Organic Fertilizer Pellet Mill

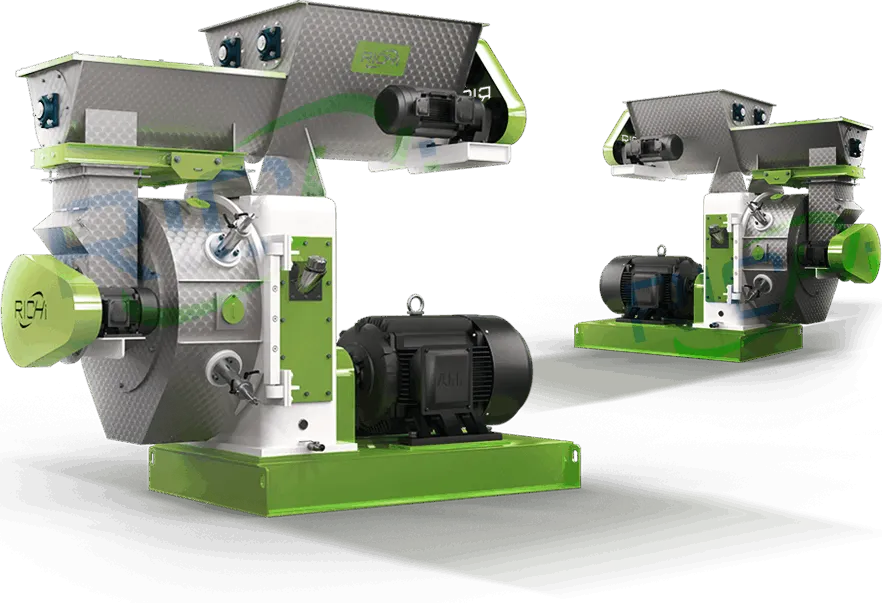

The FZLH350 organic fertilizer pellet mill is suitable for organic fertilizer processing businesses with an output of 3-5 tonnes/hour. This organic fertilizer pellet mill is your intelligent hub for transforming agricultural waste into profitable operations. Going beyond simple processing, it efficiently transforms powdery, loose, and bulky traditional compost into uniform, solid pellets.

This not only greatly optimizes product storage and transportation, but also directly enhances the fertilizer’s commercial value and competitiveness in the market. Choosing this machine means you’re not just purchasing a machine; you’re investing in a modern agricultural solution that integrates waste reduction, resource utilization, and branding. This ensures exceptional value for every unit of organic raw material, unlocking new revenue opportunities.

What is organic Fertilizer pellet mill?

If you’re looking for essential equipment to enhance your organic fertilizer product, this granulator is the answer. Leveraging sophisticated molding technology, it overcomes the application pain points of traditional powdered organic fertilizers, such as low specific gravity, bulk, and clumping.

The resulting granules possess high density, strength, and extremely low moisture content, ensuring they retain their shape during long-distance transportation and deliver precise and uniform fertilizer release upon application. This FZLH350 organic fertilizer pellet mill is suitable for granulating organic fermentation fertilizers from livestock and poultry manure, composting fertilizers, green manures, sea fertilizers, cake fertilizers, peat, soil fertilizers, three wastes, microorganisms and other urban domestic waste organic fermentation fertilizers, the final product is columnar pellets or round pellets.

Applicable Raw Materials

This versatile organic fertilizer pellet mill efficiently processes a wide spectrum of organic matter, including agricultural straw, animal manure, and even qualified municipal sludge, into uniform, high-value fertilizer pellets. From farm harvest residues to urban green waste, raw materials are as diverse as nature itself, transforming what was once considered “waste” into a valuable resource for the soil.

Emphasis on technology and quality, targeting producers who focus on product strength

why make organic fertilizer pellets ?

Technological advantages

Our deep understanding of the core technology of the ring die-roller system ensures that our equipment produces pellets with high density, excellent forming efficiency, and a smooth surface. This not only directly enhances the commercial value of your organic fertilizer products, but also demonstrates our expertise as a professional manufacturer in resolving complex process challenges.

High-Efficiency Gear Drive System

The machine utilizes a single-stage helical gear drive structure, offering transmission efficiency far exceeding traditional systems like belts. The gear train undergoes precision grinding and surface finishing, ensuring smooth operation and lower energy consumption.

Siemens Motor with long service life

Renowned for its incredible durability and exceptionally long service life, it ensures stable operation even in the high dust, humidity, and vibration conditions of organic fertilizer production. This provides a solid foundation for ensuring your return on investment and long-term production.

Sturdy and Durable Machine Design

The structure has been optimized through finite element analysis, and key load-bearing components have been reinforced to ensure resistance to deformation and vibration even under long-term high-load operation, providing a solid foundation for stable and high production.

Wide applicability of raw materials

With powerful extrusion power and a flexible die system, the extruder can easily process a wide range of organic waste, from straw and manure to mushroom residue and sludge. It boasts strong formula compatibility and a stable forming rate exceeding 95%.

WORKING

PRINCIPLE

The core of the ring die organic fertilizer pellet mill is precision engineering based on physical extrusion and die forming. It utilizes a high-strength power and transmission system to instantly transform loose powdered organic raw materials into high-density, regular granules within the die cavity. This process requires no chemical additives and relies purely on mechanical force to achieve a material transformation, making it efficient and reliable.

Parameters of FZLH350

Whatever Your Raw Materials, Finish the Job with RICHI Organic Fertilizer Pellet Mill

Main Motor Power

37kw

Forced Feeder Power

0.75kw

Finished Pellet Diameter

4~12mm

Capacity

3-5T/H

Ring Die Diameter

350mm

Additional Features

Our ring die organic fertilizer pellet mill boasts exceptional durability and high throughput as its core strengths. Designed for continuous heavy-load operation, it ensures efficient production of high-quality pellets while minimizing maintenance costs, making it a reliable foundation for your large-scale production.

