Pellet Mill For Sale Australia

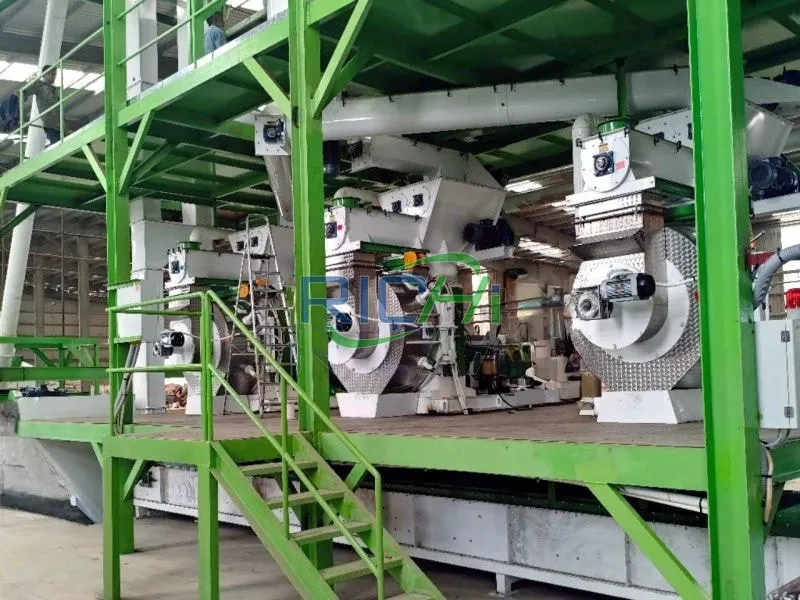

As a long-term supplier of pellet production solutions in Australia, we have delivered a wide range of complete pelletizing projects covering wood pellets, biomass, feed, organic fertilizer, waste recycling, and more.

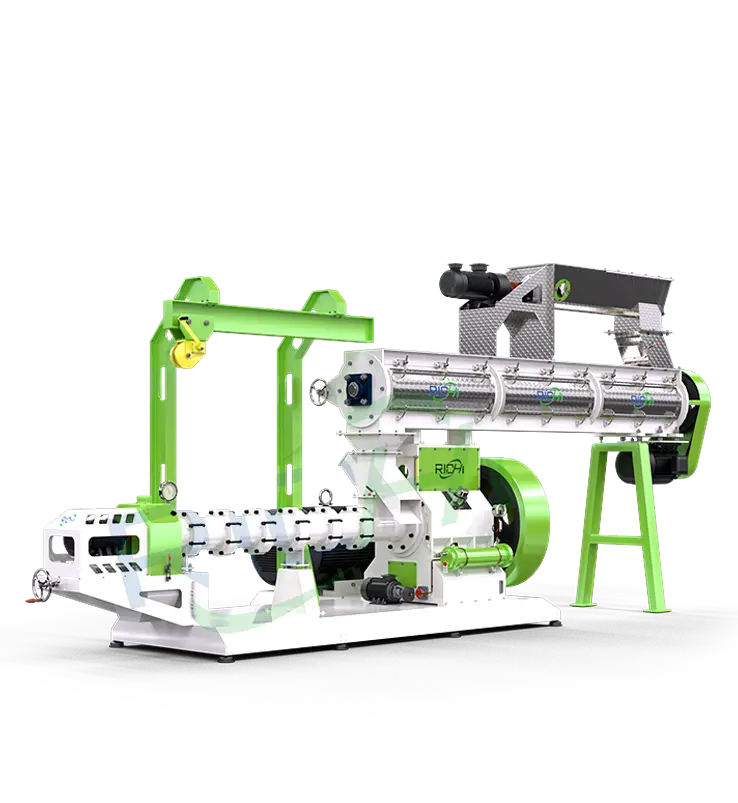

Our pellet mill for sale Australia range is built around high-performance ring die technology, supported by full sets of crushing, drying, mixing, cooling, packing, and auxiliary systems. Whether customers need a single machine or a fully engineered pellet plant, we provide customized design, manufacturing, installation, and lifelong service to ensure smooth production from the ground up.

120+ Units

Over 120 Ring Die Pellet Mills Delivered

We have supplied more than 120 sets of ring die pellet machines across Australia, serving diverse applications from wood and feed to waste recycling and specialty pellets.

35+ Projects

35+ Complete Pellet production Plants Built

Our team has engineered and delivered over 35 turnkey pellet production lines, each customized to local raw materials, capacity targets, and on-site conditions.

15+ Years

15 Years of Continuous Supply to Australia

With more than 15 years of uninterrupted exports to the Australian market, we have established a stable supply chain and long-term partnerships throughout the country.

Flagship Projects in Australia

Across Australia, we have delivered complete pellet plants for biomass, feed, fertilizer, and specialty pellets, working with farms, mills, recycling operators, pet food processors, and environmental companies. These projects demonstrate the depth of our engineering capability and the reliability of our pellet mill for sale Australia solutions. Each plant is fully customized—from raw material handling to final packaging—helping Australian customers build stable, high-yield pellet production systems tailored to local conditions.

Queensland

5T/H Pine wood pellet mill for sale australia

A forestry-based agricultural group in Queensland approached us to convert their abundant pine residues into marketable wood fuel pellets and premium wood cat litter products. They selected our ring die pellet mill for sale Australia (2 sets MZLH520 model), capable of producing two different pellet grades. Their raw materials included pine chips, fine sawdust, and offcuts with 35–55% moisture and variable particle size. After crushing and drying, pellets were formed at 6mm (fuel grade) and 2.5–3mm (cat litter grade).

- The complete line included: debarker, chipper, hammer mill, rotary dryer, double-shaft mixer, pelletiser machine Australia (MZLH520), cooler, screener, automatic bagging system, and dust-control modules.

- Total investment was around USD 620,000. We delivered layout design, process engineering, installation guidance, and long-term spare-parts supply.

8 t/h cattle & chicken manure fertilizer pellet mill for sale australia

A livestock farming cooperative in Victoria needed a stable way to convert cattle and poultry manure into organic fertilizer pellets for both internal use and commercial sale. They purchased a complete pellet press Australia system built around the FZLH420 ring die machine. Raw materials were semi-fermented manure (45–55% moisture), bedding residues, and crop dust—mixed into a uniform feedstock after composting and crushing. Pellets were produced in 4mm and 5mm sizes based on their agronomic requirements.

- The delivered line included compost turner, crusher, rotary dryer, mixer, pellet press for sale Australia (FZLH420), cooler, screener, coating machine, packing scale, and conveyors.

- Approximate investment reached USD 710,000. We supplied complete plant design, odor-control solutions, operator training, and on-site commissioning.

Victoria

Arkansas

4-5 t/h Wheat straw pellet mill for sale australia

A large sheep and beef operation in New South Wales wanted to repurpose their annual wheat straw harvest into high-value livestock bedding pellets. They chose our CZLH678 pellet machine for sale Australia due to its reliability with fibrous biomass. Raw material moisture ranged from 12–18%, with chopped straw lengths between 30–80mm before milling. Final pellets (8mm) were designed for high absorption and minimal dust.

- Included equipment: bale breaker, straw shredder, hammer mill, drum dryer, mixer, ring die biomass pellet machine Australia, cooler, screener, packing machine, and belt conveyors.

- The project investment was approximately USD 240,000. Our team supported capacity planning, energy-consumption optimization, and complete layout drawings for their existing barn infrastructure.

2-3 t/h Eucalyptus wood pellet machine for sale australia

A Western Australia plantation and mulch supplier sought a compact plant to process eucalyptus trimmings and bark into fuel pellets and horticulture-grade mulch pellets. They adopted our MZLH678 wood pellet machine Australia, producing 6mm fuel pellets and 4mm horticultural pellets. Raw materials had irregular shape and high oil content; moisture was 30–50% before drying.

- The complete line featured: wood chipper, hammer mill, rotary dryer, mixer, pellet mill MZLH678, cooler, screener, briquette reject system, and semi-auto bagging units.

- Total investment: about USD 230,000. We provided raw-material testing, pellet durability optimization, and on-site commissioning support.

Western Australia

South Australia

10 t/h sheep cattle feed pellet mill for sale australia

A mixed-livestock nutrition manufacturer in South Australia upgraded their feed facility to utilize locally available Barley straw, Oat straw, and Canola straw. They purchased a full feed pellet mill for sale Australia solution with our SZLH420 ring die press. Materials were pre-chopped to 20–30mm, with 10–15% moisture after conditioning. Final pellets were 6mm and 8mm for sheep and cattle rations.

- Delivered equipment: straw shredder, hammer mill, batch mixer, conditioning system, feed pellet machine Australia (SZLH420), cooler, crumbler, screener, molasses sprayer, bagging system, and dust-collection units.

