Organic Manure Making Machine

The FZLH768 organic manure making machine is a core piece of equipment designed for large-scale commercial production. With an exceptional processing capacity of 22-26 tons per hour, it can quickly transform vast quantities of organic waste into high-value organic fertilizer granules.

Whether it’s livestock manure, kitchen waste, or industrial waste, this manure processing machine can efficiently handle it, making it an ideal choice for building a 22-26 ton/hour organic fertilizer production line system. For fertilizer plants, large-scale livestock farms, and waste treatment centers seeking to scale and industrialize their organic waste processing operations, this equipment is a powerful engine for achieving high efficiency and returns.

What is organic manure making machine ?

The FZLH768 organic manure processing equipment is a true “transformation master,” transforming a wide range of seemingly useless waste materials into valuable resources. Furthermore, it can granulate compound fertilizers, chemicals, and feed, with applications ranging from fertilizer factories and breeding farms to sewage treatment plants and food processing plants. Investing in such a machine means acquiring not only a production machine but also a comprehensive solution for transforming a variety of organic waste materials into valuable resources.

Applicable Raw Materials

We understand that the source of organic fertilizer lies in the efficient conversion of various organic wastes. The FZLH768 organic fertilizer granulator is designed for this purpose, boasting unparalleled raw material adaptability.

Whether it’s common livestock and poultry manure, crop straw, kitchen waste, or sewage sludge, or often-overlooked, unconventional materials such as winery dregs, vinegar lees, sugar mill filter mud, mushroom cultivation waste, seaweed processing waste, and even slaughterhouse by-products, this manure making machine can successfully transform them into smooth, uniform, high-quality organic fertilizer granules.

This proves that it’s more than just a granulation machine; it’s a comprehensive solution that can “turn waste into gold,” transforming seemingly useless organic waste into valuable agricultural resources.

Whatever Your Raw Materials, Finish the Job with RICHI organic manure making machine!

turn organic manure into fertilizer?

Technological advantages

Our ring-die organic manure making machine utilizes a high-strength alloy steel ring die and an optimized roller compaction system. This ensures the output of high-quality fertilizer with uniform granules, a high degree of formation, and a smooth surface, even under high-intensity continuous production.

Its durability and granule quality far surpass those of similar products. With its excellent raw material adaptability and stable high-yield performance, our machine can easily transform a variety of organic waste materials into high-value commercial fertilizer, helping customers maximize production scale and economic benefits. It is a reliable guarantee for large-scale fertilizer companies to improve quality and efficiency.

Siemens Brand Motor Guarantee

The core power comes from a German Siemens brand motor, providing the equipment with strong and stable power output, ensuring long-term reliability and energy efficiency.

Forced Feeding and Uniform Distribution Structure

The unique forced feeder ensures smooth and uniform material feeding. The spiral feed plate design within the die housing ensures uniform material intake and balanced extrusion force, eliminating material jamming.

Efficient Gear Drive System

The high-strength gear design delivers high transmission efficiency and torque, completely eliminating roller slippage and increasing overall production capacity by over 15%.

Convenient Electric Disassembly and Assembly Device

Equipped with an electric die roller disassembly and assembly device, the ring die and pressure roller replacement is quick and labor-saving, significantly reducing maintenance downtime and improving equipment utilization.

WORKING

PRINCIPLE

Our ring die organic manure makng machine utilizes advanced mechanical extrusion technology. Its core principle is to utilize the powerful extrusion force of the ring die and rollers to cause loose powdered materials to undergo physical plastic deformation in a short period of time, ultimately compacting and cutting them into uniform, hard pellets. The entire process is efficient, continuous, and produces a very high yield.

Technical Parameters of FZLH768 organic manure making machine

For complete technical specifications, please contact us directly online.

Main Motor Power

250kw

Forced Feeder Power

1.5kw

Finished Pellet Diameter

4-12mm

Capacity

22-26T/H

Ring Die Diameter

762mm

Additional Features

Choosing the organic manure making machine means you’re producing more than just fertilizer; you’re also contributing to the future of sustainable agriculture. This equipment strictly adheres to the principles of organic fertilizer production, using animal and plant residues or excrement as raw materials. Through microbial fermentation, it produces nutrient-rich bio-organic manure fertilizer.

This organic manure fertilizer plays an irreplaceable role in providing crop nutrition, maintaining soil fertility, and protecting the ecological environment. Its impact on crop quality and soil fertility is unmatched by chemical fertilizers. Therefore, investing in this machine means investing in the production of high-quality fertilizer that truly improves soil health and enhances the quality of agricultural products, laying a solid material foundation for green agriculture.

Highly Automated Intelligent Control

The main on-site control cabinet is easy to operate and features an optional fully automatic control system that integrates with the central control room. It features intelligent functions such as production reports, accumulated working hours, oil temperature alarms, and oil change reminders.

Multiple Safety and User-Friendly Design

The unit is equipped with comprehensive safety features and prominent warning signs. The simple and intuitive operation panel ensures comprehensive operator safety and simplifies daily maintenance.

Compact Structure and High Reliability

The entire unit is compact and occupies a small footprint. High-quality materials and core components are used, and rigorous quality control and testing are performed to ensure stable operation and a low failure rate.

Professional Oil Circulation and Lubrication System

An optional independent oil circulation cooling and lubrication system effectively controls operating temperatures, significantly improving the equipment’s continuous operation capability and bearing life in high-temperature environments.

full range of production capacities to meet your production needs

There’s no such thing as a “one-size-fits-all” machine, only the right capacity. We understand that production scales and budgets vary, from farms to large-scale organic fertilizer processing plants. Therefore, we offer a complete line of organic manure making machines, ranging from compact to industrial-grade, with capacities ranging from 1 to 26 tons/hour. Whether your goal is a small-scale pilot production or large-scale commercial operation, you’ll find a precisely matched solution here, ensuring you get the best value for your investment.