Super-Strong Core Transmission Components

Gears are made of high-strength forged steel and feature extensive grinding. Imported bearings are used in key areas, ensuring a high safety factor, strong load-bearing capacity, and a long service life, specifically designed for continuous heavy-load operation.

Intelligent Lubrication and Cooling

Equipped with an external thin-film oil circulation cooling system, it ensures constant temperature operation of the main drive bearings. Furthermore, the automatic grease lubrication system allows for continuous, quantitative grease refilling without stopping the machine, reducing manual labor and improving operational reliability.

Innovative Ring Die Quick-Release Structure

The uniquely developed clamp-type mounting structure, coupled with a motorized die roller lifting mechanism, significantly reduces assembly and disassembly time for the ring die and die rollers, doubling the efficiency of core component replacement and maintenance.

Intelligent Control and Protection

An optional integrated electronic control system monitors the machine load and key parameters in real time, providing automatic overload protection and fault warning functions to ensure production safety and enable intelligent management.

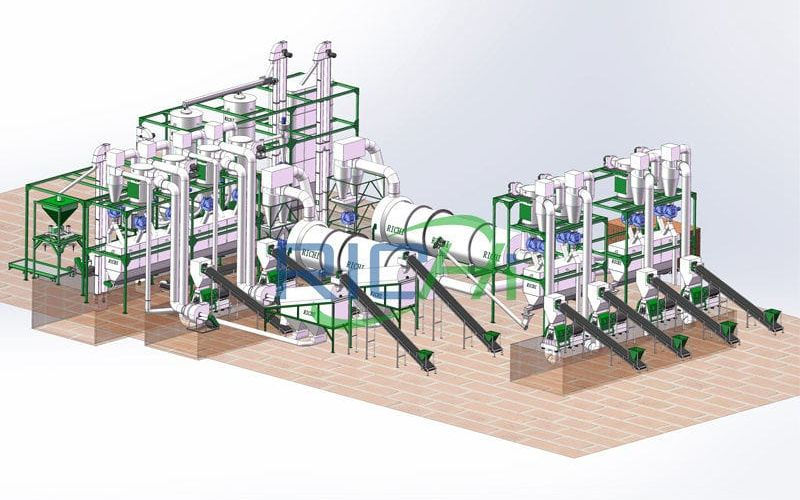

Flexible Choice – More Organic Fertilizer pellet mill Models

We’ve got a model that perfectly fits your current budget and production needs. From the steady start of a startup farm to the scaled, continuous production of a large fertilizer company, we understand that success isn’t achieved overnight. Therefore, we offer a full range of ring die organic fertilizer pelletizing solutions, ranging from 1 to 26 tons per hour. This isn’t just a numerical range; it represents the path we pave for your growth. Whether your feedstock is livestock manure, straw, or municipal sludge, each of our equipment is designed to be the most economical and efficient option today, ready to support your future expansion.

