Manure Pellet Mill

The FZLH420 manure pellet mill is suitable for processing organic fertilizer granules with an output of 6-8t/h. The processed manure pellets can be columnar or round. This type of equipment is mainly used in chicken farms, cattle farms, organic fertilizer plants, sheep farms, rural cooperatives, breeding companies, etc.

What is manure pellet mill ?

The manure pellet mill is a highly efficient pelletizing machine designed specifically for modern agriculture and organic waste recycling. It utilizes intelligent compression technology to transform waste resources such as livestock and poultry manure and straw into uniform, high-density organic fertilizer pellets, significantly improving fertilizer storage and transportation efficiency.

Through an automated control system, users can quickly adjust pellet specifications and production capacity, enabling low-energy, high-return, large-scale production. Whether operating on large farms or specialized fertilizer processing companies, this equipment can help reduce operating costs, shorten production cycles, transform waste resources into sustainable business opportunities, and contribute to the development of a circular economy in agriculture.

Applicable Raw Materials

Manure pellets are made from a wide range of raw materials, including not only common livestock and poultry manure but also agricultural waste such as straw and rice husks, as well as food processing byproducts and industrial waste, truly transforming waste into treasure.

By raw material type, the most common manure pellet mill types include: chicken manure pellet machine, cow dung pellet making machine, horse manure pellet maker, poultry manure pellet machine, pig manure pellet machine, goat and sheep manure pellet machine, etc.

Why turn manure into pellets?

Technological features

This manure pellet mill, centered around environmental innovation, is dedicated to solving the challenges of organic waste disposal. Through a low-temperature molding process, the equipment directly converts moist livestock and poultry manure into clean, pollution-free fertilizer pellets, effectively reducing environmental pollution while preserving nutrient activity.

Its modular design balances stability and ease of maintenance, making it easy for even non-professionals to operate. From family farms to ecological planting bases, this equipment provides users with a one-stop waste resource recovery solution, making environmental protection initiatives simpler and more efficient, and promoting the implementation of green agriculture.

Top-Notch Power, Excellent Efficiency

The core power components of manure pellet mill utilize Siemens motors, ensuring smooth and powerful power output and high energy conversion efficiency. This fundamentally ensures long-term reliability and excellent energy efficiency, effectively reducing operating costs.

Intelligent Anti-Blocking, Smooth Operation

Equipped with a powerful magnetic separator and iron removal device, it effectively protects the die from damage. Its unique anti-blocking design and automatic unblocking function provide timely warnings and resolve blockages, ensuring smooth and continuous production line operation.

Heavy-Duty Design, High Efficiency and Durability

The heavy-duty gear drive delivers strong and reliable power transmission, designed for continuous high-load production. Combined with automatic load control, this ensures stable operation under high loads, significantly improving production output and durability.

Hygienic Design, Easy Maintenance

Key contact parts are made of corrosion-resistant stainless steel, making them easy to clean. The curved door cover effectively reduces material residue and dead corners, meeting the hygienic standards of organic fertilizer production and easing daily cleaning and maintenance.

WORKING

PRINCIPLE

The core of the RICHI ring die manure pellet mill lies in achieving stable material formation through pure physical mechanical forces. It eliminates the complex conditioning process and directly applies high pressure to the pulverized organic raw material, forcing strong intermolecular forces between the particles, resulting in uniform, dense, and strong manure pellets.

Technical Parameters of FZLH420

For complete technical specifications, please contact us directly online.

Main Motor Power

90kw

Forced Feeder Power

1.5kw

Finished Pellet Diameter

4~12mm

Capacity

6-8T/H

Ring Die Diameter

420mm

advantages of FZLH420 manure pellet mill

When it comes to manure pelletizing, an excellent manure pellet mill provides more than just pelletizing capabilities; it also provides comprehensive control over production efficiency, finished product value, and operating costs. We focus on every detail that impacts your production profitability, ensuring that our equipment delivers exceptional performance that exceeds expectations at every stage.

High Output Efficiency and Visible Capacity

Designed for small to large-scale production, it utilizes an optimized mechanical compression principle to ensure a high pellet yield per unit time. This stable, high-capacity system enables more precise production planning and effectively meets your delivery needs for large-volume orders.

High-Quality Finished Product, Expected Premium

Pellets are compact, uniform, and consistent in color. These high-quality finished products are less prone to breakage during transportation, appearing more premium in the market, directly helping to improve your product’s competitiveness and sales price.

Multi-purpose machine, flexible investment

Another highlight is its wide adaptability to raw materials. Whether it’s conventional organic fertilizer, bio-organic fertilizer, or specially formulated compound fertilizer, it can handle it, providing a solid foundation for you to flexibly adjust your product mix and capture diverse market opportunities.

Intuitive Operation, Effortless and Hassle-Free

We adhere to a design philosophy of simplifying complexity. From the intuitive user interface to convenient daily maintenance, everything has been optimized to significantly reduce the need for specialized operators, effectively saving you training time and labor costs.

Professional Matching and Freedom of Choice

Except FZLH420, RICHI has different organic manure pellet mills for your manure fertilizer production, covering 1-26 tons per hour. All these machines have different prices. From the materials they use to the size, the prices are different. Making manure into fertilizer pellets, it is essential for you to equip with a manure pellet machine. It is a machine for recycling your waste.

RICHI manure pellet mill is suitable and popular in organic manure production line. Our equipment adopts ring die pelletizing technology. The granulation method has the highest granulation density of the entire equipment, and the granules will not be scattered during sales and transportation. This is also the most valuable organic fertilizer processing method. You can choose different designs and configurations according to your preference. Meanwhile, we can also provide suggestions for you if you need.

manure pellet mill project

At RICHI, every manure pellet mill sold is more than just a transaction; it’s the foundation for long-term partnerships with our global customers. Our presence spans Southeast Asia, Europe, South America, and other regions and countries, providing hundreds of businesses with practical organic fertilizer solutions.