- Investment was approximately USD 480,000. We offered feed-formula adjustment and performance testing to ensure stable density and digestibility.

3 t/h aqua floating fish feed pellet extruder for sale australia

A fishery group in Tasmania wanted to produce floating and sinking pellets using fish meal, shrimp shells, seaweed, and coastal by-products. They adopted our SPHS120*2 twin-screw pellet extruder for 1.5–4mm aqua feed. Raw materials had fine particle size (<1mm) and moisture around 10–12% before conditioning.

- The full plant included: grinder, pre-mixing system, floating fish feed extruder machine, fish feed dryer machine, oil sprayer, cooler, screener, micro-packing scale, and conveyors.

- Investment: approx. USD 690,000. We provided recipe support, floating-rate calibration, and long-term operation training.

Tasmania

Northern Territory

5 t/h Alfalfa Lucerne pellet mill for sale australia

A cattle station in the Northern Territory required a stable method to store and transport their surplus lucerne. They selected our pelletiser machine Australia CZLH420 to produce 6mm and 8mm feed pellets. Raw alfalfa moisture ranged from 18–28% and was pre-chopped to 10–40mm.

- The alfalfa pellet production line project included: bale breaker, alfalfa shredder, hammer mill, airflow dryer, mixer, industrial alfalfa pellet machine for sale Australia, cooler, screener, and a bagging/sealing system.

- Investment was about USD 260,000. We provided energy-efficient drying solutions and remote-monitoring support.

3-4 t/h Rat poison pellet mill for sale australia

An agricultural pest-control manufacturer in NSW required a specialized line for rodenticide pellets. They purchased our SZLH350 pellet press for sale Australia, capable of producing small-diameter pellets (2–4mm) with exacting density requirements. The raw mixture included grain flour, attractants, and active ingredients with moisture below 12%.

- The complete line included: mixer, binder-dosing system, pellet press, cooler, screener, metal-removal system, and precision packing.

- Project investment was around USD 170,000. We provided process isolation design, safety management guidelines, and closed-loop material handling.

New South Wales

Victoria

10 t/h broiler feed pellet mill for sale australia

A poultry integrator in Victoria needed to expand broiler feed capacity and improve pellet quality. They purchased our MZLH678 feed pellet mill for sale Australia along with a complete feed plant setup. Raw materials included corn, wheat, soybean meal, fats, and micro-ingredients; milled to <2mm. Pellets were 3mm and 4mm for broiler starter and grower feeds.

- The animal feed production line included: silo system, grinder, mixer, conditioning system, ring die pellet press Australia, cooler, crumbler, screener, liquid-addition system, bagging machine, and centralized dust removal.

- Investment was approx. USD 680,000. We provided full plant planning, steel-structure layout, and energy-use optimization.

1-2 t/h Dog food pellets extruder machine for sale australia

A pet food startup in Queensland aimed to launch premium dog food using local meat meal, fish powder, rice flour, and functional additives. They selected our small-scale twin-screw pet food extruder machine for sale Australia to produce 4–10mm pellets. Moisture of raw materials was 10–15%; particle size <1mm.

- Their complete pet food production line included: grinder, mixer, dog feed extruder, pet food dryer, oil sprayer, cooler, screener, flavoring machine, and packing unit.

- Investment was approx. USD 350,000. We supported formulation development, packaging design suggestions, and operator training.

Queensland

Other Projects We Completed in Australia

Beyond our major installations, we have also completed a diverse range of mid-scale pellet plants throughout Australia, supporting local agriculture, waste recycling, feed production, and biomass utilization. These projects highlight how our pellet mill for sale Australia solutions adapt to regional raw materials and help customers turn by-products into reliable, high-value pellets.

Live Project Videos in Australia

Explore real-world applications of our pellet mill for sale Australia solutions. These videos showcase complete pellet production lines operating across the country, converting wood, forage, livestock feed, and extruded pet or aquaculture feed into high-quality pellets. See our equipment in action, from raw material processing to finished pellet handling, and witness how Australian customers achieve efficient and reliable production.

What Our Australian Clients Say

We run a mixed grazing and timber property here in Victoria, and last year we invested in a complete biomass pellet line from RICHI to turn our eucalyptus residues and annual pasture cuttings into heating pellets and stock bedding. I was honestly surprised by how steady the output has been; the ring die pellet mill handles our fibrous mix far better than anything we had tested locally.

What impressed me most was how their team adjusted the conditioning system and moisture control to suit our dry Australian material, and how quickly they responded during commissioning. They didn’t just sell a pellet machine for Australia — they made sure our whole line ran properly from day one. The consistency of the pellets has opened a new income stream for us, and that reliability is exactly what we were looking for.

Daniel McAllister

Operations Manager, Regional Agricultural & Timber Enterprise, Victoria

Opportunities for Pellet Production in Australia

Australia’s diverse agricultural, forestry, and industrial sectors offer vast potential for pellet processing across multiple applications. From biomass energy to animal feed, fertilizer, and specialty pellets, there is a growing demand for high-quality, efficient pellet production. Richi Machinery provides complete pellet mill for sale Australia solutions, tailored to local raw materials, production capacities, and industry requirements, enabling Australian businesses to capitalize on these opportunities.

Our Best-Selling Pellet Production Equipment in Australia

Richi Machinery has been supplying a wide range of high-performance pellet production and auxiliary equipment across Australia. From feed processing to biomass and organic fertilizer production, our machines help Australian customers achieve high efficiency, consistent quality, and reduced operational costs. Our pellet mill for sale Australia solutions are complemented by shredders, grinders, mixers, dryers, and screening systems, enabling a complete one-stop solution for pellet production lines tailored to local raw materials and industry needs.

Pellet Mill Solutions for Australia: Your Key Questions Answeredered

This section answers the most frequent questions from Australian clients considering a pellet mill for sale australia. These questions cover raw material options, pellet types, production capacities, and applications across feed, biomass, fertilizer, and pet product industries. They reflect real considerations when choosing pellet machines, designing production lines, and handling diverse materials in the Australian context.

What is the price range for different types of RICHI pellet mills for sale australia, including small, medium, and high-capacity models?

+

The cost of a pellet mill for sale Australia can vary significantly depending on the type of material you plan to process, the required production capacity, the machine model, and any additional customization for Australian conditions. At Richi Machinery, we manufacture and export our machines directly from China, ensuring high-quality control, professional engineering, and the flexibility to design solutions for diverse materials such as feed, biomass, grass, wood, and fertilizers.

For reference, our typical ranges for feed pellet mills, grass pellet machines, and wood/biomass pellet mills are as follows:

Feed Pellet Machines (SZLH Series)

Our SZLH feed pellet mills are suitable for various livestock and aquaculture feeds, with capacities ranging from 1–40 T/H.

- SZLH250 (22 kW) – 1–2 T/H, estimated FOB price range: $7,500–$8,500

- SZLH320 (37 kW) – 3–4 T/H, estimated FOB price range: $16,500–$17,700

- SZLH350 (55 kW) – 5–6 T/H, estimated FOB price range: $28,000–$29,500

- SZLH420 (110 kW) – 10–12 T/H, estimated FOB price range: $30,000–$31,500

- SZLH508 (160 kW) – 15–16 T/H, estimated FOB price range: $42,000–$43,500

- SZLH558 (185 kW) – 20–22 T/H, estimated FOB price range: $49,500–$50,500

- SZLH678 (250 kW) – 30–33 T/H, estimated FOB price range: $66,500–$67,500

- SZLH768 (315 kW) – 38–40 T/H, estimated FOB price range: $80,000–$81,000

These machines are ideal for cattle, poultry, rabbit, or aquafeed production and allow flexible die and pellet size adjustments. Our feed pellet mill for sale Australia are engineered to handle high-fiber and high-protein raw materials commonly used in the Australian feed industry, such as alfalfa, ryegrass, and corn stover.

Biomass/Wood Pellet Machines (MZLH Series)

For wood and biomass pellets, including sawdust, wood chips, and agricultural residues, our MZLH series offers capacities from 0.2–4 T/H:

- MZLH320 (22 kW) – 0.2–0.3 T/H, estimated FOB price range: $14,000–$15,500

- MZLH350 (37 kW) – 0.3–0.5 T/H, estimated FOB price range: $20,000–$21,000

- MZLH420 (90 kW) – 1–1.2 T/H, estimated FOB price range: $29,000–$30,500

- MZLH520 (132 kW) – 1.5–2 T/H, estimated FOB price range: $44,000–$45,500

- MZLH678 (185 kW) – 2.5–3 T/H, estimated FOB price range: $66,000–$67,500

- MZLH768 (250 kW) – 3–4 T/H, estimated FOB price range: $80,000–$81,000

These wood pellet machines Australia are equipped with anti-arching feeders, force feeders, and conditioners for stable operation with variable moisture content materials. Richi Machinery’s wood pellet mill for sale Australia are ideal for eucalyptus, pine, and mixed forestry residues.

