Company News

Here is the most timely, accurate and authoritative RICHI information platform. Based on our own development, whether it is RICHI hotspots or technological innovations, we will present you with the latest time…(Continuously updating)

RICHI cattle feed production line equipment “expedition” to the United States

Release date: 2023-08-21

On August 20, RICHI complete cattle feed production line equipment expedition to the United States. The American customer is a visiting customer of the International Animal Husbandry Expo. From the initial order of 1-2t/h small feed unit to the current purchase of 12t/h fully automatic cattle feed plant with computer ingredients, after a long period of comprehensive analysis of many companies After investigation and comparison, RICHI Machinery was finally chosen.

The 12t/h cattle feed production line shipped this time includes two 1,000-ton silos. The whole production line adopts the production process of first crushing and then batching. A single cattle feed pellet machine can produce about 8-12 tons of cattle feed per hour.

All operations from the receipt of raw grains to the distribution of finished products are mechanized and automated, and the building sub-items are closely connected, making the feed production line occupy a small area and the transmission line is short, helping customers save the total investment cost to the greatest extent. .

In the later stage, we will do our best to do a good job in the installation guidance and commissioning services of the project, and make all-round preparations for the smooth commissioning of the customer.

Algeria’s 100,000 tons annually livestock and poultry feed production project is about to be put into operation

Release date: 2023-08-01

The 100,000-ton annual livestock and poultry feed production project in Algeria undertaken by RICHI is about to be put into operation! The project is the largest feed mill with the most advanced equipment in the state.

The whole animal feed mill plant project mainly consists of two 1200-ton corn steel silos, 100-ton soybean meal silos, and finished product bulk silos, etc., using fully automated production equipment, centralized monitoring, information data collection, automatic temperature measurement and ventilation for storage, and bulk finished product transportation, to achieve from raw materials Fully automated operation from entering the factory to finished product leaving the factory.

This new modern intensive livestock and poultry feed factory integrating intelligence and greening adopts RICHI’s advanced process design and fully automatic complete sets of high-efficiency equipment, which can effectively reduce production line operating costs, increase production capacity, and comprehensively improve feed and breeding quality. A ration that provides energy and nutrients necessary for healthy growth of cattle, sheep and chickens.

Driven by both domestic and foreign countries, RICHI has completed multiple delivery tasks with guaranteed quality and quantity

Release date: 2023-07-16

Recently, RICHI’s production workshop is in full swing. In order to complete the delivery of various orders on time, the manufacturing workshop and logistics department have worked at full capacity and worked overtime to complete the delivery of multiple domestic and foreign trade orders with quality and quantity.

The orders completed in China include the transformation of Shandong quality preservation device and the delivery of Anhui) double-line SZLH420 livestock and poultry feed production line. Focused on completing the complete delivery of the 10t/h premix feed mill project in Hunan (China), the 5t/h wood pellet production line project in Argentina, and the 10-15t/h livestock and poultry feed production line project in Iraq.

In terms of export, we have completed export shipments in many countries and regions. Mainly include: delivery of orders for hammer mill feed grinders and square screens in Bangladesh; delivery of 6 sets of MZLH420 biomass pellet production lines in South Korea, and delivery of 2 sets of MZLH520 biomass pellet mills in Indonesia; Thailand, Poland, Austria, Germany, Romania, South Korea Delivery of accessories such as ring molding rollers.

Among them, the old customers who have already signed the 10t/h Afghanistan chicken feed line added 2 new packing scales and 1 new electric synchronously adjustable three-roll crusher, and the delivery was completed in October.

Based on the country, look at the world. RICHI will continue to rely on high-quality high-tech products to provide every customer with high-quality stand-alone products and quality projects

The RICHI project set off for Russia again

Release date: 2023-06-09

Recently, RICHI Machinery’s precision equipment traveled across the ocean again to the Russian project site.

The Russian customer cooperated with RICHI in 2017 on the project – 1-2t/h feed production line. This time, RICHI built the 5th floating fish feed plant & 10th animal feed pellet line for it – a “turnkey boutique project” integrating plant planning, production and manufacturing, equipment delivery, installation and commissioning services.

With excellent equipment quality, advanced technical support and perfect after-sales service, Russian customers express their love for the RICHI brand, so they have always maintained close cooperation with RICHI.

