20-30 T/H Cattle Feed Manufacturing Machine Price

20-30T/H cattle feed manufacturing machine price is usually between 150,000-850,000 USD. This is a very wide price range, and this span is mainly determined by the output and scale of cattle feed processing.

Cattle feed manufacturing machines are specialized in processing various types of cattle feed. It refers to a complete set of equipment for processing cattle feed, rather than a single piece of equipment. The types of cattle feed that can be processed include grass feed pellets, concentrate feed pellets, roughage pellets, cattle mash feed, cattle premix feed, fermented cattle feed, silage cattle feed, etc.

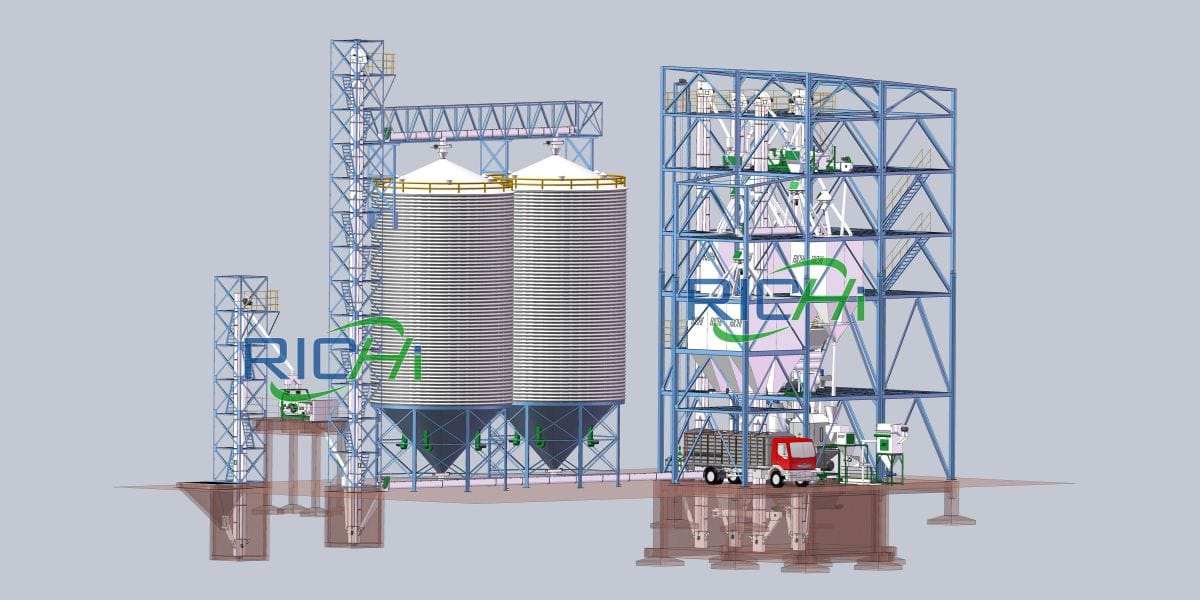

RICHI designs and provides all core feed mill equipment in the production process for the cattle feed processing industry and provides complete cattle feed factory solutions. Our cattle feed processing technology is suitable for a variety of product models and provides optional accessories to provide the optimal cattle feed production line solution for your specific production needs.

cattle feed manufacturing machine price and list

Cattle feed manufacturing machines usually include cattle feed grinders, cattle feed mixers, cattle feed pellet machines, grass crushers, bale breakers, grease adding equipment, coolers, screening machines, baling scales, cleaning equipment, and conveyors equipment, dust removal equipment, silo equipment, electronic control systems, etc.

The following will briefly introduce the functions and functions of some main cattle feed mill equipment, and give the corresponding cattle feed manufacturing machine price as a reference.

Bale breaking machine for cattle feed

This cattle feed manufacturing machine is used to break the bale of grass, hay and straw. Via air transport the cut slices are fed through a hammer mill. The hammer mill chops the product to the desired length. Stones and other contamination falls out, and the product itself can be passed through a drum screen.