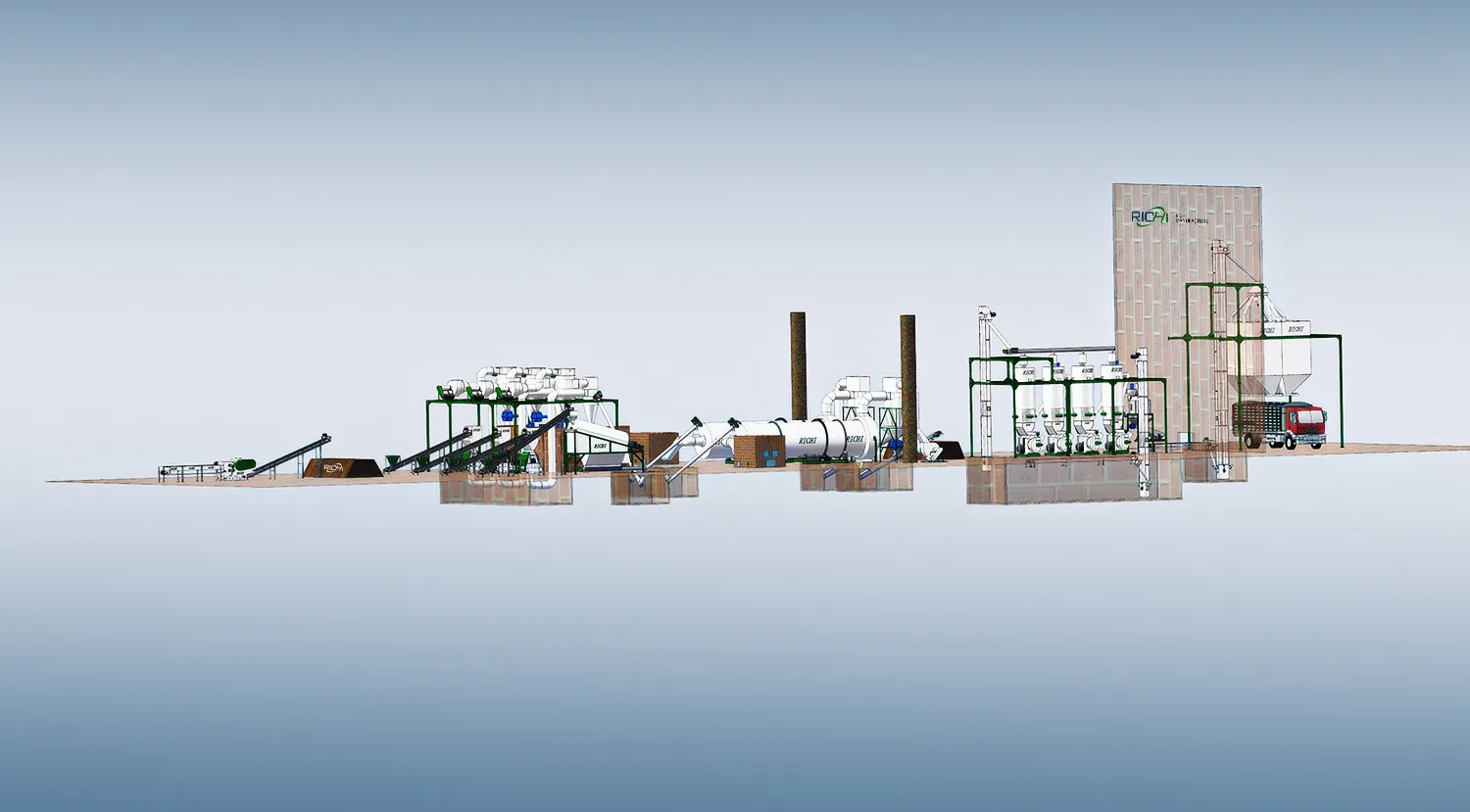

organic fertilizer pellet mill project

We can do custom design and engineering services, RlcHl provides first-class design solution tomeet the exclusive needs of different customers, We can do custom design and engineering services

USA

Chicken Manure Organic Fertilizer Pellet mill

The client is a poultry farm. The equipment was purchased to convert the large amount of chicken manure produced daily into high-value commercial organic fertilizer.

Russia

Peat Organic Fertilizer Pellet mill Machine

This machine was purchased to process the abundant local peat resources into granular soil conditioner to serve the growing greenhouse agriculture and home gardening markets.

Peru

Guano Organic Fertilizer Pellet mill machine

The client is a fertilizer company. Leveraging its long-standing guano mineral resources, the company produces standardized organic nitrogen and phosphorus fertilizers.

Canada

Straw Organic Fertilizer Pellet mill machine

The client is a grain farm. The equipment was purchased to process wheat and rapeseed straw into easy-to-spread straw fertilizer pellets.

Ecuador

Cocoa Shell Organic Fertilizer pellet mill

This client is a cocoa processing company. They produce organic fertilizer from cocoa bean processing byproducts, which feeds back into surrounding cocoa plantations.

Kazakhstan

Sheep Manure Organic Fertilizer pellet mill

This client is a livestock cooperative. They use this equipment to transform sheep manure collected from traditional pastures into granular fertilizer.

Argentina

cow dung organic fertilizer pellet mill

This client, a beef cattle ranch, established a cow dung granulation plant to transform livestock waste into commercially tradable organic fertilizer.

Thailand

Cassava Pulp Organic Fertilizer pellet mill

The client, a cassava starch processing plant, invested in this equipment to quickly convert wet pomace into granular organic fertilizer.

France

Wine Lees Organic Fertilizer pellet mill

A renowned Bordeaux winery has implemented this system to transform fermented grape pomace and wine lees into high-end fertilizer.

Global project experience and customized solutions

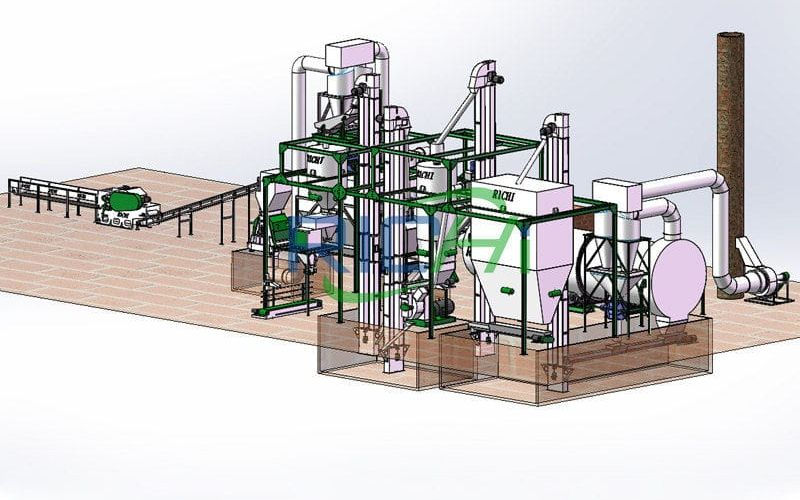

We’re more than just an equipment supplier; we’re your complete partner throughout your compost pelleting business. From a single high-yield pellet mill to complete turnkey projects encompassing crushing, fermentation, conditioning, pelleting, cooling, screening, and packaging, we offer modular, scalable production line solutions. Whether you’re processing livestock manure, straw, sludge, or specialty organic waste, we leverage our extensive project experience to provide a comprehensive suite of tailored services, from process design and equipment selection to installation and commissioning, as well as technical training. This ensures a stable output of high-value, high-quality pellets at the lowest operating costs.

Customer Testimonials

From precision agriculture in Western Europe to resource recycling projects in South Asia, our technology solutions are helping businesses of all sizes around the world realize the value of organic waste. Each partnership is a rigorous test of our equipment reliability, forward-thinking processes, and professional service.

Customer from Germany

This pelletizing line perfectly meets our standards for precision manufacturing. Its consistent pellet quality allows us to sell organic fertilizer as a standardized product.

Customer from New Zealand

Raw material: Fermented lamb. Manure and shearing waste

Customer Type: Livestock Group

On the steep pasture terrain, this equipment’s low failure rate and remote operation and maintenance capabilities completely solved our maintenance challenges.

Turkish Customer

The biggest highlight is its adaptability. The same equipment can process a variety of Mediterranean raw materials, including olive pomace and fruit and vegetable waste.

