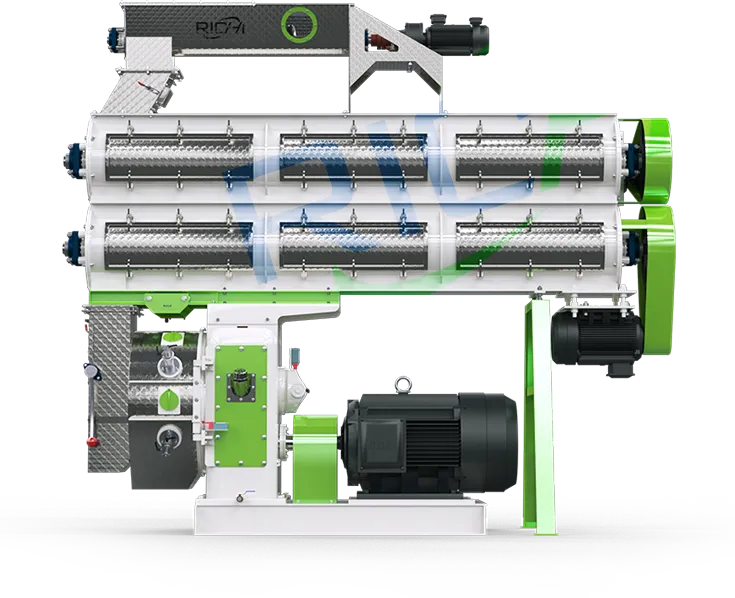

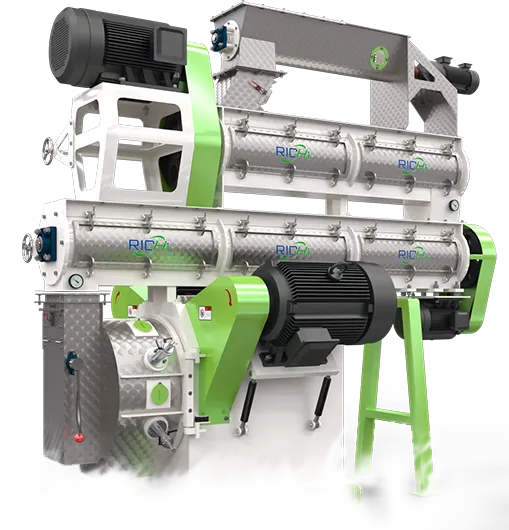

Meet our flagship animal feed pellet mill for sale – the robust SZLH420 ring die pellet machine. Engineered for demanding production lines, it delivers a consistent 8-12t/h output with superior pellet quality. We specialize in providing this key equipment, celebrated for its high performance, low energy consumption, and low-noise operation. Its reliable design and polished appearance make it the ideal core of your pellet feed plant for poultry, livestock, and aquatic feed.

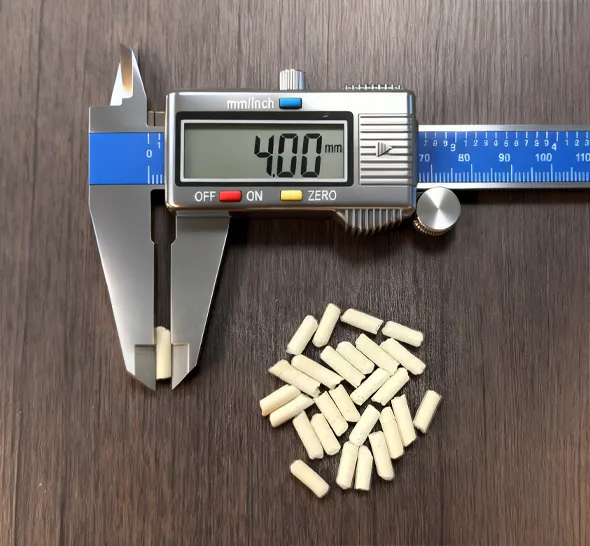

Pellet Size: 2~12mm

Price: $28,000 to $34,000

Model

SZLH420

Production Capacity

8-12T/H

Versatile Classifications & Applications

For years, Richi Machinery has specialized in the R&D and manufacturing of premium feed equipment. Our focused expertise is why the animal feed pellet mill for sale stands as a core solution for diverse feed production lines. This robust pellet mill efficiently processes various raw materials into high-quality pellets, serving as essential equipment for commercial feed mills, large-scale farming operations, and integrated aquaculture facilities.

The feed pellet mill is classified based on the specific animal feed type it is designed to produce. Each classification ensures optimal nutrition, pellet durability, and digestion. Explore our dedicated solutions below to find the perfect match for your production needs.

Engineered to produce highly digestible and nutrient-rich pellets for chickens, ducks, geese, and turkeys, promoting healthy growth and egg production.

Built to manufacture durable pellets for cattle, sheep, pigs, and other livestock, enhancing feed efficiency, weight gain, and overall herd health.

Designed to create water-stable, sinking pellets for fish and shrimp, minimizing waste and supporting optimal nutrition in aquaculture.

Precision-Engineered for Every Feed Type

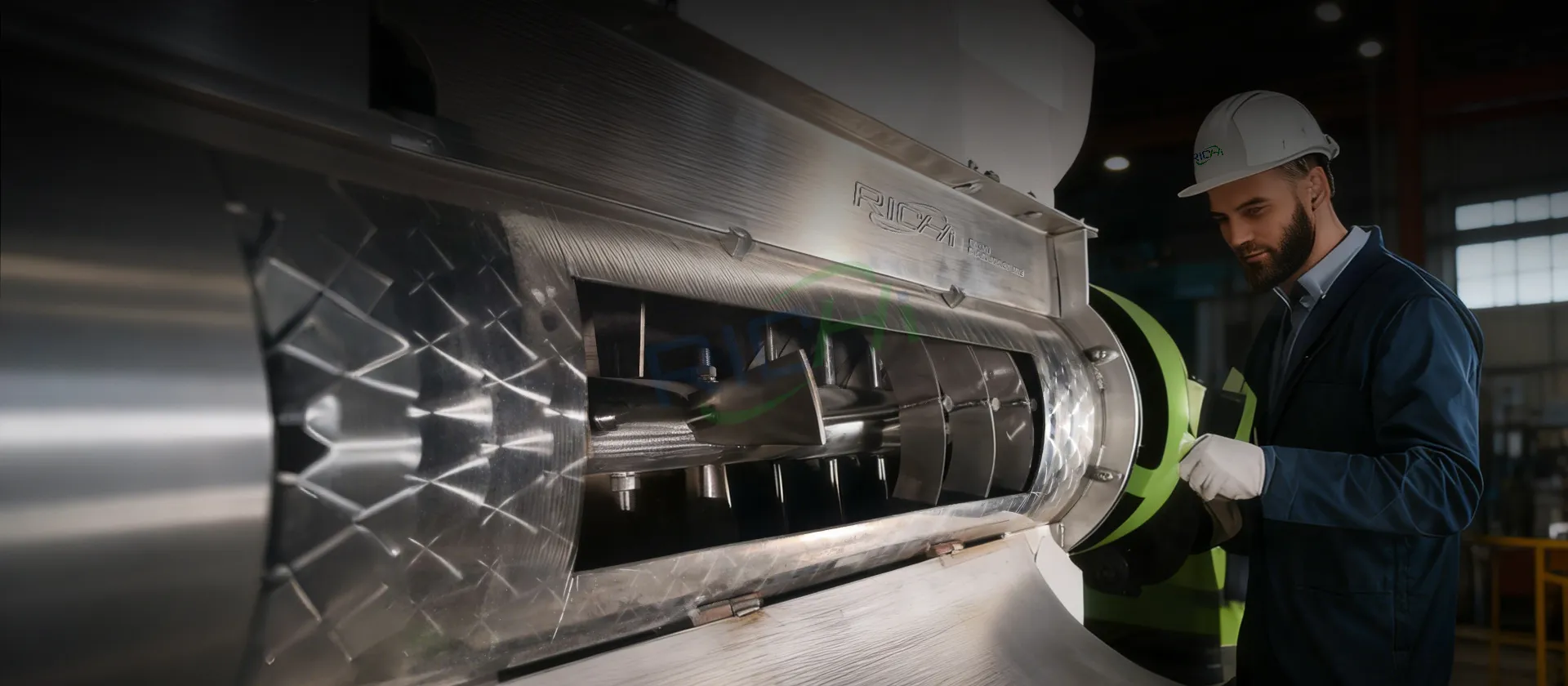

Our expertise goes beyond a standard animal feed pellet mill for sale. We offer specialized configurations built around our enhanced conditioning system. All models feature our proprietary, long-length, large-diameter conditioner. This design ensures superior steam penetration and uniform starch gelatinization for optimal pellet quality. Furthermore, our conditioners are fully customizable in length, diameter, and internal paddle configuration to meet your exact recipe requirements.