Grass Pellet Machines (CZLH Series)

Our CZLH series is designed for hay, miscanthus, reed, alfalfa, and other grass materials, with production capacities from 0.3–30 T/H:

- CZLH250 (22 kW) – 0.3–2 T/H, estimated FOB price range: $7,900–$8,500

- CZLH320 (22 kW) – 0.5–4 T/H, estimated FOB price range: $19,000–$19,800

- CZLH350 (37 kW) – 1–6 T/H, estimated FOB price range: $24,500–$25,000

- CZLH420 (90 kW) – 2–10 T/H, estimated FOB price range: $30,000–$31,000

- CZLH520 (132 kW) – 3–12 T/H, estimated FOB price range: $51,000–$51,600

- CZLH678 (185 kW) – 4–20 T/H, estimated FOB price range: $74,000–$74,100

- CZLH768 (315 kW) – 6–30 T/H, estimated FOB price range: $87,000–$87,500

These feed pellet mills Australia are particularly suitable for high-fiber and high-moisture grasses. The machines include anti-arching feeders, force feeders, and adjustable conditioners to maintain pellet quality for both feed and biomass purposes.

Richi Machinery provides these major types of pellet mill for sale Australia, demonstrating the diversity of our engineering capabilities and adaptability to multiple industries. Please note, these are only representative models.

We offer solutions for a wide range of raw materials and production capacities, and customizations are available for pellet size, moisture handling, automation, and integrated pellet line solutions. Final prices depend on your specific requirements, including material type, desired production rate, pellet size, and additional options such as pellet coolers, dryers, or dust collection systems.

To get an exact quote tailored to your needs, please share your production goals and material types with us, and we will provide a detailed pellet making machine for sale Australia proposal and pricing.

Could you provide a model parameter table for all the pellet mills you exported to Australia?

+

1. Feed Pellet Machines

| Model | Main Motor Power (kW) | Feeder Power (kW) | Conditioner Power (kW) | Die Diameter (mm) | Pellet Diameter (mm) | Capacity (T/H) |

|---|---|---|---|---|---|---|

| SZLH250 | 22 | 1.1 | 1.5 | 250 | 2–12 | 1.0–1.5 |

| SZLH320 | 37 | 1.5 | 4 | 320 | 2–12 | 3–4 |

| SZLH350 | 55 | 1.5 | 4 | 350 | 2–12 | 5–6 |

| SZLH420 | 110 | 1.5 | 7.5 | 420 | 2–12 | 10–12 |

| SZLH508 | 160 | 1.5 | 7.5 | 508 | 2–12 | 15–16 |

| SZLH558 | 185 | 1.5 | 11 | 558 | 2–12 | 20–22 |

| SZLH678 | 250 | 1.5 | 11 | 673 | 2–12 | 30–33 |

| SZLH768 | 315 | 2.2 | 11 | 762 | 2–12 | 38–40 |

2. Wood Pellet Machines

| Model | Main Motor Power (kW) | Anti-Arching Feeder Power (kW) | Force Feeder Power (kW) | Die Diameter (mm) | Pellet Diameter (mm) | Capacity (T/H) |

|---|---|---|---|---|---|---|

| MZLH320 | 22 | 2.2 | 0.75 | 320 | 4–12 | 0.2–0.3 |

| MZLH350 | 37 | 2.2 | 0.75 | 350 | 4–12 | 0.3–0.5 |

| MZLH420 | 90 | 3 | 1.5 | 420 | 4–12 | 1.0–1.2 |

| MZLH520 | 132 | 3 | 1.5 | 520 | 4–12 | 1.5–2.0 |

| MZLH678 | 185 | 3 | 1.5 | 673 | 4–12 | 2.5–3.0 |

| MZLH768 | 250 | 4 | 1.5 | 762 | 4–12 | 3.0–4.0 |

3. Straw / Grass Pellet Machines

| Model | Main Motor Power (kW) | Anti-Arching Feeder Power (kW) | Force Feeder Power (kW) | Die Diameter (mm) | Pellet Diameter (mm) | Capacity (T/H) |

|---|---|---|---|---|---|---|

| CZLH320 | 22 | 2.2 | 0.75 | 320 | 4–12 | 0.5–1.2 |

| CZLH350 | 37 | 2.2 | 0.75 | 350 | 4–12 | 1.0–1.2 |

| CZLH420 | 90 | 3 | 1.5 | 420 | 4–12 | 1.8–2.0 |

| CZLH520 | 132 | 3 | 1.5 | 520 | 4–12 | 2.8–3.0 |

| CZLH678 | 185 | 3 | 1.5 | 673 | 4–12 | 4–5 |

| CZLH768 | 250 | 4 | 1.5 | 762 | 4–12 | 6–8 |

4. Cat Litter Pellet Machines

| Model | Main Motor Power (kW) | Feeder Power (kW) | Conditioner Power (kW) | Die Diameter (mm) | Pellet Diameter (mm) | Capacity (T/H) |

|---|---|---|---|---|---|---|

| MSZLH250 | 22 | 1.1 | 1.5 | 250 | 2–12 | 1.0–1.5 |

| MSZLH320 | 37 | 1.5 | 4 | 320 | 2–12 | 3–4 |

| MSZLH350 | 55 | 1.5 | 4 | 350 | 2–12 | 5–6 |

| MSZLH420 | 110 | 1.5 | 7.5 | 420 | 2–12 | 10–12 |

| MSZLH508 | 160 | 1.5 | 7.5 | 508 | 2–12 | 15–16 |

| MSZLH558 | 185 | 1.5 | 11 | 558 | 2–12 | 20–22 |

| MSZLH678 | 250 | 1.5 | 11 | 673 | 2–12 | 30–33 |

| MSZLH768 | 315 | 2.2 | 11 | 762 | 2–12 | 38–40 |

5. Fertilizer Pellet Machines

| Model | Main Motor Power (kW) | Anti-Arching Feeder Power (kW) | Force Feeder Power (kW) | Die Diameter (mm) | Pellet Diameter (mm) | Capacity (T/H) |

|---|---|---|---|---|---|---|

| FZLH250 | 22 | 2.2 | 0.75 | 250 | 4–12 | 1–1.5 |

| FZLH320 | 22 | 2.2 | 0.75 | 320 | 4–12 | 2–3 |

| FZLH350 | 37 | 2.2 | 0.75 | 350 | 4–12 | 3–5 |

| FZLH420 | 90 | 3 | 1.5 | 420 | 4–12 | 6–8 |

| FZLH520 | 132 | 3 | 1.5 | 520 | 4–12 | 9–12 |

| FZLH678 | 185 | 3 | 1.5 | 673 | 4–12 | 18–22 |

| FZLH768 | 250 | 4 | 1.5 | 762 | 4–12 | 22–26 |

These are the main pellet mills exported to Australia by Richi Machinery. They cover feed, wood, grass/straw, cat litter, and fertilizer applications. Each machine is designed for different capacities and raw materials. We can also provide customized solutions, including die and roller adjustments, conditioning options, and full pellet line integration according to the specific requirements of Australian feed, biomass, and fertilizer producers.

We’re evaluating different pellet mill types for our Queensland operation. Could you provide pricing guidance for RICHI machinery models suitable for processing mixed hardwood/softwood, ranging from 2-5 ton per hour capacity?

+

Thank you for your inquiry from Queensland. For processing a mix of Australian hardwoods and softwoods at a 2-5 TPH capacity, we typically recommend our MZLH420 or MZLH520 biomass pellet mills. Providing a fixed price is difficult without understanding your specific raw material particle size and moisture content, but we can offer a clear range.

A complete system, including the pellet mill, feeder, and necessary preprocessing equipment, typically falls between AUD $90,000 and $220,000 (FOB China), with the final cost depending on the configuration and level of automation. The MZLH420 (90kW motor) is excellent for 1-1.2 T/H of pure hardwood, making it a strong candidate for the lower end of your range, while the MZLH520 (132kW motor) can handle 1.5-2.0 T/H and is better suited for higher outputs.

For a robust 5 TPH operation, we would likely propose multiple machines to ensure reliability. We strongly recommend sending us a 20kg sample of your mixed feedstock. Our engineers will conduct a free test pelletization in our lab, which allows us to provide a definitive equipment recommendation and a firm quotation for the most efficient pellet mill for sale Australia bound for your project.

