Compost Granulating Machine

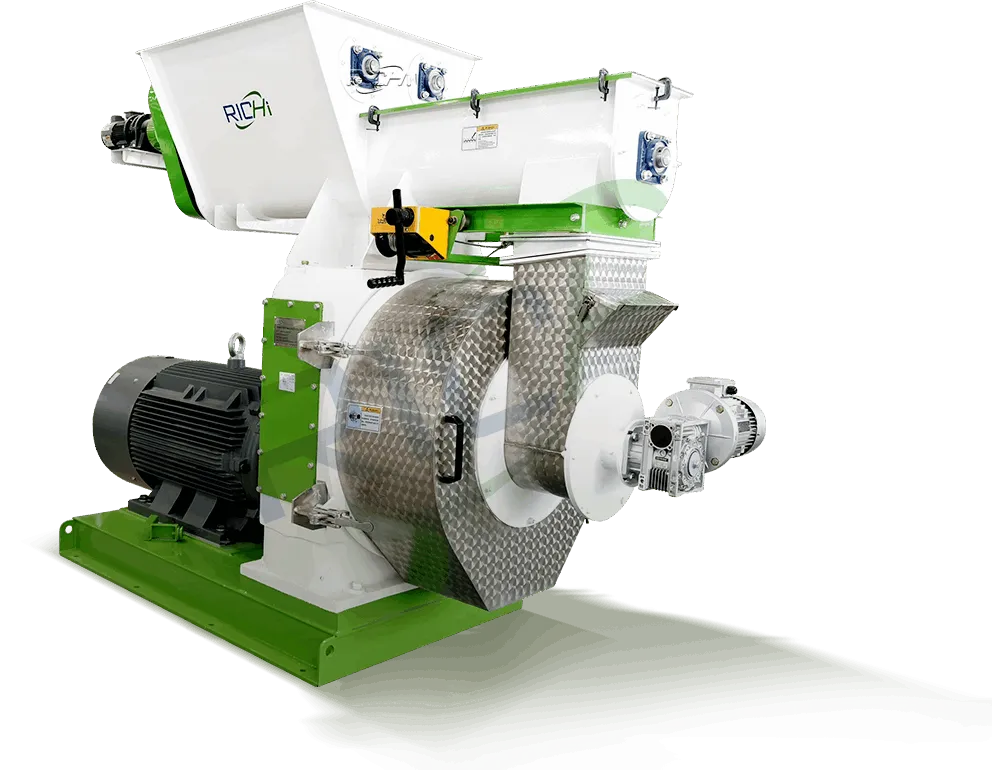

The FZLH520 compost granulating machine’s core mission is to transform organic waste, such as livestock and poultry manure and municipal garbage, into highly effective nutrients for the fields. It’s more than just a machine; it’s a “waste value conversion station.” This type of pellet mill can handle a production scale of 9-12 tons per hour.

Our compost granulators are widely suitable for processing various types of granular fertilizers, including pure organic fertilizer, compound fertilizer, and organic-inorganic compound fertilizer.

what is a compost granulator?

Utilizing advanced die-cutting granulation and microbial fermentation technology, our compost granulating machine precisely simulates and accelerates the natural decomposition process of organic matter, transforming coarse compost into uniform, nutrient-rich commercial organic fertilizer. Whether used for grain fields, fruits and vegetables, or flowers, the resulting granular fertilizer provides the comprehensive nutrients necessary for crop growth.

Choosing this RICHI machine, crafted with high-quality materials and advanced design, means you’re choosing the dual guarantee of high production capacity and quality, truly transforming waste into an agricultural treasure.

Applicable Raw Materials

Our compost granulating machine can process a wide range of raw materials, primarily livestock and poultry manure, straw, kitchen waste, municipal sludge, industrial waste, and other organic waste. After sufficient fermentation, these materials can be processed into uniform, high-quality organic fertilizer that is easy to apply.

Whatever Your Raw Materials, Finish the Job with RICHI compost granulating equipment!

Why process compost into compost granules ?

Technological features

Whether you’re planning a new plant or upgrading an existing fertilizer plant, the Compost Granulator is the ideal solution tailored to your needs. Its value lies in elevating organic fertilizer production to a new level of standardization.

The efficient ring die pelletizing system not only produces solid cylindrical pellets, but also offers the flexibility of an optional rounding device, allowing cylindrical pellets to be rolled into spheres in one go. This results in a high pelletization rate, excellent strength, and an aesthetically pleasing and practical appearance.

This directly translates into a wider range of product forms, higher product value, and greater market competitiveness. Choosing this RICHI machine means choosing a reliable path to increasing production capacity, optimizing product mix, and ultimately achieving a higher return on investment.

Core Power and Transmission

The core of the machine utilizes a Siemens motor, ensuring smooth and powerful power output. The transmission system utilizes carefully selected brand bearings and a multi-combination seal structure, fundamentally guaranteeing long-term operational stability and an exceptionally long service life.

Intelligent Lubrication and Maintenance

The standard automatic grease lubrication system provides timed and quantitative lubrication of core components. A motorized die roller assembly and disassembly device makes ring die and pressure roller replacement and maintenance extremely easy and quick, significantly reducing maintenance time and labor costs.