Our equipment demonstrates a wide range of raw material adaptability, from processing conventional feedstocks like chicken manure and cow dung to converting complex organic matter like straw, biogas residue, and even food processing waste. We understand that every farm has its own unique scale and goals, so we offer flexible production line configurations, ranging from small-scale manure pelletizing projects with a capacity of 1 ton per hour to large-scale commercial fertilizer plants with a capacity of 20 tons per hour.

Russia

Poultry Manure Pellet Mill

This client, a laying hen farm in Russia. Our poultry manure pelletizer successfully helped them convert waste into commercial fertilizer, effectively alleviating the farm’s environmental burden and generating substantial economic benefits.

Indonesia

Palm-Based Manure Pellet Mill

This client, a palm oil plantation in Indonesia. Our specialized pelletizing equipment successfully helped them transform a mixture of palm fiber and livestock and poultry manure into granular fertilizer, achieving waste recycling within the plantation.

Australia

Sheep Manure Pellet Mill

This client, a sheep farm in Australia. Our pelletizing system, with its stable operation and excellent pelletizing results, met their stringent product quality requirements and successfully entered the local high-end horticultural market.

Philippines

Swine Manure Pellet Mill

This client is a hog farming group in the Philippines. Our hog manure pelletizing line has become a key piece of equipment for achieving environmental compliance and expanding their business.

Mexico

Dairy Manure Pellet Mill

This client is a dairy company in Mexico. To improve the farm environment and repurpose manure, they installed our dairy manure pelletizer. The resulting high-quality granular fertilizer is highly sought after by surrounding agricultural cooperatives.

Kenya

Chicken Manure Pellet Mill

This client is an agricultural enterprise integrating poultry farming and fruit and vegetable cultivation. They selected our chicken manure pelletizer to convert livestock waste into high-efficiency organic fertilizer for their own use, achieving an internal ecological cycle.

Brazil

Cattle Manure Pellet Mill

This client is a beef cattle farm in Brazil with abundant cattle manure resources. They invested in a granular fertilizer production line. Our high-capacity cow dung pelletizer helped them successfully export their products to overseas agricultural markets.

Argentina

Beef Manure Pellet Mill

This client is an agricultural and livestock group. Our heavy-duty cow dung pelletizer, with its exceptional durability and high output, meets their needs for large-scale, continuous production. Our products are primarily supplied to large domestic cash crop farms.

United States

Turkey Manure Pellet Mill

This client is a turkey farming and processing company. Our customized manure pellet line not only helps them harmlessly dispose of this waste but also transforms it into a high-value organic fertilizer product, which is successfully sold to the surrounding corn and soybean belts.

Global project experience and customized solutions

In most cases, we deliver not just a single, high-quality manure pellet mill, but a complete turnkey project encompassing crushing, mixing, pelletizing, drying, cooling, screening, and packaging. From initial project consultation and process design to equipment manufacturing, installation, commissioning, and personnel training, and ultimately, spare parts supply and technical support throughout the equipment’s lifecycle, we remain your trusted partner. Choosing us means you receive comprehensive support from idea to finished product.

Customer Testimonials

From tropical rainforests to temperate farms, RICHI’s engineering expertise and equipment reliability are driving sustainable transformation in global agriculture. We deliver more than just manure pellet mill machines; we deliver solutions that withstand the test of diverse markets and environments. This is why industry leaders worldwide trust us.

Cameroon Customer

Our local palm plantation waste piled up like a mountain. The RICHI solution successfully blended palm fiber with livestock manure into pellets. This production line operates stably and has completely changed our waste disposal challenges.

Customer from Kazakhstan

Raw material: Mixture of sheep manure and straw

Production capacity: 6 t/h

In grassland areas, sheep manure resources are abundant but their utilization rate is low. RICHI’s dedicated sheep manure granulation equipment not only adapts to our climate, but the granulated fertilizer it produces also helps us enter the high-end fertilizer market in Central Asia.

Customer from Afghanistan

Local agricultural infrastructure is weak, and power supply is unstable. The simple granulation solution RICHI designed for us is easy to operate and maintain, and its production capacity fully meets the needs of our community agricultural cooperative.

German Customer

Raw material: chicken manure, green waste, food processing byproducts

Production capacity: 8t/h

We have extremely high requirements for equipment precision and automation. The intelligent manure pelletizing line provided by RICHI offers stable pellet quality and comprehensive environmental design, fully meeting the stringent EU standards.

Scientific Transformation from Raw Materials to Finished manure Pellets

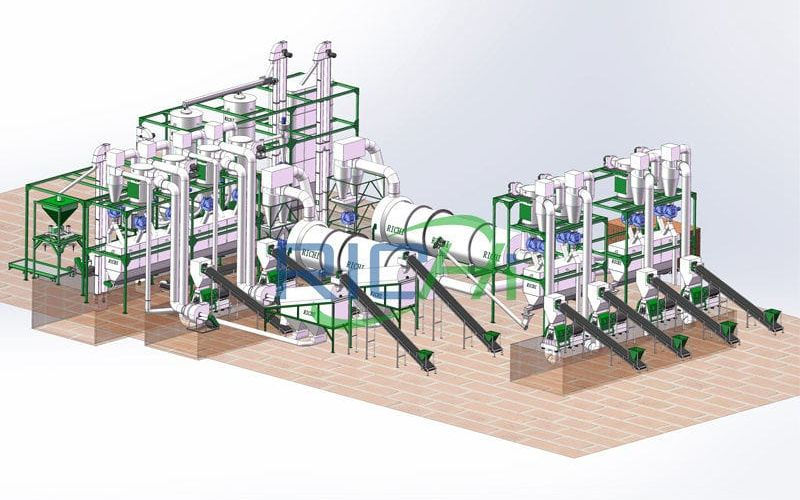

At RICHI, we understand that no two fertilizer production projects are exactly alike. Customers’ raw material characteristics, production capacity targets, plant layouts, and investment budgets vary widely, which is why we insist on providing “tailor-made” complete line solutions. We deliver far more than just a single machine; we deliver a scientific process flow and turnkey project that deeply integrates your specific needs. The essence of an efficient feces pellet production line lies in the precise connection and parameter optimization of each process step.

