BIOMASS PELLET PROJECT COST

Biomass pellet project cost is generally between 20,000-3,000,000 USD. This type of project is usually used to process biomass fuel, biomass feed, animal bedding and other pellets products. RICHI provides proven, effective biomass pellet project solutions for biomass handling and processing. The scope of supply can vary from complete biomass pellet plants to individual equipment delivery.

500+

Construction Projects

With over 500 biomass pellet plants built across 60+ countries, RICHI brings three decades of hands-on experience to your biomass pellet project cost planning. We don’t just sell machines – we deliver complete solutions optimized for your local materials, whether you’re working with wood waste, agricultural residues, or dedicated energy crops.

$400M+

Total Sales

Our $400M+ in global project experience means we understand how to balance upfront investment with long-term operating costs. From initial material testing to final commissioning, we focus on maximizing your ROI through energy-efficient design, intelligent automation, and proven reliability that keeps your production running profitably.

60+

Covering countries

Every project includes customized financial modeling showing detailed biomass pellet project cost breakdowns – including equipment, installation, and operational expenses. We’ll provide clear projections for your specific raw material and production goals, helping you make informed decisions before committing.

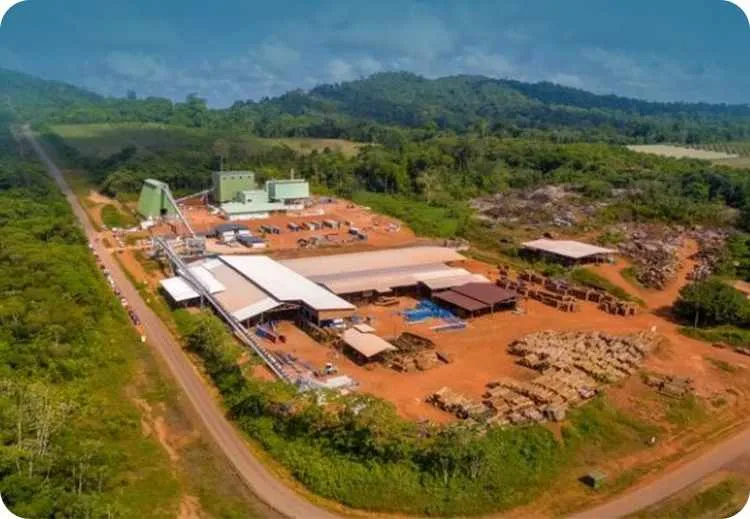

biomass pellet projects world wide

RICHI is very experienced in biomass pellet project management, ensuring deliveries that are on-time and on-budget, and produce excellent economic results for energy producers. As an advanced pellet equipment manufacturer, we have installed tens of thousands of biomass pellet production lines at home and abroad.

Currently, some key projects are mainly distributed in the United States, Canada, Indonesia, India, Argentina, Poland, Brazil, Germany, Australia, and New Zealand , South Africa, Saudi Arabia, Thailand, Malaysia, Vietnam and other countries.

Biomass pellet Project proposal

With over decades of experience in the industry, we have gained a perspective that has allowed us to match our customers’ needs with the most optimal approach while laying a solid foundation for years of sustainable growth. The followings are some featured biomass pellet production line project report, and RICHI will show you “different equipment configurations, different biomass pellet project costs”.

As a customer-centric business, we believe that our analysis of a biomass pellet project that identifies a situation, deployed solutions, implementation actions, and identification of those factors that contributed to the success, allows our customers to optimize their infrastructural needs, significantly increasing their awareness of our world-class services.

Build Your Biomass Pellet Line with High-Efficiency Equipment

Here we break down the essential machinery for a smooth-running biomass pellet production project. You’ll need robust crushers for size reduction, efficient dryers to control moisture, high-output pellet mills for consistent shaping, coolers to stabilize the pellets, and automated packing systems.

Each component we offer is designed for durability, low energy use, and easy operation with various raw materials. As a trusted pellet mill manufacturer and turnkey project expert, we provide tailored solutions and professional support at every step. Let us help you design a high-yielding production line — reach out for specific recommendations based on your needs.

Biomass shredder

Biomass fuel pelletizer

biomass feed pelletizer

Biomass dryer

biomass pellet Project Video

Our latest project videos showcase a 5T/H palm EFB pellet line in Malaysia processing oily fibers, a 20T/H mixed wood operation in Bangladesh handling high-volume production, and a 3-4T/H alfalfa pellet plant in Argentina maintaining nutrient integrity in animal feed pellets.

Each video demonstrates our engineering solutions for different material characteristics and production requirements, featuring raw material processing, system operation, and client testimonials about pellet quality and business growth.

Every biomass material has its perfect pellet solution – and these videos prove it. Whether you’re working with agricultural residues, wood waste, or specialty crops, we have the technical expertise to maximize your ROI. Contact us today to receive customized video references matching your specific material type and production goals. Let’s turn your biomass into profits together.

cost to start biomass pellet project

Investing in a biomass pellet project requires careful planning around capacity, timeline, and overall project budget. To help you evaluate potential costs and returns, we’ve compiled practical reference data based on our experience delivering turnkey solutions worldwide. The figures below outline typical biomass pellet project cost ranges depending on production scale, along with installation timelines and estimated profit recovery periods.

Our team at RICHI specializes in designing and installing robust pellet production systems tailored to various raw materials and output requirements. Whether you are looking to start a small-scale operation or a large industrial plant, the table below offers a clear overview to support your planning. For a detailed proposal that matches your specific raw material and business goals, feel free to reach out—we’ll help you build an efficient and profitable line.

| Production cycle | installation cycle | Investment Cost(usD) | Profit cycle |

|---|---|---|---|

| 0.2-1 T/H | 7-15 Days | 15,000-200,000 | 1-3 Year |

| 1-2 T/H | 7-15 Days | 20,000-300,000 | |

| 3 T/H | 15-20 Days | 30,000-350,000 | |

| 4 T/H | 20-40 Days | 50,000-400,000 | |

| 5-6 T/H | 45-60 Days | 80,000-500,000 | |

| 7-12 T/H | 60-90 Days | 120,000-1,500,000 | |

| 15-20T/H | 90-120 Days | 200,000-1,800,000 | |

| 20-30T/H | 100-140 Days | 300,000-2,000,000 | |

| 30-40T/H | 130-160 Days | 400,000-2,200,000 | |

| 40-60T/H | 160 -190 Days | 480,000-2,500,000 | |

| … | … | .. |

About the profit

Your profitability begins with converting low-value biomass into high-density pellets. We help identify optimal material combinations – from wood processing residues to agricultural byproducts – maximizing yield while controlling costs. Our systems handle varying moisture contents and compositions without compromising output quality, turning waste streams into revenue generators.