- cattle feed manufacturing machine Price: 8,000 – 40,000 USD

- Capacity: 1-20 T/H

- Main Power: 30-90 KW

Pre-Cleaning machine

The first step in cattle feed production is conveying of ingredients from bulk silos or godown to the batching bins. It is essential to remove oversize foreign materials and iron trash etc. which otherwise can affect functioning of slide gates, gravity /screw feeder in batching or downstream.

- cattle feed manufacturing machine Price: 2,000-30,000 USD

- Capacity: 15-50 T/H

- Power: 0.75-1.5 KW

cattle feed batching scale

In modern plants, automatic weighing of different materials as per formulation to make one batch is called batching or proportioning. The weighing is done through an electronic controller working on PLC or microprocessor based which can be operated through a computer.

- cattle feed manufacturing machine Price: 4,000 – 80,000 USD

- Capacity: 1-2000 KG/H

- Model: PLC Series

cattle feed grinding machine

After batching, the next step is to reduce the material to the required degree of fineness to have maximum surface area for exposure to heat and moisture to accomplish gelatinization in conditioners. The cattle feed manufacturing machine used in this section is grass and grain crusher machine.

- cattle feed manufacturing machine Price: 1,000-35,000 USD

- Capacity: 0.3-3 T/H

- Main Power: 22-93 KW

cattle feed mixing machine

Efficient mixing of micro ingredients in whole batch is significant in making quality feed. It should perform mixing to achieve minimum coefficient of variation in minimum time. Feed mixer is a very critical cattle feed manufacturing machine, especially in cattle feed mixing plant.

- cattle feed manufacturing machine Price: 2,800-36,500 USD

- Capacity: 250-2000 KG

- Main Power: 4-55 KW

cattle feed Pellet machine

After conditioning the product is passed through a die in cattle feed pellet machine with the help of rollers and powdery material is converted into cattle pellets. There are many formulas available for cattle feed, generally grass, grain or some crop waste are mainly used.

- cattle feed manufacturing machine Price: 7,000-100,000 USD

- Capacity: 1-48 T/H

- Main Power: 22-315 KW

Cattle feed pellet cooling machine

RICHI counter-flow cooler solutions ensure the correct temperature, which avoids moisture being expelled during storage and mold forming cattle pellets. The cooler is suitable for optimum cooling of extruded or pelletized products based on customer applications and preferences.

- cattle feed manufacturing machine Price: 4,000-20,000 USD

- Capacity: 3-25 T/H

- Main Power: 30-160 KW

cattle feed screening machine

Product coming out of cattle pellet cooler in cattle pellets (if crumbler bye passed) or crumbs form. These are required to be screened to remove fines and overs. Cattle feed screening machine is mainly used in this section and can also be used to clean cattle feed raw materials.