Single-Layer Conditioner animal feed Pellet Mill

This is the industry-standard and most widely applied configuration. It is ideal for producing common livestock and poultry feed pellets with high efficiency. When equipped with our optional forced feeder, it can also effectively process feed containing fibrous materials like grass or hay. This model is the perfect, cost-effective solution for general animal feed mill plants and farms focusing on standard poultry, swine, and cattle rations.

Dual-Layer Conditioner animal feed Pellet Mill

Engineered for higher-grade feed production, this type features two sequential conditioning chambers. The extended retention time allows for more thorough cooking and liquid addition. It excels at producing premium-grade poultry livestock feed for superior animal performance and standard sinking fish feed pellets. This configuration is best suited for feed manufacturers targeting the high-end livestock market or those beginning aquatic feed production.

Triple-Layer Conditioner animal feed Pellet Mill

This represents our top-tier configuration for the most demanding applications. The triple-stage process provides maximum control over conditioning time, temperature, and moisture. It is specifically designed to manufacture high-stability, floating or slow-sinking aquatic feed for fish and shrimp. It also handles complex formulations with high fat or protein content. Choose this model if you are a specialized aquafeed producer or a manufacturer requiring the ultimate in pellet durability and digestibility.

Versatile Raw Material Processing

Our animal feed pellet mill for sale is engineered to handle a comprehensive range of raw materials, demonstrating our strength as a complete feed equipment manufacturer. From common grains to specialized additives, it processes core ingredients that form balanced feed formulas. In practical applications, formulations can also include fresh forage and aquatic plants (green fodder), as well as fermented preserved feeds (silage). Our robust pellet mill is fully capable of processing these diverse material types into high-quality pellets.

Energy Ingredients

This category includes grains like corn, wheat, and barley. They provide the essential carbohydrates for animal maintenance and growth.

Protein Ingredients

Key ingredients such as soybean meal, fish meal, and rapeseed meal fall here. They supply crucial amino acids for muscle development and health.

Roughages Ingredients

Materials like alfalfa, hay, and straw add necessary fiber. They promote healthy digestion in livestock and poultry.

Feed Additives

This encompasses vitamins, minerals, premixes, and binders. Additives enhance nutritional value and pellet quality.

Witness Precision in Action

Seeing is believing. Explore the engineering excellence of our animal feed pellet mill for sale through the videos below. From its robust core operation to advanced control systems, these showcases highlight the features that make our machine a global leader, trusted in over 130 countries. Witness firsthand the reliable performance, durable construction, and versatile output that delivers lasting value for your feed pellet production line.

Uzbekistan Animal Feed Pelletizing Project

Afghanistan Animal Feed Pelletizing Project

Angola Animal Feed Pelletizing Project

Argentina Animal Feed Pelletizing Project

Superior Component Engineering

The global reputation of our SZLH420 animal feed pellet mill for sale—trusted in over 130 countries—is built on its superior internal architecture. Every component is engineered for peak performance, exceptional durability, and maximum operational efficiency. The following six structural highlights demonstrate our commitment to technical excellence and long-term value, ensuring your feed production line is powered by the best machinery available.

Core Advantages

Our SZLH420 animal feed pellet mill for sale is built on a principle of robust engineering and intelligent design. It transforms mixed feed ingredients into dense, durable pellets through a precise process of conditioning, compression, and extrusion. Every component is optimized to deliver unmatched reliability, efficiency, and ease of operation, ensuring your production line runs smoothly for years to come. Below are the key advantages that set this machine apart.

Superior Conditioning for Optimal Feed Quality

Featuring a long, large-diameter double-shaft conditioner with independent motors, it ensures thorough steam absorption and uniform ingredient cooking. With a standard 60-90 second retention time and SS304 contact parts, it guarantees hygienic, high-quality conditioning for every pellet.

Unmatched Durability & Easy Maintenance

Constructed with a highly wear-resistant housing and a quick-change die system, the mill is built to last. The split-housing design and automatic greasing mechanism significantly reduce downtime, making routine maintenance fast and simple.

Reliable, High-Efficiency Drive System

This pellet mill utilizes a high-precision hardened gear drive, proven to deliver 15-20% higher output than belt-drive models. Equipped with spherical roller bearings, it ensures stable, powerful, and energy-efficient operation under continuous heavy loads.

Flexible Customization for Your Specific Needs

We provide tailored solutions to match your exact production requirements. Customization options include the conditioner configuration (single, double, or triple-layer), specialized die and roller specifications, integration of forced feeders for fibrous materials, and compatibility with advanced automated control systems.

Precision Engineered Pelletization Process

Understanding the core mechanics behind our animal feed pellet mill for sale highlights our commitment to efficient and reliable design. The SZLH420 operates on a proven, continuous mechanical principle that transforms conditioned feed mash into uniform, dense pellets. This straightforward yet robust process ensures consistent high output and optimal feed quality.

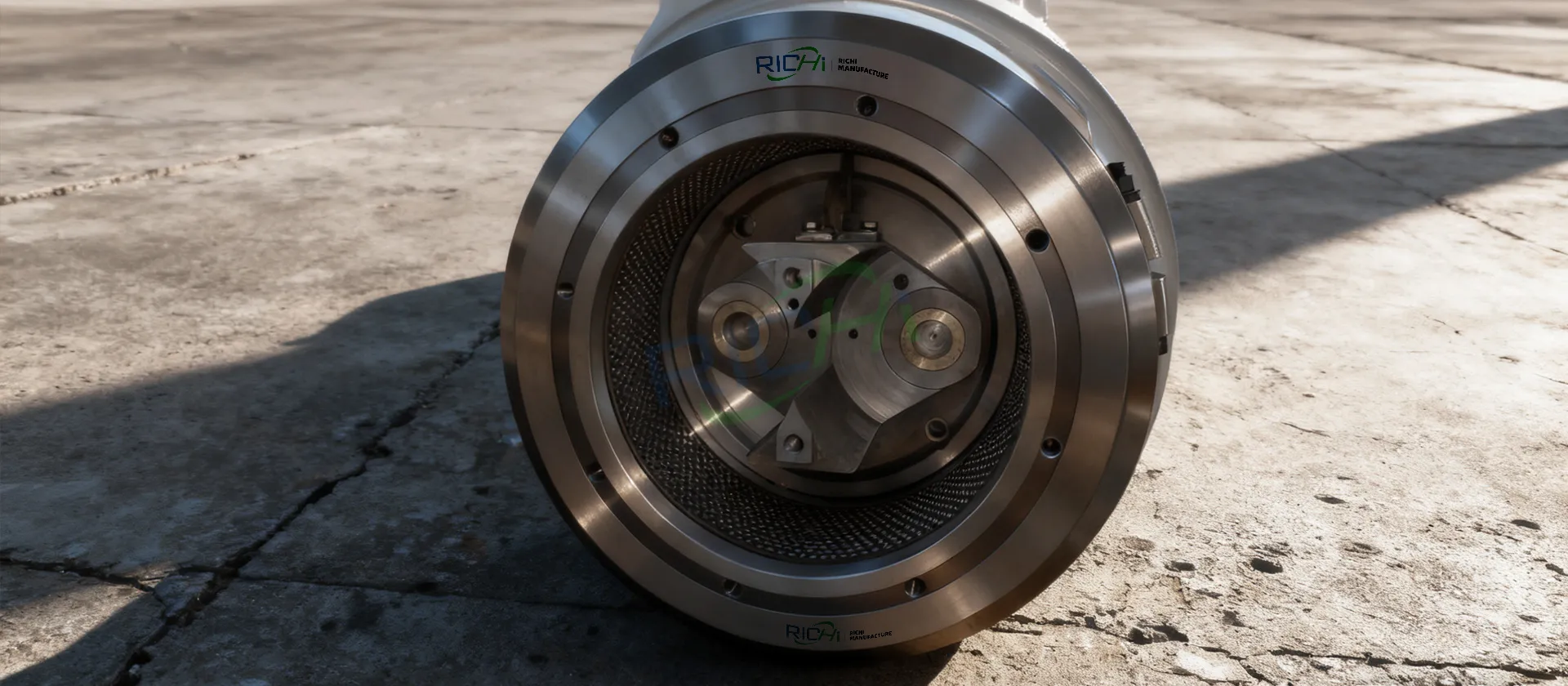

The process begins as pre-conditioned material is evenly fed into the die chamber. Centrifugal force from the rotating ring die and strategically placed scrapers distribute the mash into the pressing zones between the rollers and the die.

Here, the material undergoes intense, continuous compression. It is forced through the precision-drilled holes of the hardened ring die, forming compact strands. Finally, an adjustable cutter cleanly slices these strands into pellets of your specified length, ready for cooling and packaging.

Detailed Specifications & Model Portfolio

Review the precise technical specifications for our flagship animal feed pellet mill for sale in the table below. These parameters define its core performance and capacity, showcasing the engineering behind its reliable 8-12 t/h output. As a leading manufacturer, we offer a complete range of solutions. If your requirements differ, explore our portfolio of seven additional ring die feed pellet machine models designed for various production scales.

Find your machine’s exact match in the data below.

