Organic Fertilizer Granulator Machine

Transform waste into wealth with the FZLH678 Organic Fertilizer Granulator Machine. This versatile powerhouse is expertly designed to recycle a vast spectrum of organic materials—including chicken, cow, pig, and sheep manure, as well as agri-waste from food processing—into nutrient-rich fertilizer pellets.

Capable of meeting a 18-22 t/h production demand, it is an essential solution for diverse settings from breeding farms and slaughterhouses to sewage treatment plants.

What is organic Fertilizer Granulator ?

Meet the FZLH678 Organic Fertilizer Granulator Machine, the core of a high-output system designed to process 18-22 tons of premium fertilizer granules every hour. Engineered for profitability, this machine transforms a wide range of organic wastes into uniform, high-value fertilizer pellets. Its robust capacity makes it an ideal investment for fertilizer factories, large-scale farms, and waste processing plants seeking to turn by-products into revenue.

Applicable Raw Materials

Beyond the typical cow, chicken, pig, and sheep manure, our machine efficiently processes a wide range of materials. This includes agri-waste like sugarcane bagasse, rice husks, and crop straw; industrial bio-waste such as vinasse from breweries, mushroom cultivation substrate, and fruit pomace from juice plants; and municipal wastes including sewage sludge and food scraps. Even more specialized materials like biogas plant residue, fish processing waste, and certain types of treated kitchen garbage are viable raw materials.

Whatever Your Raw Materials, Finish the Job with RICHI Pellet Machine!

Why process organic fertilizer granules ?

Technological advantages

With a high pelletizing rate and superior granule strength, the FZLH678 organic fertilizer granulator machine ensures consistent, commercial-grade output. Furthermore, its compatibility with a fertilizer polishing machine allows you to enhance the final product’s appearance, maximizing its market appeal.

This granulator is more than just equipment; it’s your gateway to efficient, large-scale organic fertilizer production. Beyond organic fertilizer production, its multifunctional design allows it to produce compound fertilizer and even biomass pellets, providing unparalleled operational flexibility. By achieving a high pelletizing rate and converting organic waste into a valuable resource, the FZLH678 not only boosts your productivity but also champions a sustainable, circular economy.

High-Efficiency Drive System

Adopting internationally advanced direct-drive technology, our organic fertilizer granulator machine eliminates traditional belt drives and ensures zero power loss. Paired with a Siemens high-torque motor, it ensures powerful power and stable operation, increasing overall machine output efficiency by approximately 20% compared to conventional models.

Precision-Manufactured Main Unit

The housing is precision-machined in a single operation at a machining center, ensuring perfect fit and smooth operation. Gears undergo precision grinding for extremely low noise. The main shaft is machined using German deep-hole gun drilling technology, and the oil circuit is formed in one operation, ensuring a smooth lubrication system, strong load-bearing capacity, and long service life.

User-Friendly Protection Design

Equipped with an advanced and reliable mechanical overload protection device, it instantly cuts power in the event of an emergency, protecting core components from damage. The stainless steel door cover is corrosion-resistant and durable, allowing for easy inspection. A movable pneumatic oil pump allows for convenient and timely centralized lubrication, simplifying maintenance.

Top-Quality Core Components

The entire machine’s transmission core (including bearings and couplings) utilizes premium Swiss SKF bearings, offering low wear and excellent fatigue resistance. Key bearings and standard components are imported, ensuring durability and reliability from the source. Furthermore, the quick-release hoop-type ring die allows for easy assembly and disassembly, significantly reducing maintenance time.

WORKING

PRINCIPLE

Our ring die organic fertilizer granulator machine utilizes a sophisticated horizontal design. Its core principle is to compress loose powdered organic raw materials through a die using precise mechanical pressure, forming them into high-density, regular granules in a single operation. This process requires no chemical additives and is a purely physical process, ensuring high efficiency and reliability.

Technical Parameters of FZLH678 organic fertilizer granulator

For complete technical specifications, please contact us directly online.

Main Motor Power

185kw

Forced Feeder Power

1.5kw

Finished Pellet Diameter

4-12mm

Capacity

18-22T/H

Ring Die Diameter

673mm

Additional Features

In modern organic fertilizer production, simple powdered raw materials are no longer sufficient to meet the demands of efficient fertilization and commercial distribution. Our organic fertilizer granulator machine is a key piece of equipment designed for this purpose. Using advanced mechanical forming technology, it efficiently converts various organic powders into granules of uniform specifications and ideal strength. This transformation not only significantly enhances the commercial value and transportability of fertilizers, but also makes them suitable for mechanized fertilization, adding value to your fertilizer products and opening up new market opportunities.

Wide range of applicable raw materials

The true versatility of our organic fertilizer granulator machine lies in its unparalleled ability to transform a vast spectrum of organic materials—from common waste to unconventional by-products—into uniform, high-value fertilizer pellets. This remarkable adaptability ensures that regardless of your local resource availability, our granulator can turn your organic surplus into a profitable and sustainable resource.

Superior Energy Efficiency, Far Exceeding Competitive Output

This machine utilizes an advanced direct-drive transmission structure and optimized operating principle, eliminating power loss at the source. Compared to traditional belt-driven models, its output efficiency is up to 20% higher at the same energy consumption. It can quickly and evenly process large quantities of raw materials, helping you achieve higher daily production capacity.