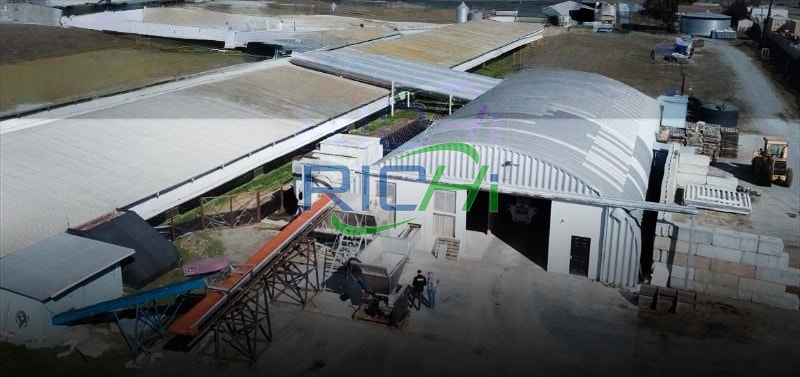

Our Solutions Are Creating Value Around the World

Over the years, we have successfully delivered a wide range of organic manure making machine projects to customers around the world. Our equipment has been exported to numerous countries including the United States, Vietnam, Brazil, Romania, Australia, Indonesia, Canada, Russia, and France—serving diverse clients from poultry and livestock farms to large agricultural enterprises and fertilizer processing companies. The raw materials handled by our systems vary widely, covering chicken manure, cattle and sheep manure, livestock waste, compost, and even integrated NPK&BB fertilizer formulations.

What sets us apart is not only our advanced granulation technology, but also our ability to provide complete organic manure fertilizer production lines, tailored to meet different processing requirements. From small-scale 1t/h installations for family farms to fully automated 40t/h production plants for industrial clients, our solutions are designed to deliver stable performance, high efficiency, and sustainable results. Each project reflects our commitment to helping customers turn organic waste into valuable fertilizer resources, promoting greener agriculture and circular economy worldwide.

United States

Organic Layer Chicken Making Machine

A U.S. poultry farming group installed this organic manure making machine to process layer chicken manure into nutrient-rich organic fertilizer for nearby corn and soybean farms.

Vietnam

Organic Animal Manure Making Machine

In Vietnam, a livestock feed cooperative adopted this machine to recycle mixed animal manure from pig and cattle farms into organic fertilizer for rice and vegetable cultivation.

Brazil

Organic Livestock Manure Making Machine

A Brazilian ranching enterprise uses this equipment to convert livestock waste into organic fertilizer, reducing disposal costs and supplying fertilizer to local pasturelands.

Romania

Organic Chicken Manure Making Machine

A Romanian family farm invested in this chicken manure processing line to turn daily poultry waste into organic fertilizer, improving soil quality for grain and sunflower crops.

Australia

Organic Cattle and Sheep Manure Making Machine

An Australian mixed-farming company employs this manure making system to handle cattle and sheep manure, producing eco-friendly fertilizer for large-scale pasture improvement.

Indonesia

Organic Animal Manure Making Machine

In Indonesia, an integrated agribusiness group introduced this manure processing unit to convert animal waste from its breeding farms into organic fertilizer for oil palm plantations.

Canada

Organic Poultry Manure Making Machine

A Canadian poultry producer implemented this equipment to recycle chicken and turkey manure into organic fertilizer, supporting sustainable agriculture across its contract farms.

Russia

Organic Animal Manure and NPK Fertilizer Making Machine

A Russian agro-industrial complex invested in this dual-purpose system to process animal manure and blend it with NPK nutrients, producing premium organic-compound fertilizer.

France

Organic Animal Manure Making Machine

A French agricultural enterprise utilizes this machine to transform livestock manure into high-grade organic fertilizer for vineyards and organic vegetable farms.

Global project experience and customized solutions

With years of practical experience in organic fertilizer engineering, we provide more than just equipment — we deliver complete, customized solutions for organic manure granulation and production lines. Our expertise covers every stage of the process, from raw material fermentation, crushing, mixing, and granulation to drying, cooling, screening, and packaging.

Whether it’s a small-scale farm upgrading its waste treatment capacity or a large fertilizer plant expanding industrial production, we design systems that match each client’s specific raw materials and capacity goals. Supported by a professional technical team and advanced manufacturing capabilities, we ensure every project achieves stable operation, high output, and superior fertilizer quality — proving why we are trusted by organic fertilizer producers worldwide.

Customer Testimonials

Our reputation in the organic fertilizer industry has been built on years of consistent performance, advanced process design, and dependable service. Across the world, agricultural enterprises, livestock farms, and environmental solution providers rely on our organic manure making machines and integrated production lines to transform organic waste into valuable fertilizer products. Each successful project is a reflection of our technical strength, engineering precision, and deep understanding of organic fertilizer processing needs.

Client Testimonial

We were looking for a reliable solution to handle large volumes of mixed manure. The system provided by this team exceeded expectations — from layout design to on-site installation, everything was handled with precision. Our fertilizer output is stable, and the organic manure granule quality is excellent.

Client Testimonial

Raw material: Decomposed plant residues and composted animal manure

Production capacity: 5 t/h

What impressed us most was how well the organic manure production line was adapted to our raw materials. The engineers customized the drying and granulation process specifically for tropical conditions. It’s a professional team that truly understands agriculture.