Our sawmill in Tasmania generates about 1 ton of Blue Gum and Blackwood off-cuts hourly. What type of pellet making machine Australia would you recommend, and what’s the realistic output we can expect from these dense hardwoods?

+

Blue Gum and Blackwood are excellent but challenging materials due to their density and high lignin content. For a 1 TPH target with these specific Tasmanian hardwoods, we would recommend our MZLH420 wood pellet machine Australia model. This industrial-grade machine features a 90kW motor and a specially reinforced gearbox designed for continuous duty with abrasive materials.

However, you must temper your output expectations for pure, dense hardwood. While this model can achieve 1-1.2 T/H with pine, the extreme density of Blue Gum will likely reduce the output to approximately 0.7-0.9 T/H. The key to success is meticulous preparation: the feedstock must be reduced to a consistent 3-5mm particle size and dried to a moisture content of 10-12%.

We would equip this pellet making machine for sale Australia with a die specifically designed for hardwood, featuring a longer compression zone to properly plasticize the lignin. This setup will produce premium, high-heat-value pellets ideal for the local heating market or for export.

I run a mixed dairy and beef operation in Gippsland, Victoria. We need to produce 3-4 T/H of high-quality feed pellets containing lucerne, cereal grains, and protein meals. What specific features should we look for in a feed pellet mill for sale Australia?

+

For a high-output dairy and beef operation like yours in Gippsland, you need a robust and versatile feed pellet mill. The cornerstone of your operation should be a ring die pellet mill for sale Australia, specifically a model like our SZLH350.

The critical features to look for are a high-quality, gear-driven transmission (not belt-driven) for consistent power, a heavy-duty ring die and roller assembly designed for various formulations, and an efficient steam conditioner to gelatinize starches for better digestibility. Given your mix of fibrous lucerne and granular cereals, a machine with a variable-speed feeder is essential to fine-tune the flow for perfect pellet quality.

We would configure your feed pellet mill for sale Australia with a die that has a compression ratio suitable for both dense cattle pellets and potentially smaller dairy ration pellets. Our systems are designed to handle precisely these kinds of variable recipes, ensuring you produce durable, nutritionally superior feed.

We’re planning a commercial wood pellet operation in Western Australia using plantation pine and local jarrah waste. For an 8-10 T/H output, what’s the lead time for a complete wood pellet machine Australia setup, and how do you handle voltage compatibility with our 415V 3-phase power?

+

An 8-10 T/H commercial wood pellet line is a significant project, and we commend your planning. For this capacity, we would typically engineer a solution using multiple pellet mills, such as two of our MZLH768 models, to ensure stability and allow for maintenance without a full shutdown.

The lead time for a complete system of this scale is typically 60-75 days from order confirmation. This includes the manufacturing, assembly, and factory testing of all components, from the chippers and dryers to the pellet mills and coolers.

Regarding voltage, this is a standard part of our export process. All our motors and control systems are configured to meet Australian standards, which means they are supplied for 415V, 50Hz, 3-phase power operation. We provide complete electrical schematics for your local electrician to follow, ensuring a smooth and compliant installation. We manage the entire logistics chain to get your wood pellet mill for sale Australia safely to a major port like Fremantle.

Our mango farm in Northern Queensland needs to process 500kg-1T per hour of waste (pits, skins, rejected fruit) into animal feed pellets. What small pellet mill Australia configuration would work for this seasonal operation?

+

Processing mango waste is an excellent way to add value and reduce waste. For your seasonal and relatively low-volume needs, we recommend a compact and flexible solution based on our SZLH250 model, which is a perfect small pellet mill for sale Australia for farm-based applications. The key challenge with mango waste is its high moisture and sugar content.

The configuration must include a preliminary shredder for the pits and a paddle mixer to blend the wet and dry components uniformly. You would likely need to incorporate a dry carrier material, such as rice bran or sawdust, to achieve the proper consistency and moisture level (ideally below 15%) for pelleting. This small pellet mill australia, with its 22kW motor, is energy-efficient for seasonal use and can produce high-quality feed pellets from this unique mix. We can design a simple, cost-effective line that is easy to operate and store during the off-season.

We’re a waste management company in Sydney looking to process mixed cardboard and paper waste into fuel pellets. What type of biomass pellet machine Australia is suitable for this application, and are there any special modifications needed?

+

Converting mixed cardboard and paper into Refuse Derived Fuel (RDF) pellets is a forward-thinking application. For this, a standard biomass pellet machine Australia like our MZLH series can be used, but it requires critical modifications. The primary challenge is the low lignin content, which acts as a natural binder in wood.

We would need to equip the paper pellet making machine with a deeply grooved, low-compression-ratio die to facilitate the formation of pellets from the fluffy material. Often, the addition of a small percentage of a binder, such as waste vegetable oil or lignosulphonate, is necessary for durability. Furthermore, we would recommend installing a heavy-duty preconditioner to thoroughly mix any additives and pre-compact the material.

It’s crucial that the feedstock is consistently shredded and has a controlled moisture content. We have successfully deployed several customized pellet press for sale Australia units for similar RDF projects, and we can provide a lab report based on your specific waste stream sample.

For a new aquaculture feed mill in South Australia targeting barramundi and prawn production, we need to produce 5 T/H of slow-sinking 2mm-4mm pellets. What ring die pellet mill for sale Australia would you recommend, and what’s involved in die changes for different sizes?

+

Aquaculture feed production requires precision engineering. For a 5 T/H output of high-quality barramundi and prawn feed, we recommend our SZLH420 ring die pellet mill for sale Australia. This machine provides the necessary power and control for sensitive recipes. Achieving slow-sinking pellets requires precise control over density, which is managed through the recipe, conditioning parameters, and the die specification.

We would supply this feed pellet machine australia with quick-release die clamps. Changing from a 2mm to a 4mm die is a straightforward process that your trained operators can perform in under an hour. It involves releasing the clamp, sliding the old die out, and inserting the new one. We provide full training on this procedure and can supply a range of dies optimized for different sink rates and species. The durability of these micro-diameter pellets is critical, and our machines are designed to achieve this with minimal fines.

Our vineyard in Margaret River generates substantial grape marc waste. We’re considering a small pellet mill Australia to convert this into fertilizer pellets. What preprocessing equipment would we need for this high-moisture material?

+

Grape marc is an excellent feedstock for organic fertilizer pellets, but its high moisture content (often 60-70%) is the primary challenge. A standalone small pellet mill australia cannot process it directly. The essential preprocessing steps are dewatering and drying. We would recommend a configuration that starts with a screw press to remove a significant portion of the free water.

The pressed marc would then need to pass through a rotary dryer, potentially powered by waste heat from another process, to reduce the moisture to the ideal 12-15% for pelleting. After drying, a hammer mill would ensure a consistent particle size. Only then would the material be ready for our robust pelletiser machine australia. We design and supply these complete, integrated systems, ensuring all components work harmoniously to turn your waste into a valuable product.

We operate a large feedlot in New South Wales and need to upgrade our existing equipment to produce 15 T/H of finishing ration pellets containing cottonseed meal and wheat. What industrial-scale pellet press Australia models would you suggest?

+

For a large-scale feedlot requiring a reliable 15 T/H output, you need an industrial-grade solution. We would recommend our SZLH508 industrial pellet mill for sale Australia. This machine is a workhorse, featuring a 160kW motor and a heavy-duty construction designed for 24/7 operation. It is perfectly suited to handle abrasive and high-oil content ingredients like cottonseed meal mixed with wheat.

The key to efficiency in such a large operation is durability and minimal downtime. This model features our proprietary quick-release die system and is built with oversized bearings and a robust gearbox to withstand the constant load. Investing in this caliber of pellet press australia ensures consistent pellet quality, high throughput, and lower long-term operating costs for your feedlot.

Our forestry cooperative in the Green Triangle region has access to radiata pine and blue gum residues. We’re planning a 12 T/H biomass pellet export operation. What’s the total project timeline from ordering a wood pellet mill for sale Australia to commissioning?

+

A 12 T/H export-oriented biomass pellet plant is a major undertaking, and timeline planning is crucial. The total project timeline from your official order to commissioning is typically 5-7 months. This breaks down as follows: Manufacturing and factory acceptance testing of all equipment (including multiple pellet mills, dryers, and chippers) will take approximately 70-80 days.

Sea freight and logistics to a port like Melbourne or Portland usually take 25-35 days. Once the equipment arrives on site, the erection, installation, and commissioning period, which we guide remotely with detailed documentation and live video support, will take another 4-6 weeks, depending on your local team’s size and site readiness. We provide a critical path project plan with every major order for a wood pellet machine for sale Australia to ensure we are all aligned.

We manufacture organic fertilizers from chicken litter and green waste in Perth. Our current output is 3 T/H, but we need to expand to 6 T/H. What pelletiser machine Australia configuration handles these corrosive materials best?