Safe Sealing and Control

The feeding port features an adjustable soft seal structure, effectively preventing steam and dust leakage. The door of this compost granulating machine cover utilizes a new door hinge with integrated mechanical protection and an emergency stop switch, ensuring convenient opening and closing while prioritizing operational safety.

High-Efficiency Pelletizing Assembly

The core ring die is constructed of high-quality alloy steel and reinforced through a special process, making it wear-resistant and corrosion-resistant. A unique roller-die gap adjustment mechanism ensures uniform and compact pellets. An optional oil circulation cooling system is designed specifically for high-intensity continuous production.

WORKING

PRINCIPLE

The core of our compost granulating machine lies in its “gentle yet powerful” physical compaction process. It uses precisely controlled mechanical pressure to directly compress loose powdered organic fertilizer raw materials into dense, solid granules. This process requires no chemical binders or external heating, perfectly preserving the organic matter and active ingredients in the raw materials.

Technical Parameters of FZLH520

For complete technical specifications, please contact us directly online.

Main Motor Powerr

132kw

Forced Feeder Power

1.5kw

Finished Pellet Diameter

4-12mm

Capacity

9-12T/H

Ring Die Diameter

520

advantages of compost granulating machine

The essence of compost organic fertilizer is to return to the natural cycle and infuse the soil with vitality. Our compost granulator deeply understands this concept. It is dedicated to efficiently and mechanizedly transforming organic materials such as animal and plant residues, livestock and poultry manure, and crop straw into a form optimal for soil absorption: granular organic fertilizer.

This process simulates microbial decomposition, releasing mineral elements and providing comprehensive nutrients for crops. We manufacture more than just a machine; it’s a vital tool for modern green agriculture. The high-quality granules it produces are both aesthetically pleasing and practical, making it an ideal device for achieving sustainable agricultural development and improving soil fertility, helping you realize the significant impact of organic fertilizer on agricultural production.

Efficient Forming, Meet Standards in One Go

This compost granulating machine utilizes a room-temperature direct granulation process, eliminating the need for additional drying. High-intensity extrusion forms the material in one go, resulting in firm, uniform pellets with an extremely high pelletization rate. The finished product directly meets all technical specifications for organic fertilizer, saving time and effort.

Excellent Production Capacity, Compatible with Production Lines

The scientifically designed compost granulating equipment features a compact and rational structure, offering outstanding single-machine output. It easily coordinates with upstream and downstream equipment, seamlessly integrating into continuous production lines, fully meeting your stringent requirements for large-scale, uninterrupted production.

Energy-Efficient and Durable, with Significant Benefits

The optimized design of the core power and transmission system significantly reduces energy consumption compared to similar equipment. Furthermore, key components are constructed of high-strength, wear-resistant materials, resulting in a low failure rate and a long service life, providing greater long-term economic benefits.

Flexible Application, Multi-Purpose Machine

The hydraulic system allows precise adjustment of extrusion intensity, easily adapting to varying material and process requirements. Suitable not only for organic and compound fertilizers, but also for a variety of applications in feed, biomass fuel, and other industries, achieving multi-functionality and doubling your investment value.

More specifications available

From start-up farms to large-scale compost granular fertilizer processing, our granulation technology meets production needs at all levels. Our product line covers a wide output range from 1 to 26 tons per hour, backed by a mature and scalable machinery manufacturing platform. Whether you need to process livestock manure or straw and food waste, we offer core equipment from pilot lines to continuous industrial production lines, ensuring your project can smoothly transition from pilot to full-scale production.

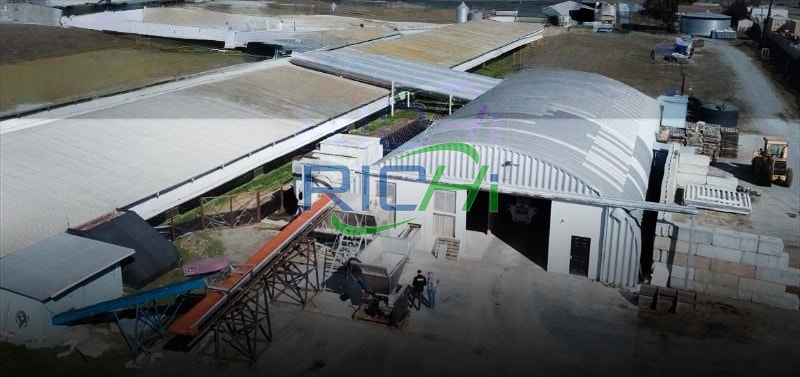

compost granulating machine project

Globally Trusted Organic Fertilizer Granulation Solutions

Our footprint spans dozens of countries and regions. From large-scale farms in Southeast Asia to environmental projects in Europe, from municipal sludge treatment in North America to sugarcane bagasse resource utilization in South America, our equipment, with its stable and reliable performance, transforms a wide range of organic waste into “black gold” worldwide.

Whether it’s manure from livestock and poultry farming groups, off-cuts from fruit and vegetable markets, municipal sludge, or organic waste from alcohol and sugar refineries, our production lines have successfully handled them all. We deliver far more than just a pelletizer; we deliver complete production lines from crushing, fermentation, mixing, pelletizing, cooling, and packaging. We are also highly flexible in project scale. We have provided turnkey 20-ton-per-hour production lines for industrial-scale plants with an annual output of 10,000 tons, as well as compact and efficient solutions with a 1-ton-per-hour output for family farms focused on recycling.