Stable Product Quality and High Commercial Value

Thanks to the precise design of the ring die and rollers, the machine generates powerful and uniform extrusion and friction during the pelletizing process, ensuring that each fertilizer pellet is compact, firm, and uniform in shape. This not only significantly improves pellet formation rate and crushing strength, but also ensures consistent quality of the final product, making it more competitive in the market.

Flexible Adaptability: One Machine Meets Multiple Needs

The machine offers powerful process flexibility. By quickly adjusting operating parameters or replacing components such as the ring die, you can easily change the specifications and shape of the finished product, seamlessly switching between different formulations or custom requirements. This “one machine, multiple uses” feature allows you to quickly respond to market changes and maximize the return on investment of the equipment.

A full range of production capacity solutions tailored to your production goals

Whether you’re a livestock farm, a startup, or a large-scale fertilizer processing plant, we can provide precisely matched production capacity. Our organic fertilizer granulator line offers a comprehensive selection of models, ranging from 1 to 26 tons per hour. This means you can find the solution that best suits your needs, whether you’re undertaking small-batch specialty production or large-scale industrial continuous operations. Each piece of equipment inherits our core granulation technology and durable quality, ensuring that every granule, from the smallest to the largest, meets the same standard of excellence. Let us use our professional equipment to help you seamlessly transition from production planning to market expansion.

Trusted Globally- Witnessed fertilizer Solutions Worldwide

Our footprint is the foundation of your confidence. From large agricultural cooperatives in Southeast Asia to environmental technology companies in Europe, our organic fertilizer granulation equipment has been operating reliably in over 50 countries and regions. We deliver far more than just a single machine; we deliver complete production lines, from crushing, fermentation, mixing, to granulation, cooling, and packaging.

From sewage treatment plants processing municipal sludge to sugar companies reusing bagasse, we provide proven and reliable granulation solutions for complex raw materials such as chicken manure, cow dung, straw, and food waste. Our projects range from community-scale processing of 1 ton per hour to industrial-scale production exceeding 20 tons per hour, demonstrating the robust scalability of our solutions. Choosing us means choosing a reliable partner with a global vision and local expertise.

Russia

Pig Manure organic fertilizer granulator machine

A pig farming enterprise introduced organic fertilizer granulator machine line to efficiently convert the pig manure produced daily in the farm into organic granular fertilizer.

United States

Chicken Manure organic fertilizer granulator machine

A poultry farming group in the southeastern United States uses this fertilizer granulator system to process chicken manure on a large scale, producing commercial fertilizer that meets organic certification.

Indonesia

Palm Waste organic fertilizer granulator machine

An Indonesian palm plantation has installed this fertilizer granulator to convert palm oil press waste into specialized fertilizer for the plantation, achieving internal recycling within the plantation industry.

Romania

Grape Pomace organic fertilizer granulator machine

Serving a large Romanian winery, this machine converts grape pomace from its winemaking into high-quality organic fertilizer, thus achieving the recycling of agricultural waste.

France

Fruit and Vegetable Waste Organic Fertilizer Granulator

A regional organic farm in France uses this machine to process fruit and vegetable market leftovers and processing waste to produce specialty fertilizers suitable for horticulture.

South Africa

Livestock Manure Organic Fertilizer Granulator

Installed at a South African livestock cooperative, this machine centrally processes cattle and sheep manure, effectively addressing pasture pollution and producing commercial organic fertilizer.

Germany

Biogas Residue organic fertilizer granulator machine

A German green energy plant has selected this machine to convert fermentation residues from its biogas project into slow-release granular fertilizer, achieving a circular connection between energy and agriculture.

South Korea

Food Waste organic fertilizer granulator machine

A South Korean environmental technology company uses this organic fertilizer granulator system to convert sorted food waste into safe fertilizer, supporting the resource recovery of municipal waste.

Argentina

Soybean Straw organic fertilizer granulator machine

Large-scale farms in Argentina use this organic fertilizer granulator equipment to process soybean straw waste from soybean cultivation, producing organic granular fertilizer suitable for field use.