- cattle feed manufacturing machine Price: 2,000-10,000 USD

- Capacity: 3-20 T/h

- Main Power: 1.5-5.5 KW

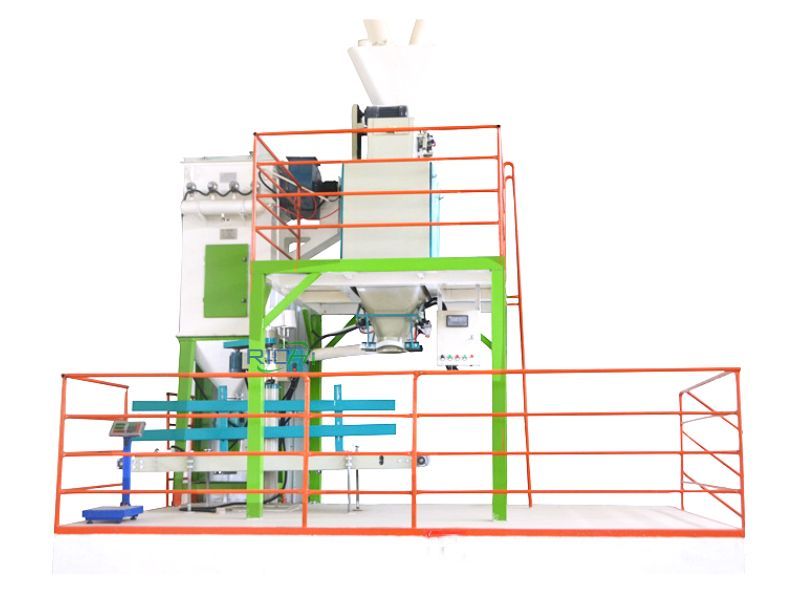

cattle feed bagging machine

The cattle feed manufacturing machine used in this section is a packaging scale. After cattle feed pellet screener, the finished product is filled into bags. In small to medium plants, bagging can be carried out manually but for higher output it is better to go for automatic bagging machine.

- cattle feed manufacturing machine Price: 5,000-10,000 USD

- Capacity: 6-12 Bags/Min

- Main Power: 1.1-5 KW

The above are only the main equipment for cattle feed processing. In the actual configuration of cattle feed equipment, many auxiliary equipment are needed, such as silo system, grass dryers, boilers, dust collectors, air compressors, grease adding equipment, etc.

If you want to start a cattle feed processing business, configure cattle feed equipment and customize the cattle feed production process, contact us to get a complete set of solutions!

Different output and process, different cattle feed manufacturing machine price

Cattle feed processing scales with different outputs and process design plans are also different, so the models and quantities of cattle feed equipment configured are also different, and these will ultimately lead to different cattle feed manufacturing machine prices. Even if two customers have the same output requirements, differences in process design will cause differences in feed equipment prices.

Several cattle animal feed production line plans are listed below, and the corresponding complete set of cattle feed equipment prices are given as parameters:

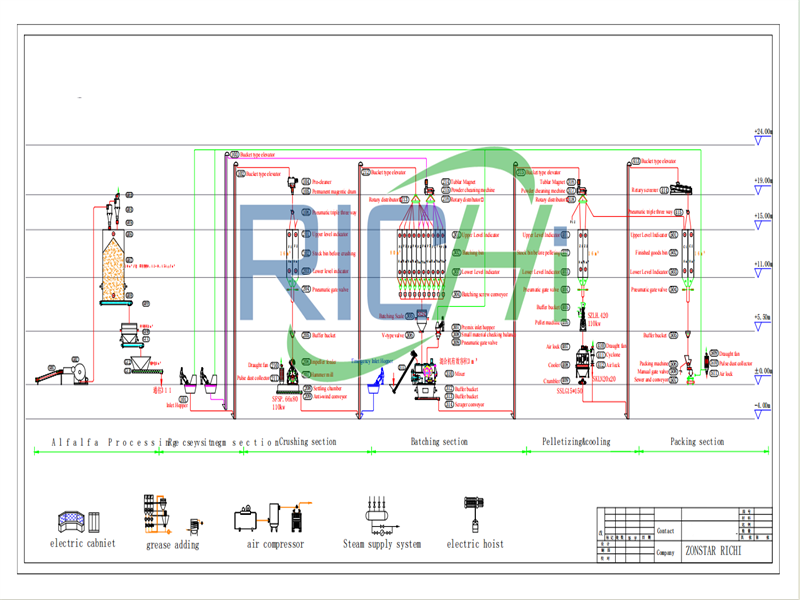

10T/H grass cattle feed manufacturing machine price and configuration

This is a design of 10T/H fully automatic cattle feed plant with 70-90% fresh grass materials. This solution is suitable for cattle feed mills that use fresh pasture as raw material. The price of the cattle feed equipment configured in this solution is higher than that of the general corn cattle feed plant.