Modern pelletizing technology makes the difference between profit and loss. Our energy-optimized designs reduce power consumption by up to 35% through intelligent motor systems and heat recovery. With automated process controls maintaining ideal compression ratios and temperature profiles, you’ll achieve higher throughput with minimal operator intervention and maintenance downtime.

Different markets demand different specifications. Our flexible systems produce everything from industrial-grade utility pellets to premium ENplus-certified biomass fuels, allowing you to target the most profitable segments. Consistent density (650kg/m³+), low abrasion (<0.8%), and superior durability (97.5%+) ensure your products command top market prices.

Interested in our projects?

Ready to turn biomass into profits? Explore our proven pellet production solutions and start your journey today!

The Prospect of biomass Pellet Processing

The global biomass pellet sector is experiencing robust growth, driven by renewable energy mandates and carbon neutrality commitments across 60+ countries. From wood processing residues in North America to agricultural waste in Southeast Asia and dedicated energy crops in Europe, regional material variations demand tailored engineering solutions. With over 30 years field experience, we’ve helped 500+ clients navigate these opportunities through customized production lines that maximize ROI while meeting international quality standards.

Our team provides end-to-end support from material testing to operational optimization, ensuring your project achieves target production costs and output specifications. We offer comprehensive feasibility analysis including capital investment projections and payback period calculations based on your local feedstock conditions. Contact us today for a free preliminary design proposal – let’s transform your biomass resources into profitable, sustainable energy together.

Practical Questions About Biomass Pellet Project?

Over 500 projects have taught us what really matters on the ground – from handling abrasive rice husk to maintaining consistent pellet quality with mixed biomass. Here we address the most frequent technical and operational questions our clients face, with answers based on real production data, not theory.

Need specific advice? Share your material type and capacity needs – our engineers will provide customized solutions within 4 hours.

What are the types of biomass pellet projects?

+

RICHI’s biomass handling concept incorporates all process stages, from infeed to storage, and process solutions for any climate and biomass species. Currently, the types of biomass pellet production projects that RICHI can provide cover the following:

- Alfalfa pellet production line

- EFB pellet plant

- rice husk pellet plant

- paper pellet plant

- grass pellet project

- hay pellet project

- hops pellet project

- bagasse pellet project

- bamboo pellet project

- peanut shell pellet project

- corn stalk pellet project

- rice straw pellet project

- wheat straw pellet project

- leaf pellet project

- cassava pellet project

- hemp pellet project

- coffee pellet project

- coco peat pellet project

- coal pellet project

- miscanthus pellet project

- cotton stalk pellet project

- sunflower shell pellet project

- coconut shell pellet project

- …

What costs make up the biomass pellet project cost?

+

Biomass pellet project cost is the total cost that an enterprise needs to invest when establishing new production facilities or expanding existing production capabilities. These biomass pellet project costs usually include the following areas:

- 1. Land cost: This includes the cost of purchasing or leasing land, as well as the cost of land development, consolidation and infrastructure construction.

- 2. Construction costs: including the cost of building factories, warehouses, office buildings, dormitories and other production and living facilities.

- 3. Equipment acquisition cost: the cost of purchasing production equipment, machines, tools, etc.

- 4. Installation and debugging costs: including equipment installation, debugging and trial production costs.

- 5. Raw material cost: the cost of various raw materials used in the biomass pellet production process.

- 6. Labor costs: wages, benefits and training fees paid to employees.

- 7. Energy and water costs: Production requires a certain amount of energy and water, including electricity, gas, water, etc.

- 8. Other indirect expenses: including administrative expenses, sales expenses, financial expenses, etc.

The above are the main components of the biomass pellet plant project cost. Biomass pellet enterprises need to conduct specific analysis and budget according to the actual situation to ensure the effectiveness of the investment and maximize the benefits.

We have the experience and know-how to cover your biomass pellet manufacturing needs. Our focus is to bring your performance forward. Our expertise in sustainable energy production is at your disposal.

Does the biomass pellet project cost vary for different projects?

+

Each biomass pellet project is unique and accordingly, the price of each biomass pellet project is also different. The difference in project costs mainly stems from different customers’ raw materials, process requirements, and equipment configurations…

1 T/H biomass pellet project In Vietnam

- Country: Vietnam

- Production: 2500 t/a

- Ingredients: wet corn Straw waste

- biomass pellet project cost: 180,000 USD

4 T/H biomass pellet project In India

- Country: India

- Production: 10,000 T/A

- Ingredients: bamboo, rice husk

- biomass pellet project cost: US$270,000

20 T/H biomass pellet project In United States

- Country: United States

- Production: 50,000 T/A

- Ingredients: Miscanthus, Hay, flax straw

- biomass pellet project cost: US$550,000

15 T/H biomass pellet project In Malaysia

- Country: Malaysia

- Production: 35,000 T/A

- Ingredients: palm waste, straw, husk, wood waste

- biomass pellet project cost: 410,000USD

4 T/H biomass pellet project In indonesia

- Country: indonesia

- Production: 10,000 T/A

- Ingredients: palm waste, Sawdust

- biomass pellet project cost: 190,000 USD

20-25 T/H biomass pellet project In Thailand

- Country: Thailand

- Production: 55,000 T/A

- Ingredients: Peanut shells, straw, rice husks

- biomass pellet project cost: 770,000 USD

2-3 T/H biomass pellet project In canada

- Country: South Africa

- Production: 6,000 T/A

- Ingredients: Straw, hay, Sawdust, blocks, planks

- biomass pellet project cost: $160,000

10-12 T/H biomass pellet project In Pakistan

- Country: Pakistan

- Production: 30,000 T/A

- Ingredients: cotton stalk, sawdust

- biomass pellet project cost: $785,000 USD

Behind every biomass pellet project, there is a story. As an industry leader in quality infrastructure choices, Richi Machinery is offering its customers solutions and services that allow them to achieve groundbreaking results.