+

Scaling up your organic fertilizer operation requires equipment specifically designed to handle corrosive materials like chicken litter. To double your capacity to 6 T/H, we would recommend our FZLH420 chicken manure pellet machine for sale Australia. The critical feature for your application is the use of corrosion-resistant materials.

We offer the option to fabricate the conditioner, the die housing, and all contact parts from 304 or 316 stainless steel to significantly slow degradation. Furthermore, the die and rollers for fertilizer are designed with wider holes and a different compression profile to handle the high-organic, often fibrous nature of the composted material. This robust configuration ensures your expansion is successful and your equipment maintains a long service life despite the challenging feedstock.

For our almond processing facility in Riverland, we want to pelletize almond shells and hulls for boiler fuel. What capacity pellet machine for sale Australia would handle 2 T/H of this abrasive material, and what wear protection is available?

+

Almond shells are highly abrasive and require a durable machine. To reliably achieve 2 T/H, we recommend our MZLH520 biomass pellet machine Australia. Beyond the robust base machine, wear protection is paramount.

We offer a comprehensive package that includes a die and rollers treated with a proprietary tungsten carbide overlay, which can increase service life by 3-4 times compared to standard parts. Additionally, we can fit the inlet and feeder with hardened steel liners. Using a pellet machine for sale Australia equipped with these specialized wear parts transforms a challenging, abrasive material into a consistent, high-value fuel source for your boiler, offering an excellent return on investment.

We’re establishing a kangaroo grass and native seed pellet operation for the restoration mining sector in the Pilbara. Production needs are modest – about 1 T/H. What small pellet mill for sale Australia would suit this remote location?

+

For your specialized native seed pellet operation in the remote Pilbara, reliability and simplicity are key. Our SZLH320 is an ideal small pellet mill for sale Australia for this 1 T/H application. Its 37kW motor is well-suited for the power constraints often found in remote locations. The gentle but effective action of our ring die system is excellent for preserving seed viability, which is critical for restoration work.

We can configure this pellet mill australia as a semi-mobile skid-mounted unit, making it easier to transport and set up on-site. We also emphasize remote-operational training and include a comprehensive spare parts kit to ensure minimal downtime, as you cannot afford delays in your important rehabilitation work.

Our mushroom farm in the Adelaide Hills needs to process spent substrate into fertilizer pellets. The material is quite fibrous. What type of pellet making machine for sale Australia handles this best, and what moisture content is ideal?

+

For your crucial rehabilitation project in the Pilbara, we specifically recommend our CZLH350 stalk & grass pellet mill. This model is part of our series specifically engineered for fibrous, low-bulk-density materials like native grasses.

Here’s why this machine is a superior fit for your application:

Gentle Pelletizing Action: The CZLH350 is designed to apply the optimal pressure needed to form durable pellets without generating the excessive heat and shear force of a feed mill. Preserving the germination rate of your native seeds is paramount, and this machine’s parameters are better suited for this delicate task.

Built for Fibrous Materials: It comes standard with a forced feeder that actively pushes the fluffy grass and seed mix into the die, preventing bridging and ensuring consistent production—a common challenge with low-density materials.

Right-Sized for Remote Operations: With a 37 kW main motor, the CZLH350 is highly efficient for your 1 T/H target and is better suited for the power generation realities of a remote site. We can further configure this small pellet mill for sale Australia as a containerized or skid-mounted unit, making transportation and setup in the Pilbara significantly easier.

Remote Support Focus: We understand that downtime is not an option. The package includes an extensive operational training video library and a critical spare parts kit designed for remote maintenance, ensuring your team can keep the operation running smoothly.

This specialized pellet making machine for sale Australia is engineered to support the important work of land restoration by producing high-quality seed pellets efficiently and reliably. We would be happy to discuss a small-scale test using your specific seed mix to demonstrate its effectiveness.

Our mushroom farm in the Adelaide Hills needs to process spent substrate into fertilizer pellets. The material is quite fibrous. What type of pellet making machine for sale Australia handles this best, and what moisture content is ideal?

+

Processing spent mushroom substrate into fertilizer pellets is an excellent way to create value from a by-product, and the fibrous nature of the material requires specific equipment for optimal results.

For your application, we do not recommend a standard pellet mill. Instead, the ideal solution is our FZLH series organic fertilizer pellet mill. This machine is specifically engineered for challenging, fibrous organic materials like your mushroom substrate. Unlike standard models, it features a heavy-duty forced feeder that actively pushes the fluffy, low-bulk-density material into the compression zone, preventing bridging and ensuring a consistent, uninterrupted flow into the die. This is critical for achieving stable production with fibrous feedstocks.

Regarding moisture content, your material requires precise preparation. The ideal range for pelleting spent substrate is typically between 18% and 25%. This is slightly higher than for wood or feed because the organic fibers need more moisture to become pliable and bind effectively under pressure. If the moisture is too low (below 15%), the pellets will be weak and crumble easily. If it’s too high (above 28%), the material may gum up the die, producing soft, irregular strands instead of solid pellets. Using a simple moisture meter to check before pelleting is highly recommended.

Since you haven’t specified a target output, we offer the FZLH series in multiple models. For a smaller farm operation, the FZLH320 with a 22 kW motor is a popular and efficient choice. For larger volume processing, the FZLH350 (37 kW) or FZLH420 (90 kW) would be more suitable. Our engineering team can help you select the perfect model once we understand your daily or weekly production goals.

This specialized pellet making machine for sale Australia is part of a complete solution we can provide to efficiently transform your spent substrate into a dense, durable, and marketable organic fertilizer product.

We’re a cooperative of wheat farmers in the Wheatbelt looking to add value by pelletizing straw for export. For a 20 T/H operation, what dust control systems are integrated into your pellet mills Australia?

+

A 20 T/H wheat straw pellet operation is a substantial and impressive project. Dust control is a major consideration for both operational safety and product yield. In our large-scale pellet mills australia systems, we integrate a comprehensive dust removal system. This typically includes high-efficiency cyclones at primary dust generation points like the hammer mill and cooler, coupled with a pulse-jet baghouse filter system that captures fine particulate matter.

These systems are connected through a network of ducting with strategically placed access points. The collected dust can often be recycled back into the pelleting process, minimizing product loss. We design this as an integral part of the plant layout, ensuring a safe working environment and compliance with environmental standards.

Our research institution in Canberra needs a versatile laboratory-scale pellet machine Australia for testing various biomass and feed formulations. What’s the minimum practical capacity, and can it handle different die sizes?

+

For research and development purposes, versatility is more important than high capacity. Our laboratory-scale pellet machine australia has a minimum practical capacity of about 500 kg per hour, which is perfect for formulation testing. This benchtop unit is incredibly versatile and is specifically designed for rapid die changes.

We can supply a kit with multiple die sizes, typically ranging from 2mm to 8mm, allowing you to test pellet formation across a wide spectrum of materials and diameters. The machine operates on a standard 3-phase power supply and comes with detailed protocols to ensure your research data is consistent and reproducible. It is the perfect tool for de-risking larger commercial investments.

We process macadamia nuts in Northern NSW and want to pelletize shells for smoking chips. What’s the simplest pellet press for sale Australia setup for this low-volume, seasonal operation?

+

After more careful consideration of your specific application, we recommend the MZLH320 small wood pellet machine as the simplest yet most durable solution for your low-volume, seasonal operation in Northern NSW.

Here’s a detailed analysis of why this model is the correct technical choice:

1. Material Compatibility: Engineered for Abrasive Biomass

Macadamia shells are notoriously hard and create significant wear on equipment. Our MZLH320 biomass pellet machine Australia is specifically engineered for abrasive lignocellulosic materials.

- Wear Resistance: Unlike feed pellet mills, its core components—the ring die and rollers—are manufactured from superior alloy steels and undergo specialized heat treatment for maximum wear resistance. This significantly extends the life of these consumable parts, reducing your long-term operating costs.

- Binding Mechanism: This mill works by applying high pressure and temperature to plasticize the natural lignin in the biomass, which acts as a binder. This process is ideal for macadamia shells, which contain no starch, resulting in dense, slow-burning smoking chips with excellent structure.

2. Simplified, Robust Process

The MZLH320 setup remains straightforward but is built to last:

- Pre-processing: The shells must first be crushed in a hammer mill to achieve a consistent 3-5mm particle size.

- Conditioning: As the shells are typically very dry, you will likely only need to add a small amount of moisture (up to ~12-15% total content) in a simple paddle mixer to facilitate binding. No complex steam conditioning is required.

- Operation & Storage: This compact system is easy to operate and can be cleaned and stored during the off-season.