Pakistani Customer

Raw material: A mixture of bagasse and filter mud.

Customer Type: Sugar Group

After two years of continuous operation in high-temperature and dusty environments, the core components remain in excellent condition. The return on investment exceeded expectations.

Complete Solutions: How to process organic fertilizer pellets?

We understand that an excellent organic fertilizer pellet mill is only one key component of efficient production. True success stems from a fully production line. Therefore, we go beyond simply providing equipment and strive to be your comprehensive partner. From initial process planning and design, to equipment selection and customization, all the way to final installation, commissioning, and technical support, we offer a one-stop, turnkey solution. Based on extensive project experience, we have optimized the following efficient and proven core pellet processing path: crushing pretreatment—precise ingredient batching and conditioning—high-pressure pelletizing and molding—efficient drying, cooling, screening, and finished product quantitative packaging.

organic fertilizer pellet mill

Here, loose compost is

given a standardized form,

achieving both nutrient lock-in

and increased commercial value.

This process ensures a seamless transition from raw material to finished product, helping you optimize your investment and build a stable and profitable organic fertilizer pellet mill plant.

Complete Equipment Set——Build your organic fertilizer pellet production system

A high-performance organic fertilizer pellet mill is the heart of your production line, but it’s far more than the whole. We are committed to providing a complete equipment ecosystem covering the entire organic fertilizer pellet making process—from raw material crushing, fermentation and turning, precise batching, to pelletizing, efficient drying, fine screening, and final packaging. Drawing on our extensive project experience, we integrate and optimize each piece of equipment to ensure they operate seamlessly as a coordinated whole, helping you build a stable, efficient, and cost-effective pellet production base.

Organic fertilizer pellet mill FAQs

When purchasing and using organic fertilizer pellet mill equipment, every decision is about return on investment. Drawing on our experience with over 2,000 projects worldwide, we’ve compiled the practical questions most concerned by our customers below, providing you with proven, reliable answers.

What’s the FZLH350 organic fertilizer pellet mill price

+

The price of FZLH350 organic fertilizer pellet mill is generally 20,000-30,000 USD

In organic fertilizer processing, the most commonly used machine is fertilizer pellet machine. Nowadays, organic fertilizer pellet machines are in great demand, and many organic fertilizer processors are considering replacing equipment or joining the industry. Today we will introduce you to some factors that affect the price of granulators so that you can buy good quality crushing equipment.

- Production costs of equipment: The choice of materials is directly related to the price of organic fertilizer pellet mill. The better the steel and the more expensive the equipment, the higher the price. In addition, the labor costs of R&D equipment, sales costs, procurement costs, etc. will more or less have a certain impact on the price.

- Manufacturer: The greater the strength of the manufacturer, the better their costs. Their FZLH350 organic fertilizer pellet mills have good quality, good performance and high cost performance. As for those manufacturers with strength and complete after-sales service systems, although the cost of the equipment they produce is higher, the quality and service are much better.

- Equipment model: Granulators of different specifications also have different prices. The output, volume, and discharging granularity of each machine are different, which determines the price of this machine. The price difference between small and large manure pellet mills is tens of thousands of dollars or more.

- User needs: In different periods, there are different supply relationships between supplies. In the case of large market demand and insufficient supply, if the demand is insufficient, the market price of related equipment will be higher. When supply exceeds demand, equipment prices will fall further.

When users choose a FZLH350 organic fertilizer pellet mill manufacturer, they should conduct an on-site inspection of the entire organic fertilizer production line so that they can select the equipment with the highest performance-price ratio.

Do you have more detailed parameters of FZLH350 organic fertilizer pellet mill?

+

| Model | FZLH350 |

| Output (t/h) | 3-5 |

| Main motor power (kw) | 37 |

| Main motor series | 8P |

| Ring die diameter (mm) | 350 |

| Finished pellet diameter (mm) | 4-12mm |

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

What is the normal service life of an organic fertilizer pellet mill, and what is the approximate annual maintenance cost as a percentage of the equipment value after three years?

+

A well-maintained organic fertilizer pellet mill from Richi Machinery can typically operate effectively for over 10 years. The service life is heavily influenced by the raw materials processed, operating hours, and adherence to the maintenance schedule.

Regarding maintenance costs after the third year, as the equipment is no longer under the standard warranty, costs are primarily for wear parts and routine servicing.

On average, annual maintenance costs for an organic fertilizer pellet mill at this stage range from 2% to 5% of the initial equipment value. This cost largely depends on the consumption of critical wear parts like the ring die and rollers.

Using high-quality original parts from Richi Machinery, while potentially having a higher upfront cost, extends the service intervals and improves overall stability, ultimately leading to lower long-term operating costs and less unplanned downtime.

What proportion of the total organic fertilizer pellet production cost is electricity, and are there any specific solutions for energy optimization?

+

Electricity is a significant operational cost, typically accounting for 25% to 40% of the total production cost for organic fertilizer pellets. The primary consumer is the pellet mill’s main motor. At Richi Machinery, we integrate several energy-saving features into our fertilizer pellet mill design.

- Firstly, we use high-efficiency industrial motors that meet international standards.

- Secondly, our transmission system employs precision-machined gears, which are more efficient than standard belt drives, reducing energy loss.

A well-designed and optimized entire production line also contributes to lower overall energy use.

I want to process organic fertilizer pellets, and the raw material is mainly a mixture of vinasse and mushroom residue. Which mold compression ratio is more suitable for such high-fiber content material?

+

For high-fiber materials like a mixture of vinasse and mushroom residue, we recommend a medium to low compression ratio for the ring die in your organic fertilizer pellet mill.