- Process design: Crushing system——Drying system——Second Crushing system——Mixing system——Pelletizing and cooling system——Packing system

- Complete cattle feed manufacturing machine price: 680,000 USD

| Cattle feed manufacturing machine list | Model |

| Belt conveyor | TDSJ120*600、PDS-500 |

| cattle feed Straw/Grass crusher | 9FQ50-120 |

| Drum dryer for cattle feed | ф2400*100000 *3 Layer |

| Pulse dust collector | TBLMa.36b |

| Cyclone | ф800*2、SK1000、SK1200 |

| Single shaft double ribbon mixer | SLHY5.0L |

| Buffer bin | 4m³/bin |

| Scraper conveyor | TGSU32 |

| U-screw conveyor | TLSSU35 |

| Storage bin | 4m³ |

| cattle feed Pellet machine | SZLH.508 |

| Stainless steel Feeder | WLQ32 |

| Force feeder | M-508 |

| Stainless steel conditioner | TZ42*300 |

| Cooling Machine | SKLN20*20 |

| Rotary screener | SFJH125*2C |

| Packing machine | DCS-50 |

| Based on this 10t/h cattle grass feed process design, the configured cattle feed equipment also includes Air Cannon, Draught fan, Bucket elevator, Air lock, Pneumatic gate valve, Belt and sewing machine, Oil adding machine, Boiler system, Air compressor and srorage tank, etc. | |

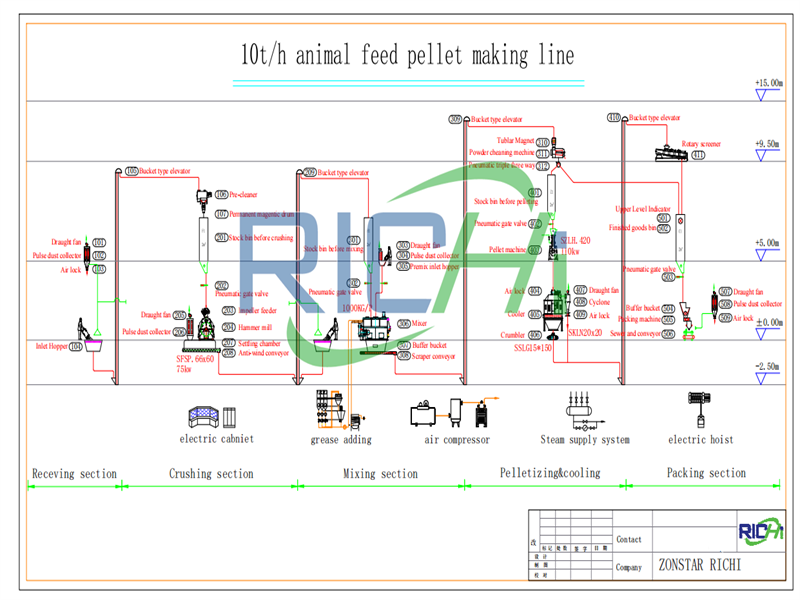

10T/H manual cattle feed manufacturing machine price and configuration

This is a 10T/H Cattle Feed Line With Manual Batching System solution. This solution is suitable for cattle feed mills with small investment budgets but low labor costs. This process is suitable for the production of cattle pellet feed and cattle mash feed.

- Process design: Raw materials receiving and cleaning section——Crushing section——Mixing section——Pelletizing& Cooling Section——Packing section and centralized dedusting section

- Complete cattle feed manufacturing machine price: 170,000 USD

| Cattle feed manufacturing machine list | Model |

| Pulse dust collector | TBLMB.12B\TBLMa.24A |

| Drum type precleaner | SCY63 |

| Permanent magnetic sleeve | TCXT20 |

| cattle feed Hammer mill | SFSP66*60 |

| Powder precleaner | SCQZ60*50*100 |

| cattle feed Mixer | SLHY2.5L |

| cattle feed Pellet machine | SZLH420 |

| Stainless steel conditioner | TZ38*300 |

| Feeder | WLQ25 |

| Cooling Machine | SKLN20×20 |

| Cyclone | SK1000 |

| Rotary screener | SFJH125*2C |

| Final pellets stock bin | 4m³ |

| Automatic Packing machine | DSC-50 |

| Oil adding machine | YZTG100a |

| Boiler system | 1.0T,0.7Mpa |

| Air compressor and srorage tank | 22KW |

| Based on this 10t/h manual batching cattle grass feed process design, the configured cattle feed equipment also includes Draught fan, Bucket elevator, Air lock, Pre-Crushing bin, Belt and sewing machine, Screw conveyor (5m Air locked), Premix adding hopper, MCC Control Center ;Mimic Control Panel, etc. | |