Empowering the Organic Fertilizer Industry with Engineering Excellence

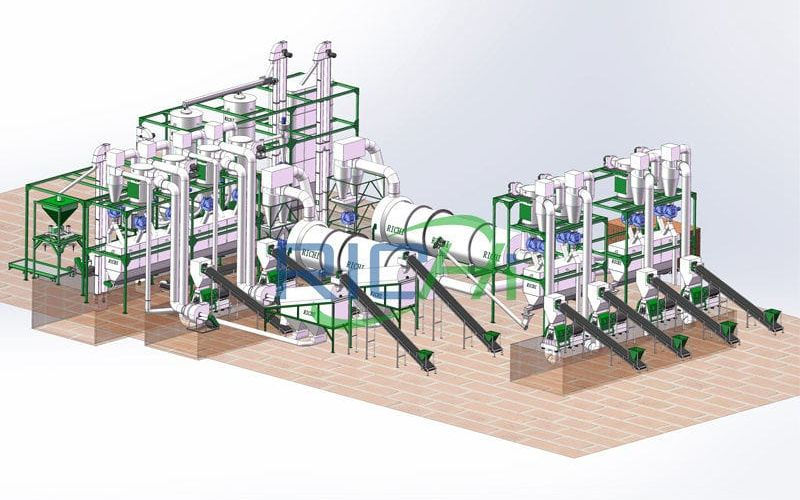

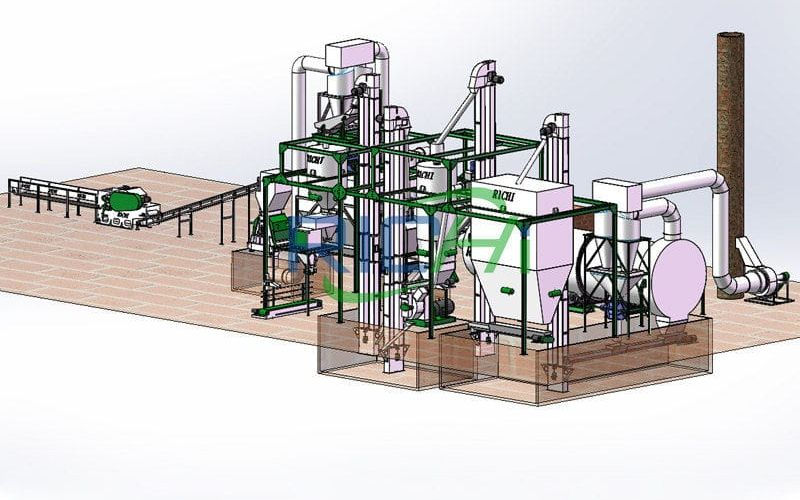

We understand that stable organic fertilizer granule production requires more than just a single organic fertilizer granulator. Therefore, we offer a complete turnkey project: from initial raw material compatibility analysis and plant layout planning to core fermentation, crushing, mixing, granulation, drying, cooling, coating, screening, and packaging equipment, we precisely configure and integrate them for you. More importantly, with our extensive practical experience, we can provide the optimal process path based on your specific raw material characteristics and production capacity requirements, ensuring that your investment is not just a machine, but an efficient, stable, and profitable organic fertilizer production line.

Client Testimonials

Our technical solutions and manufacturing standards have been rigorously validated in diverse global environments. From process design to production support, our unwavering focus on customer success is the fundamental reason we have earned long-term partnerships with international clients.

These genuine customer feedback from across continents confirms the exceptional performance of our equipment under diverse and complex conditions, demonstrating the global adaptability of our solutions.

Customer from Kazakhstan

This organic fertilizer granulating system perfectly meets the large-scale production needs of our ranch. It successfully converts cattle and sheep manure into organic fertilizer that meets export standards, creating a new profit growth point for the ranch.

Customer from Malaysia

Raw material: Palm Fruit Bunches and Pressing Residues

Production capacity: 20 t/h

The equipment maintains stable operation even in high temperature and humidity environments. It helps us convert palm oil mill byproducts into high-value organic fertilizer, achieving a perfect closed-loop industrial chain.

Customer from Pakistan

This granulator equipment has completely solved our sugarcane mill’s waste disposal challenges. The resulting fertilizer pellets have ideal strength and are highly competitive in the local agricultural product market.

Customer from New Zealand

Raw material: Cow Manure and Bedding

Production capacity: 20 t/h

The organic fertilizer granules making machine’s excellent corrosion resistance perfectly handles the high-salinity environment of our farm, efficiently converting livestock manure into organic fertilizer that meets strict environmental standards.

Comprehensive solutions from raw materials to finished products

We understand that high-quality organic fertilizer granules rely on optimized processes. The raw material characteristics, production capacity requirements, and site conditions you process vary, so we never offer a one-size-fits-all solution. We specialize in tailoring the entire process, from raw material pretreatment to finished product packaging, to ensure every step is precisely tailored to your specific needs. Whether it’s livestock manure, agricultural waste, or other organic raw materials, we provide professional technical assessment and process design. Leveraging our comprehensive service capabilities, we offer a one-stop solution encompassing equipment manufacturing, installation and commissioning, technical training, and lifetime parts support, helping you build an efficient and stable organic fertilizer production base.

organic fertilizer granulator

Precise molding and

efficient granulation

transform powdered

raw materials into high-value commodities

As the core of the entire production line, our organic fertilizer granulating system uses unique compression molding technology to ensure granules with ideal strength, uniform shape, and uniform quality. This lays a solid foundation for subsequent processes and directly determines the commercial value of the final product.

Professional Solutions from Single Machines to Systems

Excellent pellets are the result of a coordinated process. We not only provide core organic fertilizer granulator machine, but also focus on optimizing the efficiency of the entire production system. Based on your raw material characteristics and production capacity goals, we scientifically configure a full line of auxiliary equipment to ensure seamless integration between various units, ensuring efficient and stable operation from raw material pretreatment to finished product packaging. Here are some key organic fertilizer processing equipment.

Technical Q&A

In an organic fertilizer granulation project, every step of the process impacts the ultimate profitability. We’ve compiled key questions, from equipment selection and raw material compatibility to capacity optimization, to provide you with clear and professional technical guidance.

What is the price of FZLH678 organic fertilizer granulator machine?

+

The price of FZLH678 fertilizer granulator machine is generally: 45,000-60,000 USD

RICHI new type organic fertilizer granulators are widely used, and the price is naturally of great concern. However, the price of any commodity is not fixed and will change as some factors change. Organic fertilizer granulator is no exception. So, what factors will affect the price of organic fertilizer granulator?

There are many factors that affect the fertilizer granulator machine price. In addition to national policies, there are also the price of steel, the price of raw materials, the price of organic fertilizer, etc.

Of course, the organic fertilizer granules making machine will also be affected by the brand itself. When you buy big brands, you are bound to pay higher prices. But at the same time, we also gained more advanced technology and more guaranteed quality and service.