PARAMETERS OF SZLH420 (8-12T/H)

Main motor power

110kW

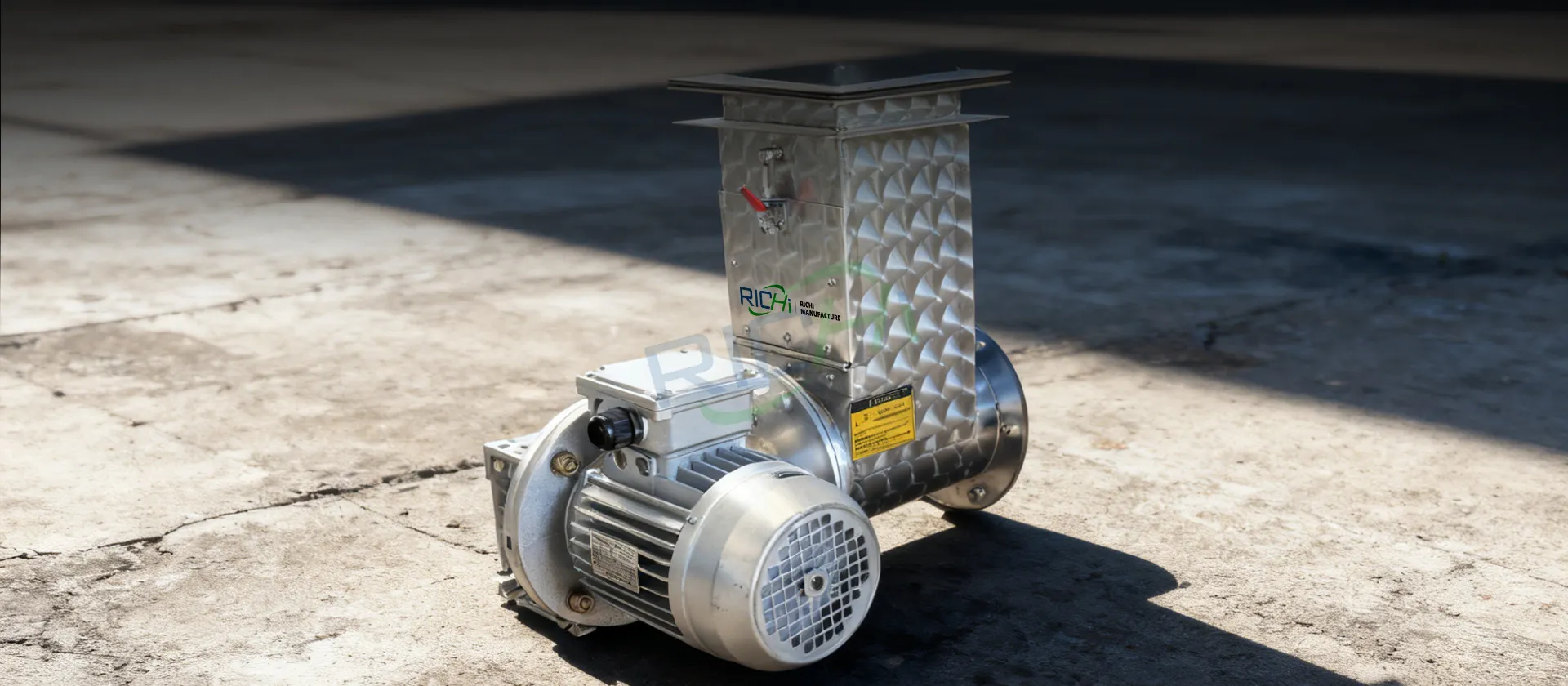

Feeder power

1.5kW

Conditioner power

7.5kW

Ring die inner diameter

420mm

Finished pellet diameter

2-12mm

Optimized Process for Every Feed Type

A key strength of our animal feed pellet mill for sale is its adaptable performance across diverse formulations. The optimal pellet quality for each animal species requires specific process parameters. Below are the tailored configurations for the SZLH420, demonstrating our deep expertise in feed processing technology. These guidelines ensure you achieve maximum efficiency and the highest quality pellets for your specific production needs.

Chicken Feed Pelletizing Parameters

Our animal feed pellet mill for sale is ideally configured for high-volume poultry operations. It processes finely ground mash (2.0-3.0mm) into small, durable pellets (2-4mm diameter). Using a conditioning temperature of 85°C and an extended 60-120 second retention time in a single or double-layer conditioner, it ensures optimal starch gelatinization. This process results in a consistent 8-12 T/H output of highly digestible feed with the ideal hardness for chickens.

Cattle & Sheep Feed Pelletizing Parameters

For ruminant feed, the process focuses on creating dense, coarse pellets. The mill is set to handle mash with a larger particle size (3-5mm). It forms larger pellets (6-12mm diameter) using a lower ring die compression ratio. A standard single-layer conditioner provides sufficient 30-60 second conditioning at 80°C. This setup delivers a robust 10-13 T/H output of pellets that promote healthy rumination and reduce waste.

Pig Feed Pelletizing Parameters

Producing superior swine feed requires a balance of palatability and nutrient integrity. The mill processes 2-3mm mash into pellets typically 2-4mm in diameter. A moderate compression ratio is used. Conditioning at 82°C for 60-120 seconds in a one or two-layer system ensures proper cooking without degrading heat-sensitive ingredients. This reliable process supports a high output of 10-12 T/H, crucial for large-scale pig farming operations.

Sinking Fish Feed Pelletizing Parameters

Manufacturing water-stable sinking feed demands precise control. The SZLH420 is configured with a fine grind (1.0-2.0mm) and a high compression ratio for pellet durability. A two or three-layer conditioner is essential, providing prolonged conditioning (90-180 seconds) at 90°C to achieve the necessary starch binding. This specialized setup yields a controlled 6-7 T/H output of dense, slow-sinking pellets that minimize nutrient leaching.

Shrimp Feed Pelletizing Parameters

This represents the most specialized application for our animal feed pellet mill for sale. It requires an ultra-fine raw material (95% ≥80 mesh) and the highest compression ratio to form tiny, highly stable pellets (1.2-2.0mm). A triple-layer conditioner is mandatory, delivering extended 120-180 second conditioning at 92-95°C. This intensive process ensures maximum water stability for a premium output of 1.2-1.5 T/H of high-value shrimp feed.

Global Project Showcase

Our animal feed pellet mill for sale is the core of complete feed production lines we have successfully delivered across every continent. Beyond supplying individual machines, we engineer tailored solutions for diverse clients. The following projects highlight our experience with various feed types, pellet sizes, raw materials, and production scales worldwide.

Animal feed pellet mill for sale USA

A large-scale dairy cooperative chose our solution to process alfalfa and grass into nutritious cattle pellets, enhancing feed efficiency across their farms.

Feed type: cattle feed

Pellet size: 4-6mm

Animal feed pellet mill for sale in Algeria

Feed type: chicken feed

Pellet size: 2.5-3.5mm

Animal feed pellet mill for sale in Uzbekistan

Feed type: poultry feed

Pellet size: 3-4mm

This commercial feed mill integrated our pellet line to produce balanced poultry rations using local grains and soybean meal for the growing market.

Animal feed pellet mill for sale in Oman

Feed type: cattle feed

Pellet size: 4-6mm

Animal feed pellet mill for sale in Indonesia

Feed type: shrimp feed

Pellet size: 1.5-2.0mm

Animal feed pellet mill for sale in Russia

A leading agribusiness firm installed our system to manufacture high-volume feed for their integrated poultry operations, ensuring consistent pellet quality.

Feed type: poultry feed

Pellet size: 3-5mm

Animal feed pellet mill for sale in South Africa

Feed type: cattle feed

Pellet size: 6-8mm

Trusted by Industry Leaders

From a single animal feed pellet mill for sale to a fully automated, turnkey feed production plant, we provide the complete engineering and equipment solution. Our expertise ensures your project, whether for a family farm or a multinational corporation, is built for efficiency, durability, and optimal return on investment.

Client Voices: Success Stories Worldwide

Our engineering solutions, from core equipment to complete plant design, have earned consistent praise from feed producers across the globe. These testimonials reflect our commitment to delivering reliable performance and tangible value, tailored to each client’s unique raw materials, production goals, and local market demands.

Argentina Client

Feed type: cattle feed

Pellet size: 8-10mm

RICHI’s team designed a robust line perfectly suited for our large-scale alfalfa processing. The pellet mill handles high-fiber material superbly, producing dense, durable pellets that are ideal for our beef cattle operations. Their engineering support was outstanding.

Australia Client

Feed type: sheep feed

Pellet size: 4-6mm

Operating in a remote region, we needed a reliable and low-maintenance system. The RICHI pellet mill has exceeded expectations for our mixed grain and forage sheep feed. Its stability and ease of operation have been crucial for our family-run farm’s efficiency.

Philippines Client

Feed type: swine feed

Pellet size: 3-4mm

Expanding our integrated pig farm required a high-output line. RICHI provided not just the machine but a complete process optimization. The pellet quality is consistent, and our feed conversion rates have improved noticeably since installation.