Does the biomass pellet project cost vary with different process design options?

+

With different output, different raw materials, and different plans, the price of the biomass pellet project will definitely be different. Below are some project plans we have designed for our customers, along with the ex-factory price of the complete set of equipment for the biomas pellet production project.

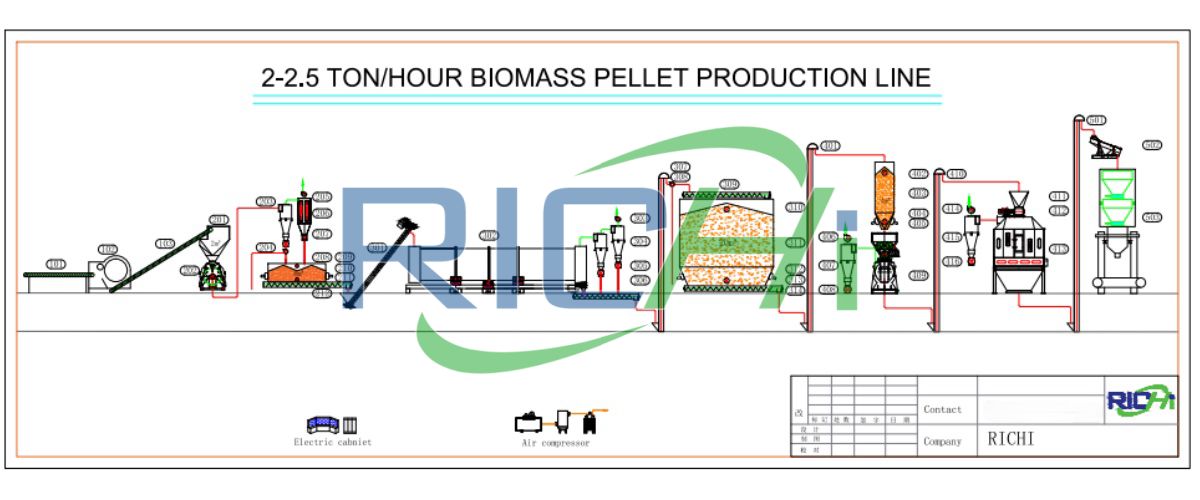

2-2.5 t/h Biomass Pellet Project Design for singapore customer

Cost:160,000 USD

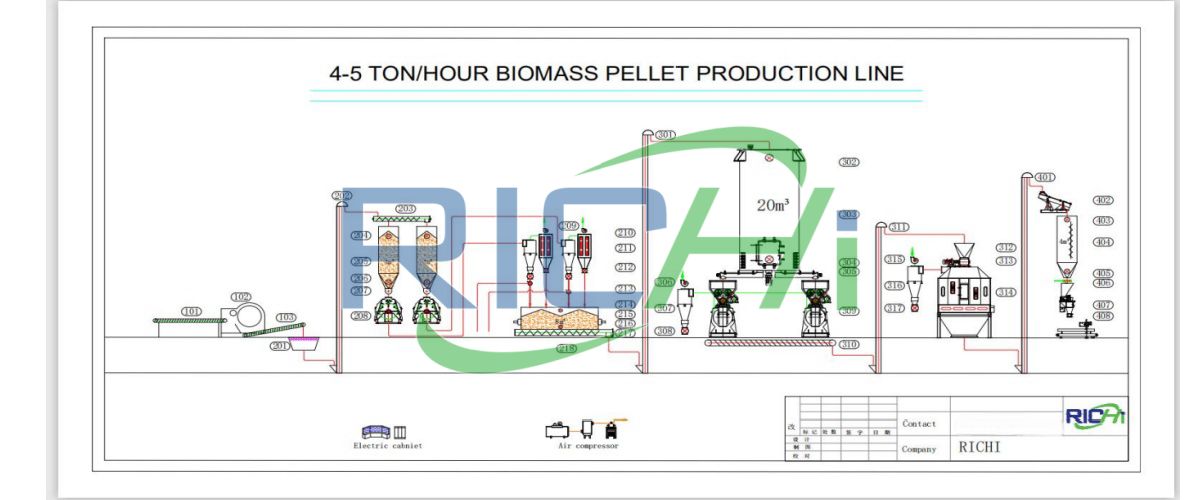

4-5 t/h Biomass Pellet Project Design for mexico customer

Cost:320,000 USD

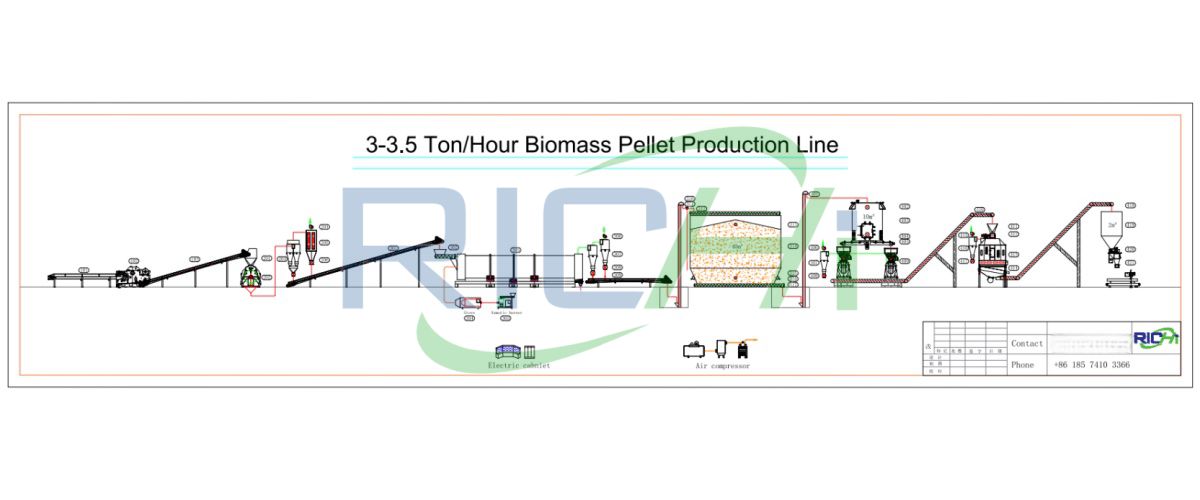

3-3.5 t/h Biomass Pellet Project design for brazil customer

Cost:240,000 USD

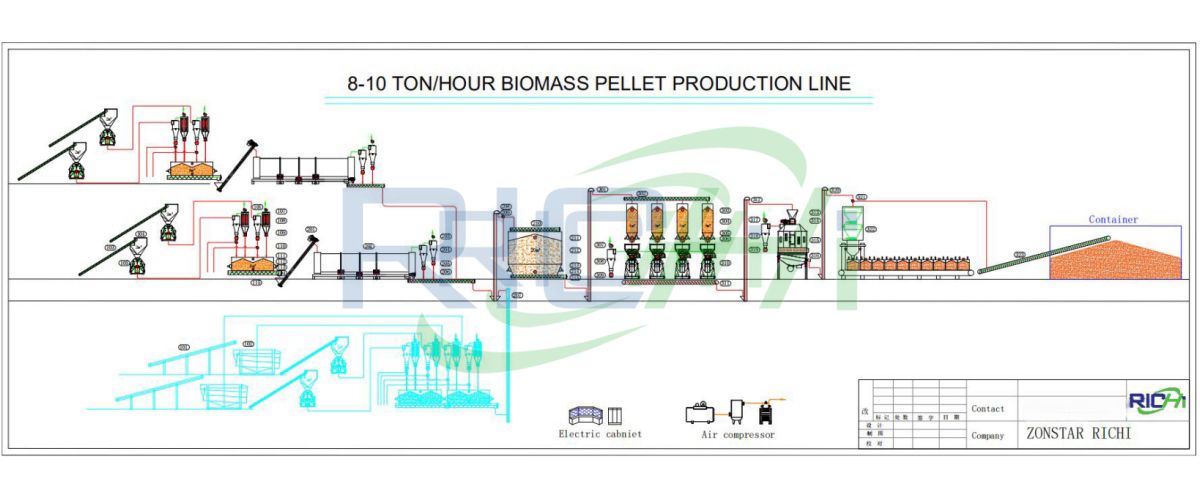

8-10 t/h Biomass Pellet Project Design for U.K. customer

Cost:840,000 USD

We realize that each of our clients has a unique brand, target market, capabilities and goals. In these plan studies, you will see how Richi Machinery handled successful infrastructural biomass pellet projects that resulted in short- and long-term success for our customers.