Client Testimonial

The equipment runs smoothly and requires minimal maintenance. We now turn all farm waste into valuable organic manure fertilizer. Their technical team gave us full support during commissioning — very knowledgeable and dependable people.

Client Testimonial

Raw material: Sheep and cow manure from local herders

Production capacity: 10 t/h

This project changed how our communities manage waste. The system is easy to operate, and the manure granules are highly suitable for local soil conditions. The supplier provided thorough training and guidance — we felt supported every step of the way.

Customized Organic Manure Granulation Solutions

Every organic manure production project starts with understanding the material itself — its moisture, texture, composition, and end-use requirements. That’s why our solutions go far beyond supplying a single granulator. We provide a fully customized process design for complete organic manure pellet production lines, ensuring that each stage is precisely adapted to the client’s raw materials, plant layout, local climate, and investment scale.

A typical organic manure granule production process includes raw material collection and sorting, fermentation or composting, crushing, mixing with additives, granulation, drying, cooling, screening, and packaging. Each section is carefully engineered to achieve stable output, uniform particle size, and optimal nutrient retention. For example, when handling high-moisture poultry manure, we integrate efficient drying systems and odor control measures, while projects using livestock or mixed manures may require specialized mixers or multi-stage conditioners.

Pelletizing System

Turning organic manure

into high-quality fertilizer granules

From early-stage consultation and project planning, to manufacturing, installation, commissioning, operator training, and spare parts supply — our team provides end-to-end technical support throughout the entire equipment lifecycle.

We work closely with every client to ensure that the final production line is not only efficient and reliable, but also truly fits their operational goals and long-term sustainability plans. Each project is a tailored engineering solution, built on experience, precision, and commitment to excellence in organic fertilizer production.

Complete Equipment Solutions for Organic Manure Production

We provide a comprehensive set of supporting equipment designed for every stage of organic manure production. Our equipment allows you to process not only granules but also manure powder. Each piece of machinery is selected and configured according to the client’s raw materials, production scale, and process requirements, ensuring smooth operation, high efficiency, and optimal fertilizer quality. From initial material preparation to final packaging, our solutions cover the entire workflow of an organic fertilizer production line.

FAQ About Organic Manure Making Machines

Choosing the right organic manure making machine can be complex, as it depends on your raw materials, production capacity, and operational goals. Farmers, livestock operations, and agricultural enterprises often have questions about how to optimize processes, select equipment, and ensure high-quality fertilizer output. The following are the most common questions we receive, reflecting real concerns and practical considerations for running a successful organic manure production line.

How much does an organic manure making machine cost?

+

This is a key question, and the answer depends on whether you need a single core unit or a complete organic manure production line covering everything from pretreatment to packaging.

- Price of a Single Organic Fertilizer Pelletizer

If you already have some pretreatment equipment and only need to upgrade the core pelletizing process, our ring die organic manure making machines are an efficient and cost-effective option. Prices vary depending on capacity and configuration:

- Entry-level (1-3 tons/hour): Models such as the FZLH250 (approximately $12,000-$15,000) and FZLH320 (approximately $14,000-$16,000) are suitable for small and medium-sized farms.

- Workhorse (3-12 tons/hour): Models such as the FZLH350 (approximately $19,000-$21,000) to FZLH520 (approximately $44,000-$46,000) meet the needs of most commercial fertilizer plants.

- Industrial-grade (18-26 tons/hour): Such as the FZLH768 model (approximately $75,000-$82,000), designed for large-scale continuous production.

- Complete Organic manure Production Line Pricing

If you plan to build a complete organic manure processing plant from scratch, the investment will cover the entire system from crushing, fermentation, mixing, granulation, cooling, screening, to packaging. The investment amount is directly linked to your target production volume:

- Small-scale production line (1-4 tons/hour): The initial investment is approximately $20,000 to $350,000.

- Medium-scale production line (5-12 tons/hour): The investment range is generally around $60,000 to $800,000.

- Large-scale production line (12-20 tons/hour and above): The investment scale can start at $200,000 and go up to $1,500,000 or more to support large-scale, intensive production.

Please note that the final price will be affected by factors such as the specific configuration, degree of automation, and location. Our experts will be happy to tailor a precise solution that meets your budget and production needs.

What are the detailed technical parameters of FZLH768 organic manure making machine?

+

| Model | FZLH768 |

| Output (t/h) | 22-26 |

| Main motor power (kw) | 250 |

| Main motor series | 8P |

| Ring die diameter (mm) | 762 |

| Finished pellet diameter (mm) | 4-12 |

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

Can the organic manure making machine process fresh chicken manure directly, or should it be fermented first?

+

We strongly advise against processing fresh manure directly in any organic fertilizer granulator, including our models. Fresh chicken manure, and most other fresh manures, have several characteristics that are detrimental to the granulation process and the final product.

- Firstly, the high moisture content and sticky nature of fresh manure will clog the die holes of the granulation machine, leading to machine stoppage and potential damage.

- Secondly, the high ammonia levels and active pathogens can be harmful and are not suitable for immediate application to crops.

- Most importantly, the fermentation process is what transforms raw manure into a stable, humus-rich, and biologically active organic material. This pre-composting is essential for achieving the right consistency and binding properties for successful powder fertilizer granulator operation.

Properly fermented material has a lower, more manageable moisture content and a fibrous structure that binds together under pressure, resulting in stable, high-quality pellets from your organic manure making machine.

What types of livestock manure work best for producing uniform fertilizer pellets?

+

Virtually all types of livestock manure can be successfully processed with a well-designed organic fertilizer granulation system. However, some are more straightforward than others.