Iraq Client

Feed type: poultry feed

Pellet size: 2.5-3.5mm

Facing challenges with local ingredient variability, we needed an adaptable system. RICHI’s pellet mill, with its precise conditioning control, delivers uniform pellets from our formulations. It’s the backbone of our growing poultry feed business.

Senegal Client

Feed type: cattle feed

Pellet size: 6-8mm

Turning abundant local peanut shells into valuable feed was our goal. RICHI proposed a custom solution with a specialized pre-treatment setup. Now, we produce cost-effective, nutritious cattle feed, adding great value to a former waste product.

Precision in Every Pellet: Choosing the Right Size

A pellet’s diameter directly impacts animal nutrition, feed efficiency, and production economics. Our animal feed pellet mill for sale is engineered to deliver exact specifications. Below, we detail seven standard sizes, their primary applications, and the critical technical considerations for selecting the right ring die and process configuration to achieve optimal results.

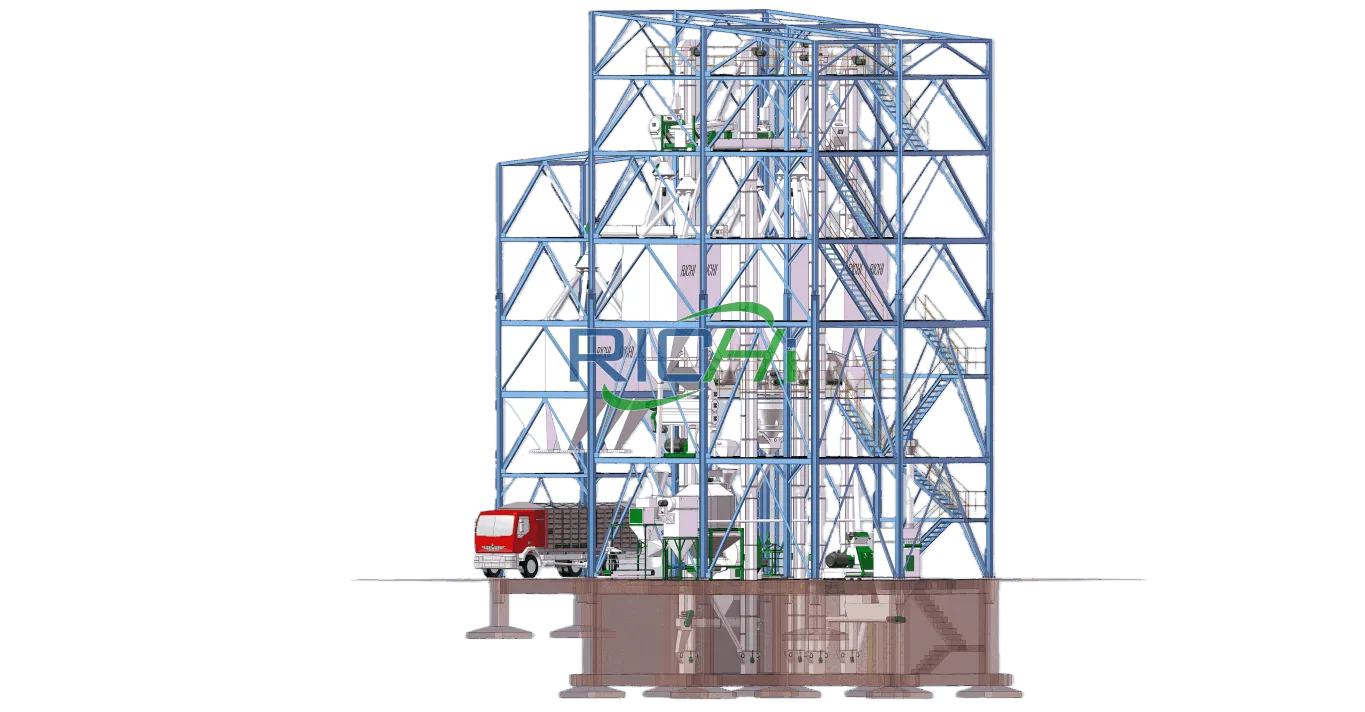

Your Complete Feed Production Line Partner

Purchasing an animal feed pellet mill for sale is just the first step. We specialize in delivering complete, custom-engineered production lines from initial concept to steady-state operation. Every feed type—whether for poultry, livestock, or aquaculture—requires a distinct process flow.

Our solutions are never one-size-fits-all; we design each line based on your specific raw material characteristics, target pellet specifications, nutritional formula, available factory layout, and investment plan. We provide full lifecycle support encompassing consultation, engineering, manufacturing, installation, commissioning, operator training, and lifelong spare parts supply.

Silo

Cleaning

Grinding

Mixing

Batching

Pelleting

Cooling

Screening

Packaging

06.Pelletizing System

This is where

mixed ingredients

are transformed.

Complete Supporting Equipment for Your Plant

storage silo equipment

01

cleaning equipment

02

grinding equipment

03

mixing equipment

04

cooling equipment

05

screening equipment

06

packaging equipment

07

A high-performing animal feed pellet mill for sale is the core, but a successful production line requires perfectly integrated supporting systems. As a full-line manufacturer, we provide every piece of equipment needed from raw material intake to finished bag palletizing.

We don’t just supply individual machines; we engineer the complete material flow, selecting and configuring each component—from grinders and feed mixer machines to coolers, conveyors, and dust control systems—to match your specific process requirements and ensure seamless, efficient operation.

Species-Specific Feed Solutions

Every animal species has unique nutritional and physical feed requirements. At RICHI, we engineer tailored solutions that pair the optimal animal feed pellet mill with perfectly matched auxiliary equipment. Below, explore our standard, field-proven process configurations for major feed categories, each designed to maximize pellet quality, digestibility, and production efficiency for your specific market.

Your Questions on the feed Pellet Mill Answered

Purchasing a new feed pellet mill is a significant investment in your production line. We’ve compiled the most frequent and practical questions from feed mill managers, farm owners, and industry professionals exploring the 8-12 t/h capacity range. This section provides clear, honest answers to help you evaluate if this animal feed pellet mill for sale is the right fit for your operation.

What is the price range for an animal feed pellet mill for sale, and what does it depend on?

+

The animal feed pellet mill price varies significantly based on the machine’s capacity (throughput in tons per hour), motor power, construction features, and level of customization. A key factor is the model size, which dictates its output range. For reference, here is an indicative price guide for our core SZLH series of ring die pellet mills, designed for commercial animal feed production:

- Entry-Level Models (For Small Farms & Startups):

- SZLH250 (22KW): Capacity 2-3 t/h. Price Range: $6,500 – $9,500.

- SZLH320 (37KW): Capacity 3-4 t/h. Price Range: $14,000 – $19,000.

- Mid-Range Models (For Medium-Sized Feed Preparation Plants):

- SZLH350 (55KW): Capacity 5-6 t/h. Price Range: $26,000 – $33,000.

- SZLH420 (110KW): Capacity 8-12 t/h. This is our highly popular model for balanced output and investment. Price Range: $27,000 – $35,000.

- Heavy-Duty Models (For Large-Scale Industrial Production):

- SZLH508 (160KW): Capacity 15-16 t/h. Price Range: $38,000 – $47,000.

- SZLH558 (185KW): Capacity 18-22 t/h. Price Range: $46,000 – $54,000.

- SZLH678 (250KW): Capacity 28-32 t/h. Price Range: $63,000 – $72,000.

- SZLH768 (315KW): Capacity 38-42 t/h. Price Range: $76,000 – $85,000.

Important Note on Pricing:

The above represents our primary animal feed pellet mill for sale series, but it is not an exhaustive list. We offer a full spectrum of equipment for feed processing. The final feed pellet mill price is influenced by your specific requirements, including:

- Feed Type: Poultry, livestock, or aquatic feed each require different conditioning systems (single, double, or triple-layer) and die specifications.