What equipment do I need to set up a biomass pellet project?

+

The equipment configuration of the biomass pellet project is relatively complex, and this “complexity” is mainly for biomass pellet projects processing multiple biomass raw material pellets, because some customers will use multiple raw materials for the same production line, which requires the configuration of multiple Section to “process” these raw materials so that these raw materials can meet the conditions for entering the biomass pelletizer.

We customize biomass pellet production processes based on factors such as raw material size, moisture content, process requirements, plant conditions, and investment budget. Accordingly, we configure equipment of varying types and grades.

The following are just some of the most common biomass pellet processing equipment. In addition to the following, we can design and manufacture equipment covering all types of biomass pellet processing.

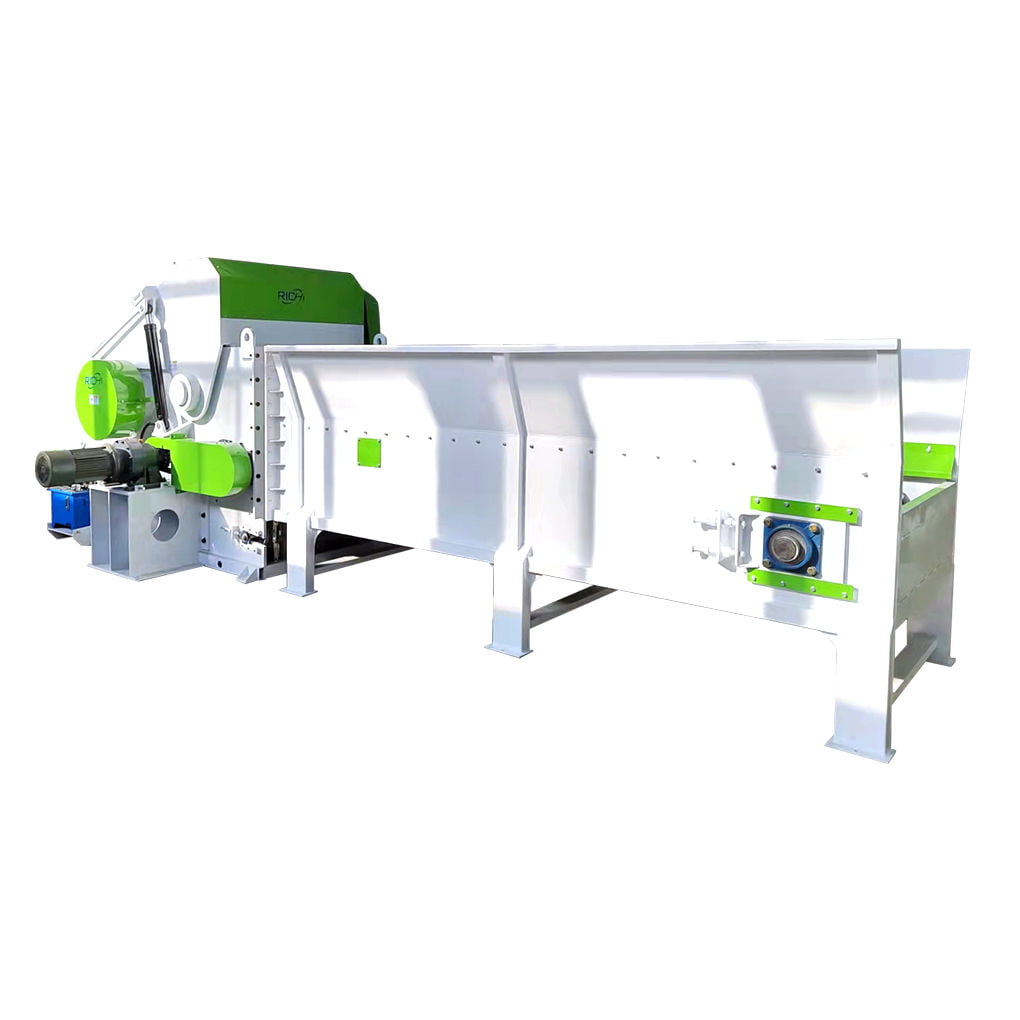

Bale breaker

Capacity:

1-15T/H

Main Power:

30-150KW

straw grass crusher

Capacity:

0.3-3 T/H

Main Power:

22-93 KW

Hammer Mill crusher

Capacity:

3-25T/H

Main Power:

30-160KW

Pallet Shredder

Capacity:

3-12T/H

Main Power:

50-110KW

RICHI designs and builds key process machines, as well as complete biofuel pellet plant solutions for the global renewable energy sector.

We have the ability to manufacture and supply each and every key processing machine in the biomass pellet production line. We offer single biomass machines for production of agricultural and forestry waste pellets, solid biofuel, and waste pellets.

Does the Biomass pellet project cost vary with different production scales?

+

The output of the project is the main factor affecting the biomass pellet project cost. Because the greater the output, the greater the output of the equipment required, and the higher the price.

Of course, the cost of the entire biomass pellet project is also affected by raw materials, process design and equipment selection. Therefore, there is also a situation where the cost of some 20t/h pellet projects may be lower than the cost of 10t/h pellet projects.

Generally speaking, based on RICHI’s project data over the past few decades, we can provide you with a reference range for the cost of biomass pellet projects:

- 1-1.5T/H Biomass pellet project cost: 50,000-200,000USD

- 2-2.5T/H Biomass pellet project cost: 70,000-280,000 USD

- 3-3.5T/H Biomass pellet project cost: 100,000-380,000 USD

- 4-5T/H Biomass pellet project price: 120,000-450,000 USD

- 6-7.5T/H Biomass pellet project cost: 150,000-600,000 USD

- 8-10T/H Biomass pellet project cost: 250,000-1,100,000USD

- 12-15T/H Biomass pellet project cost: 320,000-1,300,000USD

- 15-20T/H Biomass pellet project cost: 380,000-1,500,000 USD

- …

RICHI offers an innovative and comprehensive biomass pellet plant solution tailored for the biofuel industry. Our cutting-edge approach addresses the increasing demand for sustainable energy sources.

The solution encompasses a range of crucial elements, from initial design and engineering to manufacturing and installation, ensuring a seamless integration into the biofuel pellet production process.

Why start biomass pellet project?

+

Low cost, as pellet prices remain competitive compared with fossil fuels, which are more sensitive to market fluctuations.

It is possible to use renewable fuels in the form of wood pellets or briquettes.

High energy density of pellets enables simple fuel logistics, which reduces the environmental impact.

It’s a green choice. Replacing an old boiler with a pellet boiler significantly reduces CO2 emissions from district heating and process steam. Switching to a pellet plant is good for the environment.

Startup is fast and easy in comparison to other types of biofuel plants. The biomass pellet project cost reacts quickly to load changes, making it an excellent solution for a peak load and back-up plant.

In addition, the construction of a feed mill factory may also involve some special links, such as the procurement and storage of raw materials, monitoring and quality control of the production process, etc.

During the production process, attention must also be paid to the crushing and granulation of raw materials to ensure the quality and safety of the feed.

For the construction of animal feed factory projects, environmental protection and safety requirements also need to be taken into consideration, such as providing environmental protection certificates if there are environmental protection requirements.

What does the processing cost of biomass pellets include?

+

The processing costs of biomass pellets generally include: direct materials, direct labor, and manufacturing expenses.

- Direct materials refer to various raw materials and main materials, auxiliary materials, outsourced semi-finished products, spare parts for repair, packaging materials, fuel, etc. that can constitute the product entity or contribute to the formation of the product.

- Direct labor refers to the wages of production workers directly engaged in product manufacturing, including:

- Basic salary and wage-based bonuses, allowances, labor insurance benefits and various subsidies, etc.

Manufacturing expenses refer to various indirect expenses incurred by an enterprise to produce products and provide labor services, including:

wages and wage surcharges, depreciation fees, repair fees, machine material consumption, amortization of low-value consumables, labor protection fees, water and electricity expenses, office expenses, travel expenses, downtime losses during seasonal and repair periods, and other expenses that cannot be directly included in the production cost of the product. (Find RICHI on YouTube)

What does the total capital expenditure (CAPEX) for building a biomass pellet plant typically include?

+

When planning the construction of a wood pellet plant, understanding the total capital expenditure (CAPEX) is essential for investors and project developers. A typical biomass pelletizing project involves several key cost components that collectively define the initial investment.

The major segments of CAPEX generally include:

- Site Preparation & Civil Works: Costs related to land leveling, foundation construction, drainage, and access roads.

- Equipment Acquisition: This covers the core processing machinery such as crushing, drying, pelletizing, cooling, and screening equipment, as well as automation and control systems.

- Utilities & Infrastructure: Expenses for electrical connections, water supply, air compression, and thermal energy systems (e.g., biomass-fired furnaces for drying).

- Dust Control & Safety Systems: Essential for meeting environmental and workplace safety standards.

- Installation & Commissioning: Professional services for equipment setup, calibration, and trial runs.

- Engineering & Project Management: Costs for system design, process planning, and expert supervision.

It’s worth noting that the final biomass pellet project price can vary significantly based on raw material type, production capacity, and level of automation. Each biomass pelleting project has unique demands, and tailored solutions often lead to better long-term efficiency and ROI.

For those considering a biomass pelletizing project, partnering with an experienced equipment and engineering provider can help optimize both initial investment and operational performance.

What impact does choosing equipment with different technologies (such as different models of pelletizers) have on cost and product quality?

+

The choice of pelleting technology, particularly the model and type of pellet mill, significantly impacts both the overall biomass pellet project cost and the final product quality. This decision is one of the most critical in the entire wood pellet plant construction process.