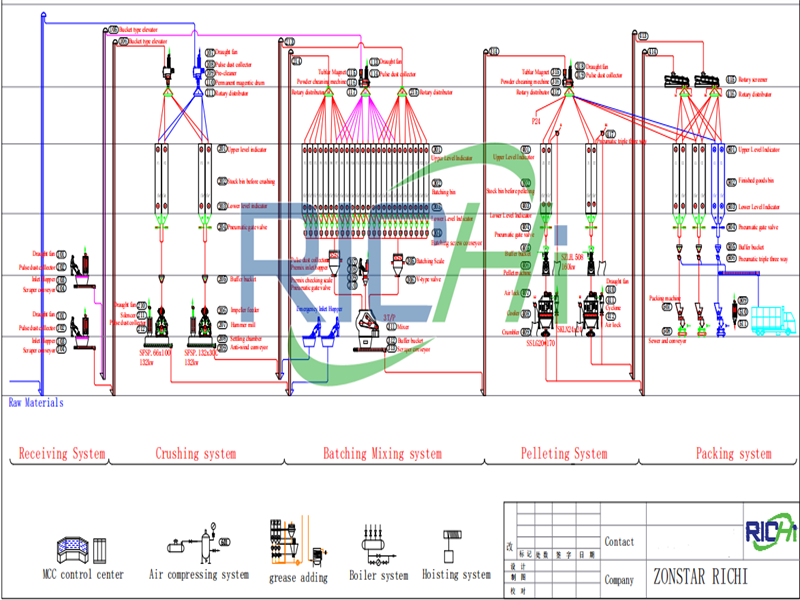

30T/H cattle feed manufacturing machine price and configuration

This is a 30 T/H Computer Batching Cattle Pellet Feed Line. The complete set of cattle feed equipment is very high-configuration and has a very high degree of automation. This process can be used in high-end cattle feed plants with large processing scale and sufficient investment budget. The process is suitable for processing both grass-containing and grass-free cattle feed pellets.

- Process design: Materials receiving& pre-cleaning system——Crushing system——Batching& mixing system——Pelletizing& cooling& screening system——Packing& dust collecting system

- Complete cattle feed manufacturing machine price: 740,000 USD

| Cattle feed manufacturing machine list | Model |

| Draught fan | 4-72-3.2A |

| Pulse dust collector | TBLMa.12A、TBLMa.48A |

| Scraper conveyor | TGSS25 |

| Bucket elevator | TDTG40/28 |

| Drum type precleaner | SCY80 |

| Permanent magnetic sleeve | TCXT30 |

| Rotary distributor | TFPX4、TFPX10、TFPX8 |

| Powder cleaning sieve | SCQZ90*80*110 |

| cattle feed Hammer Mill | SFSP66*100、SFSP138*50E |

| Batching scale | PLC1.5A |

| Small material checking balance | PLC0.25B |

| Single-shaft mixer | SLHJ6.0A |

| cattle feed Pellet machine | SZLH508 |

| SS Conditioner | TZ42*3000 |

| Variable-frequency Feeder | TWLL32 |

| cattle feed Cooling Machine | SKLN24x24 |

| cattle feed Rotary screener | SFJZ150*2C |

| cattle feed Packing machine | DCS-50 |

| Based on this 30t/h cattle feed process design, the configured cattle feed equipment also includes Upper level indicator, Cone bucket, Lower level indicator, Pneumatic gate, Buffer hopper, Variable frequency feeder, Bucket Elevator, Air lock, Buffer bin, Heating oil storage tank, etc. | |

RICHI Machinery can customize designs according to customer needs. No matter your budget is high or low, no matter what kind of cattle feed you want to process, no matter what your raw materials are, no matter what unique process requirements you have, contact us to get complete cattle feed solutions and cattle feed manufacturing machine prices, Feel the professionalism and strength of RICHI’s engineering team!