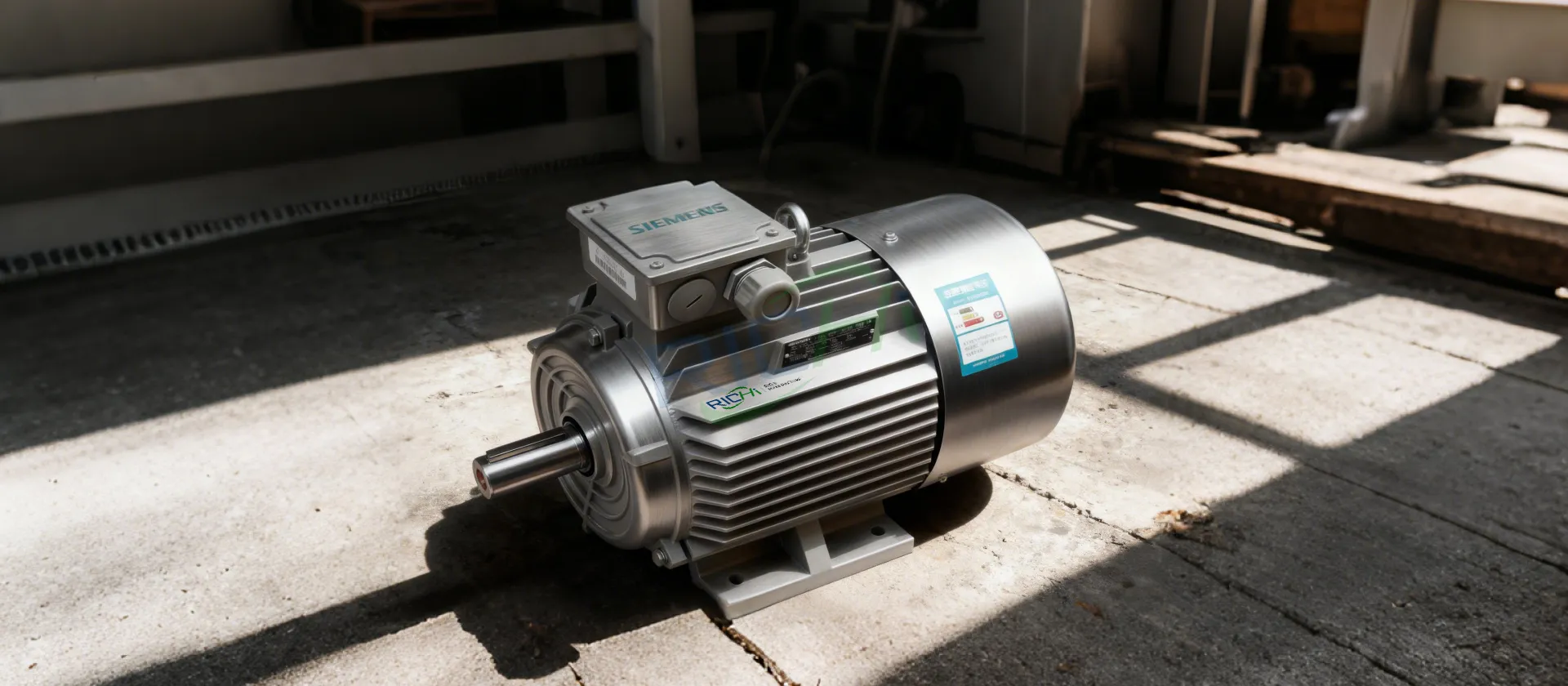

- Customization: Options like the motor brand (e.g., Siemens), automatic lubrication systems, specific ring die materials, and integration with control panels affect the cost.

- Project Scope: Pricing for a complete turnkey feed production line, which includes conveyors, mixers, and pellet cooler machines, differs from a standalone pellet machine quote.

To receive an accurate and personalized quotation for the animal feed pellet mill for sale that fits your production goals and budget, please contact our sales team with your detailed requirements. Tell us your target capacity, feed type, and any special needs for a tailored solution and precise pricing.

We mainly produce feed for our 50,000-bird poultry farm. Is an 8-12 t/h pellet mill too large for our needs, or would a smaller model be sufficient for future expansion?

+

For a 50,000-bird operation with potential for growth, the 8-12 t/h model is a strategic and efficient choice. While a smaller mill might meet your immediate daily tonnage, it would require running at or near full capacity for extended periods.

Our 8-12 t/h animal feed pellet mill for sale allows you to meet your current demand in shorter, more energy-efficient production runs, preserving machine life and leaving ample capacity for future flock expansion or custom feed production for other local farms. This model provides the flexibility to scale your business without needing another capital investment soon.

Our current issue is high power costs. Compared to a belt-driven model, what is the realistic energy saving percentage with your gear-drive animal feed pellet mill for sale, and what’s the payback period?

+

Our direct gear-drive transmission system is engineered for maximum power transfer with minimal energy loss. In real-world operating conditions, clients typically report 15-22% lower power consumption compared to equivalent belt-drive models.

The savings come from eliminating belt slippage and using a high-efficiency motor paired with precision-hardened gears. The payback period on the higher initial investment through electricity savings alone is often between 14 to 22 months, depending on your local energy rates and production hours. This makes our animal feed pellet mill for sale a cost-saving asset over its entire lifespan.

We need to switch between producing chicken feed and pig feed weekly. How difficult and time-consuming is it to change the ring die and rollers on your machine?

+

We designed our pellet mill with exactly this kind of operational flexibility in mind. The patented quick-release split housing allows a trained two-person crew to complete a full die and roller changeover in under 45 minutes.

You do not need to disassemble major components or realign the main shaft. We supply customized tool kits and provide detailed video guides and on-site training during commissioning. For clients with frequent recipe changes, we also offer our Quick-Change Die Cart system as an accessory to make the process even smoother and safer.

For processing local grass hay into cattle pellets, does the standard model handle high-fiber materials well, or do we need to add a forced feeder as an extra option?

+

Processing high-fiber materials like grass hay requires overcoming the natural low bulk density and flow characteristics of the mash. While the standard feeder is robust, for consistent, trouble-free production with over 15% fibrous content, we strongly recommend the optional forced feeder (or “feeder conditioner”).

This accessory uses paddles to positively push material into the conditioning chamber, preventing bridging and ensuring a steady, uniform feed rate. This is a common and effective customization for ranches and feedlots, and our engineers can specify the right configuration based on your specific hay analysis.

We have limited factory space. What are the exact floor dimensions and height requirements for installing this animal feed pellet mill for sale, including the necessary clearance for operation and maintenance?

+

Proper planning is key. The base footprint of the SZLH420 pellet mill itself is approximately 2.8m (L) x 1.8m (W). However, you must account for operational space. We recommend a total allocated floor area of at least 5m x 4m. This allows safe access for die changes, routine greasing, and tool handling.

For height, the machine is about 2.2m tall, but you must consider the space above for lifting the die assembly during changes (a small hoist is ideal) and for connecting overhead feed and discharge spouting. Our project team provides detailed layout drawings during the quotation phase to optimize your available space.

Beyond the machine price, what are the typical costs for essential annual spare parts, like a new ring die and set of rollers, to budget for long-term operation?

+

Transparent lifecycle costing is part of our service. For the SZLH420 running on standard poultry or livestock feed 16 hours a day, a high-quality ring die should last 800-1,200 hours, and rollers 400-600 hours, depending on abrasiveness. Budgeting for one set of rollers and approximately 1.5 ring dies per year is a prudent estimate.

Based on current rates, the annual cost for these core wear parts typically ranges between $3,000 to $5,000. Using our genuine, heat-treated alloy parts ensures this predictability and protects your main shaft and bearings from damage caused by inferior components.

Our raw material moisture content can vary seasonally. How effectively does your conditioner system compensate for this to maintain consistent pellet quality and hardness?

+

Our long, large-diameter conditioner is specifically designed to manage moisture and temperature variables. Equipped with independent variable-speed drives on the shafts and steam/water injection nozzles at multiple points, it provides ample retention time (adjustable from 60 to 120 seconds) for uniform heat and moisture transfer.

For clients with highly variable raw materials, we integrate a moisture feedback control system. This system automatically adjusts liquid addition in real-time based on the mash condition exiting the mixer, ensuring the material entering the pellet mill has a consistent temper, which is the single biggest factor in producing stable, hard pellets batch after batch.

For making sinking fish feed, is the standard single-layer conditioner adequate, or is the double-layer version mandatory for achieving proper water stability?

+

For true, commercially viable sinking fish feed that requires high water stability (over 30 minutes), the standard single-layer conditioner is not sufficient. The double-layer (or even triple-layer) conditioner is strongly recommended, and in most cases, mandatory.

The multi-stage process allows for precise, sequential addition of steam and binders, significantly extending the total conditioning time and temperature.

This ensures complete starch gelatinization, which is the “glue” that holds the pellet together in water. We will analyze your specific fish feed formula to recommend the exact conditioner configuration needed to meet your durability targets.

We operate 16 hours a day. What is the recommended daily maintenance routine to prevent unplanned downtime with this animal feed pellet mill for sale?

+

A disciplined daily routine is the best insurance. It should take your operator 15-20 minutes at shift end. Key tasks include:

- 1) Visually checking for oil leaks from the gearbox and grease leaks from bearings.

- 2) Listening for unusual noises during the final run.

- 3) Checking and recording the amperage load – a sudden change indicates a problem.

- 4) Ensuring the automatic greaser (if equipped) has adequate grease.

- 5) Clearing any residual material from the feeder and conditioner.

- 6) Performing a general visual inspection of belts and guards.

We provide laminated checklists in multiple languages and build these procedures into our on-site training program.

What is the realistic lead time from placing an order to having the machine delivered and installed at our site in Vietnam?

+

For a standard SZLH420 configuration destined for a port like Hai Phong or Ho Chi Minh City, the typical lead time is 8-10 weeks from order confirmation. This includes manufacturing, testing, and preparation for sea shipment. Delivery to your inland site depends on local logistics, which our logistics partner in Vietnam can manage.

For complete lines or machines with significant customizations (like special conditioners), we add 2-3 weeks for engineering and sourcing. We provide a detailed project timeline with every order, and our after-sales team coordinates closely with your team for a smooth installation.