Impact on upstream industries. Since the main material of the organic fertilizer granulator machine price is steel, steel has the greatest impact on the price of the compost granulating machine. The price of steel fluctuates from time to time, which will inevitably affect the price change of organic fertilizer granulator machine.

Impact on downstream industries. The materials that organic fertilizer granulator machines are often used to granulate include animal manure, various agricultural and forestry wastes, and various urban wastes. The prices of these raw materials will inevitably affect the price of organic fertilizer granulators.

What are the detailed parameters of the FZLH678 organic fertilizer granulator machine?

+

| Model | FZLH678 |

| Output (t/h) | 18-22 |

| Main motor power (kw) | 185 |

| Main motor series | 8P |

| Ring die diameter (mm) | 673 |

| Finished pellet diameter (mm) | 4-12 |

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

Our cattle farm produces 20 tons of fresh manure daily with 70% moisture content. Does it require composting before granulation? What’s the estimated investment for a complete processing system?

+

At Richi Machinery, we recommend composting high-moisture cattle manure before granulation. Fresh manure at 70% moisture will hinder the granulation process in your organic fertilizer granulator machine. Through composting, moisture reduces to optimal 25-35% levels while stabilizing organic matter. For 20 tons daily raw material input, we suggest our medium-scale organic fertilizer production line including compost turner, crusher, mixer, granulation equipment and auxiliary systems. Total investment typically ranges between $85,000-$120,000 depending on automation level and site conditions. Our engineers can provide detailed cost analysis after understanding your specific requirements.

Chicken manure has strong adhesion and tends to clog mold holes. What special designs does your organic fertilizer granulator machine incorporate to address this?

+

Our new type organic fertilizer granulator features several anti-clogging mechanisms specifically for adhesive materials like chicken manure. The self-cleaning ring die design incorporates compressed air purge systems that automatically clear potential blockages. We also use specialized stainless steel molds with optimized hole patterns and surface treatments that reduce material adhesion. For particularly sticky mixtures, we recommend our vertical stirring tooth granulator which operates without traditional ring dies, completely eliminating clogging concerns while maintaining high granulation efficiency.

Can your equipment process wool-based organic fertilizer pellets?

+

Yes, Richi Machinery’s fertilizer granulation equipment can effectively process wool-based mixtures when properly formulated. Pure wool lacks the necessary binding properties, but when blended with sheep manure (40-50%), cattle dung (20-30%) and appropriate moisture (25-35%), our organic fertilizer granulating machine produces excellent pellets.

The wool fibers actually enhance pellet durability while providing slow-release nitrogen benefits. We recommend our heavy-duty granulator machine for fertilizer with reinforced mixing components to handle the fibrous nature of wool blends. Many customers successfully produce premium wool-based fertilizers using our systems.

Our sugar mill generates large quantities of bagasse with high fiber content. Can we produce organic fertilizer pellets without adding binders? How about the finished product strength?

+

Bagasse’s natural lignin content provides adequate binding capability for granulation in our specialized organic fertilizer granulator machine. Through proper pretreatment including fine crushing to 60-80 mesh and moisture adjustment to 28-32%, our equipment can produce pellets with crushing strength exceeding 10 Newton without additional binders. The key is our unique compression system that applies graduated pressure, allowing fibrous materials to interlock naturally. Finished pellets demonstrate excellent durability with dust rates below 1.5%, suitable for commercial handling and transportation.

We mainly handle mushroom cultivation waste with annual output around 5,000 tons. What capacity organic fertilizer granulator machine should we choose? What preprocessing equipment is needed?

+

For 5,000 tons annual output (approximately 15-20 tons daily), we recommend our FZLH320 organic fertilizer granulator with 2-3 ton/hour capacity. The complete mushroom waste processing line should include: shredder for breaking up spent substrate, mixer for moisture and nutrient adjustment, composting system for material stabilization, and finally our powder fertilizer granulator for pellet formation. Richi Machinery provides customized solutions considering your specific mushroom species and substrate composition to maximize nutrient preservation in the final granules.

For municipal sludge fertilizer projects containing fine sand particles, will this accelerate mold wear in the organic fertilizer granulator machine? What’s the typical mold lifespan?

+

Sand particles do impact mold longevity, but Richi Machinery addresses this through multiple approaches. Our heavy-duty granulator fertilizer machines feature wear-resistant alloy molds with surface hardening treatment (HRC 58-62). For sandy materials, we recommend specialized chrome-carbide molds that typically maintain precision for 3,000-4,000 production hours. We also install magnetic separators in preprocessing stages to remove metallic particles. With proper pretreatment including screening, our customers typically achieve 12-18 months mold lifespan even with challenging materials like municipal sludge.

We have both pig manure and straw materials. Is mixed or separate processing more economical? What are the process differences?

+

Mixed processing generally proves more economical and technically superior. Combining pig manure (providing nitrogen and binding properties) with straw (adding carbon and fiber structure) creates an ideal granulation formula.

Our organic fertilizer granules making machine handles such mixtures efficiently through its advanced mixing-granulation integration system. The process involves: straw crushing to 2-3mm, mixing with decomposed pig manure at 3:1 ratio, moisture adjustment to 30-35%, then direct granulation. This approach reduces equipment investment by 25% compared to separate processing while producing superior pellets with balanced nutrients.

After sorting and dewatering, food waste still contains significant oil content. How does this affect granulation in the organic fertilizer granulator machine? What adjustments are needed?