Typical core processes include: raw material pretreatment and blending – efficient deep fermentation – refined crushing and mixing – intelligent control and granulation – post-processing (cooling, drying, screening) and precise packaging. Throughout the entire process, we start from your initial conditions and conduct rigorous process design and equipment selection to ensure that the final production line not only runs smoothly, but also strikes an optimal balance between investment and operating costs, creating tangible benefits for you.

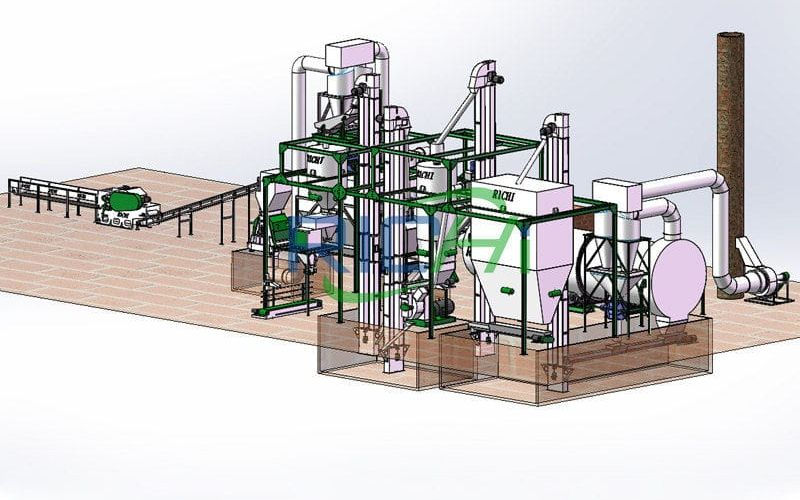

Manure Pelletizing System

Every high-quality granule

comes from precise

control of this critical process.

Each step reflects our precise control over efficiency and cost, ensuring the delivery of a stable, high-yield, and sustainably profitable manure pellet production line.

Precision-engineered Complements

A superior manure pellet mill requires an equally specialized processing system to realize its full potential. We not only manufacture core pelleting equipment but also provide key equipment for the entire process, from fermentation and pretreatment to finished product packaging. Based on your raw material characteristics and process objectives, we scientifically select equipment and integrate systems to ensure precise matching of every step—from pulverization to mixing, drying, cooling, and screening—to create a complete, efficient, stable, and first-class feces pellet production line.

Core supporting equipment includes: pulverization equipment, high-efficiency turning and mixing equipment, homogenizing and mixing equipment, drying and cooling equipment, precision screening equipment, automated packaging equipment, material conveying systems, spraying equipment, and intelligent control systems.

DISCOVER OUR PRODUCTS

Founded in 1995, Richi Machinery has been developing steadily andsteadily in the field of pellet processing. it is mainly engaged in theR&D and manufacturing of pellet plant equipment

We primarily process pig manure with a high moisture content. Direct pelletizing can easily clog the die. Does your equipment have pretreatment solutions for high-moisture materials?

+

Yes, this is a very common challenge we address. High-moisture pig manure is not suitable for direct pelleting in any ring die pellet mill. At Richi Machinery, we don’t just sell a machine; we provide a complete process solution. For high-moisture materials, we always recommend a pretreatment stage that includes solid-liquid separation (using a screw press) followed by efficient mixing with dry auxiliary materials like crushed straw, sawdust, or previously recycled fine pellets.

This mixture is then conditioned to achieve the ideal moisture content (typically between 15-25%) and fiber structure for successful pelleting. Our engineers will design this pretreatment system to ensure your pig manure is perfectly prepared for our manure pellet machine, preventing die clogging and ensuring stable, high-yield production.

A cattle farm would like to pelletize cow manure and waste grass together. Are there any special requirements for the pelletizer’s compression ratio when mixing these two materials?

+

Absolutely. Combining cow manure with waste grass is an excellent way to create a balanced organic fertilizer, but it does require specific equipment adjustments. The grass adds significant fiber, which increases the material’s elasticity and requires greater compressive force to form durable pellets.

For such mixtures, our Richi manure granulator would be configured with a ring die that has a higher compression ratio. This forces the fibrous material through longer, narrower die holes under greater pressure, ensuring the particles bond tightly together to form a hard, low-dust pellet. During the project design phase, we analyze your specific material ratios to recommend the perfect ring die specification for your operation.

We are a medium-sized chicken farm with a small daily production volume. Are there any economical pelletizing solutions suitable for our small-scale operation and low investment budget?

+

We understand that not every operation is large-scale, which is why Richi Machinery offers a range of manure pelletizers to suit different budgets and production goals. Our MZLH series, for example, includes models perfectly suited for outputs starting from 1 ton per hour.

These models retain the core principles of our larger machines—such as robust gearbox transmission and high-quality ring dies—but in a more compact and cost-effective package. We can provide a simplified production line that focuses on the essential steps: fermentation, crushing, pelleting, and screening, significantly reducing your initial investment while still delivering a high-quality, commercial-grade pellet.

What’s the FZLH420 manure pellet mill price?

+

The price of FZLH420 manure pellet mill is generally 30,000-40,000 USD

The price of FZLH420 manure pellet mill equipment is not static. It is affected by many factors, such as configuration, manufacturer, competitiveness, etc. Different influencing factors will have great differences in the market quotation of its equipment.

Market demand: When the market has high requirements for manure pellet mills, but there are few such equipment on the market, the price of organic fertilizer granulators will be relatively high. On the contrary, if the market demand is not large, but the more equipment circulating in the market, the lower the price of the organic fertilizer pellet mill will be.

Configuration factors: Since the specific conditions of each manufacturer are different, the organic fertilizer manure pellet mills they configure are also different. Generally speaking, the larger the equipment model and capacity configured by the user, the higher the requirements for the equipment. The higher the market price will be, and the smaller the equipment model and capacity configured, the lower the market price will be.