We are new to pelleting. Do you provide on-site operator training, and what does that training typically cover?

+

Absolutely. Comprehensive training is a cornerstone of our service. A Richi Machinery engineer will be on-site during commissioning for 5-7 days.

The training is hands-on and covers: Safe startup/shutdown procedures, daily maintenance checks, adjustment of the feeder and conditioner for different formulas, proper die and roller installation, troubleshooting common issues (e.g., low pellet hardness, capacity drop), and basic principles of steam quality.

We leave you with detailed operation and maintenance manuals and video resources. Our support continues remotely, and we are always a phone call away for your operators.

What kind of steam boiler pressure and dry saturated steam quality is required to run this animal feed pellet mill for sale at its optimal performance?

+

Optimal pelleting requires dry saturated steam, not wet or superheated steam. We recommend a boiler capable of delivering steam at a constant pressure of 6-8 bar (85-115 psi) at the boiler outlet.

The steam pipeline must be properly insulated and fitted with a pressure reducing valve, moisture separator, and trap to ensure the steam arriving at the conditioner valve is as close to 100% dry as possible.

Poor steam quality (over 5% moisture) is a leading cause of poor conditioning and inconsistent pellets. Our engineers can review your boiler specs and suggest the right ancillary steam system components.

Can this machine be integrated with our existing pre-mix system and cooler, and what interface specifications do you need from us to ensure compatibility?

+

Yes, integration with existing equipment is a common request. To ensure seamless integration, we need from you:

- 1) The discharge height and connection flange size of your mixer.

- 2) The inlet height and dimensions of your cooler.

- 3) The control system type (e.g., manual, PLC) you wish to interface with. We will then design and supply all intermediate spouting, screw conveyors, and air slide systems with the correct adapters.

For control integration, we provide standard relay logic or communication protocols (e.g., Modbus) to allow your main control panel to start/stop and monitor the animal feed pellet mill for sale.

For producing rabbit feed with very small pellets (2mm), what is the minimum practical die thickness and compression ratio you recommend to prevent clogging?

+

Producing small 2mm pellets for rabbits is a precision task. To prevent die hole clogging while achieving adequate pellet durability, we recommend a specific die specification. The effective thickness should be between 35-40mm, with a compression ratio in the range of 1:9 to 1:11.

This provides enough resistance to form a firm pellet without creating excessive back-pressure that can cause heat buildup and material baking inside the die holes. Using a die with a tapered inlet (relief) is also critical. We have successfully supplied many such dies for rabbit feed producers across Europe and Asia.

What is your policy and standard warranty period for the core components like the gearbox, main shaft, and ring die housing?

+

We stand firmly behind the build quality of our machinery. Our standard warranty is 12 months from the date of shipment for the entire animal feed pellet mill for sale, covering defects in material and workmanship.

For core components that are critical to operation—specifically the gearbox, main shaft, and pellet mill housing—we provide an extended warranty of 18 months. This extended coverage reflects our confidence in these heavily engineered parts.

Please note that wear parts like the ring die and rollers are covered under a separate 6-month warranty against manufacturing defects. All warranty terms are clearly outlined in our sales contract.

Can you provide specific examples of your animal feed pellet mill for sale being used in major agricultural markets, and what factors influence the total project cost?

+

Absolutely. Our animal feed pellet mill for sale, particularly the versatile SZLH420 model, has been successfully deployed in over 130 countries, forming the core of strategic partnerships with thousands of clients worldwide.

The total project cost varies significantly as it reflects a complete, custom-engineered solution—not just the price of the pellet mill.

It includes the entire production line design, auxiliary equipment (like hammer mill feed grinders, mixers, coolers), automation level, specific material upgrades, and on-site commissioning services tailored to each client’s unique feed type and operational goals.

Here are a few recent, representative examples that illustrate the global scope and adaptability of our solutions:

- Germany: A premium feed manufacturer selected the SZLH420 for a high-precision line producing a range of 1-5mm pellets. The project cost of approximately $350,600 reflects advanced automation controls, specialized stainless-steel contact parts for hygiene, and integration with their existing, sophisticated plant infrastructure to meet stringent EU standards.

- Thailand: A large integrated poultry operation invested in an SZLH420-based line for 2-4mm broiler feed. The total project cost of around $240,900 included a complete, high-capacity turnkey system from raw material intake to bagging, designed for high humidity conditions and continuous 24/7 operation.

- Kazakhstan: For a major cattle feed expansion, the client chose the SZLH420 to produce dense 2-4mm pellets. The project cost of about $1920,600 covered a heavy-duty line engineered to process local grains and rugged forage, featuring robust dust collection systems and equipment rated for extreme continental climate temperatures.

- Côte d’Ivoire & Ghana: In these key West African markets, projects centered on the SZLH420 for producing 2-6mm and 2-5mm pellets, respectively. Costs $310,000 represent comprehensive solutions that often include enhanced power stability features, local technician training programs, and spare part packages tailored for regional logistics.

- New Zealand: A dairy farming cooperative implemented an SZLH420 system for high-quality 2-4mm supplements. The project cost of approximately $250,000 focused on durability for abrasive ingredients, mobility within a multi-farm use model, and remote monitoring capabilities suited for their operational structure.

These examples demonstrate that while the reliable SZLH420 animal feed pellet mill for sale is the consistent heart of these projects, the final investment is defined by our deep expertise in creating a total system that aligns with your local raw materials, target feed specifications, production scale, and regional operational challenges. We build partnerships, not just ship machines.

We are planning a new commercial feed mill targeting an output of 8-12 tons per hour. Can your SZLH420 animal feed pellet mill for sale serve as the core of such a project, and what comprehensive services does Richi Machinery provide beyond just supplying the machine?

+

Your target of 8-12 t/h is the ideal operational range for our SZLH420 animal feed pellet mill for sale, making it the perfect core engine for a commercial feed mill or a large-scale animal feed pellet plant. As an integrated engineering partner, Richi Machinery’s role extends far beyond simply selling you a pellet machine. We are a turnkey solution provider, capable of undertaking every stage of your project.

We begin with a comprehensive analysis of your specific goals, raw material profiles, and budget to design an optimal production line.

Our service encompasses the entire lifecycle of the project: detailed engineering design, accurate budgeting, procurement and manufacturing of all feed pellet mill machinery (not just the pelletizer), on-site construction supervision, thorough trial operation, and final system acceptance. We deliver a complete, functional feed pellet production line, ready for efficient operation.

The complete system we design is structured for ease of operation and is fully customizable. It integrates several key stages: conveying, precise grinding, homogeneous mixing, efficient pelleting with the SZLH420, counterflow cooling, accurate screening, and automated packing.

A key strength of the SZLH420 animal feed pellet mill for sale is its flexibility; it can be fitted with ring dies featuring a variety of apertures (from 1.5mm to 12mm) and specific thicknesses. Our engineers will help you select the perfect die specification based on your feed formula—whether for poultry, livestock, or aquatic feed—to achieve the best balance of pellet quality, durability, and production economy.

The final equipment configuration and, consequently, the project investment will vary based on the functions you require. A complete feed mill plant solution typically includes raw material processing equipment, the core pelletizing unit, drying/cooling equipment, finished product handling systems, packaging units, and auxiliary support systems.

If you are seeking a manufacturer with the engineering depth to deliver a complete 8-12 t/h plant solution—not just an animal feed pellet mill for sale—we invite you to connect with our project team for a detailed solution design, a customized equipment configuration list, and a transparent production line quotation.

We’re setting up a new feed production line in Nigeria and need a reliable, high-capacity feed pellet mill for commercial use. What industrial feed pellet mill do you recommend for a mix of poultry and cattle feed?

+

For a new commercial line in Nigeria processing both poultry and cattle feed, we recommend our SZLH series animal feed pellet mill for sale in the 8-12 t/h or 14-16 t/h capacity range. These models are the workhorses of the industry, specifically designed for the high-volume, multi-feed type production you describe.

They feature a robust gear-drive transmission to handle the differing compression needs of poultry and cattle pellets, and they can be equipped with a versatile double-layer conditioner. This setup allows for precise steam adjustment—higher for poultry feed to gelatinize starches and slightly lower for cattle feed to preserve fiber structure.

Our engineers will work with you to design a complete line that includes the appropriate pre-grinding and post-cooling systems to maximize the efficiency of your pellet mill investment.

I run a small farm in the UK with about 200 cattle. Do you offer a small feed pellet mill that’s both affordable and efficient enough for my scale, or should I look at a commercial feed pellet mill?

+

Thank you for your inquiry from the UK. We specialize in commercial and industrial feed production equipment with minimum outputs starting at 1-2 tons per hour. For a farm with 200 head of cattle, the daily feed requirement typically falls well below the minimum efficient capacity of our smallest animal feed pellet mill for sale.

Running such a machine for only a short time each day is not cost-effective due to high energy consumption per ton and significant wear during startup/shutdown cycles. For your scale, we would advise exploring smaller, farm-scale pelletizers from local suppliers better suited to very low-volume production.