France

animal manure compost granulator

Serving an intensive dairy farm in Normandy, France, this system is specifically designed to convert the large amount of daily manure produced into high-quality bedding and soil conditioner, achieving internal recycling within the farm.

Australia

sheep manure compost granulator

Customized for a large sheep farm in South Australia, this system’s core task is to process accumulated sheep manure into granular organic fertilizer that is easy to transport and sell, successfully opening up a new revenue stream.

Canada

poultry manure compost granulator

Installed at an integrated poultry operation, this system efficiently processes poultry manure. The resulting granular fertilizer is primarily supplied to surrounding blueberry and greenhouse vegetable plantations.

Mexico

kitchen waste compost granulator

Helping an environmental technology company in Mexico City convert centrally collected food waste into a stable granular fertilizer, effectively supporting the local municipal waste reduction program.

United States

chicken manure compost granulator

A large laying hen farm in the Midwest of the United States uses this system to convert chicken manure into low-odor, pathogen-free, standardized commercial organic fertilizer, solving its biggest environmental challenge.

Brazil

organic waste compost granulator

This system, supplied to a bioenergy company, processes the waste residue (filter mud and bagasse) produced after sugarcane extraction into high-calorific value biomass fuel pellets, realizing the energy utilization of waste.

South Africa

livestock manure compost granulator

Serving a renowned winery in the Western Cape Province of South Africa, this project specifically processes the large amount of grape pomace produced after winemaking, converting it into nutrient-rich, specialized horticultural fertilizer.

Thailand

cow dung compost granulator

A cooperative in Nakhon Ratchasima Province, Thailand, has installed this production line to centrally process cattle manure from scattered farmers, producing standardized organic fertilizer that benefits local rice and fruit cultivation.

Türkiye

chicken manure compost granulator

A poultry farming group in Bursa, Turkey, has adopted this equipment, which not only achieves harmless treatment of chicken manure but also increases product value through pelletization. The fertilizer is now exported to the Middle Eastern market.

Global project experience and customized solutions

Regardless of your production scale, we offer precisely matched solutions. Our comprehensive line of compost granulating machines offers standard outputs ranging from 1 to 26 tons per hour, offering a full range of options for compact to large-scale production. You don’t need to overspend or compromise on inappropriate production capacity. We can work with you to select the perfect, efficient equipment based on your raw material characteristics, investment budget, and production goals.

Customer Testimonials

From South American estates to Eastern European farms, from Southeast Asian plantations to Middle Eastern agribusinesses, our equipment, with its exceptional reliability and adaptability, has become the preferred choice for customers operating in diverse climates and using a variety of raw materials. These genuine feedback from the field is the strongest testament to our product value and technological strength.

Customer from Ecuador

This compost granulating machine has completely changed the fertilizer model for our rose plantation. It perfectly combines our own plant residue with a small amount of livestock manure to produce a long-lasting granular fertilizer, which has improved the quality of our roses by at least 20%.

Russian Customer

Raw material: Wheat Straw, Livestock Manure

Production capacity: 10T/H

Under harsh climatic conditions, the compost granulating equipment’s stability and ability to process high-fiber raw materials are crucial. It successfully converts our farm’s straw and livestock manure into standard fertilizer, helping us achieve a sustainable agricultural cycle in the region.

Customer from Iraq

We introduced this compost manufacturing plant to address the massive amount of waste date pits and palm leaves generated annually by the date palm industry. It not only addresses environmental concerns but also creates a new soil conditioner product, which has been very well received by the market.

Customer from Romania

Raw material: Mixed livestock manure (cattle, sheep, poultry)

Production capacity: 10T/H

Our cooperative unites hundreds of small-scale livestock farmers. This organic compost granulator helps us achieve unified manure processing and commercialization. Its flexible formulation capabilities allow us to produce customized fertilizers based on customer needs.

customized compost granulation system design

We offer far more than just a single pelletizer; we provide a complete compost granulation production line solution tailored to your specific raw materials, production capacity targets, and site conditions. Your compost granulation flow chart should be unique. Whether processing chicken manure, straw, or municipal sludge, we intervene from the initial consultation phase to design the most cost-effective process path.

This encompasses the entire process, from fermentation, crushing, batching, and granulation to cooling, screening, and packaging, ensuring that the final compost granulation equipment setup perfectly matches your production needs. Our partnership spans the entire equipment lifecycle. From concept design, equipment manufacturing, installation, and commissioning, to operator training and ongoing spare parts supply, we provide one-stop support. This ensures that your investment is not only in advanced compost granulation technology, but also in the guarantee and commitment of long-term stable production.

compost granulator

efficiently converting

pretreated raw materials

into standard granules.

The compost granulation process flow reflects our precise control over efficiency and cost, ensuring the delivery of a stable, high-yield, and sustainably profitable manure pellet production line.

Professional Guarantee from Single Machine to whole System

We not only provide high-performance pelletizing machines, but also specialize in configuring the most optimized complete compost granulating line solution based on your raw material characteristics and production capacity goals. From raw material pretreatment to finished product packaging, each supporting equipment works precisely with the pelletizer to ensure the entire line operates like a precision instrument.