RICHI’s complete set aquatic feed production line equipment successfully completed & delivery to Uzbekistan

Release date: 2023-05-19

Recently, RICHI’s 5t/h sinking fish feed production plant project in Uzbekistan successfully completed the export shipment. The complete set of equipment for this project has undergone strict checks in every step from design, procurement, production, inspection, packaging, etc., and the products meet international quality standards to ensure that every piece of equipment sent to customers is a masterpiece.

The Uzbekistan customer established a friendly cooperative relationship with our company in 2019, and signed a set of 3-5t/h livestock and poultry feed production line, and the delivery was completed at the end of the year.

Due to the high trust in RICHI’s excellent product quality, professional technical services, and rich installation experience, this year, in order to expand production capacity, another 5t/h sinking fish feed production line project was added. The 5t/h sinking fish feed plant delivered a total of 3 containers, which were successfully dispatched on May 7.

The complete set of delivery items includes optimized and upgraded host equipment: feed grinder, twin-shaft paddle mixer, aquatic feed pellet mahince, counter-flow cooler machine, rotary classifier, and other supporting equipment and accessories.

Afghanistan’s 10 t/h chicken poultry feed line equipment delivered smoothly

Release date: 2023-04-29

Recently, RICHI has worked together to successfully complete the delivery of feed machinery and equipment to an old customer in Egypt amid continuous days of heavy rain. The main products of this shipment are new SFSP feed crusher, SWLY impeller feeder, new SFJH rotary classifying screen, double packing scale and other animal feed mill equipment and auxiliary equipment.

The Egyptian customer was previously a customer of SZLH420 poultry feed complete production line, and this time a new production line was added on the basis of the original one. The whole set of raw feed production line was constructed by RICHI. RICHI’s product quality has won the trust and recognition of customers, which gave us the opportunity to cooperate again.

10 T/H wood pellet production line in the United States put into operation

Release date: 2023-04-02

The 10t/h wood pellet production line undertaken by RICHI has been fully completed in Indonesia and has been successfully accepted and put into production.

This project is a 10-ton-per-hour wood pellet production line. The total power of the equipment is about 1848kw. The workshop covers an area of 3600 square meters, including the raw material warehouse and the finished product warehouse. The client requested a directional design.

Process flow: The output of the biomass pellet production line in the United States is 10T/H, and the raw materials are various, mainly including trail logs felled in the forest, scraps, sawdust, wood shavings, etc. from the wooden door factory. Raw materials go through slicing—crushing—screening—drying—mixing—granulation—cooling—storage—and packaging into finished biomass pellets.

Russia’s 5-6 t/h extruded aquatic feed production line will be put into operation soon

Release date: 2023-03-17

The extruded aqua feed production line with an output of 5-6 tons per hour constructed by RICHI was successfully accepted in March 2023, specializing in the production of trout feed.

The extruded aqua feed plant is designed to produce 5-6T/H per hour, and the total power of the equipment is about 324KW.

The process mainly includes: raw material receiving, cleaning, coarse crushing, primary batching and mixing, secondary crushing, secondary mixing, conditioning, and puffing, granulation and spraying, product grading and packaging and other processes.

The entire production line has reasonable design, compact structure, stable and efficient operation, and passed the acceptance at one time.