Materials with high fiber content are elastic and create high resistance when forced through the die holes. A lower compression ratio, which means a shorter effective hole length, reduces this resistance and allows for smoother extrusion.

This prevents issues like excessive heat generation, machine blockage, and high energy consumption. Using a die with a high compression ratio for such materials would over-compress the fibers, leading to clogging and rapid wear.

Our technical team at Richi Machinery has extensive experience with various organic materials and can provide specific die recommendations and pre-sale testing to ensure the optimal configuration for your raw materials.

When processing chicken manure, what moisture content range should be controlled to ensure both the molding rate of organic fertilizer pellets and prevent mold hole blockage in the pellet machine?

+

Achieving the correct moisture content is critical for pelletizing chicken manure. We recommend a moisture range of 15% to 20% before the material enters the organic fertilizer pellet mill. If the moisture is too high, the material becomes too soft and viscous, causing it to plug the die holes and fail to form proper pellets.

If the moisture is too low, the material lacks the necessary plasticity, resulting in low forming rate with many broken pellets and excessive powder. The material should feel moist to the touch but should not release water when squeezed.

For consistent results, we advise using a mixer with steam or liquid addition capability before the pellet mill. This allows for precise moisture adjustment and conditioning, which significantly improves pellet quality and production stability.

For a full set of organic fertilizer pellet processing equipment with capacities of 2 t/h and 5 t/h, what are the specific differences in operational costs besides output?

+

Beyond the higher initial investment for a 5 t/h line, operational cost differences are significant. Power consumption for the 5 t/h pellet mill will be higher, but the power cost per ton of pellets is often lower due to better efficiency at scale.

Labor costs are similar; one operator can often manage either line, making the labor cost per ton lower for the 5 t/h system. Wear part consumption is proportional to output.

A 5 t/h system will consume ring dies and rollers faster in terms of total operating hours, but the consumption rate per ton of production can be comparable or even better than a 2 t/h system if the line is well-optimized.

Maintenance might require slightly more downtime for the larger system, but this is managed through planned maintenance schedules. The key is that the 5 t/h line spreads its fixed operational costs over a greater output, generally leading to a lower cost per ton and a faster return on investment for high-volume producers.

If the raw material formula needs frequent adjustment, what corresponding settings does the organic fertilizer pellet processing equipment require?

+

For frequent formula changes, flexibility is key. The core adjustment is made at the mixing and conditioning stage. A programmable batching system allows for easy recall of different recipes.

For the organic fertilizer pellet mill itself, operators may need to slightly adjust the gap between the ring die and the rollers to find the optimal pressure for the new mix.

With experience, these adjustments become quick. For clients with highly variable feedstocks, Richi Machinery can design a control system that allows for saving and recalling different parameter sets, streamlining the changeover process.

Why are organic fertilizer pellets very hot when they just leave the pellet mill, and why is a cooling process essential?

+

The high temperature is a direct result of the pelletizing process. As the raw material is forced through the die holes under immense pressure, intense friction is generated. This friction, combined with the mechanical energy of compression, converts into heat, raising the pellet temperature to between 70°C and 90°C.

Cooling is a mandatory step for several reasons.

- First, it hardens the pellets by solidifying the binders and melted components, making them durable enough for handling, storage, and transport.

- Second, it reduces the moisture content by several percentage points, which is critical for preventing caking and microbial spoilage during storage.

- Finally, it brings the pellets to a safe ambient temperature for bagging.

What is the correct maintenance method for the mold when the organic fertilizer pellet mill is shut down for a long time?

+

Proper mold storage during extended shutdowns is vital to prevent rust and corrosion, which can permanently damage the precision holes. The correct procedure is as follows:

- First, thoroughly clean the ring die immediately after the last production run. Remove all residual material from both the inside and outside surfaces and the die holes.

- Second, perform a complete internal inspection for any cracks or abnormal wear.

- Then, apply a thin, protective layer of neutral oil or food-grade grease over the entire die, inside and out.

- Finally, store the die in a dry, indoor environment, preferably covered or wrapped to keep dust and moisture out. It should be placed on a wooden pallet or shelf, not directly on a concrete floor. For clients, we provide detailed storage checklists to ensure their critical components are protected.

How long is the typical debugging period from the installation of the organic fertilizer pellet mill to stable pellet output?

+

The typical debugging and commissioning period for a complete organic fertilizer pellet production line ranges from 10 to 20 working days. This period includes several key stages.

The first week is typically dedicated to mechanical installation, alignment, and electrical connection under the guidance of our installation engineers. The subsequent 1-2 weeks involve process commissioning.

This is where we use the client’s actual raw materials to fine-tune the entire line. We adjust parameters in the mixer, conditioner, and the pellet mill itself to achieve stable operation and consistent pellet quality.

The exact duration can vary depending on the complexity of the line, the consistency of the raw materials, and how quickly the desired product specifications are met. Our goal is to ensure the line operates stably and the client’s operators are confident before we conclude the commissioning service.

The above is an introduction to the general principles and ?

+

Operators should ideally have a basic understanding of mechanical principles and electrical systems. Prior experience with industrial machinery is a significant advantage. The formal training provided by Richi Machinery typically lasts 5 to 7 days.

This training is hands-on and covers several key areas. It includes daily operational procedures like startup, shutdown, and feeding control. Trainees learn routine maintenance tasks such as lubrication, inspection, and the correct method for replacing wear parts like the rollers and die.

A crucial part of the training is troubleshooting common problems, such as blockages, low pellet quality, or unusual vibrations. We provide comprehensive operation and maintenance manuals and are available for remote support after the training to ensure long-term operational success.

What is the normal wear cycle for the pressure roller and ring die, and how to judge whether they need to be replaced?