Chicken manure, once properly composted to reduce its initial stickiness and ammonia content, is excellent for granulation due to its high nutrient density.

Cow manure is often considered one of the best materials for making organic fertilizer granules because its fibrous structure after composting provides natural binding properties, leading to very strong and uniform pellets.

Pig manure can also be used effectively, though its higher fat content sometimes requires more careful moisture control and mixing with bulking agents.

The key to achieving uniform pellets from any manure type lies not just in the manure itself, but in the pre-processing steps and the robustness of the fertilizer granulation equipment. Our engineers can provide specific recipe guidance to ensure consistent results with your available raw materials.

How do mixed manures, like pig and cow waste, affect granulation efficiency of the organic manure making machine?

+

Using mixed manures is a common and often beneficial practice. In fact, blending different manures can create a more balanced nutrient profile in your final organic fertilizer pellets. From a granulation perspective, mixing manures can actually improve efficiency.

For instance, the fibrous nature of cow manure can help offset the higher moisture and fat content of pig manure, creating a composite raw material with ideal physical characteristics for the granulation of fertilizers. This blend often results in a powder that compacts more easily in the granulator machine for fertilizer, leading to higher formation rates and more durable pellets. Our new type organic fertilizer granulator is designed to handle such variations in raw material composition, and we often recommend specific mixing ratios to optimize the process for our clients.

Can vegetable and fruit residues be added to livestock manure for organic fertilizer?

+

Absolutely. Incorporating vegetable and fruit residues is an excellent way to create a superior, well-balanced organic fertilizer. These residues are typically high in carbon, which helps to balance the high nitrogen content of livestock manure, leading to a more ideal Carbon-to-Nitrogen (C/N) ratio for both composting and plant nutrition.

Furthermore, they add valuable organic matter and micronutrients. When ground and mixed with manure, they act as a bulking agent during the composting phase, improving aeration. In the granulation phase, this mixed material often processes even better than manure alone, as the diverse fibrous structures can interlock and bind more effectively under the pressure of the organic fertilizer granulating machine, resulting in a high-quality, low-dust fertilizer granulation.

For a farm producing 20 tons of manure per day, which organic manure making machine capacity is most suitable?

+

This is a critical planning question. The choice of your organic manure making machine depends directly on your desired operating hours. Let’s analyze based on a daily input of 20 tons (20,000 kg) of processed, fermented raw material ready for granulation.

- If you plan to run your fertilizer granulation equipment for a single 8-hour shift, you would need a machine capable of processing at least 2.5 tons per hour (20 tons / 8 hours).

- For this scenario, our FZLH320 model (2-3 T/H) would be an ideal match. It can comfortably handle the required throughput within a standard workday.

- If you wish to complete the granulation in a shorter time, say 5 hours, you would need a capacity of around 4 tons per hour. In this case, the FZLH350 model (3-5 T/H) would be the recommended choice, giving you some extra capacity for future growth or to handle peak loads.

Our sales team will work with you to understand your entire operational workflow to recommend the perfect commercial compost granulator that fits your production schedule and business goals.

How much fermentation or composting time is needed before granulation for high-nitrogen materials?

+

For high-nitrogen materials like poultry manure, the fermentation period is crucial and typically ranges from 15 to 30 days. This process is not just about time; it’s about achieving specific milestones. The windrow composting method with regular turning is the most common approach. The material must go through a thermophilic phase where temperatures reach 55-65°C (131-149°F) for a sustained period to eliminate pathogens and weed seeds.

The pile will then cool down, and the process is complete when the material is dark, crumbly, and has an earthy smell with no original manure odor. Attempting granulation of organic fertilizer before this point will lead to poor pellet quality and potential biological instability in the bag. We can supply the complete composting equipment, like turners, to ensure your raw material is perfectly prepared for the organic fertilizer granule machine.

Can the organic manure making machine handle high-fiber raw materials like straw or rice husks mixed with manure?

+

Yes, our organic manure making machine is specifically engineered to handle fibrous materials. In fact, straw and rice husks are excellent amendments. The key is proper pre-processing. These high-fiber materials must be shredded or crushed into a fine powder before being mixed with the manure and fed into the powder fertilizer granulator. When finely ground, these fibers act as a natural binding agent, creating a strong matrix within the pellet.

Our machines feature a robust gearbox and a high-compression ring die design that applies tremendous pressure, effectively forcing these fibrous materials to bond and form dense, durable pellets. This capability is a hallmark of a high-quality organic fertilizer granulation machine designed for real-world feedstock variety.

Is it possible to adjust the organic manure making machine for both small-scale and large-scale production lines?

+

While a single organic manure making machine unit is calibrated for an optimal throughput range, the concept of scalability is fundamental to our system designs. For small-scale production, we offer standalone granulators like our FZLH250 model, which is a perfect small scale organic fertilizer granulator for farms or pilot projects. For large-scale, continuous commercial production, this same granulation technology is scaled up in our high-capacity models like the FZLH768.

More importantly, the entire process line—from feeding and mixing to cooling and screening—is designed to be modular. This means you can start with a compact setup and later add pre-mixers, additional dryers, or automated packaging systems to scale up your operation. As a leading organic fertilizer granulator manufacturer, we specialize in creating flexible plans that grow with your business.

How do seasonal variations in manure moisture affect the granulation process?

+

Seasonal moisture variation is a common challenge that our equipment and process expertise are designed to overcome. For instance, manure tends to be wetter in rainy seasons and drier in summer. The organic fertilizer granulation process is highly sensitive to moisture content; too wet, and the material clogs the machine; too dry, and the pellets will not form properly. Our approach is two-fold.