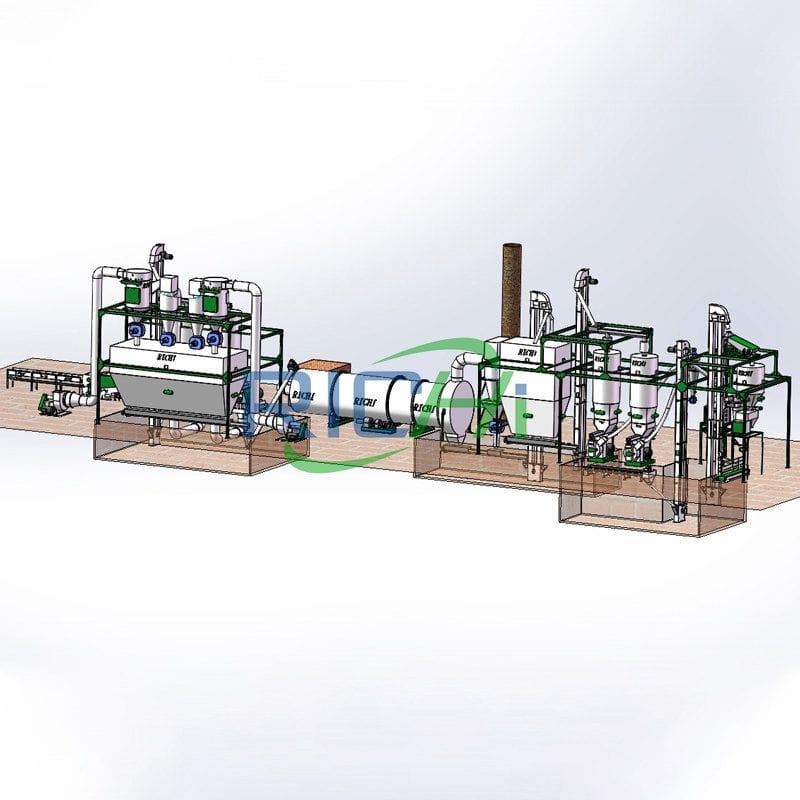

The construction of a 50000t/a complete wood pellet production line equipment installation is in progress

Release date: 2023-06-29

Since the beginning of January, the wood pellet production line with an annual output of 50,000 tons in Heilongjiang, China, undertaken by RICHI, has been delivering continuously.

In response to the customer’s construction progress requirements, RICHI sent 10 on-site installers to work overtime to install the wood pellet making equipment. At present, the installation is proceeding in an orderly manner, and we strive to complete the installation of all equipment and enter the commissioning stage by the end of June.

The client is a domestic listed company in China, planning to build a new biomass fuel pellet plant project. The completion of the project has strong demonstration and promotion value for promoting the construction of “zero waste city” and creating “recycling and low-carbon development”.

It is also the main channel for the local government to dispose of waste wood from wildfires. The speed of project progress has received special attention from the local government, which requires full firepower and rapid production.

The project has an annual output of 50,000 tons of wood pellet production plant. After crushing, crushing, drying, storage, granulation, cooling, packaging and palletizing and other processes, it is finally made into high-quality cylindrical biomass pellet fuel.

Undertake the construction of 15-20 t/h livestock and poultry feed production line equipment and leave for Oman

Release date: 2022-11-29

Recently, the 15-20t/h livestock and poultry feed production line project in Oman has successfully completed production. After a series of production processes such as strict quality inspection, audit, packaging, and loading, it has been checked at all levels and is in an orderly manner.

The equipment will be transported to the project site by sea . This project is another cooperation with an old customer, which fully reflects the brand reputation and recognition of RICHI Feed Machinery Engineering in foreign markets.

The project adopts a crushing line, a batching and mixing line, and a granulating line, and the production process is crushed first and then batched. In order to help customers achieve maximum production increase and energy saving, the entire feed production line implements fully automated production, and the design of each building sub-item is compact and integrated, and the layout is reasonable, helping customers seize market opportunities.

According to the actual needs of customers, the production line has created high-capacity, high-quality exclusive complete production projects for customers in an all-round way, from reasonable design layout, directional process design to high-efficiency and energy-saving equipment selection, and has been highly recognized by customers.

10 tons per hour organic fertilizer pellet production line equipment delivery

Release date: 2022-09-29

Recently, the 10t/h bio-organic fertilizer production line complete set of equipment designed, manufactured and constructed by RICHI MACHINERY was lined up on a heavy truck and headed to Jiangxi Province, China, to help the construction and development of local green, healthy and organic agriculture.

The project is a production line of 10 tons of organic fertilizer granules per hour. The whole process goes through the raw material receiving section, crushing section, ingredient mixing section, granulating section, drying section, cooling and packing section, etc., and finally produces high-quality cylindrical organic fertilizer pellets. The finished product particles are uniform and full, which improves market competitiveness for customers.

RICHI made a directional design for this project, and scientifically configured equipment in line with the actual situation of the customer, effectively reducing investment costs. Personalized and differentiated products have won high recognition from customers.

180,000 t/a livestock poultry ruminant feed production line equipment set sail for Inner Mongolia

Release date: 2022-08-13

Recently, Inner Mongolia has delivered 180,000 tons of livestock and poultry + ruminant feed production line equipment per year. The project is a production line with an annual output of 180,000 tons of livestock and poultry + ruminant feed (including silos).

It adopts the process of three crushing lines (one reserved), two ingredient mixing lines, and three granulation lines (one reserved), and has the functions of secondary crushing and secondary granulation. A single stock poultry feed pellet making machine can produce 8-12 tons of livestock and poultry or ruminant feed per hour.