Higher-capacity, heavy-duty pellet mills typically require a larger initial investment. However, they often deliver a lower cost per ton over time due to superior energy efficiency, higher output, and reduced downtime.

Conversely, opting for a smaller or less robust model might lower the upfront biomass pellet project price but can lead to higher operational costs and more frequent maintenance, especially when processing abrasive or diverse raw materials.

The influence on product quality is equally important. Advanced mills provide more precise control over pellet density, temperature, and durability, directly resulting in a higher-quality pellet that meets premium market standards. The right technology ensures consistency, which is vital for building a strong market reputation.

For a biomass pelleting project, there is no universal solution. The optimal equipment selection depends entirely on the specific raw material composition and production goals.

This is where expert engineering support becomes invaluable. A partner with deep experience can recommend a customized configuration that balances capital expenditure with long-term reliability and product excellence, ensuring the success of your biomass pelletizing project.

In addition to the biomass pellet production line, what other auxiliary facilities (such as warehouses, fire protection, and environmental protection facilities) will incur significant costs?

+

Beyond the core processing equipment, several auxiliary facilities contribute significantly to the total biomass pellet project cost. These are essential for operational safety, efficiency, and regulatory compliance, and must be factored into the initial budget for any wood pellet plant construction.

The most notable auxiliary facilities include:

- Raw Material & Finished Product Storage: Large, covered warehouses are necessary to protect feedstock from moisture and to store finished pellets. Their size and construction quality directly impact inventory flexibility and product integrity.

- Dust Collection and Air Emission Control Systems: These are critical for both environmental protection and worker safety. Robust dust extraction systems at transfer points and processing stations represent a considerable but vital investment.

- Fire Prevention and Fighting Systems: Given the combustible nature of dust and biomass, automated sprinkler systems, fire alarms, and specialized equipment are mandatory and form a key part of the infrastructure cost.

- Utility Hook-ups and Infrastructure: This includes transformers for high-power electrical supply, water lines, compressed air systems, and potentially steam boilers for drying, all requiring substantial installation work.

The design and scale of these facilities greatly influence the final biomass pellet project price. An experienced partner understands how to optimize this balance, ensuring your biomass pelleting project is not only compliant but also cost-effective to operate.

Their expertise in layout and integration can prevent costly oversizing or problematic undersizing, making their guidance invaluable from the initial planning stages of your biomass pelletizing project.

What proportion of the total investment does the cost of equipment (crusher, dryer, granulator, cooling and packaging machine) usually account for?

+

The core processing equipment—including biomass crushers, biomass dryers, pellet mills, coolers, and packaging systems—typically represents the most substantial portion of the initial investment. In a standard wood pellet plant construction, this equipment can account for approximately 40% to 60% of the total biomass pellet project cost.

This range is influenced by several factors. The choice between standard and heavy-duty models, the level of automation, and the production capacity directly impact this percentage.

Opting for high-efficiency, reliable machinery might increase the initial equipment share of the budget but significantly reduces operational costs and downtime over the plant’s lifetime, improving the overall return on investment.

It’s a critical balance. Underestimating this part of the biomass pelleting project can lead to bottlenecks and quality issues, while over-specifying can unnecessarily inflate the total biomass pellet project price.

This is where precise engineering and a deep understanding of material science become invaluable. The right configuration, tailored to your specific raw material and output goals, is essential for optimizing both the upfront cost and long-term profitability of your biomass pelletizing project.

How much money is needed to build a medium-sized (e.g. 20,000-50,000 tons per year) biomass pellet production line?

+

Providing a precise figure for a mid-capacity biomass pellet plant is challenging, as the final investment is highly customised. However, for a turnkey 20,000 to 50,000-tonne per year production line, the total capital requirement typically falls within a range of $500,000 to $1.5 million USD.

This estimate for the biomass pellet project cost encompasses all critical stages, from initial site preparation and core equipment acquisition to installation and commissioning. The significant variation in the biomass pellet project price is primarily due to several key factors:

The largest variables are the choice of primary equipment—such as high-capacity pellet mills and automated dryers—and the extent of auxiliary infrastructure needed, including raw material storage and dust control systems. Furthermore, the characteristics of your raw material significantly influence the engineering design and equipment selection, directly impacting the overall budget.

A successful wood pellet plant construction project relies on accurate planning. An experienced partner can provide a detailed financial outline tailored to your specific feedstock and production goals, ensuring your biomass pelleting project is both technically sound and economically viable. This level of customised analysis is crucial for optimising the investment for your specific biomass pelletizing project.

How do the cost structures differ for production lines of different capacities (e.g., 10,000 tons per year vs. 100,000 tons per year)? Are there economies of scale?

+

Absolutely. The scale of operation fundamentally influences both the cost structure and economic viability of a biomass pellet production facility. Understanding the distinction between a 10,000 TPY and a 100,000 TPY line is crucial for any investor.

The key difference lies in how costs scale. For a smaller plant, equipment, while a significant investment, is often simpler and more standardized. However, fixed costs like permitting, site engineering, and certain infrastructure form a larger proportion of the total biomass pellet project cost. This can result in a higher cost per tonne of production capacity.

In contrast, a large-scale wood pellet plant construction benefits profoundly from economies of scale. While the absolute biomass pellet project price is higher, the cost per tonne of capacity decreases significantly. This is because major capital items like buildings, administrative facilities, and power connections are utilized more efficiently. Furthermore, high-volume production allows for the integration of advanced, automated equipment that drastically reduces labor and energy costs per tonne, optimizing the long-term operational economics.

Therefore, a well-engineered biomass pelleting project carefully balances the initial investment against throughput. The design focus for a large facility shifts towards maximizing automation, material handling efficiency, and energy integration. Navigating this complexity requires a partner with not just equipment supply but deep expertise in process design to ensure the biomass pelletizing project achieves the lowest possible production cost.

How long does it typically take for a biomass pellet project to go from planning to production? How does this time cost affect the overall investment?

+

The timeline from initial planning to production for a biomass pellet plant can vary considerably, but a typical timeframe ranges from 8 to 14 months. This duration is a critical, though often overlooked, component of the overall project financials.