Different project, different cattle feed manufacturing machine price

Currently, our cattle feed equipment has been exported to the United States, Canada, Russia, Australia, New Zealand, South Africa, Indonesia, India, Thailand, Iran, Argentina, Brazil and other countries. These cattle feed plant projects not only cover the production scale of 20-30t/h, but also basically cover all types of cattle feed processing.

Saudi Arabia

15-16T/H cattle feed manufacturing machine in Saudi Arabia

- Feed type: Grass-containing cattle feed pellets

- Date: March 30th, 2023

- The install period: 60 Days

- Workshop size(L*W*H): 16m*8m*12m

- cattle feed manufacturing machine price: 480,000 USD

Indonesia

3-5T/H cattle feed manufacturing machine in Indonesia

- Feed type: Grass-free cattle feed pellets

- Date: April 9th, 2023

- The install period: 30 Days

- Workshop size(L*W*H): 10m*5m*12m

- cattle feed manufacturing machine price: 110,000 USD

South Africa

3-4T/H cattle feed manufacturing machine in south africa

- Feed type: Grass-free cattle feed pellets

- Date: Nov 1st, 2022

- The install period: 45 Days

- Workshop size(L*W*H): 60m*24m*12m

- cattle feed manufacturing machine price: 150,000 USD

Argentina

5 t/h cattle feed manufacturing machine in Argentina

- Feed type: Grass-free cattle feed pellets

- Date:2022.10.11

- Feed Pellet Size:6-8 mm

- The install period:50 Days

- cattle feed plant machinery price:184,500 USD

United States

10-12 T/H cattle feed machine in United States

- Feed type: Grass-containing cattle feed pellets

- Date: May 2023

- Feed Pellet Size: 4-8 mm

- The install period: 40 Days

- cattle feed manufacturing machine price: 380,000 USD

El Salvador

5 T/H cattle feed manufacturing machine In El Salvador

- Feed type: Grass-containing cattle feed pellets

- Date:2023.11.19

- Control Mode:Full Automatic

- The install period:90 Days

- cattle feed manufacturing machine price:450,000 USD

Uzbekistan

0.8-4T/H cattle feed manufacturing machine in Uzbekistan

- Feed type: Grass-containing cattle feed pellets

- Date:May 19, 2023

- Pellet Size:4-8 mm

- MAIN POWER:283KW

- cattle feed manufacturing machine price: 85,000-95,000 USD

Russia

30-35 T/H cattle feed manufacturing machine in russia

- Feed type: Grass-containing cattle feed pellets

- Date:June 2023

- Feed Size:2-8mm pellets

- The install period:10 months

- cattle feed manufacturing machine price: 1,800,000 USD

Brazil

20-25T/H cattle feed manufacturing machine in brazil

- Feed type: Grass-containing cattle feed pellets

- Date:June 2024

- Pellet Size:2-8mm

- The install period:60 Days

- Cattle Feed Manufacturing Plant Cost: 800,000 USD

What factors will affect cattle feed manufacturing machine price?

Cattle feed manufacturing machine prices vary widely among different models and brands. The key factors that affect cattle feed manufacturing machine price will be discussed here to help you better understand why prices vary.

01 Power and performance:

The power and performance of cattle feed manufacturing machine is one of the main factors that determine its price. Typically, more powerful and higher-performance cattle feed equipment is relatively more expensive because of its higher production capacity and efficiency.

02 Brand and Reputation:

Different brands of cattle feed equipment enjoy different reputations and recognitions in the market. Well-known brands usually have good quality and reliability, so the cattle feed manufacturing machine prices are higher. And some emerging brands or low-profile brands tend to offer more competitive prices.