3. Cost-Effectiveness for Your Niche

While the initial investment in the MZLH320 wood pellet extruder machine is slightly higher than a feed pellet mill, its specialized design for abrasive materials translates to lower downtime, fewer replacement parts, and more reliable seasonal production. This makes it a more cost-effective and trouble-free investment over its entire lifecycle for your valuable niche product.

Conclusion and Recommendation

For your macadamia shell smoking chip project, the MZLH320 wood pellet mill for sale Australia is the optimal choice, perfectly balancing operational simplicity with the necessary durability. This robust pellet press for sale Australia is ideally suited to transform your waste stream into a high-value culinary product consistently and reliably.

Our rendering plant in Queensland needs to produce 10 T/H of meat and bone meal pellets. What special considerations are needed for this high-fat content material in a feed pellet machine Australia?

+

Pelleting meat and bone meal (MBM) is challenging due to its high fat and protein content, which can act as a lubricant and hinder binding. For a 10 T/H output, you need a specialized feed pellet machine Australia like our SZLH420, but with key modifications.

- The most critical consideration is temperature control. We would use a double-pass conditioner to precisely heat the MBM to a point where the proteins denature and become sticky, acting as a binder, without cooking the fat out.

- Secondly, we would use a die with a very thick effective thickness and a special release pattern to build up sufficient pressure and back-pressure for the pellets to form properly.

Our experience in configuring a feed pellet mill for sale Australia for high-fat materials is extensive, and we can guarantee a stable, durable pellet that meets market specifications.

Can your pellet mills process materials other than wood and standard animal feed, such as for alternative fuels or organic fertilizers?

+

Yes, the fundamental technology of our pellet mills is highly adaptable to a wide range of materials beyond traditional wood and feed. This versatility is a key strength. Our machines have been successfully used to produce pellets from alternative fuel sources like paper waste, cardboard (OCC), and certain types of clean agricultural residues.

They are also perfectly suited for the production of organic fertilizer pellets from composted manure and other organic amendments. The critical factors are achieving the correct particle size and moisture content and selecting the appropriate die specification for the material’s fiber and binding properties. We welcome clients to send us sample materials for testing at our facility to confirm feasibility and optimize the machine configuration.

We are looking to establish a 1-2 TPH feed mill in New South Wales. What does a complete pellet line from Richi Machinery typically include for this capacity?

+

For a robust 1 to 2-ton-per-hour feed mill operation in Australia, a complete pellet line from Richi Machinery is engineered for efficiency and durability. It’s more than just a pellet mill for sale Australia; it’s an integrated system. The core is, of course, our reliable ring die pellet machine. Preceding this, the line includes a hammer mill for grinding raw materials, a twin-shaft paddle mixer for homogeneous blending, and a conditioning system where steam is added to optimize pellet quality.

Following the pellet mill, a counterflow pellet cooler is essential to bring the pellets down to ambient temperature, and a vibrating screener removes fines for a clean final product. We can also include screw conveyors and bucket elevators for automated material handling, culminating in a semi-automatic packing scale. This entire system is designed for seamless integration and is shipped ready for installation, providing a solid foundation for your livestock or poultry feed business.

What is the typical output and power consumption of your larger 5 TPH wood pellet production lines?

+

For a commercial 5 TPH wood pellet production line, a single standard pellet mill is generally not sufficient. Achieving this output with abrasive wood materials typically requires either a very large single mill or multiple mills operating in parallel.

For instance, our high-capacity MZLH768 wood pellet mill has a main motor of 250 kW and an output of 3-4 T/H. Therefore, to reliably achieve 5 TPH, we would likely recommend a configuration using two pellet mills, such as two MZLH678 models (each with a 185 kW motor and 2.5-3 T/H output). The total power draw for just the two pellet mills and their dedicated feeders would be approximately 380 kW.

When you integrate the substantial power needs of the preprocessing stage—which includes a heavy-duty wood chipper (~55-90 kW), a wood hammer mill (90-132 kW), and a large rotary dryer (which can itself consume 50-150 kW depending on the heat source)—the total connected load for a full 5 TPH wood pellet plant can easily reach 600-800 kW or more. We specialize in engineering these complex, high-capacity systems and provide a detailed power audit with any proposal for a pellet mill for sale Australia.

For a small-scale farm in Tasmania wanting to produce their own cattle feed, what is the smallest pellet mill you offer and what is its capacity?

+

For small-scale farms, our most compact and economical model is the SZLH250 ring die small animal feed pellet machine. This machine is an excellent entry-level solution. It is equipped with a 22 kW main motor and is designed to produce 1-1.5 T/H of cattle feed pellets. This output is perfectly suited to meet the needs of a single farm, allowing for the production of feed in batches.

The total power requirement for a basic setup including a small crusher, mixer, and the pellet mill itself would typically be around 40-50 kW. Its relatively modest power requirement and compact footprint make it a very practical choice for regional Australian farms. We provide this pellet mill for sale Australia-wide, with full remote support for installation and operation.

You mention a 2 TPH biomass line. What specific model achieves this, and what is its main motor power?

+

For a dedicated 2 TPH biomass pellet production line processing materials like hardwood sawdust or straw, the recommended model from our range is the MZLH520. This biomass-specific pellet mill is powered by a robust 132 kW main motor and is engineered to deliver an output of 1.5-2.0 T/H, making it the perfect match for your 2 TPH target.

It comes complete with an anti-arching feeder (3 kW) and a force feeder (1.5 kW) to ensure consistent material flow into the die, which is critical for biomass pelleting. When planning for this mill, you must also account for the significant power consumption of the necessary auxiliary equipment, such as a hammer mill and dryer, which will form part of the complete line we quote for your pellet mill for sale Australia project.

We need a pellet mill for poultry feed production with a target of 10 T/H. What is the main motor power and model we should consider?

+

To achieve a reliable output of 10 T/H for poultry feed production, we recommend the SZLH420 poultry feed pellet making machine. This industrial-grade machine features a powerful 110 kW main motor and is consistently rated for an output of 10-12 T/H with standard feed recipes. This model includes a conditioner (7.5 kW) for optimal steam addition and a feeder (1.5 kW).

It is a workhorse in the feed industry, known for its durability and stability under continuous operation. When you are evaluating a high-capacity pellet mill for sale Australia for your poultry feed business, the SZLH420 offers an excellent balance of output, energy efficiency, and proven performance.

What is the power range for your largest pellet mills, such as those used in major feed mills?

+

Our largest pellet mills are designed for high-volume, industrial-scale production. The top-of-the-line model in our feed series is the SZLH768. This is a heavy-duty machine equipped with a substantial 315 kW main motor, designed to produce 38-40 T/H of animal feed pellets. When you include the power for its feeder (2.2 kW) and conditioner (11 kW), the unit itself requires around 328 kW.

These industrial machines represent the high end of the power spectrum for a single pellet mill and are engineered for 24/7 operation in major feed mills. We provide complete technical specifications and infrastructure requirements for such a pellet mill for sale Australia to ensure your facility is fully prepared for a successful installation.

For a 3 TPH biomass plant in Queensland, what pellet mill model and power should we base our electrical planning on?

+

For a 3 TPH biomass plant in Queensland, the ideal pellet mill from our range is the MZLH678. This model is built to handle the abrasive nature of biomass materials like wood waste or bagasse. It is driven by a 185 kW main motor and has a specified output of 2.5-3.0 T/H.

You should base your initial electrical planning for the pelleting section on this 185 kW draw, plus an additional 4.5 kW for its integrated feeding system (anti-arch and force feeders). We will provide the exact power requirements for the entire line, including drying and grinding, in a detailed project proposal for this pellet mill for sale Australia.

Is there a significant difference in power consumption between producing feed pellets and wood pellets for the same output?

+

Yes, there is a very significant difference. Pelleting biomass materials like wood requires considerably more energy than pelleting animal feed. This is due to the tough, fibrous lignin in wood that must be plasticized under heat and pressure. For example, to achieve approximately 2 T/H, a feed pellet mill like our SZLH350 uses a 55 kW motor.

In contrast, a biomass pellet mill like our MZLH520, designed for the same output, requires a much larger 132 kW motor. This higher power requirement is a critical factor in project planning and operating cost calculations. When you inquire about a pellet mill for sale Australia, we always specify whether the machine is configured for feed or biomass to ensure accurate power and cost assessments.

What is the main motor power of your most popular mid-range feed pellet mill?

+

Our most popular model for mid-range feed production is the SZLH350. It strikes an excellent balance between capacity, energy consumption, and investment cost. This pellet mill is equipped with a 55 kW main motor and reliably produces 5-6 T/H of high-quality feed pellets. Its versatility and efficiency make it a frequent choice for growing Australian feed mills looking for a dependable animal feed pellet mill for sale Australia. The total power for a complete line based on this mill would typically be in the 130-160 kW range, depending on the auxiliary equipment selected.