+

High oil content (above 3-5%) can cause several issues in standard granulation equipment including reduced particle bonding, mold slippage, and finished product softening. Richi Machinery’s solution involves multiple approaches:

- First, we recommend adding oil-absorbing materials like rice husk or zeolite during mixing.

- Second, our specialized organic granular fertilizer making machine incorporates heated molds (60-80°C) that improve material plasticity despite oil content.

- Third, we adjust compression ratios and implement post-granulation cooling systems to ensure pellet stability. Most food waste projects achieve excellent results with these customized adjustments.

Grape pomace has high acidity. Will direct granulation corrode the organic fertilizer granulator machine? What pretreatment is required?

+

While grape pomace’s acidity (typically pH 3.5-4.5) presents corrosion concerns, Richi Machinery’s equipment features multiple protective measures. Our granulator machine for fertilizer uses 304 stainless steel contact parts and special anti-corrosion coatings on critical components. However, we still recommend neutralization pretreatment: mixing pomace with 5-8% alkaline materials (agricultural lime or wood ash) during composting, bringing pH to 6.0-7.0. This not only protects equipment but also creates more plant-friendly fertilizers. Many wineries successfully use our systems for pomace valorization without corrosion issues.

We want to mix livestock manure with chemical fertilizers to produce organic-inorganic compound fertilizers. Are there special requirements for the organic fertilizer granulator machine?

+

Producing organic-inorganic compounds requires specific equipment features that standard organic fertilizer granulators may lack. Richi Machinery’s compound fertilizer granulation equipment incorporates corrosion-resistant materials to handle chemical components, precision liquid addition systems for binder distribution, and specialized vapor treatment for ammonium-based formulations.

Our dual-shaft mixing system ensures homogeneous blending before granulation. We also provide formulation technical support to optimize your nutrient ratios and ensure granulation success. Over 60% of our commercial compost granulator customers eventually expand into compound fertilizer production using our versatile systems.

As a startup farm with limited budget, should we begin with a small organic fertilizer granulator or invest directly in a standard production line?

+

For startup operations, Richi Machinery generally recommends beginning with our small scale organic fertilizer granulator systems. This approach allows you to master the granulation process with lower initial investment (typically $15,000-$35,000) while establishing your market.

Our modular design enables future expansion – you can start with basic granulation unit and gradually add preprocessing and finishing equipment as your business grows. Many successful operations began with our entry-level systems and expanded to full production lines within 2-3 years. We provide upgrade planning as part of our service to ensure your initial investment remains valuable during expansion.

What is the maximum allowable raw material moisture content for the organic fertilizer granulator machine? What consequences occur if standards are exceeded?

+

Our organic fertilizer granulation equipment performs optimally with material moisture between 25-35%. While our machines can temporarily handle up to 40% moisture through system adjustments, exceeding this threshold causes several issues: reduced granulation rate below 85%, increased mold clogging frequency, pellet deformation during drying, and potential motor overload.

For high-moisture materials, we integrate preprocessing systems like dewatering presses or dry material mixers. Richi Machinery’s technical team always conducts material testing to recommend the optimal moisture adjustment solution for your specific materials.

How often do the ring die and pressure rollers need replacement in organic fertilizer granulator machine? What is the replacement cost?

+

Replacement intervals vary significantly based on material abrasiveness and maintenance practices. For standard organic materials, Richi Machinery’s ring dies typically last 1,500-2,000 operating hours, while pressure rollers require replacement every 800-1,200 hours. With highly abrasive materials like municipal sludge, these intervals may reduce by 30-40%. Replacement costs range between $2,000-$8,000 depending on machine size and specifications. We maintain comprehensive spare parts inventory and offer maintenance contracts to minimize downtime. Many customers stock critical spares based on our recommended schedules.

What proportion of organic fertilizer production costs come from power and labor? Are there energy-saving solutions available?

+

In typical organic fertilizer granulation operations, power consumption accounts for 25-35% of production costs, while labor represents 15-25%. Richi Machinery addresses this through multiple energy optimization features: high-efficiency motors reducing power consumption by 15-20%, intelligent control systems optimizing energy use, and heat recovery systems capturing thermal energy for drying processes. Our automated lines require only 2-3 operators per shift, significantly reducing labor costs. We provide detailed cost-benefit analysis during project planning to help customers maximize operational efficiency.

How many operators does an organic fertilizer pellet production line require? What technical skill level is needed?

+

A complete organic fertilizer granules manufacturing machine line from Richi Machinery typically requires 3-4 operators: one for raw material preparation, one for granulation control, and one for packaging and quality control. With higher automation levels, this can reduce to 2 operators.

We design our systems for operator-friendly operation with touchscreen interfaces and automated process control. Comprehensive training is provided covering basic operation, routine maintenance, and troubleshooting. Most operators become proficient within 2-3 weeks. We also offer remote assistance and regular refresher training to ensure optimal operation.

How long does it typically take from equipment installation to formal production?

+

The implementation timeline varies by project scale. For standard organic fertilizer granulator machine installations, typical timelines are: foundation construction (1-2 weeks), equipment installation (1 week), commissioning and parameter adjustment (3-5 days), and operator training (1 week).

Complete projects typically achieve production readiness within 3-4 weeks after equipment arrival. Richi Machinery provides project managers who coordinate all stages and maintain weekly progress updates. We’ve developed streamlined installation procedures through hundreds of successful projects worldwide.