First, our organic fertilizer granulating machine often includes an adjustable feed system and internal design that can tolerate a range of moisture levels. Second, and more critically, we design the pretreatment stage to include moisture management. This involves using dewatering presses for very wet manure or adding water/humectants for overly dry material. This ensures a consistent, ideal moisture content (typically around 25-30%) is always delivered to the granulator, guaranteeing stable pellet quality year-round.

Can the same machine produce organic manure pellets from both poultry litter and mixed crop residues?

+

Yes, this is a core strength of our fertilizer granulator machines. The ability to process diverse feedstock is what sets a versatile organic granular fertilizer making machine apart from a basic one. The transition from processing pure poultry litter to a mix containing crop residues is straightforward.

It may involve a simple adjustment to the feeding rate or the compression ratio between the roller and the die to account for the different fiber content and binding characteristics. Our machines are built with this flexibility in mind, making them an ideal organic waste converter machine for operations that source a variety of agricultural wastes. We provide the operational parameters and support to help you switch between different material recipes seamlessly.

How long do the key parts of the organic manure making machine last under continuous operation?

+

The longevity of core components is a primary focus in our manufacturing. The ring die and pressure rollers, which are the heart of the granulation process, are made from high-chromium alloy steel and undergo specialized heat treatment for extreme surface hardness and core toughness. Under normal continuous operation with properly prepared raw materials, a ring die can typically last between 1,500 to 2,500 hours before needing reconditioning or replacement.

The rollers have a similar lifespan. The main gearbox, a critical power transmission component, is designed for a service life of over 10,000 hours. It’s important to note that lifespan is heavily influenced by material abrasiveness and maintenance. As a reliable organic fertilizer granulator supplier, we provide detailed maintenance schedules and high-quality spare parts to maximize your equipment’s uptime.

Can the organic manure production line be customized to match different plant layouts and budgets?

+

Without a doubt. At Richi Machinery, we do not believe in a one-size-fits-all solution. We specialize in custom-engineered organic fertilizer production lines. Whether you have a narrow, long space or a compact square area, our engineering team will design a layout that optimizes material flow and operator access.

Similarly, we can tailor the line to your budget. This could mean starting with a semi-automatic system focused on the core equipment like the granulator and a dryer, with plans to add automation and packaging later. Or, it could involve selecting different levels of automation for various stages. We present multiple options, ensuring you get a fertilizer granulation equipment line that meets your specific production needs, space constraints, and financial parameters.

What is the typical energy consumption for a 5–10 t/h organic manure production line?

+

Energy consumption is a key operational cost, and we design our systems for efficiency. A complete production line in this capacity range, including mixing, granulation, drying, cooling, and screening, is a significant power user. The organic manure making machine itself is the main consumer. For a system with a 5 T/H granulation capacity,

the total connected power for the entire line might be in the range of 250-300 kW. For a 10 T/H system, it could be 450-550 kW. It’s crucial to understand that this is the total installed power; actual consumption depends on daily runtime and machine load. Our technical proposals always include a detailed power analysis, and we often incorporate energy-saving features like variable frequency drives (VFDs) on motors to reduce actual electricity usage.

Are odor and dust control solutions integrated for poultry and livestock operations?

+

Yes, we treat environmental control as an integral part of a modern organic fertilizer plant. For odor, the primary solution is the enclosed design of our fermentation and drying systems. The hot, humid air from the dryer, which carries most of the residual odors, can be ducted to a bio-scrubber or a condensing system, effectively neutralizing smells before release. For dust, which is generated during crushing, screening, and packaging, we design and supply integrated baghouse dust collection systems.

These collectors capture over 99% of particulate matter, ensuring a clean working environment and meeting environmental regulations. This focus on low dust fertilizer granulation and odor management is part of our commitment to providing turnkey, socially responsible solutions.

How easy is it for workers with no technical experience to operate the organic manure making machine?

+

We have designed our systems with operator-friendliness as a priority. The control system for the organic fertilizer granulation machine is centralized on a user-friendly PLC panel with a clear interface. Start-up and shutdown sequences are logical and well-documented.

Furthermore, we mitigate operational complexity through stable machine design; once the correct parameters (like material moisture and feed rate) are set for a specific recipe, the machine runs consistently. However, the most important factor for ease of use is the training we provide. During commissioning, our field engineers will spend several days on-site, providing hands-on training to your staff until they are confident in routine operation, basic troubleshooting, and daily maintenance tasks.

Can the organic manure processing system be scaled up later if production requirements increase?

+

This is one of the most common and important questions we receive, and the answer is a definitive yes. We design all our projects with future expansion in mind. The modular nature of fertilizer granulation equipment means that scaling up is a straightforward process.

For example, you can start with a single organic fertilizer granulator for sale from our mid-range models. When demand grows, you can upgrade to a high capacity fertilizer granulator model. Simultaneously, you can increase the capacity of upstream and downstream processes, such as adding a larger mixer, a second dryer, or an automated coating system. Our initial plant layout will reserve space and consider utility connections for this future growth, protecting your initial investment.

What type of maintenance is required to maintain organic manure pellet quality over time?

+

Consistent pellet quality is directly tied to proactive maintenance. The maintenance regimen for an organic manure making machine includes:

As-Needed: Replacing the ring die and rollers when pellet quality declines (e.g., increased fines, soft pellets). The key is to use high-quality, genuine Richi Machinery spare parts to ensure performance and longevity. A well-maintained machine not only produces superior organic fertilizer granules but also has a significantly longer operational life.