Equipment manufacturer factors: Different manure pellet mill manufacturers have different strength, scale, production experience, and production materials. Therefore, the cost of their production equipment is also different, which affects the quotation of the equipment. If the equipment manufacturing cost is high, the price will be high; if the processing cost is low, the price will be relatively low.

Competitiveness factors: In the current economic downturn, there is great competition in various industries, and the same is true for manufacturers of manure pellet mills. The greater the competition, the lower the price of the equipment produced, and the competition is not If the price is large, the price of the organic fertilizer granulator equipment will be relatively high.

Materials used: Materials also have a certain impact on the price of manure pellet mills. Since the quality of materials directly affects the performance of organic fertilizer granulators and the quality of organic fertilizers, if the equipment and materials are good, then the organic fertilizer produced will be The granulator has high quality, good performance and long service life, but of course the price is also high. Therefore, the different materials used in the organic fertilizer granulator will also have a certain impact on its price.

Could you provide a more detailed data sheet for the FZLH420 manure pellet mill?

+

| Model | FZLH420 |

| Output (t/h) | 6-8 |

| Main motor power (kw) | 90 |

| Main motor series | 8P |

| Ring die diameter (mm) | 420 |

| Finished pellet diameter (mm) | 4-12mm |

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

Who is suitable to invest in manure pellet mill and manure pellets processing business?

+

The following groups of people or businesses are well-suited to investing in this business:

- Large-Scale Livestock and Poultry Farm Owners

Core Advantage: You own the most essential raw material—livestock manure—at an extremely low cost and a stable supply. Investing in pelletizing equipment can transform a troublesome source of pollution into substantial additional revenue, effectively addressing environmental pressures and achieving a circular economy of “turning waste into treasure.”

- Existing Fertilizer Processors and Distributors

Core Advantage: You already have established sales channels and market knowledge. Adding an organic fertilizer pellet product line will enrich your product portfolio, meet the growing demand for organic agriculture, capture the huge growth market beyond traditional chemical fertilizers, and enhance your overall competitiveness.

- Organic Farmers and Green Planting Bases

Core Advantage: You are already a consumer of high-end organic fertilizer. Building your own processing line not only ensures high-quality, low-cost fertilizer for your own use and guarantees crop quality from the source, but also allows you to sell excess production capacity to external customers, creating a dual-income model of “self-production and sales + external profit.”

- Environmental Engineering and Waste Treatment Companies

Core Advantages: Your core business is processing various types of organic waste. Introducing a manure pellet mill can upgrade processing services to resource-based product output, significantly increasing project added value and profitability, transforming environmental protection from a “cost center” to a “profit center.”

- Investors Seeking New Opportunities in the Agricultural Sector

Core Advantages: You have both capital and market acumen. Organic agriculture is a clear future trend. Investing in this sector means tapping into a booming industry with policy support and growing demand. By establishing a modern pellet processing plant, you can build a branded business with long-term growth potential.

Investors suitable for this business may possess raw materials, market share, industry chain expertise, or a visionary who is optimistic about the future of green agriculture. The core value of this investment lies in transforming environmental challenges into economic opportunities, aligning the dual goals of environmental protection and profitability.

Sheep manure has a high fiber content and poor viscosity, making it difficult to pelletize using a standard manure pelletizer. Do you have special ring die designs for this material?

+

You have identified the key challenge with sheep manure pelleting. Its low lignin content and high fibrous nature make it less prone to natural binding. A “standard” pelletizer will indeed struggle. This is where our expertise in custom ring die design becomes critical.

For sheep manure, we recommend and supply a ring die with several specific features: a thicker die profile to increase material retention time under pressure, smaller hole diameters to create more resistance, and a specially engineered “release bore” profile that encourages the formed pellet to be cleanly cut off. This custom design, combined with potential process adjustments like adding a small percentage of a binder, allows our manure compost machine to successfully transform difficult sheep manure into premium pellets.

We would like to pelletize a mixture of duck manure and mushroom residue. What is the approximate ratio of these two raw materials for optimal pelletizing results and pellet hardness?

+

This is an excellent question that highlights the need for customized solutions. There is no single “perfect” ratio, as it depends on the initial moisture and fiber content of both your duck manure and mushroom residue. However, as a general starting point from our project experience, a mixture in the range of 60% fermented duck manure to 40% mushroom residue often provides a good balance. The mushroom residue acts as a superb dry bulking agent and fiber source, absorbing excess moisture from the manure and providing structure. The final optimal ratio is determined through lab analysis and small-scale trials at our facility. We can guide you through this testing process to define the precise formula that will work best in your manure pellet mill for a high-hardness, low-breakage product.

As a large livestock group, we require cow manure pelletizing equipment with a capacity of over 3 tons per hour. Will the lifespan of core components such as the ring die and rollers ensure continuous production?

+

For large-scale operations like yours, equipment durability is not just a feature—it’s a necessity for profitability. Our high-capacity manure pellet machines, such as the FZLH series, are engineered specifically for continuous, 24/7 production environments. The ring dies and rollers are manufactured from premium alloy steels (e.g., 40CrNiMo) and undergo a deep carburizing and hardening process, achieving a surface hardness of HRC 56-60.

This gives them exceptional wear resistance. Under normal operating conditions and with proper maintenance, our customers typically achieve a lifespan of 2,000 to 3,000 production hours for these core components before reconditioning is needed. We also ensure quick availability of these wear parts to minimize your downtime.

The stable bedding (consisting of horse manure and sawdust) produced by a horse farm is very loose. Can it be used directly for pelleting without special processing? Will this result in low production capacity?

+

This material can be used, but not “directly” without some form of conditioning. The loose, bulky nature of used stable bedding means it has a very low bulk density, which would lead to very low production capacity and poor pellet quality in a manure pelletizer. The key is proper pretreatment. The material must first be composted to stabilize it and break down some of the more resilient fibers.