In order to help customers reduce costs and improve production efficiency, the entire line from the receipt of raw grains to the distribution of finished products is mechanized and automated. All building sub-items are integrated into one piece, with a small footprint and short transmission lines, which greatly saves the total cost.

In the follow-up, the project will continue to start, and the on-site construction is also continuing to advance.

Algeria 5-6 t/h bio-organic fertilizer complete production line signed

Release date: 2022-07-30

Recently, RICHI successfully signed a 5-6 ton bio-organic fertilizer complete production line project with an Algerian customer, and will design, manufacture and undertake the project throughout the process.

The project owner is an old customer who has cooperated with RICHI for many years. After inspecting and comparing multiple suppliers, the customer finally chose RICHI again.

The main raw materials of this project are soybean meal, castor, bone powder, tobacco powder, etc., and the whole process goes through the raw material receiving section, crushing section, batching mixing section, granulating section, drying section, cooling and packaging section, etc., and finally made into high-quality cylinders shaped organic fertilizer granules. The finished product pellets are uniform and full, which greatly enhances the market competitiveness for customers.

RICHI made a directional design for this project, scientifically configured it according to the actual situation of the customer, and effectively reduced the investment cost for the customer. During the acceptance, the customer gave high praise and affirmation to the project’s installation details, fertilizer granulation equipment quality and other aspects.

Brazil 5 t/h wood pellet production line shipped

Release date: 2022-07-29

On July 29, RICHI successfully completed the delivery of a 5 t/h wood pellet production line for a Brazilian customer.

The project adopts RICHI’s mature wood chip biomass pellet plant technology, and is equipped with RICHI fully automatic 420 biomass pellet machine. The raw material is mainly composed of dried sawdust, straw and other coarse fiber raw material mixture. After drying-crushing-storage-granulation-cooling-packing (bulk) and other processing steps, waste is turned into treasure, and finally made into clean biomass energy. While advocating energy conservation and environmental protection, it promotes a sustainable world sexual development.

The complete set of 5t/h sawdust pellet machine plant was delivered on July 29, with a total of 2 containers. The main equipment includes: MZLH420 biomass pellet mill, double-layer scraper conveyor, bucket elevator, permanent magnet Cylinder, bag filter, cyclone dust collector, etc.

Next, RICHI will promptly arrange project installation personnel to go to South Korea for project installation, commissioning guidance, technical services and other work.

The 45T/H high-end livestock and poultry feed production line project was successfully accepted

Release date: 2022-06-10

The high-grade poultry feed production line with an output of 45 tons per hour designed and constructed by RICHI was completed and successfully passed the acceptance inspection. This marks that the two complete sets of projects are officially put into production and operation, helping customers to develop rapidly.

The project entered the site for installation in June 2021, completed the installation in September, started debugging in May 2022, and passed the acceptance test on June 1st.

Since this project is the transformation of the original factory production line, the usable area is limited, and the finished product and raw material warehouse area is limited. We have designed a real-time online loading process for finished products, which can be used for bulk packing and packaging at the same time. The packing scale is designed on the second floor. When packing finished products, they can be loaded while packing, effectively saving about 500 square meters of finished product warehouse area.

In order to help customers improve market competitiveness and meet the needs of surrounding high-end poultry feed, our company has fully calculated the high addition amount requirements when designing and selecting the oil post-spraying addition system. The amount of oil post-spraying addition is as high as about 8%. With a directional design, a good spraying effect is obtained. The final finished particles are smooth and beautiful, achieving high compression ratio and high output.

The 20 t/h livestock and poultry feed production line project in Anhui, China was completed and put into operation

Release date: 2022-05-22

A few days ago, the 20t/h livestock and poultry feed production line projec, undertaken by RICHI, was successfully completed and passed the inspection.

The project will be completed and accepted on May 21, 2022, and all technologies and quality have passed the inspection standards.

According to the customer’s own development needs, RICHI designed a 4 sets SZLH420 livestock and poultry feed production line, using six crushing lines, three ingredient mixing production lines, four SZLH420 poultry cattle feed pellet machine lines, and five finished product packaging and palletizing lines. The final designed hourly production of livestock and poultry pellets is 40 Ton. Two lines are reserved for engineering installation, which is convenient for customers to expand production capacity in the future.

The entire production line integrates advanced feed pelleting technology, and adopts RICHI’s efficient, environmentally friendly and stable equipment configuration and control system from crushing, mixing, pelleting and other technological processes.