Our solutions are designed for operations where feed production is a core business, such as dedicated animal feed production plants or very large integrated farms with several thousand animals.

What’s the main difference between a standard electric feed pellet mill and a heavy-duty feed pellet mill? I’m processing tough forage for my goat farm in Australia and need something durable.

+

The key differences lie in construction, power, and intended duty cycle, which are crucial for processing tough forage in Australia. A standard electric mill often uses a belt drive, lighter-duty bearings, and a thinner housing. It’s designed for intermittent use with less abrasive materials. For fibrous goat feed containing tough forage, a true heavy-duty animal feed pellet mill for sale is essential.

Our heavy-duty models, like the SZLH series, feature a direct gear drive for maximum torque, a housing made from wear-resistant alloy, oversized spherical roller bearings, and a forced feeder option to push fibrous material into the die consistently. This build quality ensures it can run continuously under high pressure without overheating or premature wear, making it a durable, long-term asset for your farm.

We are a large broiler operation in the Philippines looking to upgrade. Is an automatic feed pellet mill with a built-in conditioner worth the investment for consistent chicken feed pellet quality?

+

For a large-scale broiler operation in the Philippines, investing in an automatic animal feed pellet mill for sale with an integrated conditioner is not just worthwhile—it’s critical for profitability. Consistency in pellet quality directly impacts feed conversion ratios (FCR) and bird health.

Our automated systems maintain a precise ratio of feed intake to steam injection in the conditioner, ensuring every batch of mash has the exact same moisture and temperature before pelleting. This results in pellets with uniform hardness and durability, reducing fines and waste.

The automation also allows one operator to manage multiple machines, optimizes energy use, and provides production data for analysis. The return on investment comes from improved FCR, lower labor costs, and higher overall feed quality.

I need to produce both floating and sinking fish feed for my aquaculture business in Vietnam. Can one multi-functional feed pellet mill handle both, or do I need two separate machines?

+

This is a common question from aquafeed producers in Vietnam. For floating feed, the process requires extrusion, not ring die pelleting. A ring die pellet mill produces sinking feed.

Therefore, one multi-functional animal feed pellet mill for sale cannot produce true floating feed. However, our ring die mills are excellent for producing high-density sinking fish feed.

For businesses requiring both types, we offer complete solutions: a twin-screw extruder for floating feed and a dedicated ring die pellet mill for sinking feed. These can be part of a single, integrated plant with shared pre-processing (grinding, mixing) and post-processing (drying, coating) sections.

Our project engineers can design a flexible layout that allows you to run both production lines efficiently, maximizing your market coverage.

As a feed pellet mill supplier, can you provide a complete turnkey solution including a mixer and conditioner for a new rabbit feed pellet mill line in Pakistan?

+

Absolutely. Richi Machinery specializes in delivering complete turnkey feed production solutions. For a rabbit feed pellet mill line in Pakistan, we would provide a fully integrated system.

This starts with hammer mills for fine grinding of ingredients, followed by a precision batch mixer to ensure a homogenous blend of fibers, grains, and micronutrients. The conditioned mash then enters our specialized animal feed pellet mill for sale, configured with a die specifically for small-diameter rabbit pellets (2-4mm).

The line is completed with a counterflow cooler to bring pellets to ambient temperature without moisture loss and a screening system to remove fines. We handle the entire process from design and manufacturing to installation, commissioning, and operator training on-site in Pakistan.

What kind of output can I realistically expect from a high-efficiency feed pellet mill for pig feed if I run it 10 hours a day? I’m comparing models before purchasing for my farm in India.

+

For pig feed production in India, the realistic output depends heavily on the pellet size and formula. With our high-efficiency SZLH350 model (rated 5-6 t/h), running 10 hours a day with an 85% operational efficiency factor (accounting for minor stops, cleaning, etc.), you can expect a solid daily production of 42 to 51 tons of finished pellets.

This output assumes you are producing standard 3-4mm grower/finisher pellets. If producing smaller nursery pellets, the output may slightly decrease due to higher die resistance.

The key to achieving this consistently is pairing the animal feed pellet mill for sale with a properly sized boiler for steady steam supply and a skilled operator. We can provide detailed production projections based on your specific pig feed formulas.

Are there specific features I should look for in a layer feed pellet mill to ensure optimal nutrition and egg production? I’m a poultry farmer in Kenya expanding my operation.

+

For layer feed in Kenya, the goal is a durable pellet that prevents selective feeding and delivers consistent nutrition.

When selecting an animal feed pellet mill for sale for layer operations, prioritize these features:

- First, a conditioner that can accurately apply heat without degrading heat-sensitive additives like vitamins and enzymes—our multi-stage conditioners offer precise temperature control.

- Second, a die with the correct compression ratio (typically medium) to create a firm pellet that doesn’t crumble but isn’t so hard it reduces intake.

- Third, a robust feeder system to handle the often higher calcium (limestone) content in layer mash without bridging.

We configure our mills to produce a consistent 3-4.5mm pellet that supports steady egg production and shell quality.

We are a cooperative of several farms in Brazil looking to buy a feed pellet mill for shared use. What features in a continuous feed pellet mill ensure minimal downtime and easy maintenance?

+

For a cooperative in Brazil with shared use, reliability and easy maintenance are paramount.

The ideal animal feed pellet mill for sale for your needs should have: A quick-release, split-vision ring die housing that allows a die change in under an hour without specialized tools, minimizing downtime between different member’s feed batches.

An automatic centralized greasing system that lubricates all major bearings during operation, reducing daily manual maintenance. Additionally, components like the feeder and conditioner shafts should have easy-access inspection ports.

We often recommend our models with these features for cooperative settings, and we provide extra training to ensure multiple users from different farms can operate and perform basic maintenance safely and correctly.

I see a wide range of feed pellet mill prices online. As a feed pellet mill manufacturer, what factors most influence the price of a cattle feed pellet mill for sale, and how can I ensure I’m getting good value?

+

The price variation in cattle feed pellet mills stems from several key factors. The drive system (gear vs. belt), the power and brand of the main motor (e.g., Siemens vs. generic), the quality of the bearing assemblies, and the thickness/ material of the ring die housing are major cost drivers.

A cheaper machine often uses lower-grade steel, standard bearings, and a belt drive, leading to higher long-term maintenance and shorter lifespan. When evaluating an animal feed pellet mill for sale, look beyond the sticker price.

Ask for the specifications of these core components, the expected lifespan of the die and rollers, and the warranty terms. With Richi Machinery, you invest in a mill built with industrial-grade components designed for a 15+ year service life, ensuring lower cost per ton over its lifetime—this is true value.

For a starter operation in Mexico focusing on poultry and livestock, is a feed pellet mill starter kit with basic accessories a good option, or is it better to invest in individual components?

+

For a serious starter operation in Mexico, we strongly advise against a generic “starter kit.” These kits often pair a low-cost mill with undersized or incompatible accessories. A better approach is to invest in a properly engineered system.

We start by assessing your target capacity (e.g., 2-3 t/h for a small commercial start-up). We then recommend a matched animal feed pellet mill for sale along with the correctly sized grinder, mixer, and cooler.

While this requires a higher initial investment than a kit, it ensures all components work harmoniously, preventing bottlenecks, achieving consistent pellet quality from day one, and allowing for efficient future expansion. We help starter businesses plan a phased investment if needed.

What is the typical lifespan of a ring die in a high-output feed pellet mill used for producing shrimp feed? I need to calculate long-term operating costs for my business in Indonesia.

+

Producing shrimp feed is one of the most abrasive processes due to fine grinding and high mineral content. In a high-output animal feed pellet mill for sale running shrimp feed 20 hours a day, the lifespan of a standard alloy steel ring die is typically between 800 to 1,200 production hours.

Using a high-chromium or stainless steel die, which we recommend for shrimp feed, can extend this to 1,500-2,000 hours but at a higher initial cost. To calculate your cost, consider the die price divided by its lifespan in tons produced.

For example, a $2,000 die lasting 1,500 hours at 0.8 t/h adds about $1.67 per ton to your operating cost. Our technicians in Indonesia can help you analyze your specific formula to recommend the most cost-effective die material for your operation.

We import feed machinery to Europe and are looking for a reliable wholesale feed pellet mill factory to partner with. What certifications and after-sales support do you offer for your animal feed pellet mill in Europe?

+

As a manufacturer seeking a long-term partner for the European market, Richi Machinery is an ideal choice. Our animal feed pellet mill for sale complies with CE machinery directives, and we can provide full technical documentation packs.

Our after-sales support is built for distributors: we offer comprehensive product training at our facility or yours, a generous spare parts discount structure, and technical support in English and other major European languages.

Most importantly, we provide marketing and technical collateral to help you sell, and our engineering team is available for joint customer visits to support large project bids, ensuring you can confidently offer a complete, professional solution to your clients.

Can you customize a horizontal feed pellet mill to fit the specific space constraints in our existing feed mill in South Africa? We need to replace an old unit without redesigning the whole floor plan.