From raw material processing equipment like pulverizers, turners, and mixers to pelletizing equipment like dryers, coolers, and screens, we offer a complete range of equipment for fermentation, blending, forming, finishing, and packaging. Our comprehensive conveying systems and automated packaging scales ensure efficient and seamless operation of your production line. We offer manual, semi-automatic, and fully automated solutions.

Compost Granulating Machine FAQs

Before investing in compost granulating machinery, thoroughly understanding the details is crucial for success. We’ve compiled some of our customers’ most common practical questions and provided professional answers to help you make the most informed decision.

What’s the compost granulator machine price?

+

The price of compost granulator machine FZLH520 is generally 40,000-50,000 USD

There are many factors that affect the price of compost granulators. These factors cover everything from the quality of the equipment to market demand. The following are some of the main factors that affect the price of manure granulator:

Market demand and competition: Market demand and competition will also directly affect the price of organic fertilizer granulator. In a highly competitive market, prices may decrease due to competition; in a market with strong demand, prices may increase.

Equipment standards and models: Organic compost pellet making machines of different standards and models have different performances and capacities, so the prices will also be different. Generally speaking, the price of large and high-capacity organic fertilizer granulators will be higher than that of small equipment.

Manufacturing process and materials: The manufacturing process and materials used in the fertilizer granulator machine will directly affect the quality and life of the equipment. High-quality craftsmanship and durable materials will increase the price of the device.

Technological innovation and automation level: The machines with newer technology and higher automation levels generally have higher production efficiency and lower failure rates, so the price will increase accordingly.

Brand and reputation: Organic fertilizer granulation machines produced by well-known brands and manufacturers with excellent reputation may be more expensive, but they generally mean more reliable quality and excellent after-sales service.

What are the detailed technical parameters of the FZLH520 compost granulating machine?

+

| Model | FZLH520 |

| Output (t/h) | 9-12 |

| Main motor power (kw) | 132 |

| Main motor series | 8P |

| Ring die diameter (mm) | 520 |

| Finished pellet diameter (mm) | 4-12 |

| Device Configuration | Ring die material: 42CrMo Stainless steel feeder: with anti-caking function Door of pelleting room: 6mm /SUS304 Forced feeding: Worm gear reducer Gear box: HT250 Gear: 42CrMo Gear shaft: 42CrMo Spindle: 42CrMo Empty shaft: 42CrMo Bearings: The gear shaft and main shaft bearings are SKF, and the pressure roller bearings are domestic high-quality bearings Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Lubrication system: Configurable automatic oil injection system |

What raw materials are suitable for a compost granulating machine?

+

Our compost granulating equipment is highly versatile and can process a wide range of organic materials after proper fermentation. This includes all types of livestock manure (chicken, cattle, pig, sheep), agricultural waste (straw, rice husks, bagasse), municipal sludge, food waste, garden waste, mushroom residue, and distillery grains. The key is achieving the correct moisture content and particle size before granulation, which our engineers can guide you on.

Who is the ideal customer for a compost granulating machine and production line?

+

Our clients range from individual farmers to large corporations. Ideal candidates include:

Agro-Industrial Processors (e.g., sugar mills, distilleries): To valorize their organic by-products.

Livestock & Poultry Farms: To manage manure and create a new revenue stream.

Organic Fertilizer Producers: To create commercial-grade pelletized products.

Municipalities & Waste Management Companies: To recycle green waste and sludge into useful soil amendments.

Agricultural Cooperatives & Large Plantations: To achieve self-sufficiency in fertilizer production.

Our cattle farm has a lot of wet manure. Can your compost granulating machine process it directly, or must it be dried first?

+

For a successful compost granulation process, the raw material moisture must be precisely controlled. High-moisture fresh manure will clog the machine. The material must first go through a composting and fermentation phase to stabilize it. After fermentation, if the moisture is still above the ideal range (typically 25%-35%), you will need a dryer before the granulation step. We include this critical pre-conditioning in our compost granulation system design to ensure your line runs smoothly.

My main raw material is a mix of chicken manure and straw. Will the compost granulating machine clog easily? Are there special requirements for crushing fineness?

+

A chicken manure and straw mixture is an excellent feedstock for our compost granulator equipment. The straw adds fiber, which can actually aid in forming stable pellets. To prevent clogging, the straw must be finely crushed to a particle size of generally less than 2mm. This ensures a homogeneous mix that flows easily through the die holes of our compost granulating machine. Our vertical crushers are perfectly suited for this preparatory task.

We are a municipal sludge treatment plant. Can your compost granulating machine handle such high-viscosity material?

+

Yes, we have extensive experience in designing compost granulation systems for municipal sludge. High-viscosity materials require specific adjustments to the compost granulator process, such as a specially designed feeding system and potentially a different die-hole configuration to prevent binding. We often recommend our new type compost granulator for such challenging materials, as it incorporates features to handle high adhesion.

For my small family farm using food and garden waste, do you have a small farm compost granulator with a capacity of around 1 ton per hour?

+

Absolutely. Our FZLH250 model compost granulator is an ideal solution for small to medium-scale operations like yours. It has a capacity of 1-1.5 tons per hour, making it a compact yet powerful automatic compost granulator perfect for turning your compost into valuable, easy-to-use pellets.

The bagasse from our sugar mill is very fibrous. What is the pellet formation rate like, and will it be very power-intensive?