Can finished pellet size and shape be adjusted? How long does it take to change molds in the organic fertilizer granulator machine?

+

Yes, Richi Machinery’s organic fertilizer granulator machine produces various pellet sizes (2-10mm) and shapes (cylindrical, oval, or irregular) through interchangeable molds. Mold replacement typically takes 2-4 hours depending on operator experience. Our quick-disconnect mold system reduces this to 1-2 hours for trained personnel. We provide comprehensive mold libraries and technical support to help customers select optimal specifications for their market requirements. Many customers maintain multiple molds for producing different products for various customer segments.

Can the organic fertilizer granulator machine operate stably in high temperature and humidity environments? What factory conditions are required?

+

Our equipment is engineered for stable operation in challenging environments including tropical climates with 90%+ humidity and 40°C+ temperatures. Special features include moisture-proof electrical components, enhanced ventilation systems, and corrosion-protected mechanical parts.

Basic requirements include: indoor space with temperature maintained below 45°C, relative humidity below 95%, stable power supply (±5% voltage variation), and adequate ventilation (at least 3-5 air changes per hour). We provide detailed factory preparation guidelines and can recommend appropriate environmental control systems if needed.

If we plan to expand production capacity in the future, can existing equipment be upgraded to meet demand?

+

Richi Machinery designs all organic fertilizer granulation equipment with future expansion in mind. Our modular systems allow capacity increases through several approaches: adding auxiliary granulation units, upgrading drive systems, or integrating higher-capacity preprocessing equipment.

Typical upgrade paths can increase production by 30-100% while preserving 60-80% of original equipment value. We maintain upgrade records for all equipment and provide expansion consulting as part of our long-term customer support. Many customers have successfully scaled their operations 2-3 times through our systematic upgrade programs.

Do you provide production process guidance including raw material formulas and parameter adjustments?

+

Comprehensive technical support is fundamental to our service at Richi Machinery. Every organic fertilizer granulator machine purchase includes detailed process documentation, formula databases for various materials, and parameter optimization guides.

Our technical team provides onsite training covering recipe development, process adjustment, and quality control methods. We maintain an ongoing support relationship, regularly sharing process improvements and new formula developments from our global customer network. This commitment to knowledge transfer ensures our customers achieve optimal results from their investment in our equipment.

What featured organic fertilizer granulator machine projects have you worked on?

+

organic fertilizer granulator machine In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: industrial waste

- project price: 80,000 USD

organic fertilizer granulator machine In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: livestock manure

- project price: US$110,000

organic fertilizer granulator machine In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: poultry litter

- project price: US$430,000

organic fertilizer granulator machine In Lithuania

- Country: Lithuania

- Production: 35,000 T/A

- Ingredients: food waste

- project price: 410,000USD

organic fertilizer granulator machine In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: chicken manure

- project cost: 570,000 USD

organic fertilizer granulator machine In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- project cost: 190,000 USD

organic fertilizer granulator machine In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: livestock manure

- project cost: $160,000

organic fertilizer granulator machine In Pakistan

- project cost: $385,000 USD

- Country: Pakistan

- Production: 30,000 T/A

- Ingredients: cow manure, Bagasse

How to process organic fertilizer granules? Complete organic fertilizer process flow

+

The extrusion granulation method uses extrusion force to extrude the mixed wet raw materials through a die. This method is suitable for raw materials with certain plasticity, such as organic fertilizers, compound fertilizers, etc. The steps of a complete organic fertilizer production line include: raw material mixing → feeding → granulation → cutting → drying → screening → packaging.

1.Prepare raw materials

- Collect organic raw materials, including farmland straw, livestock and poultry manure, food processing waste, etc.

- Carry out raw material processing, such as crushing, mixing, etc.

2.Fermentation and composting

- Stack the processed raw materials in the fermentation pile.

- Turn the pile regularly to promote the fermentation process.

- Control the compost temperature and humidity to ensure fermentation effect.

3.Anaerobic fermentation

- Move the organic raw materials that have undergone preliminary fermentation to the anaerobic fermentation tank.

- Control the oxygen supply in the fermentation tank to promote the decomposition of organic matter.

- Stir the fermentation material regularly to ensure uniform and sufficient fermentation.

4.Accumulation

- Stack the fermented organic matter in an open dump.

- Control the oxygen supply and humidity of the accumulation and maintain appropriate accumulation conditions.

5.Crushing and screening

- Use crushing equipment to finely crush organic matter.

- After screening, the appropriate particle size is separated.

6. Formulation and Mixing

- Mix finely divided organic matter with other additives according to the product formula ratio.

- Control mixing uniformity to ensure product quality.

7. Granulation

- Granulate the mixed organic matter through organic fertilizer granulator machine.

- Control the temperature and humidity of the granulation equipment to ensure particle shape and density.

8. Drying

- Use drying equipment to dehydrate and dry organic fertilizer particles with excessive humidity.

- Control the temperature and wind speed of the drying equipment to ensure the quality of organic fertilizer pellets.

9. Packaging and storage

- Pack the dried organic fertilizer particles and use appropriate packaging materials.

- Store organic fertilizer granules to ensure quality and shelf life.

10. Finished product inspection

- Conduct quality inspection on packaged organic fertilizer granules.

- Check the nutrient content, microbial content and other indicators of organic fertilizer.

11. Product sales

- Put qualified organic fertilizer products on the market.

- Carry out market promotion and distribution channel construction.

The above is the basic process flow of organic fertilizer production line, which can be reasonably adjusted and optimized according to actual production needs.