Daily: Visual inspection for unusual wear or leaks, checking and tightening all bolts, and lubricating bearings as needed.

Weekly/Monthly: Inspecting the condition of the ring die and rollers for wear, checking all drive belts for tension, and cleaning out accumulated material from the feeder and conditioner.

Do you provide installation, training, and operational support for first-time users?

+

Comprehensive support is a cornerstone of our service at Richi Machinery. For every project, we offer a complete support package. This includes:

Operational Support: We provide detailed operation and maintenance manuals. Furthermore, our technical support team is available for remote assistance via phone or video call. For complex issues, we can arrange for an engineer to visit your site promptly.

Installation & Commissioning: We can dispatch experienced engineers to your site to supervise the installation, ensure everything is correctly aligned and connected, and conduct the initial startup of the organic fertilizer granules making machine.

Training: Our engineers provide extensive hands-on training for your production, maintenance, and quality control teams, covering everything from daily operation to troubleshooting.

Can the organic manure making machine handle mixed raw materials with variable moisture and nutrient content?

+

Handling variability is a key test of a robust organic fertilizer granulation machine. Our machines are certainly designed to cope with a reasonable range of variation. The forced feeding system ensures a consistent volume of material enters the granulation chamber, compensating for some differences in density. However, for optimal performance and consistent pellet quality, we strongly recommend stabilizing the raw material stream as much as possible before it reaches the granulator.

This is achieved in the mixing stage. We design and supply precision mixers that homogenize different batches of composted material, creating a uniform blend of moisture and nutrients. This pre-conditioning step is what allows our granulator machine for fertilizer to produce a consistent, high-quality product batch after batch, even when the source materials have natural variations.

Are spare parts and technical support available for international customers?

+

Yes. As an organic fertilizer granulator manufacturer with a global footprint, supporting our international clients is a top priority. We have a dedicated export department and a streamlined process for shipping spare parts worldwide—all directly from our factory to ensure authenticity and timely delivery.

Our warehouse stocks a wide range of critical spare parts, such as ring dies, rollers, bearings, and gears, ready for dispatch. Technical support is available through multiple channels, including email, WhatsApp, and video conferences, allowing us to provide immediate assistance regardless of your time zone. Our goal is to be your reliable partner, not just a one-time equipment seller.

How to process organic manure pellets?

+

Detailed Explanation of Core Process Flow and Supporting Equipment

1. Raw Material Pretreatment and Preparation

Main Equipment: Crusher, Screener

After systematically collecting various types of organic waste, a crusher is first used to pulverize bulky raw materials. Then, a drum screen effectively removes impurities such as stones and metals, producing uniform, qualified raw materials for subsequent fermentation.

2. Efficient Aerobic Fermentation

Main Equipment: Trough Turner, Crawler Turner

This is the core step in converting waste into composted organic matter. Trough turners or crawler turners are responsible for regularly turning the materials in the fermentation tanks. By precisely controlling temperature, humidity, and ventilation, they create an optimal environment for microbial activity, ensuring complete detoxification and composting.

3. Precise Formulation and Mixing

Main Equipment: Automatic Batching Machine, Horizontal/Vertical Mixer

Based on the target crop and soil requirements, an automatic batcher is used to scientifically mix the composted base material with nutrients such as nitrogen, phosphorus, and potassium. The composted base material is then fed into a horizontal or vertical mixer for efficient and uniform mixing to ensure consistent nutrient distribution.

4. Core Forming: Ring Die Granulation

Main Equipment: Ring Die Organic Fertilizer Granulator

The evenly mixed powdered material is fed into our core equipment, the ring die organic fertilizer granulator. Under the tremendous mechanical pressure, the material is extruded through the ring die holes into cylindrical granules with uniform density and high strength.

5. Cooling, Screening, and Deep Drying

Main Equipment: Cooler, Drum Screener, (Optional) Dryer

The granules fresh from the granulator are hot and soft, requiring cooling and finalization in a cooler. They are then screened through a drum screener to select qualified granules, and the powder is returned for re-granulation. (Optional) For customers with strict moisture requirements, a rotary drum dryer can be added to ensure consistent product quality.

6. Surface Polishing and Coating

Main Equipment: (Optional) Spheronizer, Coating Machine

To enhance the product’s appearance and functionality, the granules can be polished to a rounded shape using a spheronizer, eliminating sharp edges and corners for a smoother, more durable finish. A coating machine can also be added to coat the granules with anti-caking agents or slow-release nutrient coatings, significantly enhancing the product’s quality and performance.

7. Quantitative Packaging and Warehousing

Main Equipment: Automatic Quantitative Packaging Scale

The finished product is weighed, bagged, and sealed by an automatic quantitative packaging machine before being transported to the finished product warehouse, ready for market.

If you would like a customized equipment list and detailed plan for this production line, our engineers are available to provide comprehensive support from planning to commissioning.

What organic manure making machine projects have you worked on?

+

organic manure making machine In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: industrial waste

- project price: 80,000 USD

organic manure making machine In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: livestock manure

- project price: US$110,000

organic manure making machine In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: poultry litter

- project price: US$430,000

organic manure making machine In Lithuania

- Country: Lithuania

- Production: 35,000 T/A

- Ingredients: food waste

- project price: 410,000USD

organic manure making machine In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: chicken manure

- project cost: 570,000 USD

organic manure making machine In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- project cost: 190,000 USD

organic manure making machine In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: livestock manure

- project cost: $160,000

organic manure making machine In Pakistan

- project cost: $385,000 USD

- Country: Pakistan

- Production: 30,000 T/A

- ingredients: cow manure, Bagasse

How to choose organic manure making machine?