+

There is no single universal wear cycle for rollers and ring dies; it depends on the abrasiveness of the raw materials, production hours, and operating pressure. A ring die might last 800 to 1500 hours, while rollers typically last 400 to 800 hours under normal conditions with moderately abrasive materials.

The key indicator for replacement is a sustained drop in production capacity and pellet quality. If you observe that the pellet mill can no longer reach its rated output even with the roller-to-die gap correctly adjusted, or if it produces an increasing amount of powder and weak, easily broken pellets, it is a clear sign that the die holes are worn out and the rollers have lost their traction.

Regular measurement of the roller diameter and visual inspection of the die hole surface are part of a proactive maintenance plan we help our clients implement.

How does Richi Machinery ensure after-sales response speed, and can you provide online technical support?nd ?

+

Richi Machinery is committed to minimizing client downtime through a responsive, multi-level support system. We guarantee an initial response to any service request within 4 hours.

Our support team is equipped to provide immediate online technical support via WhatsApp, video calls, and remote desktop assistance to diagnose and resolve a wide range of issues in real-time.

For problems that cannot be resolved remotely, we have a network of service engineers and can dispatch a specialist to the site, with the goal of having an engineer on-site within 72 hours for critical situations, depending on location. We also maintain a strategic inventory of commonly required spare parts to ensure fast shipment.

If we want to switch from powdered organic fertilizer to producing organic fertilizer pellets in the future, what core equipment needs to be added to the existing production line?

+

To transition from organic fertilizer powder to organic fertilizer pellets, you will need to add a complete pelletizing and post-processing section to your existing line.

- The core equipment includes an organic fertilizer pellet mill, which is the heart of the new process.

- A pellet cooler is mandatory to harden and dry the hot pellets exiting the mill.

- A rotary screening machine is then needed to separate finished pellets from excess powder, which is recycled.

- Finally, a coating machine can be added to apply a protective layer to the pellets, and an automatic packaging scale is required for bagging the final product.

Richi Machinery specializes in designing these integrated systems and can provide a seamless upgrade plan for your existing powder line.

Is it easy to upgrade the current 1 t/h organic fertilizer pellet production line to 3 t/h in the future?ples and ?

+

Yes, with proper initial planning, upgrading from 1 t/h to 3 t/h is a feasible project. The ease of upgrade depends heavily on the initial design. At Richi Machinery, when we design a 1 t/h line, we often consider future expansion.

This means we might specify a pellet mill frame and base that can accommodate a larger motor and a bigger ring die. The key components that would typically need upgrading are the pellet mill itself (or its main motor and drive system), the cooler, and the screening machine to handle the higher capacity.

Conveyors and other auxiliary equipment may also need to be assessed. We advise clients to discuss their future expansion plans with us during the initial design phase so we can create a layout and select some foundational equipment that minimizes the cost and complexity of the future upgrade.

Can an organic fertilizer pellet mill be compatible with producing biomass pellets?

+

While both machines use a ring die and rollers to form pellets, an organic fertilizer pellet mill is generally not ideal for producing high-density biomass pellets from materials like wood or straw.

The key differences lie in the design and material of the compression parts. Biomass pellet mills are built to handle highly abrasive lignocellulosic materials and operate at higher compression ratios to achieve the necessary density and durability. Their ring dies and rollers are made from specialized, more wear-resistant alloys.

While an organic fertilizer pellet mill might be able to produce low-density biomass pellets from some softer materials, the wear on the components would be rapid, and the pellet quality would not meet standard market requirements. For dedicated biomass production, we recommend a pellet mill specifically engineered for that purpose.

How to ensure that the hardness of every batch of organic fertilizer pellets meets transportation requirements?

+

Consistent pellet hardness is achieved through strict process control and is a key focus of our system design at Richi Machinery.

- The primary factors are raw material formulation, conditioning, and the pelletizing process itself. A consistent and properly balanced recipe is the foundation.

- The most critical control point is the pellet mill operation. Maintaining the correct roller-t1o-die gap and using a ring die with the appropriate compression ratio for the specific raw material are essential.

- Finally, the cooling process must be consistent, as proper cooling is what finalizes the pellet’s hardness.

- By monitoring and controlling these parameters—and by using a well-designed and stable fertilizer pellet mill—you can ensure that every batch of pellets has the structural integrity to withstand the rigors of transportation without excessive breakage or dust formation.

Can you tell me what cases you have worked on with organic fertilizer granulators?

+

Below are some of the organic fertilizer pellet machine projects we have exported recently.

organic fertilizer pellet mill In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: industrial waste

- project price: 80,000 USD

organic fertilizer pellet mill In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: livestock manure

- project price: US$110,000

organic fertilizer pellet mill In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: poultry litter

- project price: US$430,000

organic fertilizer pellet mill In Lithuania

- Country: Lithuania

- Production: 35,000 T/A

- Ingredients: food waste

- Project price: 410,000USD

organic fertilizer pellet mill In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: chicken manure

- Project cost: 570,000 USD

organic fertilizer pellet mill In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- Project cost: 190,000 USD

organic fertilizer pellet mill In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: livestock manure

- Project cost: $160,000

organic fertilizer pellet mill In Pakistan

Project cost: $385,000 USD

Country: Pakistan

Production: 30,000 T/A

Ingredients: cow manure, Bagasse

How to process organic fertilizer pellets? Complete 3-4 t/h organic fertilizer pellet process flow

+

The organic fertilizer production process flow is as follows:

1. Fermentation process

Livestock and poultry manure centralized treatment plants or organic fertilizer production companies will use special vehicles to collect livestock and poultry manure from various farms on a regular basis to avoid secondary pollution of roads and roads, and the recovered livestock and poultry manure will be directly entered into the fermentation area. After primary fermentation and secondary aging, it is stacked.