For a 15 T/H cattle feed production line, what pellet mill model and power capacity would you propose?

+

To meet a 15 T/H cattle feed production target, we would propose the SZLH508 animal feed pellet making machine. This is a robust machine designed for continuous duty in large feed mills. It is powered by a 160 kW main motor and has a proven capacity of 15-16 T/H. This model ensures the production of durable pellets necessary for cattle rations. Planning for this pellet mill for sale Australia requires accounting for its total connected load, including the 7.5 kW conditioner and other line equipment, which we detail in our comprehensive project quotes.

We are planning a 1-2 TPH feed mill operation in New South Wales. Which Richi Machinery pellet mill model would you recommend and what is the total power requirement?

+

Thank you for your question from New South Wales. For a 1-2 ton per hour feed mill operation, we would actually recommend our SZLH250 model as the ideal core for your production line, not the SZLH320.

The SZLH250 pellet mill, with its 22 kW main motor, is perfectly sized for your target capacity, delivering a proven output of 1-1.5 T/H for standard feed formulations. This gives you the efficient performance you need without the excess capital and operating cost of an oversized machine.

However, your point about total power requirement is absolutely critical. While the SZLH250 itself runs on 22 kW, a functional production line requires significant additional power. You’ll need a hammer mill (typically 15-22 kW for this capacity), a mixer (3-4 kW), and a counterflow cooler (2.2-3 kW). When you add the pellet mill’s feeder (1.1 kW) and conditioner (1.5 kW), plus various conveyors and elevators (adding roughly 7-10 kW), the total connected load for a complete 1-2 T/H feed pellet line typically ranges from 50-65 kW.

This precise power planning is exactly why we provide every client with a detailed electrical layout and power schedule specific to their configured line. Getting this right is crucial for planning your electrical infrastructure, particularly in rural Australian locations where power availability may need careful consideration.

The SZLH250 represents the most efficient and cost-effective solution for your needs. We have supplied this reliable model to numerous Australian farming operations where it has proven ideal for producing quality cattle, poultry and sheep feed pellets. When you’re ready to move forward, we can provide a complete proposal including all auxiliary equipment to ensure you get a fully functional pellet mill for sale Australia operation that meets your exact production requirements.

What are the key advantages of your turnkey pellet mill plants for the Australian market, especially for someone new to the industry?

+

Our turnkey pellet mill plants are designed to remove the complexity of sourcing and integrating separate components, which is a significant advantage for clients across Australia, from Perth to Queensland. When you partner with Richi Machinery, you are not just buying a machine; you are acquiring a complete solution.

We handle the entire process from initial design and equipment manufacturing to providing detailed installation guides and comprehensive operational training. Since we manufacture all core equipment—including the pellet mill, hammer mill, mixer, and cooler—we ensure perfect compatibility and assume single-point responsibility for the entire line’s performance.

This approach minimizes your project risk and accelerates your time to production. For a reliable and high-performance pellet mill for sale Australia-wide, our turnkey solution represents the most efficient path to success.

For a small-scale farm operation in Tasmania, what options do we have for a small pellet plant?

+

For small-scale farms in regions like Tasmania or Northern Territory, Richi Machinery offers scalable and cost-effective small pellet plant solutions. These compact lines are perfect for producing on-farm feed for cattle, sheep, or poultry, or for processing local biomass. A typical setup might include a small hammer mill, a feed mixer, and our versatile flat die pellet mill, which is an excellent choice for lower output requirements.

These systems are designed for ease of use and maintenance, and they retain the core principles of quality pelleting. We offer different configurations to match your specific raw materials and budget, providing a practical and efficient pellet mill for sale Australia’s diverse agricultural community.

Your commercial pellet machines are advertised for Australia-wide service. How do you manage shipping, delivery, and technical support remotely?

+

This is a crucial question. As the manufacturer, Richi Machinery has a well-established logistics process for shipping heavy machinery to all major Australian ports, including Sydney, Melbourne, Brisbane, and Fremantle. We professionally handle the export documentation, container stuffing, and sea freight. Upon arrival, our trusted local freight partners manage the delivery to your site.

Regarding technical support, our commitment is comprehensive. We provide detailed foundation drawings and installation manuals well in advance. During installation and commissioning, we offer real-time guidance via video call.

We maintain a large inventory of pellet mill spare parts, ensuring fast shipment to minimize any potential downtime. This direct-to-customer model ensures you receive factory-level expertise and a reliable pellet mill for sale Australia without intermediary markups.

What is the typical lead time for a 3 TPH biomass pellet production line, and what is included in the pellet mill installation support?

+

The lead time for a complete 3 TPH biomass pellet production line is typically between 45 to 60 days after order confirmation, as major components are built to order.

Our installation support is extensive. While we do not have local agents, our remote support is highly effective. It includes the provision of complete electrical and layout diagrams, pre-delivery videos of similar running lines, and step-by-step photo documentation for assembly.

Our engineers are available for live video conferences to guide your team through the critical stages of assembly and the first trial run. This ensures your personnel are fully trained and confident in operating the equipment, making your investment in a biomass pellet mill a sound one for the Queensland market or elsewhere.

We are comparing different pellet machine suppliers in Sydney. Why should we choose Richi Machinery?

+

When comparing pellet machine suppliers in Sydney, the key differentiator is that Richi Machinery is the direct manufacturer. Many “suppliers” are merely traders or resellers. By choosing us, you eliminate the middleman, which translates to a more competitive price for the same or higher quality equipment. More importantly, you gain direct access to our engineering team for technical advice and customizations.

We have full control over the manufacturing process, using superior materials and quality control. Our long-term focus is on building a relationship, not just making a sale, and we support you with genuine pellet mill spare parts for the entire lifecycle of the machine. For a pellet mill for sale Australia clients can trust, the direct manufacturer offers unparalleled value and security.

For a cattle feed pellet mill, what specific features does your machine have to handle tough, fibrous ingredients?

+

Our cattle feed pellet mill is specifically engineered with reinforced components to handle the tough and fibrous nature of ruminant feed rations. The core of this robustness lies in the ring die and roller assembly. We use high-grade alloy steel for the dies, with specialized compression ratios and die hole designs that facilitate the formation of dense, durable pellets from fibrous materials like alfalfa, hay, and oilseed meals.

The rollers are also designed for high torque, ensuring a powerful pull-in and compression action. Furthermore, the heavy-duty gearbox and main shaft are engineered to withstand the constant high load. This rugged construction ensures consistent production of high-quality cattle feed, making it a durable and productive pellet mill for sale Australia’s extensive grazing and feedlot industries.

What type of pellet cooler is most effective for poultry feed, and why?

+

For poultry feed, which is often produced in large volumes and is sensitive to heat stress and nutrient degradation, the counterflow pellet cooler machine is universally considered the most effective type. Unlike simple air-cooling systems, a counterflow cooler moves the cool air in the opposite direction to the flow of hot pellets.

This method is highly efficient, extracting heat and moisture uniformly without causing thermal shock, which can make pellets brittle. It ensures the pellets are cooled throughout, not just on the surface, which is critical for preserving the nutritional integrity of the feed and preventing spoilage during storage. We include this superior cooling technology as standard in our poultry feed pellet machine lines for Australia.

Can you supply auxiliary equipment like a wood chipper and hammer mill for our pellet line in Western Australia?

+

Yes, without a doubt. To achieve high-quality pellets, the preparation of the raw material is just as important as the pelleting process itself. Richi Machinery manufactures a full range of auxiliary equipment that is perfectly matched to our pellet mills.

This includes industrial-grade wood chippers for processing logs and branches, powerful wood hammer mills for further reducing chips to a fine flour, and efficient rotary or belt dryers for moisture control. By sourcing your complete wood pellet making equipment from us, you guarantee compatibility, optimize the entire production flow, and have a single point of contact for service and parts, which is a significant advantage for a project in Western Australia.

How does your ring die pellet machine perform with Australian hardwoods compared to softwoods?

+

Australian hardwoods, such as Eucalyptus, are renowned for their density and high lignin content, which presents a unique challenge for pelleting. Our ring die pellet machine is specifically configured to handle these tough materials. The key is in the die specification. For hardwoods, we recommend a die with a longer compression zone (a greater effective thickness) and a hardened surface treatment to resist the extreme abrasion.

The machine itself is powered with a strong enough motor and gearbox to provide the necessary torque to compress the dense fiber. While hardwoods require more power and cause more wear than softwoods, our machines are built for this duty, producing exceptionally high-density and high-heat-value pellets. We provide expert die selection advice for any biomass pellet mill Queensland or other states require.