+

Choosing appropriate compost pellet making machine is crucial to agricultural production, and needs to consider equipment type, production needs, operating efficiency, investment costs and supplier services. Through steps such as clear needs, market research, comparative analysis, understanding of services, communication and negotiation, the most suitable equipment can be selected to improve fertilizer utilization efficiency and protect the environment.

Choosing appropriate organic fertilizer equipment is an important link in agricultural production and is of great significance for improving fertilizer utilization efficiency, protecting the environment and promoting sustainable development. Here we will introduce how to choose suitable organic fertilizer equipment from the following aspects.

1. Understand the basic types of organic fertilizer equipment

There are many types of organic fertilizer pellet mill equipment, and common ones include composting equipment, fermentation equipment, drying equipment, etc.

Different types of equipment are suitable for different production scenarios and needs. Before selecting equipment, you need to fully understand the performance characteristics, scope of application, advantages and disadvantages of various equipment, so that you can choose based on actual needs.

2. Consider production scale and demand

Production scale and demand are key factors in selecting organic fertilizer manure pellet mill. Generally speaking, the larger the production scale, the larger the required equipment scale.

At the same time, various needs in the production process need to be considered, such as raw material types, processing techniques, product quality, etc. Only by fully understanding the production needs and scale can we choose the most suitable organic fertilizer equipment.

3. Pay attention to the operating efficiency and stability of the equipment

The operating efficiency and stability of equipment have an important impact on production efficiency and product quality. When selecting equipment, you need to pay attention to its energy consumption, processing speed, degree of automation, etc.

At the same time, it is also necessary to understand the maintenance requirements and fault rates of the equipment to ensure long-term stable operation of the equipment.

4. Consider the investment cost and return benefits of equipment

The investment cost and return benefit of the equipment are important factors to consider when choosing organic fertilizer compost granulating machine. Generally speaking, the higher the investment cost of equipment, the more powerful its performance and functions.

However, when selecting equipment, it is also necessary to comprehensively consider the cost performance and return benefits of the equipment to ensure a good return on investment.

5. Understand the service and support of equipment suppliers

When choosing organic fertilizer granulator machine, you also need to consider the service and support of the equipment supplier. A good supplier should be able to provide comprehensive technical support, after-sales service, maintenance and other services to ensure that the equipment can be maintained and maintained in a timely manner during use.

To sum up, choosing the right organic manure making machine requires comprehensive consideration of multiple factors, including equipment type, production scale and demand, operating efficiency and stability, investment cost and return benefits, as well as supplier service and support. Only by comprehensively considering these factors can we choose the most suitable organic fertilizer equipment for ourselves and provide strong support and guarantee for agricultural production.

In the actual selection process, it is recommended to take the following steps:

- Clarify production needs and scale, and determine the type and scale of required organic manure making machine;

- Conduct research on organic fertilizer equipment on the market to understand the performance characteristics, scope of application, advantages and disadvantages of various equipment;

- Comparatively analyze the investment costs, return benefits and operating efficiency of different equipment, and select the equipment with the best price/performance ratio;

- Understand the service and support of equipment suppliers, and choose suppliers with good reputation and service guarantee;

- Before purchasing equipment, fully communicate and negotiate with the supplier to clarify the delivery date, installation and commissioning, after-sales service and other matters of the equipment;

- During the use of the equipment, operate and maintain it in strict accordance with the operating procedures to ensure long-term stable operation of the equipment.

Through the above steps, we can choose suitable organic manure making machine, improve fertilizer utilization efficiency, protect the environment, promote sustainable development, and provide better support and guarantee for agricultural production.

How to choose an organic manure making machine manufacturer?

+

When choosing an organic manure making machine manufacturer, you need to consider its background, strength, product quality, technical level, after-sales service, maintenance, price, cost performance, production capacity and delivery time. After comprehensive evaluation, select the manufacturer that best meets your needs to ensure smooth production and stable product quality.

Choosing a reliable manufacturer is the key to ensuring smooth production and stable product quality. Here are some suggestions to help you make an informed decision when choosing an organic manure making machine manufacturer:

- Understand the background and strength of the manufacturer:

When choosing an organic manure making machine manufacturer, you must first understand the manufacturer’s background and strength. You can learn about the manufacturer’s history, scale, technical level, production experience and other information by checking the manufacturer’s official website, visiting the manufacturer for on-site inspections, communicating with the manufacturer’s sales staff, etc. Make sure the manufacturer you choose has stable production capacity and good reputation. - Examine product quality and technical level:

The quality and technical level of organic manure making machine are directly related to production efficiency and product quality. Therefore, when choosing a manufacturer, you should focus on examining the quality and technical level of its products. You can learn whether the equipment produced by the manufacturer meets relevant national standards, whether it has advanced technology and processes, and whether it can ensure the stable and reliable quality of the organic fertilizer produced. - Understand the after-sales service and maintenance system:

When choosing a reliable organic manure making machine manufacturer, in addition to paying attention to product quality and technical level, you also need to understand its after-sales service and maintenance system.

A good manufacturer should be able to provide complete after-sales service, including support in equipment installation and debugging, operation training, fault repair, etc. At the same time, manufacturers should also have a professional maintenance team that can handle equipment failures in a timely manner and ensure the normal operation of the equipment. - Compare prices and cost-effectiveness:

Price is also an important consideration when choosing a manufacturer. Prices of products from different manufacturers may vary, so comparison and evaluation are required. When comparing prices, not only the price of the equipment must be considered, but also the performance, service life, maintenance costs and other factors of the equipment to evaluate the cost-effectiveness of the equipment. Choosing a cost-effective manufacturer can reduce production costs while ensuring production efficiency and product quality. - Consider the manufacturer’s production capacity and delivery time:

When choosing an organic manure making machine manufacturer, you also need to consider its production capacity and delivery time. If your production needs are large, you need to choose a manufacturer with sufficient production capacity to ensure that the equipment can be supplied in time. At the same time, you also need to understand the manufacturer’s delivery date to ensure that the equipment can be delivered on time without affecting your production plan.