After composting, it often needs to be shredded or crushed to achieve a uniform particle size. In many cases, it may also need further drying. Once processed to the correct moisture and particle size, this mixture pellets very well. Our engineers can design the necessary pretreatment line to transform your stable bedding into an ideal feedstock for pelleting, turning a waste product into a valuable commodity.

We are processing quail manure, a small but high-value raw material. We want the finished pellets to be of high quality. Can your manure pelletizer ensure a smooth appearance and low powder content in the pellets?

+

Yes, producing high-quality, polished pellets from valuable materials like quail manure is a specialty of our equipment. The smooth appearance and low powder content are achieved through precise control of the pelleting conditions in our manure making machine. We achieve this by using a ring die with a highly polished, smooth hole surface finish and the exact compression ratio for your material’s recipe.

This ensures the material flows smoothly through the die without tearing. Furthermore, our machines are equipped with adjustable cutters, allowing you to cleanly cut the pellets to a uniform length without creating fines. The result is a premium, dust-free pellet that maximizes the market value of your quail manure fertilizer.

When processing goose manure, we found that it contained a lot of feathers, which easily entangled the equipment. How does your manure pelletizer’s feed system handle this foreign material challenge?

+

Feathers are a known challenge in poultry manure processing. To address this, our manure processing machine line includes several protective measures. First, we recommend installing a powerful, standalone magnetic separator and a specific “tramp iron trap” in the feeding conveyor before the material reaches the pellet mill. More critically, the feed inlet to our pellet mill is designed to prevent bridging and wrapping.

For severe feather contamination, we can equip the feeder with a rotating “picker” mechanism that actively pulls feathers and long fibers into the pressing chamber without allowing them to entangle. Inside the chamber, the severe shear forces between the roller and die often shred the feathers, incorporating them into the pellet. A comprehensive solution starts with proper system design to protect the machine.

We plan to pelletize a mixture of pig manure, biogas residue, and furfural residue. These materials have very different physical properties. How can we determine the most appropriate ring die aperture and compression ratio?

+

This complex mixture is a perfect example of a project that requires expert engineering. The combination of wet biogas residue, fibrous pig manure, and often dry, fluffy furfural residue makes a one-size-fits-all approach impossible. At Richi Machinery, we determine the optimal parameters through a proven three-step process.

- First, we conduct a detailed physical and chemical analysis of your specific sample materials.

- Second, we use this data to run trials in our technical center on a pilot-scale manure pelletizer, testing different ring die specifications (e.g., 6mm or 8mm aperture, and compression ratios from 1:6 to 1:9).

- Finally, based on the trial results that produce the best pellet quality and output, we will specify and manufacture the custom ring die for your production machine. This scientific approach eliminates guesswork and ensures your success.

What are the key differences between a ring die pelletizer and a tooth agitator pelletizer for processing livestock and poultry manure? How should we choose?

+

This is a fundamental question for any fertilizer producer. While both can form granules, they are suited for different end goals. A tooth agitator granulator (or “new-type organic granulator”) works on a agglomeration principle, tumbling moist material to form soft, irregular balls. It is less sensitive to moisture and fiber but produces lower-density pellets that are prone to breaking down and are not ideal for long-distance transport or commercial sale.

In contrast, a ring die manure pellet mill uses extreme pressure to force material through a hardened steel die, creating dense, cylindrical pellets with a polished appearance. This process results in granules with high mechanical strength, low moisture content, and excellent storage and transport properties—essential for a commercial fertilizer product. For anyone serious about producing a high-value, marketable pellet from manure, the ring die pelletizer is the unequivocally superior and industry-standard choice. The tooth agitator is a low-cost option for on-farm, non-commercial use.

What is the level of automation in the manure pellet production line? Can the entire process, from feeding to finished product packaging, be fully automated? How many operators would be needed?

+

We offer varying levels of automation to match your investment and labor strategy. A fully automated manure pellet production line from Richi Machinery is absolutely achievable. This would involve PLC-controlled systems that link the feed rate of the mixer, the operation of the manure pellet mill (with automatic lubrication and load control), the cooler, the screener, and the packaging machine.

In such a setup, the primary role of the operators (typically 2-3 per shift) shifts from manual labor to monitoring the control panel, managing the raw material infeed, and handling packaged pallets. For smaller operations, we provide semi-automated lines where key processes are linked by conveyors but may require more manual intervention. We design the line to fit your operational philosophy.

If a small amount of stone or metal is accidentally mixed into the material, does the manure pelletizer have a self-protection device? Will the entire ring die be scrapped?

+

While a pellet mill itself is a powerful machine without a “clutch,” we build in crucial passive protection. The combination of a high-strength, forged alloy steel main shaft and a shear pin (or hydraulic coupling) in the drive train acts as the primary safety. If a non-compressible object like a stone or metal piece is caught, the immense torque will snap the shear pin, instantly stopping the transmission and preventing catastrophic damage to the gearbox or main shaft.

While this event may cause superficial scratching to the die surface, it is highly unlikely to scrap an entire ring die. The machine will need to be opened, the object removed, and the shear pin replaced—a relatively inexpensive and quick procedure. We strongly recommend pre-screening and magnetic separation to prevent these incidents altogether.

Can the particle size of the finished manure pellets be adjusted? Is replacing a ring die of a different size complicated, and how long does it typically take?

+

Yes, the final pellet diameter is determined solely by the hole size in the ring die. To change the particle size, you must replace the entire ring die with one that has the desired aperture (e.g., from 4mm to 6mm). The process of changing a die is a standard maintenance operation.

With proper tools and training, our machines are designed for efficient die replacement. For an experienced operator, the entire process—from shutting down the machine, removing the old die, installing the new one, and reassembling—typically takes between 1 to 2 hours. We provide detailed manuals and video guides to ensure your team can perform this task confidently.

Is the equipment noisy and dusty during operation? Do we need to equip the workshop with additional environmental protection equipment?

+

A operating manure pelletizer generates noise from the mechanical drive and the pelleting process itself, typically in the range of 85-95 dB(A). It also creates dust, primarily at the discharge point where hot pellets are cut. Therefore, we always recommend implementing basic environmental controls in your workshop.