+

Bagasse’s high fiber content can lead to excellent pellet strength if processed correctly. The formation rate is high with the right equipment setup. While fibrous materials do require more compression force, leading to a slightly higher power consumption than softer materials, our compost granulating machine is engineered for high torque and energy efficiency. The overall power cost remains manageable, especially when considering the value of the final product.

We want to use distiller’s grains, but they are acidic. Will this corrode the ring die and rollers of the compost granulating machine?

+

This is a valid concern. For acidic materials like distiller’s grains, Ricchi Machinery strongly recommends using ring dies and rollers made of stainless steel or alloy steel with high corrosion resistance. While this represents a higher initial investment, it dramatically extends the service life of these core components, protecting your compost granulator equipment from premature wear and failure.

How do we pre-process spent mushroom substrate to use it in your compost granulating machine?

+

Spent mushroom substrate is a great material. The pre-processing is straightforward: first, you need to break up the clumps, for which a crusher or grinder is ideal. Then, the most critical step is adjusting the moisture content to the optimal range for granulation. If it’s too dry, a small amount of water can be added during mixing. Our team can provide a detailed compost granulation flow chart specific to your substrate.

My raw materials are very diverse, including various manures and agricultural waste. If my formula changes frequently, is it troublesome to adjust the equipment?

+

One of the key advantages of our compost granulation system is its flexibility. For changes in the raw material recipe, no mechanical adjustment to the granulator itself is typically needed. The process is controlled by the mix you create before it enters the machine. As long as the mixed material’s physical properties (moisture, particle size) are within the optimal range, our automatic compost granulator will produce consistent pellets without requiring recalibration for each formula change.

How to process compost granules? Complete 9-12 T/H compost granulation process

+

Want to transform organic waste like livestock manure and straw into high-value fertilizer pellets? Our compost pelleting line integrates proven compost pelleting technology. Below is a detailed explanation of the core compost pelleting steps.

1. Fermentation Pretreatment

Livestock manure, plant straw, and other raw materials are mixed in appropriate proportions and fully aerobic fermented through composting or trough fermentation. Precise control of temperature, humidity, and ventilation during this stage is crucial for the microbial decomposition of organic matter.

2. Raw Material Processing

The fermented and mature compost is first screened to thoroughly remove impurities such as rocks and plastic. It is then finely crushed in a pulverizer to ensure uniform particle size, paving the way for high-quality pelleting.

3. Scientific Formulation and Mixing

Based on the target crop and soil requirements, the crushed compost base is formulated with a specific ratio, and NPK, trace elements, or functional microbial agents are added. A high-efficiency mixer ensures even nutrient distribution.

4. Core Granulation

The uniformly mixed powdered material is fed into the compost granulating machine, where it is extruded and shaped under the mechanical pressure of a ring die and rollers, producing cylindrical pellets with high density and good strength. This compost pelletizing process requires no heating, preserving the active organic matter to the greatest extent possible.

5. Post-Pellet Processing and Packaging

Pellets fresh from the pelletizer have a high moisture content and require drying and cooling to enhance their hardness for storage. Finally, the finished product is weighed, sealed, and stored in a cool, well-ventilated area via an automated packaging system.

6. Optional Value-Added Processes

Spheronization: To meet market preferences for spherical pellets, a spheronization device can be added after pelletizing to roll cylindrical pellets into smooth, rounded spheres, resulting in a superior appearance and increased strength.

Surface Coating: To effectively prevent pellet agglomeration, lock in nutrients, or add functional substances such as probiotics, a spraying system can be installed to evenly coat the pellet surface with a protective layer or active ingredients.

For granulating fibrous compost from city green waste, does your compost granulating machine require a special ring die?

+

or standard fibrous materials like composted leaves and branches, our standard ring dies are perfectly adequate and do not require a special type. Our compost granulator equipment is designed with a deep die-hole engagement and optimal compression ratio to handle fibrous materials effectively, ensuring a high-quality, durable pellet.

Our pig farm plans to set up a 5 t/h compost granulation plant. Besides the granulator, what other key equipment is essential for continuous production?

+

A complete and efficient 5 t/h compost granulation plant requires a coordinated system. The essential equipment includes:

Auxiliary: Belt conveyors to link all stages and an automatic packaging scale.

We at Ricchi Machinery provide the entire compost granulation equipment setup as a turnkey solution.

Pre-processing: A crusher and a mixer to prepare the feedstock.

Granulation: The core compost granulating machine.

Post-processing: A dryer to reduce moisture, a cooler to harden pellets, and a screening machine to separate fines from finished pellets (which are recycled).

What is the cost of a compost granulation plant?

+

The cost of a compost granulation plant varies significantly based on capacity, automation level, and specific equipment configuration. For reference, a small-scale line might start around $40,000, while a large, fully automated system can exceed $1,500,000.

The most accurate way to determine the compost granulator price is to consult with our engineers. They will design a customized solution based on your raw materials and output goals, providing a transparent and detailed quotation for the entire compost granulation production line.

What is the lifespan of the core components of a ring die compost granulating machine, and what is the approximate cost to replace a ring die or roller?