To sum up, choosing a reliable organic manure making machine manufacturer requires comprehensive consideration of multiple factors, including the manufacturer’s background and strength, product quality and technical level, after-sales service and maintenance system, price and cost-effectiveness, as well as the manufacturer’s production capacity and delivery date etc.

Through comprehensive evaluation and comparison, select the fertilizer granulation equipment manufacturer that best meets your needs, laying a solid foundation for smooth production and stable product quality.

What is the prospect of organic manure fertilizer production?

+

Organic fertilizer, made by organic manure making machine, also known as “farm fertilizer”, refers to a type of fertilizer that contains organic matter and can not only provide a variety of inorganic and organic nutrients for crops, but also fertilize and improve the soil.

It mainly includes human waste, manure, compost, green manure, cake fertilizer, biogas fertilizer, etc. It has the characteristics of many types, wide sources, and long fertilizer effect.

Organic fertilizers are the recycling and reuse part of nutrients in agriculture, and with the increase in chemical fertilizer application and crop harvests, the amount of organic fertilizers has also increased.

Industrial chain supply and demand layout of organic fertilizer industry

In the upstream of the industrial chain, the raw material supply link is key. The main raw materials of organic fertilizers include livestock manure, agricultural waste, industrial waste, domestic waste and urban sludge.

These raw materials come from a wide range of sources, but quality and stability may vary depending on factors such as region and season.

Therefore, organic fertilizer production companies need to actively find and establish stable raw material supply channels to ensure the quality and supply stability of raw materials.

In terms of supply and demand layout, the organic fertilizer industry needs to pay attention to the stability of raw material supply, the efficiency and cost control of production and processing, the expansion of sales channels and customer relationship management.

At the same time, as countries attach importance to environmental protection and sustainable agricultural development, the organic fertilizer industry is also facing policy support and market opportunities. Enterprises need to seize the opportunity, strengthen technological innovation and brand building, and improve product quality and service levels to stand out in the fierce market competition. (Find RICHI on YouTube)

The midstream link is the production and processing of organic fertilizers. This link includes the pretreatment, fermentation, granulation, drying, screening and other processes of raw materials. Through scientific production processes and technical means, raw materials are transformed into high-quality organic fertilizer products.

In this process, companies need to invest a lot of capital and technical strength to ensure that the quality and performance of products meet market demand.

The downstream link is the sales and application of organic fertilizers. As people’s attention to environmental protection and health continues to increase, the market demand for organic fertilizers is also gradually increasing. Sales channels include agricultural supply stores, e-commerce platforms, cooperatives and other forms.

At the same time, organic fertilizers made by organic manure making machine are increasingly used in agriculture, forestry, landscaping and other fields. Enterprises need to pay close attention to market dynamics and customer needs, and constantly adjust product structure and sales strategies to meet the diverse needs of the market.

60000 +

Backed by a 60,000 m² advanced production complex

140 +

Global footprint extends across 140+ international markets

2000 +

Over 2,000 successful production system installations

2013

RICHI MANUFACTURE

Established in 1995, RICHI MACHINERY has grown from a medium-sized enterprise to become China’s largest pellet production line manufacturer. With two major manufacturing bases spanning hundreds of thousands of square meters, we specialize in custom pellet machines and complete plant solutions, handling every production stage in-house—from R&D to delivery.

Our vertically integrated facilities (including dedicated sections for production, testing, and logistics) ensure premium quality, environmental responsibility, and operational reliability for feed, biomass, and fertilizer industries worldwide. For nearly three decades, we’ve partnered with clients to enhance productivity, minimize risks, and achieve sustainable outcomes through innovative engineering.

Zhengzhou Headquarters

R&D, global operations and strategic management converge

Jiaozuo New Production Base (2025)

Featuring automated production lines and Industry 4.0 technologies

Kaifeng Original Complex (Since 1995)

Our manufacturing legacy began and quality traditions endure

Certifications & Patents

As a world-leading feed mill equipment manufacturer, RICHI Machinery demonstrates its engineering prowess through internationally recognized certifications and proprietary innovations.

Our ISO quality management system, CE compliance, BV-certified production processes, GOST-R for Russian compliance, ATEX explosion-proof certification for EU safety standards, FDA registration for U.S. market access, and EHEDG hygienic design certification validate our commitment to global standards, while 50+ patented technologies in pellet mills, extruders and automation systems deliver unmatched performance.

When you choose RICHI, you’re selecting globally validated, future-proof solutions backed by the industry’s most comprehensive certification portfolio.

01

Consultation

Our experts provide professional advice to understand your specific feed production requirements.

02

Design

We develop customized solutions with optimized layouts and equipment configurations for your project.

03

Manufacturing

All feed mill equipment is precision-built using quality materials in our ISO-certified factories.

04

Shipping

We handle secure packaging and global logistics with reliable delivery timelines.

05

Installation

Our engineers supervise on-site assembly and commissioning for smooth operation.

06

Training

Comprehensive operator instruction ensures proper use and maintenance of equipment.

07

After-sales

Dedicated support team provides troubleshooting and technical assistance.

08

Spare Parts

Genuine components are available worldwide with fast delivery service.