What is involved in the routine maintenance service for a pellet mill, and what spare parts should we keep in stock?

+

Proactive maintenance is the key to maximizing the uptime of your pellet mill. Our maintenance service guidance includes daily, weekly, and monthly checklists. Daily tasks include lubricating the bearings and checking for unusual noises. Weekly, you should inspect the condition of the rollers and die. The primary spare parts we recommend keeping in stock are a set of pellet mill dies and rollers, which are wear parts.

It is also prudent to have a spare set of belts, seals, and rollers for the conveyor systems. As the manufacturer, we can provide you with a customized spare parts package based on your specific machine model and production volume. Having these critical parts on hand ensures that any planned or unplanned maintenance does not halt your operation for long, securing your investment in a pellet mill for sale Australia.

We need a machine for producing sheep feed pellets. Is your equipment suitable for mixed rations with high grain content?

+

Our equipment is exceptionally well-suited for producing sheep feed pellets, including rations with high grain content like barley, wheat, and oats. The pelleting process actually benefits such rations by gelatinizing the starches in the grains, which improves digestibility and feed conversion efficiency.

Our conditioning process ensures the mixed mash is properly steamed and heated, making the starch soft and pliable before it enters the pellet mill die. This results in strong, durable pellets that reduce waste and fines. The versatility of our cattle feed pellet mill for sale Australia makes it equally effective for sheep, allowing you to produce a superior nutritional product for your flock.

What dust control solutions do you integrate into your pellet plant designs?

+

Dust control is a critical aspect of any pellet plant for operational safety, environmental compliance, and product loss prevention. Richi Machinery integrates comprehensive dust removal systems into our plant designs. The primary solution is the use of high-efficiency cyclone dust collectors, which are excellent for capturing the bulk of the particulate matter from processes like grinding and cooling.

For finer dust, especially at packing stations, we can incorporate pulse-jet baghouse dust collectors. These systems are strategically placed at all major dust generation points and are connected via a network of ducting. This integrated approach ensures a cleaner, safer working environment and is a standard consideration for our pellet plant auxiliary equipment Australia clients receive.

What is the main motor power of your most popular mid-range feed pellet mill?

+

Our most popular model for mid-range feed production is the SZLH350. It strikes an excellent balance between capacity, energy consumption, and investment cost. This pellet mill is equipped with a 55 kW main motor and reliably produces 5-6 T/H of high-quality feed pellets.

Its versatility and efficiency make it a frequent choice for growing Australian feed mills looking for a dependable pellet mill for sale Australia. The total power for a complete line based on this mill would typically be in the 130-160 kW range, depending on the auxiliary equipment selected.

We have access to large quantities of council green waste in Melbourne and want to produce garden mulch pellets. For a 4 T/H operation, what preprocessing steps are crucial before the material reaches the pellet making machine Australia?

+

For council green waste, preprocessing is 80% of the challenge in producing quality mulch pellets. Before the material even reaches your pellet making machine Australia, it must go through several crucial steps. First, a trommel screen or disc screen is needed to remove contaminants like plastics and stones. Then, a magnet removes ferrous metals.

The organic fraction then needs to be shredded with a slow-speed, high-torque shredder, followed by grinding in a hammer mill to achieve a consistent particle size. Finally, the moisture content must be carefully adjusted and balanced, often requiring drying. We design and supply this entire preprocessing line, ensuring that the feedstock entering the pellet mill is clean, consistent, and optimized for producing a premium, contamination-free garden mulch pellet.

Given Australia’s strict biosecurity laws, what cleaning and preparation is required for a pellet mill for sale Australia when switching between different animal feed types, say from poultry to ruminant feeds?

+

Australia’s strict biosecurity laws, particularly regarding Ruminant Feed Ban, are taken very seriously, and we design our equipment with this in mind. When switching from poultry to ruminant feed, a rigorous clean-out procedure is mandatory. Our pellet mill for sale Australia systems are designed for cleanability, with smooth internal surfaces and minimal dead spots.

The recommended process involves a “dry clean” using compressed air and brushes to remove the bulk of the material, followed by a “wet wash” with a approved detergent or sanitizer, often using a built-in CIP (Clean-in-Place) system if specified. All contact parts, including the feeder, conditioner, and pellet chamber, must be thoroughly cleaned. We provide detailed, step-by-step cleaning protocols and can design your system with additional access panels and ports to make this critical process as efficient and effective as possible, ensuring your compliance with Australian regulations.

We are planning a wood pellet production operation in New South Wales and came across your case study about a 2-2.5 T/H project. Can you provide more specific details about this wood pellet mill for sale Australia installation and explain why your equipment is well-suited for Australian conditions?

+

Thank you for your interest in our Australian project portfolio. The 2-2.5 T/H wood pellet production line you’re referring to was a successful installation for a client processing pure sawdust into 6-8mm pellets for the industrial biomass market. This project exemplifies our approach to delivering robust, compliant, and efficient solutions for the Australian market.

Here are the specific details and key reasons why this pellet mill for sale Australia was so effective:

Project Specifications:

- Core Equipment: The heart of the operation was our MZLH520 ring die pellet mill, a model we consistently recommend for its durability with abrasive Australian hardwoods.

- Complete System: The client invested not just in a single machine, but a full pelletizing system. This included a counterflow pellet cooler to properly stabilize the pellets and a vibrating screening machine to remove fines, ensuring a premium, market-ready product.

- Output & Layout: The line was designed for a consistent output of 2-2.5 tonnes per hour within a compact workshop footprint of 13m x 16m. Our team completed the installation and commissioning within a tight 15-day window, minimizing the client’s downtime.

Why This pellet mill for sale Australia Succeeded:

- Compliance & Safety: A critical factor for any Australian operation. The entire electrical system was engineered from the ground up to strictly adhere to Australian AS/NZ 3000 standards. We integrated a comprehensive emergency stop system and provided independent power switches for each equipment module, a feature highly valued by local safety auditors.

- Proven Performance with Local Materials: The client’s raw material was pure sawdust, a common by-product in NSW. Our MZLH520 model, with its high-torque gearbox and specially hardened die, is built to maintain consistent pressure and output with such materials, provided the moisture content is optimally prepared (in this case, below 15%).

- Customized Engineering: While this project used sawdust, the principles of customization are universal. For a different client with mixed hardwood species, we would adjust the die compression ratio and possibly recommend a pre-conditioning step. This flexibility is a hallmark of our service. We don’t just sell a standard pellet machine for sale Australia; we engineer a solution.

For a business in New South Wales looking to establish or upgrade a wood pellet operation, this project serves as a reliable benchmark. The guiding price for a complete system at this scale typically starts in the range of USD $70,000, though this can vary based on the level of automation and specific site requirements.

We would be pleased to discuss how this proven model can be adapted to your specific raw material profile and production goals for a highly efficient pellet mill for sale Australia.

We are a small poultry farm in Queensland looking to produce our own feed for broilers. We have space constraints and need a simple, cost-effective solution. Can you provide an example of a completed 1-2 T/H feed pellet mill for sale Australia project and explain how it was tailored for a similar operation?

+

Your situation is a common one for which we have developed a highly effective, compact solution. We recently completed a project for a poultry operation with goals very similar to yours: to produce 1-2 tonnes per hour of high-quality broiler feed pellets on-site, within a limited footprint and with a focus on operational simplicity and cost-efficiency.

Here is a detailed overview of that project and the strategic thinking behind it:

Project Overview: A Compact, Self-Sufficient Feed Solution

This client was not aiming for commercial feed sales but sought to gain control over their broilers’ nutrition and reduce their reliance on purchased feed. The core of the solution was a complete, integrated line built around a reliable feed pellet mill for sale Australia.

Key Specifications & Customized Design:

- Output & Pellet Size: The system was designed for a flexible output of 1-2 T/H, producing pellets in the 2-6mm range ideal for various broiler growth stages.

- Power & Efficiency: The total connected load was optimized at approximately 60 KW, making it efficient to run without requiring a massive power infrastructure upgrade.

- Streamlined Process: The process design was deliberately straightforward yet comprehensive: Crushing → Mixing → Pelletizing → Cooling → Screening. This ensures a consistent, high-quality pellet without unnecessary complexity.

- Space-Optimized Layout: A key achievement was designing the entire production line to fit within a facility with strict height limitations. We utilized a vertical arrangement for the cooler and screener to maximize floor space, a common challenge for Australian farms looking to retrofit existing sheds.

Why This “All-in-One” pellet mill for sale Australia Worked So Well:

- Beyond the Machine: The client purchased a complete pellet mill for sale Australia solution, not just a single machine. The line included a grinder for consistent particle size, a precision mixer for uniform nutrition, the pellet mill itself, and a cooling & screening system to deliver durable, ready-to-use pellets.