This includes providing hearing protection for operators and installing a local exhaust hood above the pellet mill outlet connected to a simple bag-filter dust collection system. For the cooler and screener, we offer integrated cyclone or bag-house dust collectors. We consider these not as optional extras, but as integral components of a professional and responsible manure processing plant, and we include them in our plant layout designs.

If we want to expand from producing organic fertilizer to producing organic-inorganic compound fertilizer in the future, will the existing manure pelletizer still be suitable?

+

Definitely. This is a key strategic advantage of investing in a Richi ring die pellet mill from the start. Our manure pellet machines are designed to be highly versatile. The process of pelleting organic-inorganic blends is fundamentally the same; the machine simply applies high pressure to compact the mixed powder.

The inclusion of mineral fertilizers like N, P, and K may require us to supply a ring die with a different, more corrosion-resistant material (such as stainless steel) to handle the salt content, but the core machine itself remains perfectly suitable. This future-proofs your investment and allows you to diversify your product line as market demands shift.

In addition to the main machine, do the auxiliary equipment you provide (such as crushers and dryers) integrate seamlessly with the manure pelletizer? What is the approximate overall energy consumption?

+

As a turnkey project supplier, Richi Machinery’s core competency is the seamless integration of all equipment. We do not simply source individual machines; we design the entire system. This means the crusher’s output particle size is matched to the requirements of the pellet mill, the dryer’s capacity and temperature profile are calculated to prepare the material perfectly, and all components are connected with correctly sized conveyors and control systems.

This ensures smooth material flow and stable operation. Regarding energy consumption, for a complete line with a 1 ton/hour output, the total connected power is typically between 90-120 kW. For a 3 ton/hour line, it can range from 250-350 kW. The actual energy use depends on the specific raw material characteristics, but we provide detailed power calculations during the project proposal phase.

What does your technical training include? If the equipment malfunctions later, can you provide remote technical guidance or quickly supply spare parts?

+

Our technical training is comprehensive and hands-on. It typically covers: safe operation procedures, daily maintenance routines, troubleshooting common issues (like uneven feeding or low pellet hardness), and step-by-step guidance on critical tasks like ring die and roller replacement.

We conduct this training during the installation and commissioning phase at your site. For after-sales support, we have a 24/7 remote assistance program. Our engineers can connect via video call to help diagnose issues. Furthermore, we maintain a large stock of fast-moving spare parts (rollers, dies, shear pins, bearings) to ensure we can dispatch them to you within days, not weeks, minimizing your production downtime.

How to process organic manure pellets? Complete 6-8 t/h manure pellet process flow

+

The following will introduce the production process of manure organic fertilizer production line:

1. Raw material preparation

The raw materials of granular organic fertilizer mainly include animal and plant residues, agricultural waste, feces and other organic matter. During the production process, these raw materials need to be processed and processed.

First, the raw materials are crushed to make their particle size uniform; then, the crushed raw materials are composted, adding an appropriate amount of water and fermentation agent to promote the decomposition and transformation of organic matter; finally, the composted raw materials are screened and removed. Impurities, remove impurities and substances that are not conducive to particle formation.

2. Fermentation treatment

Composted raw materials need to be fermented. First, the raw materials are piled to form a certain compost volume. Then, by controlling the temperature, humidity, ventilation and other conditions of the compost pile, the decomposition and fermentation of organic matter are promoted.

During the fermentation process, the pile needs to be turned regularly to increase the supply of oxygen and accelerate the decomposition of organic matter and the fermentation rate. Through fermentation treatment, the organic matter in the raw materials is converted into stable organic fertilizer.

3. Granulation treatment

The organic matter after fermentation needs to be granulated. The purpose of granulation processing is to form organic materials into granules for easy storage, transportation and application. Granulation is usually carried out using a manure pellet mill.

- First, the fermented organic matter is ground to make its pellets uniform in size;

- then, the ground organic matter is mixed with a binder to increase the stability of the pellets;

- finally, the mixture is pressed and shaped through a manure pellet mill, forming pellet manure organic fertilizer.

4. Drying treatment

The granulated organic fertilizer needs to be dried. The purpose of drying treatment is to reduce the moisture content of the pellets and improve the stability and storage of the pellets. Usually a dryer is used for drying. The granulated organic fertilizer is put into the manure dryer, and the water inside the granules is evaporated by the action of hot air, so that the granules reach a certain moisture content. Dried organic fertilizer can be stored for a long time and is not easy to deteriorate.

5. Packaging and storage

The dried pellet organic fertilizer needs to be packaged and stored. It is usually packaged in sealed packaging materials such as plastic bags to prevent moisture and air from entering. Packaged organic fertilizers should be stored in a cool, dry, and ventilated warehouse away from direct sunlight and rain. At the same time, attention should be paid to moisture-proofing to prevent organic fertilizers from deteriorating and failing.

The production process of organic fertilizer pellets includes steps such as raw material preparation, fermentation treatment, granulation treatment, drying treatment, packaging and storage.

By controlling these steps scientifically and rationally, granular bio-organic fertilizers with stable quality and rich nutrition can be produced to provide effective nutritional supplements for agricultural production.

How to choose manure pellet mill?

+

The so-called manure pellet mill equipment selection is to select the best solution from a variety of different models and specifications of equipment that can meet the same needs and make a purchase decision through technical and economic analysis and evaluation. Reasonable selection of equipment can maximize economic benefits from limited funds.

The principles that should be followed when selecting compost granulating machine are as follows:

- The first thing to consider is its suitability for production. Only equipment that is suitable for production can achieve its investment effect;

- The second is technological advancement. Technical advancement must be based on production suitability and aim to obtain maximum economic benefits;

- Finally, unify production applicability, technological advancement and economic rationality.

Generally speaking, technological advancement and economic rationality are unified. Because technologically advanced equipment not only has high production efficiency, but also produces high-quality products.