+

The lifespan of a ring die and rollers depends heavily on the abrasiveness of your raw materials. Under normal conditions, a ring die can last between 1 to 3 years, while rollers may last 0.5 to 2 years. Replacement costs are tied to the machine’s size. For a mid-range machine (e.g., 5-6 t/h), a new ring die can cost between $3,000 and $8,000, and a set of rollers between $1,500 and $4,000. Using high-wear, resistant materials can extend this lifespan considerably.

Are the technical requirements high for operating a compost granulation machine? Do you provide training?

+

Our automatic compost granulator is designed for user-friendliness. The technical requirement for daily operation is not high. However, we insist on providing comprehensive training for all our clients. This covers operation, routine maintenance, troubleshooting, and safety procedures. We ensure your team is fully confident in running the compost granulator equipment before we leave the site.

What is the typical delivery cycle from order placement to installation and commissioning for a compost granulator machine?

+

The delivery cycle depends on the complexity of your order. For a standard compost granulating machine, delivery is typically 15-30 days. For a complete, custom-designed compost granulation production line, the timeline is usually 30-60 days. This includes manufacturing, factory testing, and shipping. We always provide a clear project timeline after order confirmation.

If the compost granulating machine breaks down during production, what kind of technical support and emergency guidance can you provide?

+

Richi Machinery offers robust, multi-level support. We provide 24/7 online technical support for immediate remote troubleshooting. For issues that cannot be resolved remotely, we have a global network of service engineers and can dispatch a specialist to your site. Furthermore, we maintain a comprehensive inventory of common spare parts to minimize your downtime, ensuring you get the full value from your compost granulator equipment.

Our local climate is very humid. How can we prevent the finished pellets from absorbing moisture and caking? Does the compost granulating machine itself offer a solution?

+

While the granulator itself forms the pellets, the solution to moisture absorption lies in the integrated compost granulation system. We equip our production lines with an optional coating machine. After cooling, pellets pass through this unit, where a fine powder or liquid anti-caking agent is applied, creating a protective layer that effectively prevents moisture absorption and caking during storage.

What specific designs does your compost granulating machine have to address dust and noise issues?

+

Our compost granulating equipment incorporates several features for a cleaner, quieter operation. The feeding system uses adjustable soft seals to minimize dust and steam leakage at the inlet. For noise control, the heavy-duty gearbox is precision-machined for smooth, quiet operation, and the entire machine features a robust construction that minimizes vibration, a primary source of noise.

The voltage at our factory is unstable. Will this affect the normal operation and pellet quality of the compost granulating machine?

+

Yes, unstable voltage can be detrimental. It can cause inconsistent motor speed, leading to variations in the compression force inside the compost granulating machine. This results in poor pellet formation, low yield, and even machine jamming. We strongly recommend installing a voltage stabilizer or variable frequency drive as part of the installation.

Besides organic fertilizer, can this compost granulating machine also be used to produce biomass fuel pellets?

+

Yes, absolutely. The fundamental principle of compressing dry, powdered material is the same. Our compost granulating machine is a versatile piece of compost granulator equipment that can easily produce biomass pellets from materials like sawdust, straw, and other agricultural residues. Often, only a change in the ring die specification is needed to produce the desired pellet diameter for fuel.

What is the power of your equipment? We want to evaluate the energy cost of the compost granulator production line.

+

The power consumption is directly related to the production scale. The main motor power for our granulators ranges from 22 kW for our smallest model (FZLH250, 1-1.5 t/h) up to 250 kW for our high-capacity models (FZLH768).

However, evaluating the energy cost of the entire compost granulator production line is more complex, as it must include all auxiliary equipment like crushers, mixers, dryers, and conveyors. We provide a detailed power consumption breakdown for the entire proposed system during the project quotation phase.

If I want to expand production capacity in the future, is the compost granulator equipment I buy now support subsequent upgrades and expansion?

+

We design our compost granulation systems with scalability in mind. While the granulator itself has a fixed maximum capacity, the overall production line can be designed for future expansion.

This can involve oversizing certain auxiliary equipment (like mixers and dryers) initially or planning the layout to easily add a second, larger compost granulating machine in the future. Discussing your long-term vision with our engineers during the initial design phase is the best way to ensure a future-proof investment.

How to choose compost granulating machine?

+

Today, when green and organic agriculture are receiving increasing attention, the demand for organic fertilizer manufacturing equipment is also growing. So, how to choose an organic fertilizer manufacturing equipment with reasonable price and high quality?

1. When choosing compost granulating machine, you must not only consider the price, but also consider the following factors:

- Applicability: Choose the appropriate organic fertilizer pellet mill model and size according to your own needs to avoid being too large or too small.

- Production capacity: Select appropriate equipment production capacity based on expected production scale and market demand.

- Finished product quality: Ensure that the finished product quality of the equipment meets the requirements, such as moisture content, nutrient content, etc.

- Energy consumption and maintenance costs: Consider the energy consumption and maintenance costs of the equipment, and try to choose energy-saving and easy-to-maintain equipment.

- Reliability: Choose brands and models with advanced technology and reliable quality to ensure the stability and durability of the compost granulating machine.

- After-sales service: Choose brands and manufacturers with good after-sales service so that problems can be solved in time.

2. Here are some suggestions for purchasing compost granulating machine:

Market development and promotion: In terms of product sales and promotion, actively explore the market, broaden sales channels, and increase product visibility and reputation.

Understand market information: Before purchasing equipment, fully understand the market information, compare the fertilizer granulation equipment prices and performance of different brands and models, and be aware of it.