The process involves several sequential phases: feasibility studies and permitting, detailed engineering design, equipment procurement, civil works and construction, followed by equipment installation and final commissioning. Each of these stages depends heavily on thorough preparation and expert coordination.

Delays at any point, particularly in securing permits or during the construction phase, directly increase the overall biomass pellet project cost. This is due to extended overheads, financing expenses, and potential penalties.

Furthermore, a prolonged timeline delays the start of revenue generation, impacting the project’s return on investment. This makes efficient project management not just a matter of scheduling, but a crucial factor in controlling the final biomass pellet project price.

An experienced partner streamlines this entire process. Their expertise in navigating technical design, equipment procurement, and system integration for a biomass pelletizing project can significantly de-risk the schedule, ensuring your wood pellet plant construction is completed both on time and within budget, thereby protecting your investment.

What are the main components of the operating expenses (OPEX) of a biomass pellet project?

+

Understanding the ongoing operational expenditures (OPEX) is just as critical as the initial capital outlay for evaluating the true biomass pellet project cost. These recurring costs directly determine long-term profitability.

The primary components of OPEX typically include:

- Raw Material Procurement: This is often the largest ongoing expense, highly dependent on feedstock type, local availability, and logistics.

- Energy Consumption: The drying and pelletizing processes are energy-intensive. Costs for electricity and thermal energy (often from biomass or gas) form a significant part of the monthly budget.

- Labor: This includes wages for plant operators, maintenance staff, and administrative personnel. Higher automation levels can reduce this cost over time.

- Maintenance & Spare Parts: Regular upkeep of wear-prone parts like pellet mill dies and rollers is essential to avoid unplanned downtime and ensure consistent output quality.

- Storage & Logistics: Costs associated with warehousing finished pellets and transporting them to market.

The design choices made during the wood pellet plant construction phase have a profound impact on these operational costs. Investing in high-efficiency, reliable equipment from the outset can significantly reduce energy and maintenance expenditures. A well-planned biomass pelleting project, tailored to the specific raw material characteristics, optimizes consumption rates and minimizes waste, thereby improving the overall economics of the biomass pelletizing project.

What percentage of the production cost per ton of pellets does raw material cost typically represent?

+

Raw material cost is typically the most significant variable in the ongoing production expense. On average, feedstock can account for 40% to 60% of the total cost per tonne of pellets produced.

This percentage is highly fluid and depends heavily on local availability, the type of biomass used (e.g., sawdust, shavings, agricultural waste), and associated logistics like transportation and storage. Fluctuations in supply and quality can cause this figure to vary considerably.

This variability underscores why the initial engineering phase of a wood pellet plant construction is so critical. A project designed to handle a diverse range of feedstock provides crucial flexibility to source the most cost-effective and available materials locally, thereby insulating the operation from market volatility.

While the upfront biomass pellet project price is a primary concern, a design that optimizes material usage and processing efficiency directly controls the largest portion of your long-term operational costs, ensuring the economic resilience of your biomass pelleting project.

Ultimately, the success of a biomass pelletizing project hinges not just on equipment selection, but on a deep understanding of how to process available raw materials in the most economical and efficient way possible.

How should we select the core equipment (such as pelletizer, dryer, and crusher) used in biomass pellet project?

+

Selecting the right core equipment is the most critical technical decision in planning a biomass pellet project, as it directly dictates output, quality, and operating costs. The process is not about choosing individual machines, but about configuring a synchronized system.

The optimal selection for a pellet mill, dryer, and hammer mill is primarily determined by two factors: the characteristics of your raw material and your target production capacity. For instance, abrasive materials like certain agricultural residues require pellet mills with reinforced dies and rollers, while fibrous wood may need specific pre-treatment. The initial moisture content dictates the type and size of the dryer.

Mismatched equipment is a common source of failure, leading to high energy consumption, frequent breakdowns, and inconsistent pellet quality. This ultimately increases the long-term biomass pellet project cost despite a potentially lower initial equipment price.

Therefore, a successful wood pellet plant construction relies on a deeply customized approach. There is no universal solution. A partner with extensive experience across diverse feedstock—from softwood to agricultural waste—can analyze your specific material and recommend a robust configuration.

This ensures each machine operates at peak efficiency, protecting your investment and maximizing the return of your biomass pelletizing project. Proper sizing and integration from the outset are what separate a profitable operation from an underperforming one.

What is the approximate energy consumption (electricity, heat) cost to produce one ton of biomass pellets?

+

Estimating a single, universal figure for energy cost per tonne is difficult as it is highly dependent on raw material type and plant efficiency. However, for a well-designed operation, total energy consumption can typically range from 90 to 150 kWh per tonne of pellets produced.

This includes both electrical power for grinding and pelletizing, and thermal energy for drying. The initial moisture content of the feedstock is the primary variable; wetter material requires substantially more thermal energy to dry, directly increasing the cost.

This variance highlights why equipment selection and system design are paramount. Modern, energy-optimized mills and dryers specifically matched to the material profile can significantly reduce consumption figures towards the lower end of this range. Investing in such efficiency during the wood pellet plant construction phase is a strategic decision that drastically reduces ongoing operational expenses, directly improving the long-term economics of your biomass pelletizing project.

Ultimately, while the initial biomass pellet project price is a key consideration, the design’s focus on minimizing energy consumption is what ensures competitive production costs and strong profitability over the plant’s lifetime.

How do you plan the installation sequence to ensure project progress? Will you provide installation guidance and technical commissioning?

+

Of course. Proper installation sequencing is fundamental to avoiding costly delays and is a critical aspect of managing the overall biomass pellet project cost. A well-defined timeline typically follows these stages:

- Site and Foundation Preparation: Civil works for equipment foundations and structural supports must be fully completed before any equipment arrives.

- Major Equipment Placement: Once the site is ready, heavy core machinery like dryers and pellet mills are positioned first.

- Auxiliary System Installation: This includes connecting ducting, cyclones, electrical panels, and control systems around the placed equipment.

- Commissioning and Debugging: The final and most critical phase involves powering up the system, calibrating each component, and running material tests to achieve specified output and quality.

Regarding support, comprehensive installation guidance and on-site technical commissioning are not just an added service—they are an essential part of a successful startup.