01 Selection of main parameters of the equipment

① Productivity

The productivity of manure pellet mill equipment is generally expressed by the product output of the equipment per unit time (minutes, hours, shifts, years).

Equipment productivity must be compatible with the company’s business policy, factory planning, production plan, transportation capacity, technical strength, labor force, power and raw material supply.

You cannot blindly demand that the higher the productivity, the better. Otherwise, the production will be unbalanced and not only will not be able to give full play to the effect is to cause losses.

② Craftsmanship

The most basic thing about manure pellet mill is that they must meet the technical requirements of the fertilizer process. The ability of the organic fertilizer granulator machine to meet the requirements of the production process is called processability.

In addition to the basic requirements, the requirements for equipment operation and control are also very important. Generally, the manure pellet mill is required to be light in operation and flexible in control.

02 Equipment reliability and maintainability

① Equipment reliability is a prerequisite for maintaining and improving equipment productivity.

People who invest in equipment hope that the equipment can work without failure in order to achieve the expected purpose. This is the concept of equipment reliability. Reliability lies largely in equipment design and manufacturing. Therefore, the design and manufacturing quality of the equipment must be considered when selecting manure pellet mill equipment.

When selecting equipment reliability, it is required to make the mean failure interval of its main components as long as possible. Specifically, the safety factor, redundancy design, environmental design, component stability design, safety design and human resources can be selected from the equipment design. Analyze machine factors and other aspects.

With the continuous updating of products, the reliability requirements of equipment are also constantly increasing. Equipment designers and manufacturers should provide reliability indicators of product design to facilitate users to select manure pellet mill equipment.

② Maintainability of equipment

People always hope that the manure pellet mill equipment they invest in can be easily repaired once it breaks down, that is, the equipment has good maintainability. When selecting equipment, the maintainability of the equipment can be measured from the following aspects:

- The technical drawings and information of the equipment are complete. It is convenient for maintenance personnel to understand the structure of the equipment and is easy to disassemble and inspect.

- The structural design should be reasonable. The overall layout of the equipment structure should comply with the principle of accessibility. Each component and structure should be easily accessible for inspection and maintenance.

- Structure simplicity. On the premise of meeting the usage requirements, the structure of the equipment should be as simple as possible. The fewer parts that need to be repaired, the better. It should be easier to disassemble and quickly replace wearing parts.

- Principles of standardization and combination. The manure pellet mill equipment uses standard parts and components as much as possible, can be easily disassembled into several independent parts, devices and components, and can be assembled into a complete machine without special means.

- Advanced structure. The equipment should be designed using the principles of automatic adjustment, automatic wear compensation and preventive measures as much as possible.

- Condition monitoring and fault diagnosis capabilities. Instruments, meters, sensors and supporting instruments on the manure pellet mill equipment can be used to monitor the temperature, pressure, voltage, current, vibration frequency, power consumption, efficiency, automatic detection of finished products and equipment output parameter dynamics of relevant parts of the equipment to judge the technology of the organic manure making machine.

- Provide special tools and instruments, appropriate spare parts, or have convenient supply channels.

03 Equipment safety and operability

① The safety of equipment is the performance of the manure pellet mill equipment in ensuring production safety, that is, the equipment should have the necessary safety protection design and devices to avoid human and machine accidents and economic losses.

During equipment selection, if you encounter newly put into use safety protection components, you must ask them to provide experimental and usage reports and other information.

② The operability of manure pellet mill equipment belongs to the category of ergonomics. The general requirements are convenience, reliability, safety, and compliance with ergonomic principles. The main matters that usually need to be considered are as follows:

- The operating mechanism and its location comply with the requirements of labor protection regulations and are suitable for operators of average size.

- Fully consider the physiological limits of the operator, and do not allow the operator to withstand ultra-high physical limits of operating force, activity rhythm, movement speed, endurance, etc. within the legal operating time.

- The design of the equipment and its operating room must meet the requirements that are conducive to reducing the mental fatigue of workers.

04 Environmental protection and energy saving of equipment

The environmental protection of equipment usually refers to the degree of impact of its noise, vibration and harmful substance emissions on the surrounding environment. When selecting equipment, it must be required that its noise, vibration frequency and harmful substance emissions are controlled within the scope of national and regional standards. .

When selecting, no matter what type of enterprise, the manure pellet mill equipment purchased must comply with various standards and requirements stipulated in the “Energy Law” of the country where it is located.

05 Economy of equipment

The main economic factors that should be considered when selecting equipment include:

- Initial investment;

- Adaptability to the product;

- Production efficiency;

- Durability;

- Energy and raw material consumption;

- Maintenance and repair costs, etc.

The initial investment of manure pellet mill equipment mainly refers to purchase fees, transportation and insurance fees, installation fees, auxiliary facilities fees, training fees, customs fees, etc.

When purchasing manure pellet mill equipment, you cannot simply seek cheap prices and reduce the evaluation criteria of other influencing factors. In particular, you must fully consider the costs of downtime losses, maintenance, spare parts and energy consumption, as well as various management fees.

In short, the economic efficiency of equipment is measured based on the equipment life cycle cost, and the highest economic benefit of equipment investment is pursued on the basis of reasonable life cycle cost.

How to choose a manure pellet mill manufacturer?

+

The purchase of manure pellet mills is directly related to the production efficiency and product quality of the organic fertilizer production line. Therefore, it is particularly important to choose a suitable equipment manufacturer. RICHI will discuss the key factors that should be considered when choosing an organic fertilizer pellet machine manufacturer.

1. Understand the strength of the manufacturer

When choosing an equipment manufacturer, you must first understand its comprehensive strength. This includes the manufacturer’s production scale, technical level, research and development capabilities, market reputation, etc. You can comprehensively evaluate the strength of the manufacturer by visiting its production base, learning about its past project cases, and asking professionals in the industry.

2. Examine equipment performance

The performance of the equipment is directly related to the production efficiency and product quality of the manure pellet mill.