Budget and return on investment: Develop a reasonable budget and consider the return on investment cycle to avoid blindly pursuing low prices and ignoring long-term benefits.

Manufacturer direct sales are preferred: Choose to purchase equipment directly from the manufacturer to avoid middlemen and get more favorable prices and better after-sales service.

Inspect prototypes and cases: Go to the compost granulating machine manufacturer to inspect prototypes and cases to understand the actual situation of the equipment and increase trust.

Signing the contract and retaining the balance: When signing the contract, clarify the rights and obligations of both parties, and retain a certain proportion of the balance as a quality deposit.

Purchase accessories and services: Purchase relevant accessories and services as needed, such as dust collectors, control systems, etc., to improve the overall performance of the equipment.

Gradual upgrade and optimization: Based on actual production experience and technological development, gradually upgrade and optimize equipment to improve production efficiency and product quality.

Follow policy and industry trends: Pay attention to relevant policy support and industry trends to keep abreast of market changes and new technology applications.

Establish cooperative relationships: Establish long-term cooperative relationships with excellent compost granulating machine manufacturers to jointly carry out technology research and development and product upgrades to achieve mutual benefit and win-win results.

Environmental awareness: When purchasing manure pellet mill equipment, pay attention to environmental indicators and choose equipment that meets environmental requirements to reduce the impact on the environment.

Personnel training and technical support: After purchasing equipment, timely personnel training and technical support are provided to ensure smooth operation and maintenance.

Regular inspection and maintenance: Regularly inspect and maintain the equipment to ensure normal operation and extend service life of the equipment.

Pay attention to waste utilization: When using compost granulating machine to process waste, pay attention to the utilization value of the waste and look for more application scenarios and business opportunities.

What special compost granulating machine projects have you worked on?

+

compost granulating machine In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: industrial waste

- project price: 80,000 USD

compost granulating machine In Mexico

- Country: Mexico

- Production: 10,000 T/A

- Ingredients: livestock manure

- project price: US$110,000

compost granulating machine In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: poultry litter

- project price: US$430,000

compost granulating machine In Lithuania

- Country: Lithuania

- Production: 35,000 T/A

- Ingredients: food waste

- project price: 410,000USD

compost granulating machine In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: chicken manure

- project cost: 570,000 USD

compost granulating machine In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: animal manure, straw

- project cost: 190,000 USD

compost granulating machine In canada

- Country: canada

- Production: 6,000 T/A

- Ingredients: livestock manure

- project cost: $160,000

compost granulating machine In Pakistan

- project cost: $385,000 USD

- Country: Pakistan

- Production: 30,000 T/A

- Ingredients: cow manure, Bagasse

How to choose compost granulating machine manufacturer?

+

Which compost granulator manufacturer is better and how to choose?

With the continuous promotion of organic fertilizers in agricultural production, the proportion of organic fertilizers in the fertilizer market is also increasing year by year. However, organic fertilizer manufacturers are still in the development stage, with a small number of manufacturers, small production scale, and relatively low quality organic fertilizers. Therefore, more and more investors are investing in the organic fertilizer industry.

The investment in an organic fertilizer production line is relatively large. How to choose a strong compost fertilizer equipment manufacturer and a high-quality organic fertilizer production line to ensure the stable and efficient production of organic fertilizer has become a problem that these investors need to consider. Let’s talk about this topic next.

When purchasing organic fertilizer granulator machine, it is best to conduct an on-site inspection. Only after passing the on-site inspection can you choose the correct manufacturer and product through your own observations.

- First of all, need to check the strength of the compost granulating machine manufacturer. Only a regular large manufacturer has the strength to produce professional organic fertilizer equipment or large-scale organic fertilizer production lines. After all, the cost of making these equipment is relatively high.

- Secondly, it depends on whether the manufacturer has advanced processing equipment or a group of professional engineers. Only professional and technical personnel can make the product’s functions perfect and minimize errors.

- Then it also depends on whether the manufacturer has successful cases and how many successful cases there are. Manufacturers with successful cases must have certain experience and can help you formulate and assist you in establishing an organic fertilizer factory.

- There is also after-sales service from the organic manure making machine manufacturer. The purpose of establishing an organic fertilizer factory is to ensure long-term and stable production. After any equipment has been running for a long time, some problems or failures will inevitably occur. Only perfect after-sales service can handle and solve these problems in a timely manner. problems or failures to ensure the normal and stable operation of the organic fertilizer factory.

In general, choosing a suitable organic manure making machine manufacturer is an important guarantee for the stable operation of the production line and improving production efficiency. If you have any questions about the organic fertilizer granulator, please feel free to consult Richi Machinery directly online!

How does a compost granulator work?

+

At its heart, a compost granulator (or pellet mill) works by squeezing dry, powdered compost under immense pressure to form dense, uniform pellets. Think of it like a giant “play-doh fun factory” for organic fertilizer. It doesn’t use heat or chemical binders; it relies purely on mechanical pressure and the natural lignins and plasticity within the compost itself.

The Step-by-Step Process Inside a Ring Die Granulator

This is the most common industrial type. Here’s the compost granulator working principle:

Step 1: Feeding the Powder

Finely crushed and dry compost powder is fed into a hopper at the top of the machine. An internal screw feeder (or “feeder scraper”) then consistently and evenly delivers this powder into the machine’s pressing chamber.