How to choose organic fertilizer granulator machine?

+

The selection of fertilizer granule making machine will directly affect the production cost and product quality of organic fertilizer, as well as the size of the production site and the surrounding environment.

With the rapid development of organic agriculture, the demand for organic fertilizers is increasing. As an important equipment for the production of organic fertilizer, the choice of organic fertilizer granulator directly affects the production efficiency and quality of organic fertilizer. So, how to choose a suitable organic fertilizer granulator? Here we will introduce it in detail from the following aspects.

1. Understand the types of organic fertilizer granulators

Organic fertilizer granulators are mainly divided into two types: flat die granulators and ring die granulators. The flat die pellet machine has a simple structure, low pressure in the pelletizing chamber, and loose requirements for raw materials. However, the production efficiency is low, the discharge material is loose, and the molding rate is unstable.

The ring die fertilizer pellet machine has high pressure, high production efficiency and high molding rate, but has a complex structure and high manufacturing cost. Therefore, when choosing an organic fertilizer granulator, you must choose the appropriate model based on actual needs and production conditions.

2. Consider the production capacity of the organic fertilizer granulator machine

When choosing organic fertilizer granules manufacturing machine, you must choose the appropriate production capacity according to your own production needs.

If the production demand is large, you can choose an organic fertilizer pellet machine with a higher output; if the production demand is small, you can choose an organic fertilizer pellet machine with a lower output. At the same time, factors such as energy consumption and operating costs of the organic fertilizer granulator must also be considered.

3. Pay attention to the quality of organic fertilizer granulator

The quality of the organic granular fertilizer making machine directly affects its service life and performance. When choosing an organic manure pellet mill, you should pay attention to its manufacturing materials, technology, structure and other aspects.

A high-quality organic fertilizer granulator should have the characteristics of reasonable structure, excellent manufacturing, and smooth operation, which can ensure long-term stable operation and improve production efficiency.

4. Consider the operation and maintenance of organic fertilizer granulator machine

When choosing an organic fertilizer pellet making machine, you should also consider its ease of operation and maintenance. The easy-to-operate and maintain organic fertilizer granulator can reduce labor costs and maintenance costs and improve production efficiency.

Therefore, when choosing an organic fertilizer granulator, you should pay attention to the design of its operating interface, maintenance and other aspects.

5. Compare the prices of different fertilizer granule making machines

The prices of organic fertilizer granules making machines of different brands and models vary greatly. When choosing an organic fertilizer granulator, you should compare and choose based on your own budget.

At the same time, you should also pay attention to the cost-effectiveness of the organic fertilizer pellet mill and choose an organic fertilizer granulator that meets your needs and is reasonably priced.

In short, when choosing an organic fertilizer granulator machine, you must comprehensively consider the above aspects according to your actual needs and production conditions.

Only by choosing a suitable organic fertilizer granulator can you ensure the production efficiency and quality of organic fertilizer and improve agricultural production efficiency. Feel free to contact RICHI Machinery for quotation!

How to choose an organic fertilizer granulator machine manufacturer?

+

When choosing an organic fertilizer granulator machine manufacturer, you need to consider multiple factors to ensure you choose the right manufacturer. Here are some suggestions for consideration:

- It is necessary to investigate and understand the organic fertilizer granulating machine manufacturers on the market. Relevant information can be obtained through the Internet, industry exhibitions, professional forums and other channels. When understanding the basic information of a manufacturer, you need to pay attention to the manufacturer’s size, strength, qualifications, product quality and services.

- It is necessary to determine the technical strength of the manufacturer. The fertilizer granulator has a high technical content, so the manufacturer needs to have corresponding technical strength and R&D capabilities. The technical strength of the manufacturer can be evaluated by understanding the manufacturer’s technical team, technical level, intellectual property rights, etc.

- You need to consider the cost-effectiveness of the manufacturer’s products. When choosing a fertilizer granulation equipment manufacturer, you should not only focus on the price but ignore the quality and performance of the product. It is necessary to conduct a comprehensive evaluation of the manufacturer’s products, including product performance, reliability, service life, after-sales service, etc.

- You need to understand the manufacturer’s cases and user feedback. The manufacturer’s cases can reflect the manufacturer’s actual experience and strength, and user feedback can help understand the manufacturer’s product and service quality. When choosing a manufacturer, you need to understand this information to better evaluate the manufacturer’s strength and service quality.

- Communicate and exchange with manufacturers. When choosing an organic fertilizer granulator machine manufacturer, you need to fully communicate with the manufacturer to understand the manufacturer’s service attitude, professional level, delivery time and other information. Through communication and communication, the strength and service quality of manufacturers can be better evaluated, and stronger support can be provided for selecting the right manufacturer.

To sum up, choosing a suitable compost granulating machine manufacturer needs to consider many factors, including the manufacturer’s scale and strength, technical strength, product cost performance, cases and user feedback, as well as communication and exchanges with manufacturers.

By comprehensively considering these factors, the manufacturer’s strength and service quality can be better evaluated, providing stronger support for selecting the right manufacturer.

What is the future development of organic fertilizer granulator machine?

+

The following are three advantages for the future development of organic manure making machine:

01 The market demand is large and seasonal requirements are low.

In recent years, due to improper operation and other reasons, the soil compaction problem has become increasingly serious. The organic matter content in the soil has decreased, and the organic matter content has gradually decreased in many countries. Organic fertilizer has the function of conditioning the soil, which means that the demand for organic fertilizer has a broad prospect.