Therefore, when selecting equipment, an in-depth examination of its performance should be conducted. Including equipment stability, degree of automation, production efficiency, energy conservation and environmental protection, etc. At the same time, it is also necessary to consider whether the equipment complies with relevant national standards and regulations.

3. Consider after-sales service

The after-sales service of equipment is also an aspect that cannot be ignored when choosing a manufacturer. Excellent manufacturers should be able to provide complete after-sales services, including equipment installation and commissioning, operator training, regular maintenance, etc.

In addition, manufacturers should also be able to respond to customers’ maintenance needs in a timely manner to ensure that the fertilizer granulation equipment can operate stably during the production process.

Choosing a suitable manure pellet mill manufacturer requires comprehensive consideration of the manufacturer’s strength, equipment performance, after-sales service, price and cost-effectiveness, and innovation capabilities.

Only through comprehensive evaluation and careful comparison can you find the equipment manufacturer that best suits you and provide a strong guarantee for the long-term and stable operation of the organic fertilizer processing production line.

What is the prospect of manure organic fertilizer processing?

+

The so-called organic fertilizer made by manure pellet mill refers to natural fertilizer, which is widely used in agricultural production. It can improve the soil environment and allow crops to grow better. So what is the future of organic fertilizers?

01 Meet the demand for green and pollution-free food

It is of great significance to use organic fertilizers instead of traditional chemical fertilizers to provide a variety of nutrients to crops and improve the quality of agricultural products. Therefore, we should pay attention to the use of organic fertilizers, use organic fertilizers to meet people’s demand for green, pollution-free food, and make organic fertilizers more widely used in agricultural production.

02 The demand for organic fertilizers is increasing

Most countries around the world have agricultural sectors, and growing crops requires a huge amount of fertilizers. Moreover, with the rapid development of social economy, the development of organic agriculture and ecological agriculture is also gradually increasing. The market prospects for organic fertilizers are very promising.

03 Can reduce pollution

In rural areas, there are many natural fertilizers, that is, various animal feces produced by breeding enterprises, which are actually very good fertilizers. However, in the process of urbanization and the continuous large-scale development of agriculture, these organic wastes are considered It is a product of environmental pollution. Composting with organic fertilizers can mitigate the effects of these problems.

04 Improve soil environment

In recent years, soil pollution caused by traditional chemical fertilizers and excessive heavy metals in the soil have promoted the development space of my country’s organic fertilizer market. Moreover, the development of organic fertilizer industry is also one of the effective measures to prevent and control eutrophication of water bodies in my country.

05 Organic fertilizer has high nutritional content

Organic fertilizers made by manure pellet mill contain many types of nutrients, which can not only provide nutrients for crops, but also enhance their disease resistance, drought resistance, and waterlogging tolerance; they can increase production, improve crop quality, and improve food safety.

In the future, it is believed that organic fertilizers will slowly replace traditional fertilizers and be widely used in agricultural production. This shows that the market development potential of organic fertilizers is huge. (Find RICHI on YouTube)

What manure pellet mill projects have you worked on?

+

manure pellet mill In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: industrial waste

- project price: 80,000 USD

manure pellet mill In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: livestock manure

- project price: US$110,000

manure pellet mill In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: poultry litter

- project price: US$430,000

manure pellet mill In Lithuania

- Country: Lithuania

- Production: 35,000 T/A

- Ingredients: food waste

- project price: 410,000USD

manure pellet mill In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: chicken manure

- project cost: 570,000 USD

manure pellet mill In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- project cost: 190,000 USD

manure pellet mill In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: livestock manure

- project cost: $160,000

manure pellet mill In Pakistan

project cost: $385,000 USD

Country: Pakistan

Production: 30,000 T/A

Ingredients: cow manure, Bagasse

60000 +

Backed by a 60,000 m² advanced production complex

140 +

Global footprint extends across 140+ international markets

2000 +

Over 2,000 successful production system installations

2013

RICHI MANUFACTURE

Established in 1995, RICHI MACHINERY has grown from a medium-sized enterprise to become China’s largest pellet production line manufacturer. With two major manufacturing bases spanning hundreds of thousands of square meters, we specialize in custom pellet machines and complete plant solutions, handling every production stage in-house—from R&D to delivery.

Our vertically integrated facilities (including dedicated sections for production, testing, and logistics) ensure premium quality, environmental responsibility, and operational reliability for feed, biomass, and fertilizer industries worldwide. For nearly three decades, we’ve partnered with clients to enhance productivity, minimize risks, and achieve sustainable outcomes through innovative engineering.

Zhengzhou Headquarters

R&D, global operations and strategic management converge

Jiaozuo New Production Base (2025)

Featuring automated production lines and Industry 4.0 technologies

Kaifeng Original Complex (Since 1995)

Our manufacturing legacy began and quality traditions endure

Certifications & Patents

As a world-leading feed mill equipment manufacturer, RICHI Machinery demonstrates its engineering prowess through internationally recognized certifications and proprietary innovations.

Our ISO quality management system, CE compliance, BV-certified production processes, GOST-R for Russian compliance, ATEX explosion-proof certification for EU safety standards, FDA registration for U.S. market access, and EHEDG hygienic design certification validate our commitment to global standards, while 50+ patented technologies in pellet mills, extruders and automation systems deliver unmatched performance.

When you choose RICHI, you’re selecting globally validated, future-proof solutions backed by the industry’s most comprehensive certification portfolio.

01

Consultation

Our experts provide professional advice to understand your specific feed production requirements.

02

Design

We develop customized solutions with optimized layouts and equipment configurations for your project.

03

Manufacturing

All feed mill equipment is precision-built using quality materials in our ISO-certified factories.

04

Shipping

We handle secure packaging and global logistics with reliable delivery timelines.

05

Installation

Our engineers supervise on-site assembly and commissioning for smooth operation.

06

Training

Comprehensive operator instruction ensures proper use and maintenance of equipment.

07

After-sales

Dedicated support team provides troubleshooting and technical assistance.

08

Spare Parts

Genuine components are available worldwide with fast delivery service.