Step 2: The Heart of the Action – The Pressing Chamber

Inside the chamber, two critical components work together:

- The Ring Die: A large, rotating steel cylinder with many precisely drilled holes (the die holes).

- The Pressure Rollers: Two or more solid, stationary rollers positioned inside the ring die.

As the ring die rotates, the powder is drawn into the tiny gap between the inner surface of the die and the pressure rollers.

Step 3: Pre-Compression and Densification

In this narrow gap, the material is first pre-compressed. The loose powder is rolled and packed, forcing out air. The point contact between powder particles turns into surface contact, dramatically increasing the material’s density.

Step 4: Extrusion

As the ring die continues to rotate, the gap becomes even tighter, and the pressure skyrockets. This immense pressure causes the compost material to undergo plastic deformation—it temporarily behaves like a soft, moldable putty. It is then forced, or extruded, through the long, narrow holes in the ring die.

Step 5: Slicing into Pellets

Once the tightly compressed “noodles” of compost are extruded through the die holes, they are sliced to a specific length by adjustable knives (cutters) on the outside of the ring die.

Step 6: Pellet Output

The finished, cylindrical pellets are then discharged from the machine, ready for cooling, screening, and packaging.

Why Does the Powder Stick Together?

You might wonder why the pellets don’t just crumble back into dust. The binding happens through several natural mechanisms:

- Mechanical Interlocking: The extreme pressure physically forces the fine particles to lock together.

- Natural Binders: Well-fermented compost contains lignin and other organic compounds that, under pressure, act as a natural “glue.”

- Capillary Forces: A small amount of inherent moisture helps bind the particles under pressure.

What are the prospects for processing compost pellets?

+

Long-term excessive application of chemical fertilizers has destroyed the soil structure and caused soil hardening and cracking. The demand for organic fertilizers is constantly growing. Many people want to know the prospects and market analysis of organic fertilizers.

01 Great growth potential

Data shows that in recent years, the organic fertilizer industry has grown at a growth rate of about 10%-15%. Although the number of companies involved in organic fertilizer production continues to increase, the organic fertilizer gap is still large due to problems such as technology research and development and insufficient funds among companies.

02 Emerging organic fertilizers dominate the market

The core of the development of organic fertilizer is technology and technology. With the support of agricultural policies in various countries and the gradual participation of enterprises, bio-organic fertilizers are ushering in new opportunities for industrial development.

The development of the bio-organic fertilizer industry has an increasingly obvious impact on the development of special fertilizers and even the entire fertilizer industry.

03 Policy support

At present, many countries are vigorously developing organic agriculture and have issued relevant policies and documents. This indicates that the organic fertilizer market will experience explosive growth.

Organic fertilizers made by compost granulating machine are upgraded from traditional chemical fertilizers and have many advantages. They are now widely used in crops and are in huge demand. (Find RICHI on YouTube)

60000 +

Backed by a 60,000 m² advanced production complex

140 +

Global footprint extends across 140+ international markets

2000 +

Over 2,000 successful production system installations

2013

RICHI MANUFACTURE

Established in 1995, RICHI MACHINERY has grown from a medium-sized enterprise to become China’s largest pellet production line manufacturer. With two major manufacturing bases spanning hundreds of thousands of square meters, we specialize in custom pellet machines and complete plant solutions, handling every production stage in-house—from R&D to delivery.

Our vertically integrated facilities (including dedicated sections for production, testing, and logistics) ensure premium quality, environmental responsibility, and operational reliability for feed, biomass, and fertilizer industries worldwide. For nearly three decades, we’ve partnered with clients to enhance productivity, minimize risks, and achieve sustainable outcomes through innovative engineering.

Zhengzhou Headquarters

R&D, global operations and strategic management converge

Jiaozuo New Production Base (2025)

Featuring automated production lines and Industry 4.0 technologies

Kaifeng Original Complex (Since 1995)

Our manufacturing legacy began and quality traditions endure

Certifications & Patents

As a world-leading feed mill equipment manufacturer, RICHI Machinery demonstrates its engineering prowess through internationally recognized certifications and proprietary innovations.

Our ISO quality management system, CE compliance, BV-certified production processes, GOST-R for Russian compliance, ATEX explosion-proof certification for EU safety standards, FDA registration for U.S. market access, and EHEDG hygienic design certification validate our commitment to global standards, while 50+ patented technologies in pellet mills, extruders and automation systems deliver unmatched performance.

When you choose RICHI, you’re selecting globally validated, future-proof solutions backed by the industry’s most comprehensive certification portfolio.

01

Consultation

Our experts provide professional advice to understand your specific feed production requirements.

02

Design

We develop customized solutions with optimized layouts and equipment configurations for your project.

03

Manufacturing

All feed mill equipment is precision-built using quality materials in our ISO-certified factories.

04

Shipping

We handle secure packaging and global logistics with reliable delivery timelines.

05

Installation

Our engineers supervise on-site assembly and commissioning for smooth operation.

06

Training

Comprehensive operator instruction ensures proper use and maintenance of equipment.

07

After-sales

Dedicated support team provides troubleshooting and technical assistance.

08

Spare Parts

Genuine components are available worldwide with fast delivery service.