First, the odor of livestock and poultry manure is eliminated. During primary fermentation, straw, plant leaves, weed powder and other plant stems and leaves should be added in proportion. At the same time, fermentation bacteria should be added to decompose the crude fiber so that the particle size after crushing meets the particle size requirements for granulation production.

2. Mixing and granulation process

The fermentation materials that have completed the secondary aging and stacking process are crushed and entered into the mixing and stirring system. Before mixing and stirring, according to the formula, add N, P, K and other trace elements into the mixing and stirring system, start stirring, and mix the mixed materials. Material conveying to granulation system for pelleting, use an organic fertilizer pellet mill.

3. Drying and cooling process

After the granulation passes through the dryer, it enters the cooling system. After the material is brought to normal temperature, screening begins. The granules that meet the requirements enter the packaging machine for packaging. The granules that do not meet the requirements are crushed by the crusher and returned to the organic fertilizer granulator. Continue to granulate.

After the above procedures, livestock and poultry manure becomes the main raw material of organic fertilizer and enters the sales market for direct sale.

Why process organic fertilizer?

+

- Organic fertilizer contains a large amount of organic matter and has an obvious effect of improving soil and fertilizing;

- Organic fertilizer contains a variety of nutrients and contains a comprehensive balance of nutrients;

- Organic fertilizers have low nutrient content and need to be applied in large quantities, while chemical fertilizers have high nutrient content and need to be applied in small quantities;

- Organic fertilizers made by organic fertilizer pellet mill are derived from nature. There are no chemical synthetic substances in the fertilizers. Long-term application can improve the quality of agricultural products;

- During the production and processing of organic fertilizers, as long as they are fully decomposed, after application, they can improve the drought resistance, disease resistance, and insect resistance of crops, and reduce the use of pesticides;

- The advantage of organic fertilizer is that it is rich in organic matter and various nutrients. It can not only directly provide nutrients for crops, but also activate potential nutrients in the soil, enhance microbial activity and promote material transformation. The application of organic fertilizers can also improve the physical and chemical properties of the soil, increase soil fertility, and prevent soil pollution, which chemical fertilizers do not have.

Making full use of the scientific accumulation and rational application of organic fertilizer sources can not only reuse agricultural waste, reduce the investment in chemical fertilizers, protect the rural environment and create a good agricultural ecosystem, but also achieve the purpose of fertilizing the soil to stabilize and increase yields, increase production and income.

How to choose organic fertilizer pellet mill?

+

First, the needs and goals of the project need to be clarified.

This includes determining the functions and performance metrics that the fertilizer granulation equipment is intended to achieve, as well as the intended environment and conditions of use. At this stage, it is necessary to fully communicate with the project team and relevant stakeholders to understand their needs and expectations.

Market research and selection comparison.

It is necessary to collect information on various equipment, understand the characteristics, advantages and disadvantages of different equipment, and make appropriate comparisons and evaluations. At this stage, consider consulting professional engineers and manufacturers for further information and advice.

The next step is to formulate the standards and conditions for compost granulating machine selection.

Based on the project requirements and market research results, the standards and conditions for equipment selection can be clarified, including performance, quality, cost, maintenance and service requirements.

Equipment screening and testing then takes place.

According to the standards and conditions for organic fertilizer pellet mill selection, preliminary equipment screening can be carried out to determine several suitable alternative equipment. Field testing and evaluation can then be conducted to verify that the equipment meets project needs and standards.

The final step is determining the final equipment selection.

Based on the results of equipment testing and evaluation, the final equipment selection can be determined, confirmed and communicated to relevant stakeholders. During the organic fertilizer pellet mill selection process, care needs to be taken to maintain transparency and fairness to ensure that the equipment selected is the most suitable for the project needs.

In short, equipment selection is a complex process that requires comprehensive consideration of many factors.

Through appropriate market research and evaluation, as well as full communication with relevant stakeholders, the equipment that best suits the project needs can be selected to provide strong support for the smooth implementation of the project.

Equipment selection is a crucial process in various industries. In the manufacturing industry, equipment selection is directly related to product quality and production efficiency.

How to choose an organic fertilizer pellet mill manufacturer?

+

Organic fertilizer pellet mill has always been the core issue in the organic fertilizer processing process, and choosing a suitable organic fertilizer granulator manufacturer has become the primary task to solve this problem.

Innovative technology

When choosing an organic fertilizer pellet mill machine manufacturer, innovative technology is one of the primary factors to consider. The organic fertilizer granulator machine is not only a simple granulation system, but also combines automation and intelligent technology to solve the problem of organic fertilizer granulation through innovative means.

A manufacturer with leading technological level can provide you with more comprehensive organic fertilizer granule processing solutions.

Product reliability

When choosing an organic fertilizer pellet mill manufacturer, product reliability is crucial. An excellent organic fertilizer granulator not only needs to be innovative in design, but also needs to be guaranteed in quality. A stable and reliable organic fertilizer granulator can not only increase the service life, but also reduce maintenance costs and provide users with a better user experience.

Customized services

Organic fertilizer processing needs vary from person to person, so it is particularly important to choose a manufacturer that can provide customized services for organic fertilizer granulators and organic fertilizer production lines.

Customized services can not only meet the individual needs of users, but also better integrate different modular processes to provide more comprehensive solutions. A flexible and adaptable organic fertilizer pellet mill manufacturer will be your best partner.

Maintenance and service

A good fertilizer pellet mill not only needs to perform well during sales, but also cannot take it lightly in after-sales service. Choosing an organic fertilizer granulator manufacturer that pays attention to maintenance and service can provide users with more timely and comprehensive technical support to ensure that the organic fertilizer granulator is always in the best condition.