Our team provides detailed layout and foundation drawings in advance to guide your civil works. Upon equipment delivery, our experienced engineers are dispatched to oversee the mechanical installation, electrical connection, and most importantly, the system tuning and operator training.

This hands-on support ensures that the technical design is correctly implemented, which safeguards your investment by getting your biomass pelletizing project operational efficiently and to its designed performance specifications.

This approach minimizes downtime and helps ensure the projected biomass pellet project price is met without unexpected overruns from installation errors. Proper planning and expert commissioning are what de-risk the final stages of a wood pellet plant construction.

What does the construction and installation cost of a biomass pellet project include?

+

1. Components of factory construction and installation costs

There are many factors that make up the cost of factory construction and installation, the main factors include: land costs, architectural design, building materials, construction, decoration, equipment configuration, environmental maintenance, etc.

- Land cost: Site selection and land purchase are an important part of the biomass pellet project construction cost. The size of the land required, the area where the land is located, and the land price will all affect the construction cost.

- Architectural design: Architectural design accounts for a relatively small proportion of the cost, but it is still one of the key factors. The architectural design first determines the appearance, internal structure, functional layout, etc. of the factory building, which directly affects the later construction, decoration, equipment configuration, etc.

- Building materials: The selection of building materials will have a great impact on the construction and installation costs of the biomass pellet project. The quality, price, and quantity of the building materials will directly affect the quality and cost of the factory.

- Construction: Construction is an important part of the biomass pellet project construction and installation costs, which directly affects the construction quality and construction period. At the same time, the costs of labor, materials, equipment, etc. are also important factors that constitute the construction cost.

- Renovation and decoration: The later decoration and decoration costs of biomass pellet project construction and installation costs should not be underestimated. It includes decoration and decoration of floors, walls, ceilings, doors, windows, sanitary ware, etc. Among them, labor costs, material costs, etc. are important factors.

- Equipment configuration: Equipment configuration costs will also have a great impact on the cost of biomass pellet project cost, because the type, quantity, and quality of equipment will affect the quality and construction cycle of the construction project.

- Environmental maintenance: Environmental maintenance costs also have an impact on factory construction and installation costs, including landscaping, purification equipment, sanitation facilities, etc.

2. General range of factory construction and installation costs

The construction and installation costs of different types of biomass pellet factories also fall into different ranges.

Generally speaking, the biomass pellet project cost ranges from tens to thousands of dollars per square meter. In different countries and regions, the use of different factory building types will affect the construction price of the factory building.

3. Cost control and savings

Factory construction and installation costs need to be controlled at different construction stages, such as optimizing land selection, rational utilization and allocation of building materials, and accurate selection of construction equipment.

Similarly, during the construction and decoration process of factory buildings, quality control, reasonable construction, and avoidance of waste can also play a certain role in biomass pellet project cost savings.

Do governments in different countries provide subsidies, tax incentives, or financial support for biomass pellet projects? How to apply?

+

Yes, many governments worldwide actively support biomass pellet projects through various incentives, which can significantly improve the project’s financial viability. These are typically offered to promote renewable energy, reduce carbon emissions, and stimulate rural economies.

Common forms of support include:

- Capital Grants: Direct funding to offset a portion of the initial investment in equipment and construction.

- Tax Incentives: These can include credits, exemptions, or accelerated depreciation schedules, which lower the overall tax burden.

- Feed-in Tariffs or Premiums: Guaranteed pricing for the green energy produced, ensuring a more stable and predictable revenue stream.

- Low-interest Loans or Loan Guarantees: Schemes designed to improve access to capital and reduce financing costs.

The availability and specific types of programs vary drastically by country and even region. The application process is often rigorous, requiring detailed technical proposals, financial models, and environmental impact assessments.

This is where expert planning becomes invaluable. A well-documented and professionally prepared feasibility study and technical plan are frequently mandatory for a successful application.

Such documentation clearly outlines the efficiency, sustainability, and economic benefits of the proposed plant, strengthening the case for approval.

Partnering with a team that has international experience can provide crucial insight into navigating these complex bureaucratic processes, ensuring your project is positioned to capitalize on any available support that reduces the net biomass pellet project cost.

Navigating the financial landscape is a critical part of any successful wood pellet plant construction, and understanding these opportunities is the first step.

About RICHI

Since founding in 1995, RICHI MACHINERY has grown to become the world’s leading designer and builder of pellet production line systems. RICHI has delivered over 2000 projects to clients located in more than 140 countries across six continents. Altogether we have over 200 employees, and from start to finish, RICHI can design, manufacture, build and deliver your entire project – there’s no need to manage multiple project partners.

RICHI Technology

Adhering to the R&D tenet of “independent innovation”, Richi Machinery’s annual R&D investment accounts for more than 3% of total sales. It is supported by CAD, Solidworks and other computer-aided design systems, Ansys, matlab simulation analysis software, and VCC, EasyBuoder8000 and other programming software.

Project Management

For the construction of a complex pellet plant, process design, equipment manufacturing, precise logistical organization, accurate work, a combined installation team of experienced subcontractors are essential, which our company has retained for decades.

Patents & certifications

In the process of our continuous development, exploration and innovation, relying on our strength, we have more than 30 patent technologies, and all products have passed ISO international quality system certification, EU CE certification and Customs Union CU-TR certification.

Service You Can Count On

When customers need support, our customer service is the solution.

consultation

We assess our client’s long-term development needs, what the products manufactured by it require, what it intends to manufacture and what quantity it wants to produce.

Design

Advanced design technology combined with years of experience, specialist skills and innovative thinking drives advanced, cost-effective and productive solutions for our customers.

manufacturing

The technological equipment and machines comprising the pellet plant are manufactured by our permanent expert staff in continuous consultation with our engineers.

Installation

We offer a range of start-up field services across a variety of industries to get your new equipment set up and running as quickly as possible. Once installed, we test and analyze key operations to maximize performance.

Industrial maintenance

Regular maintenance achieves a longer service life for investments and maximises production efficiency. We are able to react quickly to problem situations and serve you flexibly with a package tailored to your needs.

Accessories

Your pellet plant equipment will require regular maintenance and wear parts will need to be replaced. We have a large parts inventory so you can rely on us to have in stock what you need and be able to get it to you in a timely manner.