At present, there are still few large-scale organic fertilizer manufacturers in various countries, and governments in various countries have more policy preferences for organic fertilizers. Therefore, the market prospect of compost pellet making machine is also huge.

02 Lower production costs and higher profits.

Simply based on the nutrient content, it is stipulated that the total nutrient content should be around 5% to meet the standards. The ratio of each nutrient content is not mentioned, so that companies can consider the proportion of input formula according to the specific market conditions.

In addition, organic fertilizer has lower requirements for organic fertilizer granulator machine, and the infrastructure can be a drum process. It is understood that the raw material cost of standard organic fertilizers from some manufacturers is very low, while the ex-factory price can be several times higher, resulting in huge profit margins.

03 Environmental issues.

Since the raw materials of organic fertilizers are mostly recycled resources, the hard pollution to the environment will be much lower than that of other fertilizers. This is also very important in today’s society that advocates environmental protection.

What is the current development status and future prospects of the organic fertilizer industry?

+

Organic fertilizer is made from organic matter such as livestock manure, tail vegetables, mushroom residues, etc., through microbial decomposition and composting. At present, the application of organic fertilizers in the agricultural field has gradually received attention, and has shown the following current status and development prospects:

- Current situation: As people’s awareness of food safety and environmental protection increases, the demand for organic agricultural products is gradually growing. Organic fertilizer made by organic fertilizer granulator machine is widely used as a sustainable and environmentally friendly fertilizer. Many countries and regions have established organic agriculture certification systems and introduced policies to support the development of organic agriculture.

- Agricultural sustainability: The use of organic fertilizers can improve soil structure, increase soil organic matter content, and improve soil fertility and water retention capacity. Compared with chemical synthetic fertilizers, organic fertilizers have less impact on soil health and the ecological environment, helping to achieve sustainable development of agriculture.

- Food safety and quality: The use of organic fertilizers can reduce chemical residues in agricultural products and improve food safety and quality. More and more consumers are choosing to purchase organic agricultural products, driving the demand for organic fertilizers.

- Rural economic development: The manufacture and application of organic fertilizers can promote the development of rural economy. Farmers can realize resource recycling and increase the added value of agricultural products by converting agricultural waste into organic fertilizers.

- Environmental protection: The raw materials of organic fertilizer are mainly livestock manure, straw, mushroom residue, traditional Chinese medicine residue, branch straw and other wastes. Making them into organic fertilizer not only solves the problem of waste pollution, but also realizes resource utilization. of reuse.

- Technological innovation and industrialization: With the continuous advancement of science and technology, the production technology and formula of organic fertilizer are also constantly improved and innovated. At the same time, the development of the organic fertilizer industry chain has also led to the rise of related equipment, technology and services, forming a complete industrial system.

To sum up, the current situation and development prospects of organic fertilizers are very broad.

As people pay more attention to sustainable agriculture and consumer demand for organic agricultural products grows, organic fertilizers made by organic fertilizer granulator machine will play a more important role in the agricultural field and contribute to sustainable agricultural development and food security. (Find RICHI on YouTube)

60000 +

Backed by a 60,000 m² advanced production complex

140 +

Global footprint extends across 140+ international markets

2000 +

Over 2,000 successful production system installations

2013

RICHI MANUFACTURE

Established in 1995, RICHI MACHINERY has grown from a medium-sized enterprise to become China’s largest pellet production line manufacturer. With two major manufacturing bases spanning hundreds of thousands of square meters, we specialize in custom pellet machines and complete plant solutions, handling every production stage in-house—from R&D to delivery.

Our vertically integrated facilities (including dedicated sections for production, testing, and logistics) ensure premium quality, environmental responsibility, and operational reliability for feed, biomass, and fertilizer industries worldwide. For nearly three decades, we’ve partnered with clients to enhance productivity, minimize risks, and achieve sustainable outcomes through innovative engineering.

Zhengzhou Headquarters

R&D, global operations and strategic management converge

Jiaozuo New Production Base (2025)

Featuring automated production lines and Industry 4.0 technologies

Kaifeng Original Complex (Since 1995)

Our manufacturing legacy began and quality traditions endure

Certifications & Patents

As a world-leading feed mill equipment manufacturer, RICHI Machinery demonstrates its engineering prowess through internationally recognized certifications and proprietary innovations.

Our ISO quality management system, CE compliance, BV-certified production processes, GOST-R for Russian compliance, ATEX explosion-proof certification for EU safety standards, FDA registration for U.S. market access, and EHEDG hygienic design certification validate our commitment to global standards, while 50+ patented technologies in pellet mills, extruders and automation systems deliver unmatched performance.

When you choose RICHI, you’re selecting globally validated, future-proof solutions backed by the industry’s most comprehensive certification portfolio.

01

Consultation

Our experts provide professional advice to understand your specific feed production requirements.

02

Design

We develop customized solutions with optimized layouts and equipment configurations for your project.

03

Manufacturing

All feed mill equipment is precision-built using quality materials in our ISO-certified factories.

04

Shipping

We handle secure packaging and global logistics with reliable delivery timelines.

05

Installation

Our engineers supervise on-site assembly and commissioning for smooth operation.

06

Training

Comprehensive operator instruction ensures proper use and maintenance of equipment.

07

After-sales

Dedicated support team provides troubleshooting and technical assistance.

08

Spare Parts

Genuine components are available worldwide with fast delivery service.