Customer evaluation

Customer evaluation is a key indicator to measure the comprehensive strength of an organic manure making machine manufacturer. Understanding the manufacturer’s reputation in the industry by reviewing user reviews and case sharing will help you gain a more comprehensive understanding of its product quality, service level and user satisfaction.

Choosing a well-regarded organic fertilizer granulator manufacturer will bring greater confidence to your organic fertilizer processing business.

Choosing the best organic fertilizer pellet mill manufacturer is a key step to achieve efficient and high-quality organic fertilizer processing. Innovative technology, product reliability, customized services, maintenance and service, and customer reviews, these five key factors will provide you with a wise choice guide.

In this rapidly developing field of organic fertilizers, we work together with RICHI Machinery to create a new future that is more environmentally friendly and sustainable. If you are interested in our concepts, welcome to learn more!

What’s the Prospects of the Organic Fertilizer Business

+

Organic fertilizer refers to fertilizer made from animal and plant waste, crop straw, rapeseed residue, manure and other biomass through fermentation, composting and other treatments. Organic fertilizer has the advantages of high content, stable quality, non-toxicity, and friendliness to soil and plants. Therefore, organic fertilizer has a very broad prospect in agricultural production.

- First, organic fertilizers made by organic fertilizer pellet mill have high levels of nutrients.

Compared with chemical fertilizers, organic fertilizers contain richer beneficial elements, such as organic matter, trace elements and biologically active substances. These ingredients can effectively increase soil fertility, provide the nutrients needed by plants, enable plants to grow robustly and have strong immunity, and improve the yield and quality of crops.

- Secondly, organic fertilizer has the characteristics of stable quality.

Organic fertilizers undergo processes such as fermentation and composting to eliminate impurities, pathogenic bacteria, insect eggs and other harmful substances in waste and crop straws, making the quality of organic fertilizers purer and more stable. This not only prevents soil pollution and agricultural product residue problems caused by chemical fertilizers, but also improves crop quality and food safety.

- Additionally, organic fertilizers made by organic fertilizer pellet mill are soil and plant friendly.

Organic fertilizers can improve soil texture, increase soil water retention capacity, improve soil aeration, and improve soil fertility and structure. At the same time, organic fertilizer can also promote the activity of soil microorganisms, increase the organic matter content of the soil, and improve the persistence of soil fertility. In this way, not only can soil erosion and soil erosion be reduced, but the ecological environment of the soil can also be improved and the balance of the ecosystem can be protected.

- Finally, organic fertilizer has obvious advantages in terms of environmental protection.

Organic fertilizer is made from natural organic matter, does not contain toxic and harmful substances, and will not cause pollution to soil, water sources and the environment. In contrast, chemical fertilizers can easily cause soil pollution and damage to the ecological environment due to their chemical components. The use of organic fertilizers can reduce dependence on chemical fertilizers, reduce the impact of agricultural production on the environment, and promote sustainable development.

In short, organic fertilizer has broad prospects in agricultural production. As people have higher and higher requirements for food safety and environmental protection, the demand for organic fertilizers will gradually increase. Organic fertilizers can not only increase crop yield and quality, but also improve soil texture and ecological environment.

Therefore, the promotion and application of organic fertilizers will be an important direction for agricultural development and are expected to bring greater benefits and sustainable development to agricultural production. (Find RICHI on YouTube)

60000 +

Backed by a 60,000 m² advanced production complex

140 +

Global footprint extends across 140+ international markets

2000 +

Over 2,000 successful production system installations

2013

RICHI MANUFACTURE

Established in 1995, RICHI MACHINERY has grown from a medium-sized enterprise to become China’s largest pellet production line manufacturer. With two major manufacturing bases spanning hundreds of thousands of square meters, we specialize in custom pellet machines and complete plant solutions, handling every production stage in-house—from R&D to delivery.

Our vertically integrated facilities (including dedicated sections for production, testing, and logistics) ensure premium quality, environmental responsibility, and operational reliability for feed, biomass, and fertilizer industries worldwide. For nearly three decades, we’ve partnered with clients to enhance productivity, minimize risks, and achieve sustainable outcomes through innovative engineering.

Zhengzhou Headquarters

R&D, global operations and strategic management converge

Jiaozuo New Production Base (2025)

Featuring automated production lines and Industry 4.0 technologies

Kaifeng Original Complex (Since 1995)

Our manufacturing legacy began and quality traditions endure

Certifications & Patents

As a world-leading feed mill equipment manufacturer, RICHI Machinery demonstrates its engineering prowess through internationally recognized certifications and proprietary innovations.

Our ISO quality management system, CE compliance, BV-certified production processes, GOST-R for Russian compliance, ATEX explosion-proof certification for EU safety standards, FDA registration for U.S. market access, and EHEDG hygienic design certification validate our commitment to global standards, while 50+ patented technologies in pellet mills, extruders and automation systems deliver unmatched performance.

When you choose RICHI, you’re selecting globally validated, future-proof solutions backed by the industry’s most comprehensive certification portfolio.

01

Consultation

Our experts provide professional advice to understand your specific feed production requirements.

02

Design

We develop customized solutions with optimized layouts and equipment configurations for your project.

03

Manufacturing

All feed mill equipment is precision-built using quality materials in our ISO-certified factories.

04

Shipping

We handle secure packaging and global logistics with reliable delivery timelines.

05

Installation

Our engineers supervise on-site assembly and commissioning for smooth operation.

06

Training

Comprehensive operator instruction ensures proper use and maintenance of equipment.

07

After-sales

Dedicated support team provides troubleshooting and technical assistance.

08

Spare Parts

Genuine components are available worldwide with fast delivery service.