+

Yes, space-constrained upgrades are a common request. Our standard animal feed pellet mill for sale has a horizontal design, but we can absolutely customize the layout. We can modify the orientation of the feeder inlet and pellet discharge spout to match your existing conveyor positions.

We can also offer a low-profile base frame or adjust the overall footprint dimensions within limits. The first step is for you to share your existing floor plan and the make/model of the old machine.

Our engineers will then propose a customized layout drawing for a new Richi pellet mill that drops into your current space with minimal modifications to the surrounding infrastructure, saving you significant time and renovation costs.

Do you offer a feed pellet mill with free shipping to the USA, and what does that include? We’re a small farm in Texas looking for our first machine to produce feed for our chickens and cattle.

+

Thank you for your interest from Texas. We offer competitive shipping solutions to the USA, typically CIF to a major port like Houston or Los Angeles. “Free shipping” offers often hide costs in the machine price.

We prefer transparent pricing: we quote an FOB price for the animal feed pellet mill for sale and a separate, competitive freight cost based on current rates. This allows you to compare accurately.

For a small farm, it’s important to note that our minimum viable commercial model has an output of 1-2 t/h. We recommend a detailed analysis of your daily feed needs for both chickens and cattle to ensure this capacity aligns with your operation scale before discussing logistics. We can then provide a clear, all-inclusive landed cost estimate.

What are the core components and material specifications of your SZLH420 animal feed pellet mill for sale, and can it be customized for our specific feed formula?

+

The superior durability and performance of our SZLH420 animal feed pellet mill for sale begin with its premium material configuration, which is designed for industrial-grade reliability. Unlike standard machines, we build every critical component to withstand continuous, high-pressure operation.

- For the granulation chamber, we use a stainless steel (SUS304) door cover and feed chute for superior corrosion resistance and hygiene, which is essential for sensitive feeds and easy cleaning.

- The heart of the machine, the gearbox, is constructed from high-strength HT250 cast iron for stability.

- The gears, spindle, and shafts are forged from hardened alloy steels like 42CrMo and 20CrMnTi, providing exceptional wear resistance and torque capacity.

- We ensure smooth, long-lasting operation by exclusively using imported high-precision bearings and German or Taiwanese oil seals.

- The drive system features a Siemens motor paired with a serpentine spring coupling and a mechanical safety pin, offering both efficient power transmission and reliable overload protection.

More importantly, this robust base configuration is just the starting point. We understand that no two feed operations are identical. That’s why every animal feed pellet mill for sale can be fully customized.

We don’t just adjust the voltage or the color; our engineers work with you to tailor the entire machine to your actual production needs.

This includes customizing the ring die material and compression ratio based on your specific feed raw materials and formula—whether it’s high-fiber cattle feed, high-fat aquafeed, or standard poultry rations. We can also customize the electrical control components, feeder systems, and even the pellet mill process flow to integrate seamlessly into your existing plant.

Our goal is to provide not just a machine, but a precision-engineered solution that optimizes pellet quality and output for your unique application.

What are the main factors that influence the price of an SZLH420 animal feed pellet mill, and how should a feed mill evaluate the true value of their investment?

+

This is an excellent and critical question. The price of an animal feed pellet mill for sale, including our SZLH420 model, is not a single figure but a reflection of multiple, interconnected factors. Understanding these helps you move beyond the initial price tag and assess the long-term value and total cost of ownership, which is where the real investment is defined.

1. Core Engineering & Performance Specifications:

The foundational price driver is the machine’s intrinsic performance and build quality. A pellet mill like the SZLH420, designed for high efficiency, stability, and advanced automation, commands a higher initial investment.

This cost is justified by tangible returns: significantly higher production output (8-12 t/h), lower energy consumption per ton due to its high-efficiency gear drive, and reduced labor costs through automated controls. You are paying for superior engineering that directly enhances your profitability.

2. Manufacturer’s Brand & Technical Support:

The reputation of the brand is a proxy for reliability and after-sales support. As an established manufacturer like Richi Machinery, our pricing reflects decades of engineering expertise, proven stability in thousands of installations worldwide, and a comprehensive guarantee on quality.

While the upfront cost may be higher than an unknown brand, it dramatically reduces the financial risk and downtime associated with frequent repairs, subpar performance, and a lack of technical support. You are investing in peace of mind and production continuity.

3. Customization for Your Specific Application:

The base price of an animal feed pellet mill for sale is just the starting point. The final cost is heavily influenced by the level of customization required. Will you be producing standard poultry feed, high-fat pig feed, or water-stable aquatic feed?

Each requires specific configurations: different ring die materials and compression ratios, optional forced feeders for fibrous materials, single or triple-layer conditioners, and customized motor/electrical specifications for your region’s voltage.

Our engineers tailor the machine to your exact raw materials and formula, ensuring optimal results, and this tailored engineering is factored into the value.

4. Procurement Scope & Project Partnership:

The scale of your purchase significantly impacts the unit economics. Procuring a single machine differs in price structure from engaging us as a partner for a complete turnkey production line, which includes design, auxiliary equipment, installation, and training.

Establishing a long-term partnership often leads to more favorable commercial terms, integrated solutions, and priority support, adding immense value beyond a simple transaction.

5. Regional Logistics & Support Infrastructure:

Final delivered costs vary by region due to logistics, local import regulations, and the extent of on-site support required. We factor in these variables to provide a clear, landed cost. Our global network ensures that professional commissioning and spare parts support are part of the value proposition, regardless of your location.

In summary, when evaluating an animal feed pellet mill for sale, we advise manufacturers to look beyond the sticker price. Make a comprehensive assessment based on total lifecycle cost: the machine’s performance capabilities, the manufacturer’s proven track record and support network, the degree of customization for your needs, and the scope of the partnership.

Choosing the right partner who provides a robust, customized solution and prioritizes your long-term operational success is the most effective way to control costs and maximize your return on investment.

How to choose animal feed pellet mill?

+

When choosing animal feed pellet mill, you need to consider multiple aspects to ensure that the equipment can meet production needs, improve production efficiency, and reduce costs. The following is an analysis of selecting production equipment:

- First, you need to consider the product structure.

Different products may require different equipment and process flows. For example, if you are producing broiler feed, you need a standard poultry feed pellet mill machine with a conditioner; if you are producing grass feed for cattle, you need to use a grass feed pellet mill machine. Therefore, when choosing production equipment, you need to choose the right equipment based on the product structure. - Second, you need to consider the quality requirements of the product.

Different equipment will produce different product quality due to differences in performance and precision. Therefore, when choosing an animal feed pellet mill, you need to choose equipment that can meet production needs based on the quality requirements of the product. - Third, you need to consider the use scenario of the animal feed pellet mill.

Different equipment is suitable for different production scenarios. For example, if you want to produce a large number of standard parts, you need to choose a production line with a high degree of automation; if you want to produce small batches and multiple varieties of products, you need to choose modular equipment with good flexibility. Therefore, when choosing animal feed mill equipment, you need to choose the right equipment according to the usage scenario.

In short, choosing animal feed pellet mills and feed equipment requires considering many aspects, including product structure, product quality requirements, and usage scenarios.

Only by comprehensively considering these factors can we choose the right equipment, improve production efficiency and quality, reduce costs, and obtain better economic benefits.

How to choose animal feed pellet mill manufacturer?

+

In recent years, animal feed production lines have been very popular, and animal feed pellet mills are naturally a hot topic. With the increase in animal feed pellet mill manufacturers, market competition has become increasingly fierce. How should feed factories choose equipment?

- First of all, when choosing animal feed pellet mill, you should look at the quality of the product.

For all users, product quality is the most concerned topic. If the quality of the equipment is high, the quality of the products produced will be good, and at the same time, it can save maintenance costs, and production failures will be greatly reduced.

Overall, it can greatly improve the overall production efficiency. Therefore, when choosing a feed pellet mill manufacturer, we must first pay attention to the quality and production efficiency of the product. - The reputation and strength of the animal feed pellet mill manufacturer are also very important.

Generally speaking, animal feed pellet mill manufacturers with good brands, good reputations, high credibility and considerate services are basically strong.

Some large manufacturers will have a lot of investment in scientific and technological research and development, so the continuous innovation and reform of their production processes will be very advanced. Of course, the equipment produced is of reliable quality and high wear resistance, and the service life of the animal feed pellet mill will also be very long. - When choosing a manufacturer who focus on animal feed pellet mill for sale, we must also pay attention to whether its after-sales service is perfect.

You must know that as long as it is a regular manufacturer, its after-sales service is generally very perfect.

However, when understanding, we must also pay attention to whether the after-sales service contains operator training, whether it provides users with feed pellet production line design services and other projects. In this way, the after-sales service covers a wider range, and their rights and interests are more effectively protected.

There are many animal feed pellet mill manufacturers, and all users should pay attention to factors such as product quality, manufacturer reputation and after-sales service when choosing.

Only when these aspects are thoroughly understood can we make effective judgments in a timely manner and compare prices reasonably. The selected animal feed pellet mill will be more efficient in production and the feed pellet production line will operate more efficiently.