03 Technology and Innovation:

Different technologies and innovative products exist in the cattle feed equipment market. Some devices may incorporate advanced technologies and innovations that offer more efficient and smarter features, resulting in higher cattle feed manufacturing machine prices. Traditional cattle feed equipment may be more affordable.

04 Production capacity and scale:

The impact of production capacity and scale on the price of cattle feed equipment is also obvious. Large-scale cattle feed equipment usually has higher production capacity and more complex structure, so the price is relatively high. In comparison, small cattle feed equipment may offer a better deal.

05 Processing materials and quality:

The manufacturing materials and quality have a significant impact on cattle feed manufacturing machine price. High-quality materials and workmanship often result in a higher price, but also result in a longer service life and less maintenance requirements, making them a more economical and reliable option in the long run.

06 Additional features and customization options:

Some cattle feed equipment may be equipped with various additional features and customization options such as automatic control systems, noise reduction devices, energy management systems, etc. These extra features and options add cost, leading to a higher cattle feed manufacturing machine price.

07 Geographical location and market factors:

The cattle feed manufacturing machine price is also affected by location and market factors. In some areas, prices may fluctuate due to supply and demand or market competition. Factors such as shipping costs and taxes in different regions may also affect the final cattle feed making machine price.

The cattle feed manufacturing machine price is affected by a combination of factors. Everything from power and performance to brand reputation, from technological innovation to quality of workmanship materials, as well as additional features and customization options all have an impact on price.

When purchasing cattle feed cattle feed manufacturing machine, you should consider these factors and choose the equipment that best suits your needs and budget.

How to choose suitable cattle feed manufacturing machine?

1. Determine the production scale

When choosing cattle feed manufacturing machines, you must first determine the production scale of the cattle feed plant. According to the actual situation of cattle feed processing enterprises, choose the equipment configuration and production line technology that suits you.

If the scale of the enterprise is small, you can choose a small-volume production line, while if the scale is larger, you need to choose a large-scale production line, which can increase profits.

2. Determine product category

There are many types of cattle feed products, including pellet type, mash type, grass-containing formulas, and grass-free formulas. Some use straw as the main raw material, some use bagasse as the main raw material, and some use fermentation technology, some use the silage process.

For different types and different outputs of cattle feed processing, the equipment combination and number of equipment used are different, so first determine your production scale, we will customize the corresponding cattle feed process for you, and then according to your budget and needs, choose the right device.

3. Consider reliability

The reliability of cattle feed manufacturing machine is very important. When selecting equipment, pay attention to the brand, manufacturing process, materials used, etc. of the equipment to ensure the reliability and stability of the equipment.

Good equipment manufacturers generally clearly display the entire equipment processing process to customers. From the production of the equipment to the debugging of the entire equipment, everything can be seen intuitively.

4. Consider the maintainability

Equipment serviceability is also a factor to consider. If equipment malfunctions, it is important to be able to easily repair and replace parts. Therefore, when selecting equipment, pay attention to the ease of maintenance of the equipment. Generally, good cattle feed machine manufacturers will provide you with equipment that is currently being used by your local customers.

You can visit them on site or contact them by phone to ask about the use of the cattle feed machine. On the contrary, what they dare not provide or cannot provide is basically the after-sales service without guarantee, so they cannot provide this customer information.

5. Consider the cattle feed manufacturing machine price

Cattle feed manufacturing machine price is one of the important factors to consider when purchasing cattle feed equipment. When selecting equipment, the choice should be based on the company’s budget and actual needs.

If your budget is more limited, you can choose affordable cattle feed plant machinery; if your budget is higher, you can choose equipment with better performance. If it is a breeding farm, you can consider building a small cattle feed production line, which has a simple process and low cost.

In summary, there are many factors to consider when choosing cattle feed manufacturing machine. Only by selecting appropriate equipment can the production efficiency and product quality of cattle feed processing plants be improved, costs reduced, and market competitiveness enhanced. (Find RICHI on youtube)